Fuel JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2094 of 3039

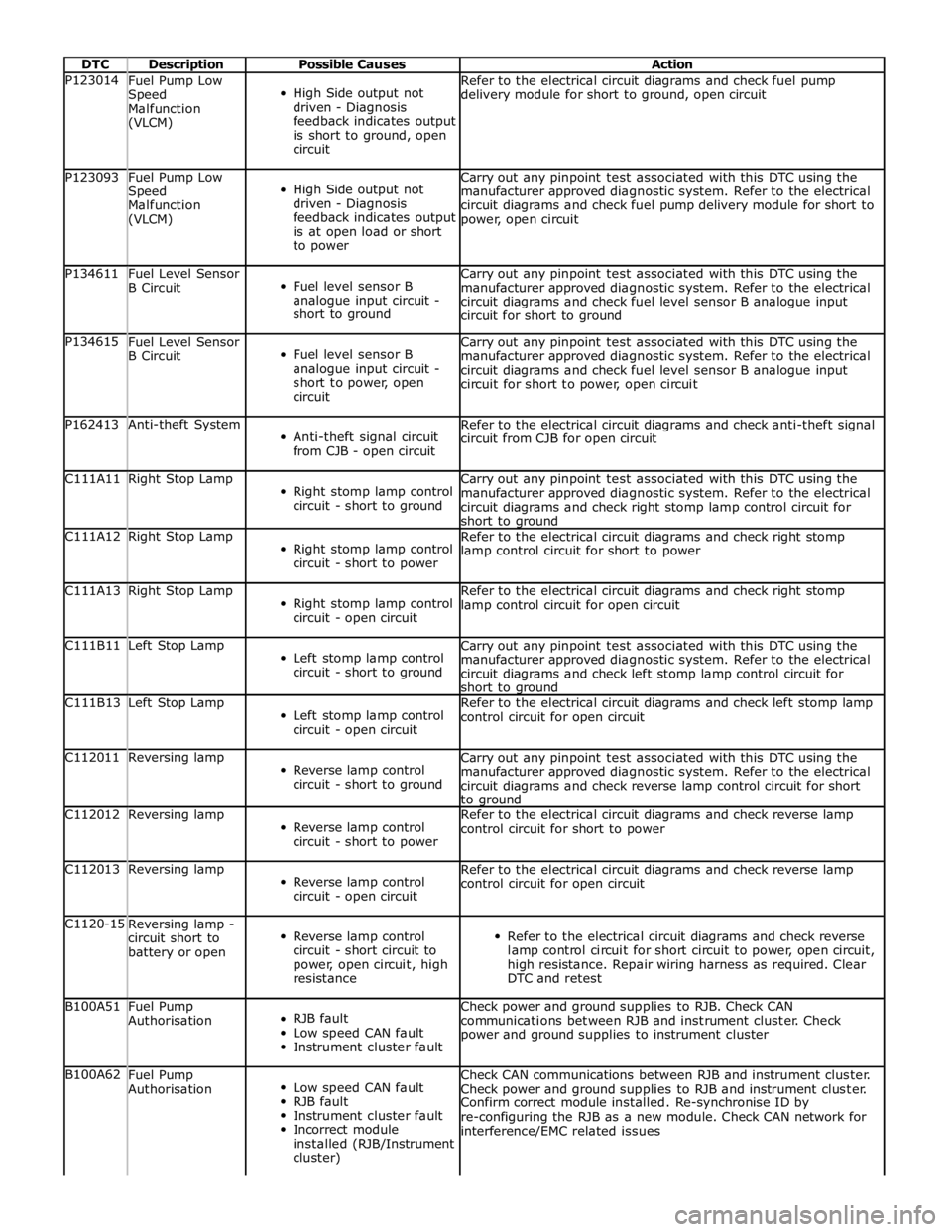

DTC Description Possible Causes Action P123014

Fuel Pump Low

Speed

Malfunction

(VLCM)

High Side output not

driven - Diagnosis

feedback indicates output

is short to ground, open

circuit Refer to the electrical circuit diagrams and check fuel pump

delivery module for short to ground, open circuit P123093

Fuel Pump Low

Speed

Malfunction

(VLCM)

High Side output not

driven - Diagnosis

feedback indicates output

is at open load or short

to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check fuel pump delivery module for short to

power, open circuit P134611

Fuel Level Sensor

B Circuit

Fuel level sensor B

analogue input circuit -

short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check fuel level sensor B analogue input

circuit for short to ground P134615

Fuel Level Sensor

B Circuit

Fuel level sensor B

analogue input circuit -

short to power, open

circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check fuel level sensor B analogue input

circuit for short to power, open circuit P162413 Anti-theft System

Anti-theft signal circuit

from CJB - open circuit Refer to the electrical circuit diagrams and check anti-theft signal

circuit from CJB for open circuit C111A11 Right Stop Lamp

Right stomp lamp control

circuit - short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check right stomp lamp control circuit for

short to ground C111A12 Right Stop Lamp

Right stomp lamp control

circuit - short to power Refer to the electrical circuit diagrams and check right stomp

lamp control circuit for short to power C111A13 Right Stop Lamp

Right stomp lamp control

circuit - open circuit Refer to the electrical circuit diagrams and check right stomp

lamp control circuit for open circuit C111B11 Left Stop Lamp

Left stomp lamp control

circuit - short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check left stomp lamp control circuit for

short to ground C111B13 Left Stop Lamp

Left stomp lamp control

circuit - open circuit Refer to the electrical circuit diagrams and check left stomp lamp

control circuit for open circuit C112011 Reversing lamp

Reverse lamp control

circuit - short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check reverse lamp control circuit for short

to ground C112012 Reversing lamp

Reverse lamp control

circuit - short to power Refer to the electrical circuit diagrams and check reverse lamp

control circuit for short to power C112013 Reversing lamp

Reverse lamp control

circuit - open circuit Refer to the electrical circuit diagrams and check reverse lamp

control circuit for open circuit C1120-15

Reversing lamp -

circuit short to

battery or open

Reverse lamp control

circuit - short circuit to

power, open circuit, high

resistance

Refer to the electrical circuit diagrams and check reverse

lamp control circuit for short circuit to power, open circuit,

high resistance. Repair wiring harness as required. Clear

DTC and retest B100A51

Fuel Pump

Authorisation

RJB fault

Low speed CAN fault

Instrument cluster fault Check power and ground supplies to RJB. Check CAN

communications between RJB and instrument cluster. Check

power and ground supplies to instrument cluster B100A62

Fuel Pump

Authorisation

Low speed CAN fault

RJB fault

Instrument cluster fault

Incorrect module

installed (RJB/Instrument

cluster) Check CAN communications between RJB and instrument cluster.

Check power and ground supplies to RJB and instrument cluster.

Confirm correct module installed. Re-synchronise ID by

re-configuring the RJB as a new module. Check CAN network for

interference/EMC related issues

Page 2095 of 3039

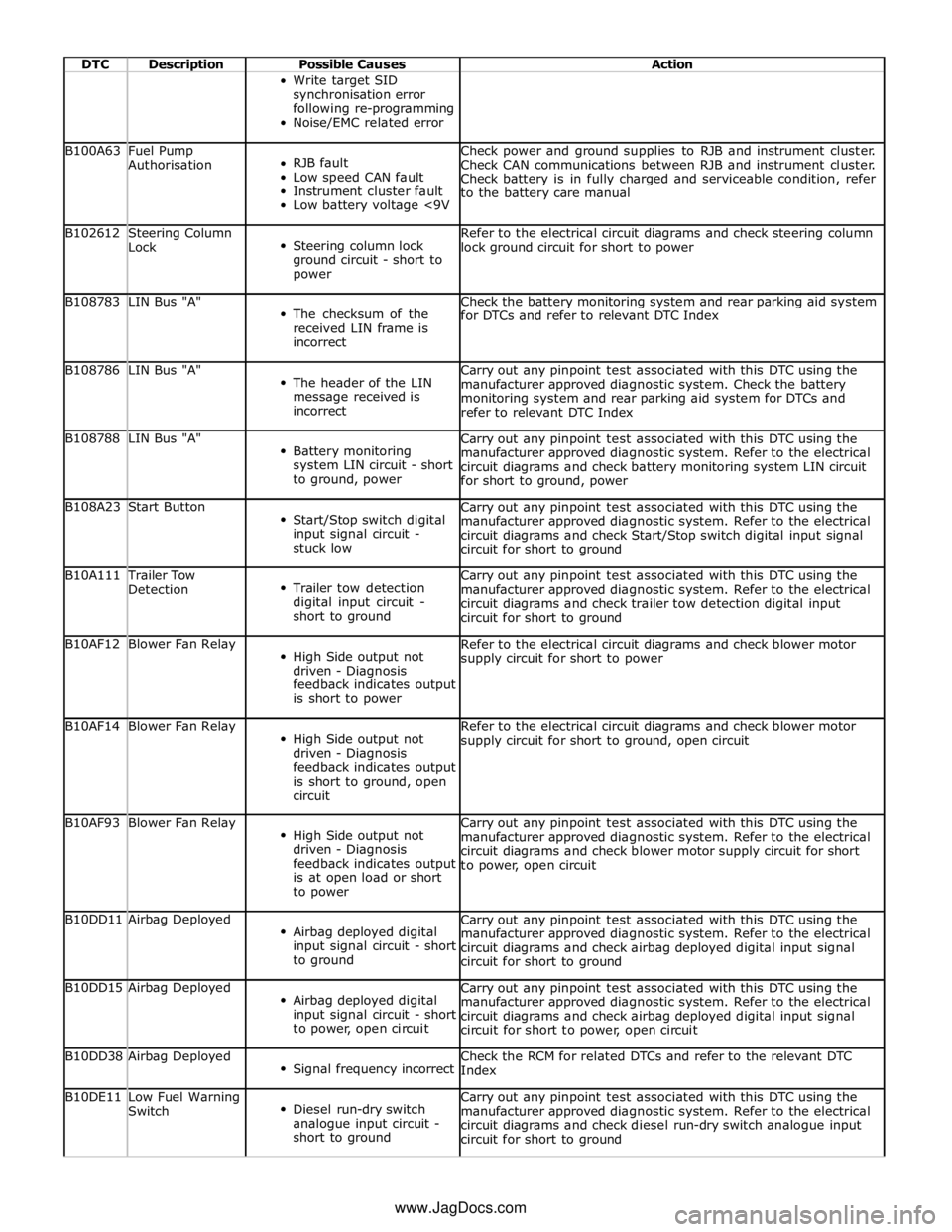

DTC Description Possible Causes Action Write target SID

synchronisation error

following re-programming

Noise/EMC related error B100A63

Fuel Pump

Authorisation

RJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V Check power and ground supplies to RJB and instrument cluster.

Check CAN communications between RJB and instrument cluster.

Check battery is in fully charged and serviceable condition, refer

to the battery care manual B102612

Steering Column

Lock

Steering column lock

ground circuit - short to

power Refer to the electrical circuit diagrams and check steering column

lock ground circuit for short to power B108783 LIN Bus "A"

The checksum of the

received LIN frame is

incorrect Check the battery monitoring system and rear parking aid system

for DTCs and refer to relevant DTC Index B108786 LIN Bus "A"

The header of the LIN

message received is

incorrect Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Check the battery

monitoring system and rear parking aid system for DTCs and

refer to relevant DTC Index B108788 LIN Bus "A"

Battery monitoring

system LIN circuit - short

to ground, power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check battery monitoring system LIN circuit

for short to ground, power B108A23 Start Button

Start/Stop switch digital

input signal circuit -

stuck low Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check Start/Stop switch digital input signal

circuit for short to ground B10A111 Trailer Tow

Detection

Trailer tow detection

digital input circuit -

short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check trailer tow detection digital input

circuit for short to ground B10AF12 Blower Fan Relay

High Side output not

driven - Diagnosis

feedback indicates output

is short to power Refer to the electrical circuit diagrams and check blower motor

supply circuit for short to power B10AF14 Blower Fan Relay

High Side output not

driven - Diagnosis

feedback indicates output

is short to ground, open

circuit Refer to the electrical circuit diagrams and check blower motor

supply circuit for short to ground, open circuit B10AF93 Blower Fan Relay

High Side output not

driven - Diagnosis

feedback indicates output

is at open load or short

to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check blower motor supply circuit for short

to power, open circuit B10DD11 Airbag Deployed

Airbag deployed digital

input signal circuit - short

to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check airbag deployed digital input signal

circuit for short to ground B10DD15 Airbag Deployed

Airbag deployed digital

input signal circuit - short

to power, open circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check airbag deployed digital input signal

circuit for short to power, open circuit B10DD38 Airbag Deployed

Signal frequency incorrect Check the RCM for related DTCs and refer to the relevant DTC

Index B10DE11

Low Fuel Warning

Switch

Diesel run-dry switch

analogue input circuit -

short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check diesel run-dry switch analogue input

circuit for short to ground www.JagDocs.com

Page 2096 of 3039

DTC Description Possible Causes Action B10DE15

Low Fuel Warning

Switch

Diesel run-dry switch

analogue input circuit -

short to power, open

circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check diesel run-dry switch analogue input

circuit for short to power, open circuit B111211 Park Aid Ignition

Parking aid ignition

supply circuit - short to

ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check parking aid ignition supply circuit for

short to ground B111212 Park Aid Ignition

Parking aid ignition

supply circuit - short to

power Refer to the electrical circuit diagrams and check parking aid

ignition supply circuit for short to power B111511

High Mounted

Stop Lamp

Control

High mounted stop lamp

control circuit - short to

ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check high mounted stop lamp control circuit

for short to ground B111611 Left Tail Lamp

Left hand tail lamp

control circuit - short to

ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check left hand tail lamp control circuit for

short to ground B111711 Right Tail Lamp

Right hand tail lamp

control circuit - short to

ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check right hand tail lamp control circuit for

short to ground B111A11

Number Plate

Lamps

Right hand or left hand

number plate lamp

control circuits - short to

ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check right hand and left hand number plate

lamp control circuits for short to ground B111A12

Number Plate

Lamps

Right hand or left hand

number plate lamp

control circuits - short to

power Refer to the electrical circuit diagrams and check right hand and

left hand number plate lamp control circuits for short to power B111A13

Number Plate

Lamps

Right hand or left hand

number plate lamp

control circuits - open

circuit Refer to the electrical circuit diagrams and check right hand and

left hand number plate lamp control circuits for open circuit B111A-15

Number Plate

Lamps - circuit

short to battery

or open

Right or left side licence

plate lamp(s) inoperative

Right or left side licence

plate lamp control

circuits - short circuit to

power, open circuit, high

resistance

Refer to the electrical circuit diagrams and check right

side and left side licence plate lamp control circuits for

short circuit to power, open circuit, high resistance. Repair

wiring harness as required. Clear DTC and retest B111D12

Boot/Trunk Motor

Open

Luggage compartment lid

latch actuator control

circuit - short to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check luggage compartment lid latch

actuator control circuit for short to power B111D14

Boot/Trunk Motor

Open

Luggage compartment lid

latch actuator control

circuit - short to ground,

open circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check luggage compartment lid latch

actuator control circuit for short to ground, open circuit B111E11 Boot/Trunk Lamps

Luggage compartment

lamp control circuit -

short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check luggage compartment lamp control

circuit for short to ground B111E12 Boot/Trunk Lamps

Luggage compartment

lamp control circuit -

short to power Refer to the electrical circuit diagrams and check luggage

compartment lamp control circuit for short to power

Page 2099 of 3039

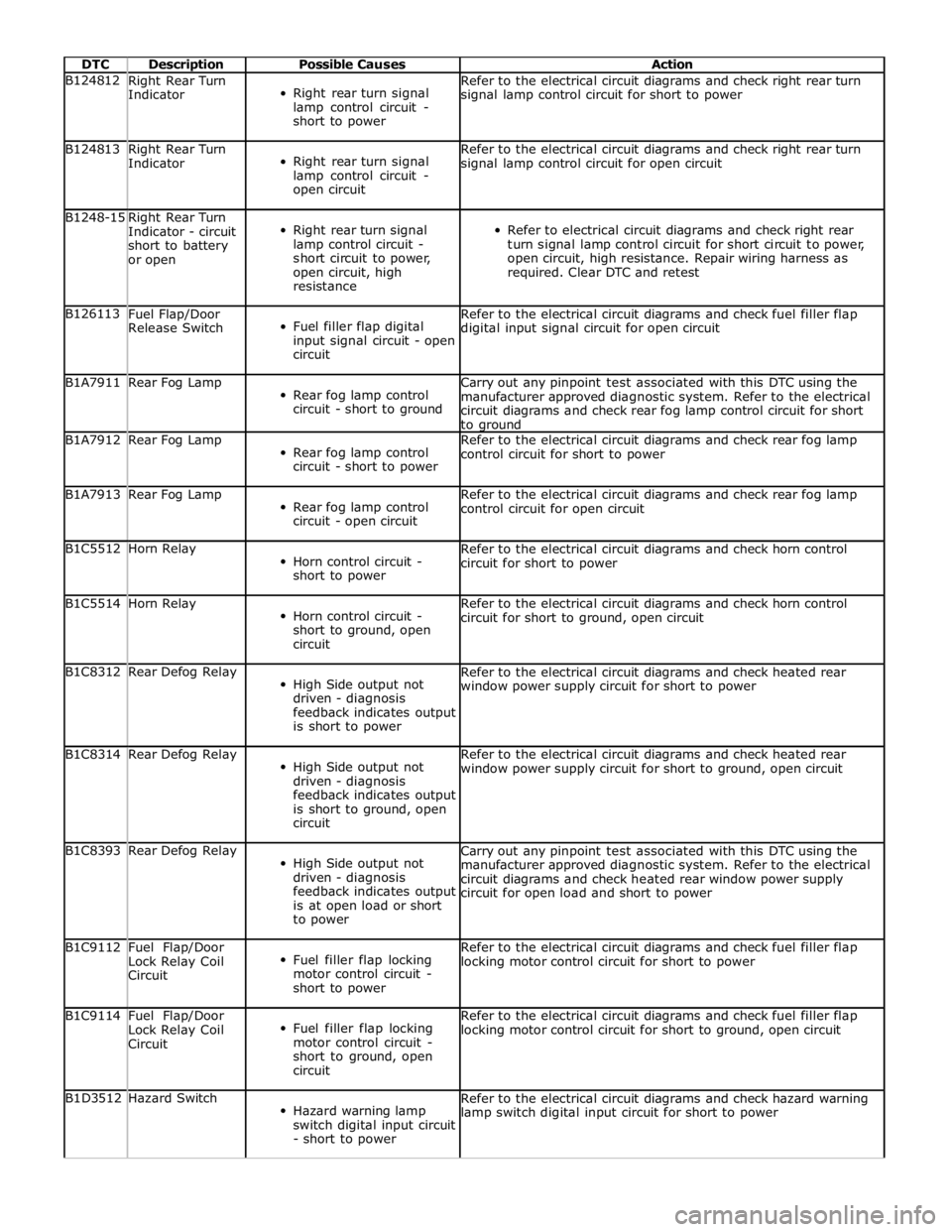

DTC Description Possible Causes Action B124812

Right Rear Turn

Indicator

Right rear turn signal

lamp control circuit -

short to power Refer to the electrical circuit diagrams and check right rear turn

signal lamp control circuit for short to power B124813

Right Rear Turn

Indicator

Right rear turn signal

lamp control circuit -

open circuit Refer to the electrical circuit diagrams and check right rear turn

signal lamp control circuit for open circuit B1248-15

Right Rear Turn

Indicator - circuit

short to battery

or open

Right rear turn signal

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check right rear

turn signal lamp control circuit for short circuit to power,

open circuit, high resistance. Repair wiring harness as

required. Clear DTC and retest B126113

Fuel Flap/Door

Release Switch

Fuel filler flap digital

input signal circuit - open

circuit Refer to the electrical circuit diagrams and check fuel filler flap

digital input signal circuit for open circuit B1A7911 Rear Fog Lamp

Rear fog lamp control

circuit - short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check rear fog lamp control circuit for short

to ground B1A7912 Rear Fog Lamp

Rear fog lamp control

circuit - short to power Refer to the electrical circuit diagrams and check rear fog lamp

control circuit for short to power B1A7913 Rear Fog Lamp

Rear fog lamp control

circuit - open circuit Refer to the electrical circuit diagrams and check rear fog lamp

control circuit for open circuit B1C5512 Horn Relay

Horn control circuit -

short to power Refer to the electrical circuit diagrams and check horn control

circuit for short to power B1C5514 Horn Relay

Horn control circuit -

short to ground, open

circuit Refer to the electrical circuit diagrams and check horn control

circuit for short to ground, open circuit B1C8312 Rear Defog Relay

High Side output not

driven - diagnosis

feedback indicates output

is short to power Refer to the electrical circuit diagrams and check heated rear

window power supply circuit for short to power B1C8314 Rear Defog Relay

High Side output not

driven - diagnosis

feedback indicates output

is short to ground, open

circuit Refer to the electrical circuit diagrams and check heated rear

window power supply circuit for short to ground, open circuit B1C8393 Rear Defog Relay

High Side output not

driven - diagnosis

feedback indicates output

is at open load or short

to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check heated rear window power supply

circuit for open load and short to power B1C9112

Fuel Flap/Door

Lock Relay Coil

Circuit

Fuel filler flap locking

motor control circuit -

short to power Refer to the electrical circuit diagrams and check fuel filler flap

locking motor control circuit for short to power B1C9114

Fuel Flap/Door

Lock Relay Coil

Circuit

Fuel filler flap locking

motor control circuit -

short to ground, open

circuit Refer to the electrical circuit diagrams and check fuel filler flap

locking motor control circuit for short to ground, open circuit B1D3512 Hazard Switch

Hazard warning lamp

switch digital input circuit

- short to power Refer to the electrical circuit diagrams and check hazard warning

lamp switch digital input circuit for short to power

Page 2115 of 3039

length.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15. NOTE: See illustration: Stripping Insulation

From the Relationship Table, find the correct length of insulation to be stripped from the pre-terminated wiring harness

and set the adjustable cable length stop to the correct length. Place the pre-terminated wiring harness in the wire

stripper and remove the insulation.

Put the cable identification sleeve(s) on to the wiring harness with the main cable colour nearest to the terminal.

During this next step do not over tighten. Place the selected butt splice connector in the crimping tool, matching the

aperture and the butt connector colours. Make sure that the window indentation in the butt connector is resting over

the guide bar on the lower jaw. Partially close the grip until the butt connector is securely held in the aperture. This will

give support to the butt connector while the pre-terminated wiring harness is inserted into it.

NOTE: See illustration: Splice Correctly Located

Insert the pre-terminated wiring harness into the butt connector and make sure that the wire is against the wire stop.

Close the grip firmly, crimping the lead to the butt connector. When the handles have been completely closed the butt

connector will be freed from the tool as the handles are released. If the handles have not been completely closed then

the jaws will hold the butt connector and it cannot be removed from the tool until the crimp is fully made by closing the

handles completely.

Make sure that the harness cable has been squarely cut and the correct length of insulation removed. If more than one

splice is needed the butt connectors must be not be crimped to the wiring harness at the same distance from the

connector. The splices must be staggered to prevent a bulk of splices in the same area of the wiring harness.

It is preferable to cover the butt splice joint with heat shrink sleeve. This is desirable not essential, except where the

electrical connector is a sealed electrical connector. Use the smaller diameter sleeve for red and blue pre-terminated

wiring harness(s) and the large diameter sleeve for the yellow pre-terminated wiring harness(s). It is advisable to place

the heat shrink over the completed joint but in some instances the sleeve will not pass over the terminal. Check, and if

required, place the correct size sleeve onto the harness cable or pre-terminated wiring harness before crimping the butt

splice to the wiring harness.

Place the harness cable into the butt splice with the splice window over the guide bar. Make sure that the cable harness

wire is against the stop in the butt splice, crimp the butt splice connector to the wiring harness.

Gently pull the harness cables each side of the butt splice to make sure that a secure joint has been made.

WARNING: Do not use a naked flame in areas where fuel or oil have been spilt. Clean the area of residual oil and

fuel and wait until the fuel spill has fully evaporated.

CAUTIONS:

When using a heat source make sure that it is localised and causes no damage to surrounding materials.

Where the repair procedure indicates that a glue lined heat shrink sleeve should be applied, apply sufficient heat

to the glue lined heat shrink to melt the glue in order to provide a water tight seal. Do not over heat the glue lined

heat shrink sleeve so that the wiring harness insulation becomes damaged.

Using a suitable heat source, shrink the sleeve over the butt splice.

If further pre-terminated wiring harness(s) are to be installed to the same electrical connector, make sure that the lead

is cut at a different length to the previous joint. This makes sure that the splices will, where possible, be staggered on

the wiring harness and prevent a bulk of splices in one area.

When all of the splices have been made, fit the terminal(s) to the electrical connector, taking care that the terminals

are correctly orientated.

Install the wiring harness cover and secure with adhesive electrical tape. Do not cover the wiring harness right to the

electrical connector as the terminals must have a little movement and not be firmly bound to the electrical connector or

wiring harness. Make sure that the cable identification sleeve(s) are showing at the wiring harness electrical connector.

www.JagDocs.com

Page 2124 of 3039

The battery backed sounder is disconnected (partial trigger only).

The vehicle battery is disconnected on a vehicle fitted with a battery backed sounder (partial trigger only).

The inclination sensor detects a change in vehicle attitude.

The intrusion detection module detects movement within the cabin.

Door Modules Component Description

The door modules provide the interface between the door latch-motors, the door latch-switches and the CJB. The door modules

provide door switch status information and enable the door latch-motors on request from the CJB or the keyless vehicle

module.

Keyless Vehicle Module

The keyless vehicle module interfaces with the Central locking, Radio Frequency (RF) receiver and collects RF signal information

which is transmitted from the Smart Key. This information is translated into commands which are passed on the medium speed

CAN bus to the:

CJB,

RJB,

door modules, and

instrument cluster.

The keyless vehicle module also monitors:

2 interior antennae,

1 luggage compartment antenna,

a rear bumper antenna, and

4 door handle antennae if the passive entry system is fitted.

On vehicles with passive entry, the additional fast latch motors are controlled via the keyless vehicle module and the locking

status is passed to the CJB on the medium speed CAN bus.

Instrument Cluster

The instrument cluster controls the alarm indicator, and in conjunction with the ECM (engine control module), the engine

immobilization. The ECM controls the engine crank and fuel functions and the instrument cluster processes the valid

transponder information.

Alarm Indicator

The alarm indicator is a LED (light emitting diode) located in the body of the sunload/light sensor. When the ignition is off the

indicator gives a visual indication of the active anti-theft system to show if the alarm system is active or not active. Operation

of the alarm indicator is controlled by the instrument cluster which varies the flash rate of the LED to indicate the system

status of the alarm and the immobilization systems.

When the ignition is on, the indicator provides a visual indication of the status of the passive anti-theft (engine

immobilization) system. If the immobilization system is operating correctly, the LED will be illuminated for 3 seconds at

ignition on and then extinguish. If a fault exists in the immobilization system, the LED will be either permanently illuminated

or flashing for 60 seconds. This indicates that a fault exists and fault code has been recorded. After the 60 second period the

LED will flash at different frequencies which indicate the nature of the fault.

Refer to: Anti-Theft - Passive (419-01B Anti-Theft - Passive, Description and Operation).

Passive Anti-Theft Horn

The passive anti-theft horn is hardwired to the CJB which activates the horn when the alarm is triggered.

Battery Backed Sounder

Operation of the battery backed sounder is controlled by the CJB on the LIN bus. The sounder is also connected with a

permanent battery supply via the CJB. An integral, rechargeable battery powers the sounder if the battery power supply from

the CJB is interrupted.

Dependant on vehicle, a incitation sensor is incorporated into the battery backed sounder, to monitor vehicle attitude, see

Inclination Sensor.

Inclination Sensor

The CJB monitors the inclination sensor and will activate the alarm system if the vehicle is being raised.

Intrusion Detection Module

The intrusion detection module comprises an ultrasonic sound wave sensor which monitors the vehicle's interior.

The intrusion detection module is activated with volumetric mode which in turn is enabled when the vehicle is double locked.

The vehicle can be locked and alarmed with the module de-activated if a pet is to be left in the vehicle for example by single-

Page 2141 of 3039

Anti-Theft - Passive - Anti-Theft - Passive - Overview

Description and Operation

Overview Published: 11-May-2011

The PATS (passive anti-theft system) prevents the vehicle's engine from being started by unauthorized persons.

Engine starting is prevented by inhibiting the fuel, engine (spark, injectors and crank) and ignition systems from operating.

This is achieved by using a uniquely coded Smart Key and an encoded data exchange between multiple control modules.

The system is automatic and requires no input from the driver.

The engine start system is initiated when the encoded data between the Smart Key and vehicle control modules is verified.

The engine can then be started when the drive selector is in the 'Park' position, and the start/stop switch and the brake pedal

are pressed simultaneously.

Page 2143 of 3039

7 Low frequency antenna - front 8 Low frequency antenna - center 9 Low frequency antenna - rear 10 Radio frequency receiver 11 Start control module 12 CJB (central junction box) 13 Instrument cluster 14 Megafuse (250 amp)

System Operation

The passive start function prevents the vehicle from being started by unauthorized persons. It does this by immobilizing the

ignition, fuel and engine crank functions. The system is automatic and requires no input from the driver.

At the request of the CJB, the keyless vehicle module prompts each of the Low Frequency (LF) antennae to output a signal. When the Smart Key is in the vehicle cabin, it detects the LF signals and responds with a Radio Frequency (RF)

data-identification signal back to the keyless vehicle module via the RF receiver.

If the data received matches that stored in the keyless vehicle module it continues the passive start process by

communicating a 'Smart Key valid’ signal to the CJB via the medium speed CAN (controller area network) bus.

Once the CJB receives the authorization and confirms a response with an internal calculation, it passes the result to the

instrument cluster on the medium speed CAN bus.

Before the instrument cluster sends a mobilization signal to the ECMit will exchange encrypted data with: The electric steering lock mechanism to authorize unlocking the steering column.

The RJB to authorize fuel pump operation. Once the RJB receives the authorization and confirms the response with an internal calculation, it will enable the FPDM (fuel pump driver module).

The CJB to authorize the ignition status. If the drive selector is in the park position and the driver presses the brake

pedal and simultaneously presses the start/stop switch, the CJB interprets this as an engine crank request. Before the

engine crank request is allowed, the CJB compares a brake pressure signal received from the ABS module. The brake pressure signal is compared to an internally stored threshold value within the CJB. If the signal is greater than the

stored threshold value, a crank request signal is sent to the ECM on the high speed CAN bus.

Once these factors have been confirmed, and the vehicle is in 'Park', the engine can be started by pressing the brake pedal and

the Stop/Start button simultaneously.

NOTES:

If the keyless vehicle module fails to locate the Smart Key, the message 'SMART KEY NOT FOUND PLEASE INSERT IN

SLOT' will appear in the instrument cluster message center. When inserted the start control module will read the transponder

within the Smart Key. If the transponder identification is valid, authorization will be transmitted to the instrument cluster on

the LIN (local interconnect network) bus.

When the vehicle is delivered from the factory the passive start function is inhibited. In this condition the vehicle can

only be started by placing the Smart Key in the start control module. The system should be switched on during the Pre-Delivery

Inspection (PDI) using the Jaguar approved diagnostic system. For additional information, refer to the PDI Manual.

To ensure optimum long term reliability of the smart key the battery must be replaced with a brand new, unused battery. If a

used battery is installed the "SMART KEY BATTERY LOW" message may not be cleared. To avoid contamination of the contacts

the battery should be removed from its packaging and installed into the smart key while wearing gloves. To confirm that the

replacement battery is working correctly press the unlock button twice while holding the smart key outside the vehicle, then

enter the vehicle with the smart key, press the start button and confirm that the "SMART KEY BATTERY LOW" message is not

displayed.

Start Control Module Component Description

The start control module is used if the keyless vehicle module is unable to authorise the Smart Key.

If the keyless vehicle module is unable to identify the Smart Key, for example if the Smart Key battery voltage is low or there

is local RF interference, the transponder within the Smart Key can be read in the conventional manner. The driver will be

alerted to this by a chime and a message in the instrument cluster message center 'SMART KEY NOT FOUND PLEASE INSERT IN

SLOT'.

Once inserted the start control module will read the transponder within the Smart Key. If the transponder identification is

valid, authorization will be transmitted to the instrument cluster on the LIN bus.

NOTE: Inserting the Smart Key into the start control module will not charge the Smart Key battery. The battery is

non-chargeable and must be replaced if defective.

Page 2146 of 3039

Check the Starter Relay circuit.

NOTE: On petrol engine variants, due to Smart Start, both sides of Relay Coil are switched directly from ECM (If

conditions correct). On diesel engine variants the low side only is switched directly from the ECM.

Check that the Steering Column Lock correctly operates and the steering wheel can turn freely.

Check that the High Speed CAN network is not malfunctioning, i.e. the CAN circuit is open or short circuit. This would mean

that the instrument cluster and ECM would be unable to communicate resulting in no Challenge being performed to enable the

ECM. This would be supported by LED Flash Code 24, see PATS Fault Code Table.

Also check the CAN network between the ABS module and the CJB. The CJB uses the CAN_BrakePressureTMC signal to

determine if the brake pedal has been pressed in order to allow an engine crank. The CJB uses a value of 0x05, if the CJB sees

a value less than this, it will not enable the Crank Request Output.

Engine cranks but will not start

If the Engine is cranking it means that the ECM has passed the authorisation required with the Instrument Cluster. If this

authorisation failed, the ECM would not engage the starter relay. This could be confirmed by verifying the PATS LED prove out

(illuminated solid for 3 seconds) or by reading DTCs from the instrument cluster and ECM.

In this case, the fuel pump circuit should be verified. The Fuel Pump Delivery Module (FPDM), which is supplied via the RJB

(authentication required with the instrument cluster) and controlled by the ECM, supplies the fuel pump.

In all cases of suspected non-start issues, the most logical failure modes should be eliminated first. i.e.

1. Check all relevant supplies and grounds to the relevant modules listed herein.

2. Note any unusual behaviour from other systems/functionality.

3. Note any functions that are not operating as expected.

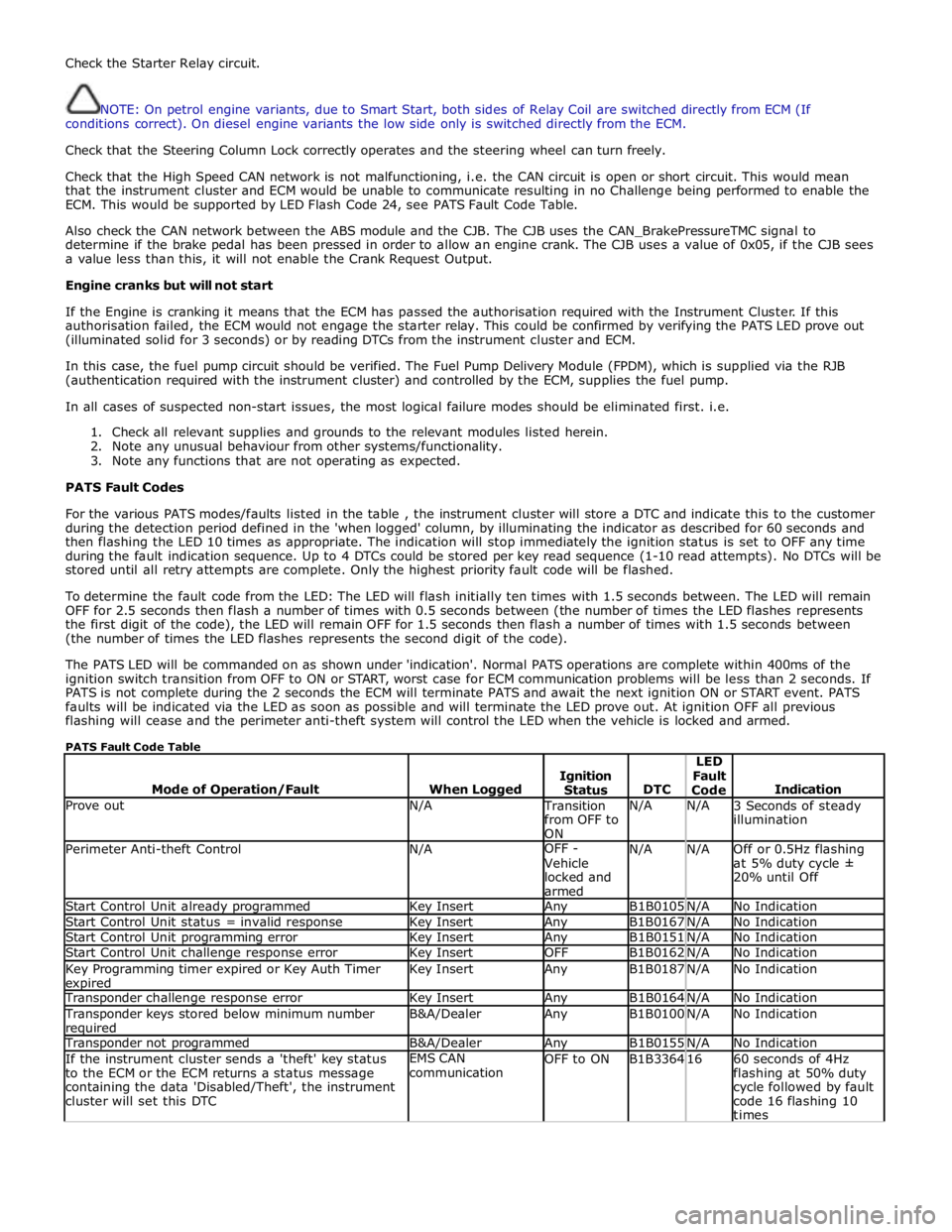

PATS Fault Codes

For the various PATS modes/faults listed in the table , the instrument cluster will store a DTC and indicate this to the customer

during the detection period defined in the 'when logged' column, by illuminating the indicator as described for 60 seconds and

then flashing the LED 10 times as appropriate. The indication will stop immediately the ignition status is set to OFF any time

during the fault indication sequence. Up to 4 DTCs could be stored per key read sequence (1-10 read attempts). No DTCs will be

stored until all retry attempts are complete. Only the highest priority fault code will be flashed.

To determine the fault code from the LED: The LED will flash initially ten times with 1.5 seconds between. The LED will remain

OFF for 2.5 seconds then flash a number of times with 0.5 seconds between (the number of times the LED flashes represents

the first digit of the code), the LED will remain OFF for 1.5 seconds then flash a number of times with 1.5 seconds between

(the number of times the LED flashes represents the second digit of the code).

The PATS LED will be commanded on as shown under 'indication'. Normal PATS operations are complete within 400ms of the

ignition switch transition from OFF to ON or START, worst case for ECM communication problems will be less than 2 seconds. If

PATS is not complete during the 2 seconds the ECM will terminate PATS and await the next ignition ON or START event. PATS

faults will be indicated via the LED as soon as possible and will terminate the LED prove out. At ignition OFF all previous

flashing will cease and the perimeter anti-theft system will control the LED when the vehicle is locked and armed.

PATS Fault Code Table

Mode of Operation/Fault

When Logged

Ignition

Status

DTC LED

Fault

Code

Indication Prove out N/A Transition

from OFF to

ON N/A N/A

3 Seconds of steady

illumination Perimeter Anti-theft Control N/A OFF -

Vehicle

locked and

armed N/A N/A

Off or 0.5Hz flashing

at 5% duty cycle ±

20% until Off Start Control Unit already programmed Key Insert Any B1B0105 N/A No Indication Start Control Unit status = invalid response Key Insert Any B1B0167 N/A No Indication Start Control Unit programming error Key Insert Any B1B0151 N/A No Indication Start Control Unit challenge response error Key Insert OFF B1B0162 N/A No Indication Key Programming timer expired or Key Auth Timer expired Key Insert Any B1B0187 N/A No Indication Transponder challenge response error Key Insert Any B1B0164 N/A No Indication Transponder keys stored below minimum number required B&A/Dealer Any B1B0100 N/A No Indication Transponder not programmed B&A/Dealer Any B1B0155 N/A No Indication If the instrument cluster sends a 'theft' key status

to the ECM or the ECM returns a status message

containing the data 'Disabled/Theft', the instrument

cluster will set this DTC EMS CAN

communication OFF to ON B1B3364 16

60 seconds of 4Hz

flashing at 50% duty

cycle followed by fault

code 16 flashing 10

times

Page 2170 of 3039

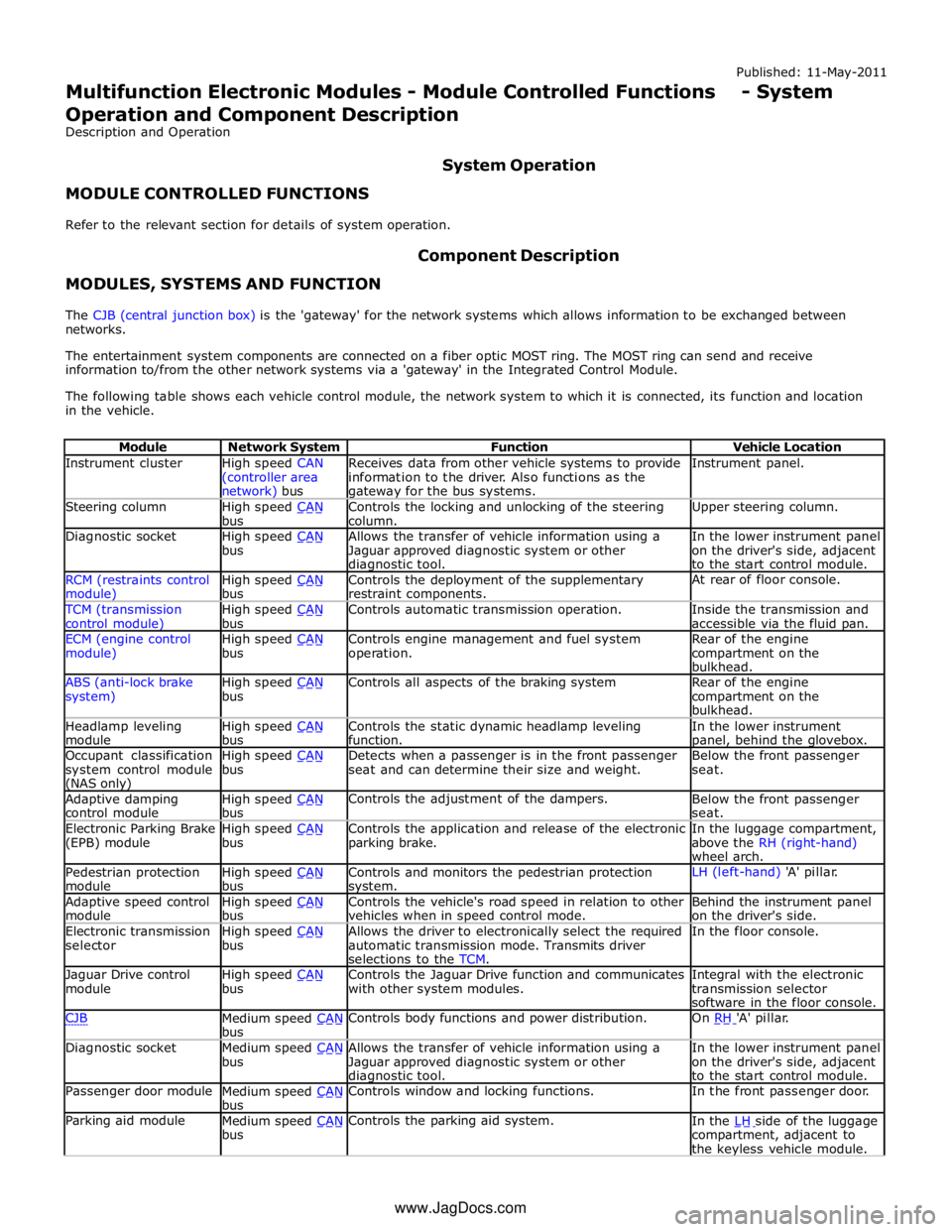

Instrument cluster

High speed CAN

(controller area network) bus Receives data from other vehicle systems to provide

information to the driver. Also functions as the gateway for the bus systems. Instrument panel. Steering column

High speed CAN bus Controls the locking and unlocking of the steering

column. Upper steering column. Diagnostic socket

High speed CAN bus Allows the transfer of vehicle information using a

Jaguar approved diagnostic system or other diagnostic tool. In the lower instrument panel

on the driver's side, adjacent

to the start control module. RCM (restraints control module) High speed CAN bus Controls the deployment of the supplementary

restraint components. At rear of floor console. TCM (transmission

control module) High speed CAN bus Controls automatic transmission operation.

Inside the transmission and

accessible via the fluid pan. ECM (engine control

module) High speed CAN bus Controls engine management and fuel system

operation. Rear of the engine

compartment on the

bulkhead. ABS (anti-lock brake

system) High speed CAN bus Controls all aspects of the braking system

Rear of the engine

compartment on the

bulkhead. Headlamp leveling

module High speed CAN bus Controls the static dynamic headlamp leveling

function. In the lower instrument panel, behind the glovebox. Occupant classification

system control module (NAS only) High speed CAN bus Detects when a passenger is in the front passenger

seat and can determine their size and weight. Below the front passenger

seat. Adaptive damping

control module High speed CAN bus Controls the adjustment of the dampers.

Below the front passenger

seat. Electronic Parking Brake

(EPB) module High speed CAN bus Controls the application and release of the electronic

parking brake. In the luggage compartment,

above the RH (right-hand)

wheel arch. Pedestrian protection

module High speed CAN bus Controls and monitors the pedestrian protection system. LH (left-hand) 'A' pillar. Adaptive speed control

module High speed CAN bus Controls the vehicle's road speed in relation to other

vehicles when in speed control mode. Behind the instrument panel

on the driver's side. Electronic transmission

selector High speed CAN bus Allows the driver to electronically select the required

automatic transmission mode. Transmits driver

selections to the TCM. In the floor console. Jaguar Drive control

module High speed CAN bus Controls the Jaguar Drive function and communicates

with other system modules. Integral with the electronic

transmission selector

software in the floor console. CJB

Medium speed CAN bus Controls body functions and power distribution. On RH 'A' pillar. Diagnostic socket

Medium speed CAN bus Allows the transfer of vehicle information using a

Jaguar approved diagnostic system or other diagnostic tool. In the lower instrument panel

on the driver's side, adjacent

to the start control module. Passenger door module

Medium speed CAN bus Controls window and locking functions. In the front passenger door. Parking aid module

Medium speed CAN bus Controls the parking aid system.

In the LH side of the luggage compartment, adjacent to

the keyless vehicle module. www.JagDocs.com