Bolt JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2979 of 3039

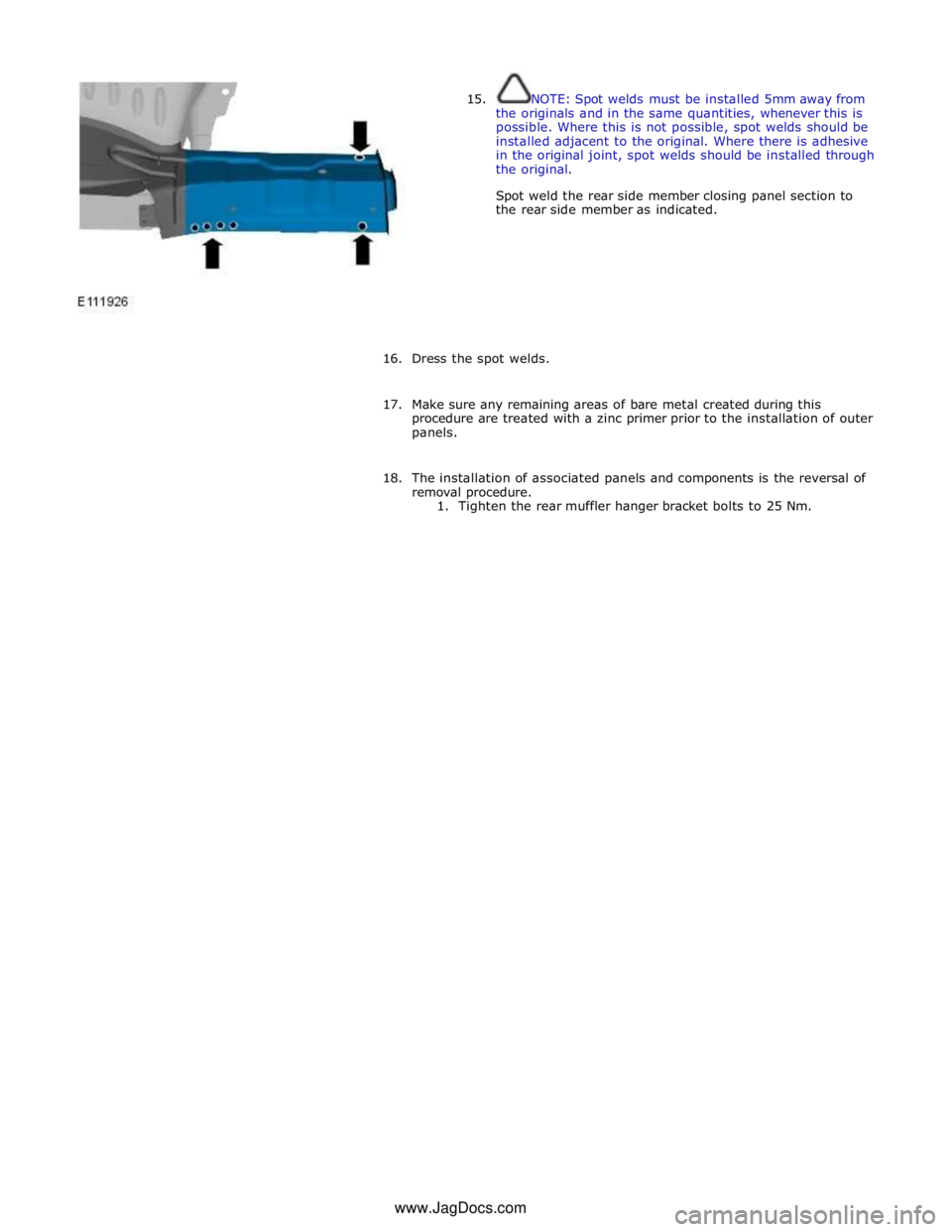

15. NOTE: Spot welds must be installed 5mm away from

the originals and in the same quantities, whenever this is

possible. Where this is not possible, spot welds should be

installed adjacent to the original. Where there is adhesive

in the original joint, spot welds should be installed through

the original.

Spot weld the rear side member closing panel section to

the rear side member as indicated.

16. Dress the spot welds.

17. Make sure any remaining areas of bare metal created during this

procedure are treated with a zinc primer prior to the installation of outer

panels.

18. The installation of associated panels and components is the reversal of

removal procedure.

1. Tighten the rear muffler hanger bracket bolts to 25 Nm. www.JagDocs.com

Page 2982 of 3039

12.

13.

14.

15. NOTE: A new striker reinforcement panel is supplied

on the quarter panel service panel.

Separate the joints, the adhesive and the NVH (noise,

vibration and harshness) component and remove the striker

reinforcement panel.

NOTE: Care should be taken when separating and

removing the ECM (engine control module) mounting

bracket if it is to be reused.

If the right-hand rear wheelhouse outer is to be repaired,

drill out the spot welds as indicated and remove the ECM

mounting bracket. Retain for reuse on installation.

NOTE: It is necessary to section the quarter panel

inner reinforcement at the point indicated, to make sure the

integrity of the safety belt anchorage point. The right-hand

panel is illustrated, the left-hand is similar.

Cut the quarter panel inner reinforcement, horizontally,

approximately 90mm from the centre of the safety belt bolt

anchorage point as indicated.

NOTE: The right-hand panel is illustrated, the

left-hand is similar although there are additional spot welds

to drill out.

Drill out the spot welds from the quarter panel inner

reinforcement section at the points indicated.

Page 3013 of 3039

Front lower arm to front subframe retaining nut and bolt 175 129 - Rear lower arm to front subframe retaining nut and bolt 175 129 - Engine mount lower retaining nut 63 46 - Steering gear retaining bolts 100 74 - Front Shock absorber and spring assembly retaining bolt 175 129 - Front subframe to body front retaining bolt Stage 1 100 73 - Stage 2 270° 270° - Front subframe to body rear retaining bolt Stage 1 80 59 - Stage 2 240° 240° - Front Stabilizer bar link retaining nuts 43 31 - Front Stabilizer bar link retaining bolts 55 41 - Rear Shock absorber and spring assembly retaining bolt 133 98 - Rear subframe reinforcement plate retaining bolts 47 35 - Rear subframe to body retaining bolts Stage 1 80 59 - Stage 2 240° 240° -

Page 3014 of 3039

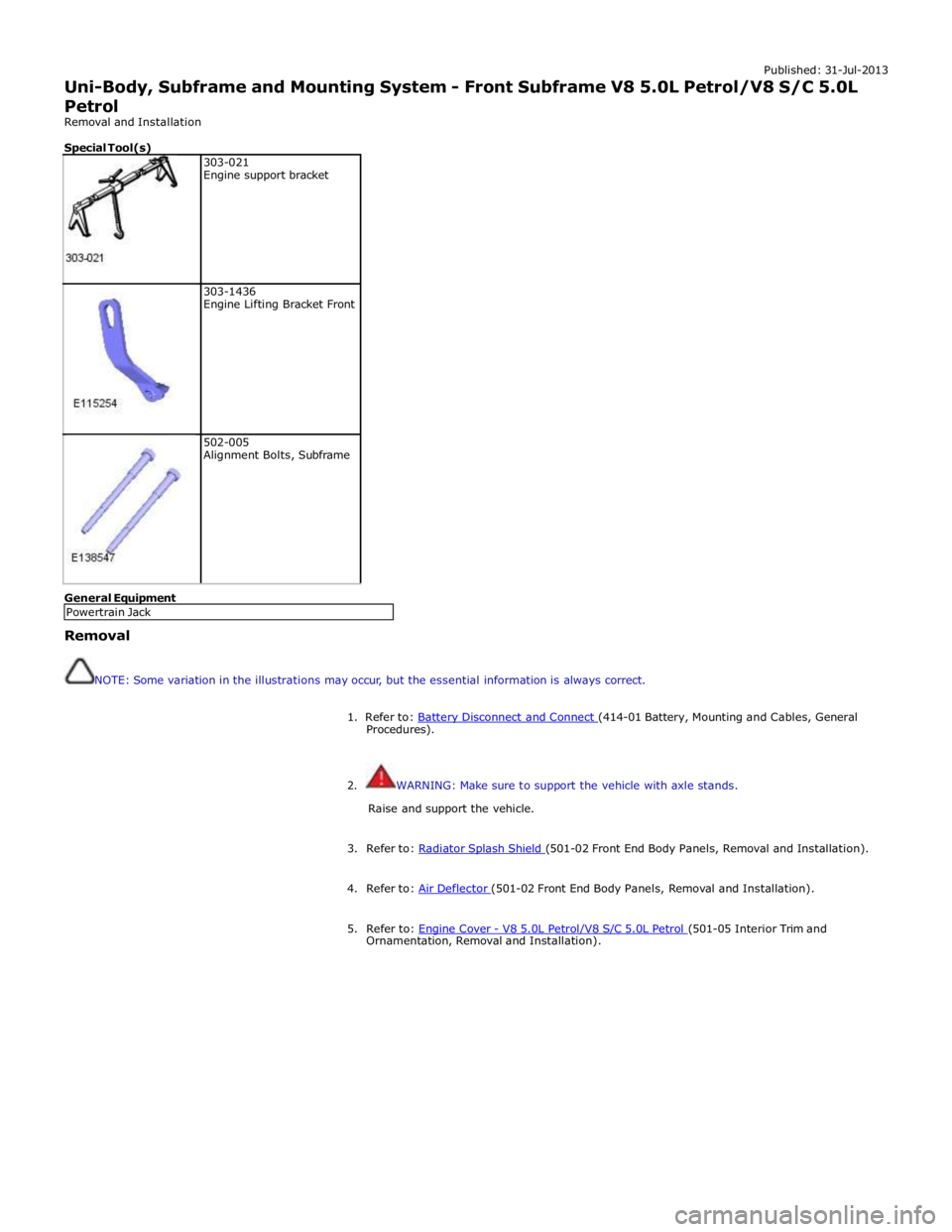

Published: 31-Jul-2013

Uni-Body, Subframe and Mounting System - Front Subframe V8 5.0L Petrol/V8 S/C 5.0L Petrol

Removal and Installation

Special Tool(s)

303-021

Engine support bracket

303-1436

Engine Lifting Bracket Front

502-005

Alignment Bolts, Subframe General Equipment

Removal

NOTE: Some variation in the illustrations may occur, but the essential information is always correct.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Radiator Splash Shield (501-02 Front End Body Panels, Removal and Installation). 4. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation). 5. Refer to: Engine Cover - V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-05 Interior Trim and Ornamentation, Removal and Installation). Powertrain Jack

Page 3020 of 3039

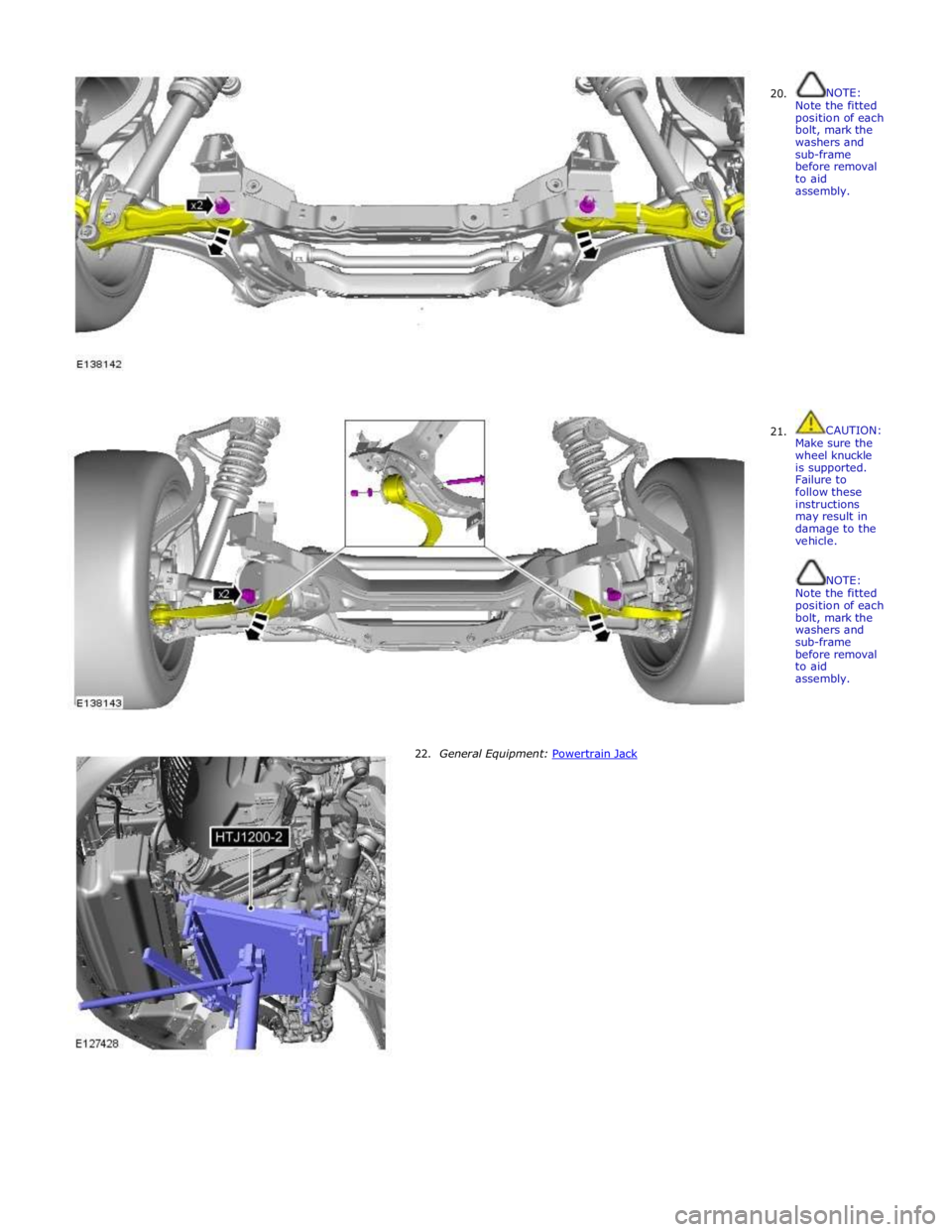

20.

21. NOTE:

Note the fitted position of each bolt, mark the washers and sub-frame before removal to aid assembly.

CAUTION:

Make sure the wheel knuckle is supported. Failure to follow these instructions may result in damage to the vehicle.

NOTE:

Note the fitted position of each bolt, mark the washers and sub-frame before removal to aid assembly.

22. General Equipment: Powertrain Jack

Page 3022 of 3039

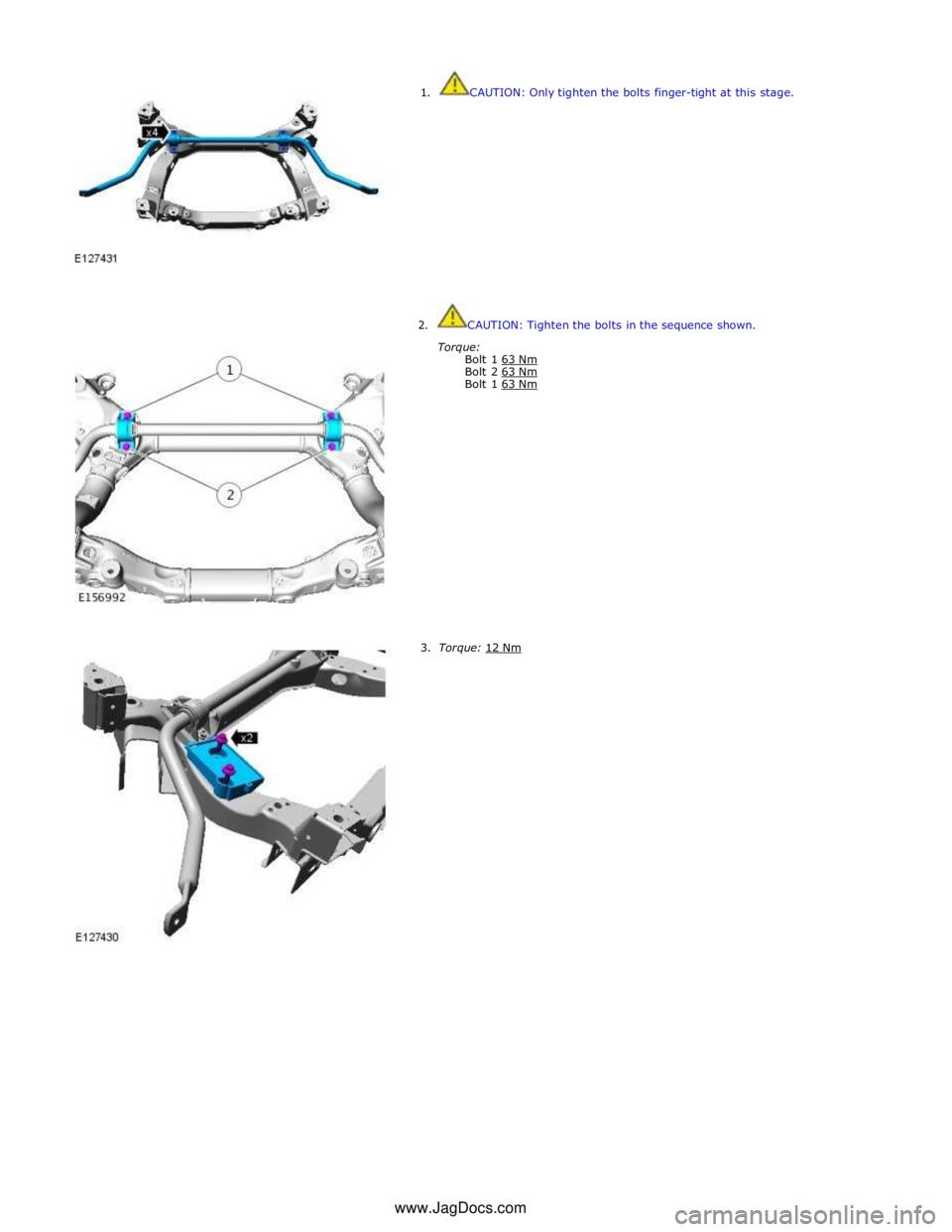

1. CAUTION: Only tighten the bolts finger-tight at this stage.

2. CAUTION: Tighten the bolts in the sequence shown.

Torque:

Bolt 1 63 Nm Bolt 2 63 Nm Bolt 1 63 Nm

3. Torque: 12 Nm www.JagDocs.com

Page 3025 of 3039

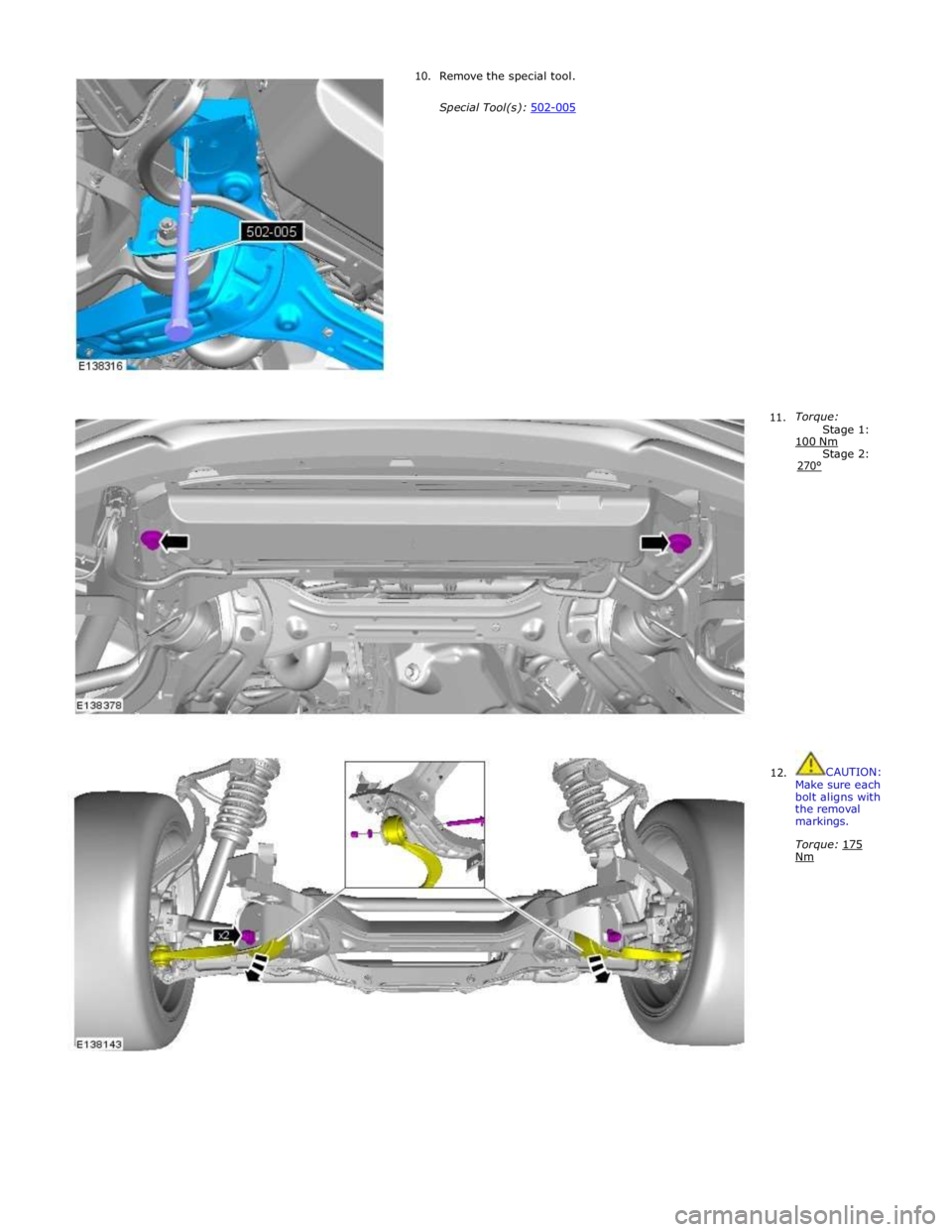

10. Remove the special tool.

Special Tool(s): 502-005

11.

Torque:

Stage 1: 100 Nm Stage 2: 270°

12. CAUTION:

Make sure each bolt aligns with the removal markings.

Torque: 175 Nm

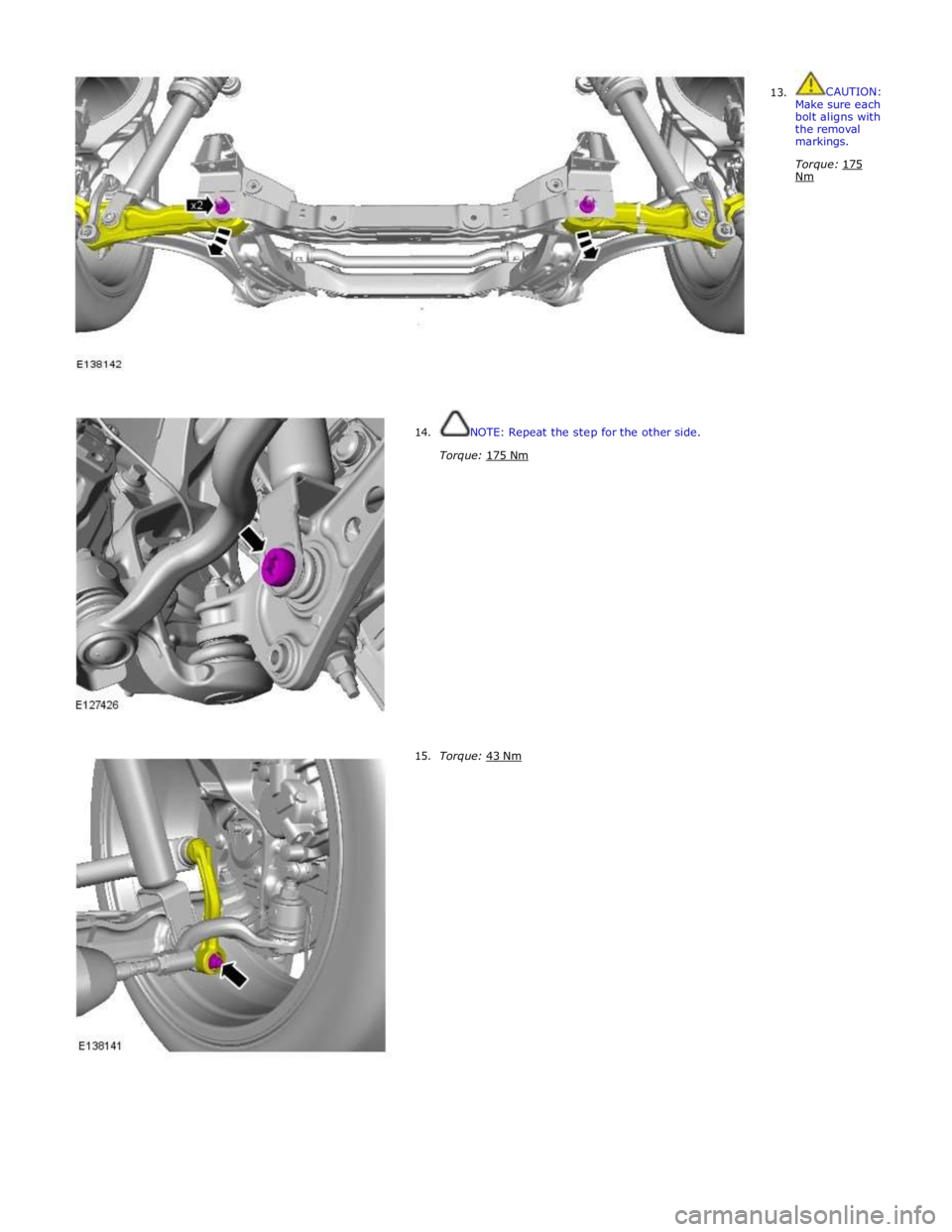

Page 3026 of 3039

13. CAUTION:

Make sure each bolt aligns with the removal markings.

Torque: 175 Nm

14.

15.

NOTE: Repeat the step for the other side.

Torque: 175 Nm

Torque: 43 Nm

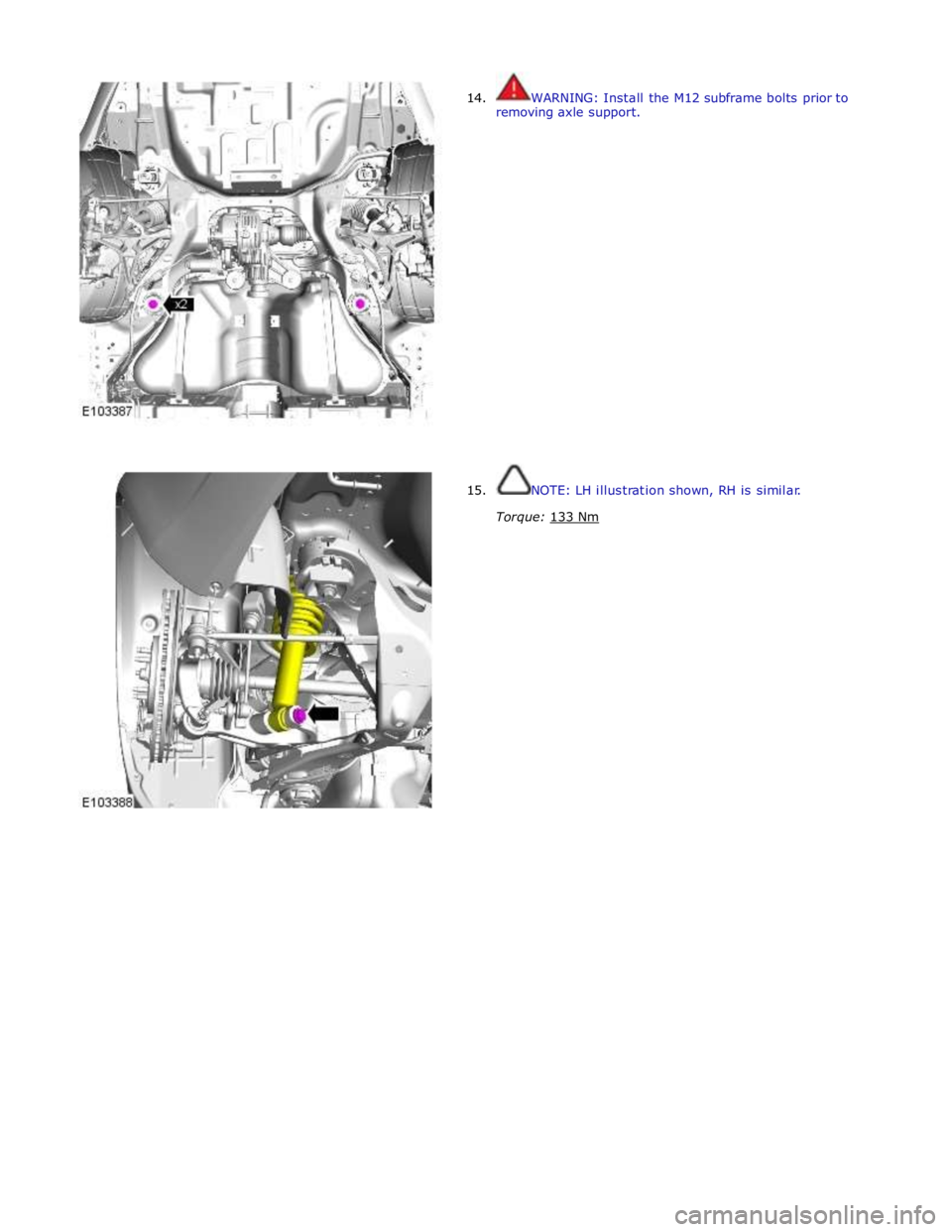

Page 3036 of 3039

14.

15. WARNING: Install the M12 subframe bolts prior to

removing axle support.

NOTE: LH illustration shown, RH is similar.

Torque: 133 Nm

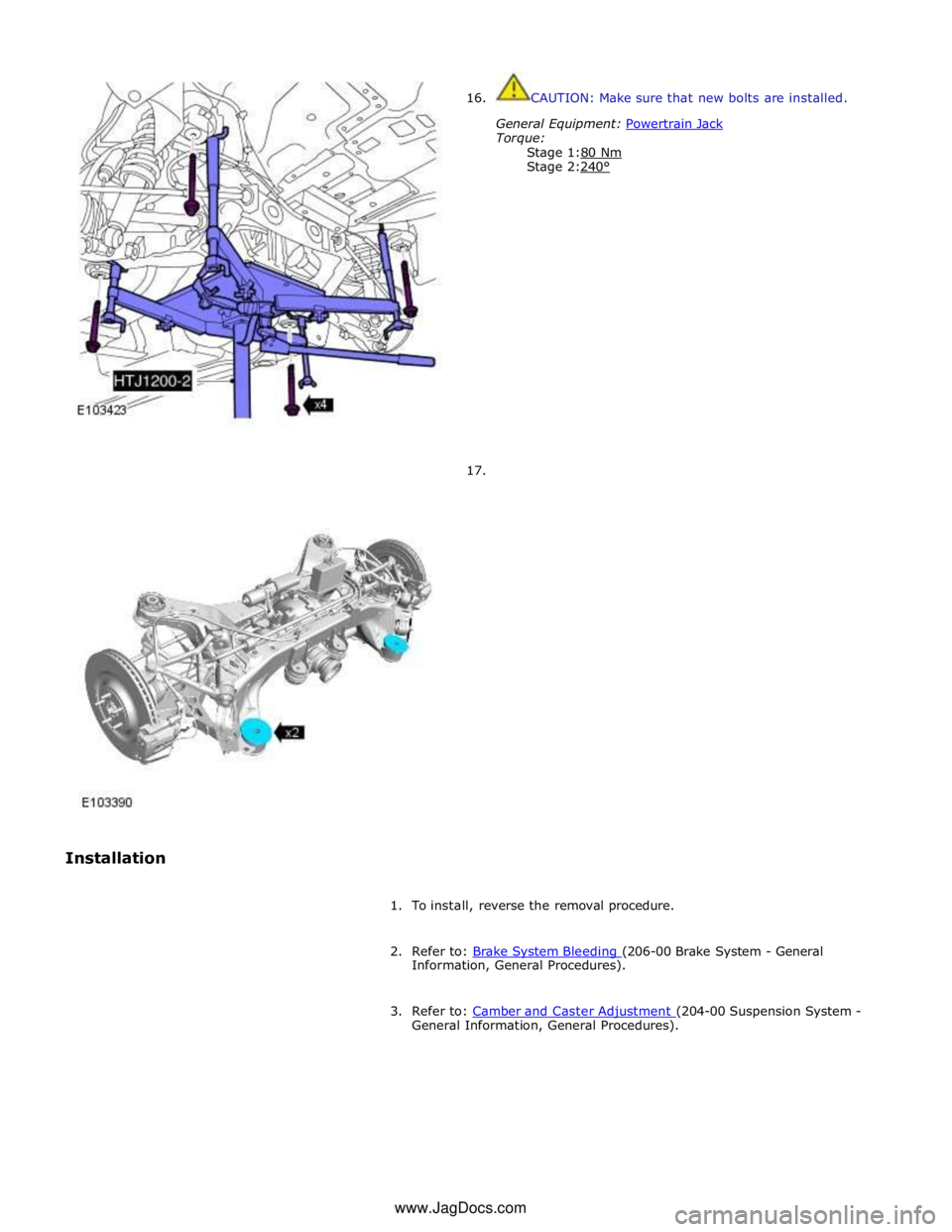

Page 3037 of 3039

Installation

16.

17.

CAUTION: Make sure that new bolts are installed.

General Equipment: Powertrain Jack Torque:

Stage 1:80 Nm Stage 2:240°

1. To install, reverse the removal procedure.

2. Refer to: Brake System Bleeding (206-00 Brake System - General Information, General Procedures).

3. Refer to: Camber and Caster Adjustment (204-00 Suspension System - General Information, General Procedures). www.JagDocs.com