ESP JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 114 of 3039

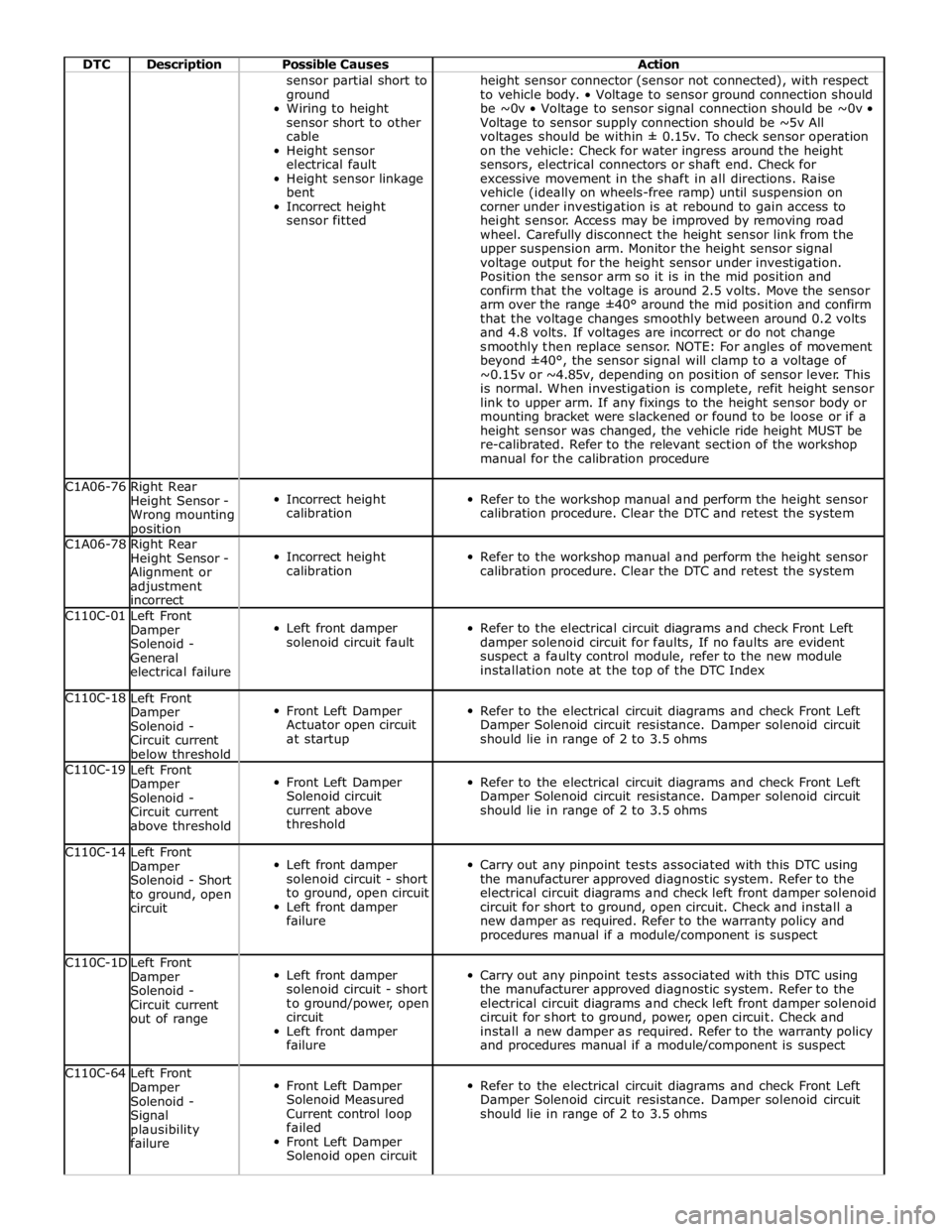

DTC Description Possible Causes Action sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A06-76

Right Rear

Height Sensor -

Wrong mounting position

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A06-78

Right Rear

Height Sensor -

Alignment or

adjustment

incorrect

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C110C-01

Left Front

Damper

Solenoid -

General

electrical failure

Left front damper

solenoid circuit fault

Refer to the electrical circuit diagrams and check Front Left

damper solenoid circuit for faults, If no faults are evident

suspect a faulty control module, refer to the new module

installation note at the top of the DTC Index C110C-18

Left Front

Damper

Solenoid -

Circuit current

below threshold

Front Left Damper

Actuator open circuit

at startup

Refer to the electrical circuit diagrams and check Front Left

Damper Solenoid circuit resistance. Damper solenoid circuit

should lie in range of 2 to 3.5 ohms C110C-19

Left Front

Damper

Solenoid -

Circuit current

above threshold

Front Left Damper

Solenoid circuit

current above

threshold

Refer to the electrical circuit diagrams and check Front Left

Damper Solenoid circuit resistance. Damper solenoid circuit

should lie in range of 2 to 3.5 ohms C110C-14

Left Front

Damper

Solenoid - Short

to ground, open

circuit

Left front damper

solenoid circuit - short

to ground, open circuit

Left front damper

failure

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check left front damper solenoid

circuit for short to ground, open circuit. Check and install a

new damper as required. Refer to the warranty policy and

procedures manual if a module/component is suspect C110C-1D

Left Front

Damper

Solenoid -

Circuit current

out of range

Left front damper

solenoid circuit - short

to ground/power, open

circuit

Left front damper

failure

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check left front damper solenoid

circuit for short to ground, power, open circuit. Check and

install a new damper as required. Refer to the warranty policy

and procedures manual if a module/component is suspect C110C-64

Left Front

Damper

Solenoid -

Signal

plausibility

failure

Front Left Damper

Solenoid Measured

Current control loop

failed

Front Left Damper

Solenoid open circuit

Refer to the electrical circuit diagrams and check Front Left

Damper Solenoid circuit resistance. Damper solenoid circuit

should lie in range of 2 to 3.5 ohms

Page 120 of 3039

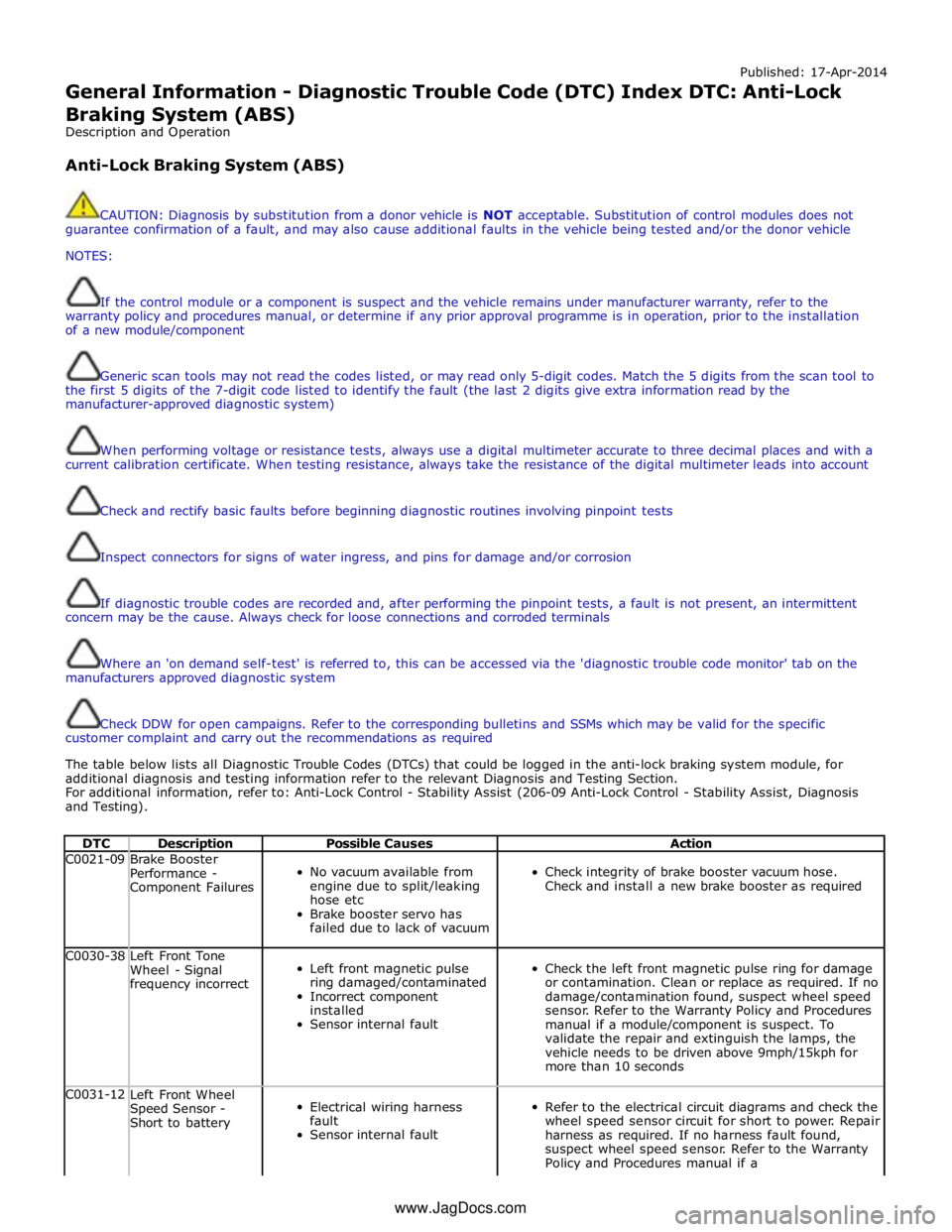

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Anti-Lock Braking System (ABS)

Description and Operation

Anti-Lock Braking System (ABS)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the anti-lock braking system module, for

additional diagnosis and testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Anti-Lock Control - Stability Assist (206-09 Anti-Lock Control - Stability Assist, Diagnosis

and Testing).

DTC Description Possible Causes Action C0021-09

Brake Booster

Performance -

Component Failures

No vacuum available from

engine due to split/leaking

hose etc

Brake booster servo has

failed due to lack of vacuum

Check integrity of brake booster vacuum hose.

Check and install a new brake booster as required C0030-38

Left Front Tone

Wheel - Signal

frequency incorrect

Left front magnetic pulse

ring damaged/contaminated

Incorrect component

installed

Sensor internal fault

Check the left front magnetic pulse ring for damage

or contamination. Clean or replace as required. If no

damage/contamination found, suspect wheel speed

sensor. Refer to the Warranty Policy and Procedures

manual if a module/component is suspect. To

validate the repair and extinguish the lamps, the

vehicle needs to be driven above 9mph/15kph for

more than 10 seconds C0031-12

Left Front Wheel

Speed Sensor -

Short to battery

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for short to power. Repair

harness as required. If no harness fault found,

suspect wheel speed sensor. Refer to the Warranty

Policy and Procedures manual if a www.JagDocs.com

Page 125 of 3039

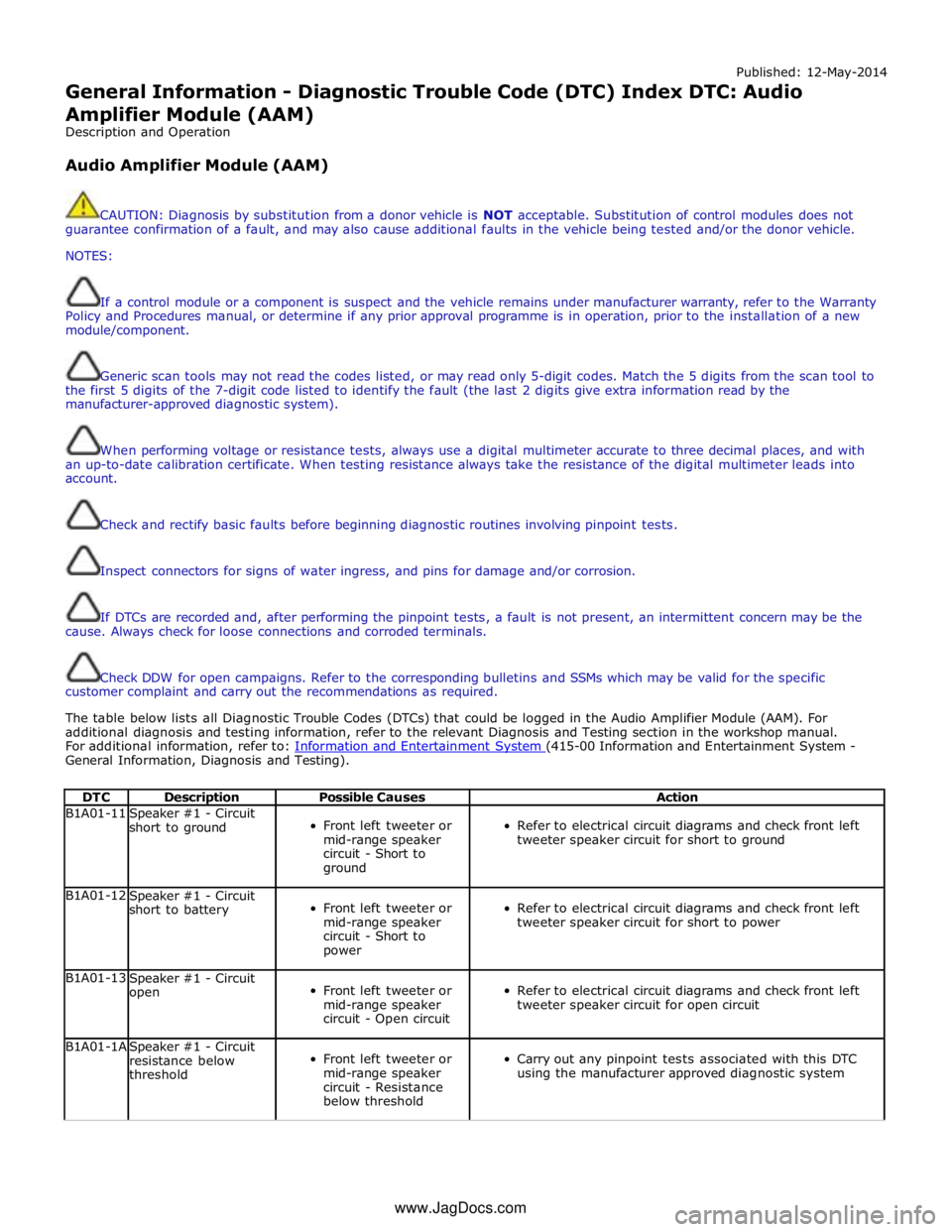

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Audio Amplifier Module (AAM)

Description and Operation

Audio Amplifier Module (AAM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Audio Amplifier Module (AAM). For

additional diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop manual.

For additional information, refer to: Information and Entertainment System (415-00 Information and Entertainment System - General Information, Diagnosis and Testing).

DTC Description Possible Causes Action B1A01-11

Speaker #1 - Circuit

short to ground

Front left tweeter or

mid-range speaker

circuit - Short to

ground

Refer to electrical circuit diagrams and check front left

tweeter speaker circuit for short to ground B1A01-12

Speaker #1 - Circuit

short to battery

Front left tweeter or

mid-range speaker

circuit - Short to

power

Refer to electrical circuit diagrams and check front left

tweeter speaker circuit for short to power B1A01-13

Speaker #1 - Circuit

open

Front left tweeter or

mid-range speaker

circuit - Open circuit

Refer to electrical circuit diagrams and check front left

tweeter speaker circuit for open circuit B1A01-1A

Speaker #1 - Circuit

resistance below

threshold

Front left tweeter or

mid-range speaker

circuit - Resistance

below threshold

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system www.JagDocs.com

Page 131 of 3039

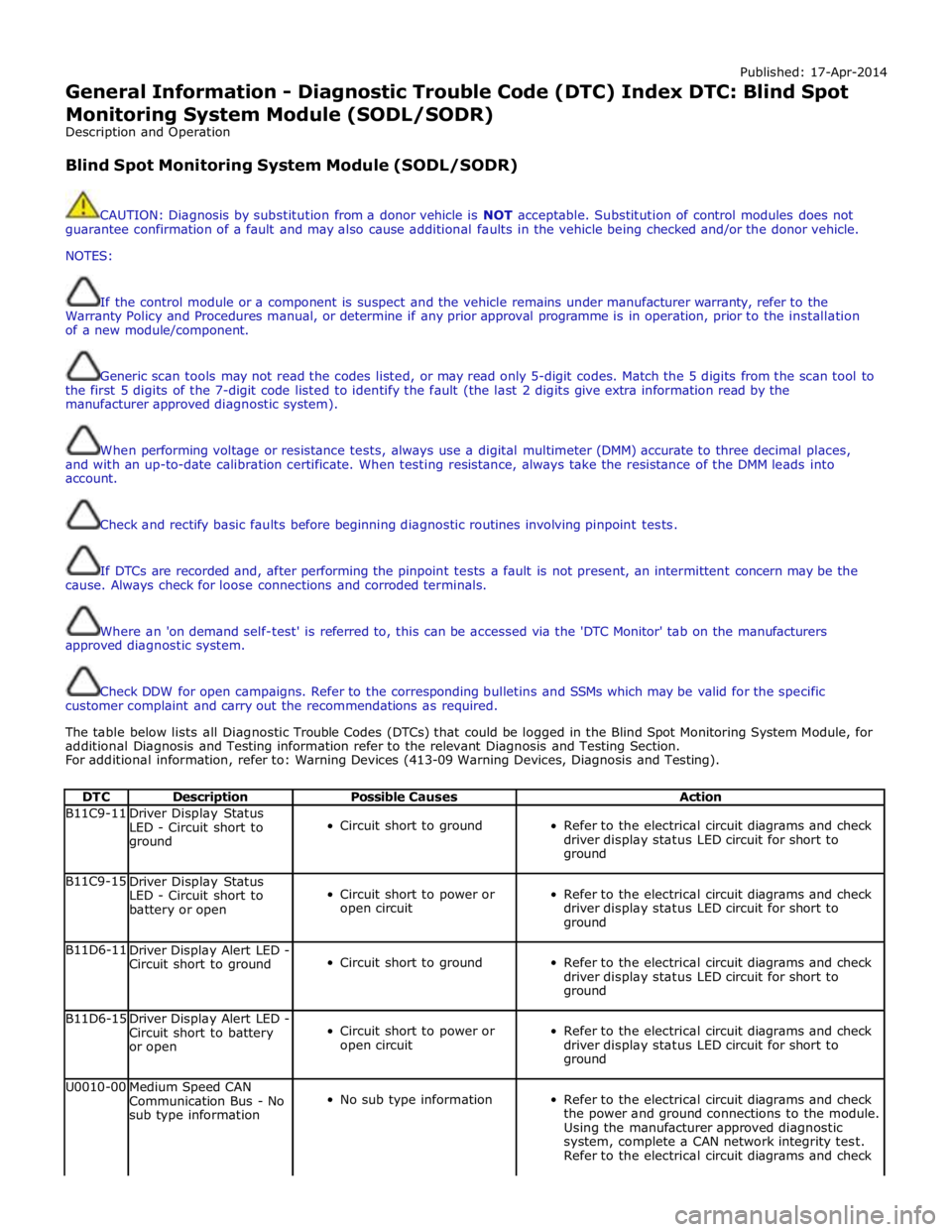

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Blind Spot Monitoring System Module (SODL/SODR)

Description and Operation

Blind Spot Monitoring System Module (SODL/SODR)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Where an 'on demand self-test' is referred to, this can be accessed via the 'DTC Monitor' tab on the manufacturers

approved diagnostic system.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Blind Spot Monitoring System Module, for

additional Diagnosis and Testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Warning Devices (413-09 Warning Devices, Diagnosis and Testing).

DTC Description Possible Causes Action B11C9-11

Driver Display Status

LED - Circuit short to

ground

Circuit short to ground

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground B11C9-15

Driver Display Status

LED - Circuit short to

battery or open

Circuit short to power or

open circuit

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground B11D6-11

Driver Display Alert LED -

Circuit short to ground

Circuit short to ground

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground B11D6-15

Driver Display Alert LED -

Circuit short to battery

or open

Circuit short to power or

open circuit

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground U0010-00

Medium Speed CAN

Communication Bus - No

sub type information

No sub type information

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

Page 134 of 3039

Published: 12-May-2014

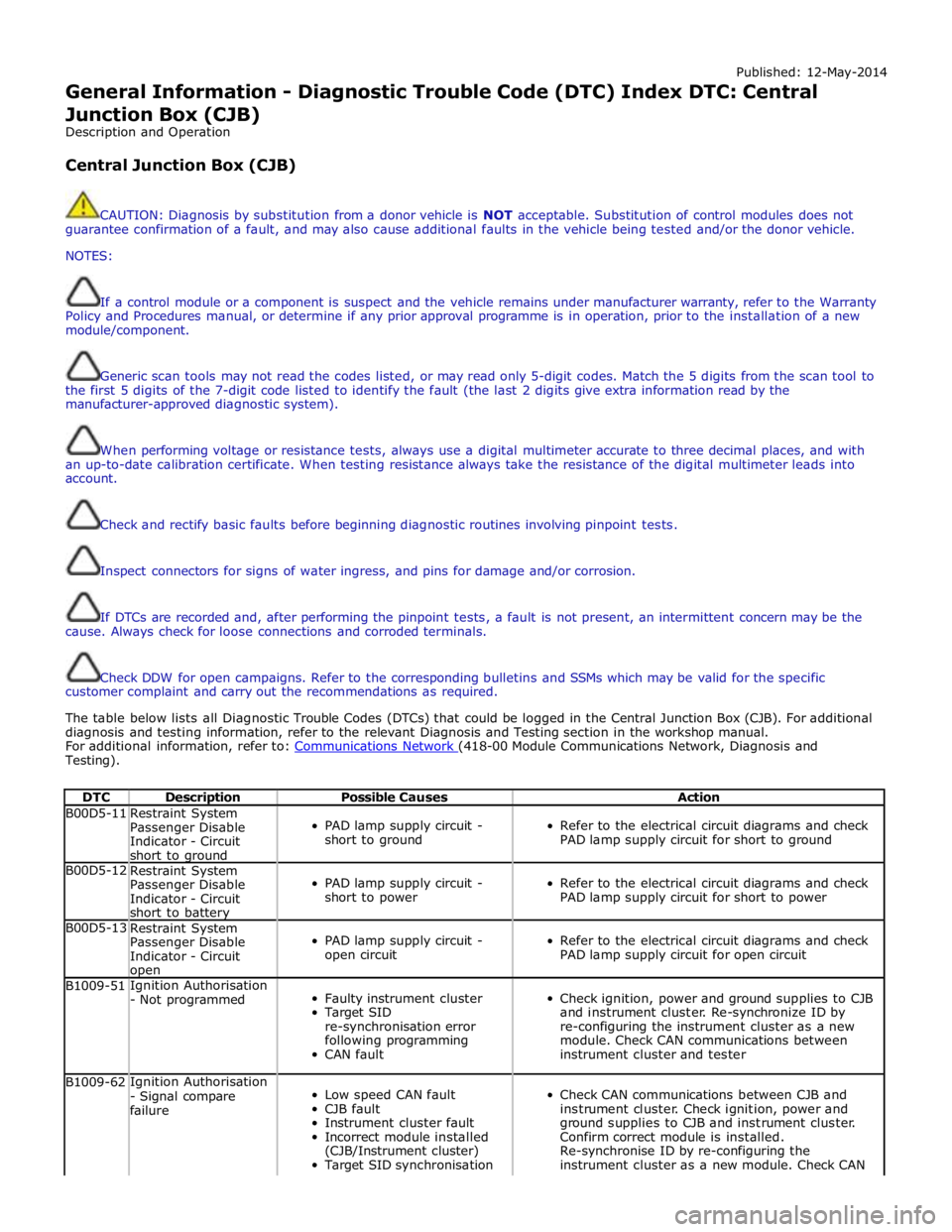

General Information - Diagnostic Trouble Code (DTC) Index DTC: Central Junction Box (CJB)

Description and Operation

Central Junction Box (CJB)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Central Junction Box (CJB). For additional

diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop manual.

For additional information, refer to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing).

DTC Description Possible Causes Action B00D5-11

Restraint System

Passenger Disable

Indicator - Circuit

short to ground

PAD lamp supply circuit -

short to ground

Refer to the electrical circuit diagrams and check

PAD lamp supply circuit for short to ground B00D5-12

Restraint System

Passenger Disable

Indicator - Circuit

short to battery

PAD lamp supply circuit -

short to power

Refer to the electrical circuit diagrams and check

PAD lamp supply circuit for short to power B00D5-13

Restraint System

Passenger Disable

Indicator - Circuit open

PAD lamp supply circuit -

open circuit

Refer to the electrical circuit diagrams and check

PAD lamp supply circuit for open circuit B1009-51 Ignition Authorisation

- Not programmed

Faulty instrument cluster

Target SID

re-synchronisation error

following programming

CAN fault

Check ignition, power and ground supplies to CJB

and instrument cluster. Re-synchronize ID by

re-configuring the instrument cluster as a new

module. Check CAN communications between

instrument cluster and tester B1009-62 Ignition Authorisation

- Signal compare

failure

Low speed CAN fault

CJB fault

Instrument cluster fault

Incorrect module installed

(CJB/Instrument cluster)

Target SID synchronisation

Check CAN communications between CJB and

instrument cluster. Check ignition, power and

ground supplies to CJB and instrument cluster.

Confirm correct module is installed.

Re-synchronise ID by re-configuring the

instrument cluster as a new module. Check CAN

Page 141 of 3039

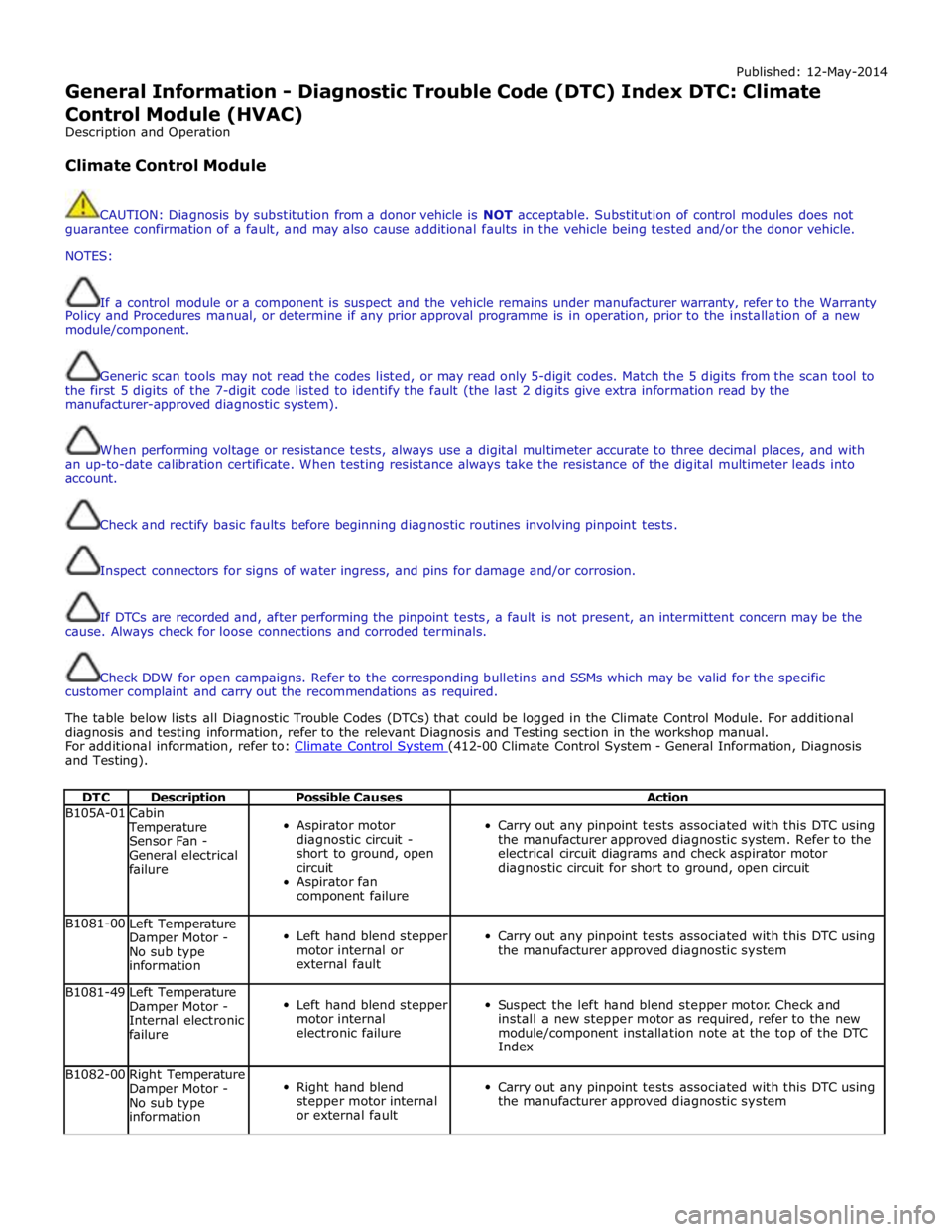

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Climate

Control Module (HVAC)

Description and Operation

Climate Control Module

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Climate Control Module. For additional

diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop manual.

For additional information, refer to: Climate Control System (412-00 Climate Control System - General Information, Diagnosis and Testing).

DTC Description Possible Causes Action B105A-01

Cabin Temperature

Sensor Fan -

General electrical

failure

Aspirator motor

diagnostic circuit -

short to ground, open

circuit

Aspirator fan

component failure

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check aspirator motor

diagnostic circuit for short to ground, open circuit B1081-00

Left Temperature

Damper Motor -

No sub type

information

Left hand blend stepper

motor internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B1081-49

Left Temperature

Damper Motor -

Internal electronic

failure

Left hand blend stepper

motor internal

electronic failure

Suspect the left hand blend stepper motor. Check and

install a new stepper motor as required, refer to the new

module/component installation note at the top of the DTC

Index B1082-00

Right Temperature

Damper Motor -

No sub type

information

Right hand blend

stepper motor internal

or external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system

Page 146 of 3039

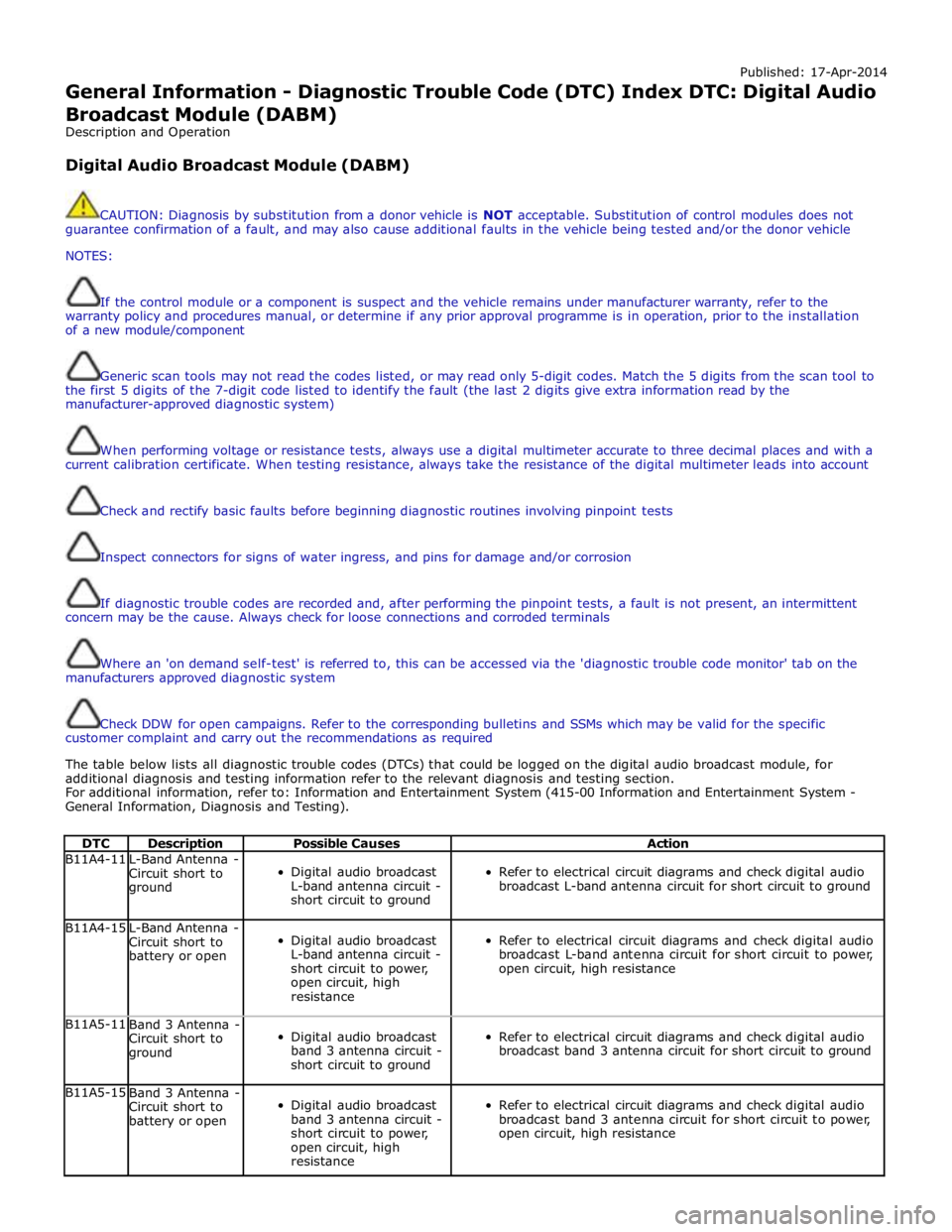

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Digital Audio Broadcast Module (DABM)

Description and Operation

Digital Audio Broadcast Module (DABM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

The table below lists all diagnostic trouble codes (DTCs) that could be logged on the digital audio broadcast module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Information and Entertainment System (415-00 Information and Entertainment System -

General Information, Diagnosis and Testing).

DTC Description Possible Causes Action B11A4-11

L-Band Antenna -

Circuit short to

ground

Digital audio broadcast

L-band antenna circuit -

short circuit to ground

Refer to electrical circuit diagrams and check digital audio

broadcast L-band antenna circuit for short circuit to ground B11A4-15

L-Band Antenna -

Circuit short to

battery or open

Digital audio broadcast

L-band antenna circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check digital audio

broadcast L-band antenna circuit for short circuit to power,

open circuit, high resistance B11A5-11

Band 3 Antenna -

Circuit short to

ground

Digital audio broadcast

band 3 antenna circuit -

short circuit to ground

Refer to electrical circuit diagrams and check digital audio

broadcast band 3 antenna circuit for short circuit to ground B11A5-15

Band 3 Antenna -

Circuit short to

battery or open

Digital audio broadcast

band 3 antenna circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check digital audio

broadcast band 3 antenna circuit for short circuit to power,

open circuit, high resistance

Page 147 of 3039

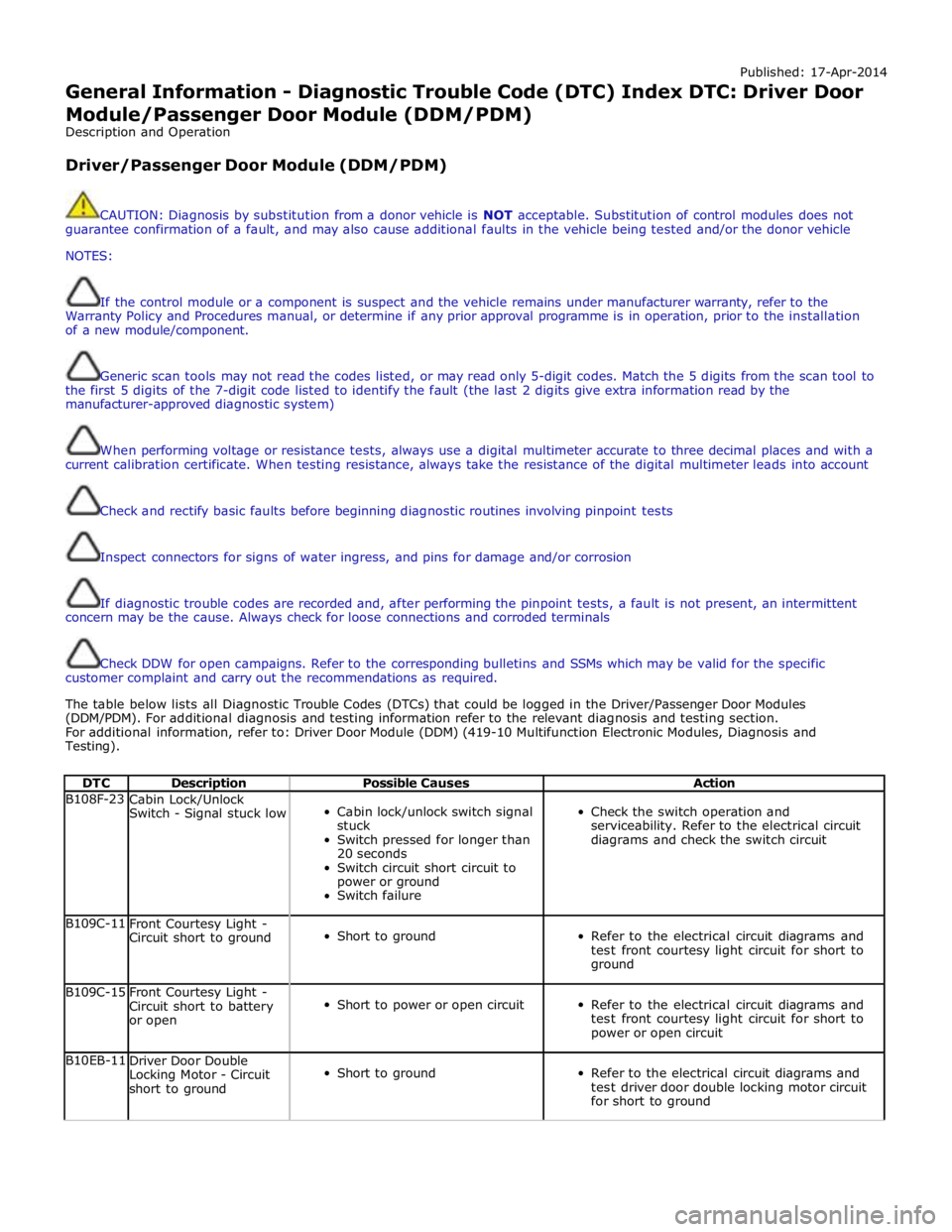

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Driver Door

Module/Passenger Door Module (DDM/PDM)

Description and Operation

Driver/Passenger Door Module (DDM/PDM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Driver/Passenger Door Modules

(DDM/PDM). For additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Driver Door Module (DDM) (419-10 Multifunction Electronic Modules, Diagnosis and

Testing).

DTC Description Possible Causes Action B108F-23

Cabin Lock/Unlock

Switch - Signal stuck low

Cabin lock/unlock switch signal

stuck

Switch pressed for longer than

20 seconds

Switch circuit short circuit to

power or ground

Switch failure

Check the switch operation and

serviceability. Refer to the electrical circuit

diagrams and check the switch circuit B109C-11

Front Courtesy Light -

Circuit short to ground

Short to ground

Refer to the electrical circuit diagrams and

test front courtesy light circuit for short to

ground B109C-15

Front Courtesy Light -

Circuit short to battery

or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test front courtesy light circuit for short to

power or open circuit B10EB-11

Driver Door Double

Locking Motor - Circuit

short to ground

Short to ground

Refer to the electrical circuit diagrams and

test driver door double locking motor circuit

for short to ground

Page 152 of 3039

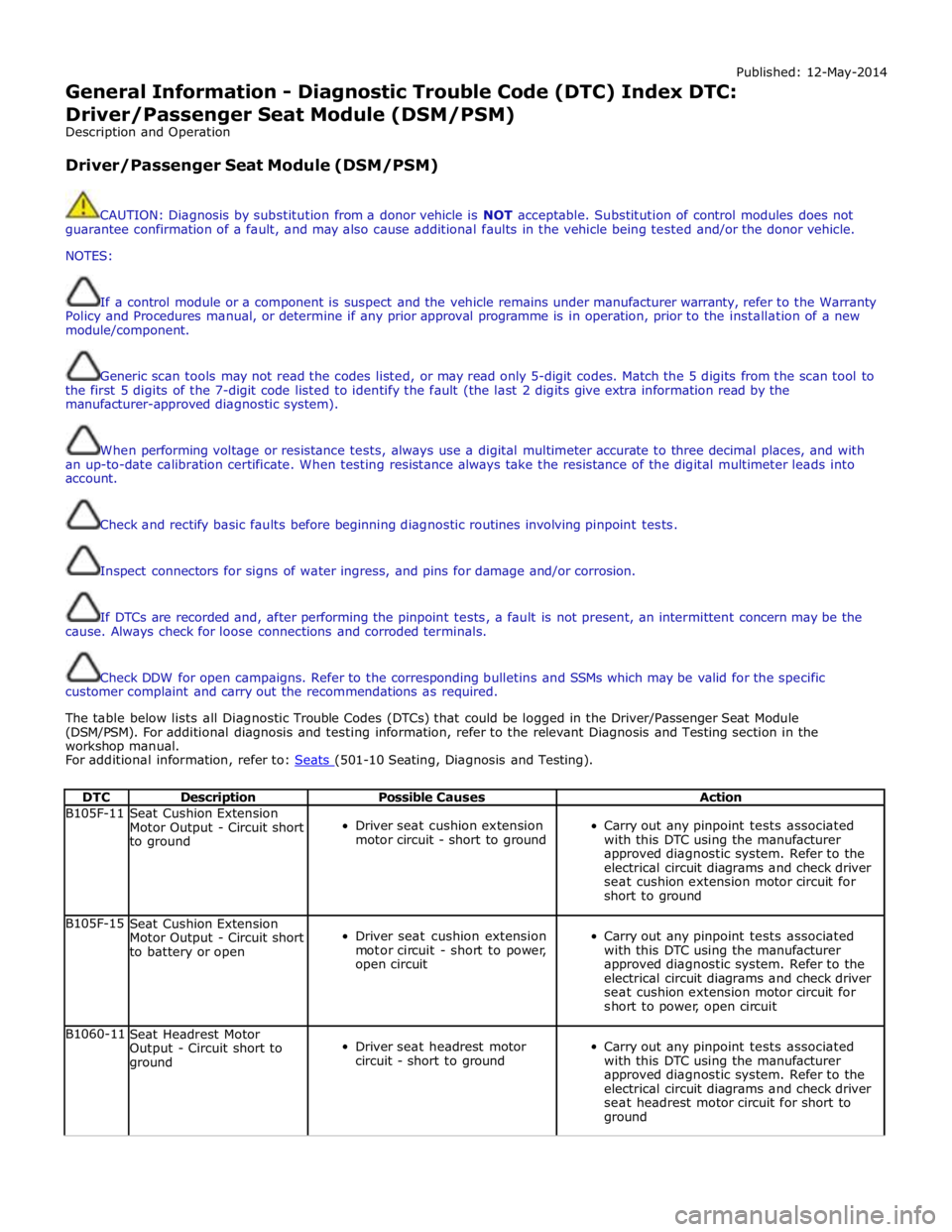

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC:

Driver/Passenger Seat Module (DSM/PSM)

Description and Operation

Driver/Passenger Seat Module (DSM/PSM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Driver/Passenger Seat Module

(DSM/PSM). For additional diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the

workshop manual.

For additional information, refer to: Seats (501-10 Seating, Diagnosis and Testing).

DTC Description Possible Causes Action B105F-11

Seat Cushion Extension

Motor Output - Circuit short

to ground

Driver seat cushion extension

motor circuit - short to ground

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check driver

seat cushion extension motor circuit for

short to ground B105F-15

Seat Cushion Extension

Motor Output - Circuit short

to battery or open

Driver seat cushion extension

motor circuit - short to power,

open circuit

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check driver

seat cushion extension motor circuit for

short to power, open circuit B1060-11

Seat Headrest Motor

Output - Circuit short to

ground

Driver seat headrest motor

circuit - short to ground

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check driver

seat headrest motor circuit for short to

ground

Page 158 of 3039

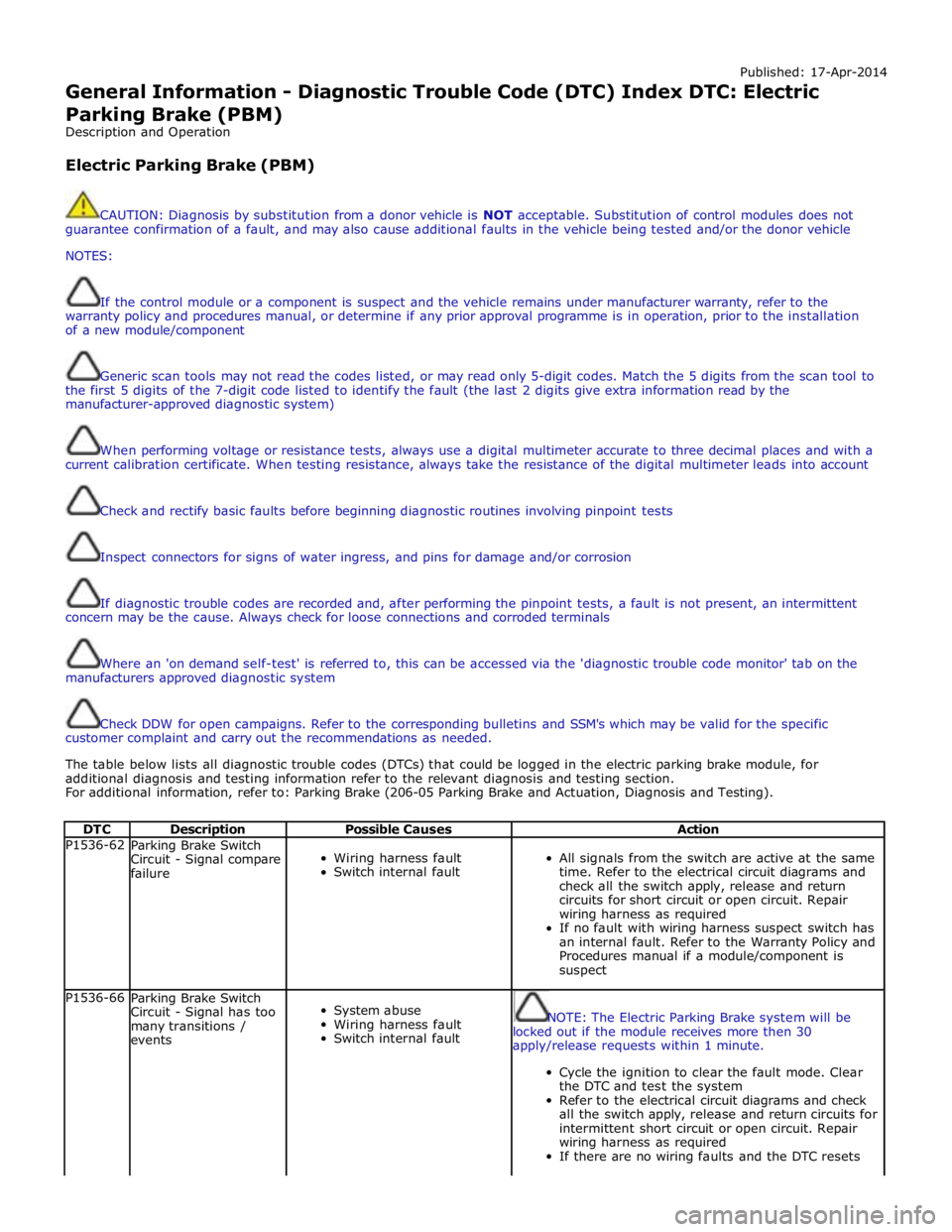

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Electric

Parking Brake (PBM)

Description and Operation

Electric Parking Brake (PBM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSM's which may be valid for the specific

customer complaint and carry out the recommendations as needed.

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the electric parking brake module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Parking Brake (206-05 Parking Brake and Actuation, Diagnosis and Testing).

DTC Description Possible Causes Action P1536-62

Parking Brake Switch

Circuit - Signal compare

failure

Wiring harness fault

Switch internal fault

All signals from the switch are active at the same

time. Refer to the electrical circuit diagrams and

check all the switch apply, release and return

circuits for short circuit or open circuit. Repair

wiring harness as required

If no fault with wiring harness suspect switch has

an internal fault. Refer to the Warranty Policy and

Procedures manual if a module/component is

suspect P1536-66

Parking Brake Switch

Circuit - Signal has too

many transitions /

events

System abuse

Wiring harness fault

Switch internal fault

NOTE: The Electric Parking Brake system will be

locked out if the module receives more then 30

apply/release requests within 1 minute.

Cycle the ignition to clear the fault mode. Clear

the DTC and test the system

Refer to the electrical circuit diagrams and check

all the switch apply, release and return circuits for

intermittent short circuit or open circuit. Repair

wiring harness as required

If there are no wiring faults and the DTC resets