JAGUAR XFR 2010 1.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2751 of 3039

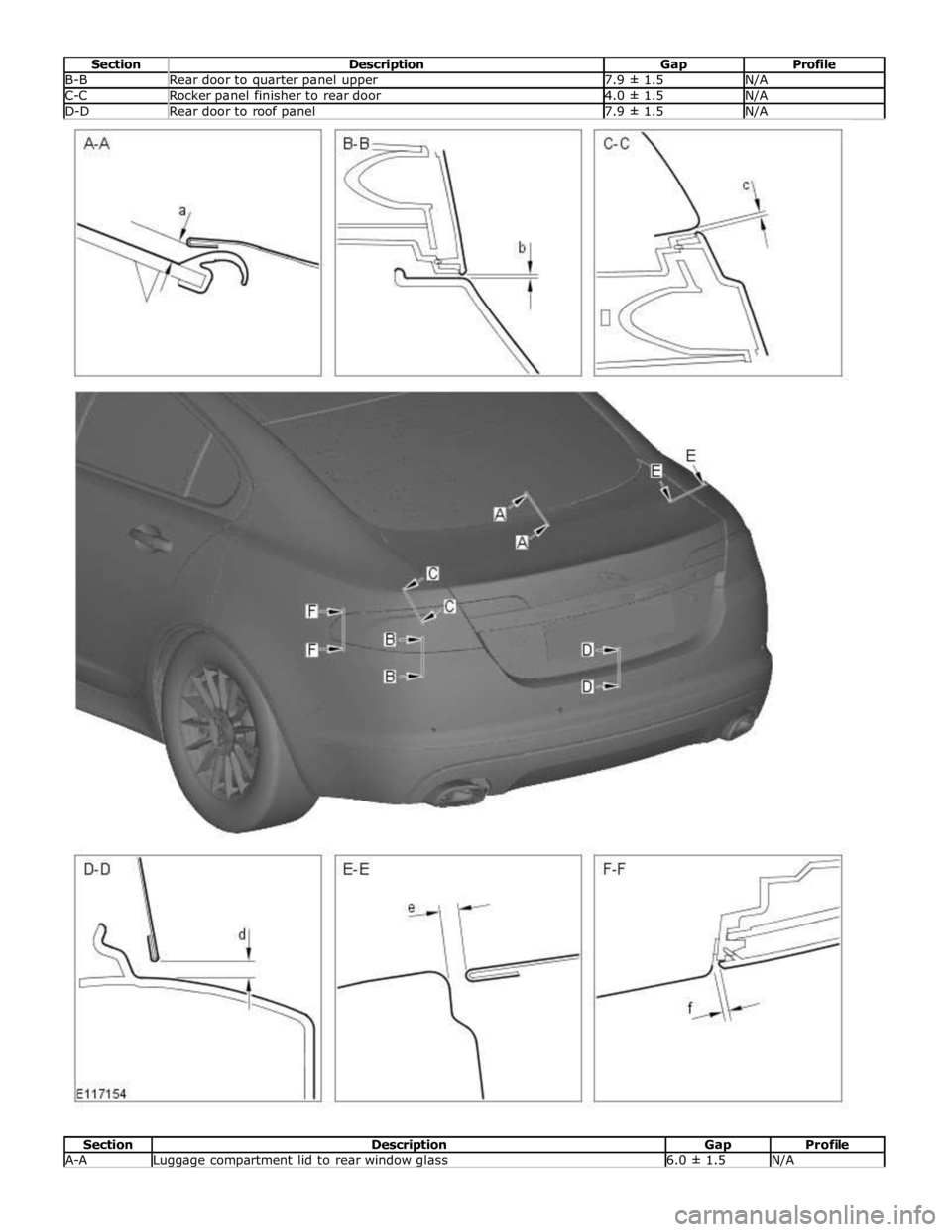

B-B Rear door to quarter panel upper 7.9 ± 1.5 N/A C-C Rocker panel finisher to rear door 4.0 ± 1.5 N/A D-D Rear door to roof panel 7.9 ± 1.5 N/A

Section Description Gap Profile A-A Luggage compartment lid to rear window glass 6.0 ± 1.5 N/A

Page 2752 of 3039

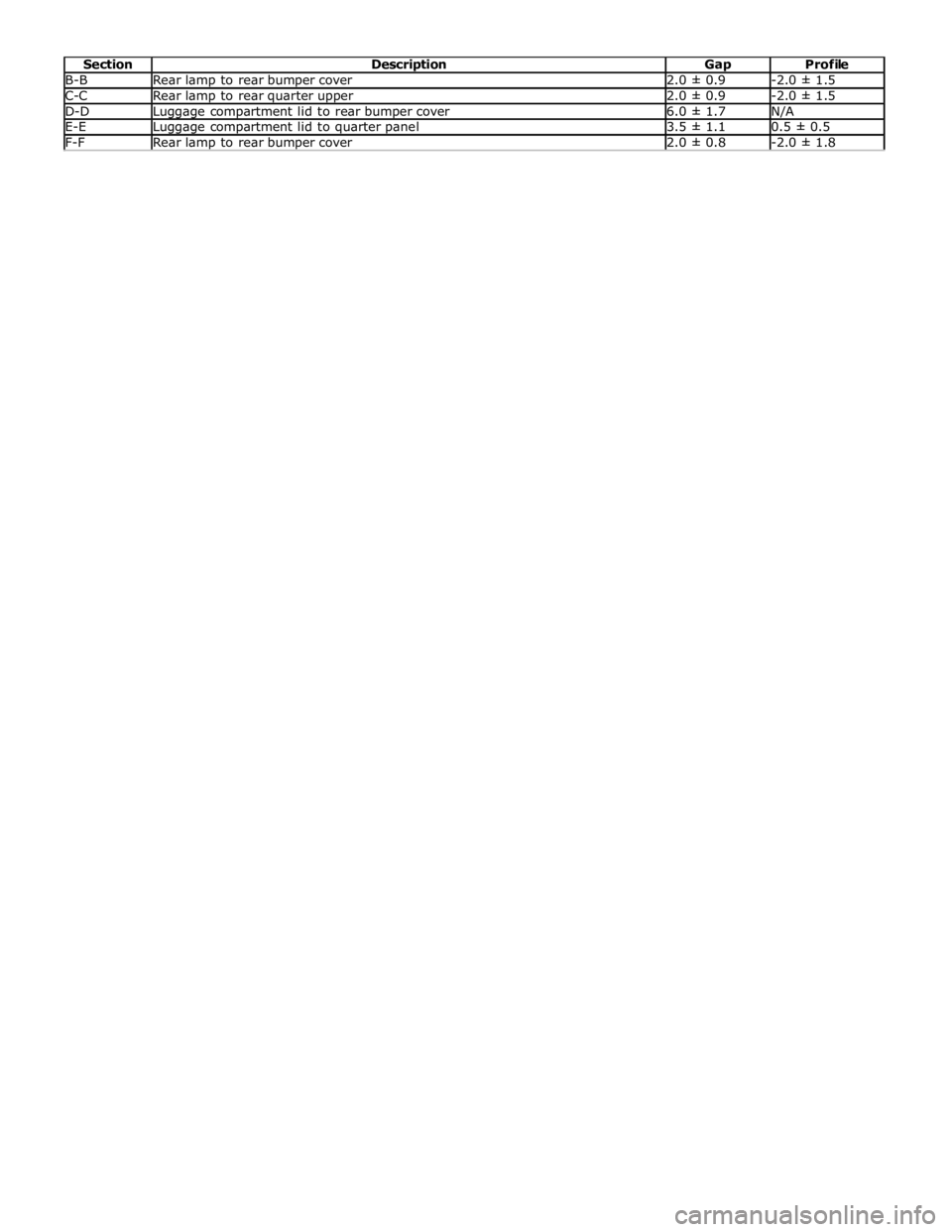

B-B Rear lamp to rear bumper cover 2.0 ± 0.9 -2.0 ± 1.5 C-C Rear lamp to rear quarter upper 2.0 ± 0.9 -2.0 ± 1.5 D-D Luggage compartment lid to rear bumper cover 6.0 ± 1.7 N/A E-E Luggage compartment lid to quarter panel 3.5 ± 1.1 0.5 ± 0.5 F-F Rear lamp to rear bumper cover 2.0 ± 0.8 -2.0 ± 1.8

Page 2753 of 3039

Page 2754 of 3039

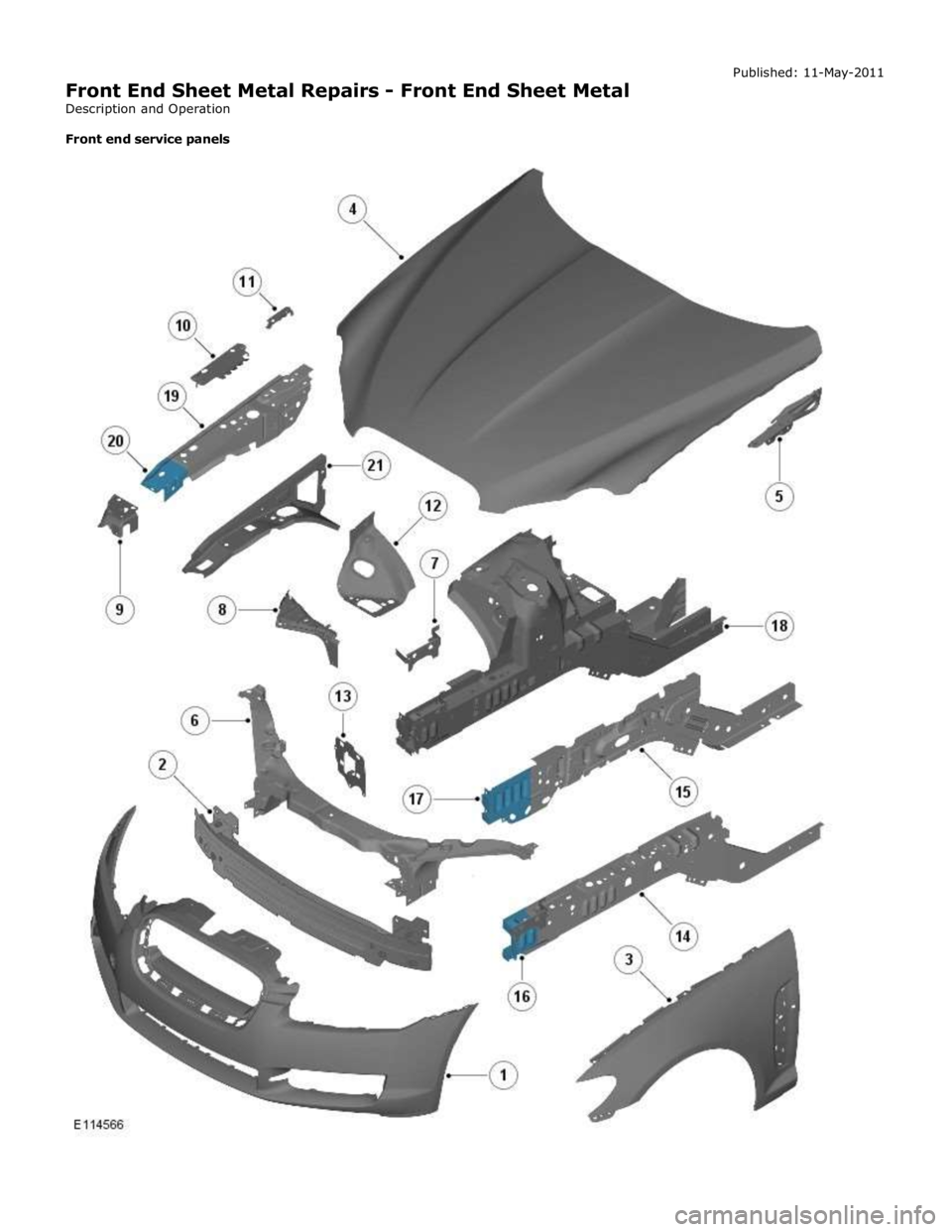

NOTE: The illustration may indicate either hand of the service panel, the opposite hand will be similar.

Item Description 1 Front bumper cover 2 Front bumper 3 Front fender 4 Hood 5 Hood hinge 6 Hood latch panel 7 Hood latch panel mounting bracket 8 Front fender support bracket 9 Fender apron panel front extension 10 Fender mounting plate 11 Hood strut mounting bracket 12 Front wheelhouse section 13 Front bumper mounting 14 Front side member 15 Front side member section 16 Front side member closing panel 17 Front side member closing panel section 18 Front side member & suspension top mount assembly 19 Fender apron panel 20 Fender apron panel front section 21 Fender apron panel closing panel Time schedules, front end

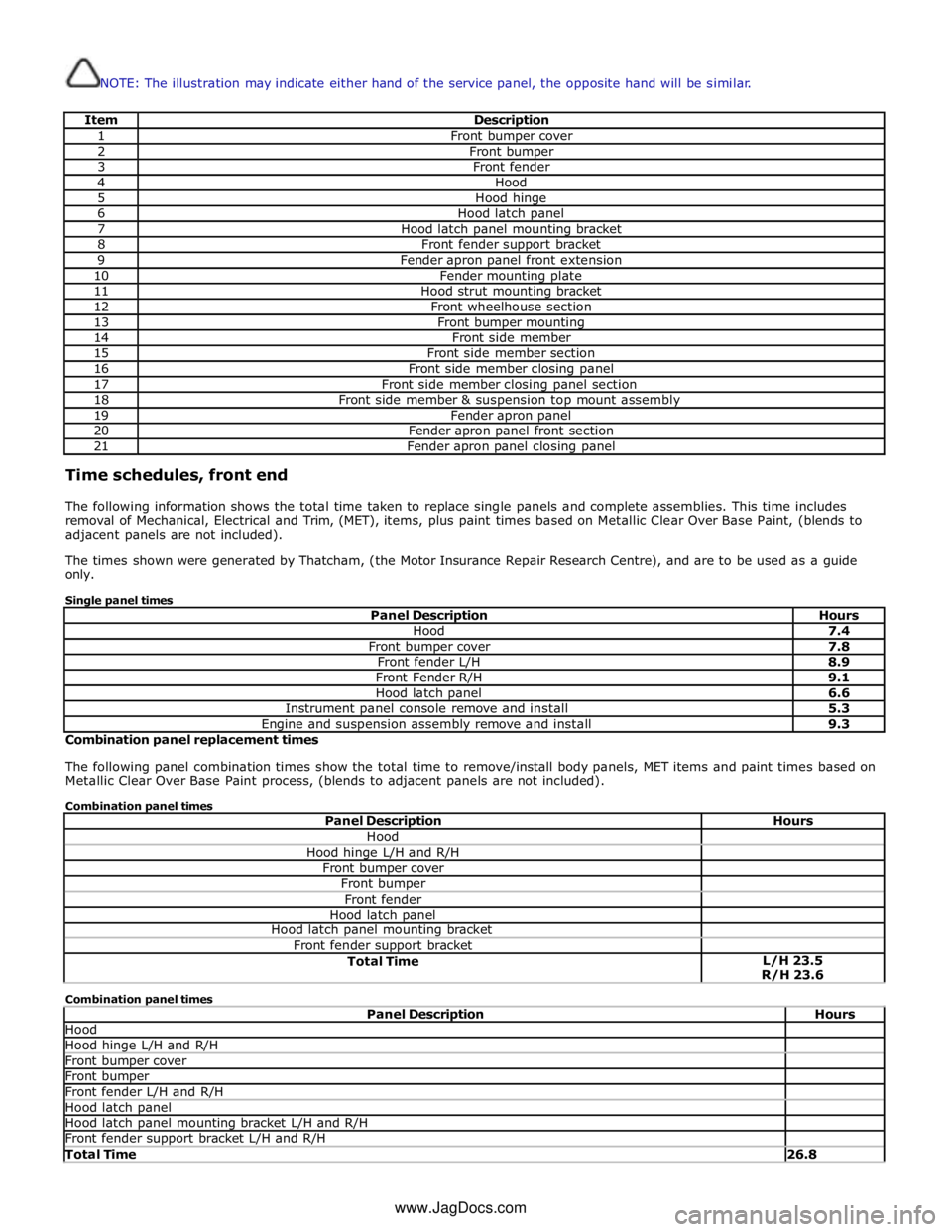

The following information shows the total time taken to replace single panels and complete assemblies. This time includes

removal of Mechanical, Electrical and Trim, (MET), items, plus paint times based on Metallic Clear Over Base Paint, (blends to

adjacent panels are not included).

The times shown were generated by Thatcham, (the Motor Insurance Repair Research Centre), and are to be used as a guide

only.

Single panel times

Panel Description Hours Hood 7.4 Front bumper cover 7.8 Front fender L/H 8.9 Front Fender R/H 9.1 Hood latch panel 6.6 Instrument panel console remove and install 5.3 Engine and suspension assembly remove and install 9.3 Combination panel replacement times

The following panel combination times show the total time to remove/install body panels, MET items and paint times based on

Metallic Clear Over Base Paint process, (blends to adjacent panels are not included).

Combination panel times

Panel Description Hours Hood Hood hinge L/H and R/H Front bumper cover Front bumper Front fender Hood latch panel Hood latch panel mounting bracket Front fender support bracket Total Time L/H 23.5

R/H 23.6 Combination panel times

Panel Description Hours Hood Hood hinge L/H and R/H Front bumper cover Front bumper Front fender L/H and R/H Hood latch panel Hood latch panel mounting bracket L/H and R/H Front fender support bracket L/H and R/H Total Time 26.8 www.JagDocs.com

Page 2755 of 3039

Hood Hood hinge L/H and R/H Front bumper cover Front bumper Front fender Hood latch panel Front fender support bracket Fender apron panel Fender apron panel closing panel Front side member & suspension top mount assembly Fender mounting plate Front fender lower mounting Engine and suspension assembly remove and install Instrument panel console remove and install Total Time L/H 44.3

R/H 44.5 Combination panel times

Panel Description Hours Hood Hood hinge L/H and R/H Front bumper cover Front bumper Front fender L/H and R/H Hood latch panel Front fender support bracket L/H and R/H Fender apron panel L/H and R/H Fender apron panel closing panel L/H and R/H Front side member & suspension top mount assembly L/H and R/H Fender mounting plate L/H and R/H Front fender lower mounting L/H and R/H Engine and suspension assembly remove and install Instrument panel console remove and install Total Time 57.6 Combination panel times

Panel Description Hours Hood Hood hinge L/H and R/H Front bumper cover Front bumper Front fender Hood latch panel Front fender support bracket Front bumper mounting Front side member section Front side member closing panel section Total Time L/H 28.0

R/H 28.1 Combination panel times

Panel Description Hours Hood Hood hinge L/H and R/H Front bumper cover Front bumper Front fender Hood latch panel Front fender support bracket Front fender support bracket mounting Front fender lower mounting Front bumper mounting Front side member Front side member closing panel Front wheelhouse section Engine and suspension assembly remove and install Total Time L/H 37.6

R/H 37.4

Page 2756 of 3039

Published: 11-May-2011

Front End Sheet Metal Repairs - Fender Apron Closing Panel Front Section

Removal and Installation

Removal

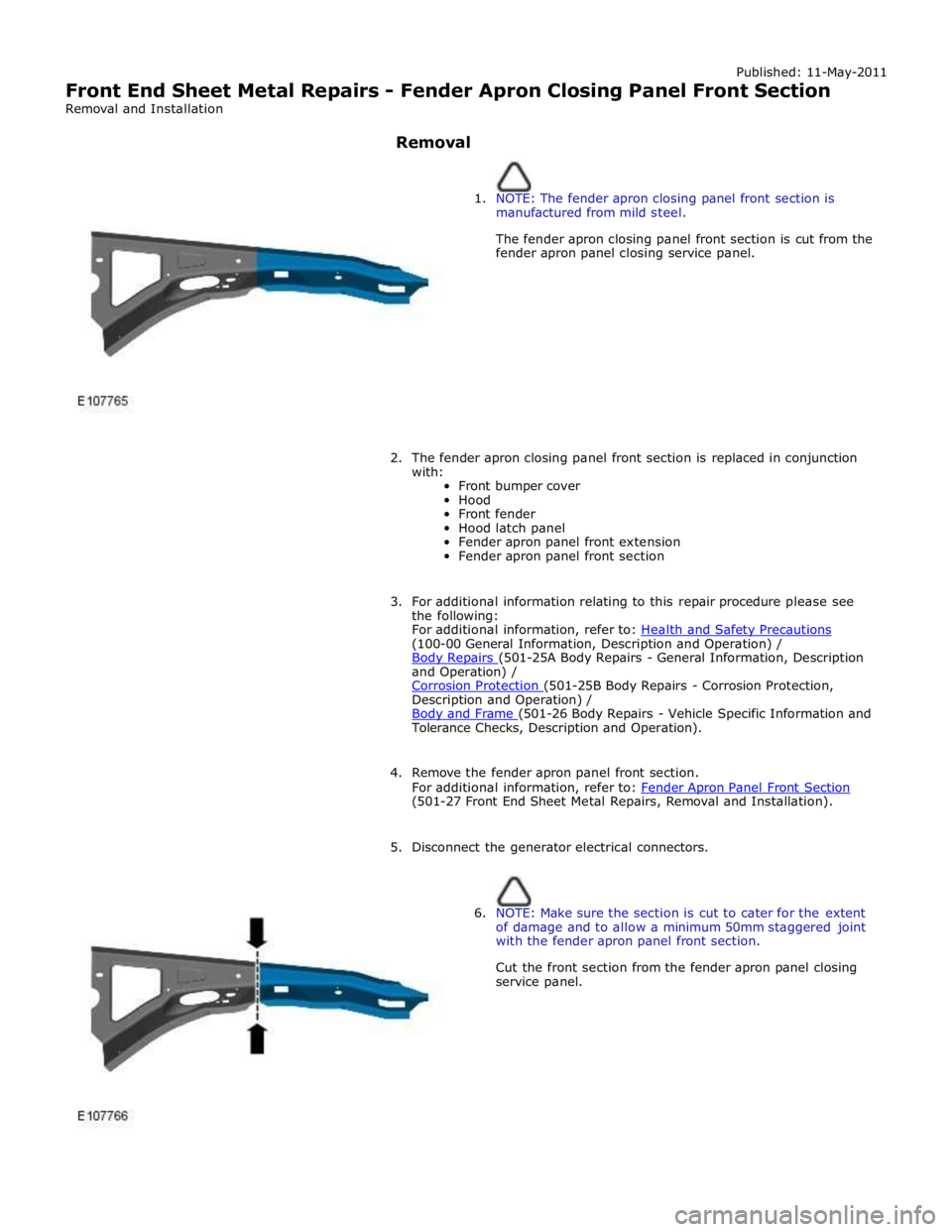

1. NOTE: The fender apron closing panel front section is

manufactured from mild steel.

The fender apron closing panel front section is cut from the

fender apron panel closing service panel.

2. The fender apron closing panel front section is replaced in conjunction

with:

Front bumper cover

Hood

Front fender

Hood latch panel

Fender apron panel front extension

Fender apron panel front section

3. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Remove the fender apron panel front section.

For additional information, refer to: Fender Apron Panel Front Section (501-27 Front End Sheet Metal Repairs, Removal and Installation).

5. Disconnect the generator electrical connectors.

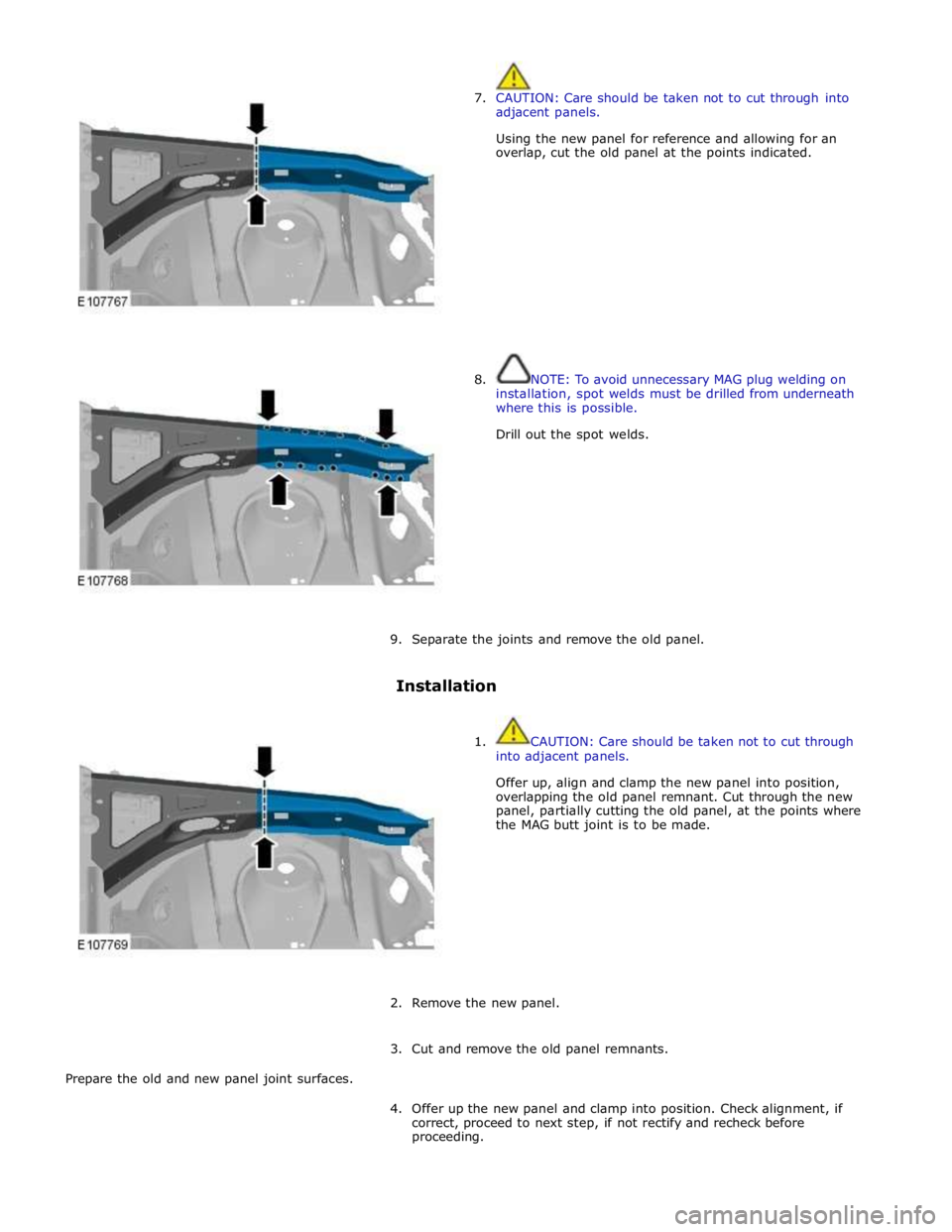

6. NOTE: Make sure the section is cut to cater for the extent

of damage and to allow a minimum 50mm staggered joint

with the fender apron panel front section.

Cut the front section from the fender apron panel closing

service panel.

Page 2757 of 3039

7. CAUTION: Care should be taken not to cut through into

adjacent panels.

Using the new panel for reference and allowing for an

overlap, cut the old panel at the points indicated.

8. NOTE: To avoid unnecessary MAG plug welding on

installation, spot welds must be drilled from underneath

where this is possible.

Drill out the spot welds.

9. Separate the joints and remove the old panel.

Installation

1. CAUTION: Care should be taken not to cut through

into adjacent panels.

Offer up, align and clamp the new panel into position,

overlapping the old panel remnant. Cut through the new

panel, partially cutting the old panel, at the points where

the MAG butt joint is to be made.

2. Remove the new panel.

3. Cut and remove the old panel remnants.

Prepare the old and new panel joint surfaces.

4. Offer up the new panel and clamp into position. Check alignment, if

correct, proceed to next step, if not rectify and recheck before

proceeding.

Page 2758 of 3039

5. Tack weld the butt joint.

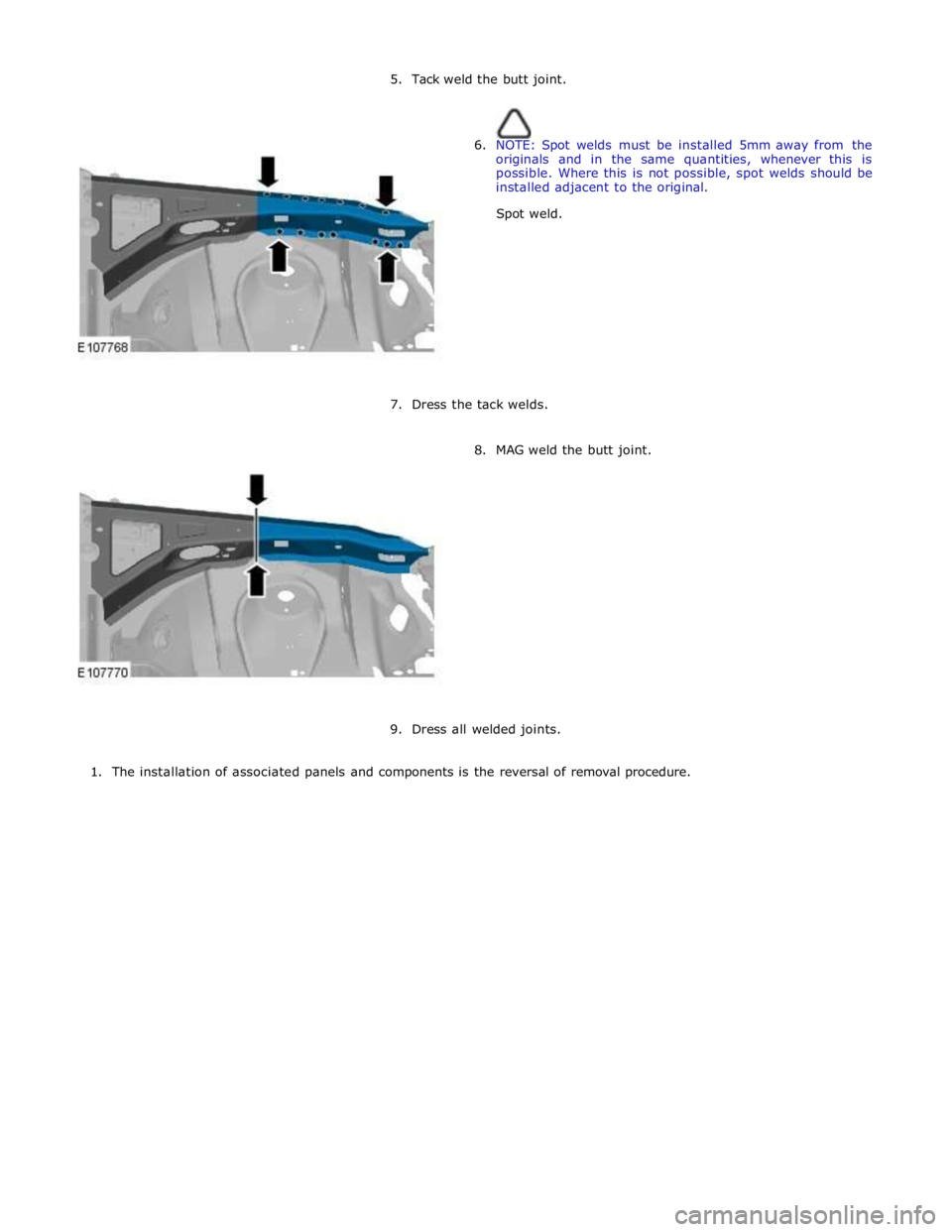

6. NOTE: Spot welds must be installed 5mm away from the

originals and in the same quantities, whenever this is

possible. Where this is not possible, spot welds should be

installed adjacent to the original.

Spot weld.

7. Dress the tack welds.

8. MAG weld the butt joint.

9. Dress all welded joints.

1. The installation of associated panels and components is the reversal of removal procedure.

Page 2759 of 3039

Front End Sheet Metal Repairs - Fender Apron Panel

Removal and Installation

Removal Published: 11-May-2011

1. NOTE: The fender apron panel is manufactured from mild

steel.

The fender apron panel is serviced as a separate weld-on

panel.

2. The fender apron panel is replaced in conjunction with:

Front bumper cover

Front fender

Fender apron panel closing panel

Hood

Hood hinge

Hood strut mounting bracket

Fender mounting plate

3. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Remove the hood.

For additional information, refer to: Hood (501-02 Front End Body Panels, Removal and Installation).

5. Remove the hood hinge.

6. Remove the fender apron panel closing panel.

For additional information, refer to: Fender Apron Panel Closing Panel (501-27 Front End Sheet Metal Repairs, Removal and Installation).

7. Disconnect the generator electrical connectors.

8. Remove the windshield wiper motor and linkage.

For additional information, refer to: Windshield Wiper Motor (501-16 Wipers and Washers, Removal and Installation).

9. Remove the ECM (engine control module).

For additional information, refer to: Engine Control Module (ECM)

(303-14A, Removal and Installation) /

Engine Control Module (ECM) (303-14B Electronic Engine Controls - V6 3.0L Petrol, Removal and Installation) /

Engine Control Module (ECM) (303-14C, Removal and Installation). www.JagDocs.com

Page 2760 of 3039

10.

11.

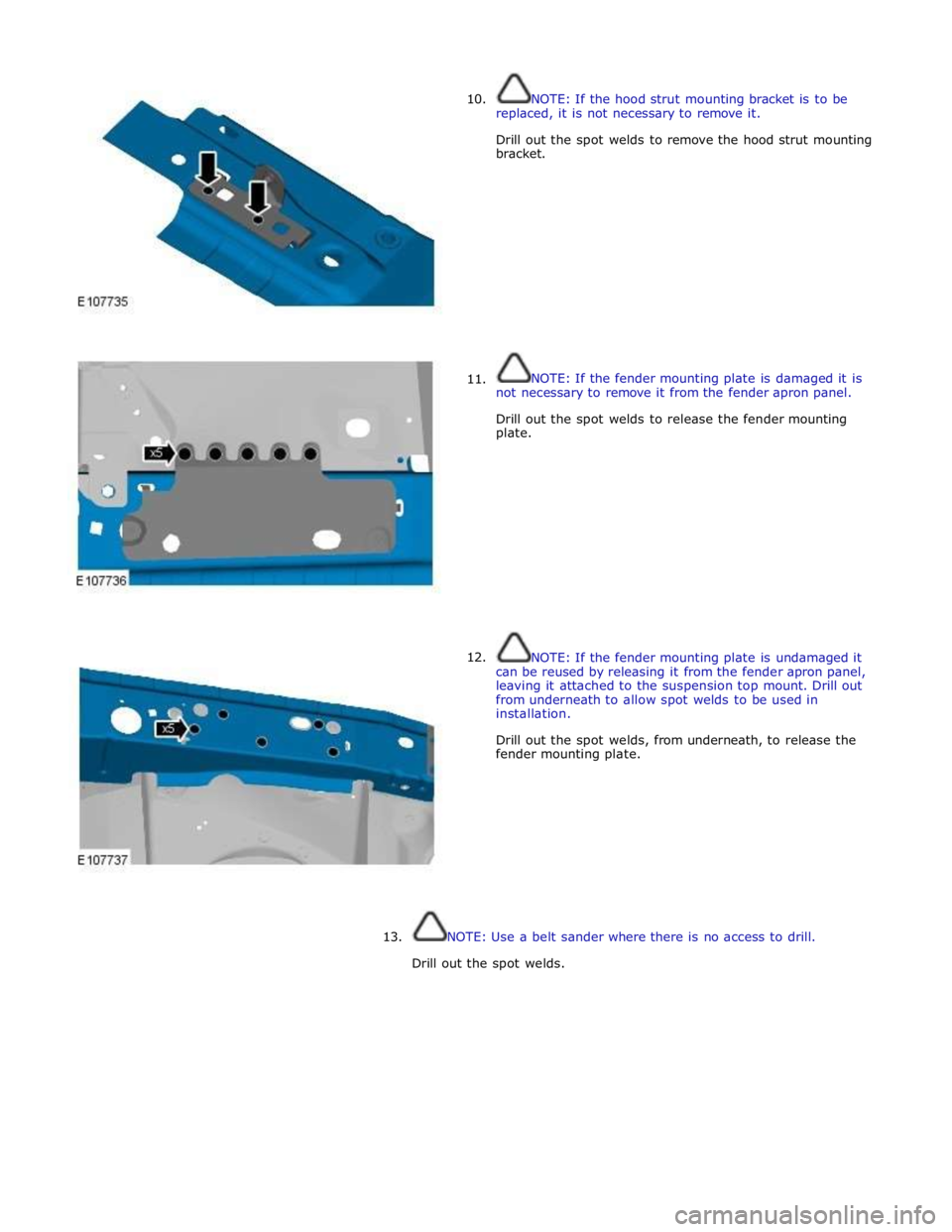

12. NOTE: If the hood strut mounting bracket is to be

replaced, it is not necessary to remove it.

Drill out the spot welds to remove the hood strut mounting

bracket.

NOTE: If the fender mounting plate is damaged it is

not necessary to remove it from the fender apron panel.

Drill out the spot welds to release the fender mounting

plate.

NOTE: If the fender mounting plate is undamaged it

can be reused by releasing it from the fender apron panel,

leaving it attached to the suspension top mount. Drill out

from underneath to allow spot welds to be used in

installation.

Drill out the spot welds, from underneath, to release the

fender mounting plate.

13.

NOTE: Use a belt sander where there is no access to drill.

Drill out the spot welds.