boot JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 347 of 3039

60 Nm.

If the rear lower arm ball joint releases from the wheel

knuckle lower pivot, using no more than 60 Nm on the

special tool adjusting bolt, proceed to step 13.

If the rear lower arm ball joint does not release from

the wheel knuckle lower pivot, using no more than 60

Nm on the special tool adjusting bolt, proceed to step

12.

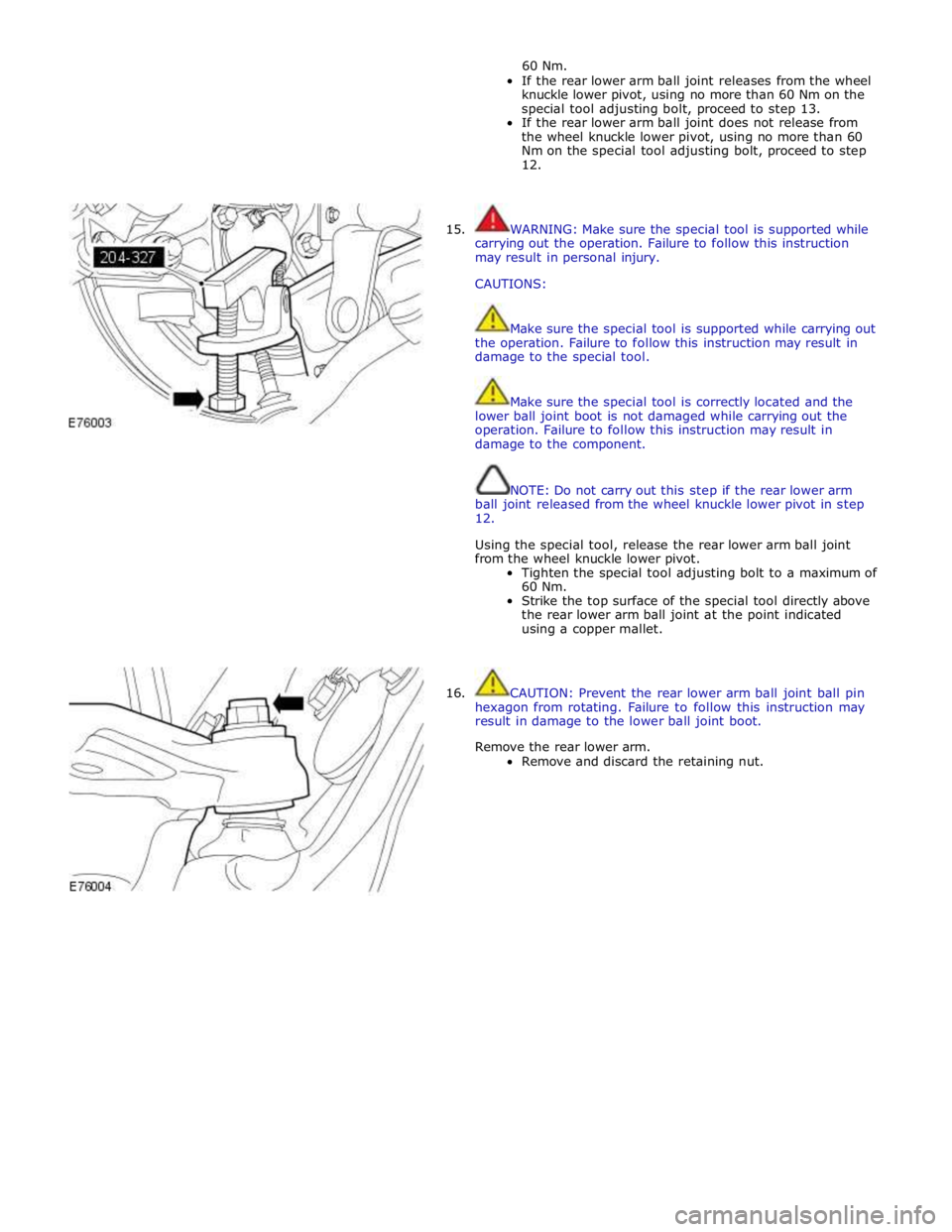

15. WARNING: Make sure the special tool is supported while

carrying out the operation. Failure to follow this instruction

may result in personal injury.

CAUTIONS:

Make sure the special tool is supported while carrying out

the operation. Failure to follow this instruction may result in

damage to the special tool.

Make sure the special tool is correctly located and the

lower ball joint boot is not damaged while carrying out the

operation. Failure to follow this instruction may result in

damage to the component.

NOTE: Do not carry out this step if the rear lower arm

ball joint released from the wheel knuckle lower pivot in step

12.

Using the special tool, release the rear lower arm ball joint

from the wheel knuckle lower pivot.

Tighten the special tool adjusting bolt to a maximum of

60 Nm.

Strike the top surface of the special tool directly above

the rear lower arm ball joint at the point indicated

using a copper mallet.

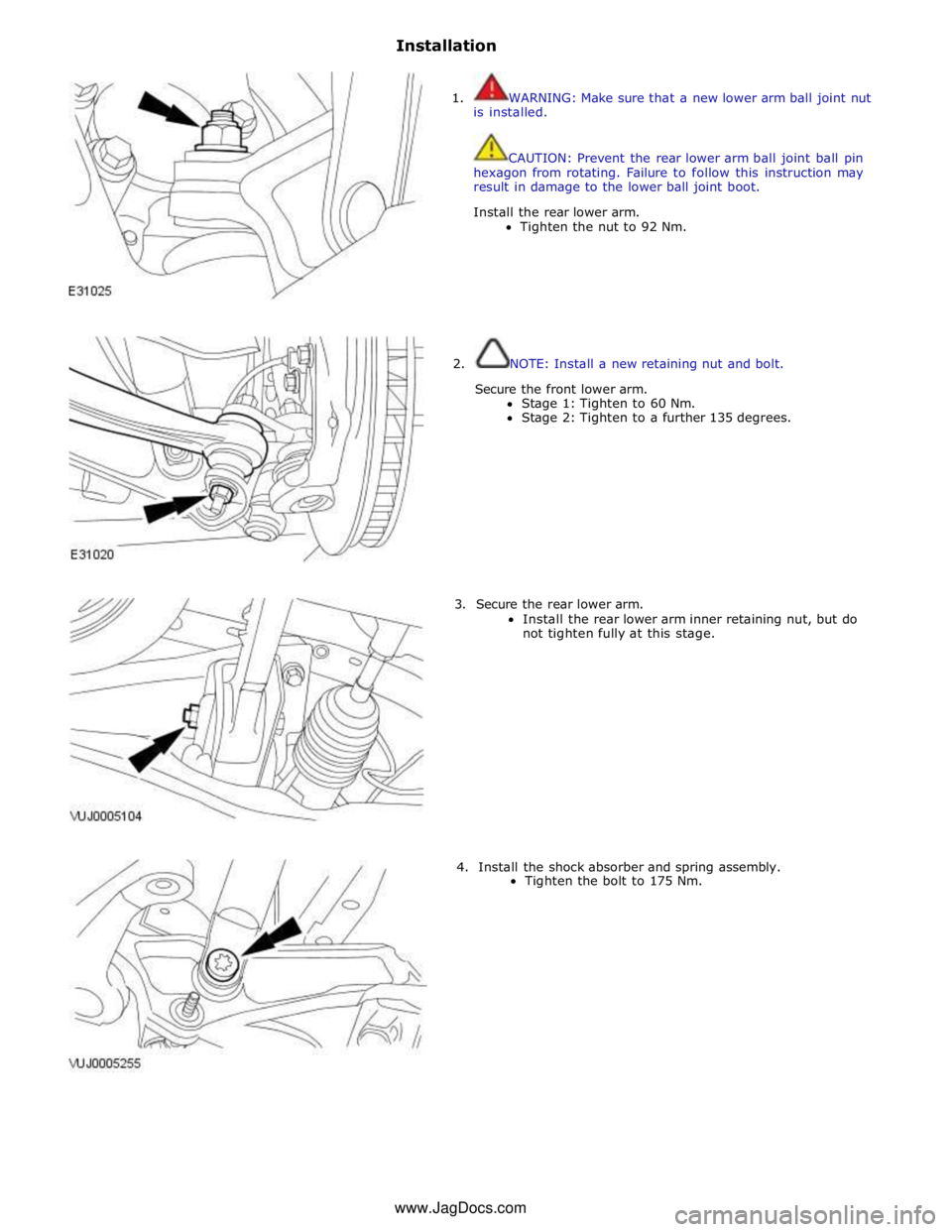

16. CAUTION: Prevent the rear lower arm ball joint ball pin

hexagon from rotating. Failure to follow this instruction may

result in damage to the lower ball joint boot.

Remove the rear lower arm.

Remove and discard the retaining nut.

Page 348 of 3039

Installation

1. WARNING: Make sure that a new lower arm ball joint nut

is installed.

CAUTION: Prevent the rear lower arm ball joint ball pin

hexagon from rotating. Failure to follow this instruction may

result in damage to the lower ball joint boot.

Install the rear lower arm.

Tighten the nut to 92 Nm.

2. NOTE: Install a new retaining nut and bolt.

Secure the front lower arm.

Stage 1: Tighten to 60 Nm.

Stage 2: Tighten to a further 135 degrees.

3. Secure the rear lower arm.

Install the rear lower arm inner retaining nut, but do

not tighten fully at this stage.

4. Install the shock absorber and spring assembly.

Tighten the bolt to 175 Nm. www.JagDocs.com

Page 355 of 3039

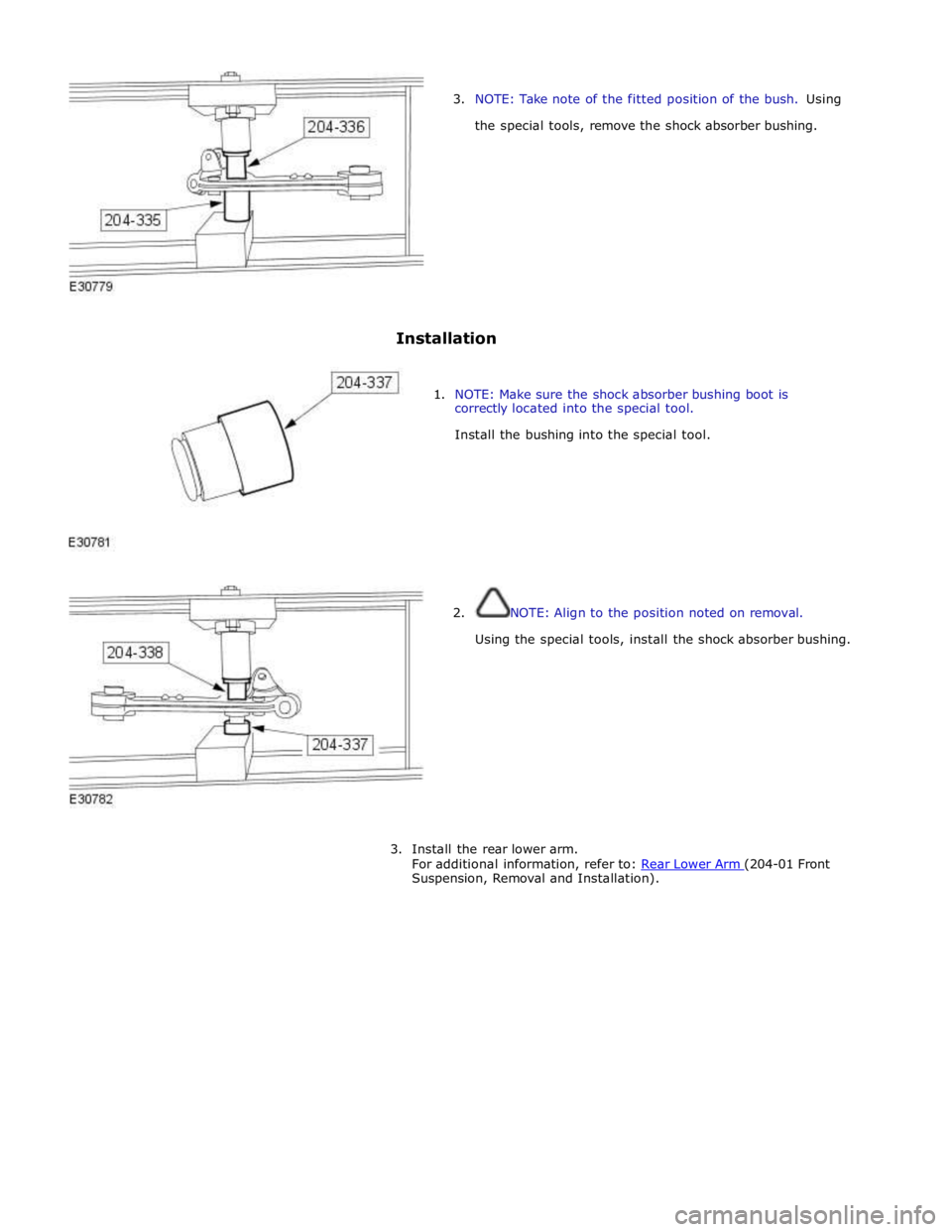

3. NOTE: Take note of the fitted position of the bush. Using

the special tools, remove the shock absorber bushing.

Installation

1. NOTE: Make sure the shock absorber bushing boot is

correctly located into the special tool.

Install the bushing into the special tool.

2. NOTE: Align to the position noted on removal.

Using the special tools, install the shock absorber bushing.

3. Install the rear lower arm.

For additional information, refer to: Rear Lower Arm (204-01 Front Suspension, Removal and Installation).

Page 575 of 3039

Rear Drive Halfshafts - Inner Constant Velocity (CV) Joint Boot

Removal and Installation

Removal Published: 11-May-2011

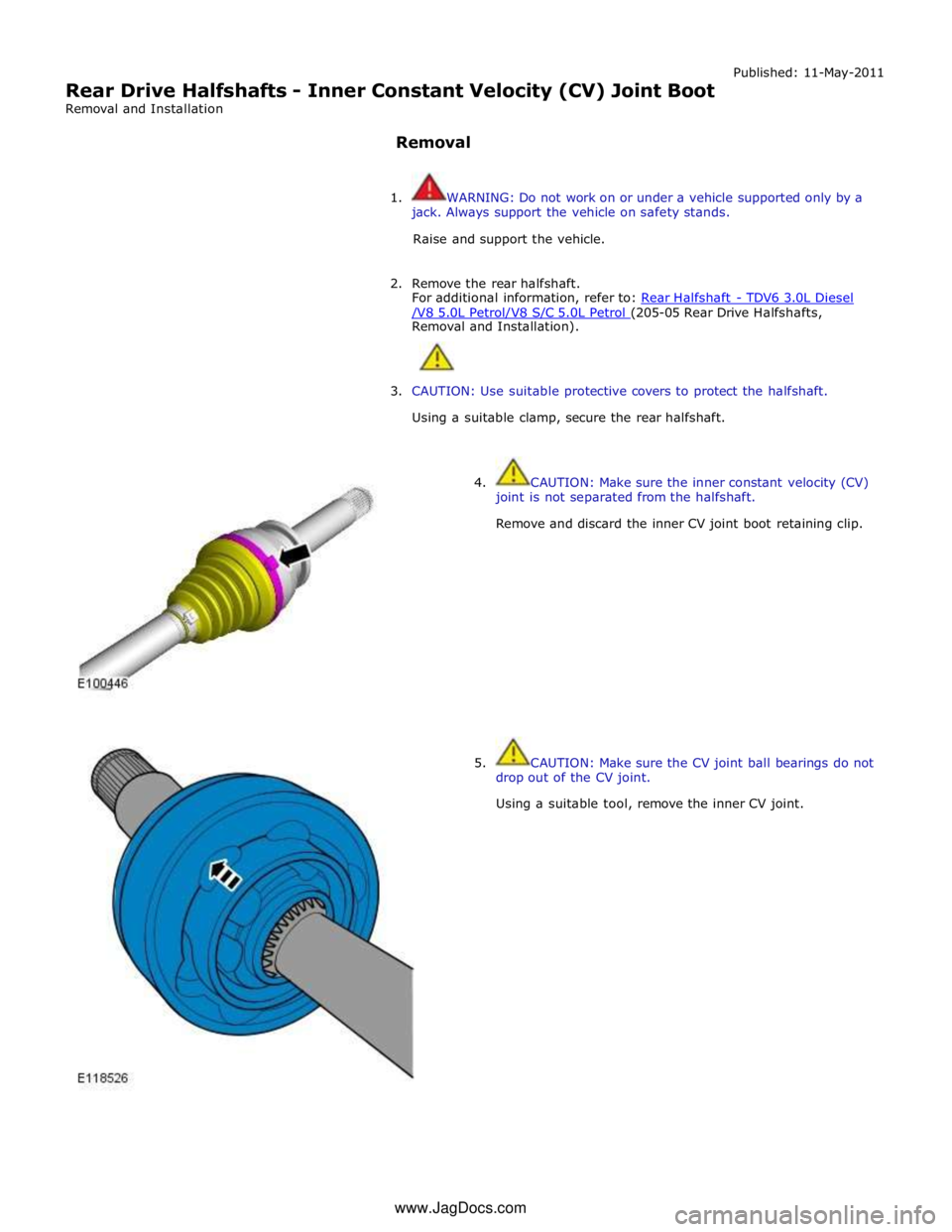

1. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the rear halfshaft.

For additional information, refer to: Rear Halfshaft - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-05 Rear Drive Halfshafts, Removal and Installation).

3. CAUTION: Use suitable protective covers to protect the halfshaft.

Using a suitable clamp, secure the rear halfshaft.

4. CAUTION: Make sure the inner constant velocity (CV)

joint is not separated from the halfshaft.

Remove and discard the inner CV joint boot retaining clip.

5. CAUTION: Make sure the CV joint ball bearings do not

drop out of the CV joint.

Using a suitable tool, remove the inner CV joint. www.JagDocs.com

Page 576 of 3039

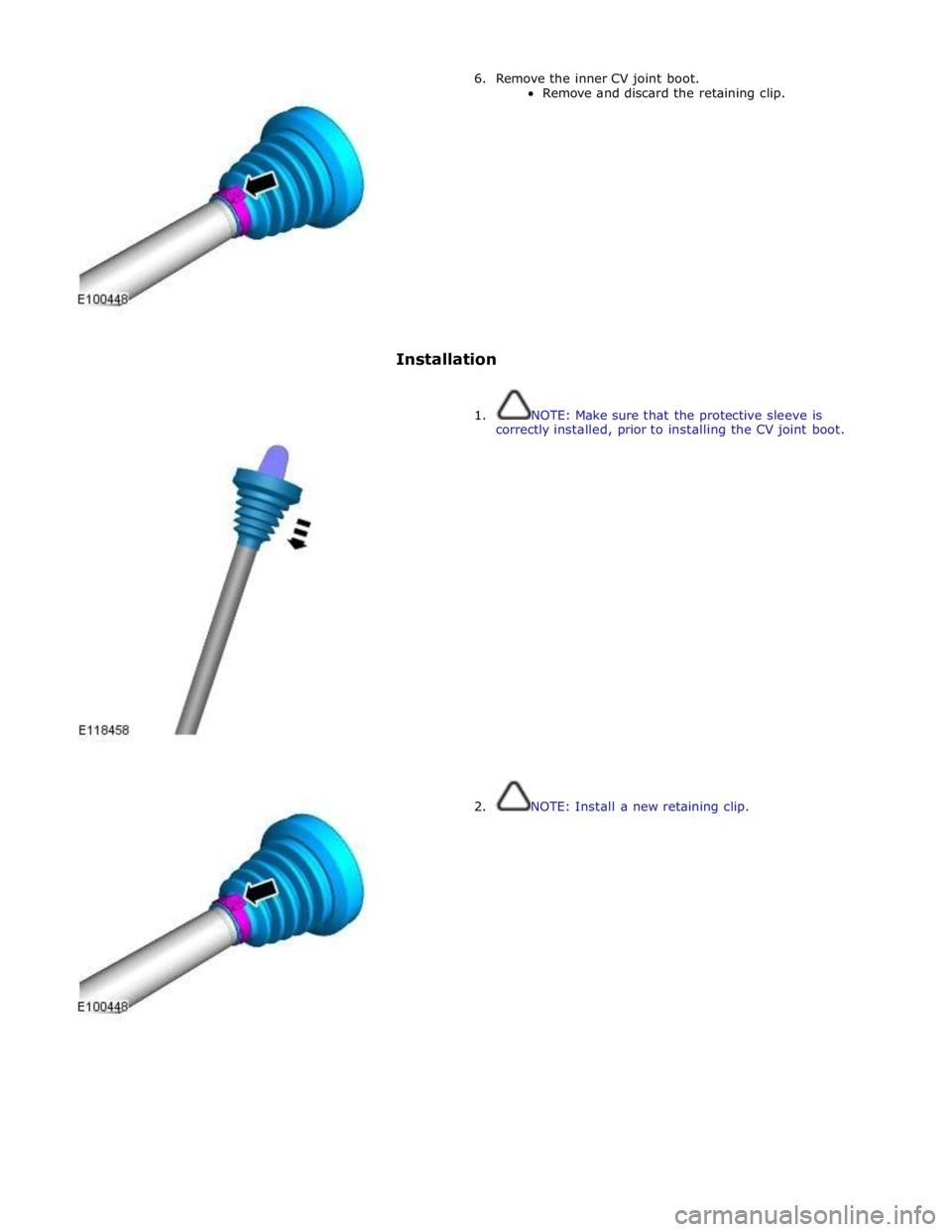

6. Remove the inner CV joint boot.

Remove and discard the retaining clip.

Installation

1. NOTE: Make sure that the protective sleeve is

correctly installed, prior to installing the CV joint boot.

2. NOTE: Install a new retaining clip.

Page 577 of 3039

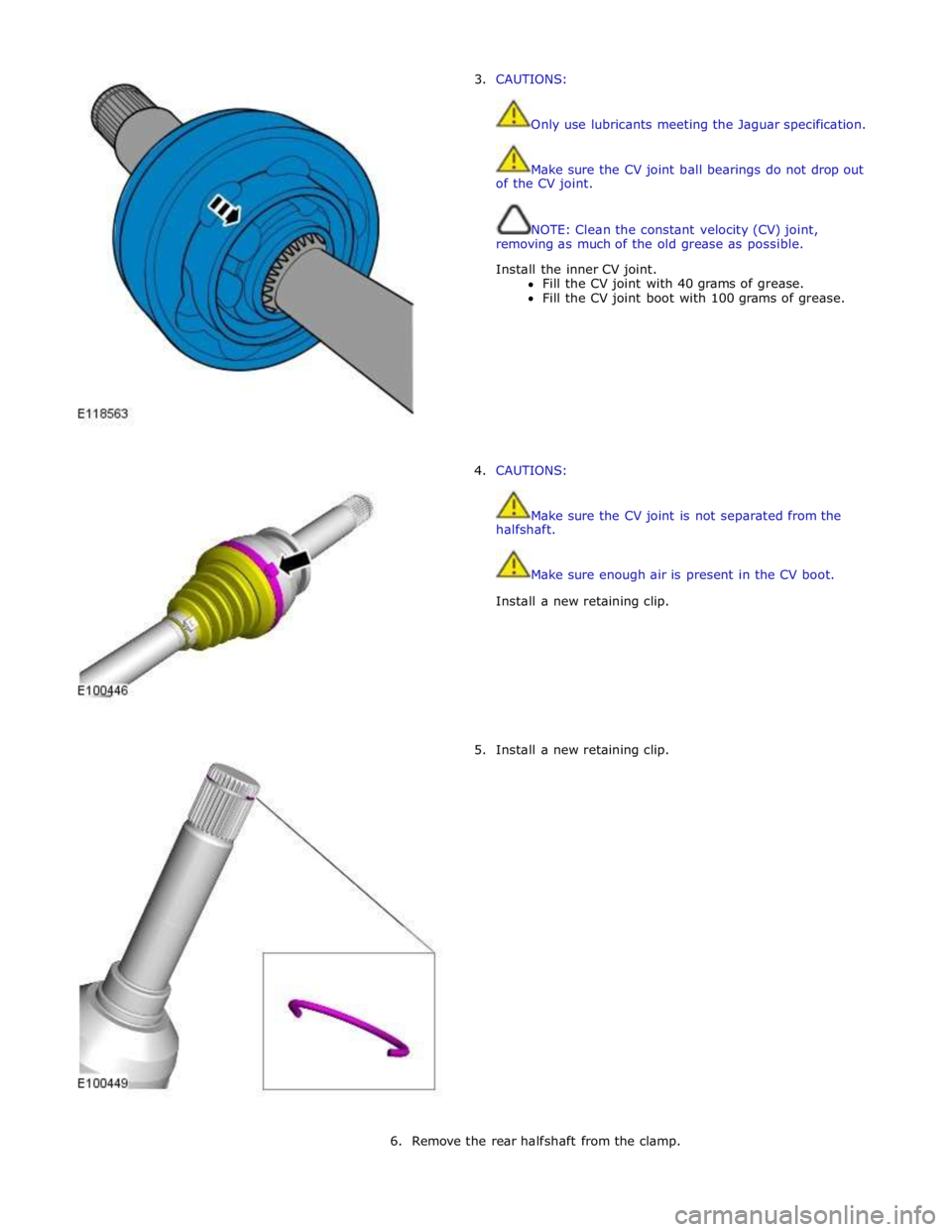

3. CAUTIONS:

Only use lubricants meeting the Jaguar specification.

Make sure the CV joint ball bearings do not drop out

of the CV joint.

NOTE: Clean the constant velocity (CV) joint,

removing as much of the old grease as possible.

Install the inner CV joint.

Fill the CV joint with 40 grams of grease.

Fill the CV joint boot with 100 grams of grease.

4. CAUTIONS:

Make sure the CV joint is not separated from the

halfshaft.

Make sure enough air is present in the CV boot.

Install a new retaining clip.

5. Install a new retaining clip.

6. Remove the rear halfshaft from the clamp.

Page 579 of 3039

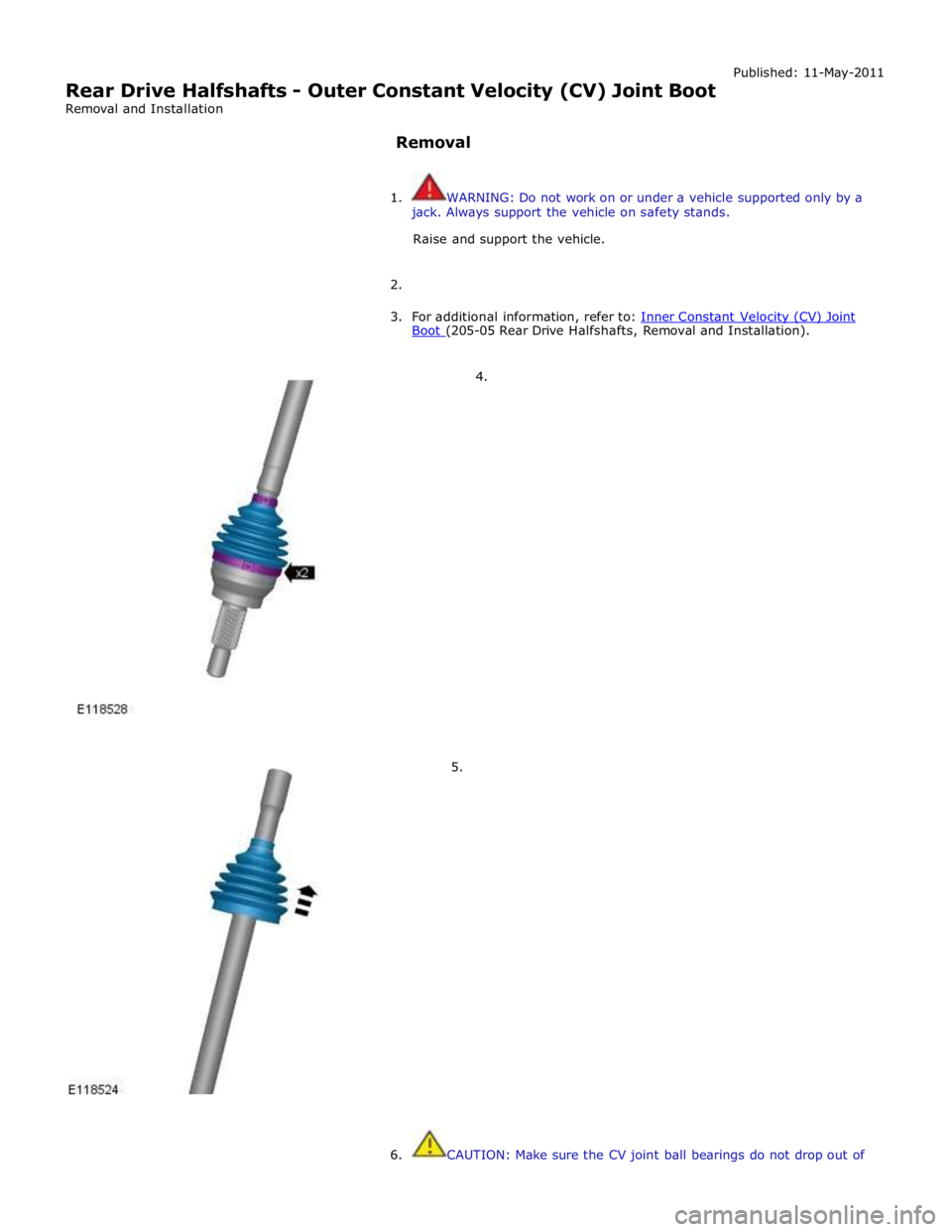

Rear Drive Halfshafts - Outer Constant Velocity (CV) Joint Boot

Removal and Installation

Removal Published: 11-May-2011

1. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2.

3. For additional information, refer to: Inner Constant Velocity (CV) Joint Boot (205-05 Rear Drive Halfshafts, Removal and Installation).

4.

5.

6. CAUTION: Make sure the CV joint ball bearings do not drop out of

Page 580 of 3039

the CV joint.

NOTE: Clean the constant velocity (CV) joint, removing as much of

the old grease as possible.

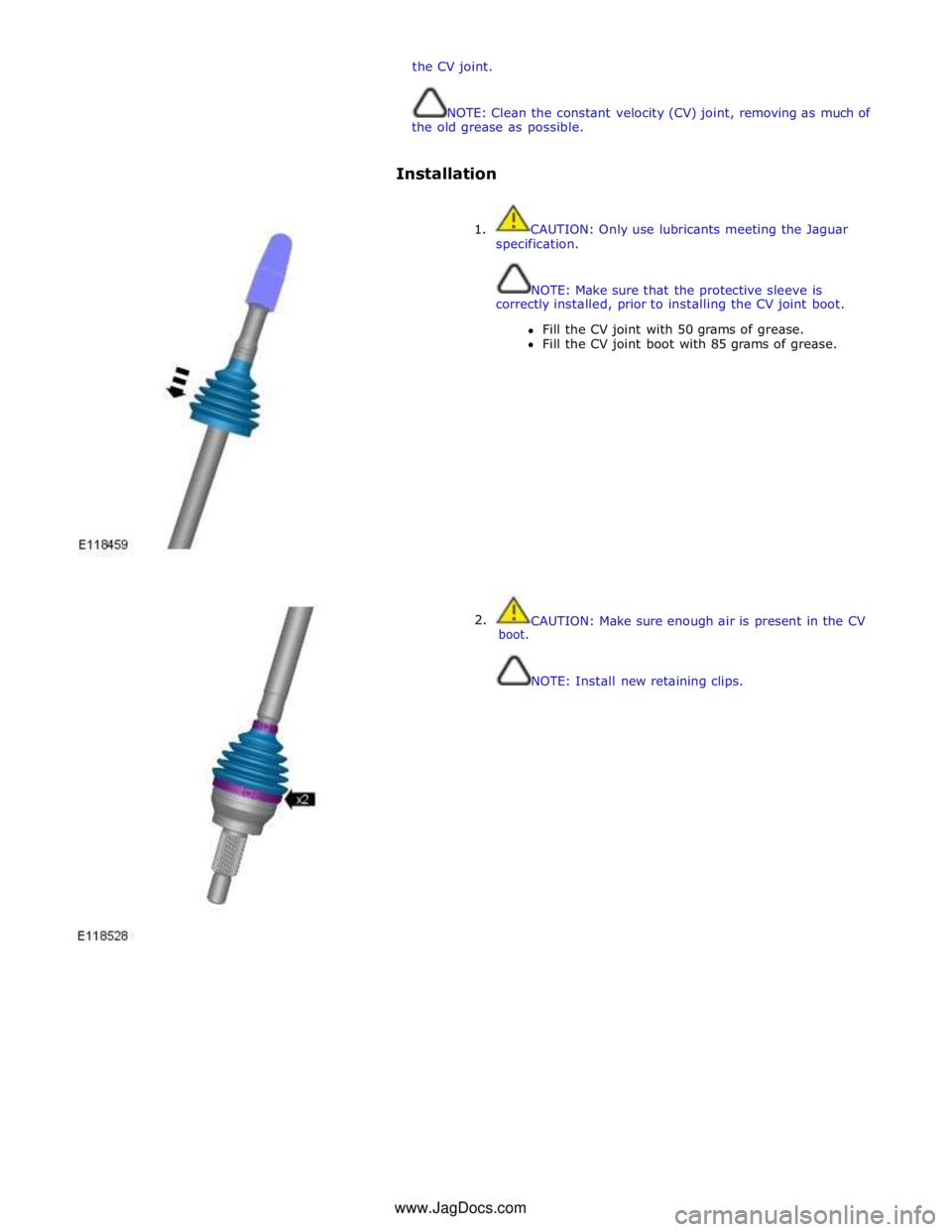

Installation

1. CAUTION: Only use lubricants meeting the Jaguar

specification.

NOTE: Make sure that the protective sleeve is

correctly installed, prior to installing the CV joint boot.

Fill the CV joint with 50 grams of grease.

Fill the CV joint boot with 85 grams of grease.

2. boot.

CAUTION: Make sure enough air is present in the CV

NOTE: Install new retaining clips. www.JagDocs.com

Page 718 of 3039

Steering System - General Information - Steering System

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the steering system operation, refer to the relevant Description and Operation sections of the

workshop manual. REFER to:

Power Steering (211-02 Power Steering, Description and Operation), Power Steering (211-02 Power Steering, Description and Operation), Power Steering (211-02 Power Steering, Description and Operation), Steering Linkage (211-03 Steering Linkage, Description and Operation), Steering Linkage (211-03 Steering Linkage, Description and Operation), Steering Linkage (211-03 Steering Linkage, Description and Operation), Steering Column (211-04 Steering Column, Description and Operation), Steering Column (211-04 Steering Column, Description and Operation), Steering Column (211-04 Steering Column, Description and Operation), Steering Column Switches (211-05 Steering Column Switches, Description and Operation), Steering Column Switches (211-05 Steering Column Switches, Description and Operation), Steering Column Switches (211-05 Steering Column Switches, Description and Operation).

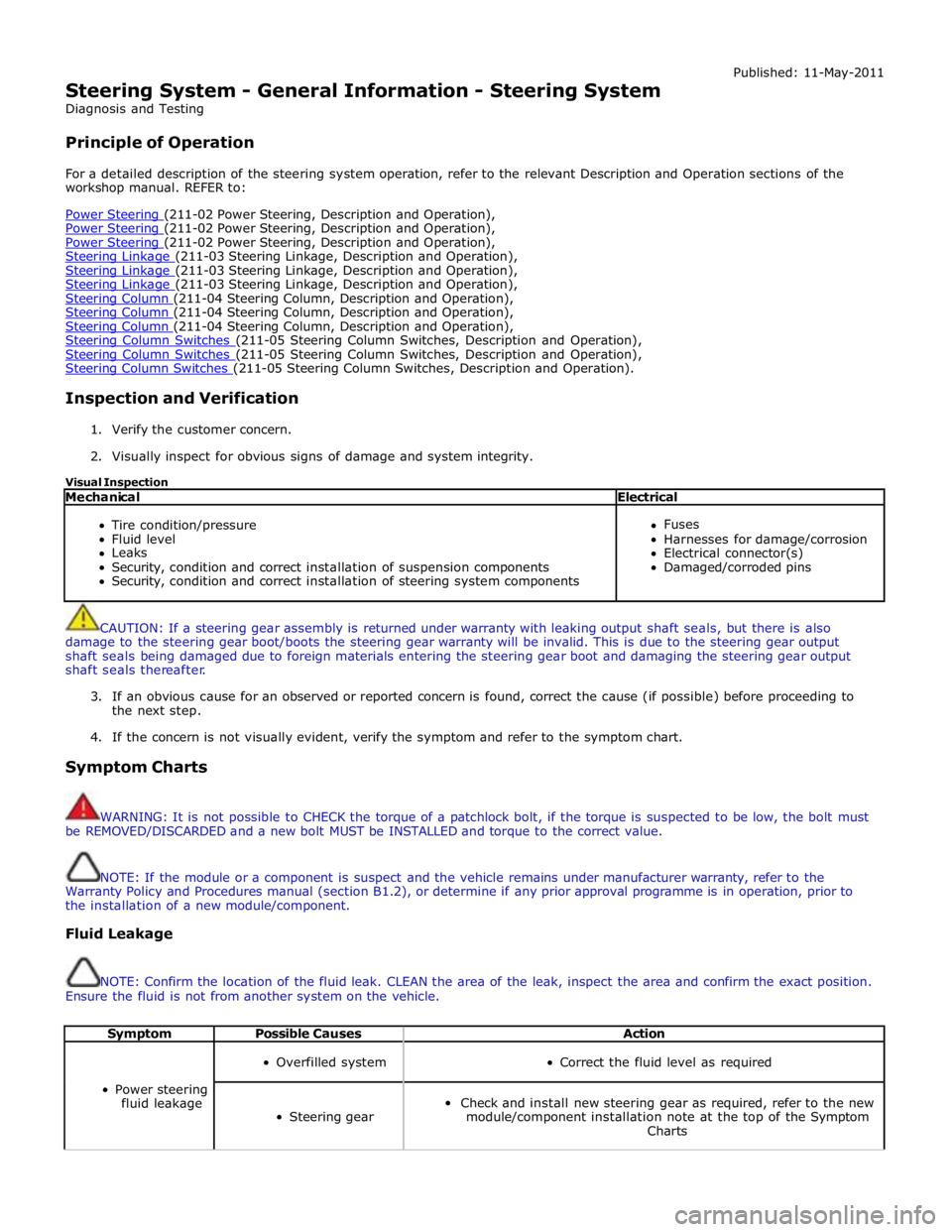

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Tire condition/pressure

Fluid level

Leaks

Security, condition and correct installation of suspension components

Security, condition and correct installation of steering system components

Fuses

Harnesses for damage/corrosion

Electrical connector(s)

Damaged/corroded pins

CAUTION: If a steering gear assembly is returned under warranty with leaking output shaft seals, but there is also

damage to the steering gear boot/boots the steering gear warranty will be invalid. This is due to the steering gear output

shaft seals being damaged due to foreign materials entering the steering gear boot and damaging the steering gear output

shaft seals thereafter.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the concern is not visually evident, verify the symptom and refer to the symptom chart.

Symptom Charts

WARNING: It is not possible to CHECK the torque of a patchlock bolt, if the torque is suspected to be low, the bolt must

be REMOVED/DISCARDED and a new bolt MUST be INSTALLED and torque to the correct value.

NOTE: If the module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Fluid Leakage

NOTE: Confirm the location of the fluid leak. CLEAN the area of the leak, inspect the area and confirm the exact position.

Ensure the fluid is not from another system on the vehicle.

Symptom Possible Causes Action

Power steering

fluid leakage

Overfilled system

Correct the fluid level as required

Steering gear

Check and install new steering gear as required, refer to the new

module/component installation note at the top of the Symptom

Charts

Page 723 of 3039

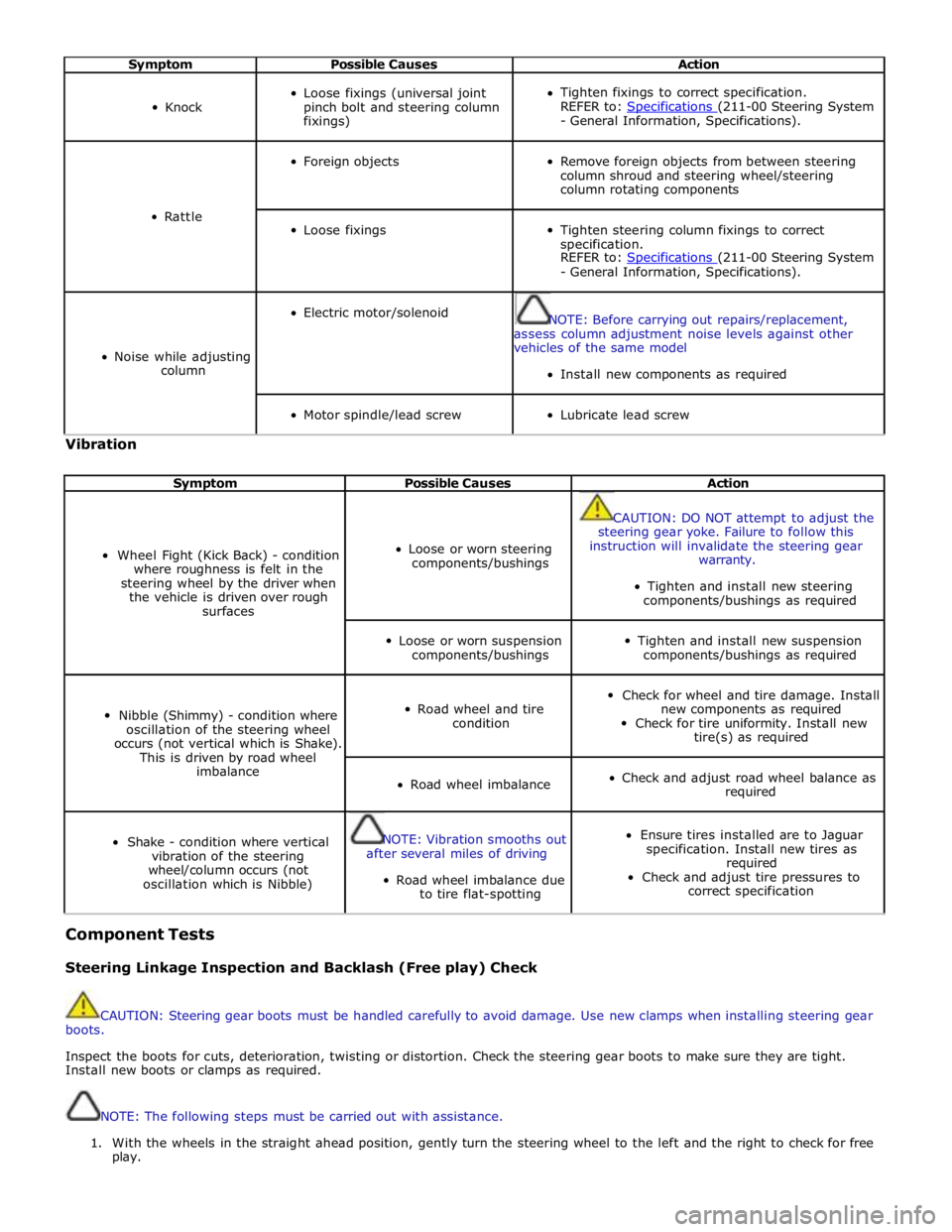

Symptom Possible Causes Action

Knock

Loose fixings (universal joint

pinch bolt and steering column

fixings)

Tighten fixings to correct specification.

REFER to: Specifications (211-00 Steering System - General Information, Specifications).

Rattle

Foreign objects

Remove foreign objects from between steering

column shroud and steering wheel/steering

column rotating components

Loose fixings

Tighten steering column fixings to correct

specification.

REFER to: Specifications (211-00 Steering System - General Information, Specifications).

Noise while adjusting

column

Electric motor/solenoid

NOTE: Before carrying out repairs/replacement,

assess column adjustment noise levels against other

vehicles of the same model

Install new components as required

Motor spindle/lead screw

Lubricate lead screw Vibration

Symptom Possible Causes Action

Wheel Fight (Kick Back) - condition

where roughness is felt in the

steering wheel by the driver when

the vehicle is driven over rough

surfaces

Loose or worn steering

components/bushings

CAUTION: DO NOT attempt to adjust the

steering gear yoke. Failure to follow this

instruction will invalidate the steering gear

warranty.

Tighten and install new steering

components/bushings as required

Loose or worn suspension

components/bushings

Tighten and install new suspension

components/bushings as required

Nibble (Shimmy) - condition where

oscillation of the steering wheel

occurs (not vertical which is Shake).

This is driven by road wheel

imbalance

Road wheel and tire

condition

Check for wheel and tire damage. Install

new components as required

Check for tire uniformity. Install new

tire(s) as required

Road wheel imbalance

Check and adjust road wheel balance as

required

Shake - condition where vertical

vibration of the steering

wheel/column occurs (not

oscillation which is Nibble)

NOTE: Vibration smooths out

after several miles of driving

Road wheel imbalance due

to tire flat-spotting

Ensure tires installed are to Jaguar

specification. Install new tires as

required

Check and adjust tire pressures to

correct specification Component Tests

Steering Linkage Inspection and Backlash (Free play) Check

CAUTION: Steering gear boots must be handled carefully to avoid damage. Use new clamps when installing steering gear

boots.

Inspect the boots for cuts, deterioration, twisting or distortion. Check the steering gear boots to make sure they are tight.

Install new boots or clamps as required.

NOTE: The following steps must be carried out with assistance.

1. With the wheels in the straight ahead position, gently turn the steering wheel to the left and the right to check for free

play.