wiring JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2496 of 3039

Symptom Possible Causes Action outside (but opens from the

inside) GO to Pinpoint Test A. Door(s) will not unlatch/open when

using inside door handle

Child lock(s) engaged

Interior door handle

condition/installation

Interior release cable disconnected

from interior door handle or door

latch

Check that the child locks are

disengaged

Check the interior door handle

condition and installation

Check the condition and security of

the interior release cable

Single Door Will Not Open From

The Inside (but opens from the

outside) GO to Pinpoint Test B. Door(s) will not lock/unlock from key

fob, key or internal lock switch

Wiring harness/connectors

Central junction box (CJB)

Door lock switch

Cable fault

Check for relevant stored DTCs

Once any DTC related faults have

been rectified continue with the

diagnostic steps below

No lock / unlock function from

key-fob GO to Pinpoint Test C. Door ajar or miss lock signal at

message centre when door(s) are

closed or alarm triggering

Wiring harness

Instrument cluster

Incorrect striker

alignment/adjustment

Ajar switch circuit short circuit to

ground

Ajar switch failure

Latch Mounted Door Ajar Switch

Test GO to Pinpoint Test D. DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Communications Network (418-00, Diagnosis and Testing) /

Locks, Latches and Entry Systems - DTC: With (501-14, Diagnosis and Testing).

Pinpoint Test

PINPOINT TEST A : SINGLE DOOR WILL NOT OPEN FROM THE OUTSIDE (BUT OPENS FROM THE INSIDE) TEST CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK THE EXTERIOR DOOR RELEASE CABLE TO EXTERIOR DOOR HANDLE IS INSTALLED CORRECTLY

1 Remove the door trim panel as necessary 2 Confirm the exterior door release cable is correctly installed to the exterior door handle Is the cable correctly installed?

Yes

GO to A2. No

Page 2505 of 3039

Body wiring harness / connectors

Door wiring harness / connectors

Alarm control module

Central junction box (CJB)

Door Latch ajar switch

To investigate the functioning of the door ajar switch contained within the door latch, to prove or eliminate the door

latch mounted door ajar switch as the root cause, follow the process below. This will prevent the unnecessary replacement of

a correctly functioning door latch 1 Remove door trim from door 2 Disconnect door harness from latch for access to connector pins for latch electrical testing 3 Inspect latch module for any visual damage NOTES:

Figure 1 - Unlatched position shown

Figure 2 - First safety latched position shown

Figure 3 - Fully latched position shown

Test will not work if latch is only in first safety latch position 4 Using a small screw driver or similar, rotate latch claw to the second fully latched position (figure 3)

5 Carry out continuity test between terminals 1 and 4 (left side) or 8 and 4 (right side) with claw closed Does the continuity test pass? Yes

The latch ajar switch is working correctly. Do not replace latch.

Investigate for fault elsewhere in vehicle system

Page 2510 of 3039

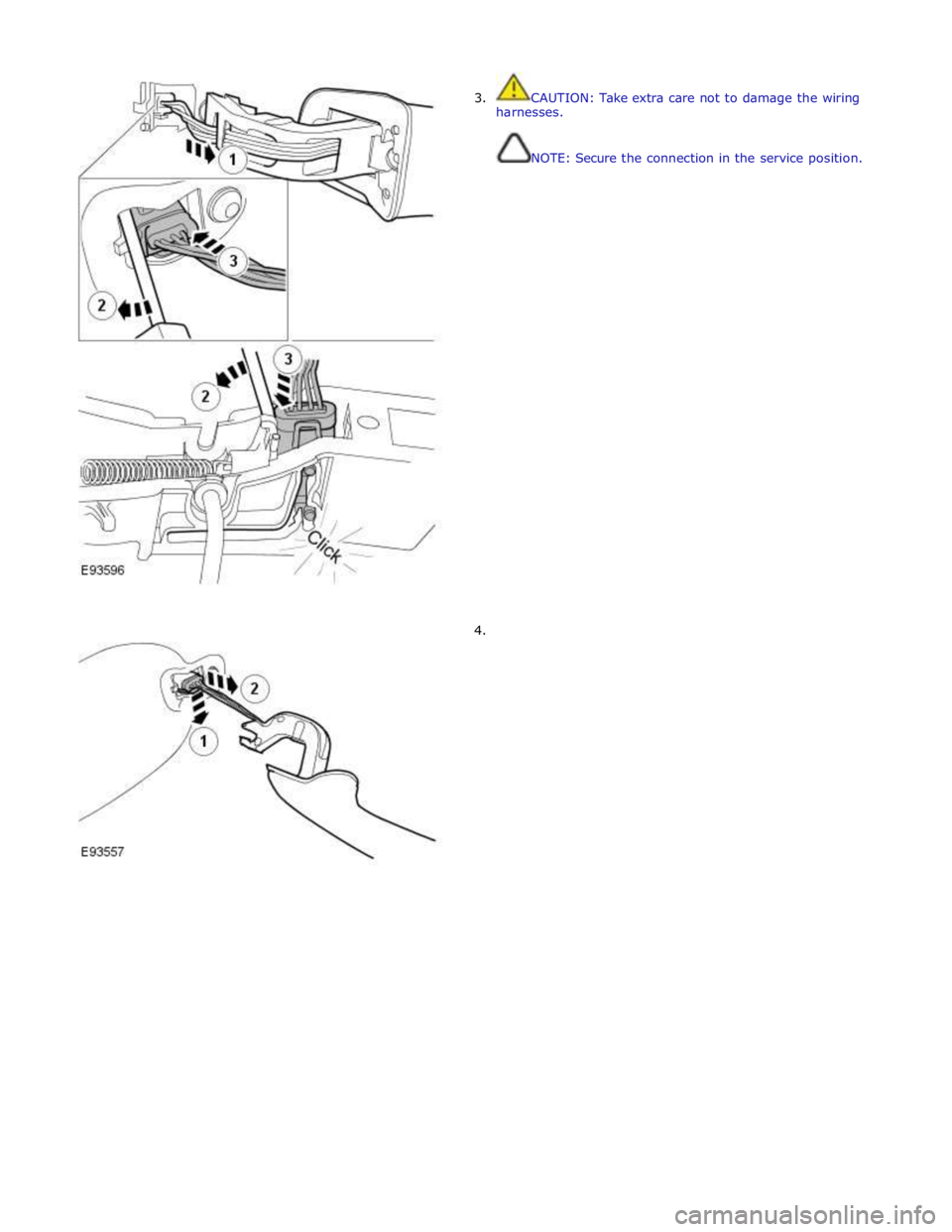

3. CAUTION: Take extra care not to damage the wiring

harnesses.

NOTE: Secure the connection in the service position.

4.

Page 2511 of 3039

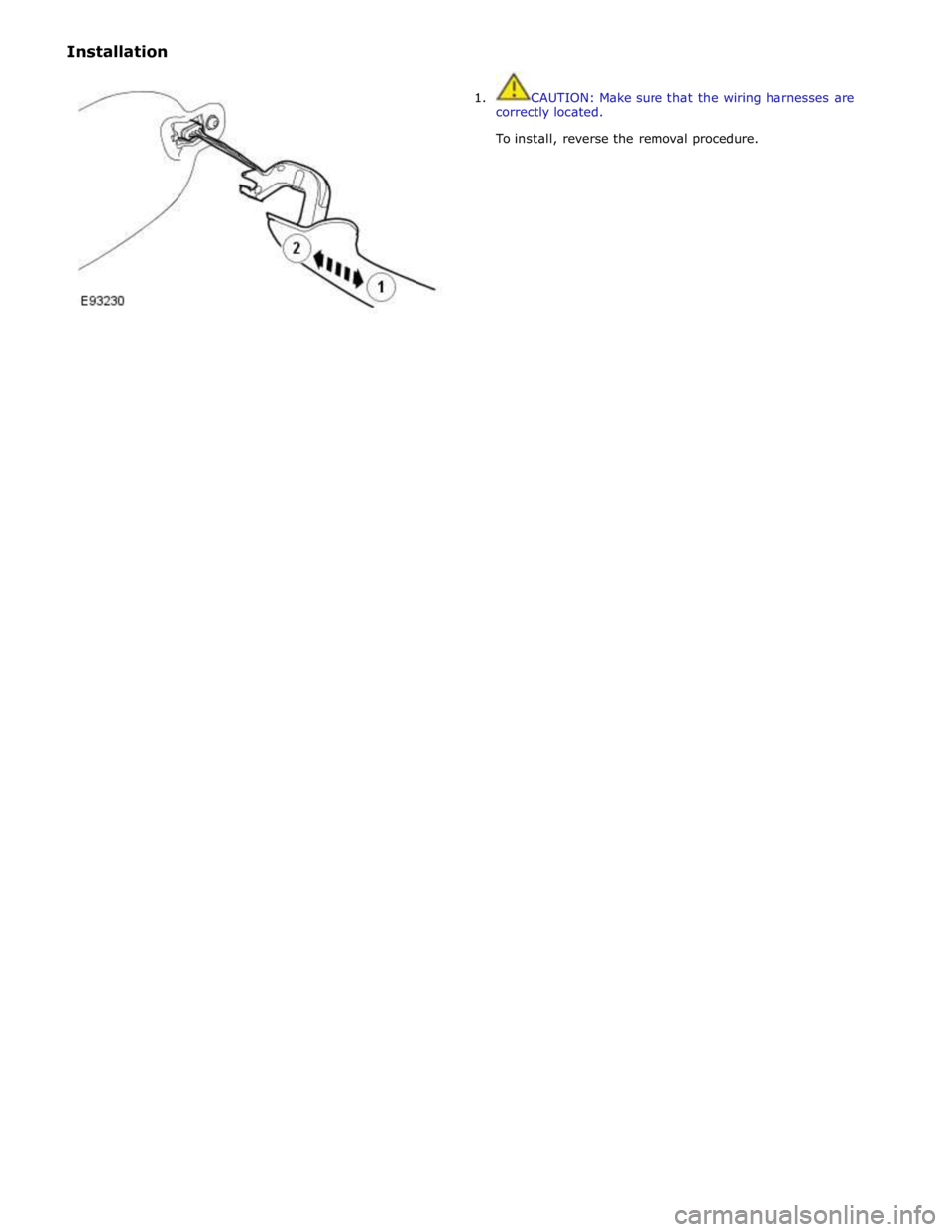

Installation

1. CAUTION: Make sure that the wiring harnesses are

correctly located.

To install, reverse the removal procedure.

Page 2515 of 3039

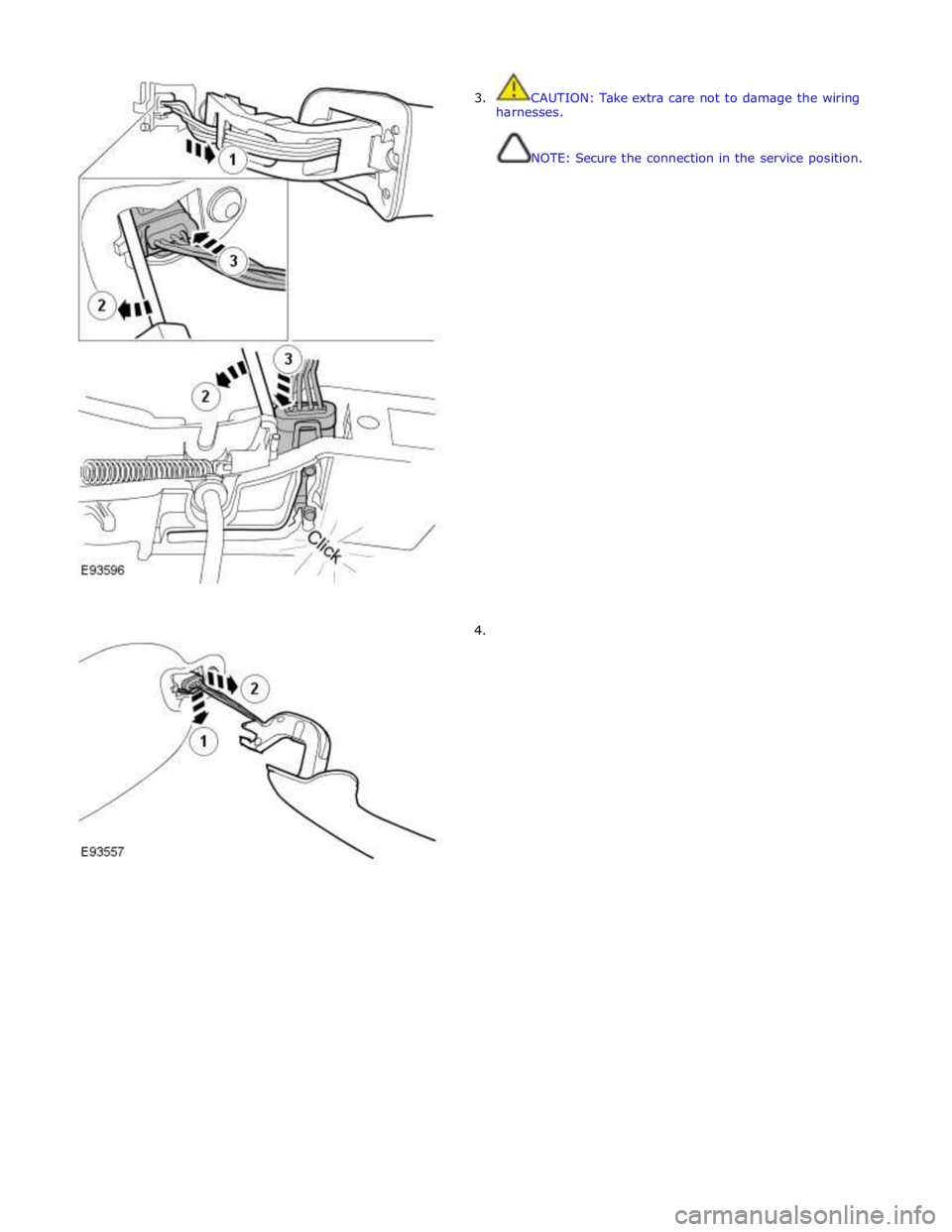

3. CAUTION: Take extra care not to damage the wiring

harnesses.

NOTE: Secure the connection in the service position.

4.

Page 2520 of 3039

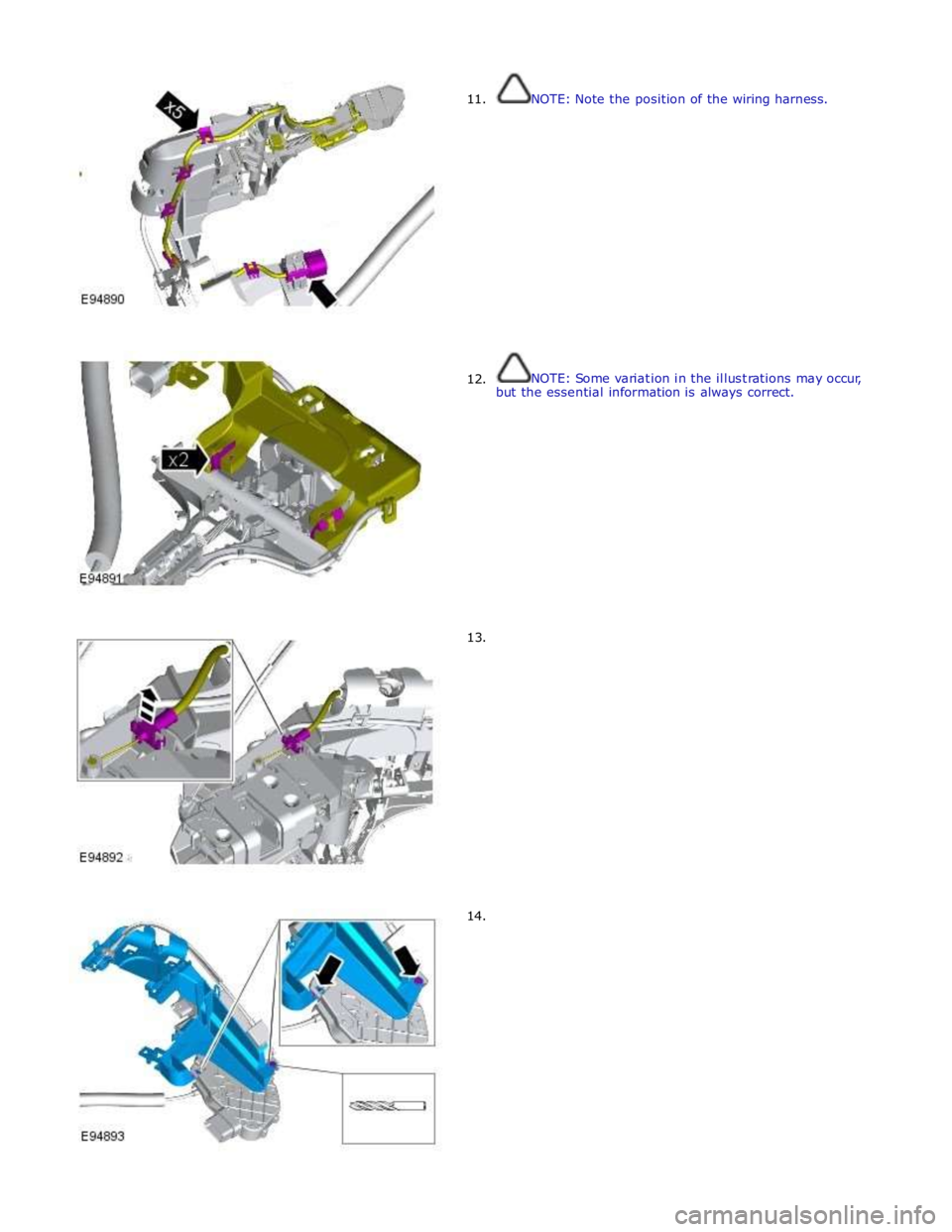

11.

12.

13.

14. NOTE: Note the position of the wiring harness.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Page 2530 of 3039

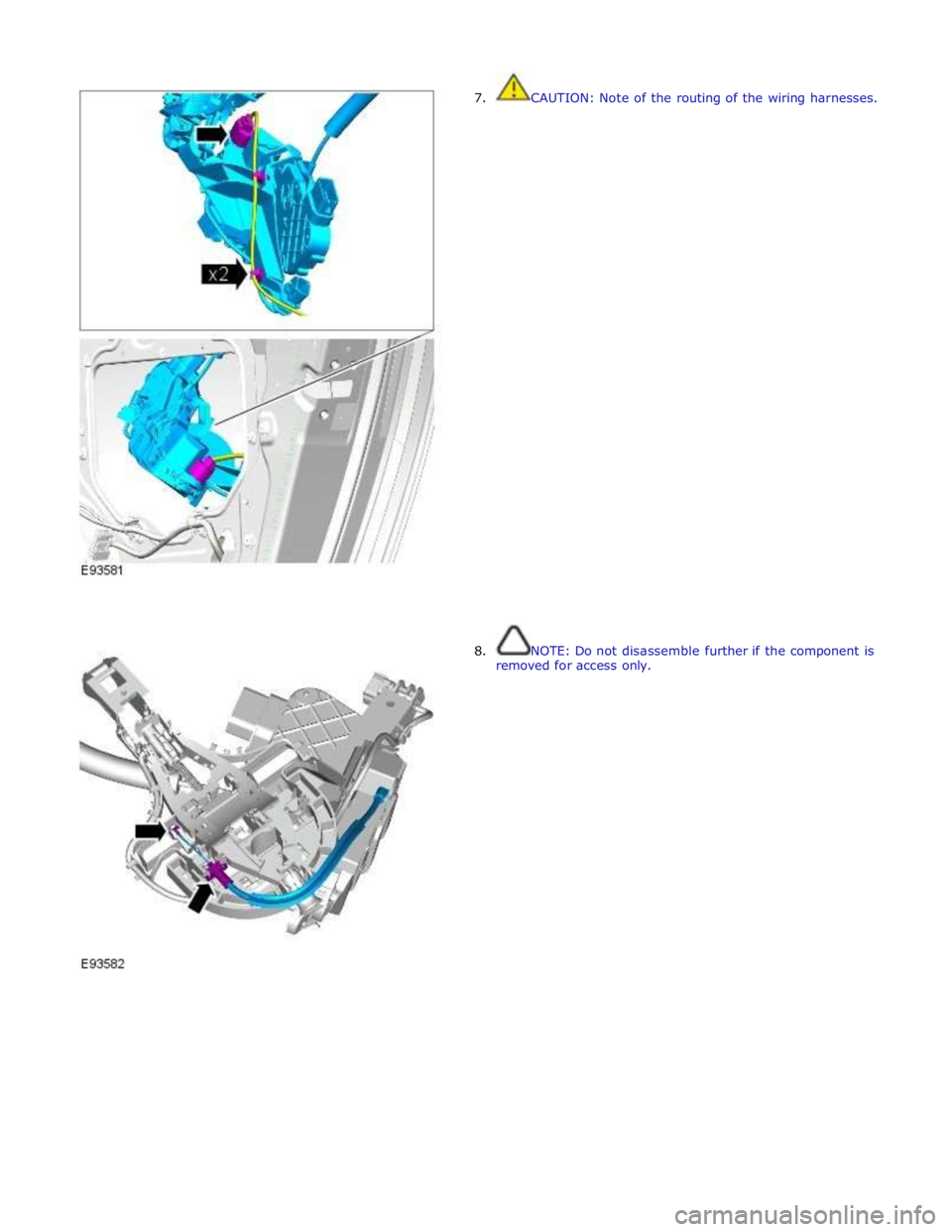

7. CAUTION: Note of the routing of the wiring harnesses.

8. NOTE: Do not disassemble further if the component is

removed for access only.

Page 2532 of 3039

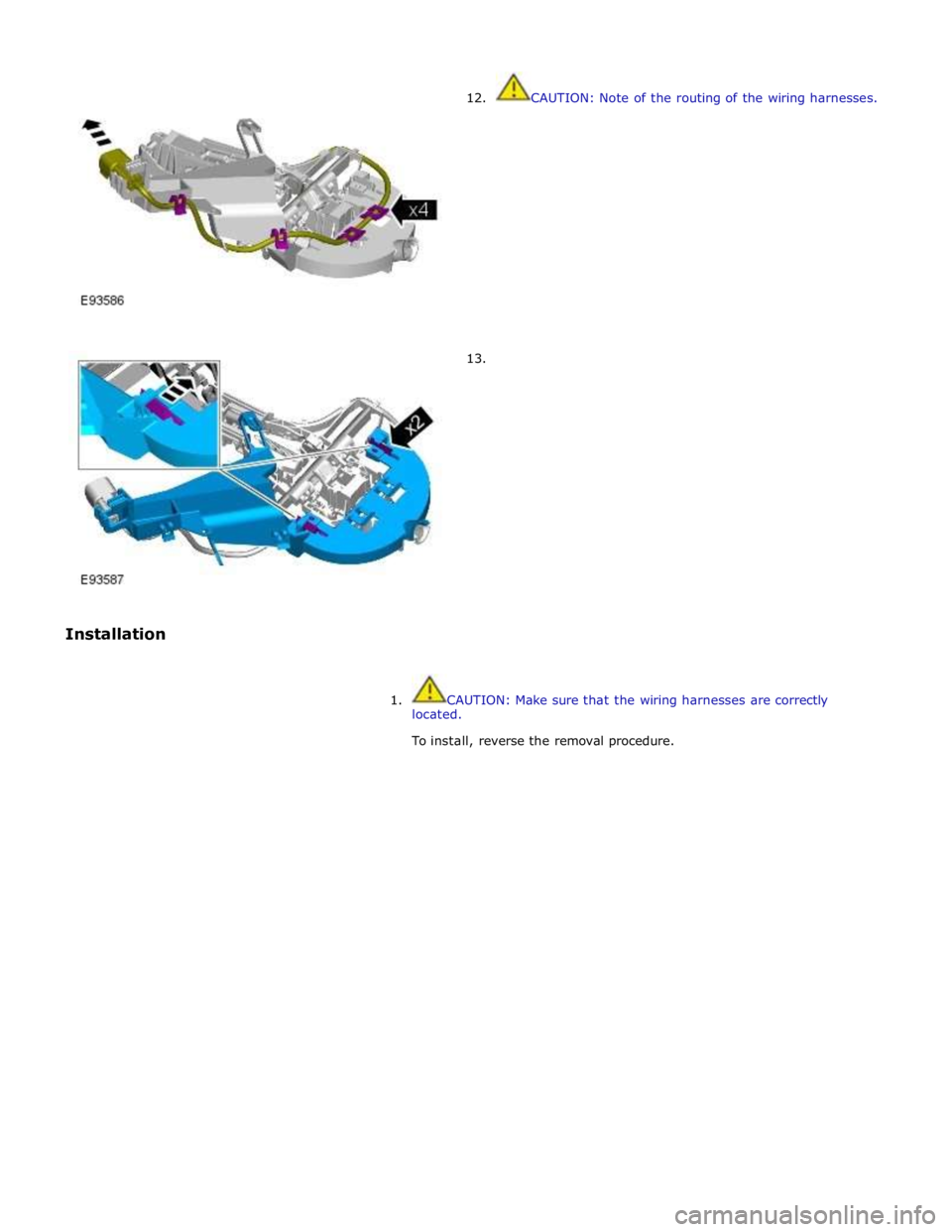

Installation

12.

13.

CAUTION: Note of the routing of the wiring harnesses.

1. CAUTION: Make sure that the wiring harnesses are correctly

located.

To install, reverse the removal procedure.

Page 2543 of 3039

Wipers and Washers - Wipers and Washers

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the wipers and washers, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: (501-16 Wipers and Washers)

Wipers and Washers (Description and Operation), Wipers and Washers (Description and Operation), Wipers and Washers (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Wiper blade(s)

Wiper pivot arm shaft

Washer reservoir

Hose(s)

Washer jet(s)

Fuse(s)

Wiring harness

Electrical connector(s)

Washer pump(s)

Wiper motor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B109512

Wiper On/Off

Relay

Wiper On/Off relay control Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

Page 2563 of 3039

Roof Opening Panel - Roof Opening Panel

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the roof opening panel, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: (501-17 Roof Opening Panel)

Roof Opening Panel (Description and Operation), Roof Opening Panel (Description and Operation), Roof Opening Panel (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Roof opening panel

Helixed drive cables

Switch

Control unit/motor

Fuses/relays (refer to electrical guide)

Wiring harness

Correct engagement of electrical connectors

Loose or corroded connections

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give extra information read by

the manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places and

with a current calibration certificate. When testing resistance, always take the resistance of the DMM leads into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B10F211 Sunroof Control

Sunroof enable signal

circuit - short to ground Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check sunroof enable signal circuit for short

to ground B10F212 Sunroof Control

Sunroof enable signal

circuit - short to power Refer to the electrical circuit diagrams and check sunroof enable

signal circuit for short to power