boot JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 745 of 3039

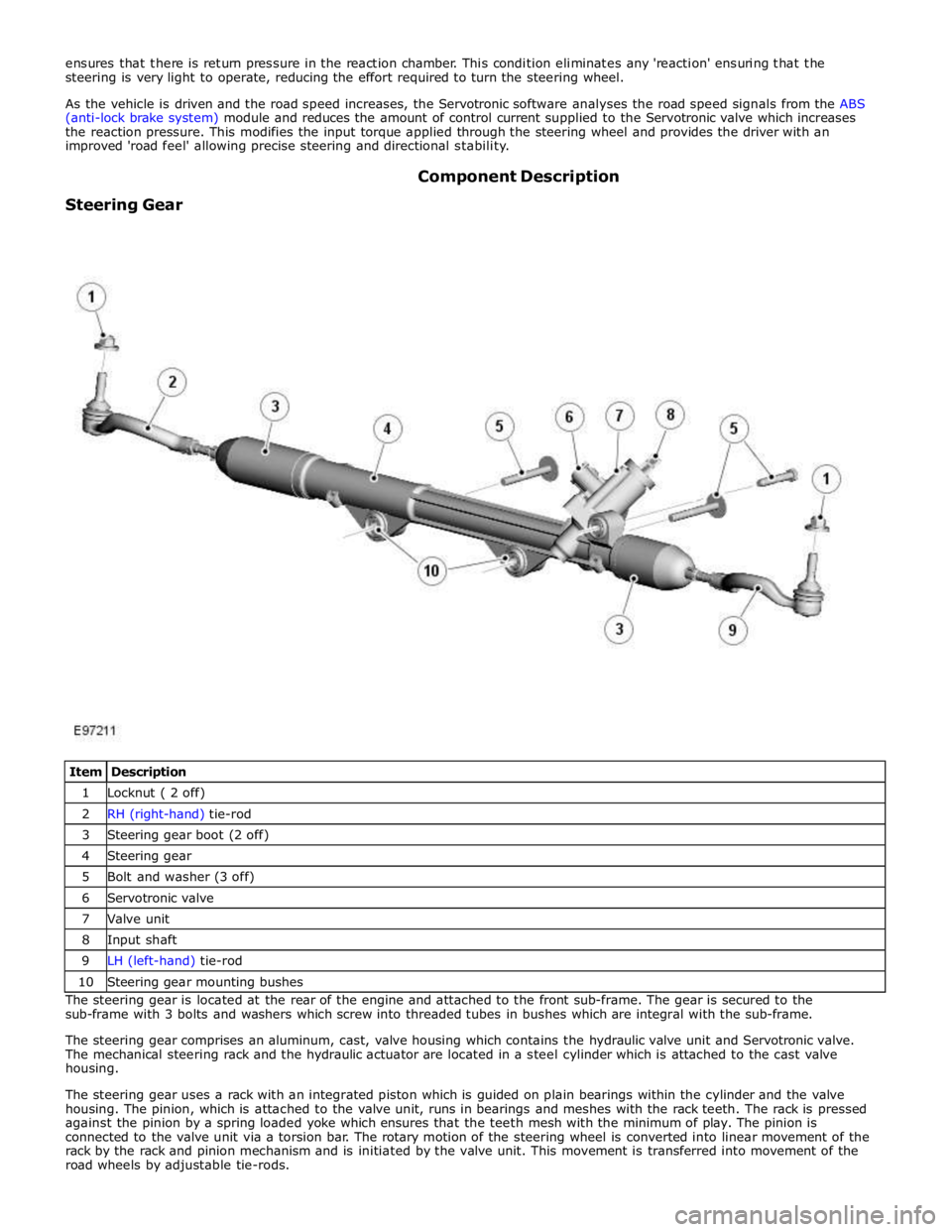

1 Locknut ( 2 off) 2 RH (right-hand) tie-rod 3 Steering gear boot (2 off) 4 Steering gear 5 Bolt and washer (3 off) 6 Servotronic valve 7 Valve unit 8 Input shaft 9 LH (left-hand) tie-rod 10 Steering gear mounting bushes The steering gear is located at the rear of the engine and attached to the front sub-frame. The gear is secured to the

sub-frame with 3 bolts and washers which screw into threaded tubes in bushes which are integral with the sub-frame.

The steering gear comprises an aluminum, cast, valve housing which contains the hydraulic valve unit and Servotronic valve.

The mechanical steering rack and the hydraulic actuator are located in a steel cylinder which is attached to the cast valve

housing.

The steering gear uses a rack with an integrated piston which is guided on plain bearings within the cylinder and the valve

housing. The pinion, which is attached to the valve unit, runs in bearings and meshes with the rack teeth. The rack is pressed

against the pinion by a spring loaded yoke which ensures that the teeth mesh with the minimum of play. The pinion is

connected to the valve unit via a torsion bar. The rotary motion of the steering wheel is converted into linear movement of the

rack by the rack and pinion mechanism and is initiated by the valve unit. This movement is transferred into movement of the

road wheels by adjustable tie-rods.

Page 769 of 3039

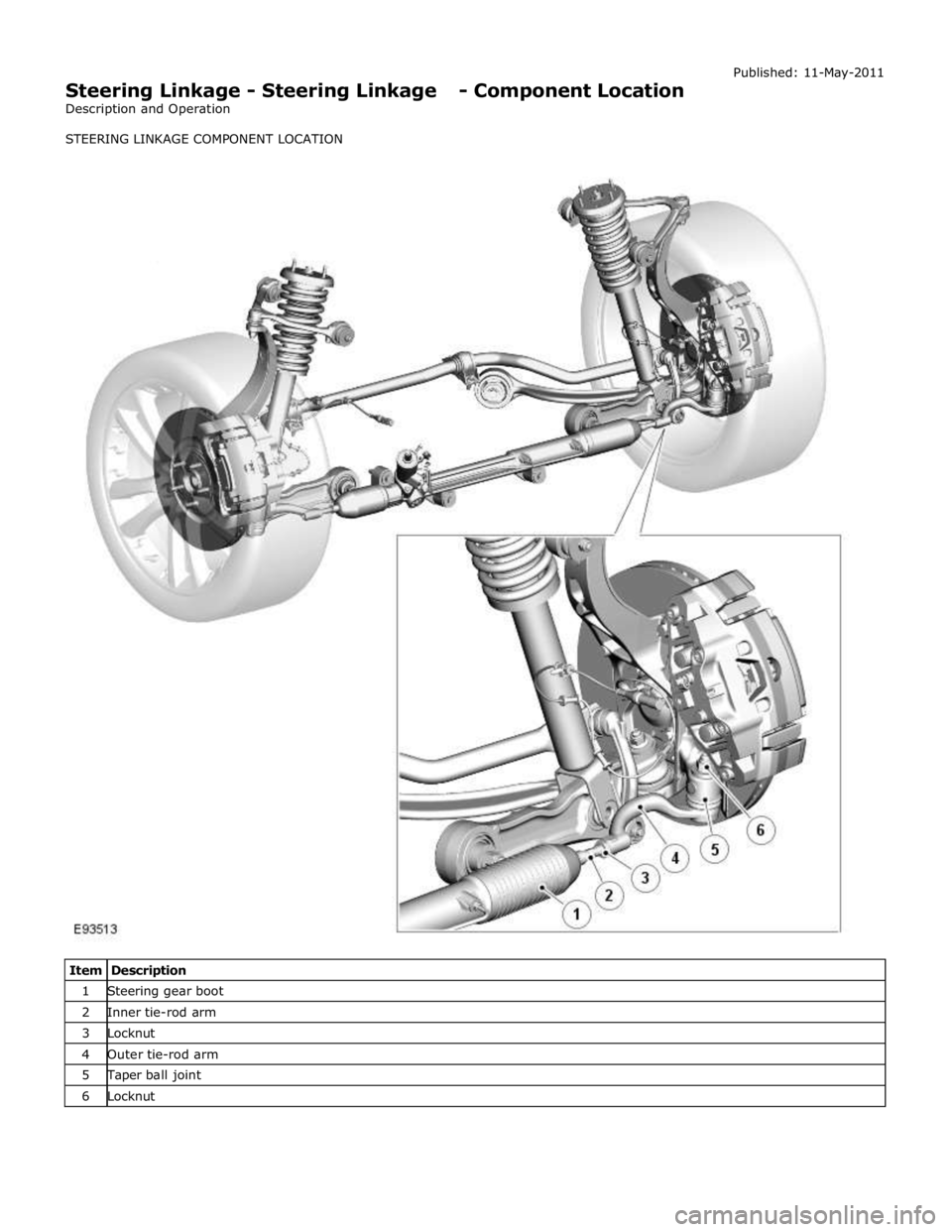

1 Steering gear boot 2 Inner tie-rod arm 3 Locknut 4 Outer tie-rod arm 5 Taper ball joint 6 Locknut

Page 770 of 3039

Steering Linkage - Steering Linkage - Overview

Description and Operation

OVERVIEW Published: 11-May-2011

The steering linkage comprises the tie rod which provides the connection between the steering gear and the front wheel

knuckle. Each end of the steering gear has a threaded hole which provides for the fitment of the inner tie rods. The external

ends of the inner tie rods are sealed with boots to prevent the ingress of dirt and moisture into the steering gear.

Page 783 of 3039

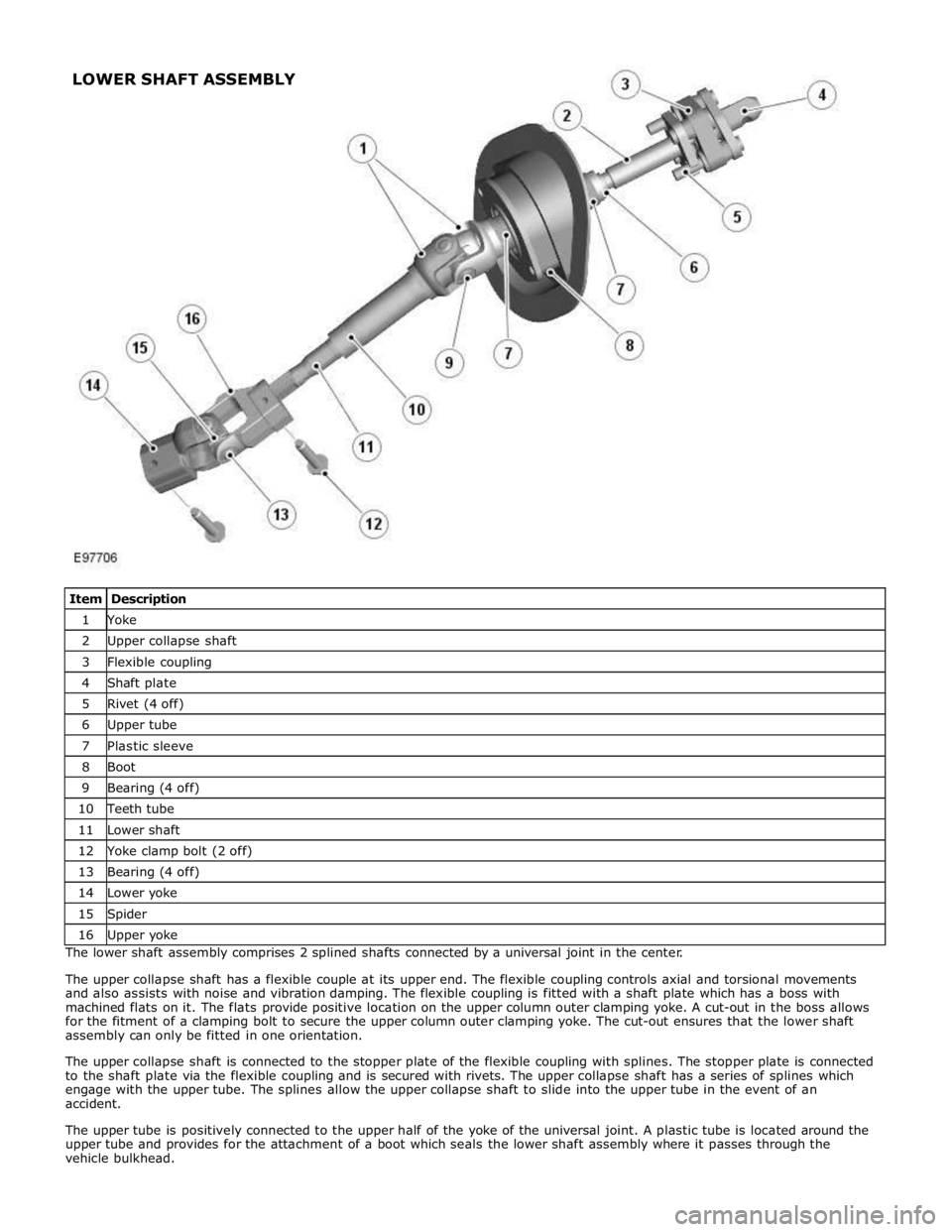

1 Yoke 2 Upper collapse shaft 3 Flexible coupling 4 Shaft plate 5 Rivet (4 off) 6 Upper tube 7 Plastic sleeve 8 Boot 9 Bearing (4 off) 10 Teeth tube 11 Lower shaft 12 Yoke clamp bolt (2 off) 13 Bearing (4 off) 14 Lower yoke 15 Spider 16 Upper yoke The lower shaft assembly comprises 2 splined shafts connected by a universal joint in the center.

The upper collapse shaft has a flexible couple at its upper end. The flexible coupling controls axial and torsional movements

and also assists with noise and vibration damping. The flexible coupling is fitted with a shaft plate which has a boss with

machined flats on it. The flats provide positive location on the upper column outer clamping yoke. A cut-out in the boss allows

for the fitment of a clamping bolt to secure the upper column outer clamping yoke. The cut-out ensures that the lower shaft

assembly can only be fitted in one orientation.

The upper collapse shaft is connected to the stopper plate of the flexible coupling with splines. The stopper plate is connected

to the shaft plate via the flexible coupling and is secured with rivets. The upper collapse shaft has a series of splines which

engage with the upper tube. The splines allow the upper collapse shaft to slide into the upper tube in the event of an

accident.

The upper tube is positively connected to the upper half of the yoke of the universal joint. A plastic tube is located around the

upper tube and provides for the attachment of a boot which seals the lower shaft assembly where it passes through the

vehicle bulkhead. LOWER SHAFT ASSEMBLY

Page 1187 of 3039

Published: 11-May-2011

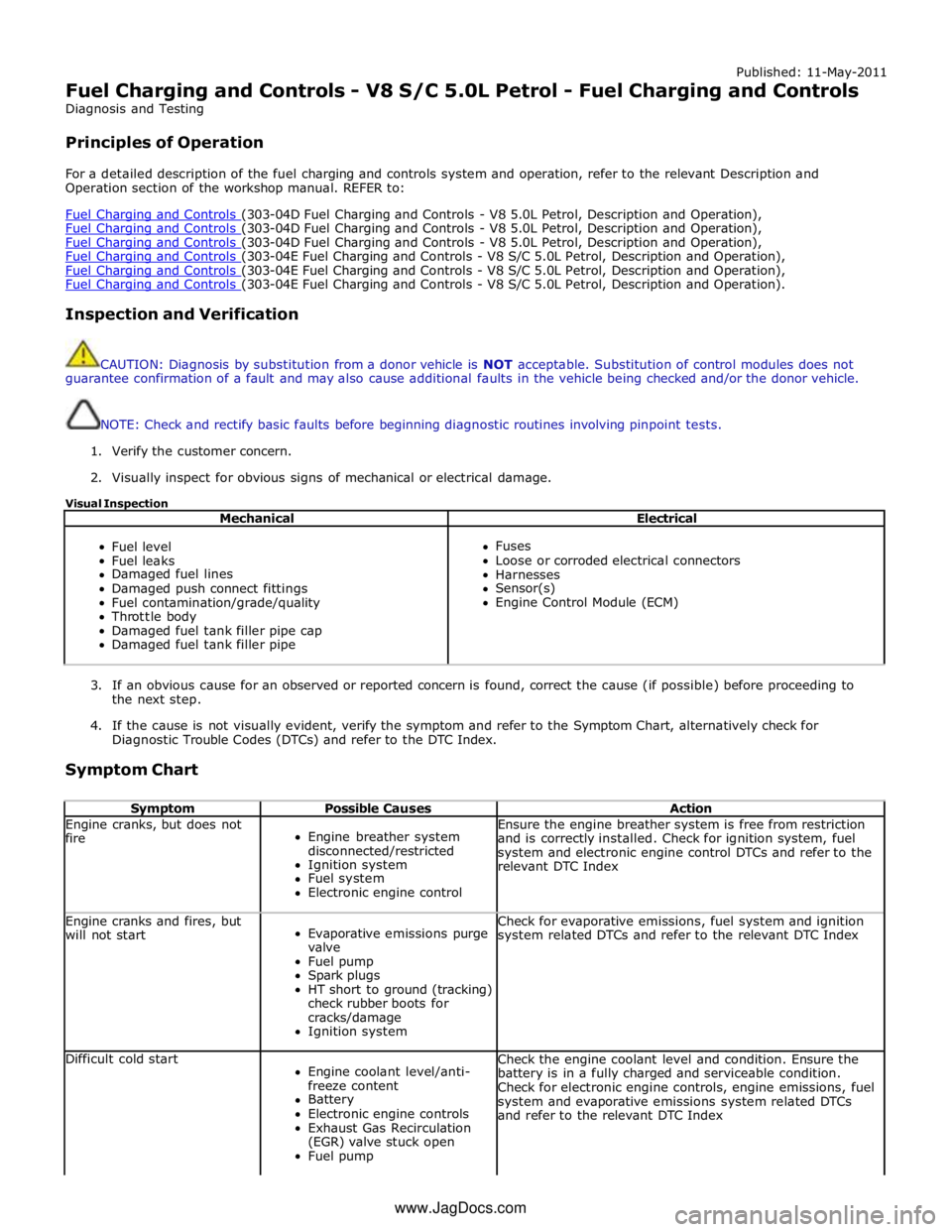

Fuel Charging and Controls - V8 S/C 5.0L Petrol - Fuel Charging and Controls

Diagnosis and Testing

Principles of Operation

For a detailed description of the fuel charging and controls system and operation, refer to the relevant Description and

Operation section of the workshop manual. REFER to:

Fuel Charging and Controls (303-04D Fuel Charging and Controls - V8 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04D Fuel Charging and Controls - V8 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04D Fuel Charging and Controls - V8 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Fuel level

Fuel leaks

Damaged fuel lines

Damaged push connect fittings

Fuel contamination/grade/quality

Throttle body

Damaged fuel tank filler pipe cap

Damaged fuel tank filler pipe

Fuses

Loose or corroded electrical connectors

Harnesses

Sensor(s)

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control Ensure the engine breather system is free from restriction

and is correctly installed. Check for ignition system, fuel

system and electronic engine control DTCs and refer to the

relevant DTC Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system Check for evaporative emissions, fuel system and ignition

system related DTCs and refer to the relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Exhaust Gas Recirculation

(EGR) valve stuck open

Fuel pump Check the engine coolant level and condition. Ensure the

battery is in a fully charged and serviceable condition.

Check for electronic engine controls, engine emissions, fuel

system and evaporative emissions system related DTCs

and refer to the relevant DTC Index www.JagDocs.com

Page 1276 of 3039

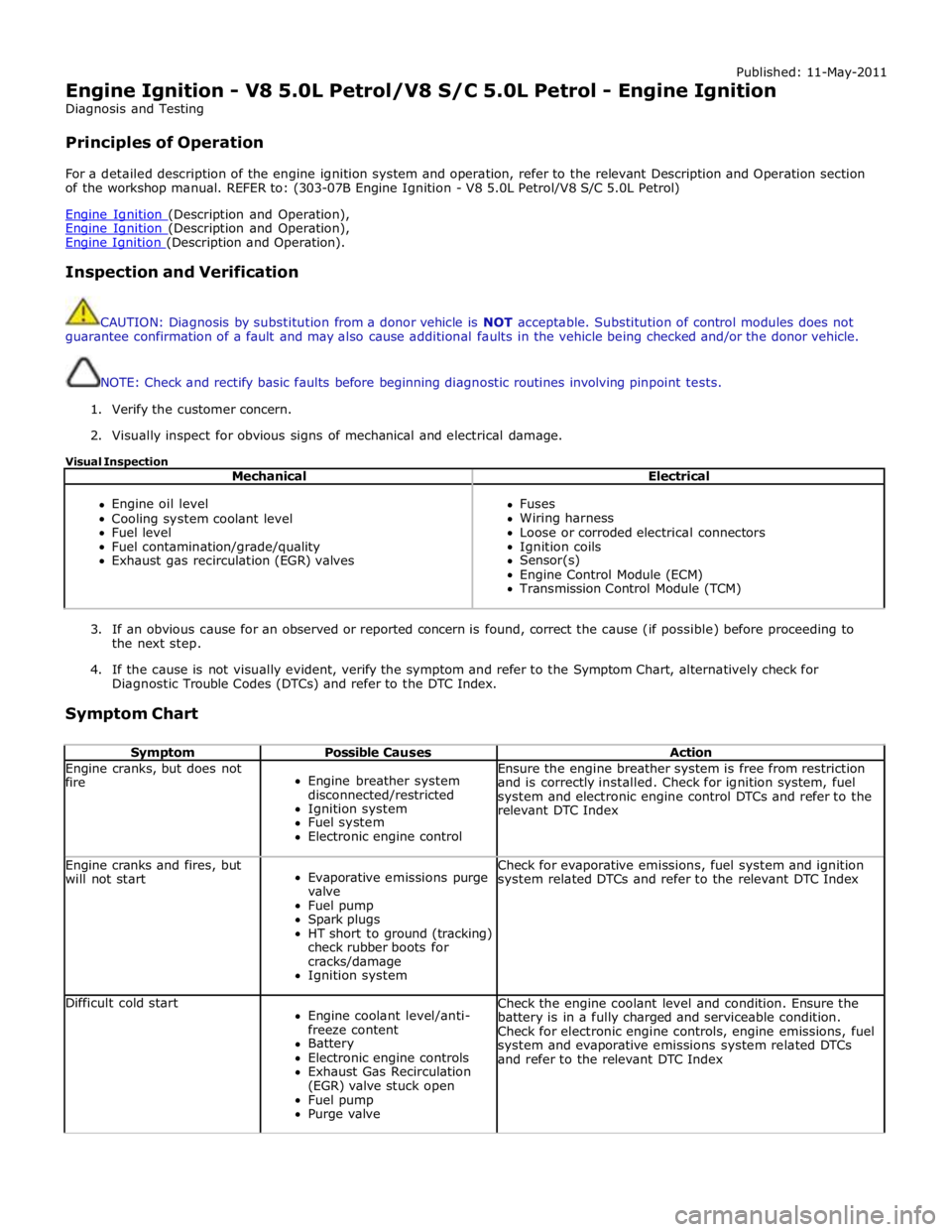

Published: 11-May-2011

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Ignition

Diagnosis and Testing

Principles of Operation

For a detailed description of the engine ignition system and operation, refer to the relevant Description and Operation section

of the workshop manual. REFER to: (303-07B Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol)

Engine Ignition (Description and Operation), Engine Ignition (Description and Operation), Engine Ignition (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical and electrical damage.

Visual Inspection

Mechanical Electrical

Engine oil level

Cooling system coolant level

Fuel level

Fuel contamination/grade/quality

Exhaust gas recirculation (EGR) valves

Fuses

Wiring harness

Loose or corroded electrical connectors

Ignition coils

Sensor(s)

Engine Control Module (ECM)

Transmission Control Module (TCM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control Ensure the engine breather system is free from restriction

and is correctly installed. Check for ignition system, fuel

system and electronic engine control DTCs and refer to the

relevant DTC Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system Check for evaporative emissions, fuel system and ignition

system related DTCs and refer to the relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Exhaust Gas Recirculation

(EGR) valve stuck open

Fuel pump

Purge valve Check the engine coolant level and condition. Ensure the

battery is in a fully charged and serviceable condition.

Check for electronic engine controls, engine emissions, fuel

system and evaporative emissions system related DTCs

and refer to the relevant DTC Index

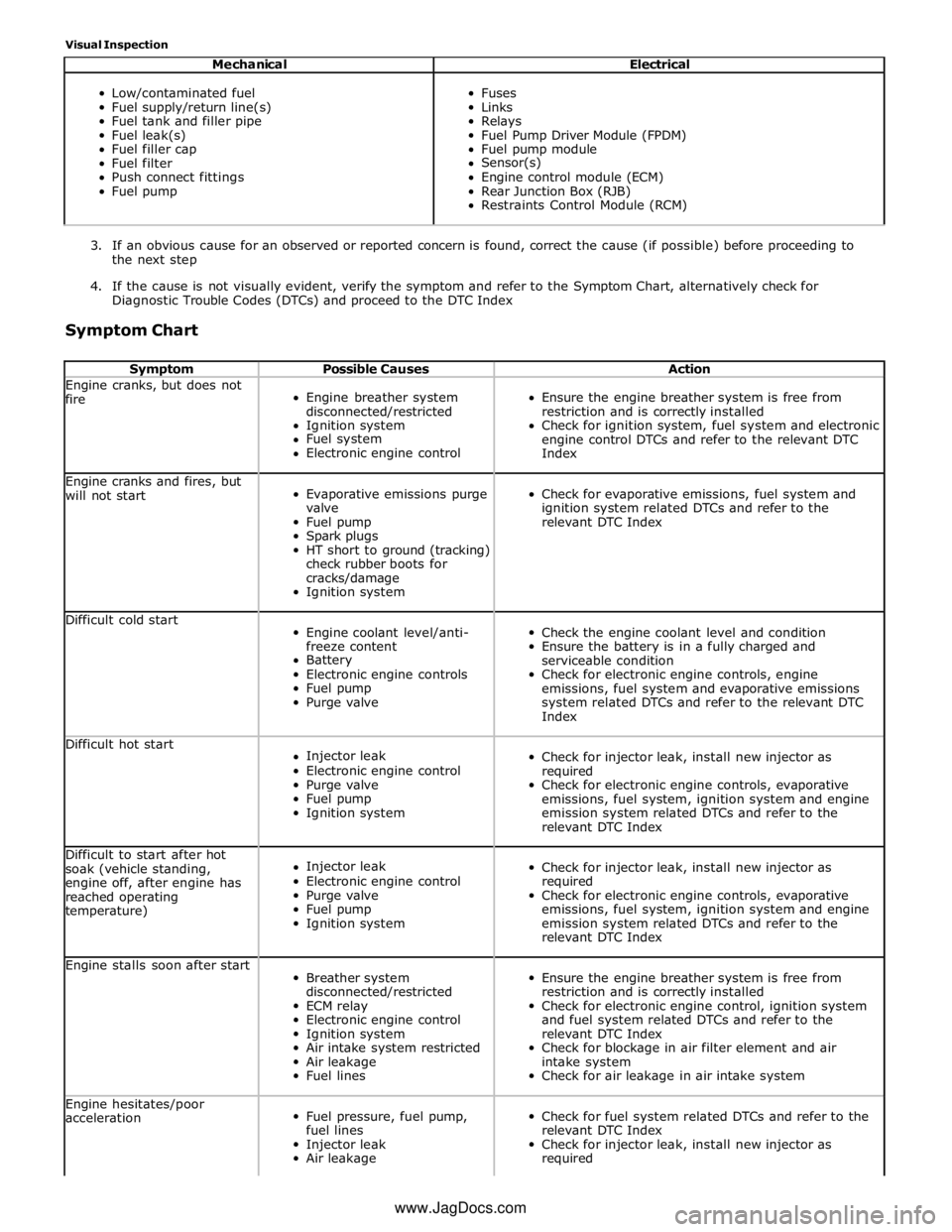

Page 1596 of 3039

Visual Inspection

Mechanical Electrical

Low/contaminated fuel

Fuel supply/return line(s)

Fuel tank and filler pipe

Fuel leak(s)

Fuel filler cap

Fuel filter

Push connect fittings

Fuel pump

Fuses

Links

Relays

Fuel Pump Driver Module (FPDM)

Fuel pump module

Sensor(s)

Engine control module (ECM)

Rear Junction Box (RJB)

Restraints Control Module (RCM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and proceed to the DTC Index

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control

Ensure the engine breather system is free from

restriction and is correctly installed

Check for ignition system, fuel system and electronic

engine control DTCs and refer to the relevant DTC

Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system

Check for evaporative emissions, fuel system and

ignition system related DTCs and refer to the

relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Fuel pump

Purge valve

Check the engine coolant level and condition

Ensure the battery is in a fully charged and

serviceable condition

Check for electronic engine controls, engine

emissions, fuel system and evaporative emissions

system related DTCs and refer to the relevant DTC

Index Difficult hot start

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Difficult to start after hot

soak (vehicle standing,

engine off, after engine has

reached operating

temperature)

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Engine stalls soon after start

Breather system

disconnected/restricted

ECM relay

Electronic engine control

Ignition system

Air intake system restricted

Air leakage

Fuel lines

Ensure the engine breather system is free from

restriction and is correctly installed

Check for electronic engine control, ignition system

and fuel system related DTCs and refer to the

relevant DTC Index

Check for blockage in air filter element and air

intake system

Check for air leakage in air intake system Engine hesitates/poor

acceleration

Fuel pressure, fuel pump,

fuel lines

Injector leak

Air leakage

Check for fuel system related DTCs and refer to the

relevant DTC Index

Check for injector leak, install new injector as

required www.JagDocs.com

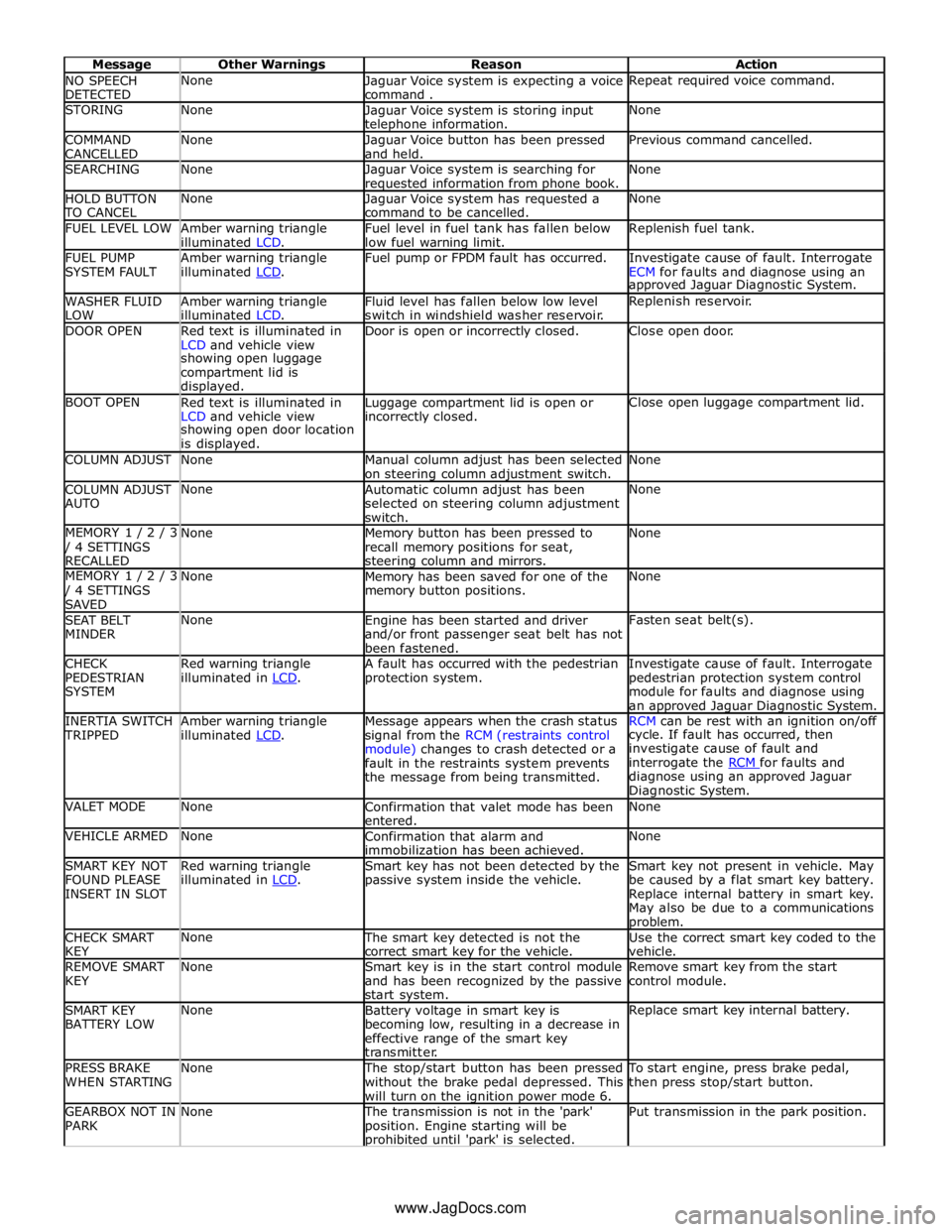

Page 1827 of 3039

NO SPEECH

DETECTED None

Jaguar Voice system is expecting a voice

command . Repeat required voice command. STORING None

Jaguar Voice system is storing input telephone information. None COMMAND

CANCELLED None

Jaguar Voice button has been pressed

and held. Previous command cancelled. SEARCHING None

Jaguar Voice system is searching for requested information from phone book. None HOLD BUTTON TO CANCEL None

Jaguar Voice system has requested a

command to be cancelled. None FUEL LEVEL LOW

Amber warning triangle

illuminated LCD. Fuel level in fuel tank has fallen below

low fuel warning limit. Replenish fuel tank. FUEL PUMP

SYSTEM FAULT Amber warning triangle

illuminated LCD. Fuel pump or FPDM fault has occurred.

Investigate cause of fault. Interrogate

ECM for faults and diagnose using an approved Jaguar Diagnostic System. WASHER FLUID

LOW Amber warning triangle

illuminated LCD. Fluid level has fallen below low level

switch in windshield washer reservoir. Replenish reservoir. DOOR OPEN

Red text is illuminated in

LCD and vehicle view Door is open or incorrectly closed. Close open door. showing open luggage

compartment lid is

displayed. BOOT OPEN

Red text is illuminated in

LCD and vehicle view Luggage compartment lid is open or incorrectly closed. Close open luggage compartment lid. showing open door location

is displayed. COLUMN ADJUST None

Manual column adjust has been selected

on steering column adjustment switch. None COLUMN ADJUST

AUTO None

Automatic column adjust has been

selected on steering column adjustment

switch. None MEMORY 1 / 2 / 3 / 4 SETTINGS

RECALLED None

Memory button has been pressed to

recall memory positions for seat, steering column and mirrors. None MEMORY 1 / 2 / 3 / 4 SETTINGS

SAVED None

Memory has been saved for one of the

memory button positions. None SEAT BELT

MINDER None

Engine has been started and driver

and/or front passenger seat belt has not

been fastened. Fasten seat belt(s). CHECK

PEDESTRIAN

SYSTEM Red warning triangle

illuminated in LCD. A fault has occurred with the pedestrian

protection system. Investigate cause of fault. Interrogate

pedestrian protection system control

module for faults and diagnose using

an approved Jaguar Diagnostic System. INERTIA SWITCH TRIPPED Amber warning triangle

illuminated LCD. Message appears when the crash status

signal from the RCM (restraints control

module) changes to crash detected or a

fault in the restraints system prevents

the message from being transmitted. RCM can be rest with an ignition on/off cycle. If fault has occurred, then

investigate cause of fault and

interrogate the RCM for faults and diagnose using an approved Jaguar

Diagnostic System. VALET MODE None

Confirmation that valet mode has been

entered. None VEHICLE ARMED None

Confirmation that alarm and

immobilization has been achieved. None SMART KEY NOT

FOUND PLEASE

INSERT IN SLOT Red warning triangle

illuminated in LCD. Smart key has not been detected by the

passive system inside the vehicle. Smart key not present in vehicle. May

be caused by a flat smart key battery.

Replace internal battery in smart key.

May also be due to a communications problem. CHECK SMART

KEY None The smart key detected is not the

correct smart key for the vehicle. Use the correct smart key coded to the

vehicle. REMOVE SMART

KEY None

Smart key is in the start control module

and has been recognized by the passive

start system. Remove smart key from the start

control module. SMART KEY

BATTERY LOW None

Battery voltage in smart key is

becoming low, resulting in a decrease in

effective range of the smart key

transmitter. Replace smart key internal battery. PRESS BRAKE

WHEN STARTING None The stop/start button has been pressed

without the brake pedal depressed. This

will turn on the ignition power mode 6. To start engine, press brake pedal,

then press stop/start button. GEARBOX NOT IN

PARK None The transmission is not in the 'park'

position. Engine starting will be prohibited until 'park' is selected. Put transmission in the park position. www.JagDocs.com

Page 2012 of 3039

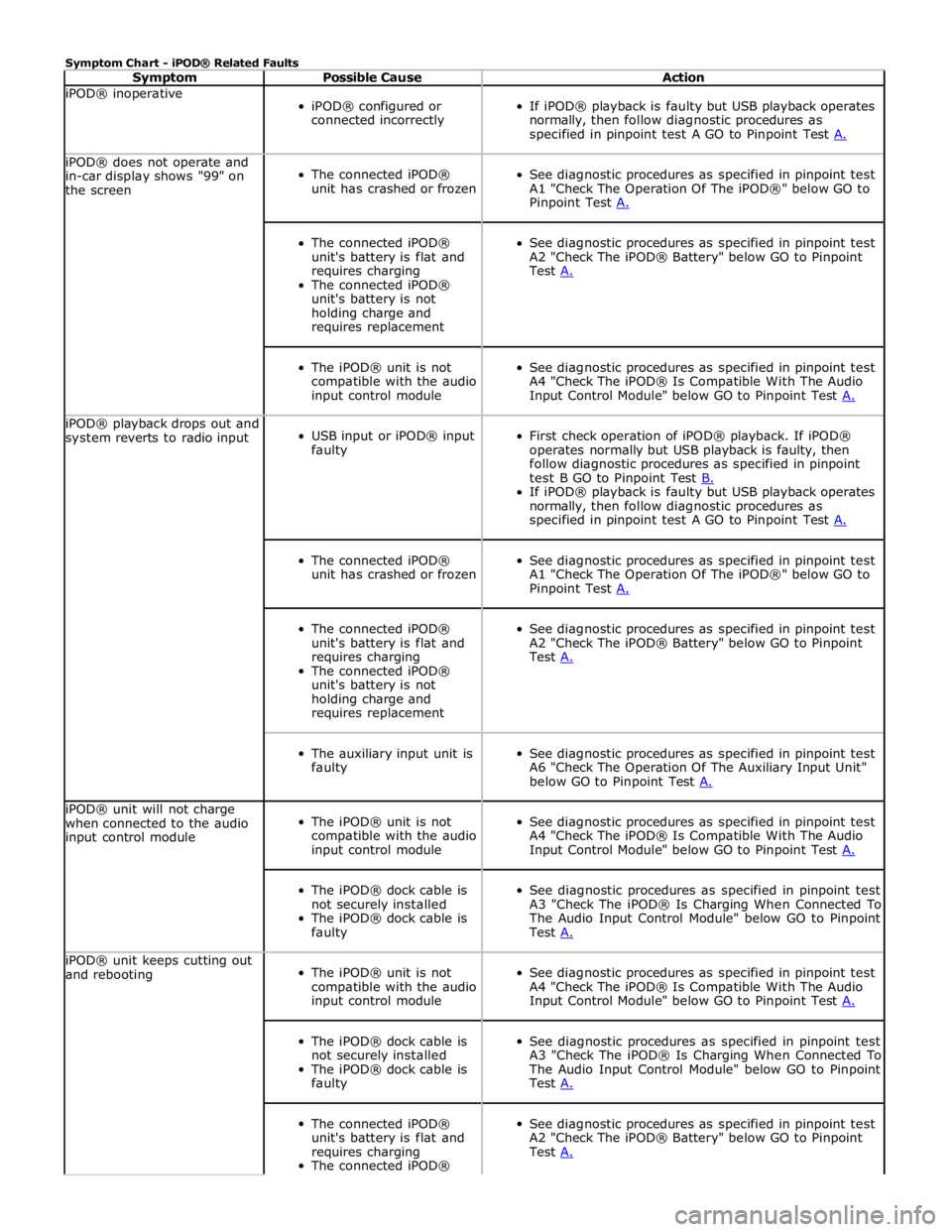

Symptom Chart - iPOD® Related Faults

Symptom Possible Cause Action iPOD® inoperative

iPOD® configured or

connected incorrectly

If iPOD® playback is faulty but USB playback operates

normally, then follow diagnostic procedures as

specified in pinpoint test A GO to Pinpoint Test A. iPOD® does not operate and

in-car display shows "99" on

the screen

The connected iPOD®

unit has crashed or frozen

See diagnostic procedures as specified in pinpoint test

A1 "Check The Operation Of The iPOD®" below GO to

Pinpoint Test A.

The connected iPOD®

unit's battery is flat and

requires charging

The connected iPOD®

unit's battery is not

holding charge and

requires replacement

See diagnostic procedures as specified in pinpoint test

A2 "Check The iPOD® Battery" below GO to Pinpoint

Test A.

The iPOD® unit is not

compatible with the audio

input control module

See diagnostic procedures as specified in pinpoint test

A4 "Check The iPOD® Is Compatible With The Audio

Input Control Module" below GO to Pinpoint Test A. iPOD® playback drops out and

system reverts to radio input

USB input or iPOD® input

faulty

First check operation of iPOD® playback. If iPOD®

operates normally but USB playback is faulty, then

follow diagnostic procedures as specified in pinpoint

test B GO to Pinpoint Test B. If iPOD® playback is faulty but USB playback operates

normally, then follow diagnostic procedures as

specified in pinpoint test A GO to Pinpoint Test A.

The connected iPOD®

unit has crashed or frozen

See diagnostic procedures as specified in pinpoint test

A1 "Check The Operation Of The iPOD®" below GO to

Pinpoint Test A.

The connected iPOD®

unit's battery is flat and

requires charging

The connected iPOD®

unit's battery is not

holding charge and

requires replacement

See diagnostic procedures as specified in pinpoint test

A2 "Check The iPOD® Battery" below GO to Pinpoint

Test A.

The auxiliary input unit is

faulty

See diagnostic procedures as specified in pinpoint test

A6 "Check The Operation Of The Auxiliary Input Unit"

below GO to Pinpoint Test A. iPOD® unit will not charge

when connected to the audio

input control module

The iPOD® unit is not

compatible with the audio

input control module

See diagnostic procedures as specified in pinpoint test

A4 "Check The iPOD® Is Compatible With The Audio

Input Control Module" below GO to Pinpoint Test A.

The iPOD® dock cable is

not securely installed

The iPOD® dock cable is

faulty

See diagnostic procedures as specified in pinpoint test

A3 "Check The iPOD® Is Charging When Connected To

The Audio Input Control Module" below GO to Pinpoint

Test A. iPOD® unit keeps cutting out

and rebooting

The iPOD® unit is not

compatible with the audio

input control module

See diagnostic procedures as specified in pinpoint test

A4 "Check The iPOD® Is Compatible With The Audio

Input Control Module" below GO to Pinpoint Test A.

The iPOD® dock cable is

not securely installed

The iPOD® dock cable is

faulty

See diagnostic procedures as specified in pinpoint test

A3 "Check The iPOD® Is Charging When Connected To

The Audio Input Control Module" below GO to Pinpoint

Test A.

The connected iPOD®

unit's battery is flat and

requires charging

The connected iPOD®

See diagnostic procedures as specified in pinpoint test

A2 "Check The iPOD® Battery" below GO to Pinpoint

Test A.

Page 2064 of 3039

DTC Description Possible Cause Action B116515

Left Front

Puddle Lamp

Output

Left front puddle lamp

control circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test left front puddle lamp control circuit

for short to power, open circuit B116611

Right Front

Puddle Lamp

Output

Right front puddle lamp

control circuit - short to

ground Refer to the electrical circuit diagrams and test right front

puddle lamp control circuit for short to ground B116615

Right Front

Puddle Lamp

Output

Right front puddle lamp

control circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test right front puddle lamp control circuit

for short to power, open circuit B111E11

Boot/Trunk

Lamps

Luggage compartment lamp

control circuit - short to

ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check luggage compartment lamp control

circuit for short to ground B111E15

Boot/Trunk

Lamps

Luggage compartment lamp

control circuit - short to

power, open circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check luggage compartment lamp control

circuit for short to power, open circuit B112412

Lamp Fade

Control

Interior lamp fade control

circuit - short to power Refer to the electrical circuit diagrams and check interior lamp

fade control circuit for short to power B113C12

Hazard Switch

Illumination

Hazard switch illumination

control circuit - short to

power Refer to the electrical circuit diagrams and check hazard switch

illumination control circuit for short to power B1A8596

Ambient Light

Sensor

Light sensor internal

electronic failure Check and install a new sensor as required U201012

Switch

Illumination

Switch/interior illumination

PWM supply circuit - short to

power Refer to the electrical circuit diagrams and check switch/interior

illumination PWM supply circuit for short to power U201014

Switch

Illumination

Switch/interior illumination

PWM supply circuit - short to

ground, open circuit Refer to the electrical circuit diagrams and check switch/interior

illumination PWM supply circuit for short to ground, open circuit