service JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 182 of 3039

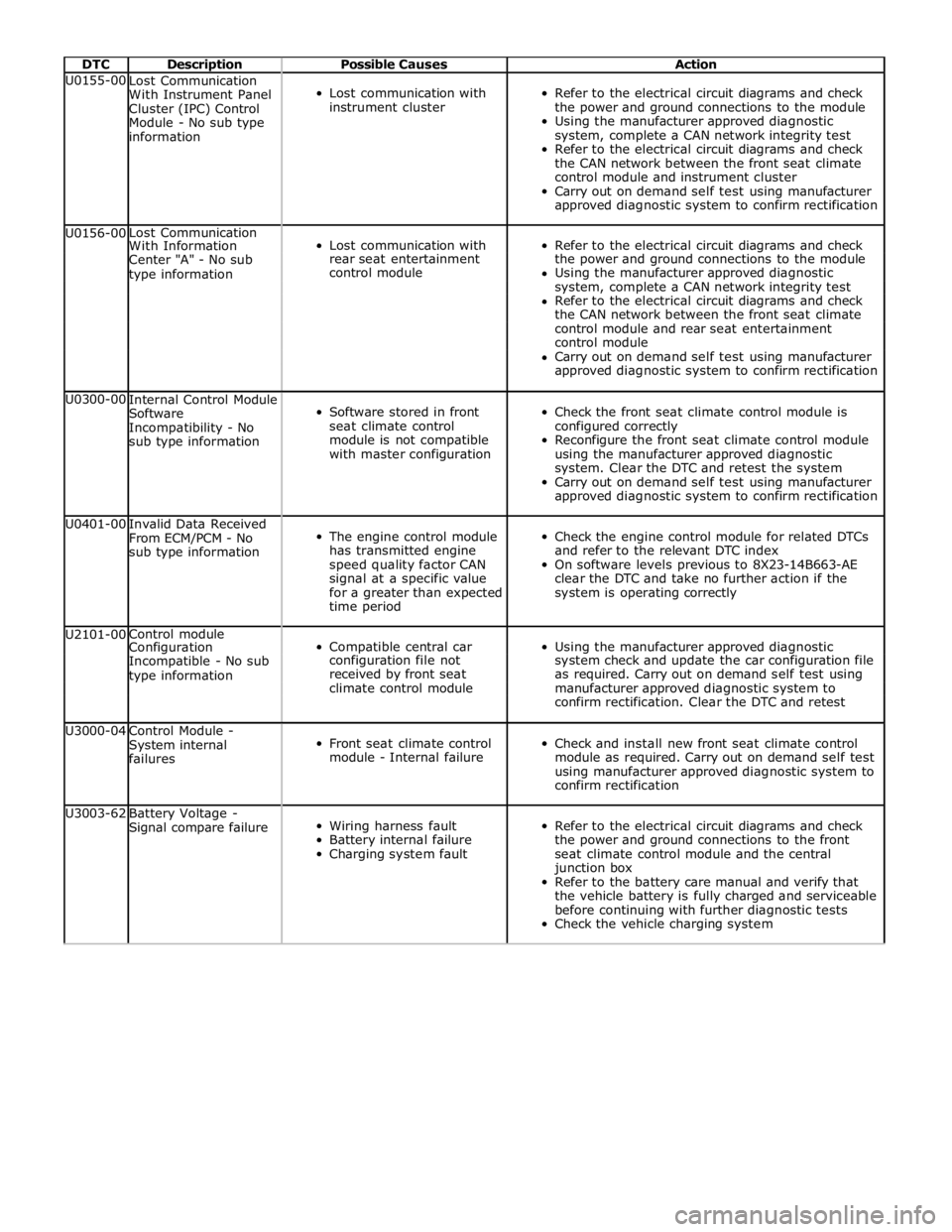

DTC Description Possible Causes Action U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Lost communication with

instrument cluster

Refer to the electrical circuit diagrams and check

the power and ground connections to the module

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test

Refer to the electrical circuit diagrams and check

the CAN network between the front seat climate

control module and instrument cluster

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0156-00 Lost Communication

Lost communication with

Refer to the electrical circuit diagrams and check With Information Center "A" - No sub rear seat entertainment the power and ground connections to the module type information control module Using the manufacturer approved diagnostic system, complete a CAN network integrity test Refer to the electrical circuit diagrams and check the CAN network between the front seat climate control module and rear seat entertainment control module Carry out on demand self test using manufacturer approved diagnostic system to confirm rectification U0300-00

Internal Control Module

Software

Incompatibility - No

sub type information

Software stored in front

seat climate control

module is not compatible

with master configuration

Check the front seat climate control module is

configured correctly

Reconfigure the front seat climate control module

using the manufacturer approved diagnostic

system. Clear the DTC and retest the system

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0401-00

Invalid Data Received

From ECM/PCM - No

sub type information

The engine control module

has transmitted engine

speed quality factor CAN

signal at a specific value

for a greater than expected

time period

Check the engine control module for related DTCs

and refer to the relevant DTC index

On software levels previous to 8X23-14B663-AE

clear the DTC and take no further action if the

system is operating correctly U2101-00 Control module

Compatible central car

Using the manufacturer approved diagnostic Configuration Incompatible - No sub configuration file not system check and update the car configuration file type information received by front seat as required. Carry out on demand self test using climate control module manufacturer approved diagnostic system to confirm rectification. Clear the DTC and retest U3000-04

Control Module -

System internal

failures

Front seat climate control

module - Internal failure

Check and install new front seat climate control

module as required. Carry out on demand self test

using manufacturer approved diagnostic system to

confirm rectification U3003-62

Battery Voltage -

Signal compare failure

Wiring harness fault

Battery internal failure

Charging system fault

Refer to the electrical circuit diagrams and check

the power and ground connections to the front

seat climate control module and the central

junction box

Refer to the battery care manual and verify that

the vehicle battery is fully charged and serviceable

before continuing with further diagnostic tests

Check the vehicle charging system

Page 188 of 3039

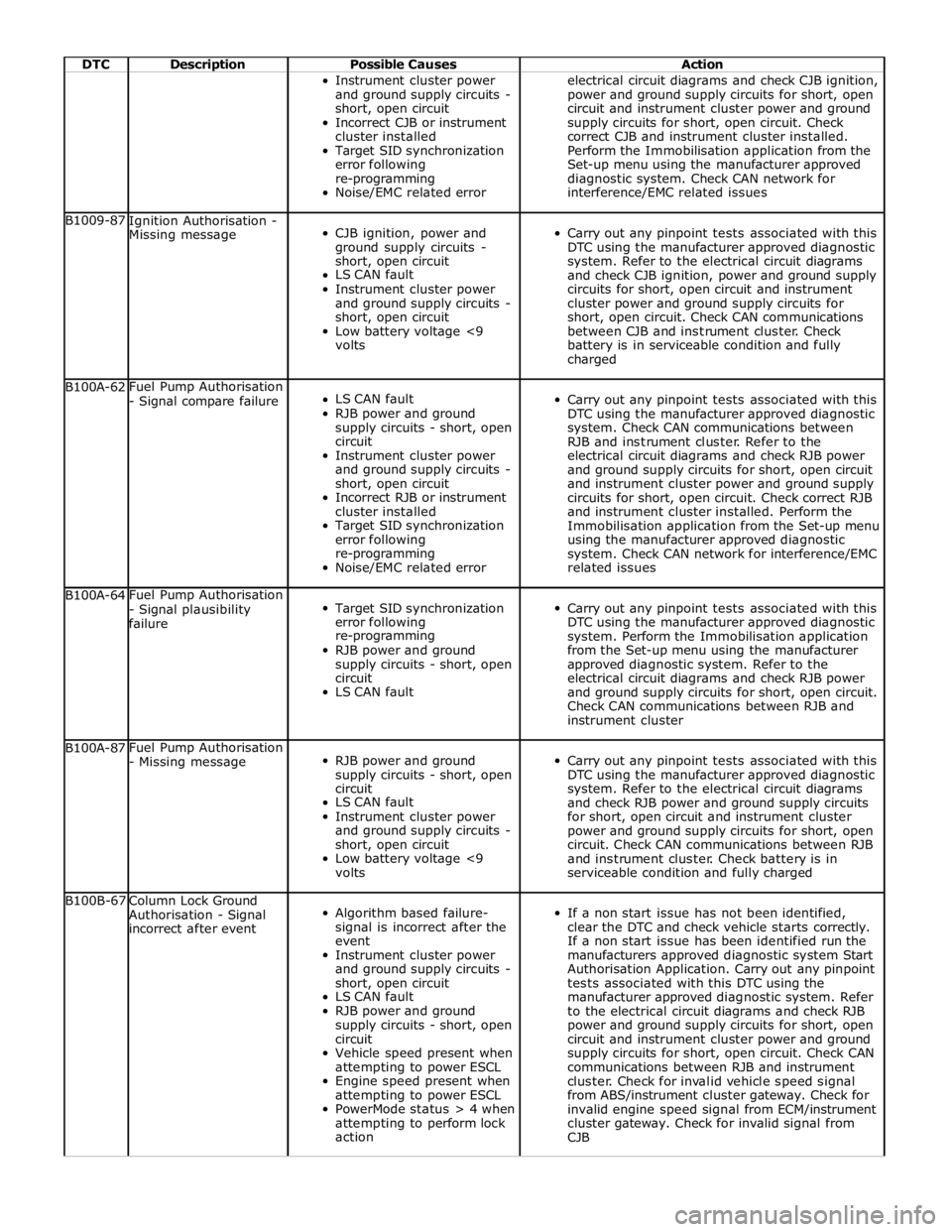

DTC Description Possible Causes Action Instrument cluster power

and ground supply circuits -

short, open circuit

Incorrect CJB or instrument

cluster installed

Target SID synchronization

error following

re-programming

Noise/EMC related error electrical circuit diagrams and check CJB ignition,

power and ground supply circuits for short, open

circuit and instrument cluster power and ground

supply circuits for short, open circuit. Check

correct CJB and instrument cluster installed.

Perform the Immobilisation application from the

Set-up menu using the manufacturer approved

diagnostic system. Check CAN network for

interference/EMC related issues B1009-87

Ignition Authorisation -

Missing message

CJB ignition, power and

ground supply circuits -

short, open circuit

LS CAN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Low battery voltage <9

volts

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check CJB ignition, power and ground supply

circuits for short, open circuit and instrument

cluster power and ground supply circuits for

short, open circuit. Check CAN communications

between CJB and instrument cluster. Check

battery is in serviceable condition and fully

charged B100A-62 Fuel Pump Authorisation

- Signal compare failure

LS CAN fault

RJB power and ground

supply circuits - short, open

circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

Incorrect RJB or instrument

cluster installed

Target SID synchronization

error following

re-programming

Noise/EMC related error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check CAN communications between

RJB and instrument cluster. Refer to the

electrical circuit diagrams and check RJB power

and ground supply circuits for short, open circuit

and instrument cluster power and ground supply

circuits for short, open circuit. Check correct RJB

and instrument cluster installed. Perform the

Immobilisation application from the Set-up menu

using the manufacturer approved diagnostic

system. Check CAN network for interference/EMC

related issues B100A-64 Fuel Pump Authorisation

- Signal plausibility

failure

Target SID synchronization

error following

re-programming

RJB power and ground

supply circuits - short, open

circuit

LS CAN fault

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Perform the Immobilisation application

from the Set-up menu using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check RJB power

and ground supply circuits for short, open circuit.

Check CAN communications between RJB and

instrument cluster B100A-87 Fuel Pump Authorisation

- Missing message

RJB power and ground

supply circuits - short, open

circuit

LS CAN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Low battery voltage <9

volts

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check RJB power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check CAN communications between RJB

and instrument cluster. Check battery is in

serviceable condition and fully charged B100B-67

Column Lock Ground

Authorisation - Signal

incorrect after event

Algorithm based failure-

signal is incorrect after the

event

Instrument cluster power

and ground supply circuits -

short, open circuit

LS CAN fault

RJB power and ground

supply circuits - short, open

circuit

Vehicle speed present when

attempting to power ESCL

Engine speed present when

attempting to power ESCL

PowerMode status > 4 when

attempting to perform lock

action

If a non start issue has not been identified,

clear the DTC and check vehicle starts correctly.

If a non start issue has been identified run the

manufacturers approved diagnostic system Start

Authorisation Application. Carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system. Refer

to the electrical circuit diagrams and check RJB

power and ground supply circuits for short, open

circuit and instrument cluster power and ground

supply circuits for short, open circuit. Check CAN

communications between RJB and instrument

cluster. Check for invalid vehicle speed signal

from ABS/instrument cluster gateway. Check for

invalid engine speed signal from ECM/instrument

cluster gateway. Check for invalid signal from

CJB

Page 193 of 3039

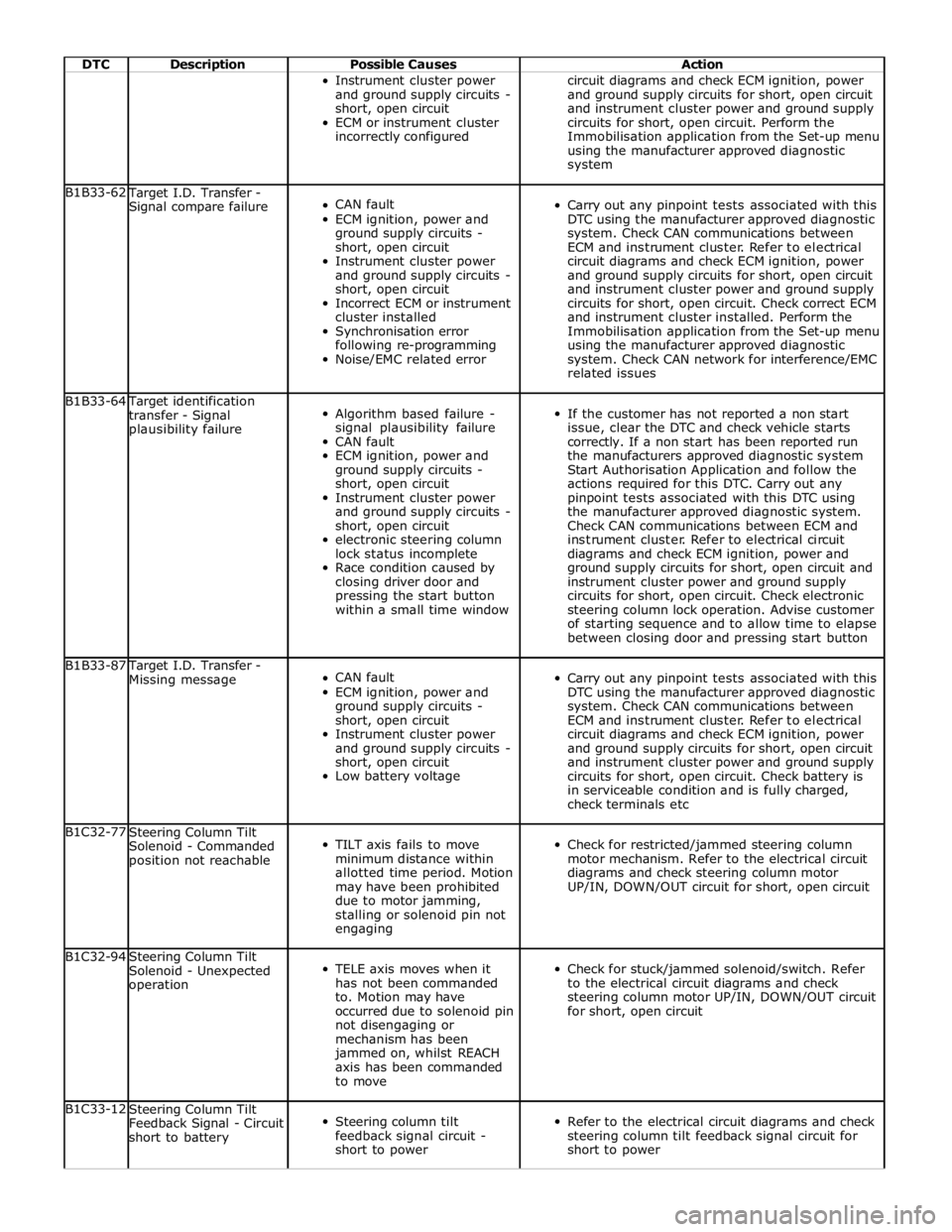

DTC Description Possible Causes Action Instrument cluster power

and ground supply circuits -

short, open circuit

ECM or instrument cluster

incorrectly configured circuit diagrams and check ECM ignition, power

and ground supply circuits for short, open circuit

and instrument cluster power and ground supply

circuits for short, open circuit. Perform the

Immobilisation application from the Set-up menu

using the manufacturer approved diagnostic

system B1B33-62 Target I.D. Transfer -

Signal compare failure

CAN fault

ECM ignition, power and

ground supply circuits -

short, open circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

Incorrect ECM or instrument

cluster installed

Synchronisation error

following re-programming

Noise/EMC related error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check CAN communications between

ECM and instrument cluster. Refer to electrical

circuit diagrams and check ECM ignition, power

and ground supply circuits for short, open circuit

and instrument cluster power and ground supply

circuits for short, open circuit. Check correct ECM

and instrument cluster installed. Perform the

Immobilisation application from the Set-up menu

using the manufacturer approved diagnostic

system. Check CAN network for interference/EMC

related issues B1B33-64 Target identification

transfer - Signal

plausibility failure

Algorithm based failure -

signal plausibility failure

CAN fault

ECM ignition, power and

ground supply circuits -

short, open circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

electronic steering column

lock status incomplete

Race condition caused by

closing driver door and

pressing the start button

within a small time window

If the customer has not reported a non start

issue, clear the DTC and check vehicle starts

correctly. If a non start has been reported run

the manufacturers approved diagnostic system

Start Authorisation Application and follow the

actions required for this DTC. Carry out any

pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system.

Check CAN communications between ECM and

instrument cluster. Refer to electrical circuit

diagrams and check ECM ignition, power and

ground supply circuits for short, open circuit and

instrument cluster power and ground supply

circuits for short, open circuit. Check electronic

steering column lock operation. Advise customer

of starting sequence and to allow time to elapse

between closing door and pressing start button B1B33-87 Target I.D. Transfer -

Missing message

CAN fault

ECM ignition, power and

ground supply circuits -

short, open circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

Low battery voltage

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check CAN communications between

ECM and instrument cluster. Refer to electrical

circuit diagrams and check ECM ignition, power

and ground supply circuits for short, open circuit

and instrument cluster power and ground supply

circuits for short, open circuit. Check battery is

in serviceable condition and is fully charged,

check terminals etc B1C32-77

Steering Column Tilt

Solenoid - Commanded

position not reachable

TILT axis fails to move

minimum distance within

allotted time period. Motion

may have been prohibited

due to motor jamming,

stalling or solenoid pin not

engaging

Check for restricted/jammed steering column

motor mechanism. Refer to the electrical circuit

diagrams and check steering column motor

UP/IN, DOWN/OUT circuit for short, open circuit B1C32-94

Steering Column Tilt

Solenoid - Unexpected

operation

TELE axis moves when it

has not been commanded

to. Motion may have

occurred due to solenoid pin

not disengaging or

mechanism has been

jammed on, whilst REACH

axis has been commanded

to move

Check for stuck/jammed solenoid/switch. Refer

to the electrical circuit diagrams and check

steering column motor UP/IN, DOWN/OUT circuit

for short, open circuit B1C33-12

Steering Column Tilt

Feedback Signal - Circuit

short to battery

Steering column tilt

feedback signal circuit -

short to power

Refer to the electrical circuit diagrams and check

steering column tilt feedback signal circuit for

short to power

Page 205 of 3039

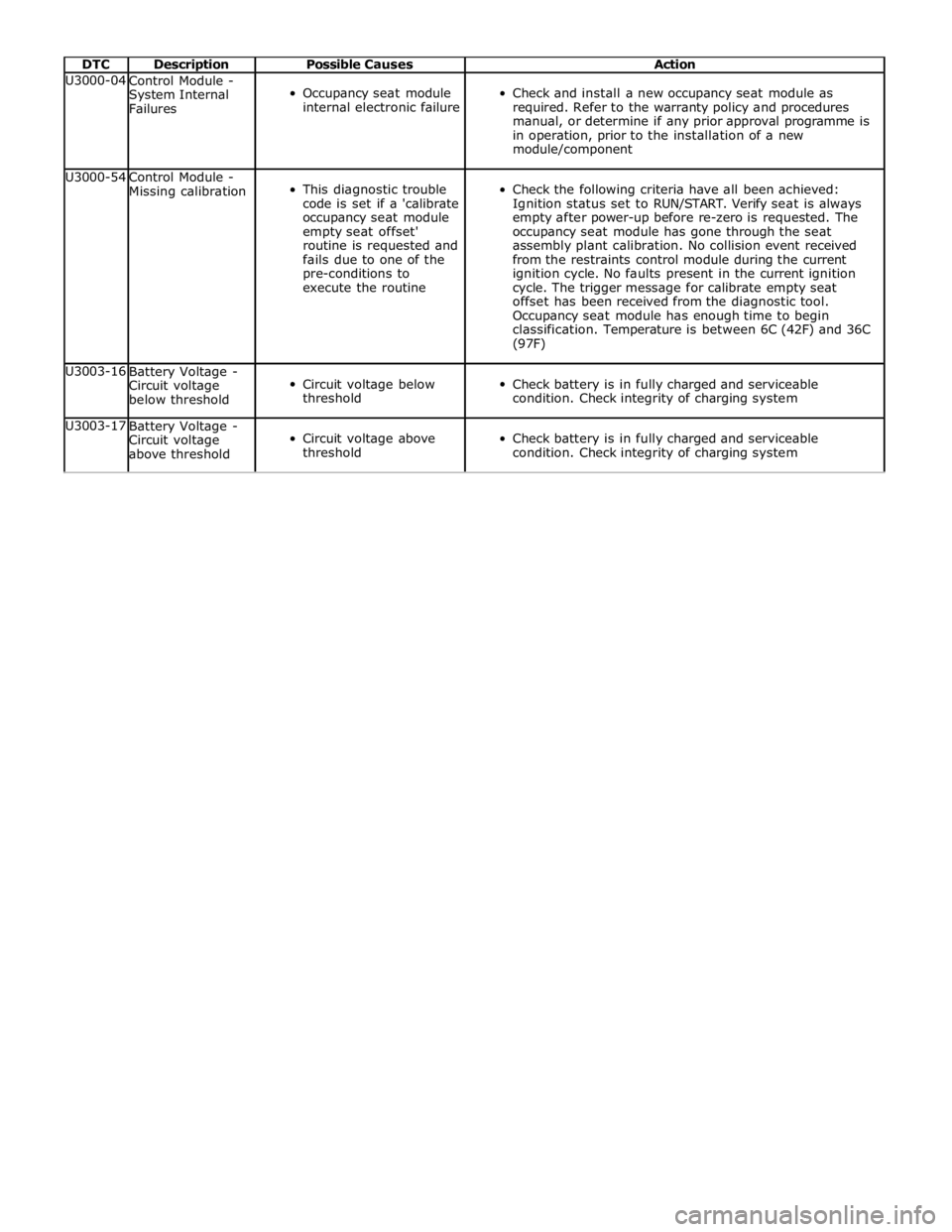

DTC Description Possible Causes Action U3000-04

Control Module -

System Internal

Failures

Occupancy seat module

internal electronic failure

Check and install a new occupancy seat module as

required. Refer to the warranty policy and procedures

manual, or determine if any prior approval programme is

in operation, prior to the installation of a new

module/component U3000-54

Control Module -

Missing calibration

This diagnostic trouble

code is set if a 'calibrate

occupancy seat module

empty seat offset'

routine is requested and

fails due to one of the

pre-conditions to

execute the routine

Check the following criteria have all been achieved:

Ignition status set to RUN/START. Verify seat is always

empty after power-up before re-zero is requested. The

occupancy seat module has gone through the seat

assembly plant calibration. No collision event received

from the restraints control module during the current

ignition cycle. No faults present in the current ignition

cycle. The trigger message for calibrate empty seat

offset has been received from the diagnostic tool.

Occupancy seat module has enough time to begin

classification. Temperature is between 6C (42F) and 36C

(97F) U3003-16

Battery Voltage -

Circuit voltage

below threshold

Circuit voltage below

threshold

Check battery is in fully charged and serviceable

condition. Check integrity of charging system U3003-17

Battery Voltage -

Circuit voltage

above threshold

Circuit voltage above

threshold

Check battery is in fully charged and serviceable

condition. Check integrity of charging system

Page 220 of 3039

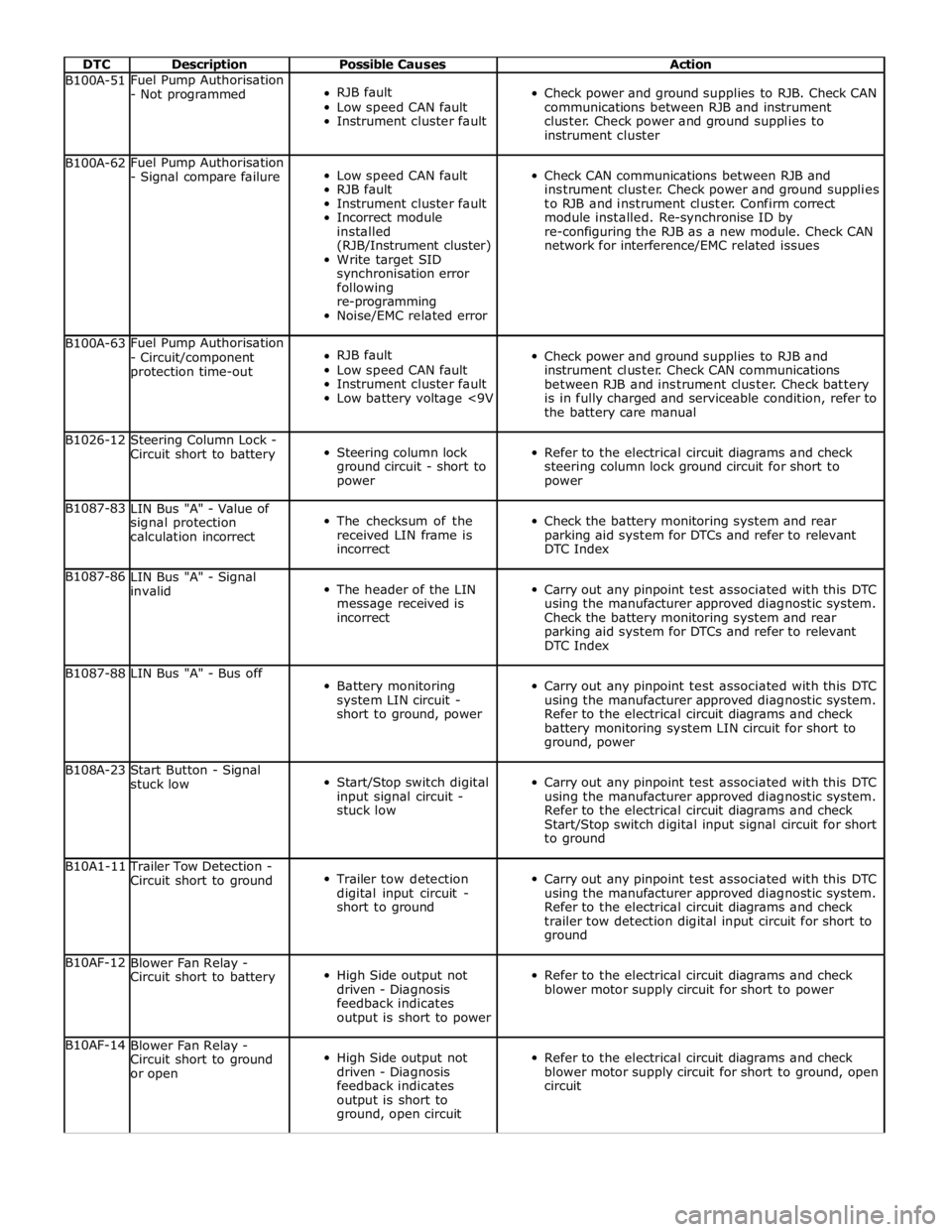

DTC Description Possible Causes Action B100A-51 Fuel Pump Authorisation

- Not programmed

RJB fault

Low speed CAN fault

Instrument cluster fault

Check power and ground supplies to RJB. Check CAN

communications between RJB and instrument

cluster. Check power and ground supplies to

instrument cluster B100A-62 Fuel Pump Authorisation

- Signal compare failure

Low speed CAN fault

RJB fault

Instrument cluster fault

Incorrect module

installed

(RJB/Instrument cluster)

Write target SID

synchronisation error

following

re-programming

Noise/EMC related error

Check CAN communications between RJB and

instrument cluster. Check power and ground supplies

to RJB and instrument cluster. Confirm correct

module installed. Re-synchronise ID by

re-configuring the RJB as a new module. Check CAN

network for interference/EMC related issues B100A-63 Fuel Pump Authorisation

- Circuit/component

protection time-out

RJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V

Check power and ground supplies to RJB and

instrument cluster. Check CAN communications

between RJB and instrument cluster. Check battery

is in fully charged and serviceable condition, refer to

the battery care manual B1026-12

Steering Column Lock -

Circuit short to battery

Steering column lock

ground circuit - short to

power

Refer to the electrical circuit diagrams and check

steering column lock ground circuit for short to

power B1087-83

LIN Bus "A" - Value of

signal protection

calculation incorrect

The checksum of the

received LIN frame is

incorrect

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-86

LIN Bus "A" - Signal

invalid

The header of the LIN

message received is

incorrect

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-88 LIN Bus "A" - Bus off

Battery monitoring

system LIN circuit -

short to ground, power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

battery monitoring system LIN circuit for short to

ground, power B108A-23

Start Button - Signal

stuck low

Start/Stop switch digital

input signal circuit -

stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

Start/Stop switch digital input signal circuit for short

to ground B10A1-11 Trailer Tow Detection -

Circuit short to ground

Trailer tow detection

digital input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

trailer tow detection digital input circuit for short to

ground B10AF-12

Blower Fan Relay -

Circuit short to battery

High Side output not

driven - Diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to power B10AF-14

Blower Fan Relay -

Circuit short to ground

or open

High Side output not

driven - Diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to ground, open

circuit

Page 223 of 3039

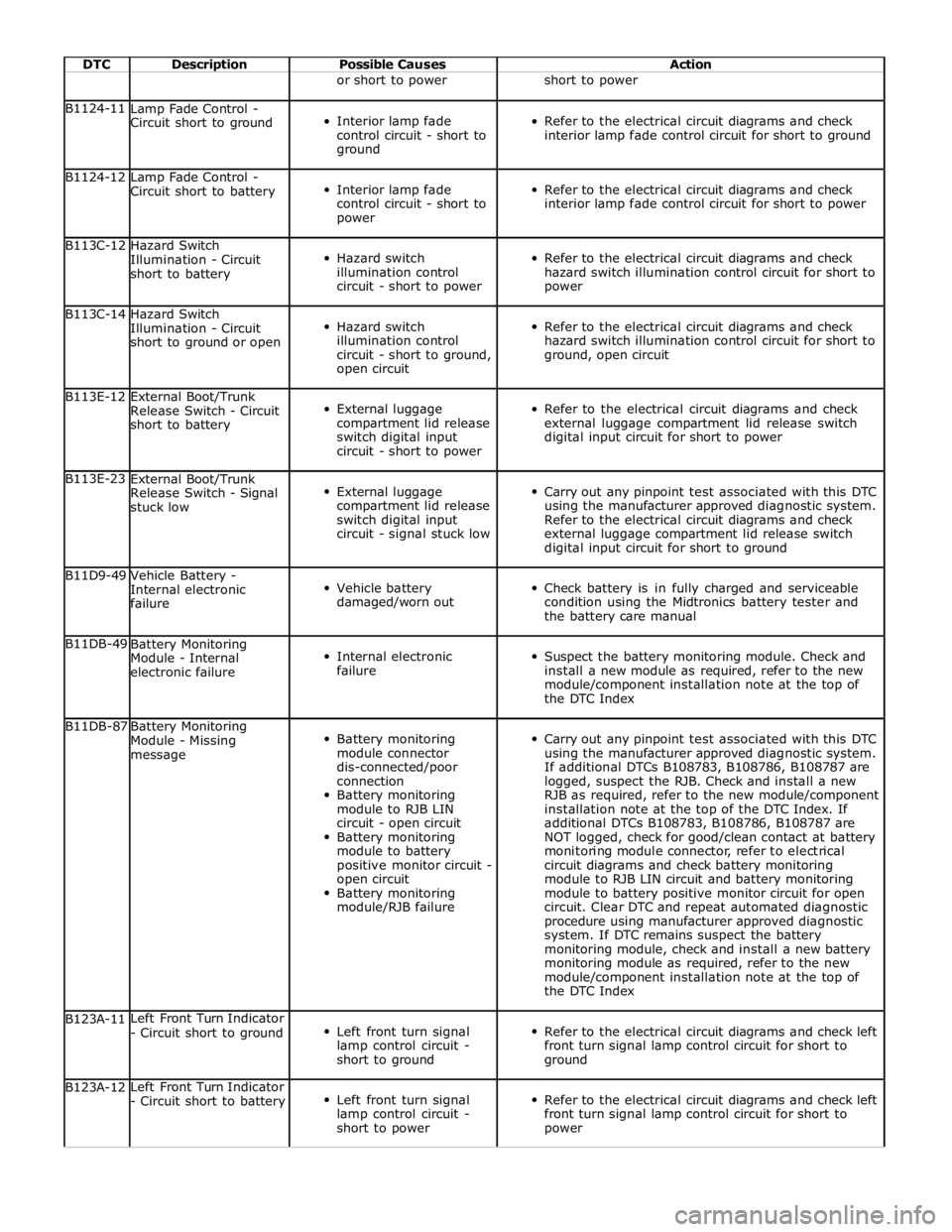

DTC Description Possible Causes Action or short to power short to power B1124-11

Lamp Fade Control -

Circuit short to ground

Interior lamp fade

control circuit - short to

ground

Refer to the electrical circuit diagrams and check

interior lamp fade control circuit for short to ground B1124-12

Lamp Fade Control -

Circuit short to battery

Interior lamp fade

control circuit - short to

power

Refer to the electrical circuit diagrams and check

interior lamp fade control circuit for short to power B113C-12

Hazard Switch

Illumination - Circuit

short to battery

Hazard switch

illumination control

circuit - short to power

Refer to the electrical circuit diagrams and check

hazard switch illumination control circuit for short to

power B113C-14

Hazard Switch

Illumination - Circuit

short to ground or open

Hazard switch

illumination control

circuit - short to ground,

open circuit

Refer to the electrical circuit diagrams and check

hazard switch illumination control circuit for short to

ground, open circuit B113E-12

External Boot/Trunk

Release Switch - Circuit

short to battery

External luggage

compartment lid release

switch digital input

circuit - short to power

Refer to the electrical circuit diagrams and check

external luggage compartment lid release switch

digital input circuit for short to power B113E-23

External Boot/Trunk

Release Switch - Signal

stuck low

External luggage

compartment lid release

switch digital input

circuit - signal stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

external luggage compartment lid release switch

digital input circuit for short to ground B11D9-49

Vehicle Battery -

Internal electronic

failure

Vehicle battery

damaged/worn out

Check battery is in fully charged and serviceable

condition using the Midtronics battery tester and

the battery care manual B11DB-49

Battery Monitoring

Module - Internal

electronic failure

Internal electronic

failure

Suspect the battery monitoring module. Check and

install a new module as required, refer to the new

module/component installation note at the top of

the DTC Index B11DB-87

Battery Monitoring

Module - Missing

message

Battery monitoring

module connector

dis-connected/poor

connection

Battery monitoring

module to RJB LIN

circuit - open circuit

Battery monitoring

module to battery

positive monitor circuit -

open circuit

Battery monitoring

module/RJB failure

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

If additional DTCs B108783, B108786, B108787 are

logged, suspect the RJB. Check and install a new

RJB as required, refer to the new module/component

installation note at the top of the DTC Index. If

additional DTCs B108783, B108786, B108787 are

NOT logged, check for good/clean contact at battery

monitoring module connector, refer to electrical

circuit diagrams and check battery monitoring

module to RJB LIN circuit and battery monitoring

module to battery positive monitor circuit for open

circuit. Clear DTC and repeat automated diagnostic

procedure using manufacturer approved diagnostic

system. If DTC remains suspect the battery

monitoring module, check and install a new battery

monitoring module as required, refer to the new

module/component installation note at the top of

the DTC Index B123A-11 Left Front Turn Indicator

- Circuit short to ground

Left front turn signal

lamp control circuit -

short to ground

Refer to the electrical circuit diagrams and check left

front turn signal lamp control circuit for short to

ground B123A-12 Left Front Turn Indicator

- Circuit short to battery

Left front turn signal

lamp control circuit -

short to power

Refer to the electrical circuit diagrams and check left

front turn signal lamp control circuit for short to

power

Page 242 of 3039

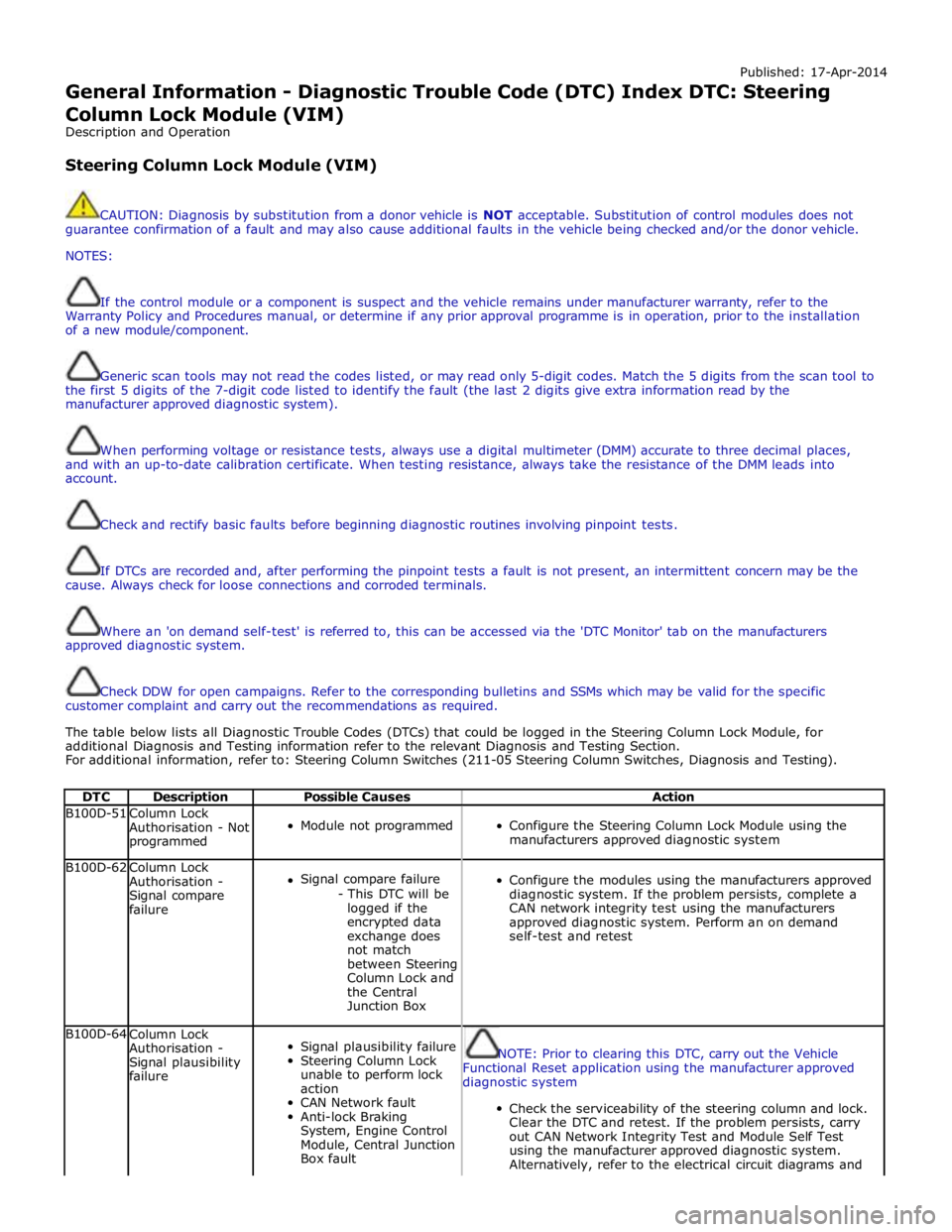

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Steering

Column Lock Module (VIM)

Description and Operation

Steering Column Lock Module (VIM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Where an 'on demand self-test' is referred to, this can be accessed via the 'DTC Monitor' tab on the manufacturers

approved diagnostic system.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Steering Column Lock Module, for

additional Diagnosis and Testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Steering Column Switches (211-05 Steering Column Switches, Diagnosis and Testing).

DTC Description Possible Causes Action B100D-51

Column Lock

Authorisation - Not

programmed

Module not programmed

Configure the Steering Column Lock Module using the

manufacturers approved diagnostic system B100D-62

Column Lock

Authorisation -

Signal compare

failure

Signal compare failure

- This DTC will be

logged if the

encrypted data

exchange does

not match

between Steering

Column Lock and

the Central

Junction Box

Configure the modules using the manufacturers approved

diagnostic system. If the problem persists, complete a

CAN network integrity test using the manufacturers

approved diagnostic system. Perform an on demand

self-test and retest B100D-64

Column Lock

Authorisation -

Signal plausibility

failure

Signal plausibility failure

Steering Column Lock

unable to perform lock

action

CAN Network fault

Anti-lock Braking

System, Engine Control

Module, Central Junction

Box fault

NOTE: Prior to clearing this DTC, carry out the Vehicle

Functional Reset application using the manufacturer approved

diagnostic system

Check the serviceability of the steering column and lock.

Clear the DTC and retest. If the problem persists, carry

out CAN Network Integrity Test and Module Self Test

using the manufacturer approved diagnostic system.

Alternatively, refer to the electrical circuit diagrams and

Page 294 of 3039

Jacking and Lifting - Jacking

Description and Operation

Safety Precautions Published: 11-May-2011

WARNING: The jack provided with the vehicle is intended to be used in an emergency for changing a deflated tire. To

avoid damage to the vehicle, never use the jack to raise the vehicle for any other purpose. Refer to the Driver Handbook when

using the jack supplied with the vehicle. Failure to follow these instructions may result in personal injury.

The following safety precautions must be observed when raising the vehicle to carry out service operations:

Never rely on a jack alone to support a vehicle. Always use suitable vehicle stands to provide rigid support.

When working beneath a vehicle, whenever possible use a vehicle hoist instead of a jack and vehicle stands.

Make sure that the vehicle is standing on firm, level ground before using a jack.

Do not rely on the parking brake alone; chock the wheels and put the automatic transmission into Park if possible.

Check that any lifting equipment used has adequate capacity for the load being lifted and is in correct working order.

Page 332 of 3039

Upper Control Arm

The forged-aluminum upper control arm is a wishbone design and connects to the vehicle body through two plain bushes, and

links to the swan neck wheel knuckle by an integral ball joint. The upper control arm is inclined to provide anti-dive

characteristics under heavy braking, while also controlling geometry for vehicle straight-line stability.

Lower Control Arm

The forged aluminum lower control arms are of the wishbone design; the arms separate to allow for optimum bush tuning:

The rear lateral control arm is fitted with a bush at its inner end which locates between brackets on the subframe. The

arm is secured with an eccentric bolt which provides the adjustment of the suspension camber geometry. The outer end

of the control arm has a tapered hole which locates on a ball joint fitted to the wheel knuckle. An integral clevis bracket

on the forward face of the lateral control arm allows for the attachment of the forward control arm. A bush is fitted

below the clevis bracket to provide for the attachment of the stabilizer bar link. A cross-axis joint is fitted to a

cross-hole in the control arm to provide the location for the clevis attachment of the spring and damper assembly.

The forward control arm is fitted with a fluid-block rubber bush at its inner end which locates between brackets on the

subframe. The arm is secured with an eccentric bolt which provides adjustment of the castor and camber geometry. The

outer end of the control arm is fitted with a cross-axis joint and locates in the integral clevis bracket on the lateral

control arm.

Wheel Knuckle

The cast aluminum wheel knuckle is a swan neck design and attaches to the upper control arm and lower lateral control arm.

The lower lateral control arm locates on a non serviceable ball-joint integral with the wheel knuckle. The lower boss on the

rear of the knuckle provides for the attachment of the steering gear tie-rod ball joint.

The wheel knuckle also provides the mounting locations for the:

wheel hub and bearing assembly

the wheel speed sensor (integral to the wheel hub and bearing assembly)

brake caliper and disc shield.

Stabilizer Bar

The stabilizer bar is attached to the front of the subframe with bushes and mounting brackets. The pressed steel mounting

brackets locate over the bushes and are attached to the cross member with bolts screwed into threaded locations in the

subframe. The stabilizer bar has crimped, 'anti-shuffle' collars pressed in position on the inside edges of the bushes. The

collars prevent sideways movement of the stabilizer bar.

The stabilizer bar is manufactured from 32mm diameter tubular steel on supercharged models and 31mm diameter tubular

steel on diesel and normally aspirated models and has been designed to provide particular characteristics in maintaining roll

rates, specifically in primary ride comfort.

Each end of the stabilizer bar curves rearwards to attach to a ball joint on a stabilizer link. Each stabilizer link is secured to a

bush in the lower lateral arm with a bolt and locknut. The links allow the stabilizer bar to move with the wheel travel providing

maximum effectiveness.

The only difference between the front stabilizer bars, in addition to the diameter, is in the shape to accommodate engine

variant:

a slightly curved bar, between bush centers, for V6 diesel (31 mm dia) and V8 gasoline supercharged (32 mm dia),

a straight bar, between bush centers, for V6 and V8 normally aspirated gasoline engines (31 mm dia).

Spring and Damper Assembly

The spring and damper assemblies are located between the lower lateral arm and the front suspension housing in the inner

wing. Dependant on vehicle model there are three types of coil spring and damper available:

a standard oil passive damper (All models except supercharged),

an adaptive damper, also known as Computer Active Technology Suspension (CATS) on 4.2L supercharged vehicles up to

2010MY, For additional information refer to Vehicle Dynamic Suspension 4.2L.

a continuously variable adaptive damper, also known as Adaptive Dynamics System on 5.0L supercharged vehicles from

2010MY. For additional information refer to Vehicle Dynamic Suspension 5.0L.

The dampers are a monotube design with a spring seat secured by a circlip onto the damper tube. The damper's lower

spherical joint is an integral part of the lateral lower control-arm, and the damper takes the form of a clevis-end, which

straddles the spherical joint.

The damper piston is connected to a damper rod which is sealed at its exit point from the damper body. The threaded outer

end of the damper rod locates through a hole in the top mount. A self locking nut secures the top mount to the damper rod.

The damper rod on the adaptive damper has an electrical connector on the outer end of the damper rod.

Supercharged 4.2L vehicles up to 2010MY: The adaptive damper functions by restricting the flow of hydraulic fluid through

internal galleries in the damper's piston. The adaptive damper has a solenoid operated valve, which when switched allows a

greater flow of hydraulic fluid through the damper's piston. This provides a softer damping characteristic from the damper. The

adaptive damper defaults to a firmer setting when not activated. The solenoid is computer controlled and can switch between

soft and hard damping settings depending on road wheel inputs and vehicle speed.

Supercharged 5.0L vehicles from 2010MY: The variable damper functions by adjustment of a solenoid operated variable orifice,

which opens up an alternative path for oil flow within the damper. When de-energized the bypass is closed and all the oil flows

Page 335 of 3039

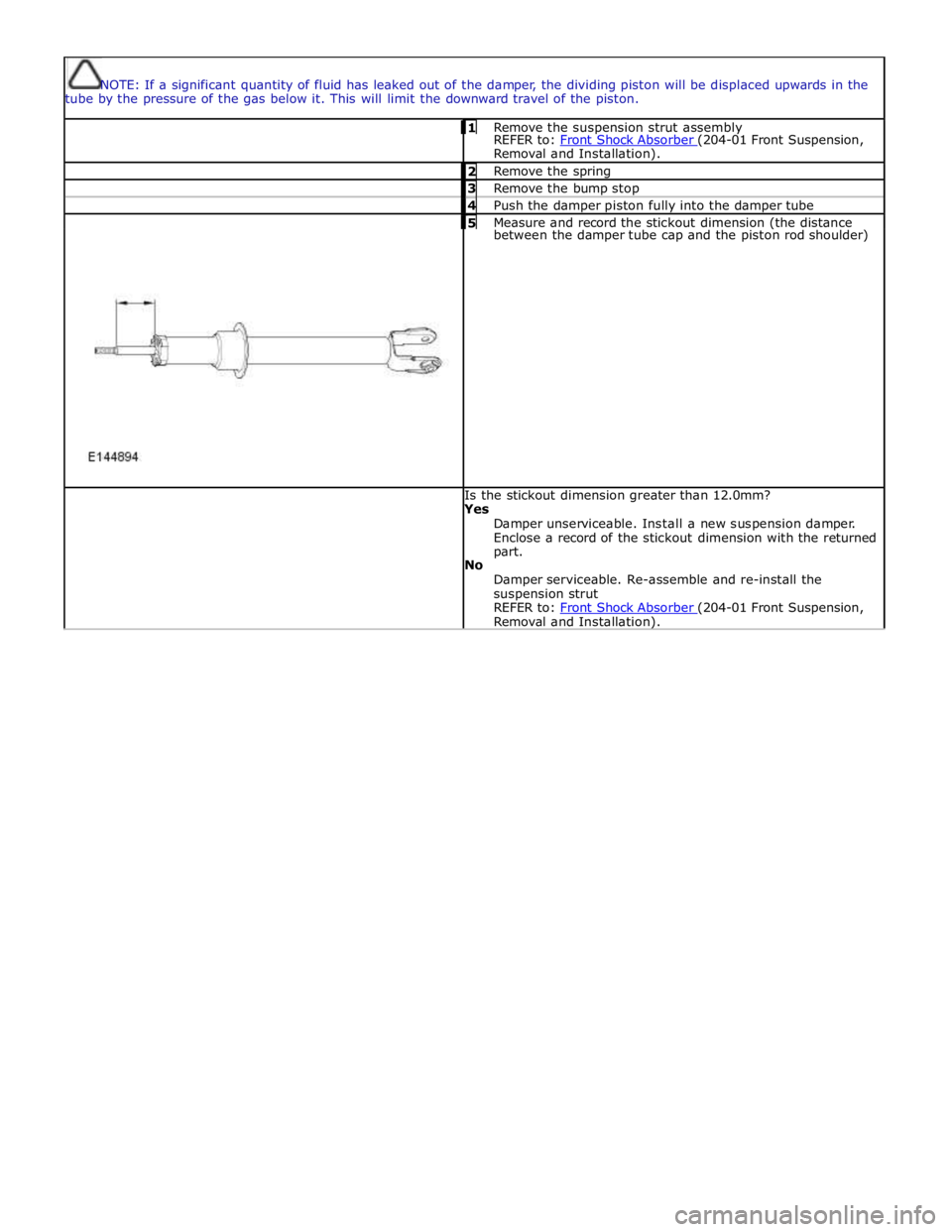

NOTE: If a significant quantity of fluid has leaked out of the damper, the dividing piston will be displaced upwards in the

tube by the pressure of the gas below it. This will limit the downward travel of the piston. 1 Remove the suspension strut assembly REFER to: Front Shock Absorber (204-01 Front Suspension, Removal and Installation). 2 Remove the spring 3 Remove the bump stop 4 Push the damper piston fully into the damper tube

5 Measure and record the stickout dimension (the distance between the damper tube cap and the piston rod shoulder) Is the stickout dimension greater than 12.0mm?

Yes

Damper unserviceable. Install a new suspension damper.

Enclose a record of the stickout dimension with the returned

part.

No

Damper serviceable. Re-assemble and re-install the

suspension strut

REFER to: Front Shock Absorber (204-01 Front Suspension, Removal and Installation).