srs JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 164 of 3039

Published: 18-Apr-2014

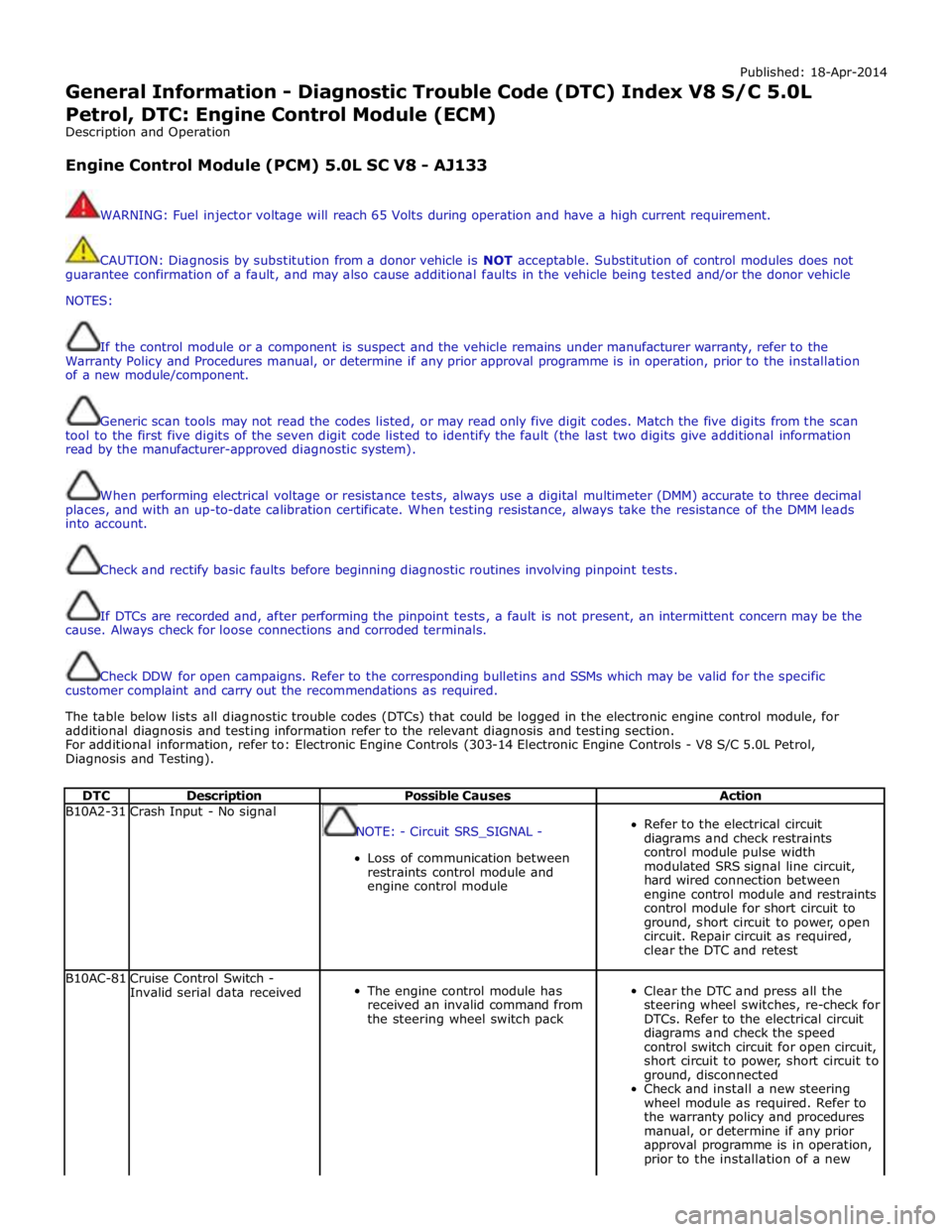

General Information - Diagnostic Trouble Code (DTC) Index V8 S/C 5.0L

Petrol, DTC: Engine Control Module (ECM)

Description and Operation

Engine Control Module (PCM) 5.0L SC V8 - AJ133

WARNING: Fuel injector voltage will reach 65 Volts during operation and have a high current requirement.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the electronic engine control module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Electronic Engine Controls (303-14 Electronic Engine Controls - V8 S/C 5.0L Petrol,

Diagnosis and Testing).

DTC Description Possible Causes Action B10A2-31 Crash Input - No signal

NOTE: - Circuit SRS_SIGNAL -

Loss of communication between

restraints control module and

engine control module

Refer to the electrical circuit

diagrams and check restraints

control module pulse width

modulated SRS signal line circuit,

hard wired connection between

engine control module and restraints

control module for short circuit to

ground, short circuit to power, open

circuit. Repair circuit as required,

clear the DTC and retest B10AC-81

Cruise Control Switch -

Invalid serial data received

The engine control module has

received an invalid command from

the steering wheel switch pack

Clear the DTC and press all the

steering wheel switches, re-check for

DTCs. Refer to the electrical circuit

diagrams and check the speed

control switch circuit for open circuit,

short circuit to power, short circuit to

ground, disconnected

Check and install a new steering

wheel module as required. Refer to

the warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

Page 166 of 3039

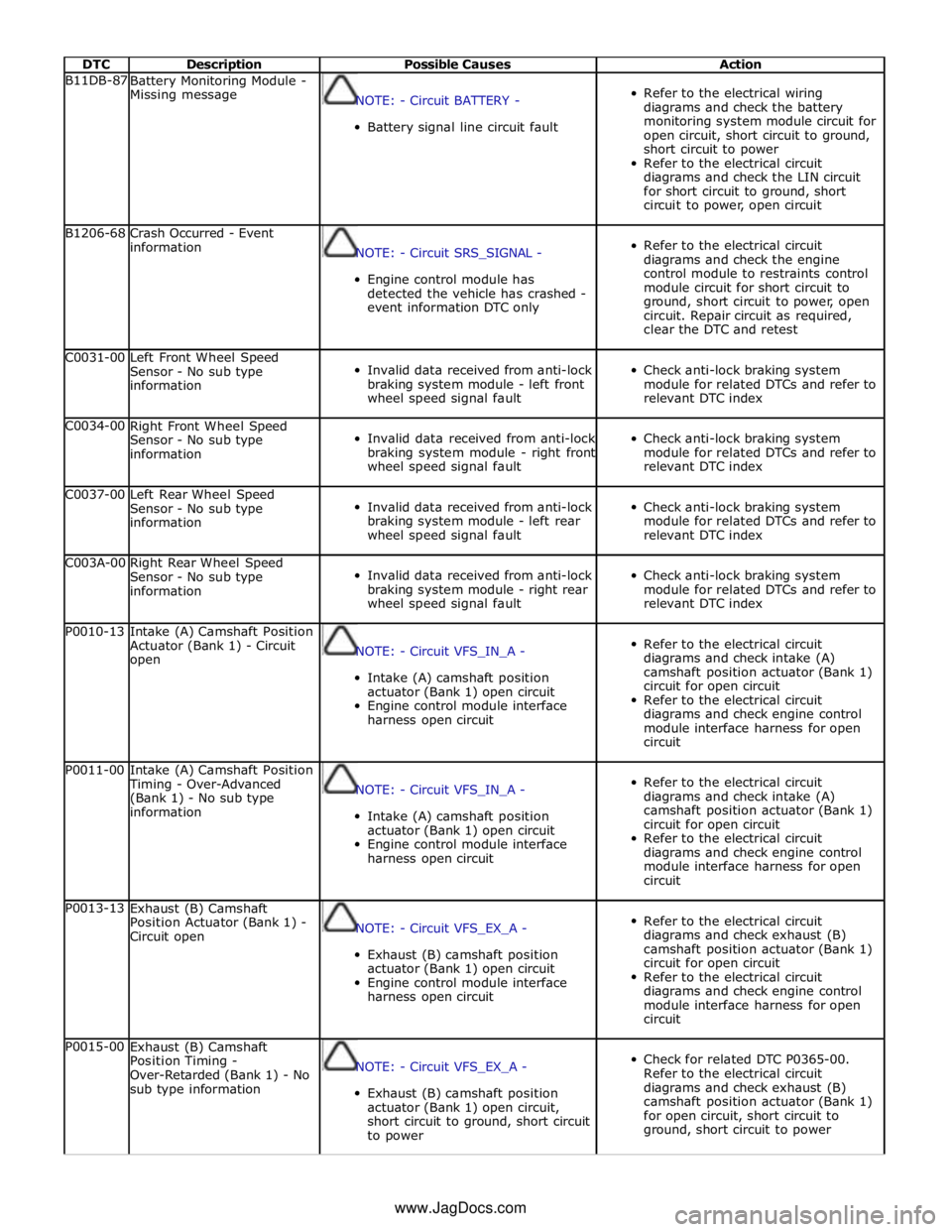

DTC Description Possible Causes Action B11DB-87

Battery Monitoring Module -

Missing message

NOTE: - Circuit BATTERY -

Battery signal line circuit fault

Refer to the electrical wiring

diagrams and check the battery

monitoring system module circuit for

open circuit, short circuit to ground,

short circuit to power

Refer to the electrical circuit

diagrams and check the LIN circuit

for short circuit to ground, short

circuit to power, open circuit B1206-68

Crash Occurred - Event

information

NOTE: - Circuit SRS_SIGNAL -

Engine control module has

detected the vehicle has crashed -

event information DTC only

Refer to the electrical circuit

diagrams and check the engine

control module to restraints control

module circuit for short circuit to

ground, short circuit to power, open

circuit. Repair circuit as required,

clear the DTC and retest C0031-00

Left Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0034-00

Right Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0037-00

Left Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C003A-00

Right Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index P0010-13

Intake (A) Camshaft Position

Actuator (Bank 1) - Circuit

open

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0011-00

Intake (A) Camshaft Position

Timing - Over-Advanced

(Bank 1) - No sub type

information

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0013-13

Exhaust (B) Camshaft

Position Actuator (Bank 1) -

Circuit open

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0015-00

Exhaust (B) Camshaft

Position Timing -

Over-Retarded (Bank 1) - No

sub type information

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit,

short circuit to ground, short circuit

to power

Check for related DTC P0365-00.

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

for open circuit, short circuit to

ground, short circuit to power www.JagDocs.com

Page 203 of 3039

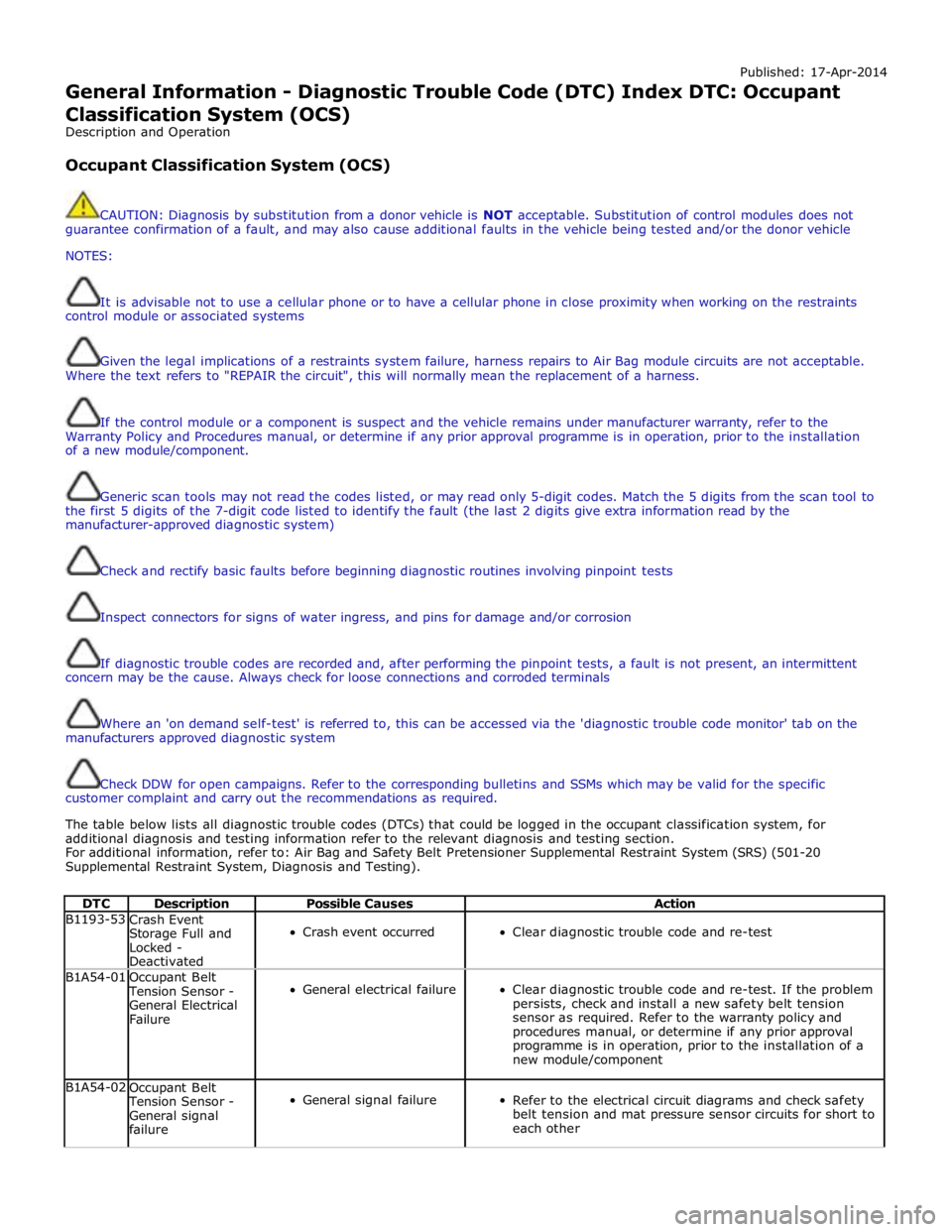

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Occupant Classification System (OCS)

Description and Operation

Occupant Classification System (OCS)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

It is advisable not to use a cellular phone or to have a cellular phone in close proximity when working on the restraints

control module or associated systems

Given the legal implications of a restraints system failure, harness repairs to Air Bag module circuits are not acceptable.

Where the text refers to "REPAIR the circuit", this will normally mean the replacement of a harness.

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the occupant classification system, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS) (501-20

Supplemental Restraint System, Diagnosis and Testing).

DTC Description Possible Causes Action B1193-53

Crash Event

Storage Full and

Locked -

Deactivated

Crash event occurred

Clear diagnostic trouble code and re-test B1A54-01

Occupant Belt Tension Sensor -

General Electrical

Failure

General electrical failure

Clear diagnostic trouble code and re-test. If the problem

persists, check and install a new safety belt tension

sensor as required. Refer to the warranty policy and

procedures manual, or determine if any prior approval

programme is in operation, prior to the installation of a

new module/component B1A54-02

Occupant Belt Tension Sensor -

General signal

failure

General signal failure

Refer to the electrical circuit diagrams and check safety

belt tension and mat pressure sensor circuits for short to

each other

Page 231 of 3039

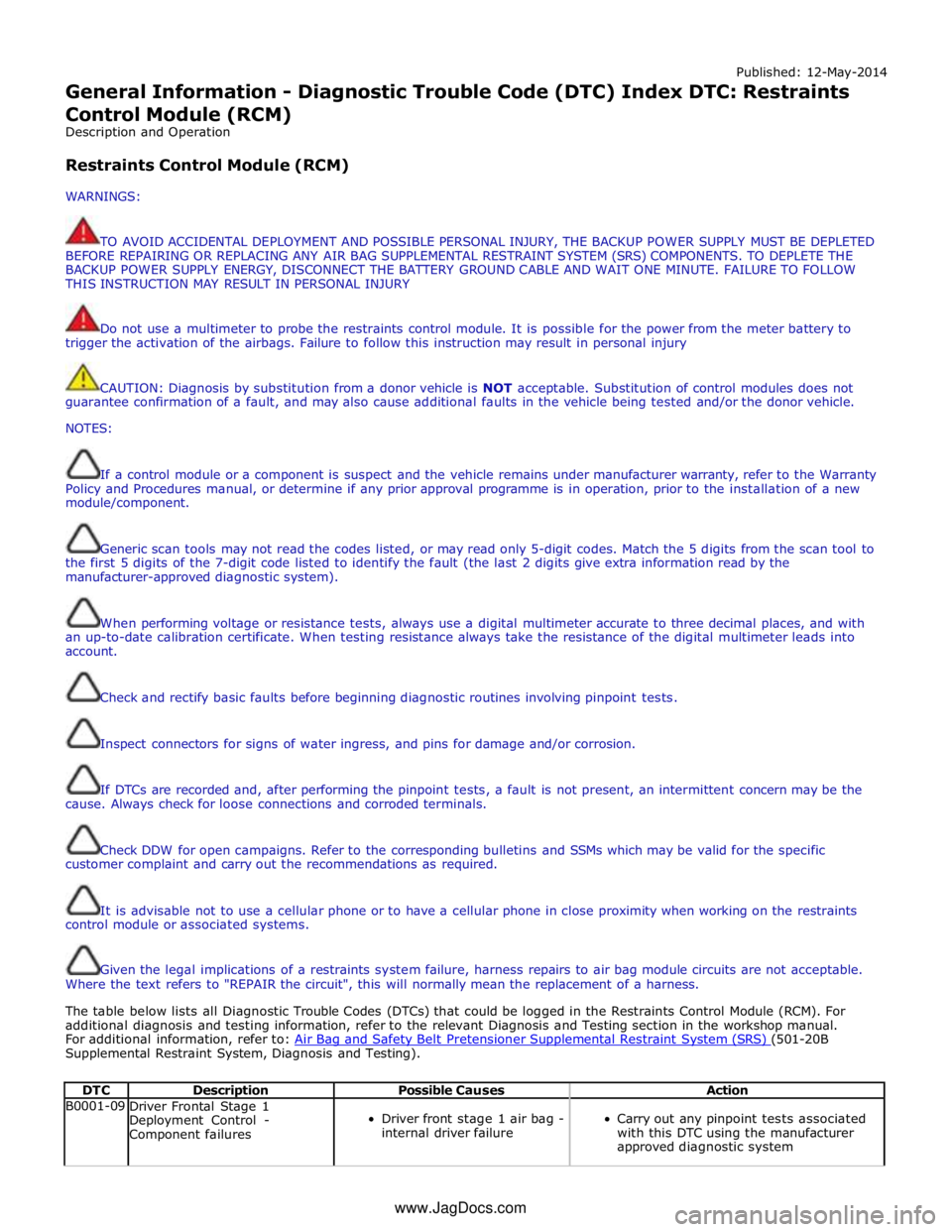

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Restraints

Control Module (RCM)

Description and Operation

Restraints Control Module (RCM)

WARNINGS:

TO AVOID ACCIDENTAL DEPLOYMENT AND POSSIBLE PERSONAL INJURY, THE BACKUP POWER SUPPLY MUST BE DEPLETED

BEFORE REPAIRING OR REPLACING ANY AIR BAG SUPPLEMENTAL RESTRAINT SYSTEM (SRS) COMPONENTS. TO DEPLETE THE

BACKUP POWER SUPPLY ENERGY, DISCONNECT THE BATTERY GROUND CABLE AND WAIT ONE MINUTE. FAILURE TO FOLLOW

THIS INSTRUCTION MAY RESULT IN PERSONAL INJURY

Do not use a multimeter to probe the restraints control module. It is possible for the power from the meter battery to

trigger the activation of the airbags. Failure to follow this instruction may result in personal injury

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

It is advisable not to use a cellular phone or to have a cellular phone in close proximity when working on the restraints

control module or associated systems.

Given the legal implications of a restraints system failure, harness repairs to air bag module circuits are not acceptable.

Where the text refers to "REPAIR the circuit", this will normally mean the replacement of a harness.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Restraints Control Module (RCM). For

additional diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop manual.

For additional information, refer to: Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS) (501-20B Supplemental Restraint System, Diagnosis and Testing).

DTC Description Possible Causes Action B0001-09

Driver Frontal Stage 1

Deployment Control -

Component failures

Driver front stage 1 air bag -

internal driver failure

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system www.JagDocs.com

Page 792 of 3039

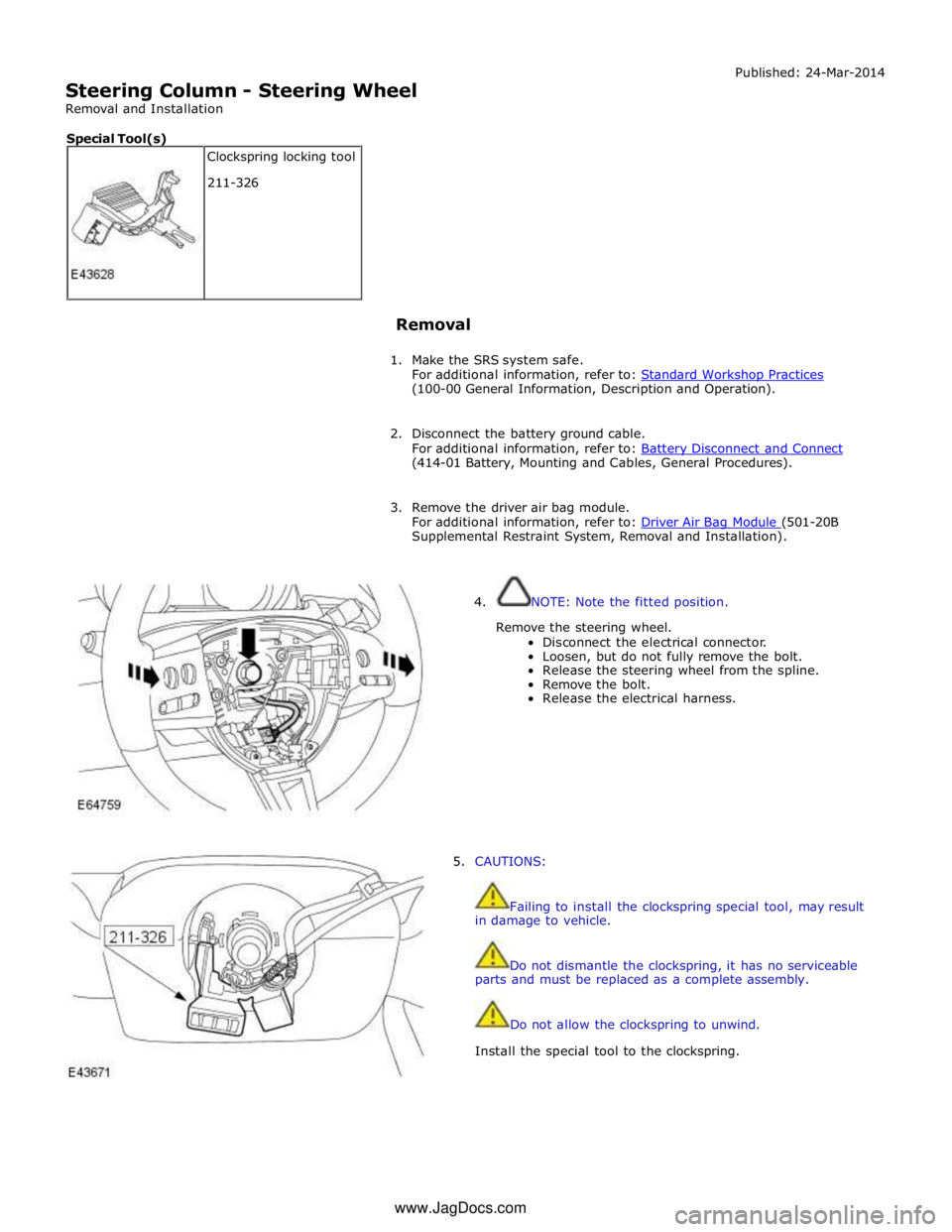

Steering Column - Steering Wheel

Removal and Installation Published: 24-Mar-2014

Removal

1. Make the SRS system safe.

For additional information, refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. Remove the driver air bag module.

For additional information, refer to: Driver Air Bag Module (501-20B Supplemental Restraint System, Removal and Installation).

4. NOTE: Note the fitted position.

Remove the steering wheel.

Disconnect the electrical connector.

Loosen, but do not fully remove the bolt.

Release the steering wheel from the spline.

Remove the bolt.

Release the electrical harness.

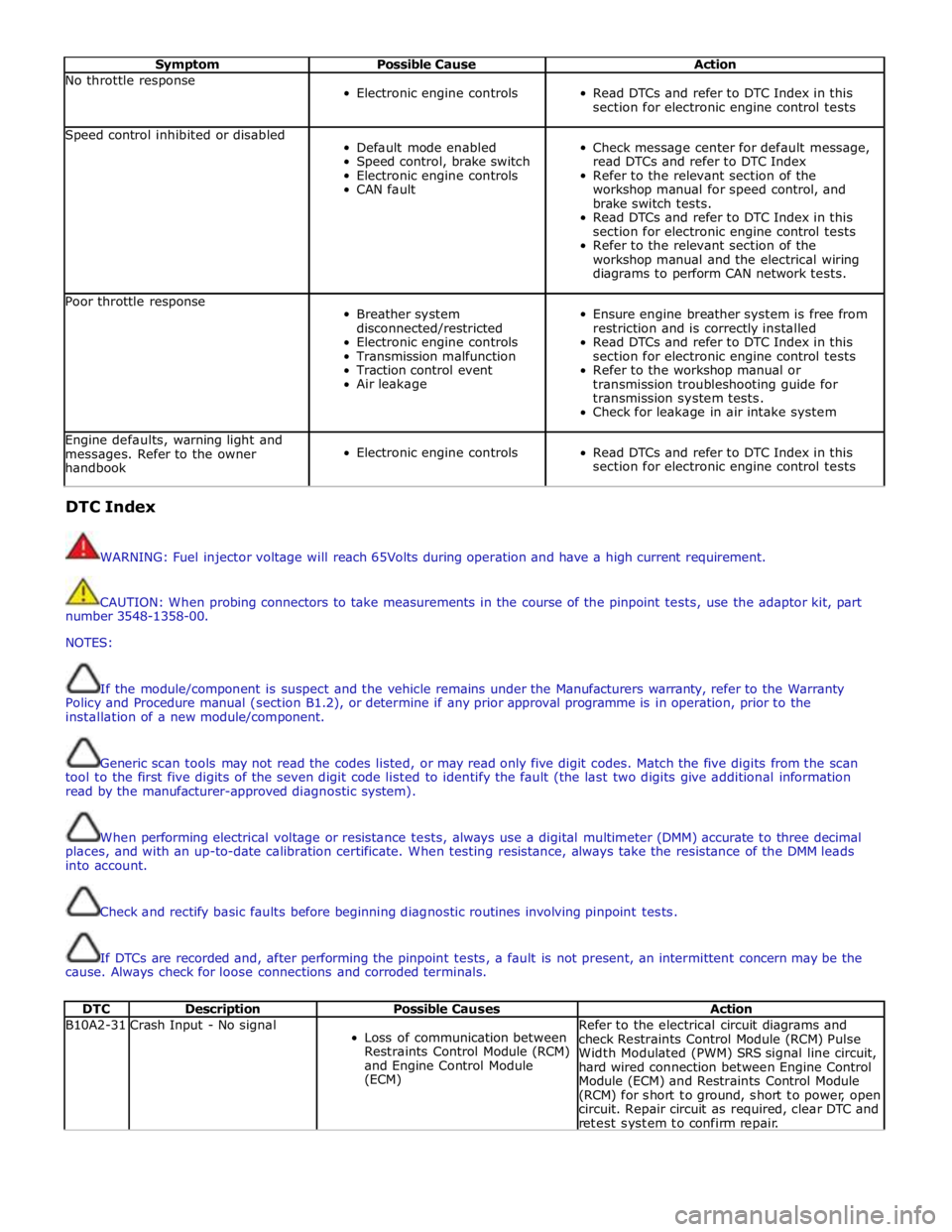

5. CAUTIONS:

Failing to install the clockspring special tool, may result

in damage to vehicle.

Do not dismantle the clockspring, it has no serviceable

parts and must be replaced as a complete assembly.

Do not allow the clockspring to unwind.

Install the special tool to the clockspring. Clockspring locking tool

211-326 Special Tool(s) www.JagDocs.com

Page 1372 of 3039

Symptom Possible Cause Action No throttle response

Electronic engine controls

Read DTCs and refer to DTC Index in this

section for electronic engine control tests Speed control inhibited or disabled

Default mode enabled

Speed control, brake switch

Electronic engine controls

CAN fault

Check message center for default message,

read DTCs and refer to DTC Index

Refer to the relevant section of the

workshop manual for speed control, and

brake switch tests.

Read DTCs and refer to DTC Index in this

section for electronic engine control tests

Refer to the relevant section of the

workshop manual and the electrical wiring

diagrams to perform CAN network tests. Poor throttle response

Breather system

disconnected/restricted

Electronic engine controls

Transmission malfunction

Traction control event

Air leakage

Ensure engine breather system is free from

restriction and is correctly installed

Read DTCs and refer to DTC Index in this

section for electronic engine control tests

Refer to the workshop manual or

transmission troubleshooting guide for

transmission system tests.

Check for leakage in air intake system Engine defaults, warning light and

messages. Refer to the owner

handbook

Electronic engine controls

Read DTCs and refer to DTC Index in this

section for electronic engine control tests DTC Index

WARNING: Fuel injector voltage will reach 65Volts during operation and have a high current requirement.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the module/component is suspect and the vehicle remains under the Manufacturers warranty, refer to the Warranty

Policy and Procedure manual (section B1.2), or determine if any prior approval programme is in operation, prior to the

installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Causes Action B10A2-31 Crash Input - No signal

Loss of communication between

Restraints Control Module (RCM)

and Engine Control Module

(ECM) Refer to the electrical circuit diagrams and

check Restraints Control Module (RCM) Pulse

Width Modulated (PWM) SRS signal line circuit,

hard wired connection between Engine Control

Module (ECM) and Restraints Control Module

(RCM) for short to ground, short to power, open

circuit. Repair circuit as required, clear DTC and

retest system to confirm repair.

Page 1589 of 3039

1 Fuel supply connection 2 Electrical connector 3 Flange locking ring and seal 4 Sucking jet connector 5 Fuel pump module 6 Fuel pick up filter 7 Level sensor float 8 RH level sensor 9 Fuel filter 10 Pressure relief valve 11 Pump supply to flange connection 12 The fuel pump is a variable speed rotary vane type. The pump is energized by the fuel pump relay which is located in the RJB and the FPDM which is located under the RH floor pan above the rear suspension stabilizer bar. The relay and FPDM are controlled by the ECM.

A fine mesh filter is located in the lower section of the pump module. This provides filtration to the fuel as it is drawn into the

module. There is a winged filter on the fuel pump that gives additional protection and a life time fuel filter integrated into the

flange which eliminates the need for an additional filter further downstream in the fuel system.

The RH fuel level sensor is mounted into the pump module housing.

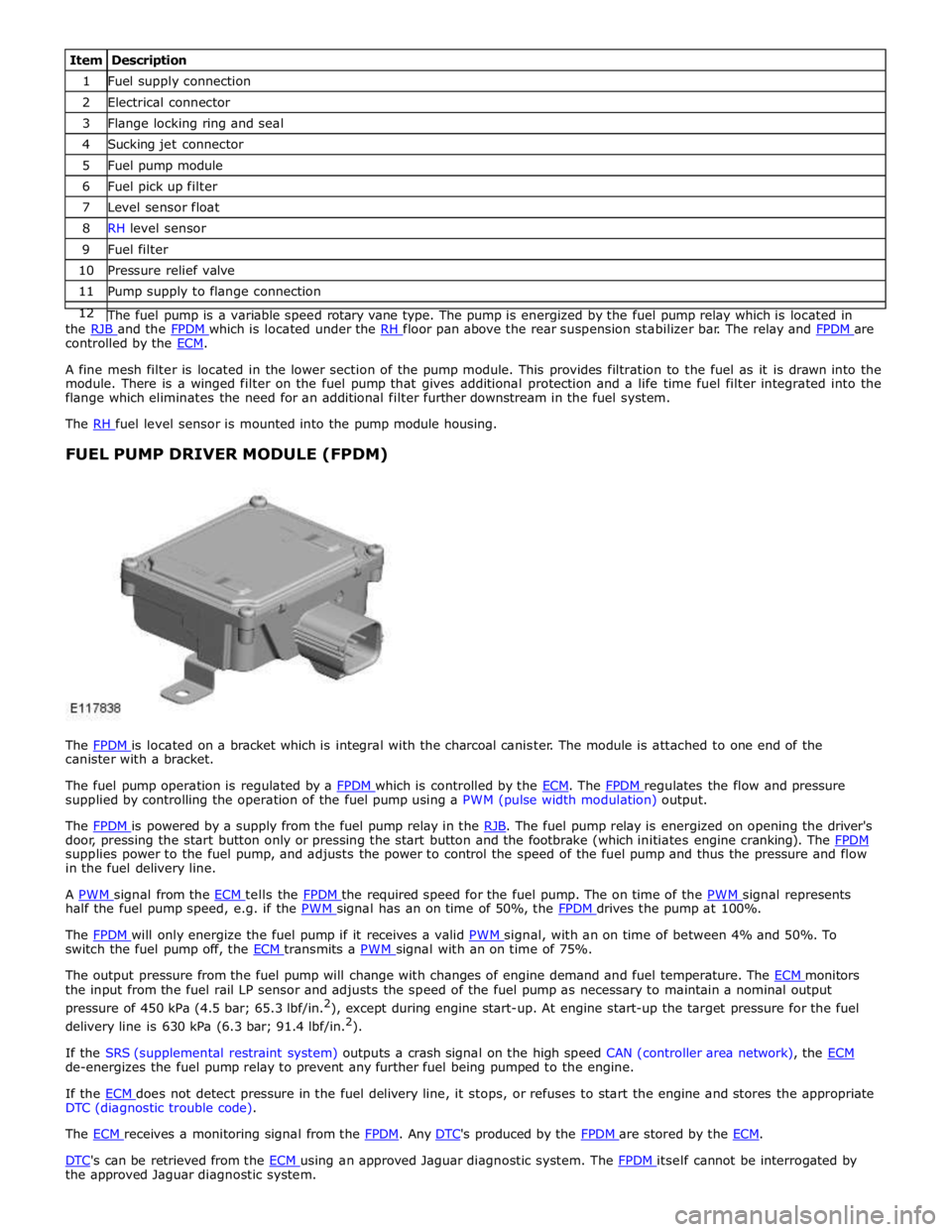

FUEL PUMP DRIVER MODULE (FPDM)

The FPDM is located on a bracket which is integral with the charcoal canister. The module is attached to one end of the canister with a bracket.

The fuel pump operation is regulated by a FPDM which is controlled by the ECM. The FPDM regulates the flow and pressure supplied by controlling the operation of the fuel pump using a PWM (pulse width modulation) output.

The FPDM is powered by a supply from the fuel pump relay in the RJB. The fuel pump relay is energized on opening the driver's door, pressing the start button only or pressing the start button and the footbrake (which initiates engine cranking). The FPDM supplies power to the fuel pump, and adjusts the power to control the speed of the fuel pump and thus the pressure and flow

in the fuel delivery line.

A PWM signal from the ECM tells the FPDM the required speed for the fuel pump. The on time of the PWM signal represents half the fuel pump speed, e.g. if the PWM signal has an on time of 50%, the FPDM drives the pump at 100%.

The FPDM will only energize the fuel pump if it receives a valid PWM signal, with an on time of between 4% and 50%. To switch the fuel pump off, the ECM transmits a PWM signal with an on time of 75%.

The output pressure from the fuel pump will change with changes of engine demand and fuel temperature. The ECM monitors the input from the fuel rail LP sensor and adjusts the speed of the fuel pump as necessary to maintain a nominal output

pressure of 450 kPa (4.5 bar; 65.3 lbf/in.2

), except during engine start-up. At engine start-up the target pressure for the fuel

delivery line is 630 kPa (6.3 bar; 91.4 lbf/in.2

).

If the SRS (supplemental restraint system) outputs a crash signal on the high speed CAN (controller area network), the ECM de-energizes the fuel pump relay to prevent any further fuel being pumped to the engine.

If the ECM does not detect pressure in the fuel delivery line, it stops, or refuses to start the engine and stores the appropriate DTC (diagnostic trouble code).

The ECM receives a monitoring signal from the FPDM. Any DTC's produced by the FPDM are stored by the ECM.

DTC's can be retrieved from the ECM using an approved Jaguar diagnostic system. The FPDM itself cannot be interrogated by the approved Jaguar diagnostic system.

Page 1661 of 3039

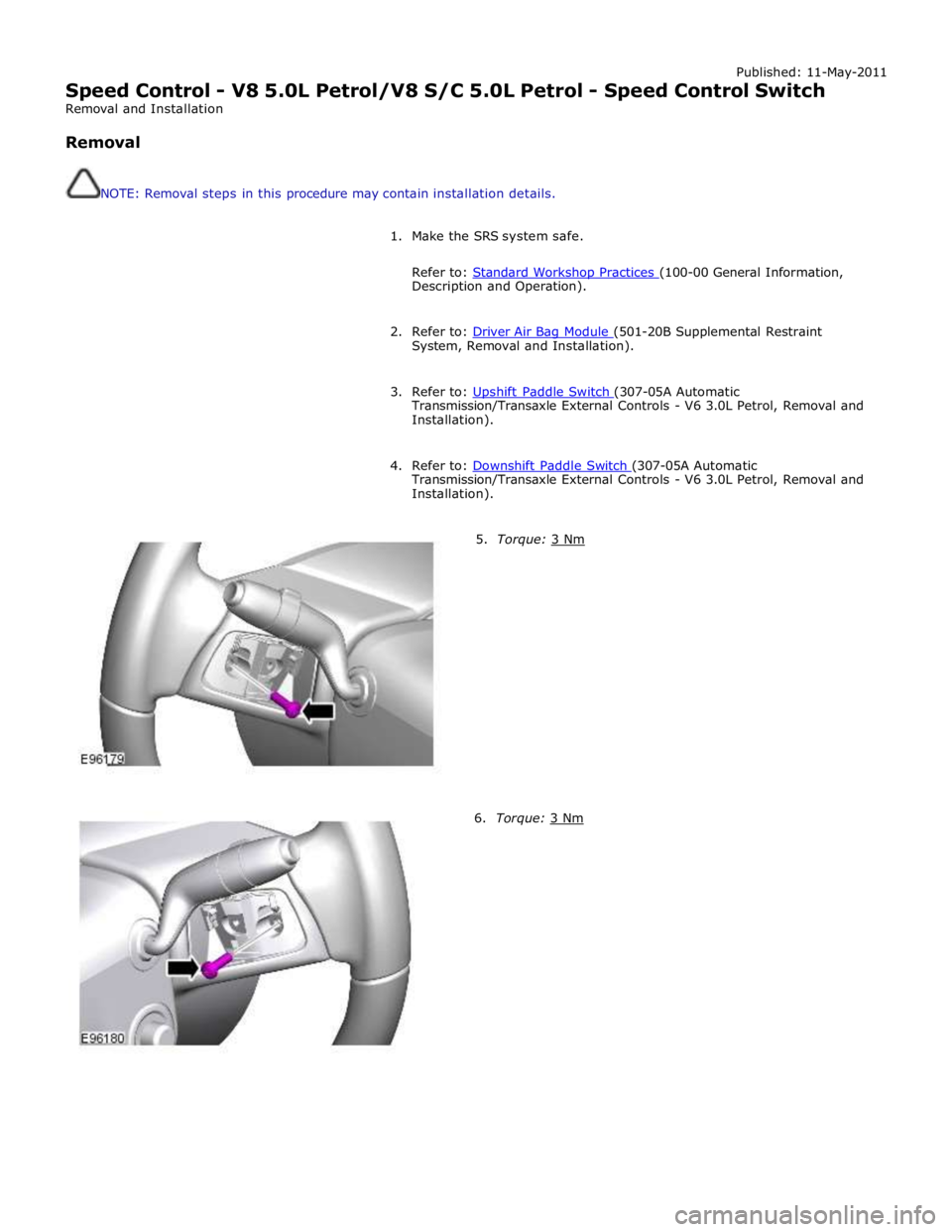

Published: 11-May-2011

Speed Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Speed Control Switch

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Make the SRS system safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Refer to: Driver Air Bag Module (501-20B Supplemental Restraint System, Removal and Installation).

3. Refer to: Upshift Paddle Switch (307-05A Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol, Removal and

Installation).

4. Refer to: Downshift Paddle Switch (307-05A Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol, Removal and

Installation).

5. Torque: 3 Nm 6. Torque: 3 Nm

Page 2001 of 3039

Published: 11-May-2011

Information and Entertainment System - Steering Wheel Audio Controls

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Make the SRS system safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Refer to: Driver Air Bag Module (501-20B Supplemental Restraint System, Removal and Installation).

3. Refer to: Upshift Paddle Switch (307-05A Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol, Removal and

Installation).

4. Refer to: Downshift Paddle Switch (307-05A Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol, Removal and

Installation).

5. Torque: 3 Nm 6. Torque: 3 Nm

Page 2036 of 3039

Rear Fog Lamp

The rear fog lamps are located in separate units attached to the luggage compartment lid. The rear fog lamps each use 3 high

intensity LED's. The fog lamp locates in a recess in the luggage compartment lid has a seal to prevent the ingress of water into the luggage compartment. The lamp is secured in the recess with a metal securing clip. The rear fog lamp is activated

using a button located on the auxiliary lighting switch in the instrument panel.

LICENCE PLATE LAMPS

Two licence plate lamps are located in the luggage compartment lid trim finisher. One is located adjacent to the emergency

luggage compartment lid release key barrel cover and the other is adjacent to the rear view camera (if fitted). The licence plate

lamps are active at all times when the side lamps are operating. Each lamp can be removed from the finisher by inserting a

wide, flat screwdriver blade or similar tool in a slot between the lamp lens and the finisher and gently levering the lamp from

the surround. The bulb is a push fit in a holder which in turn is a press fit in the lamp housing.

HIGH MOUNTED STOP LAMP

The high mounted stop lamp is located at the bottom of the rear windshield. The lamp is secured to a bezel in the parcel shelf

with 2 screws.

The high mounted stop lamp uses 12, red colored LED's which illuminate through a clear lens. The high mounted stop lamp functionality is the same as that described for the stop lamps.

TURN SIGNAL INDICATOR SIDE REPEATER LAMPS

The turn signal indicator side repeaters are located in each door mirror. On vehicles from 10MY the lamp is an LED unit which illuminates in an orange color. The LED unit is secured to the mirror bezel with 2 screws and is connected to the mirror wiring harness with a 2 pin connector.

The side repeaters have the same functionality and operate in conjunction with the front and rear turn signal indicators and

the hazard warning flashers.

HAZARD FLASHERS

The hazard flashers are activated by a non-latching switch located in the switch pack located in the center of the instrument

panel. The hazard flashers operate at all times when selected and operate independent of the ignition mode.

When the hazard flashers are selected on by the driver, a ground path is momentarily completed to the CJB which activates the front and rear and side repeater turn signal indicators. A second press of the switch is sensed by the CJB and the hazard flasher are deactivated. When the hazard flashers are active, they override any request for turn signal indicator operation.

The hazard flashers can also be activated by a crash signal from the RCM. Refer to: Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS) (501-20B Supplemental Restraint System, Description and Operation).