wiring JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2580 of 3039

Bumpers - Front Bumper

Removal and Installation Published: 11-May-2011

Removal

1. The front bumper is serviced as a separate bolt-on panel.

2. The front bumper is replaced in conjunction with:

Front bumper cover

3. WARNING: The hood and its associated components form part of the

pedestrian protection system, it is essential that any repair or

replacement operations do not affect the safe working of the system.

For additional information relating to the pedestrian safety system

please see the following:

For additional information, refer to: Pedestrian Protection System (501-20C Pedestrian Protection System, Description and Operation).

4. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

5. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

6. Remove the front bumper cover.

For additional information, refer to: Front Bumper Cover (501-19 Bumpers, Removal and Installation).

7. Release and position the front bumper wiring harness and the hood

release cable to one side.

Page 2595 of 3039

Safety Belt System - Safety Belt System

Diagnosis and Testing

Principle of Operation Published: 13-Jun-2013

For a detailed description of the seatbelt system and operation, refer to the relevant description and operation section of the

workshop manual REFER to: (501-20A Safety Belt System)

Safety Belt System (Description and Operation), Safety Belt System (Description and Operation), Safety Belt System (Description and Operation).

Safety Information

WARNINGS:

To avoid accidental deployment the back-up power supply must be depleted before beginning any work on the SRS system

or its components. Failure to follow this instruction may result in personal injury

Do not use a multimeter to probe an SRS module. It is possible for the power from the multimeter battery to trigger the

activation of the module. Failure to follow this instruction may result in personal injury

NOTE: Do not to use a cellular phone or to have a cellular phone in close proximity when working on the SRS system or

components

Power supply depletion

Before beginning any work on the SRS system or related components:

1. Remove the ignition key

2. Disconnect the battery leads, ground first

3. Wait 2 minutes for the power circuit to discharge

There are comprehensive instructions on the correct procedures for SRS system repairs, refer to the relevant section of the

workshop manual

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle

NOTE: Check and rectify basic faults before beginning diagnostic routines including pinpoint tests

1. Verify the customer concern by operating the seatbelt

2. Visually inspect for obvious signs of mechanical or electrical damage

Visual Inspection

Mechanical Electrical

Check for the installation of non-standard accessories which may affect or

obstruct the function of the seatbelt system

Frayed or damaged webbing

Missing or damaged button stop

Pretensioner(s) Buckles/Stalks

Fuses

Wiring harness fault

Correct engagement of electrical

connectors

Loose or corroded connections

Warning lamp bulb(s)

Impact sensor(s)

Buckle sensor(s)

Pretensioner(s)

Belt tension sensor(s)

Restraints control module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, carry out the test methods described below, alternatively check for diagnostic

trouble codes and refer to the relevant diagnostic trouble code index

Page 2598 of 3039

TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: SEATBELT RETRACTOR-WEBBING GUIDE LOOSE 1 Refer to 501-20 removal and installation section of the workshop manual, remove any trim panels required to expose the D loop (anchor point) and seatbelt retractor 2 Check the webbing is not trapped or twisted and is centrally located on the seatbelt retractor spindle 3 Attempt to withdraw the webbing from the seatbelt retractor NOTE: If the seatbelt webbing is jammed, the automatic locking retractor could be engaged 4 To release the automatic locking retractor, manually wind the webbing onto the spindle until the automatic locking retractor deactivates (clicking stops) 5 Fully extract webbing 6 Confirm webbing guide location is correct , Confirm the fixing lugs are correctly located in the retractor frame 7 Allow webbing to retract 8 Check for correct operation twice Does the webbing move freely then retract correctly?

Yes

Refer to the 501-20 removal and installation section of the workshop manual, reinstall any trim panels,

ensure there are no obstructions and the webbing does not catch or rub. No further action required

No

GO to Pinpoint Test D.

PINPOINT TEST D : TWIST IN WEBBING TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: TWIST IN WEBBING 1 Refer to section 501-20 removal and installation section of the workshop manual, remove any trim panels required to expose the D loop (anchor point) 2 Twist the webbing back the correct way in the loop 3 Pass the twist through the pillar loop or escutcheon as required 4 Check for correct operation twice Does the webbing move freely then retract correctly?

Yes

Refer to the 501-20 removal and installation section of the workshop manual, reinstall any trim panels,

ensure there are no obstructions and the webbing does not catch or rub. No further action required

No

GO to Pinpoint Test E.

PINPOINT TEST E : INTERFERENCE-WEBBING ROUTING TEST

CONDITIONS DETAILS/RESULTS/ACTIONS E1: INTERFERENCE-WEBBING ROUTING 1 Refer to the 501-20 removal and installation section of the workshop manual, remove any trim panels required to expose the D loop (anchor point) 2 Remove obstructions and foreign objects ensure the webbing does not catch or rub 3 Confirm the seatbelt does not contact the wiring harness 4 Check for correct operation twice Does the webbing move freely then retract correctly?

Yes

Refer to the 501-20 removal and installation section of the workshop manual, reinstall any trim panels,

ensure there are no obstructions and the webbing does not catch or rub. No further action required

No

GO to Pinpoint Test F.

PINPOINT TEST F : SEATBELT RETRACTOR-INCORRECT INSTALLATION TEST

CONDITIONS DETAILS/RESULTS/ACTIONS F1: SEATBELT RETRACTOR-INCORRECT INSTALLATION 1 Refer to the 501-20 removal and installation section of the workshop manual, remove any trim panels required to expose the D loop (anchor point) and the seatbelt retractor 2 Refer to the 501-20 removal and installation section of the workshop manual, correctly reinstall the seatbelt retractor ensure that the locating "T bar" and "anti rotation pins" are correctly located 3 Check for correct operation twice Does the webbing move freely then retract correctly?

Yes

Refer to the 501-20 removal and installation section of the workshop manual, reinstall any trim panels,

ensure there are no obstructions and the webbing does not catch or rub. No further action required

No

GO to Pinpoint Test G.

Page 2616 of 3039

and the safety belt buckle sensor. Based on this data, the RCM decides which level of airbag module deployment is required and forwards the information to the second area, the deployment handler.

The deployment handler evaluates the status of the seat track position sensor and safety belt buckle sensors before a decision

is made about which restraints should finally be deployed.

Data from the side crash sensors is used by the RCM in conjunction with acceleration data from the RCM internal accelerometer to make a deployment decision. The RCM processes the acceleration data and subject to an impact being of high enough severity, decides whether the side airbag module should be deployed.

On board testing of the airbag modules, front safety belt pretensioner firing circuits, warning indicator circuits and module

status (the crash and side impact sensors perform basic self-tests) is performed by the RCM together with the storing of fault codes.

The RCM drives the SRS indicator on the instrument pack via a CAN signal. If the warning lamp fails, a fault code is recorded and a warning tone is sounded in place of the lamp if a further fault occurs. It also provides a temporary back-up power supply

to operate the airbag modules in the event that in crash conditions, the battery supply is lost. In the event of a crash, it

records certain data which can be accessed via the diagnostic connector.

A safing sensor in the RCM provides confirmation of an impact to verify if airbag and pretensioner activation is necessary. A roll-over sensor monitors the lateral attitude of the vehicle. Various firing strategies are employed by the RCM to ensure that during an accident only the appropriate airbags and pretensioners are fired. The firing strategy used also depends on the

inputs from the safety belt switches and the occupant monitoring system.

An energy reserve in the RCM ensures there is always a minimum of 150 milliseconds of stored energy available if the power supply from the ignition switch is disrupted during a crash. The stored energy is sufficient to produce firing signals for the

driver airbag, the passenger airbag and the safety belt pretensioners.

When the ignition is switched on, the RCM performs a self-test and then performs cyclical monitoring of the system. If a fault is detected the RCM stores a related fault code and illuminates the airbag warning indicator. The faults can be retrieved by the recommended Jaguar diagnostic tool over the CAN bus. If a fault that could cause a false fire signal is detected, the RCM disables the respective firing circuit, and keeps it disabled during a crash event.

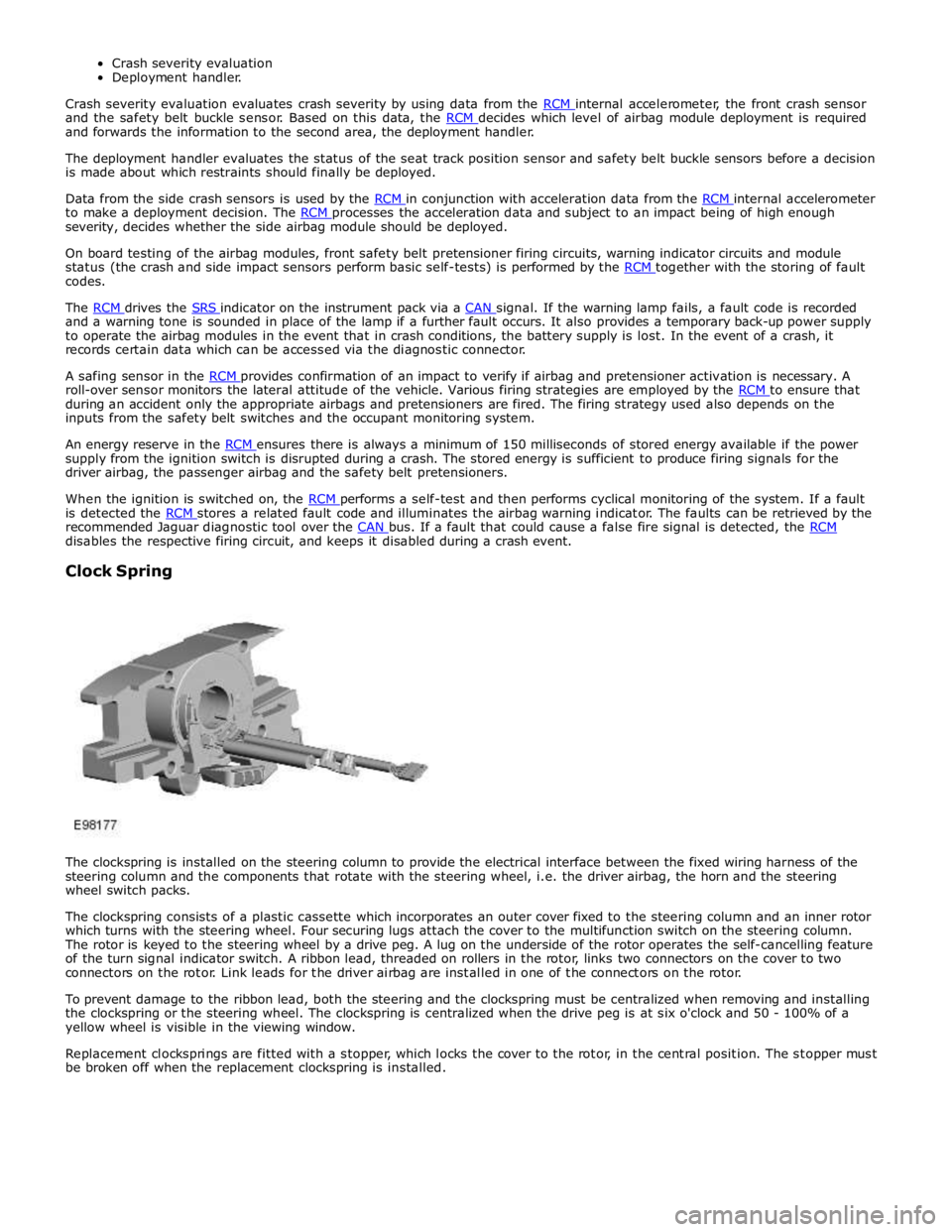

Clock Spring

The clockspring is installed on the steering column to provide the electrical interface between the fixed wiring harness of the

steering column and the components that rotate with the steering wheel, i.e. the driver airbag, the horn and the steering

wheel switch packs.

The clockspring consists of a plastic cassette which incorporates an outer cover fixed to the steering column and an inner rotor

which turns with the steering wheel. Four securing lugs attach the cover to the multifunction switch on the steering column.

The rotor is keyed to the steering wheel by a drive peg. A lug on the underside of the rotor operates the self-cancelling feature

of the turn signal indicator switch. A ribbon lead, threaded on rollers in the rotor, links two connectors on the cover to two

connectors on the rotor. Link leads for the driver airbag are installed in one of the connectors on the rotor.

To prevent damage to the ribbon lead, both the steering and the clockspring must be centralized when removing and installing

the clockspring or the steering wheel. The clockspring is centralized when the drive peg is at six o'clock and 50 - 100% of a

yellow wheel is visible in the viewing window.

Replacement clocksprings are fitted with a stopper, which locks the cover to the rotor, in the central position. The stopper must

be broken off when the replacement clockspring is installed.

Page 2624 of 3039

Published: 10-Jul-2014

Supplemental Restraint System - Air Bag and Safety Belt Pretensioner

Supplemental Restraint System (SRS)

Diagnosis and Testing

Principle of Operation

For a detailed description of the supplemental restraints system and operation, refer to the relevant Description and Operation

section in the workshop manual. REFER to: (501-20B Supplemental Restraint System)

Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS) (Description and Operation), Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS) (Description and Operation), Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS) (Description and Operation).

Inspection and Verification

WARNING: TO AVOID ACCIDENTAL DEPLOYMENT AND POSSIBLE PERSONAL INJURY, THE BACKUP POWER SUPPLY MUST

BE DEPLETED BEFORE REPAIRING OR REPLACING ANY AIR BAG SUPPLEMENTAL RESTRAINT SYSTEM (SRS) COMPONENTS. TO

DEPLETE THE BACKUP POWER SUPPLY ENERGY, DISCONNECT THE BATTERY GROUND CABLE AND WAIT ONE MINUTE. FAILURE

TO FOLLOW THIS INSTRUCTION MAY RESULT IN PERSONAL INJURY.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTE: Given the legal implications of a restraints system failure, harness repairs to Air Bag module circuits are not

acceptable. Where the text refers to "REPAIR the circuit", this will normally mean the replacement of a harness.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Restraints Control Module (RCM) (100-00 General Information, Description and Operation). Electrical

Battery condition, state of charge

Make sure all electrical connector(s) are engaged correctly on the air bag circuits

Wiring harness

Air bag module(s)

Make sure the restraints control module (RCM) is correctly installed

Fuse(s)

Sensor(s)

Pretensioner(s)

Warning lamp bulb(s) Visual Inspection

www.JagDocs.com

Page 2629 of 3039

Supplemental Restraint System - Clockspring

Removal and Installation Published: 11-May-2011

Removal

WARNINGS:

Always wear safety glasses when repairing an air bag supplemental restraint system (SRS) vehicle and when handling an

air bag module.

Carry a live air bag module with the air bag and trim cover pointed away from your body. This will reduce the risk of injury

in the event of an accidental deployment. Failure to follow this instruction may result in personal injury.

Do not set a live air bag module down with the trim cover face down. Failure to follow this instruction may result in

personal injury.

After deployment, the air bag surface can contain deposits of sodium hydroxide, a product of the gas generant

combustion that is irritating to the skin. Wash your hands with soap and water afterwards. Failure to follow this instruction

may result in personal injury.

Never probe the connectors on the air bag module. Doing so may result in air bag deployment, which may result in

personal injury. Failure to follow this instruction may result in personal injury.

Air bag modules with discolored or damaged trim covers must be replaced, not repainted.

Vehicle sensor orientation is critical for correct system operation. If a vehicle equipped with an air bag supplemental

restraint system (SRS) is involved in a collision, inspect the sensor mounting bracket and wiring pigtail for deformation. If

damaged, replace the sensor whether or not the air bag is deployed.

To avoid accidental deployment and possible personal injury, the backup power supply must be depleted before repairing

or replacing any air bag supplemental restraint system (SRS) components. To deplete the backup power supply energy,

disconnect the battery ground cable and wait one minute. Failure to follow this instruction may result in personal injury.

CAUTION: Make sure the wheels are in the straight-ahead position. Failure to follow this instruction may result in

damage to the component.

NOTE: Removal steps in this procedure may contain installation details.

1. Make the SRS system safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. CAUTIONS:

Make sure that special tool 211-326 is installed to the clockspring. 211-326

Locking Tool, Clockspring Special Tool(s)

www.JagDocs.com

Page 2638 of 3039

Published: 11-May-2011

Supplemental Restraint System - Occupant Classification Sensor

Removal and Installation

Removal

WARNINGS:

To avoid accidental deployment, the restraints control module backup power supply must be depleted. Wait at least one

minute after disconnecting the battery ground cable(s) before commencing any repair or adjustment to the supplemental

restraint system (SRS), or any component(s) adjacent to the SRS sensors. Failure to follow these instructions may result in

personal injury.

Always wear safety glasses when working on an air bag equipped vehicle and when handling an air bag module. Failure to

follow this instruction may result in personal injury.

To minimize the possibility of premature deployment, do not use radio key code savers when working on the

supplemental restraint system. Failure to follow this instruction may result in personal injury.

To minimize the possibility of injury in the event of premature deployment, always carry a live air bag module with the

bag and trim cover pointed away from the body. Failure to follow this instruction may result in personal injury.

To minimize the possibility of premature deployment, live air bag modules must only be placed on work benches which

have been ground bonded and with the trim cover facing up. Failure to follow these instructions may result in personal injury.

Never probe the electrical connectors of air bag modules or any other supplemental restraint system component. Failure

to follow this instruction may result in personal injury.

Painting over the driver air bag module trim cover or instrument panel could lead to deterioration of the trim cover and air

bags. Do not for any reason attempt to paint discoloured or damaged air bag module trim covers or instrument panel. Install a

new component. Failure to follow this instruction may result in personal injury.

CAUTIONS:

The front passenger seat occupant classification sensor is available only as a service kit. No attempt should be made to

replace individual components. Failure to follow this instruction may result in personal injury.

Check for correct operation of the front seat after completion of the procedure to make sure that the wiring harness has

not become trapped or stretched.

NOTES:

Note the routing of the seat harness.

Some variation in the illustrations may occur, but the essential information is always correct.

1. Make the air bag supplemental restraint system (SRS) safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. Refer to: Front Seat Backrest Cover (501-10 Seating, Removal and Installation).

Page 2641 of 3039

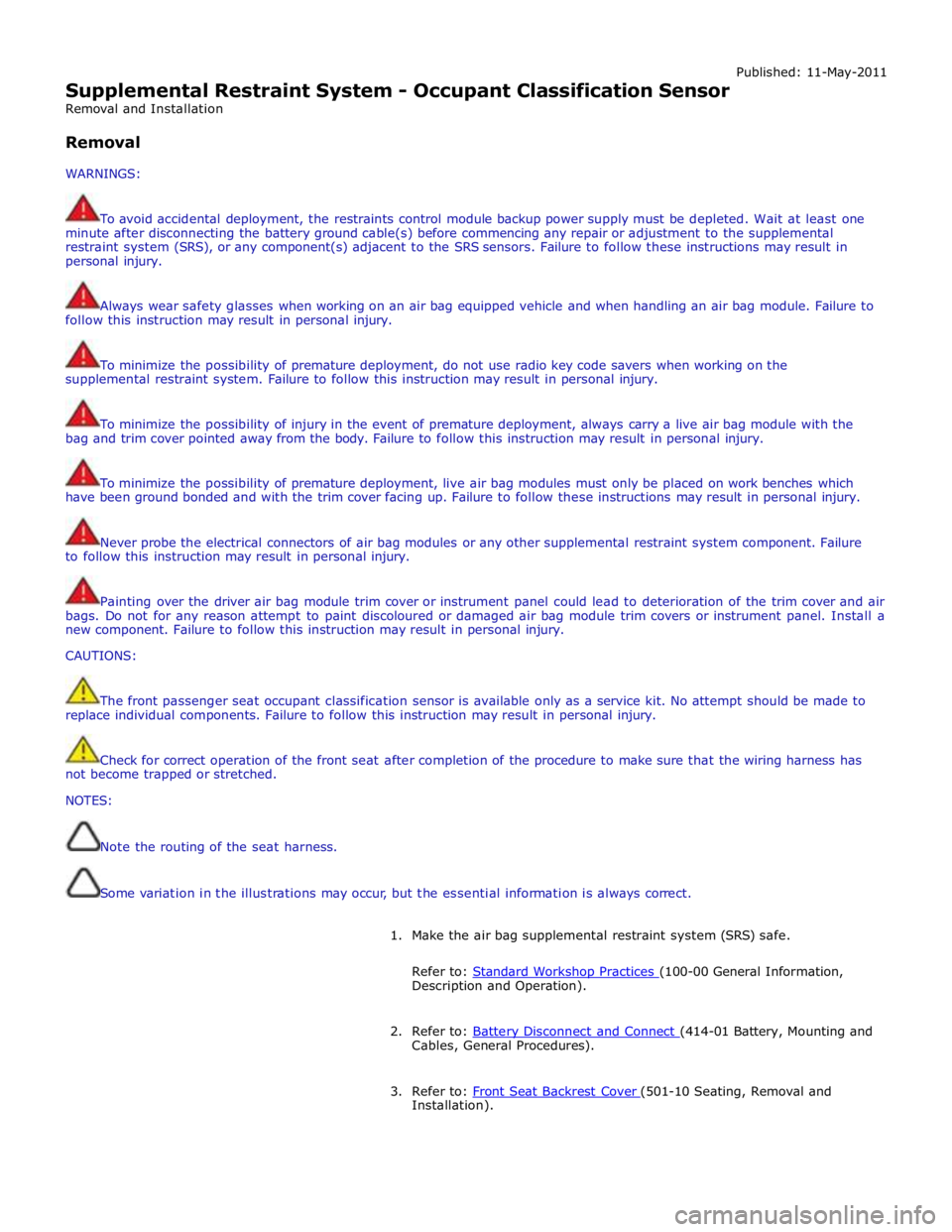

10.

11. NOTE: Note the position of the wiring harnesses to

aid installation.

Page 2642 of 3039

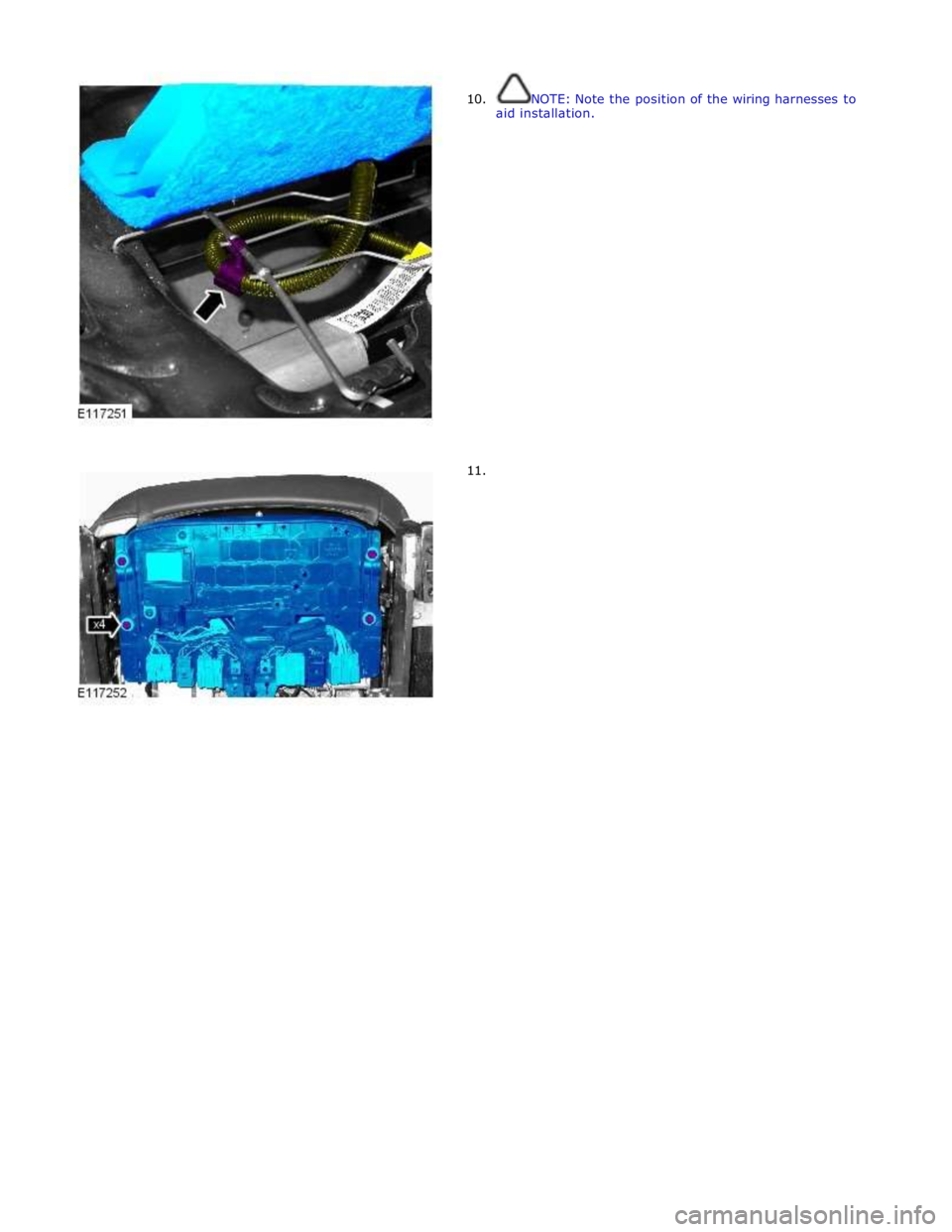

12.

13. CAUTION: Take extra care not to damage the clips.

NOTE: Note the position of the wiring harnesses to

aid installation.

Page 2650 of 3039

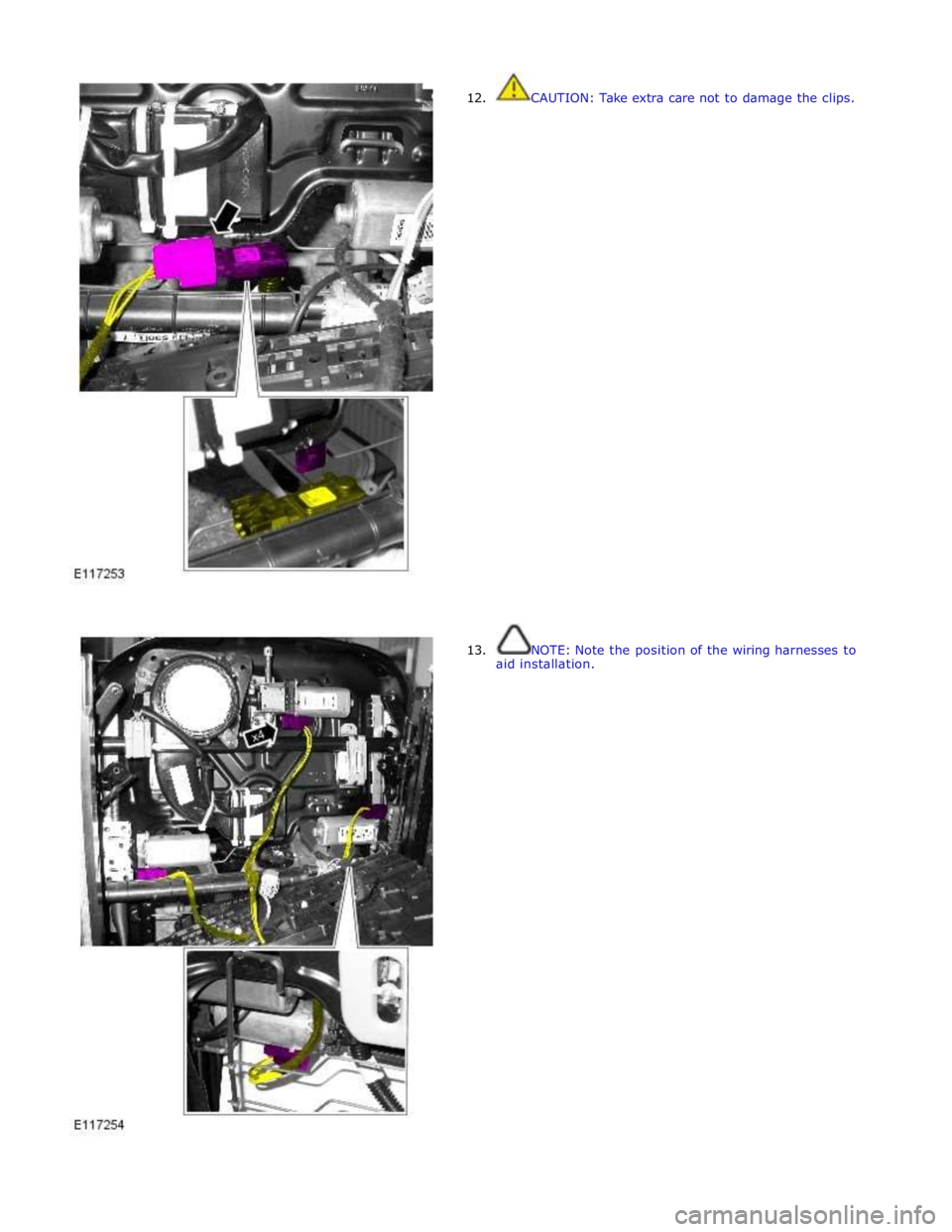

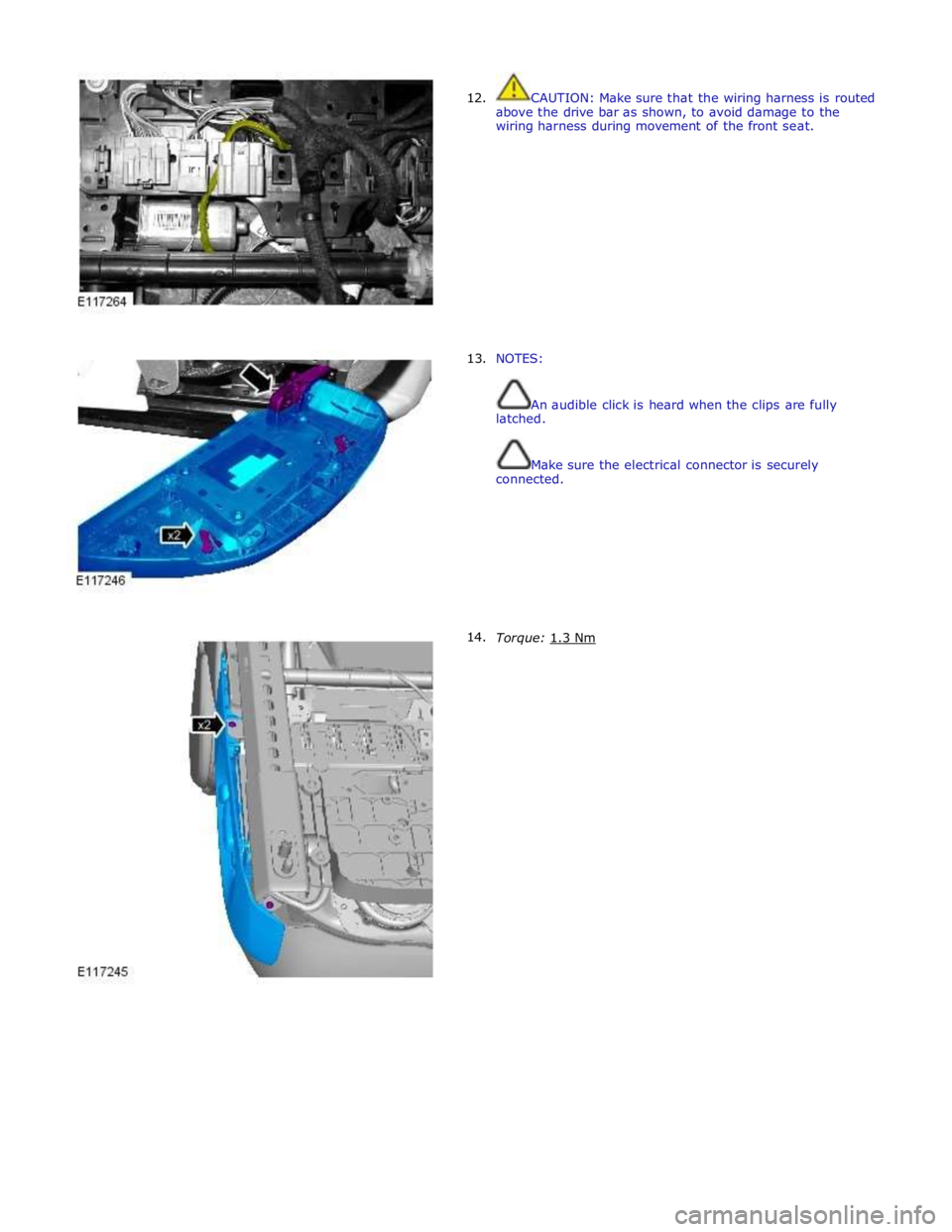

12.

13.

14. CAUTION: Make sure that the wiring harness is routed

above the drive bar as shown, to avoid damage to the

wiring harness during movement of the front seat.

NOTES:

An audible click is heard when the clips are fully

latched.

Make sure the electrical connector is securely

connected.

Torque: 1.3 Nm