service JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 398 of 3039

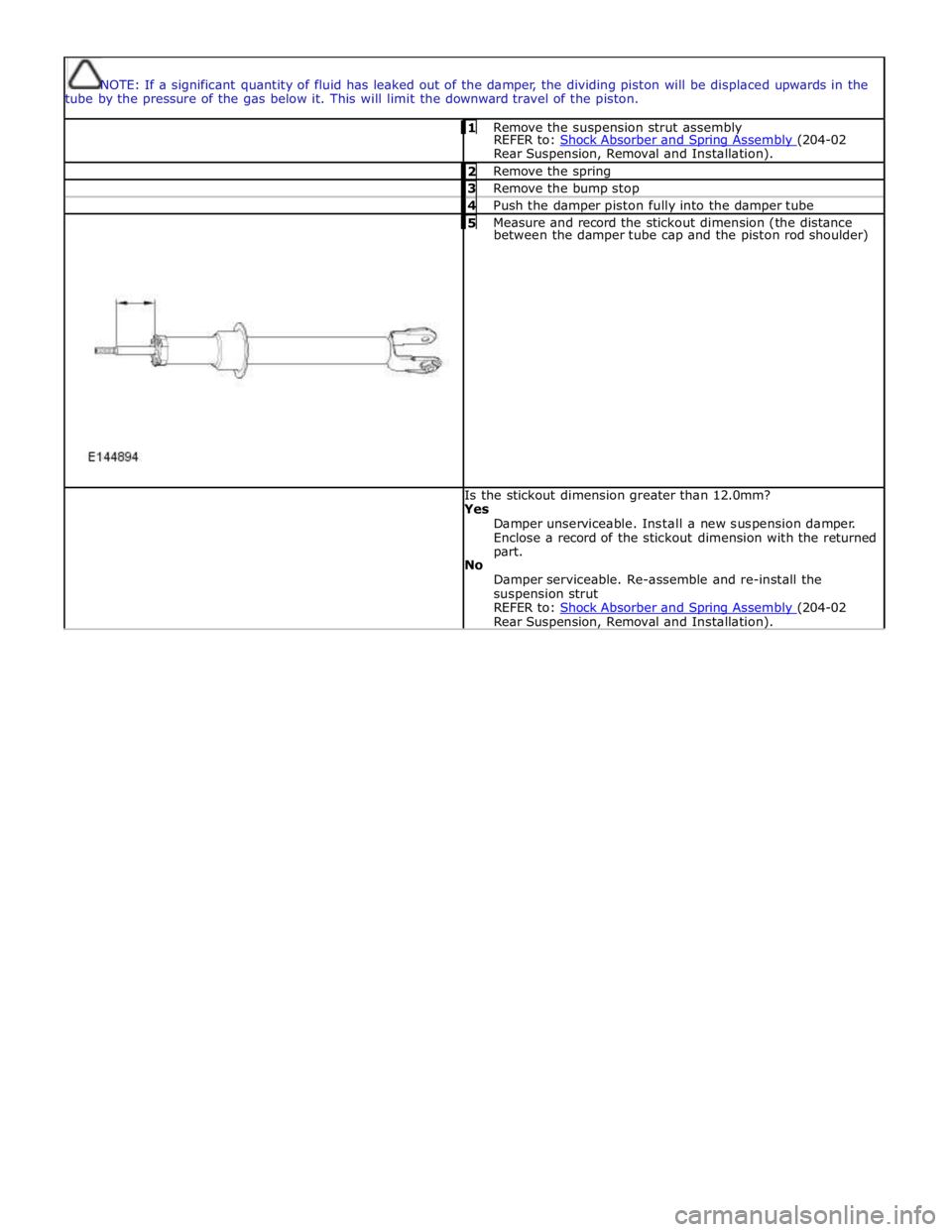

NOTE: If a significant quantity of fluid has leaked out of the damper, the dividing piston will be displaced upwards in the

tube by the pressure of the gas below it. This will limit the downward travel of the piston. 1 Remove the suspension strut assembly REFER to: Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). 2 Remove the spring 3 Remove the bump stop 4 Push the damper piston fully into the damper tube

5 Measure and record the stickout dimension (the distance between the damper tube cap and the piston rod shoulder) Is the stickout dimension greater than 12.0mm?

Yes

Damper unserviceable. Install a new suspension damper.

Enclose a record of the stickout dimension with the returned

part.

No

Damper serviceable. Re-assemble and re-install the

suspension strut

REFER to: Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation).

Page 439 of 3039

Wheels and Tires - Wheels and Tires - Overview

Description and Operation

OVERVIEW Published: 25-May-2012

A number of alloy wheel designs are available ranging from 17 to 20 inch in diameter. A Tire Pressure Monitoring System

(TPMS) is used to monitor the air pressure in each tire and inform the driver if the pressure falls below predetermined

thresholds.

All wheels are of cast construction in aluminum alloy with the choice of wheel design dependant on the vehicle trim level and

engine derivative.

On normally aspirated petrol models and all diesel models a 4J X 18 inch temporary spare wheel is supplied as standard,

supercharged petrol models are supplied with a 4Jx19 inch temporary spare wheel. In some major European markets an Instant

Mobility System is offered as an alternative to the spare wheel. The Instant Mobility System is capable of providing a

temporary repair and tire inflation to a puncture of up to 6mm in diameter in the tread area of the tire. A puncture in the tire

wall cannot be repaired using the system.

The vehicle jack and accessories are stored in the spare wheel-well in the luggage compartment.

Tire Changing

WARNINGS:

Tires must be inflated to the recommended pressures when the tires are cold (ambient temperature) only. Refer to label

on the 'B' pillar for recommended tire pressures. If the tires have been subjected to use or exposed to direct sunlight, move

the vehicle into a shaded position and allow the tires to cool before checking or adjusting the pressures.

Valve stem seal, washer nut, valve core and cap should be replaced at every tire change. Valve stem seal, washer and

nut must be replaced if the valve retention nut is loosened. Sensor units and nuts must be fitted using correct torque figures

and associated profile. Damage to the vehicle and consequently injury to the vehicle's occupants may result if these

instructions are not adhered to.

NOTE: The TPMS valve should be serviced using the suitable service kit, each time the tyre is dismounted, to ensure an

air tight seal. Attention should be made to the detail of fitting this kit.

Vehicles fitted with TPMS can be visually identified by an external metal locknut and valve of the tire pressure sensor on the

road wheels. Vehicles without TPMS will have rubber tire valve.

www.JagDocs.com

Page 491 of 3039

Published: 11-May-2011

Vehicle Dynamic Suspension - Front Suspension Vertical Accelerometer

Removal and Installation

Removal

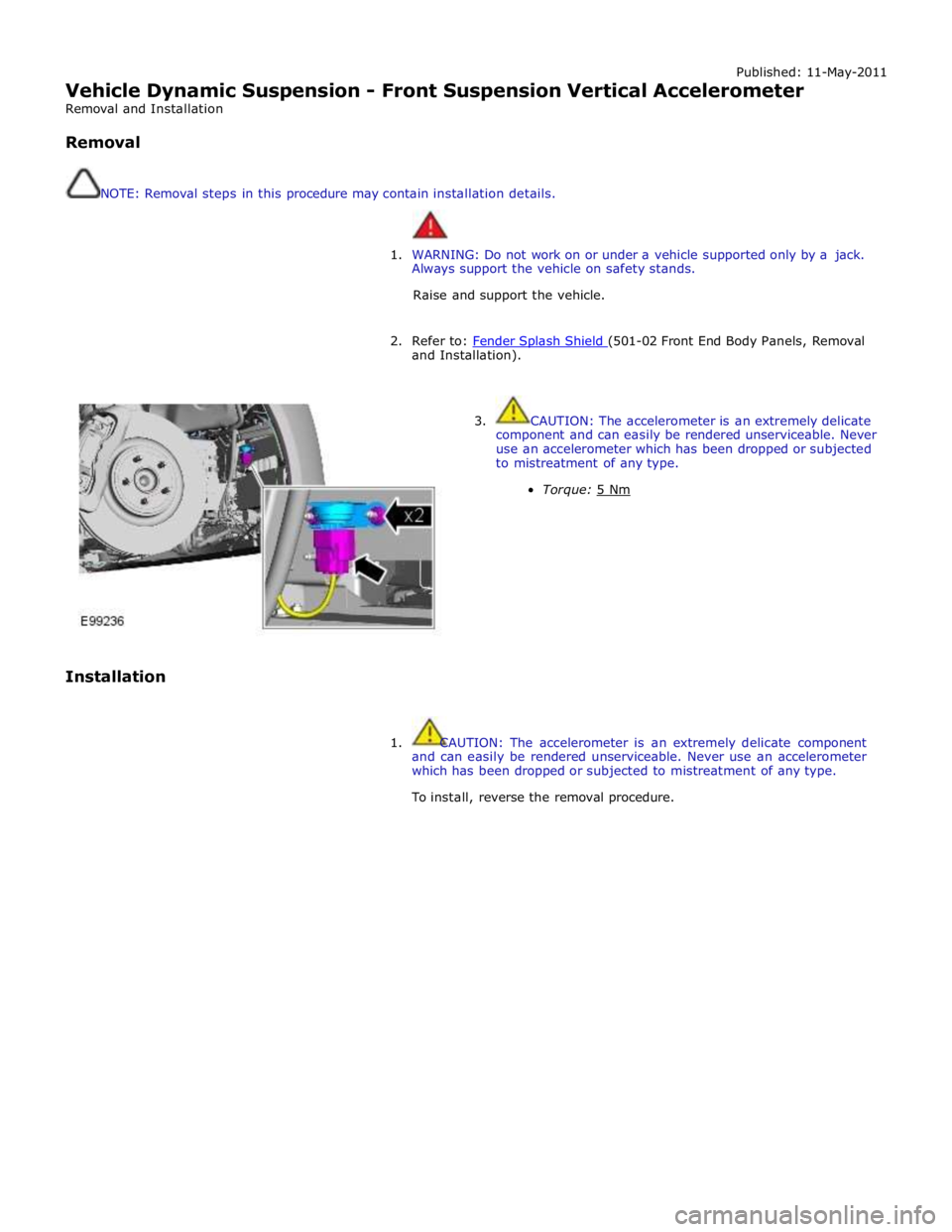

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

Installation

3. CAUTION: The accelerometer is an extremely delicate

component and can easily be rendered unserviceable. Never

use an accelerometer which has been dropped or subjected

to mistreatment of any type.

Torque: 5 Nm

1. CAUTION: The accelerometer is an extremely delicate component

and can easily be rendered unserviceable. Never use an accelerometer

which has been dropped or subjected to mistreatment of any type.

To install, reverse the removal procedure.

Page 492 of 3039

Published: 11-May-2011

Vehicle Dynamic Suspension - Rear Suspension Vertical Accelerometer

Removal and Installation

Removal

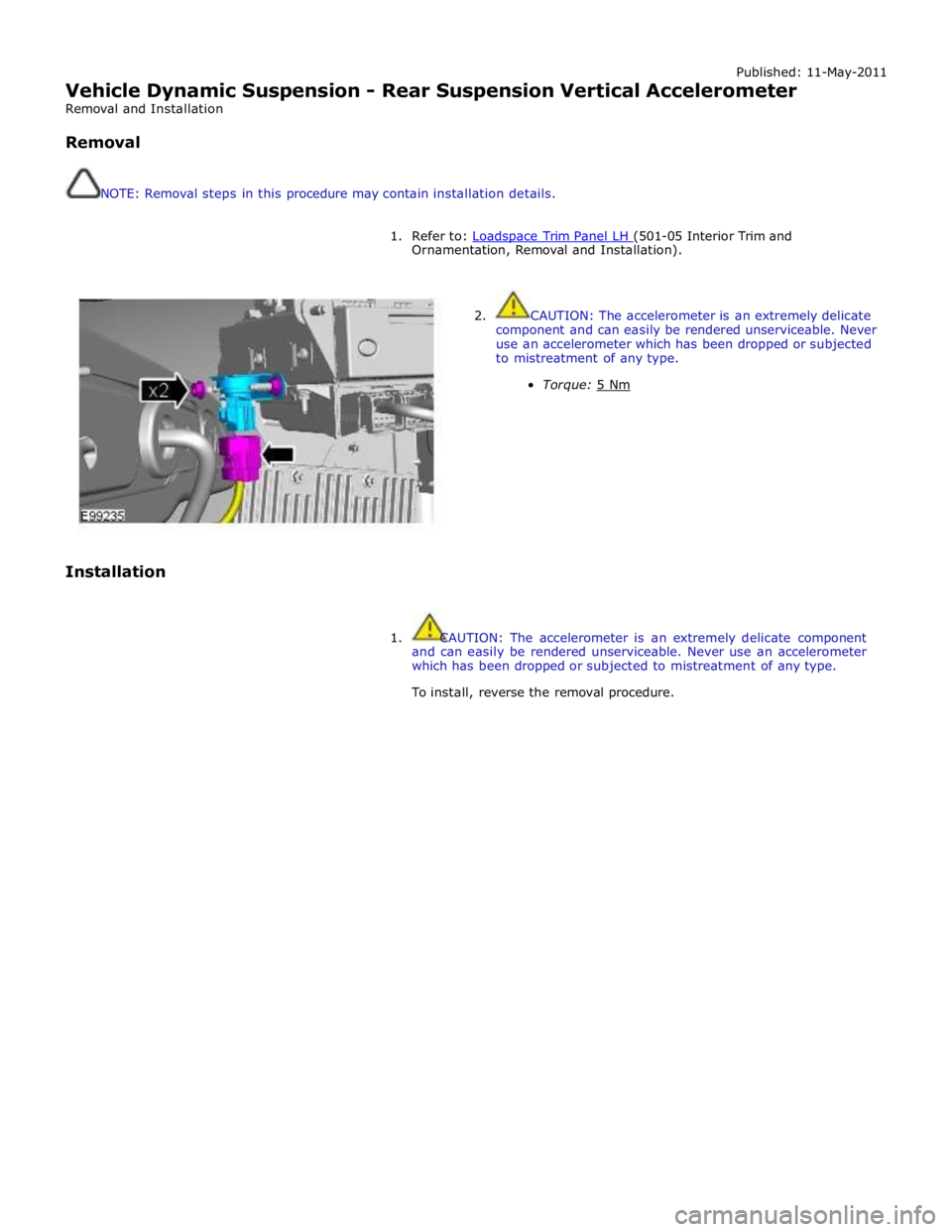

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Loadspace Trim Panel LH (501-05 Interior Trim and Ornamentation, Removal and Installation).

Installation

2. CAUTION: The accelerometer is an extremely delicate

component and can easily be rendered unserviceable. Never

use an accelerometer which has been dropped or subjected

to mistreatment of any type.

Torque: 5 Nm

1. CAUTION: The accelerometer is an extremely delicate component

and can easily be rendered unserviceable. Never use an accelerometer

which has been dropped or subjected to mistreatment of any type.

To install, reverse the removal procedure.

Page 499 of 3039

Driveline System - General Information - Driveline System

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of driveline operation, refer to the relevant Description and Operation section in the workshop

manual. REFER to:

Driveshaft (205-01 Driveshaft, Description and Operation), Driveshaft (205-01 Driveshaft, Description and Operation), Driveshaft (205-01 Driveshaft, Description and Operation), Rear Drive Axle and Differential (205-02, Description and Operation),

Rear Drive Axle and Differential (205-02, Description and Operation),

Rear Drive Axle and Differential (205-02, Description and Operation),

Rear Drive Halfshafts (205-05 Rear Drive Halfshafts, Description and Operation), Rear Drive Halfshafts (205-05 Rear Drive Halfshafts, Description and Operation), Rear Drive Halfshafts (205-05 Rear Drive Halfshafts, Description and Operation).

Inspection and Verification

CAUTION: Only serviceable items can be renewed or adjusted. Failure to follow this instruction may result in the warranty

of the component being rejected.

Certain driveline trouble symptoms are also common to the engine, transmission, wheel bearings, tires, and other parts of the

vehicle. For this reason, make sure that the cause of the trouble is in the driveline before adjusting, repairing, or installing any

new components. For additional information, refer to Workshop Manual section 100-04 Noise, Vibration and Harshness.

1. Verify the customer concern by carrying out a road test of the vehicle.

2. Visually inspect for obvious signs of mechanical damage and system integrity.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the concern is not visually evident, verify the symptom and refer to the Symptom Chart.

Identify the Condition

Gear Howl and Whine

Howling or whining of the ring gear and pinion is due to an incorrect gear pattern, gear damage or incorrect bearing preload.

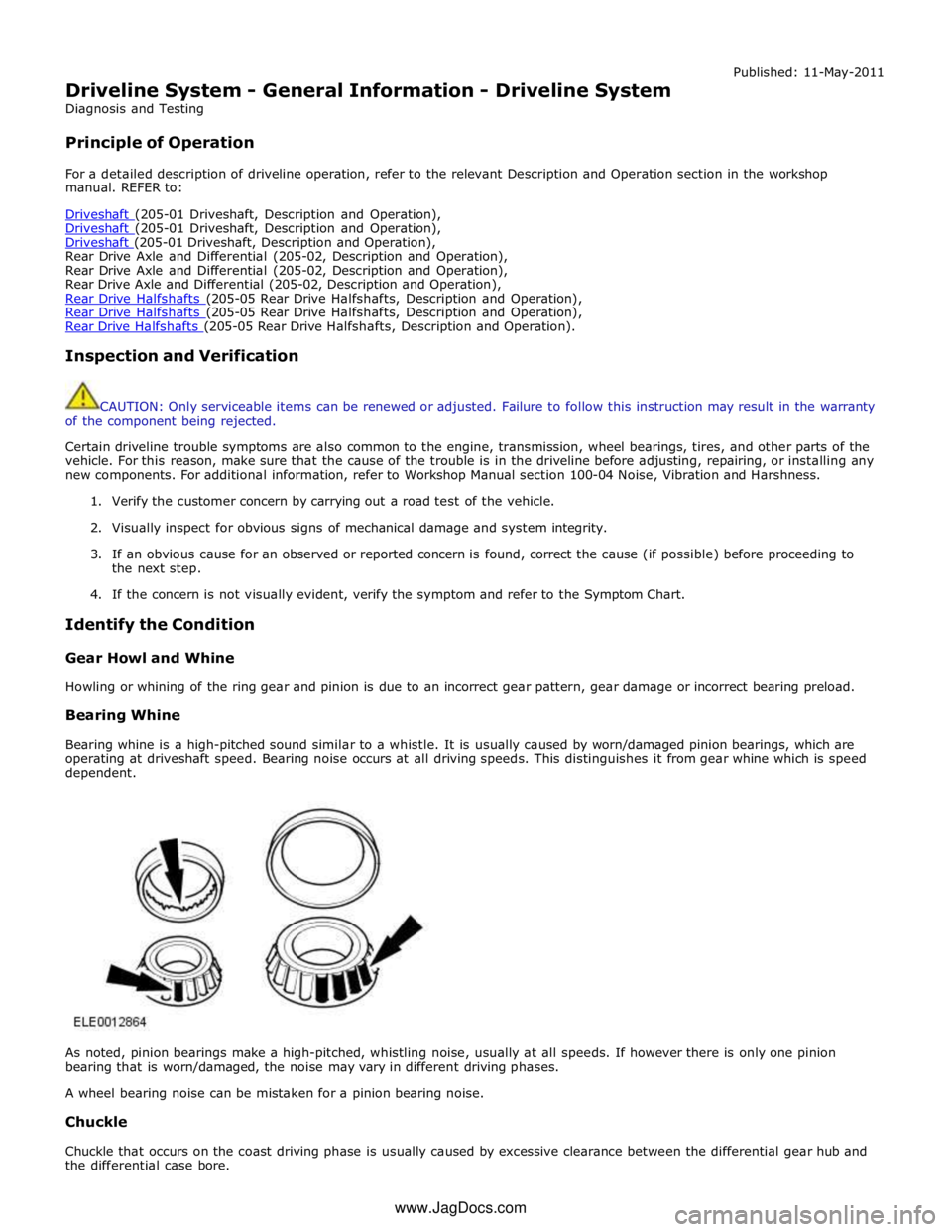

Bearing Whine

Bearing whine is a high-pitched sound similar to a whistle. It is usually caused by worn/damaged pinion bearings, which are

operating at driveshaft speed. Bearing noise occurs at all driving speeds. This distinguishes it from gear whine which is speed

dependent.

As noted, pinion bearings make a high-pitched, whistling noise, usually at all speeds. If however there is only one pinion

bearing that is worn/damaged, the noise may vary in different driving phases.

A wheel bearing noise can be mistaken for a pinion bearing noise.

Chuckle

Chuckle that occurs on the coast driving phase is usually caused by excessive clearance between the differential gear hub and

the differential case bore. www.JagDocs.com

Page 528 of 3039

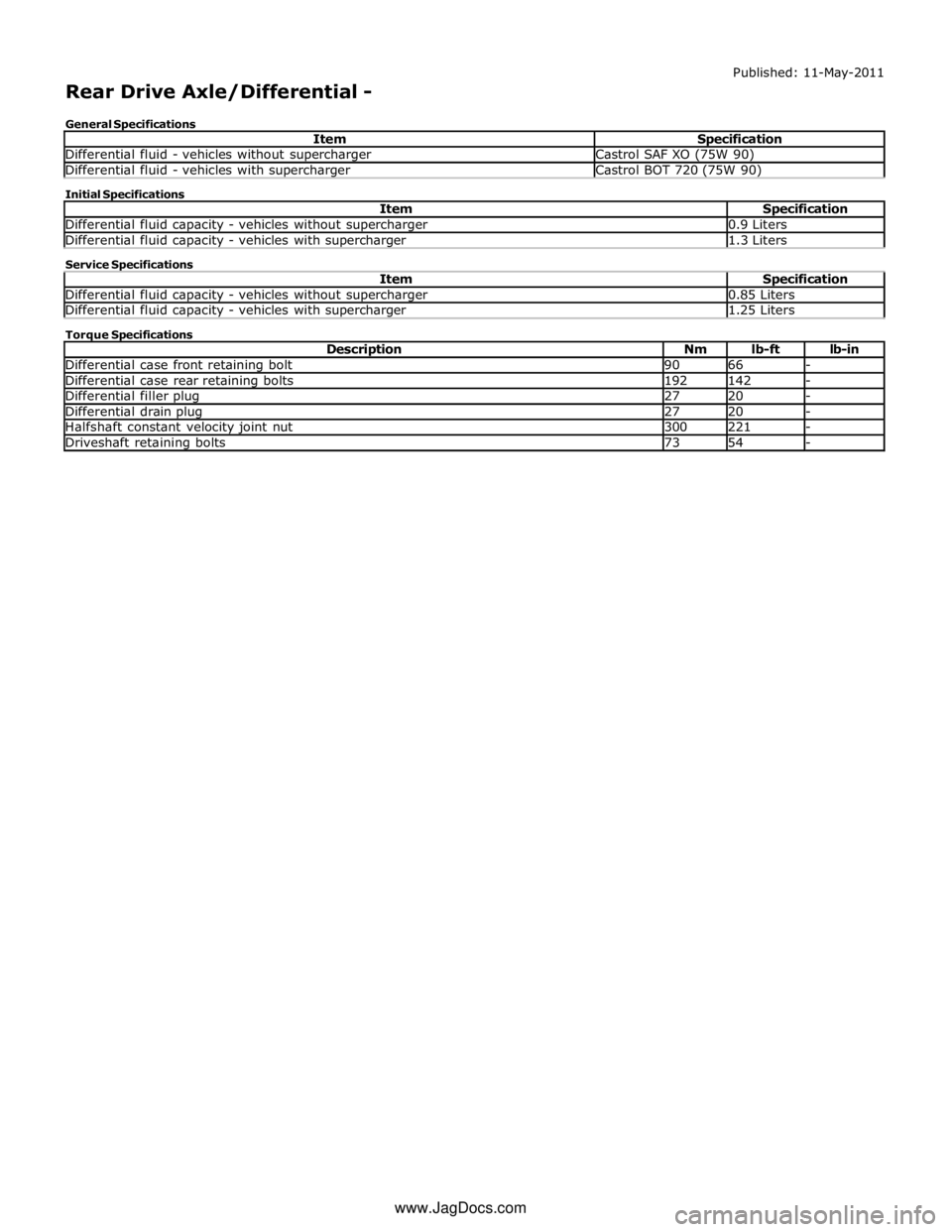

Differential fluid - vehicles without supercharger Castrol SAF XO (75W 90) Differential fluid - vehicles with supercharger Castrol BOT 720 (75W 90) Initial Specifications

Item Specification Differential fluid capacity - vehicles without supercharger 0.9 Liters Differential fluid capacity - vehicles with supercharger 1.3 Liters Service Specifications

Item Specification Differential fluid capacity - vehicles without supercharger 0.85 Liters Differential fluid capacity - vehicles with supercharger 1.25 Liters Torque Specifications

Description Nm lb-ft lb-in Differential case front retaining bolt 90 66 - Differential case rear retaining bolts 192 142 - Differential filler plug 27 20 - Differential drain plug 27 20 - Halfshaft constant velocity joint nut 300 221 - Driveshaft retaining bolts 73 54 - www.JagDocs.com

Page 633 of 3039

Published: 02-Oct-2012

Rear Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Brake

Caliper Vehicles With: High Performance Brakes

Removal and Installation

Removal

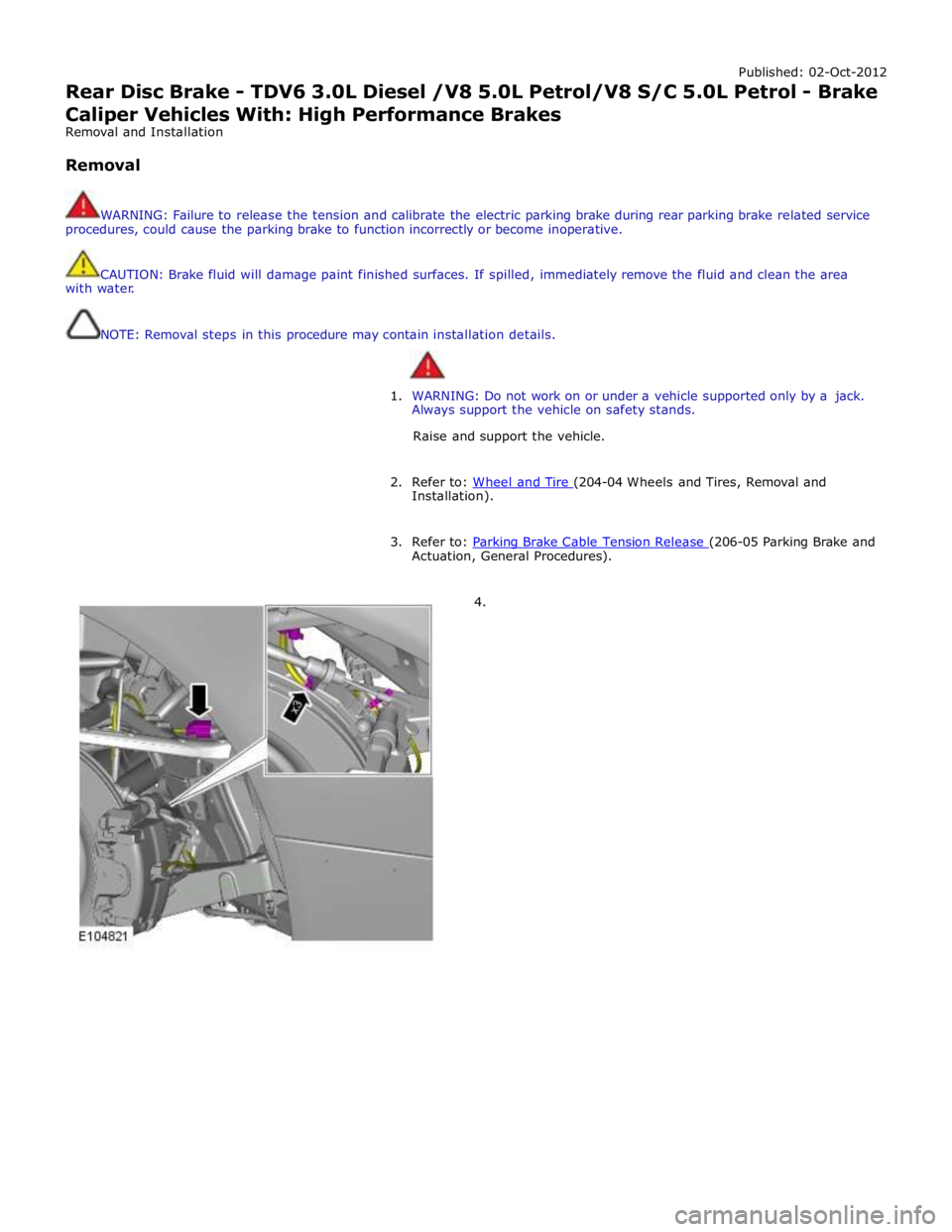

WARNING: Failure to release the tension and calibrate the electric parking brake during rear parking brake related service

procedures, could cause the parking brake to function incorrectly or become inoperative.

CAUTION: Brake fluid will damage paint finished surfaces. If spilled, immediately remove the fluid and clean the area

with water.

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

3. Refer to: Parking Brake Cable Tension Release (206-05 Parking Brake and Actuation, General Procedures).

4.

Page 638 of 3039

Published: 11-May-2011

Rear Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Brake

Pads Vehicles With: High Performance Brakes

Removal and Installation

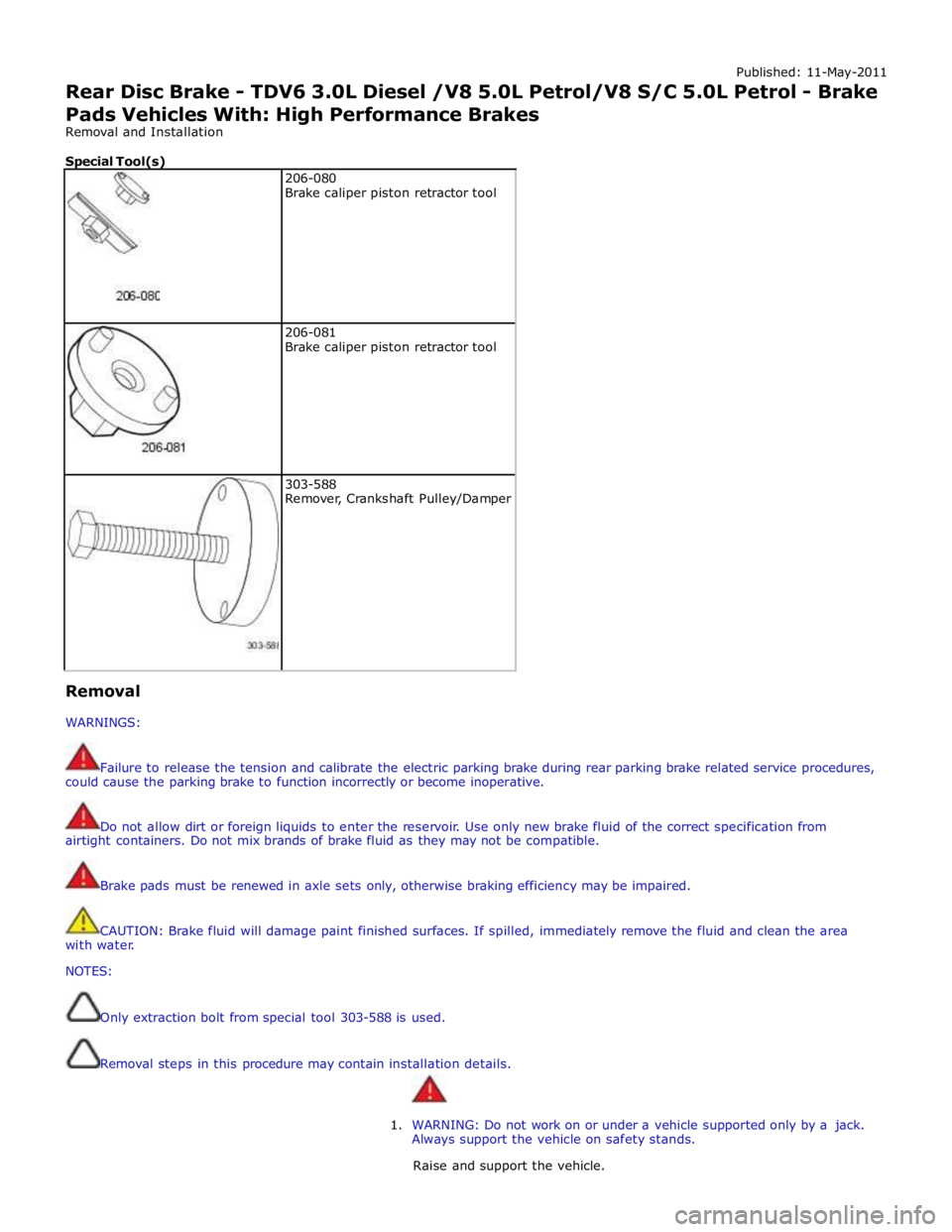

Special Tool(s)

206-080

Brake caliper piston retractor tool

206-081

Brake caliper piston retractor tool

303-588

Remover, Crankshaft Pulley/Damper Removal

WARNINGS:

Failure to release the tension and calibrate the electric parking brake during rear parking brake related service procedures,

could cause the parking brake to function incorrectly or become inoperative.

Do not allow dirt or foreign liquids to enter the reservoir. Use only new brake fluid of the correct specification from

airtight containers. Do not mix brands of brake fluid as they may not be compatible.

Brake pads must be renewed in axle sets only, otherwise braking efficiency may be impaired.

CAUTION: Brake fluid will damage paint finished surfaces. If spilled, immediately remove the fluid and clean the area

with water.

NOTES:

Only extraction bolt from special tool 303-588 is used.

Removal steps in this procedure may contain installation details.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

Page 653 of 3039

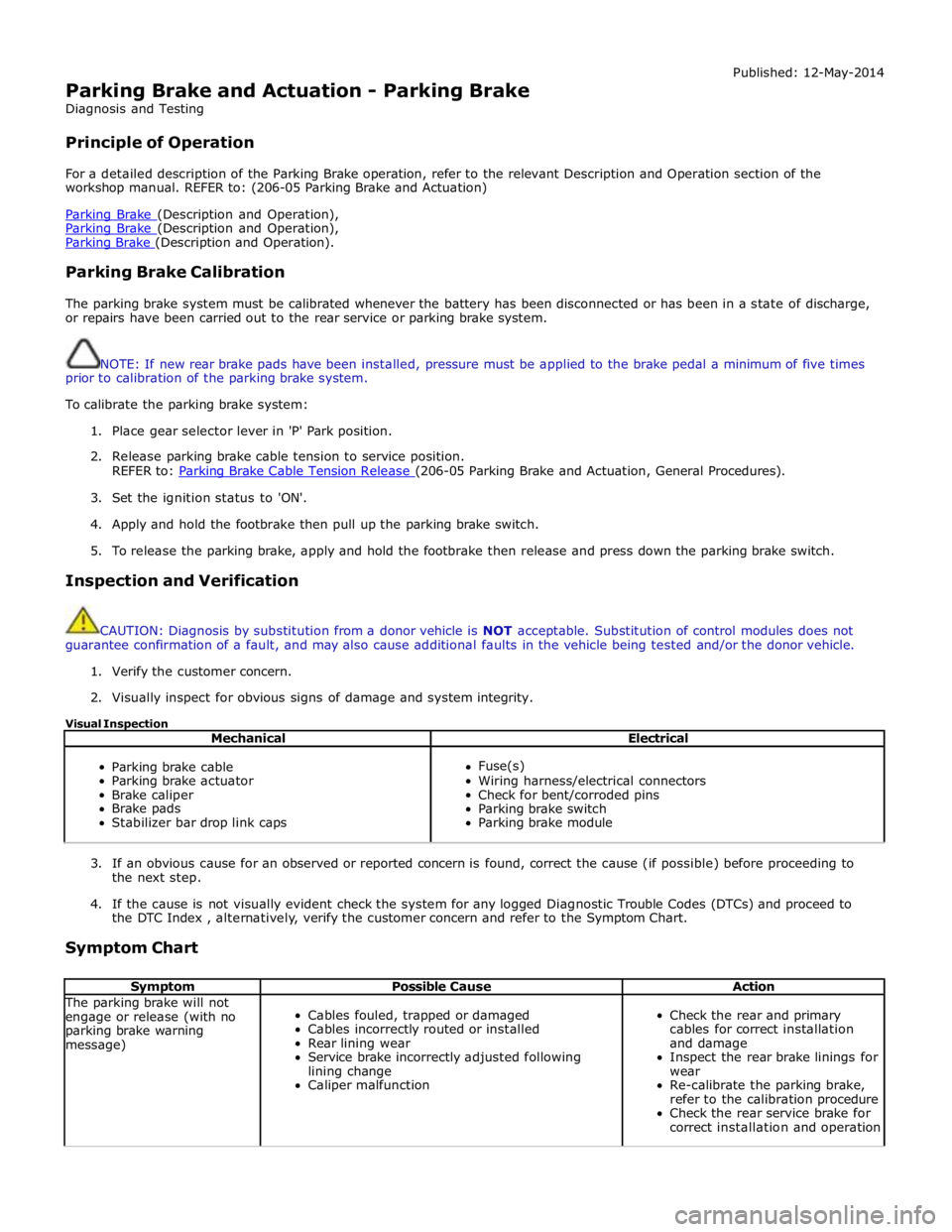

Parking Brake and Actuation - Parking Brake

Diagnosis and Testing

Principle of Operation Published: 12-May-2014

For a detailed description of the Parking Brake operation, refer to the relevant Description and Operation section of the

workshop manual. REFER to: (206-05 Parking Brake and Actuation)

Parking Brake (Description and Operation), Parking Brake (Description and Operation), Parking Brake (Description and Operation).

Parking Brake Calibration

The parking brake system must be calibrated whenever the battery has been disconnected or has been in a state of discharge,

or repairs have been carried out to the rear service or parking brake system.

NOTE: If new rear brake pads have been installed, pressure must be applied to the brake pedal a minimum of five times

prior to calibration of the parking brake system.

To calibrate the parking brake system:

1. Place gear selector lever in 'P' Park position.

2. Release parking brake cable tension to service position.

REFER to: Parking Brake Cable Tension Release (206-05 Parking Brake and Actuation, General Procedures).

3. Set the ignition status to 'ON'.

4. Apply and hold the footbrake then pull up the parking brake switch.

5. To release the parking brake, apply and hold the footbrake then release and press down the parking brake switch.

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Parking brake cable

Parking brake actuator

Brake caliper

Brake pads

Stabilizer bar drop link caps

Fuse(s)

Wiring harness/electrical connectors

Check for bent/corroded pins

Parking brake switch

Parking brake module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check the system for any logged Diagnostic Trouble Codes (DTCs) and proceed to

the DTC Index , alternatively, verify the customer concern and refer to the Symptom Chart.

Symptom Chart

Symptom Possible Cause Action The parking brake will not

engage or release (with no

parking brake warning

message)

Cables fouled, trapped or damaged

Cables incorrectly routed or installed

Rear lining wear

Service brake incorrectly adjusted following

lining change

Caliper malfunction

Check the rear and primary

cables for correct installation

and damage

Inspect the rear brake linings for

wear

Re-calibrate the parking brake,

refer to the calibration procedure

Check the rear service brake for

correct installation and operation

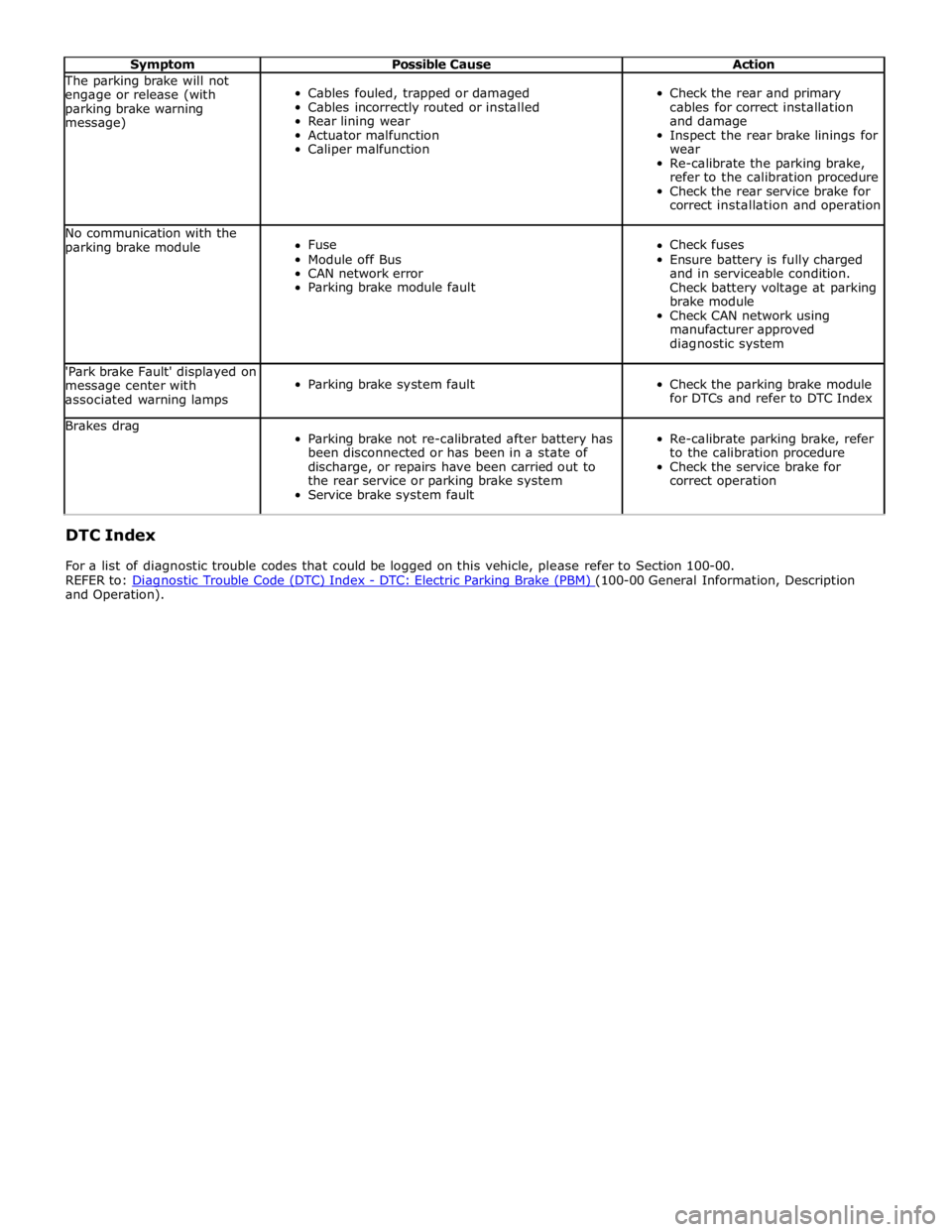

Page 654 of 3039

Symptom Possible Cause Action The parking brake will not

engage or release (with

parking brake warning

message)

Cables fouled, trapped or damaged

Cables incorrectly routed or installed

Rear lining wear

Actuator malfunction

Caliper malfunction

Check the rear and primary

cables for correct installation

and damage

Inspect the rear brake linings for

wear

Re-calibrate the parking brake,

refer to the calibration procedure

Check the rear service brake for

correct installation and operation No communication with the

parking brake module

Fuse

Module off Bus

CAN network error

Parking brake module fault

Check fuses

Ensure battery is fully charged

and in serviceable condition.

Check battery voltage at parking

brake module

Check CAN network using

manufacturer approved

diagnostic system 'Park brake Fault' displayed on

message center with

associated warning lamps

Parking brake system fault

Check the parking brake module

for DTCs and refer to DTC Index Brakes drag

Parking brake not re-calibrated after battery has

been disconnected or has been in a state of

discharge, or repairs have been carried out to

the rear service or parking brake system

Service brake system fault

Re-calibrate parking brake, refer

to the calibration procedure

Check the service brake for

correct operation DTC Index

For a list of diagnostic trouble codes that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Electric Parking Brake (PBM) (100-00 General Information, Description and Operation).