Security JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1299 of 3039

Published: 11-May-2011

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Intake Air

Distribution and Filtering

Diagnosis and Testing

Principles of Operation

For a detailed description of the intake air distribution and filtering system and operation, refer to the relevant Description and

Operation section of the workshop manual. REFER to: (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol)

Intake Air Distribution and Filtering (Description and Operation), Intake Air Distribution and Filtering (Description and Operation), Intake Air Distribution and Filtering (Description and Operation).

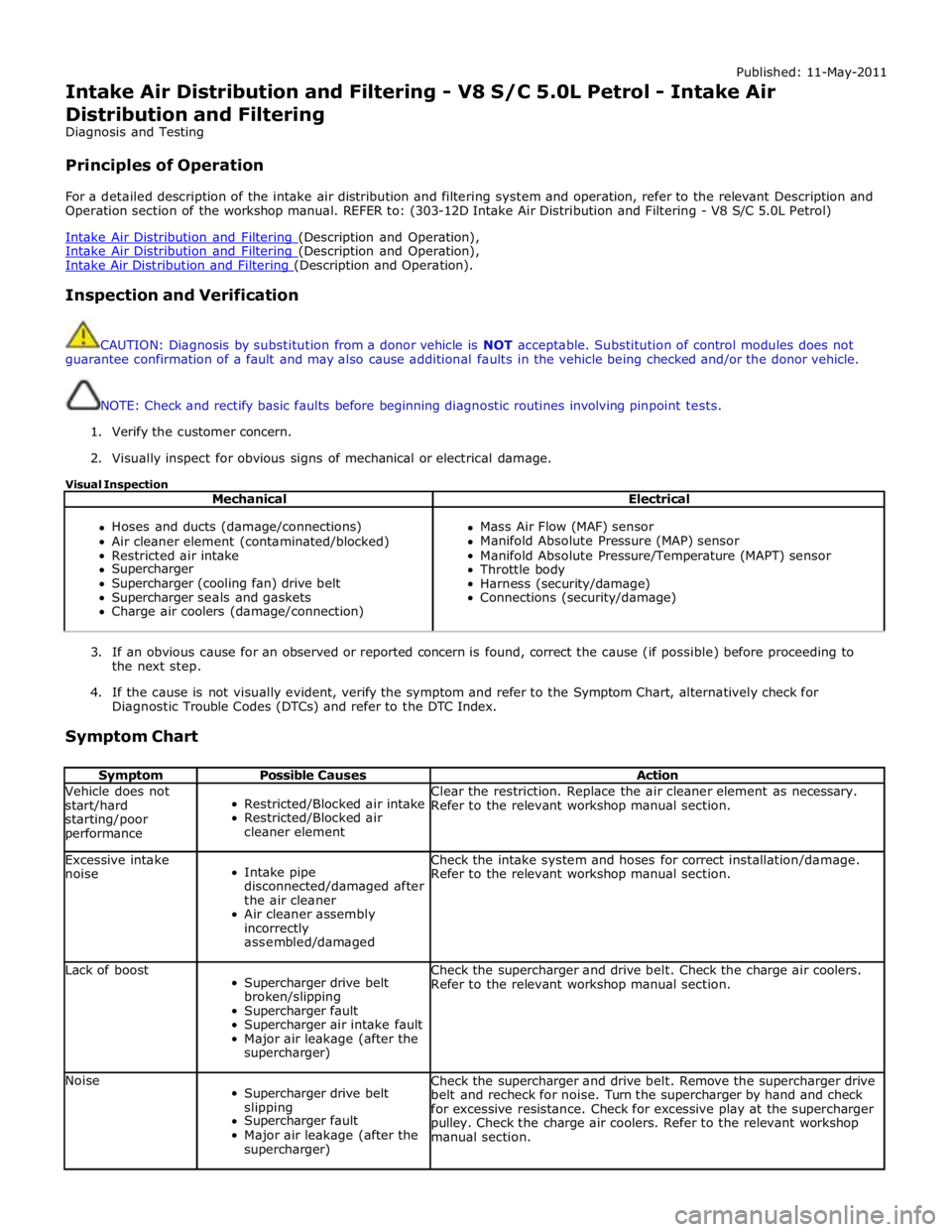

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Hoses and ducts (damage/connections)

Air cleaner element (contaminated/blocked)

Restricted air intake

Supercharger

Supercharger (cooling fan) drive belt

Supercharger seals and gaskets

Charge air coolers (damage/connection)

Mass Air Flow (MAF) sensor

Manifold Absolute Pressure (MAP) sensor

Manifold Absolute Pressure/Temperature (MAPT) sensor

Throttle body

Harness (security/damage)

Connections (security/damage)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action Vehicle does not

start/hard

starting/poor

performance

Restricted/Blocked air intake

Restricted/Blocked air

cleaner element Clear the restriction. Replace the air cleaner element as necessary.

Refer to the relevant workshop manual section. Excessive intake

noise

Intake pipe

disconnected/damaged after

the air cleaner

Air cleaner assembly

incorrectly

assembled/damaged Check the intake system and hoses for correct installation/damage.

Refer to the relevant workshop manual section. Lack of boost

Supercharger drive belt

broken/slipping

Supercharger fault

Supercharger air intake fault

Major air leakage (after the

supercharger) Check the supercharger and drive belt. Check the charge air coolers.

Refer to the relevant workshop manual section. Noise

Supercharger drive belt

slipping

Supercharger fault

Major air leakage (after the

supercharger) Check the supercharger and drive belt. Remove the supercharger drive

belt and recheck for noise. Turn the supercharger by hand and check

for excessive resistance. Check for excessive play at the supercharger

pulley. Check the charge air coolers. Refer to the relevant workshop

manual section.

Page 1369 of 3039

Published: 16-Sep-2013

Electronic Engine Controls - V8 S/C 5.0L Petrol - Electronic Engine Controls

Diagnosis and Testing

Principle of Operation

For a detailed description of electronic engine controls, refer to the relevant Description and Operation section of the workshop

manual. REFER to: (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol)

Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation).

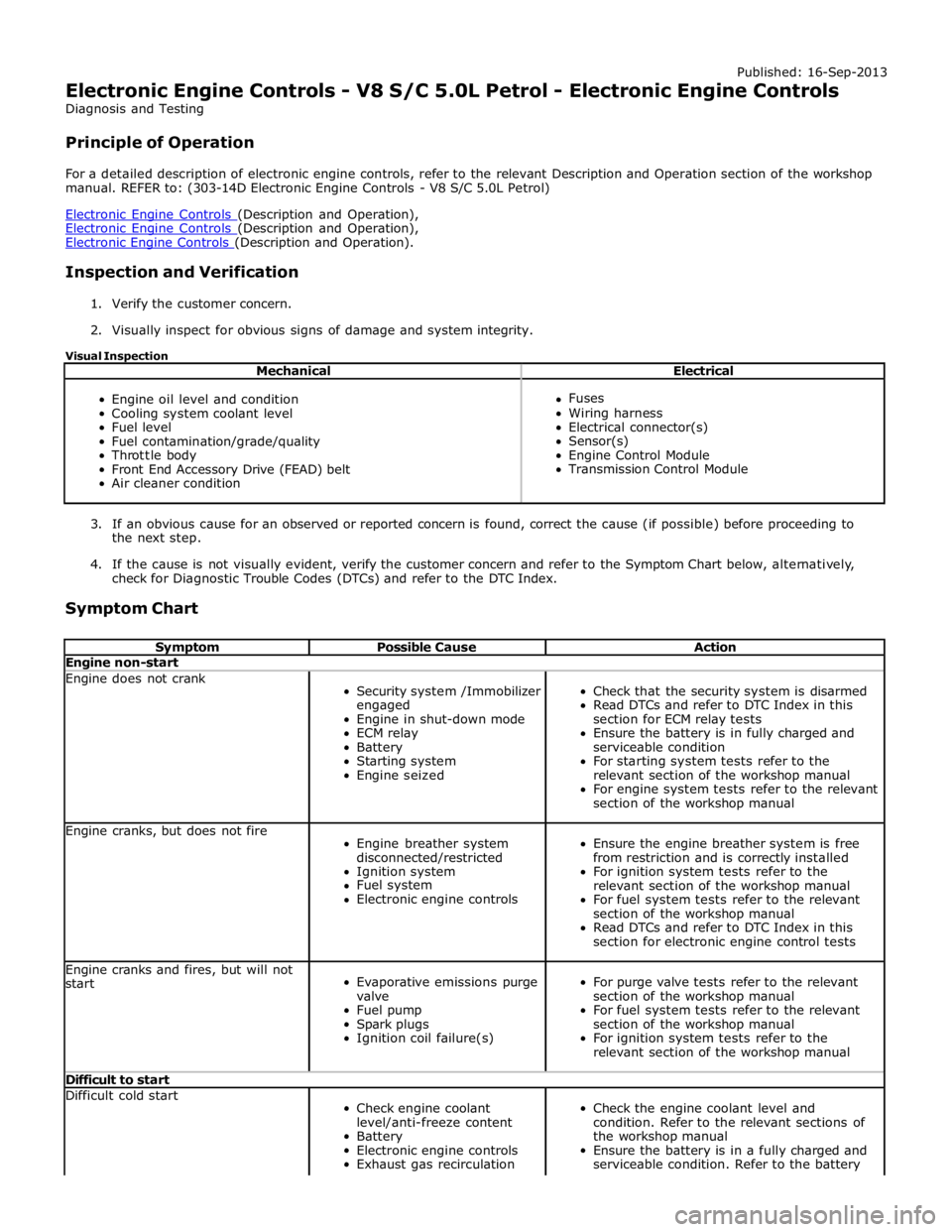

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Engine oil level and condition

Cooling system coolant level

Fuel level

Fuel contamination/grade/quality

Throttle body

Front End Accessory Drive (FEAD) belt

Air cleaner condition

Fuses

Wiring harness

Electrical connector(s)

Sensor(s)

Engine Control Module

Transmission Control Module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the customer concern and refer to the Symptom Chart below, alternatively,

check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Cause Action Engine non-start Engine does not crank

Security system /Immobilizer

engaged

Engine in shut-down mode

ECM relay

Battery

Starting system

Engine seized

Check that the security system is disarmed

Read DTCs and refer to DTC Index in this

section for ECM relay tests

Ensure the battery is in fully charged and

serviceable condition

For starting system tests refer to the

relevant section of the workshop manual

For engine system tests refer to the relevant

section of the workshop manual Engine cranks, but does not fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine controls

Ensure the engine breather system is free

from restriction and is correctly installed

For ignition system tests refer to the

relevant section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

Read DTCs and refer to DTC Index in this

section for electronic engine control tests Engine cranks and fires, but will not

start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

Ignition coil failure(s)

For purge valve tests refer to the relevant

section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

For ignition system tests refer to the

relevant section of the workshop manual Difficult to start Difficult cold start

Check engine coolant

level/anti-freeze content

Battery

Electronic engine controls

Exhaust gas recirculation

Check the engine coolant level and

condition. Refer to the relevant sections of

the workshop manual

Ensure the battery is in a fully charged and

serviceable condition. Refer to the battery

Page 1373 of 3039

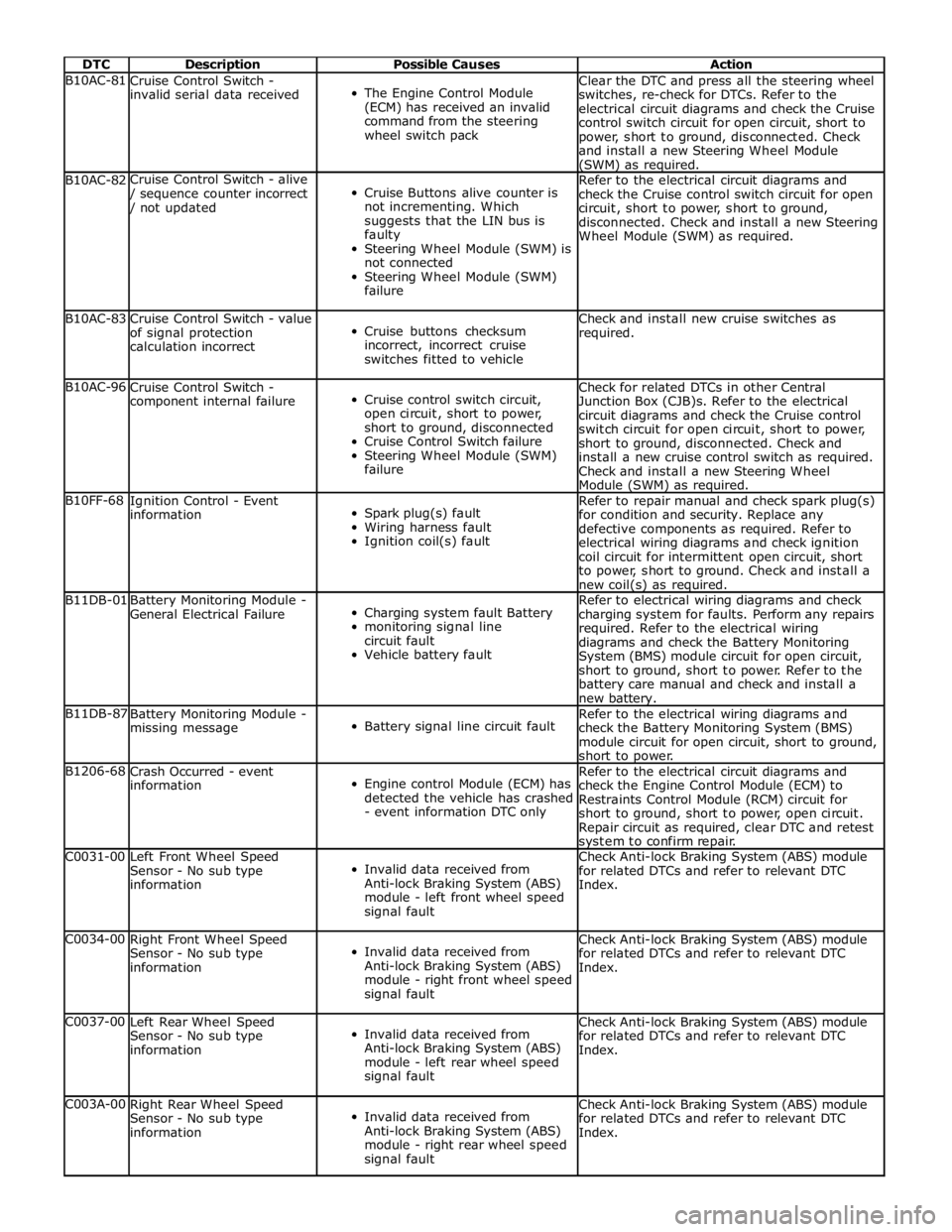

DTC Description Possible Causes Action B10AC-81

Cruise Control Switch -

invalid serial data received

The Engine Control Module

(ECM) has received an invalid

command from the steering

wheel switch pack Clear the DTC and press all the steering wheel

switches, re-check for DTCs. Refer to the

electrical circuit diagrams and check the Cruise

control switch circuit for open circuit, short to

power, short to ground, disconnected. Check

and install a new Steering Wheel Module (SWM) as required. B10AC-82 Cruise Control Switch - alive / sequence counter incorrect / not updated

Cruise Buttons alive counter is

not incrementing. Which

suggests that the LIN bus is

faulty

Steering Wheel Module (SWM) is

not connected

Steering Wheel Module (SWM)

failure Refer to the electrical circuit diagrams and

check the Cruise control switch circuit for open

circuit, short to power, short to ground,

disconnected. Check and install a new Steering

Wheel Module (SWM) as required. B10AC-83

Cruise Control Switch - value

of signal protection

calculation incorrect

Cruise buttons checksum

incorrect, incorrect cruise

switches fitted to vehicle Check and install new cruise switches as

required. B10AC-96

Cruise Control Switch -

component internal failure

Cruise control switch circuit,

open circuit, short to power,

short to ground, disconnected

Cruise Control Switch failure

Steering Wheel Module (SWM)

failure Check for related DTCs in other Central

Junction Box (CJB)s. Refer to the electrical

circuit diagrams and check the Cruise control

switch circuit for open circuit, short to power,

short to ground, disconnected. Check and

install a new cruise control switch as required.

Check and install a new Steering Wheel

Module (SWM) as required. B10FF-68

Ignition Control - Event

information

Spark plug(s) fault

Wiring harness fault

Ignition coil(s) fault Refer to repair manual and check spark plug(s)

for condition and security. Replace any

defective components as required. Refer to

electrical wiring diagrams and check ignition

coil circuit for intermittent open circuit, short

to power, short to ground. Check and install a

new coil(s) as required. B11DB-01

Battery Monitoring Module -

General Electrical Failure

Charging system fault Battery

monitoring signal line

circuit fault

Vehicle battery fault Refer to electrical wiring diagrams and check

charging system for faults. Perform any repairs

required. Refer to the electrical wiring

diagrams and check the Battery Monitoring

System (BMS) module circuit for open circuit,

short to ground, short to power. Refer to the

battery care manual and check and install a

new battery. B11DB-87

Battery Monitoring Module -

missing message

Battery signal line circuit fault Refer to the electrical wiring diagrams and

check the Battery Monitoring System (BMS)

module circuit for open circuit, short to ground,

short to power. B1206-68

Crash Occurred - event

information

Engine control Module (ECM) has

detected the vehicle has crashed

- event information DTC only Refer to the electrical circuit diagrams and

check the Engine Control Module (ECM) to

Restraints Control Module (RCM) circuit for

short to ground, short to power, open circuit.

Repair circuit as required, clear DTC and retest

system to confirm repair. C0031-00

Left Front Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - left front wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C0034-00

Right Front Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - right front wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C0037-00

Left Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - left rear wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C003A-00

Right Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - right rear wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index.

Page 1871 of 3039

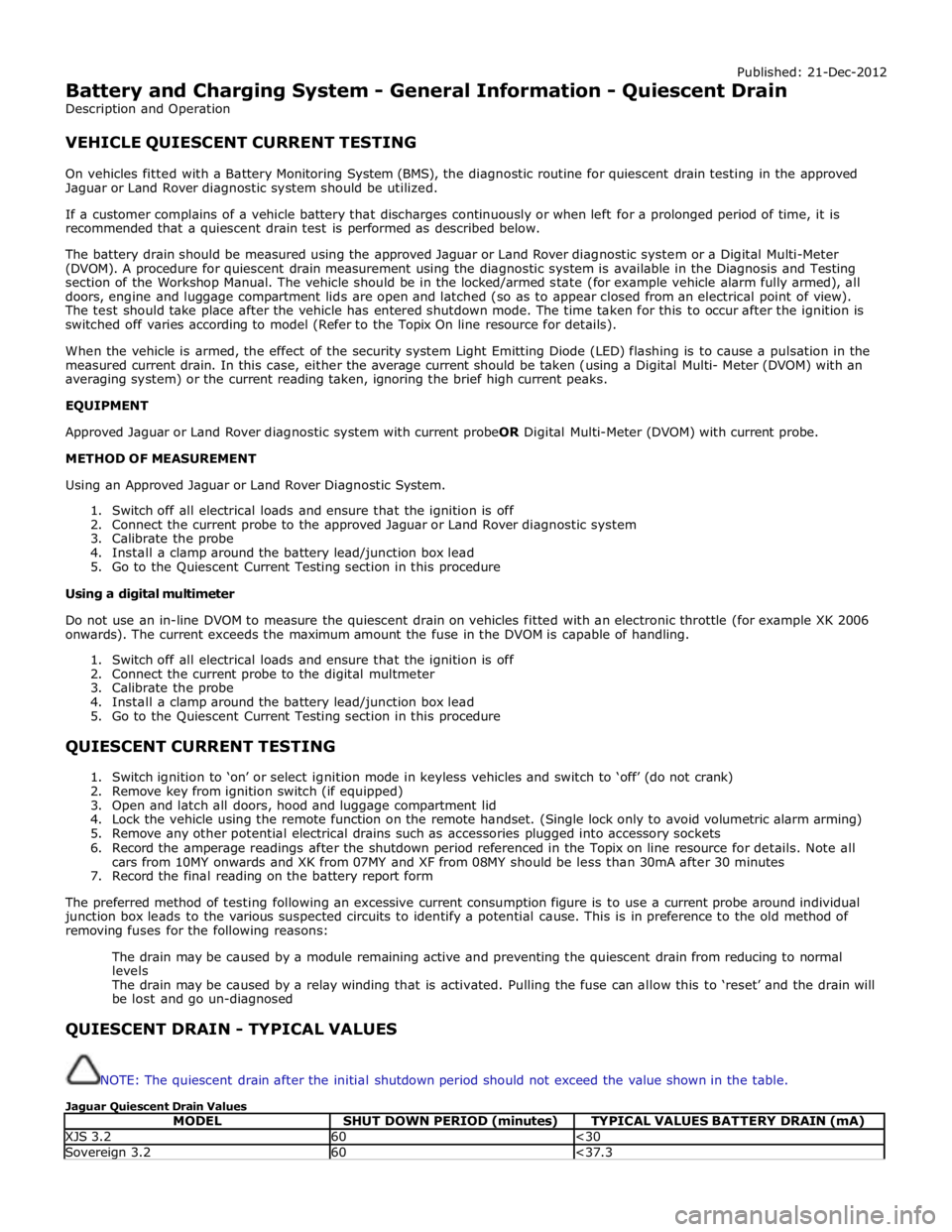

Published: 21-Dec-2012

Battery and Charging System - General Information - Quiescent Drain

Description and Operation

VEHICLE QUIESCENT CURRENT TESTING

On vehicles fitted with a Battery Monitoring System (BMS), the diagnostic routine for quiescent drain testing in the approved

Jaguar or Land Rover diagnostic system should be utilized.

If a customer complains of a vehicle battery that discharges continuously or when left for a prolonged period of time, it is

recommended that a quiescent drain test is performed as described below.

The battery drain should be measured using the approved Jaguar or Land Rover diagnostic system or a Digital Multi-Meter

(DVOM). A procedure for quiescent drain measurement using the diagnostic system is available in the Diagnosis and Testing

section of the Workshop Manual. The vehicle should be in the locked/armed state (for example vehicle alarm fully armed), all

doors, engine and luggage compartment lids are open and latched (so as to appear closed from an electrical point of view).

The test should take place after the vehicle has entered shutdown mode. The time taken for this to occur after the ignition is

switched off varies according to model (Refer to the Topix On line resource for details).

When the vehicle is armed, the effect of the security system Light Emitting Diode (LED) flashing is to cause a pulsation in the

measured current drain. In this case, either the average current should be taken (using a Digital Multi- Meter (DVOM) with an

averaging system) or the current reading taken, ignoring the brief high current peaks.

EQUIPMENT

Approved Jaguar or Land Rover diagnostic system with current probeOR Digital Multi-Meter (DVOM) with current probe.

METHOD OF MEASUREMENT

Using an Approved Jaguar or Land Rover Diagnostic System.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the approved Jaguar or Land Rover diagnostic system

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

Using a digital multimeter

Do not use an in-line DVOM to measure the quiescent drain on vehicles fitted with an electronic throttle (for example XK 2006

onwards). The current exceeds the maximum amount the fuse in the DVOM is capable of handling.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the digital multmeter

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

QUIESCENT CURRENT TESTING

1. Switch ignition to ‘on’ or select ignition mode in keyless vehicles and switch to ‘off’ (do not crank)

2. Remove key from ignition switch (if equipped)

3. Open and latch all doors, hood and luggage compartment lid

4. Lock the vehicle using the remote function on the remote handset. (Single lock only to avoid volumetric alarm arming)

5. Remove any other potential electrical drains such as accessories plugged into accessory sockets

6. Record the amperage readings after the shutdown period referenced in the Topix on line resource for details. Note all

cars from 10MY onwards and XK from 07MY and XF from 08MY should be less than 30mA after 30 minutes

7. Record the final reading on the battery report form

The preferred method of testing following an excessive current consumption figure is to use a current probe around individual

junction box leads to the various suspected circuits to identify a potential cause. This is in preference to the old method of

removing fuses for the following reasons:

The drain may be caused by a module remaining active and preventing the quiescent drain from reducing to normal

levels

The drain may be caused by a relay winding that is activated. Pulling the fuse can allow this to ‘reset’ and the drain will

be lost and go un-diagnosed

QUIESCENT DRAIN - TYPICAL VALUES

NOTE: The quiescent drain after the initial shutdown period should not exceed the value shown in the table.

Jaguar Quiescent Drain Values

MODEL SHUT DOWN PERIOD (minutes) TYPICAL VALUES BATTERY DRAIN (mA) XJS 3.2 60 <30 Sovereign 3.2 60 <37.3

Page 1889 of 3039

Battery, Mounting and Cables - Battery

Diagnosis and Testing

Principles of Operation Published: 10-Mar-2014

For a detailed description of the battery system and operation, refer to the relevant Description and Operation section of the

workshop manual. REFER to: Battery and Cables (414-01 Battery, Mounting and Cables, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Generator

Drive belt

Drive belt tensioner

Generator pulley

Check the security of the generator fixings

Generator

Battery

Battery connections

Starter motor

Harnesses and connectors

Fuses

Charge warning lamp function

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Symptom Chart

Symptom Possible Causes Action

Battery power to vehicle

interrupted

High resistance between battery terminals and

clamps

GO to Pinpoint Test

A. Midtronics EXP-1080 User Guide

Carry out the following: -

Surface Voltage Removal Process

A vehicle which has had its battery charged or been driven in a 24 hour period before the test, must have its surface charge

removed

Page 1932 of 3039

Published: 11-Jul-2014

Information and Entertainment System - General Information - Information

and Entertainment System

Diagnosis and Testing

Principle of Operation

For a detailed description of the Information and Entertainment System, refer to the relevant Description and Operation

sections in the workshop manual. REFER to: (415-01A Information and Entertainment System)

Audio System (Description and Operation), Audio System (Description and Operation), Audio System (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Information and entertainment module

Audio amplifier module

Integrated audio module

Portable audio interface module

Digital audio broadcast module

Integrated control panel

Touch screen display

Satellite radio module

Television module

Navigation system module

Telephone module

Compact disc player jammed, not loading

Scratched/dirty compact discs

Speakers

Fuses

Loose or corroded connector(s)

Information and entertainment module

Audio amplifier module

Integrated audio module

Portable audio interface module

Digital audio broadcast module

Integrated control panel

Touch screen display

Satellite radio module

Television module

Navigation system module

Telephone module

Speakers

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the relevant DTC Index.

Symptom Chart

Symptom Display Possible Causes Action Poor audio quality (all

sources) Display normal

MOST harness

connections loose

MOST harness

connections

contaminated

MOST harness

misrouted

- Too many

bends

- Bend radius

less than

25mm

Check MOST harness connectors for

security

Check MOST harness connectors for

contamination

Check the routing of the MOST harness Information and

entertainment system

inoperative Touch screen blank or

displaying a flashing

logo

MOST network fault

REFER to: Communications Network (418-00 Module Communications Network,

Diagnosis and Testing).

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00. REFER to:

(100-00 General Information)

Page 1949 of 3039

systems.

A typical example of information transfer is vehicle speed information from the ABS (anti-lock brake system) module used to

control the automatic volume control function. The vehicle speed information from the ABS module is sent on the high speed

CAN network and collected by the instrument panel gateway. The signal is passed to the medium speed CAN network and onto the ICM gateway. The ICM calculates the volume adjustment required. The corrected audio volume level signal is sent on the

MOST network to the IAM or Power amplifier (dependant on vehicle equipment level) for output to the speaker system.

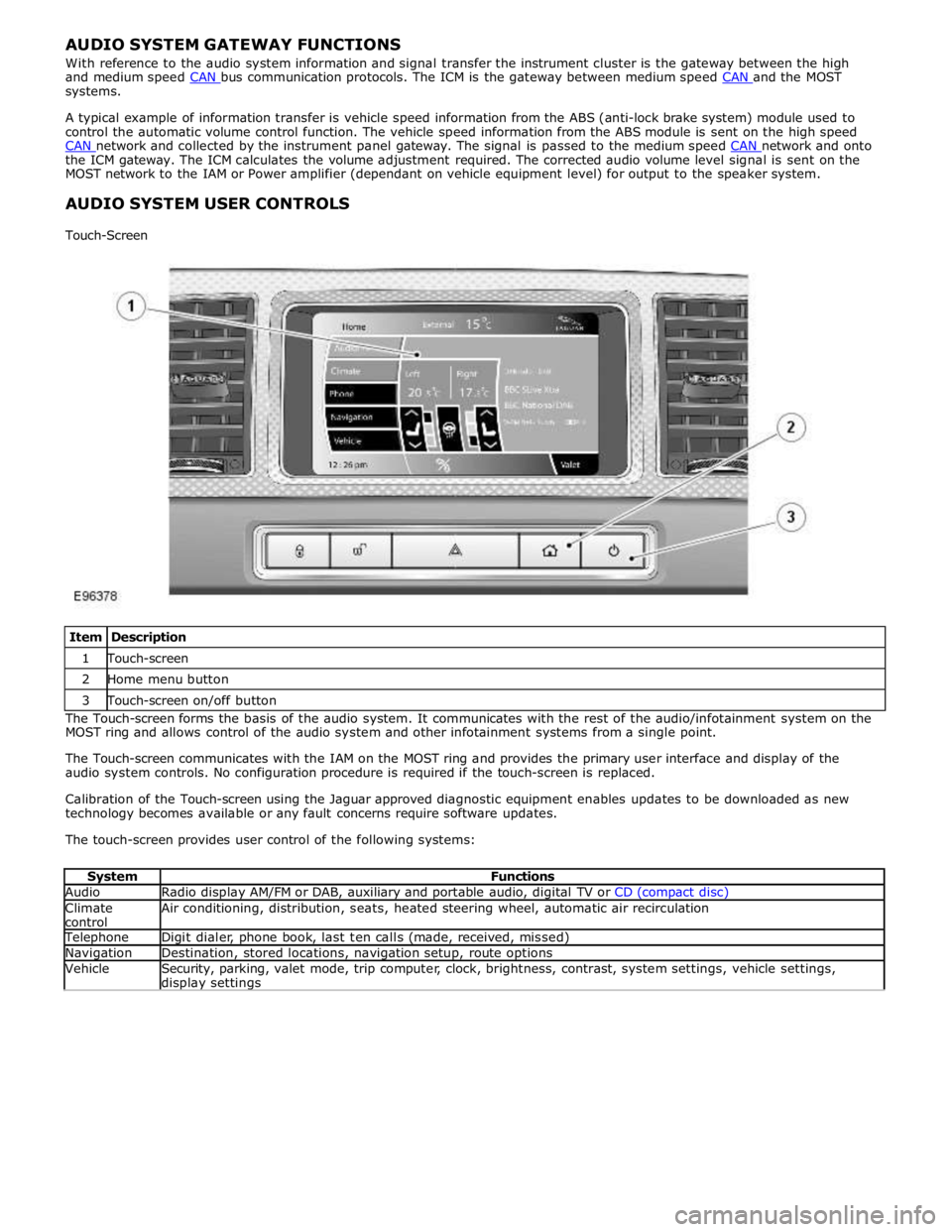

AUDIO SYSTEM USER CONTROLS

Touch-Screen

Item Description 1 Touch-screen 2 Home menu button 3 Touch-screen on/off button The Touch-screen forms the basis of the audio system. It communicates with the rest of the audio/infotainment system on the

MOST ring and allows control of the audio system and other infotainment systems from a single point.

The Touch-screen communicates with the IAM on the MOST ring and provides the primary user interface and display of the

audio system controls. No configuration procedure is required if the touch-screen is replaced.

Calibration of the Touch-screen using the Jaguar approved diagnostic equipment enables updates to be downloaded as new

technology becomes available or any fault concerns require software updates.

The touch-screen provides user control of the following systems:

System Functions Audio Radio display AM/FM or DAB, auxiliary and portable audio, digital TV or CD (compact disc) Climate

control Air conditioning, distribution, seats, heated steering wheel, automatic air recirculation Telephone Digit dialer, phone book, last ten calls (made, received, missed) Navigation Destination, stored locations, navigation setup, route options Vehicle

Security, parking, valet mode, trip computer, clock, brightness, contrast, system settings, vehicle settings, display settings

Page 1981 of 3039

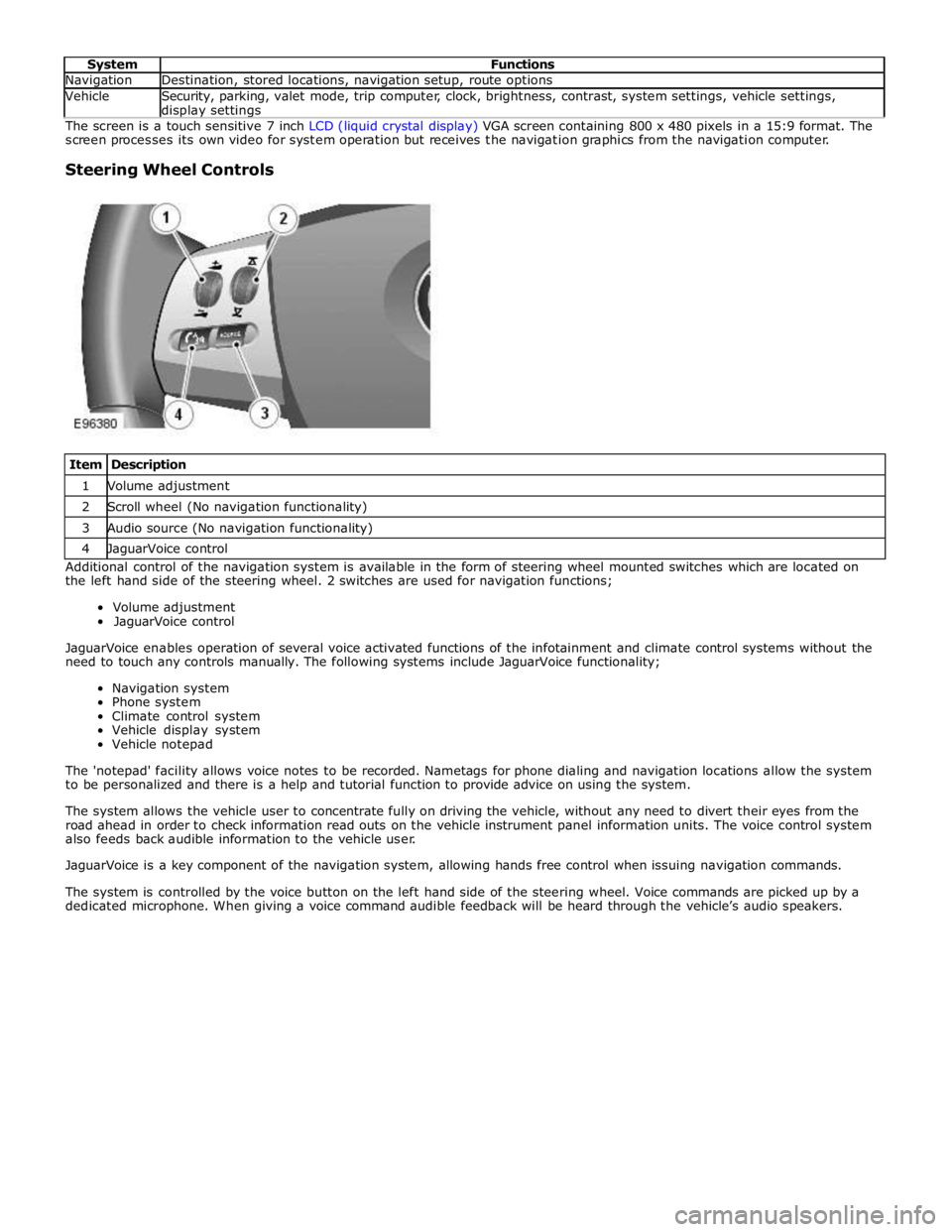

Navigation Destination, stored locations, navigation setup, route options Vehicle

Security, parking, valet mode, trip computer, clock, brightness, contrast, system settings, vehicle settings, display settings The screen is a touch sensitive 7 inch LCD (liquid crystal display) VGA screen containing 800 x 480 pixels in a 15:9 format. The

screen processes its own video for system operation but receives the navigation graphics from the navigation computer.

Steering Wheel Controls

Item Description 1 Volume adjustment 2 Scroll wheel (No navigation functionality) 3 Audio source (No navigation functionality) 4 JaguarVoice control Additional control of the navigation system is available in the form of steering wheel mounted switches which are located on

the left hand side of the steering wheel. 2 switches are used for navigation functions;

Volume adjustment

JaguarVoice control

JaguarVoice enables operation of several voice activated functions of the infotainment and climate control systems without the

need to touch any controls manually. The following systems include JaguarVoice functionality;

Navigation system

Phone system

Climate control system

Vehicle display system

Vehicle notepad

The 'notepad' facility allows voice notes to be recorded. Nametags for phone dialing and navigation locations allow the system

to be personalized and there is a help and tutorial function to provide advice on using the system.

The system allows the vehicle user to concentrate fully on driving the vehicle, without any need to divert their eyes from the

road ahead in order to check information read outs on the vehicle instrument panel information units. The voice control system

also feeds back audible information to the vehicle user.

JaguarVoice is a key component of the navigation system, allowing hands free control when issuing navigation commands.

The system is controlled by the voice button on the left hand side of the steering wheel. Voice commands are picked up by a

dedicated microphone. When giving a voice command audible feedback will be heard through the vehicle’s audio speakers.

Page 2060 of 3039

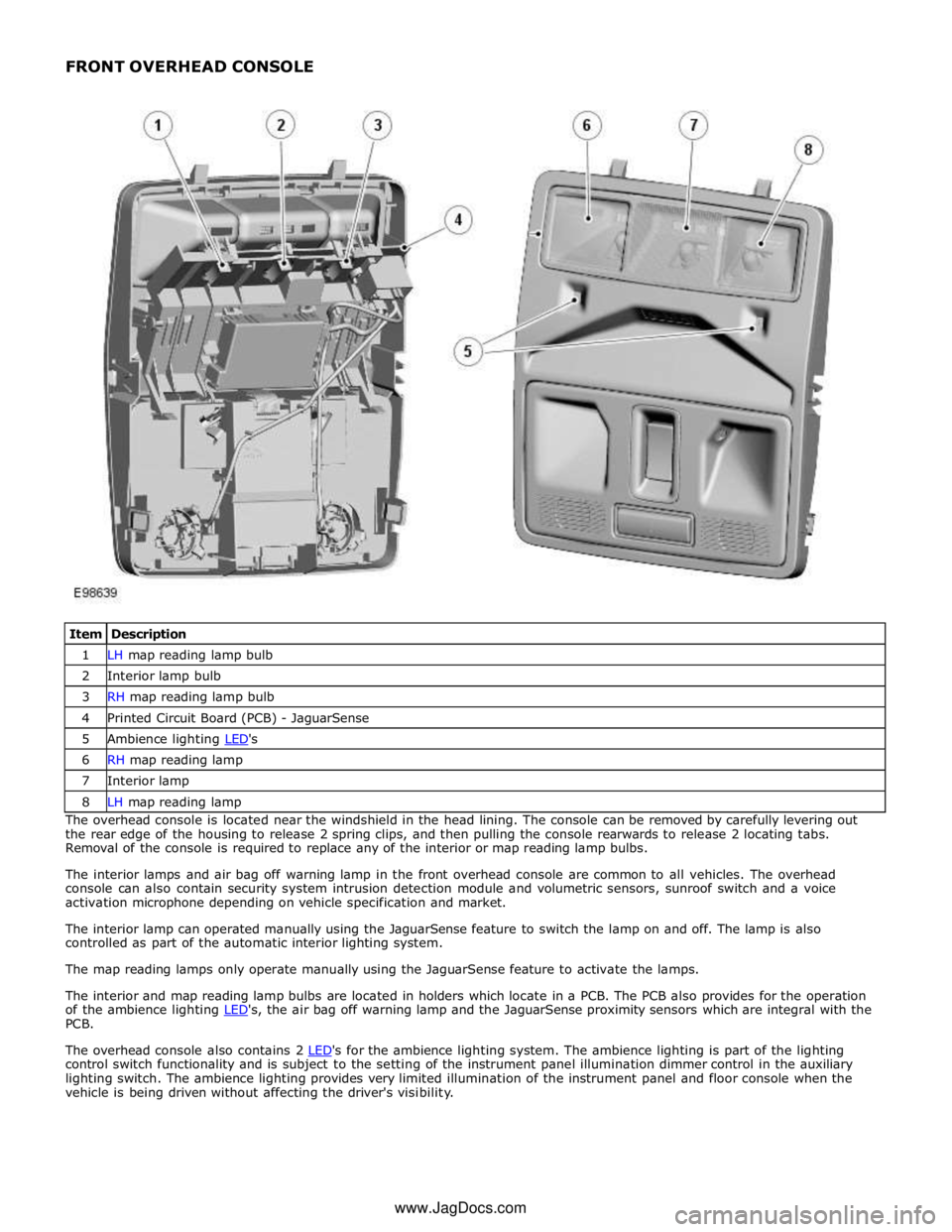

1 LH map reading lamp bulb 2 Interior lamp bulb 3 RH map reading lamp bulb 4 Printed Circuit Board (PCB) - JaguarSense 5 Ambience lighting LED's 6 RH map reading lamp 7 Interior lamp 8 LH map reading lamp The overhead console is located near the windshield in the head lining. The console can be removed by carefully levering out

the rear edge of the housing to release 2 spring clips, and then pulling the console rearwards to release 2 locating tabs.

Removal of the console is required to replace any of the interior or map reading lamp bulbs.

The interior lamps and air bag off warning lamp in the front overhead console are common to all vehicles. The overhead

console can also contain security system intrusion detection module and volumetric sensors, sunroof switch and a voice

activation microphone depending on vehicle specification and market.

The interior lamp can operated manually using the JaguarSense feature to switch the lamp on and off. The lamp is also

controlled as part of the automatic interior lighting system.

The map reading lamps only operate manually using the JaguarSense feature to activate the lamps.

The interior and map reading lamp bulbs are located in holders which locate in a PCB. The PCB also provides for the operation

of the ambience lighting LED's, the air bag off warning lamp and the JaguarSense proximity sensors which are integral with the PCB.

The overhead console also contains 2 LED's for the ambience lighting system. The ambience lighting is part of the lighting control switch functionality and is subject to the setting of the instrument panel illumination dimmer control in the auxiliary

lighting switch. The ambience lighting provides very limited illumination of the instrument panel and floor console when the

vehicle is being driven without affecting the driver's visibility. www.JagDocs.com

Page 2088 of 3039

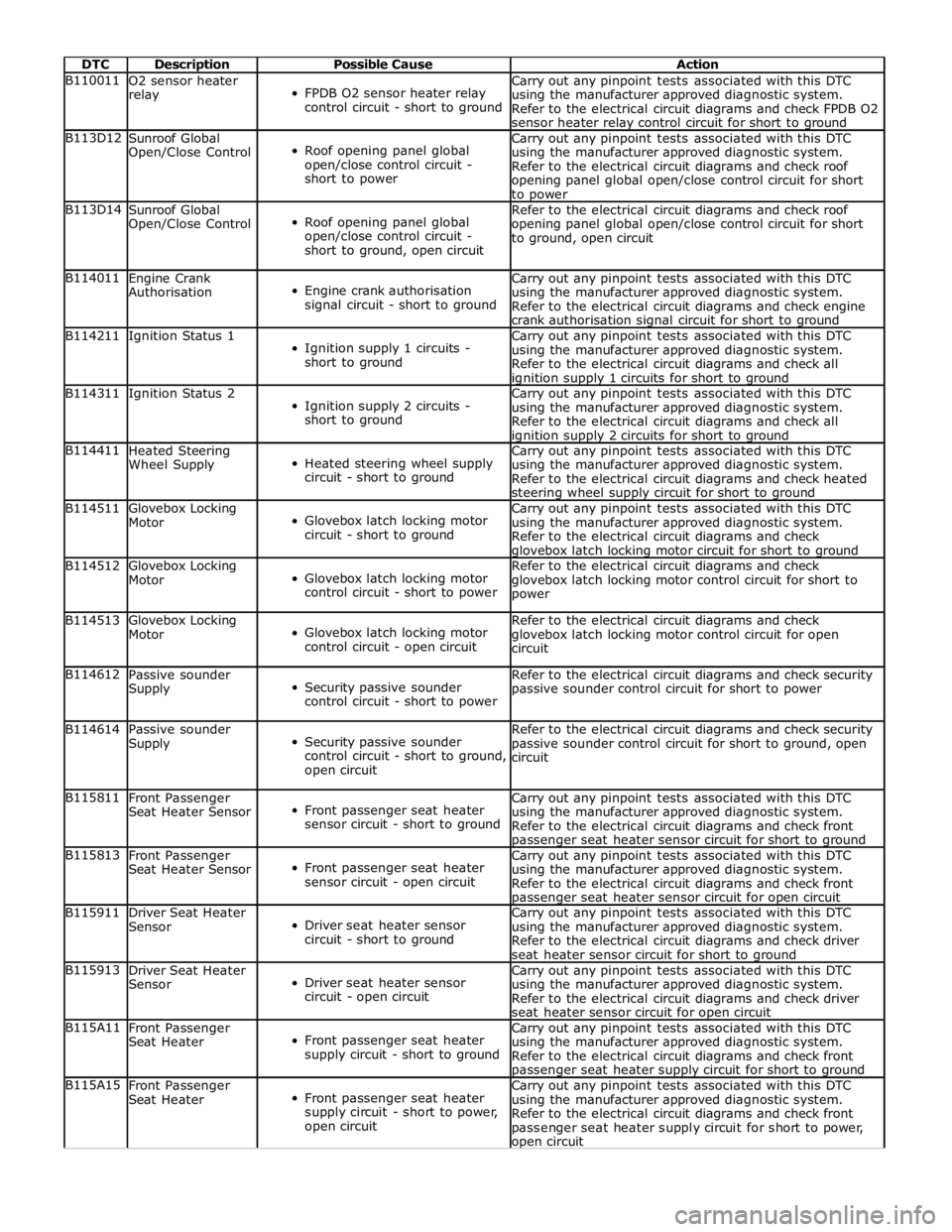

DTC Description Possible Cause Action B110011

O2 sensor heater

relay

FPDB O2 sensor heater relay

control circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check FPDB O2

sensor heater relay control circuit for short to ground B113D12

Sunroof Global

Open/Close Control

Roof opening panel global

open/close control circuit -

short to power Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check roof

opening panel global open/close control circuit for short

to power B113D14

Sunroof Global

Open/Close Control

Roof opening panel global

open/close control circuit -

short to ground, open circuit Refer to the electrical circuit diagrams and check roof

opening panel global open/close control circuit for short

to ground, open circuit B114011

Engine Crank

Authorisation

Engine crank authorisation

signal circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check engine

crank authorisation signal circuit for short to ground B114211 Ignition Status 1

Ignition supply 1 circuits -

short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check all ignition supply 1 circuits for short to ground B114311 Ignition Status 2

Ignition supply 2 circuits -

short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check all ignition supply 2 circuits for short to ground B114411

Heated Steering

Wheel Supply

Heated steering wheel supply

circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check heated steering wheel supply circuit for short to ground B114511

Glovebox Locking

Motor

Glovebox latch locking motor

circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check glovebox latch locking motor circuit for short to ground B114512

Glovebox Locking

Motor

Glovebox latch locking motor

control circuit - short to power Refer to the electrical circuit diagrams and check

glovebox latch locking motor control circuit for short to

power B114513

Glovebox Locking

Motor

Glovebox latch locking motor

control circuit - open circuit Refer to the electrical circuit diagrams and check

glovebox latch locking motor control circuit for open

circuit B114612

Passive sounder

Supply

Security passive sounder

control circuit - short to power Refer to the electrical circuit diagrams and check security

passive sounder control circuit for short to power B114614

Passive sounder

Supply

Security passive sounder

control circuit - short to ground,

open circuit Refer to the electrical circuit diagrams and check security

passive sounder control circuit for short to ground, open

circuit B115811

Front Passenger

Seat Heater Sensor

Front passenger seat heater

sensor circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check front passenger seat heater sensor circuit for short to ground B115813

Front Passenger

Seat Heater Sensor

Front passenger seat heater

sensor circuit - open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check front passenger seat heater sensor circuit for open circuit B115911

Driver Seat Heater

Sensor

Driver seat heater sensor

circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat heater sensor circuit for short to ground B115913

Driver Seat Heater

Sensor

Driver seat heater sensor

circuit - open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat heater sensor circuit for open circuit B115A11

Front Passenger

Seat Heater

Front passenger seat heater

supply circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check front passenger seat heater supply circuit for short to ground B115A15

Front Passenger

Seat Heater

Front passenger seat heater

supply circuit - short to power,

open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check front

passenger seat heater supply circuit for short to power, open circuit