JAGUAR XFR 2010 1.G Owner's Manual

XFR 2010 1.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7642/w960_7642-0.png

JAGUAR XFR 2010 1.G Owner's Manual

Page 373 of 3039

Published: 11-May-2011

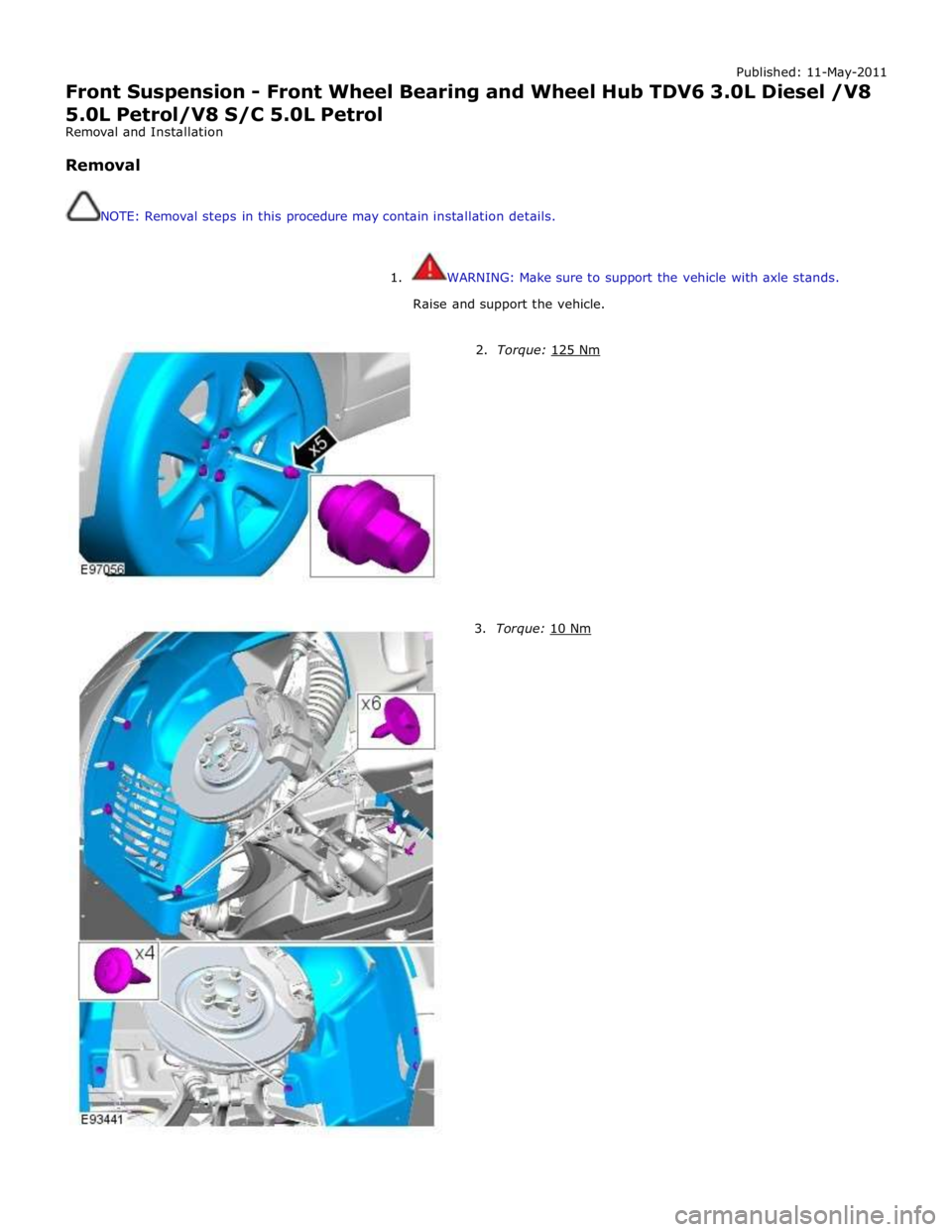

Front Suspension - Front Wheel Bearing and Wheel Hub TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Torque: 125 Nm 3. Torque: 10 Nm

Page 374 of 3039

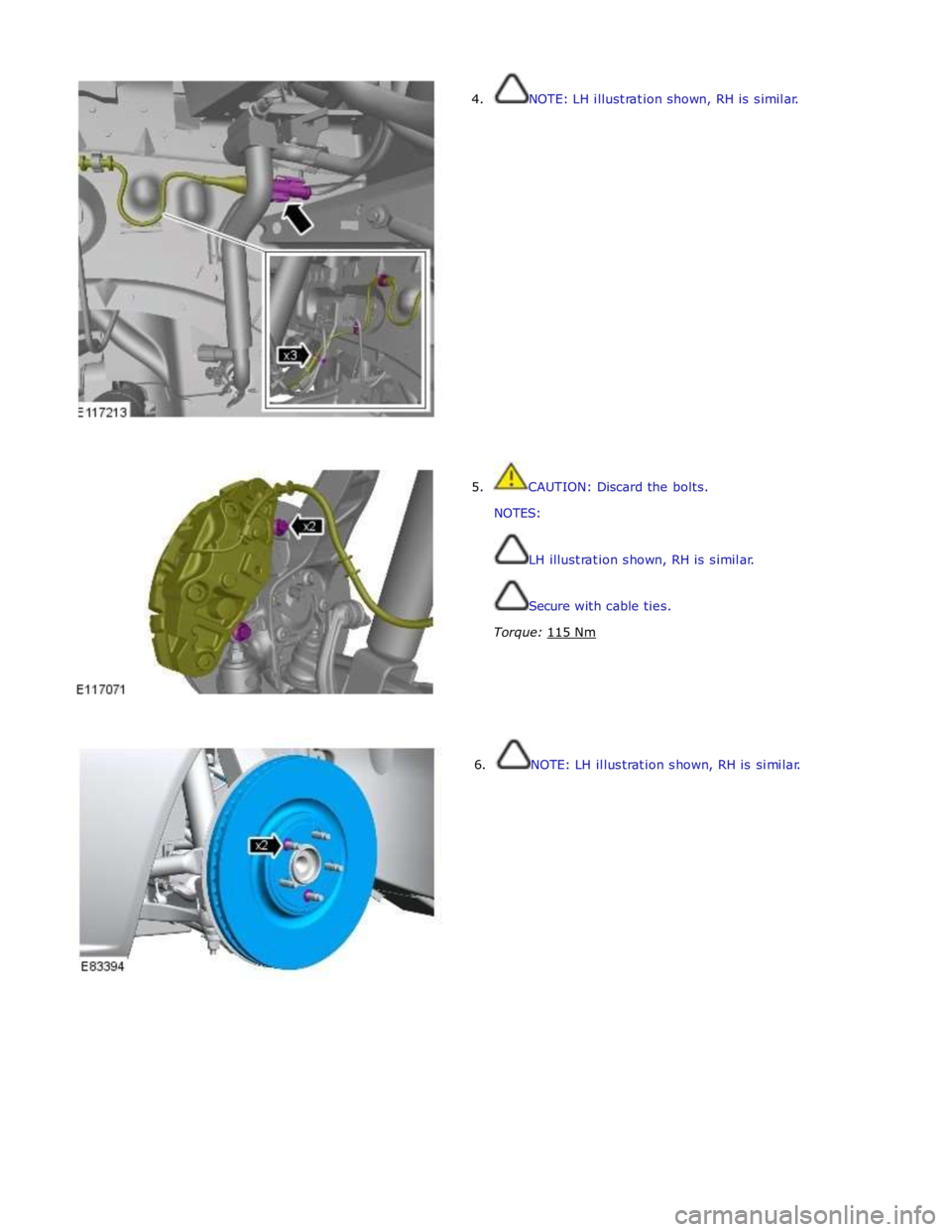

4. NOTE: LH illustration shown, RH is similar.

5. CAUTION: Discard the bolts.

NOTES:

LH illustration shown, RH is similar.

Secure with cable ties.

Torque: 115 Nm

6. NOTE: LH illustration shown, RH is similar.

Page 375 of 3039

7. CAUTIONS:

Discard the bolts.

Make sure that the area around the component is

clean and free of foreign material.

Do not attempt to release the wheel hub by hitting it

with a hammer directly, loosen the wheel hub retaining

bolts partially before applying an even amount of force to

the head of each bolts to release the wheel hub from the

wheel knuckle. Failure to follow this instruction may cause

damage to the component.

NOTES:

Some variation in the illustrations may occur, but the

essential information is always correct.

LH illustration shown, RH is similar.

Install the components to their original fitted

positions.

Torque: 90 Nm

Installation

1. To install, reverse the removal procedure. www.JagDocs.com

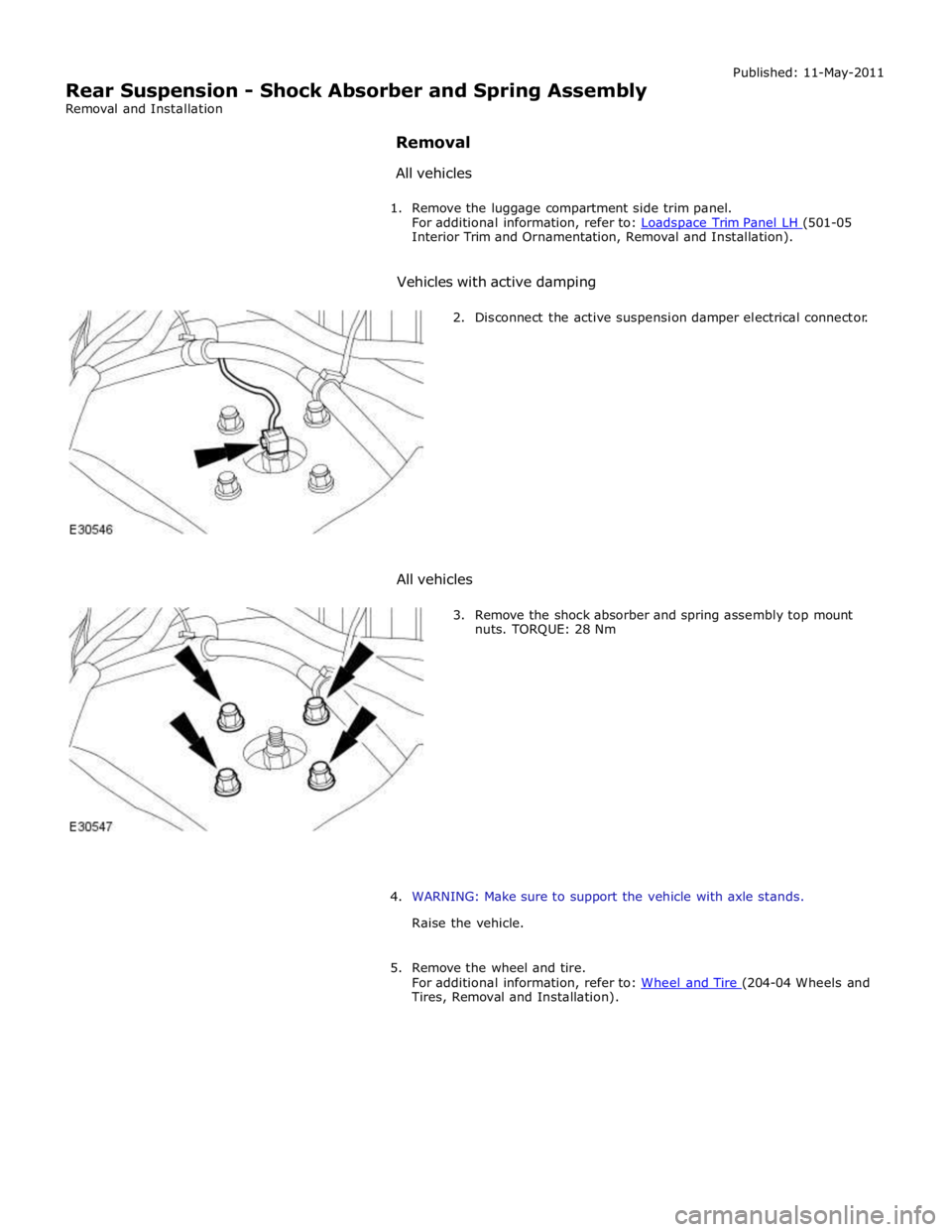

Page 403 of 3039

Interior Trim and Ornamentation, Removal and Installation).

Vehicles with active damping

2. Disconnect the active suspension damper electrical connector.

All vehicles

3. Remove the shock absorber and spring assembly top mount

nuts. TORQUE: 28 Nm

4. WARNING: Make sure to support the vehicle with axle stands.

Raise the vehicle.

5. Remove the wheel and tire.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

Page 404 of 3039

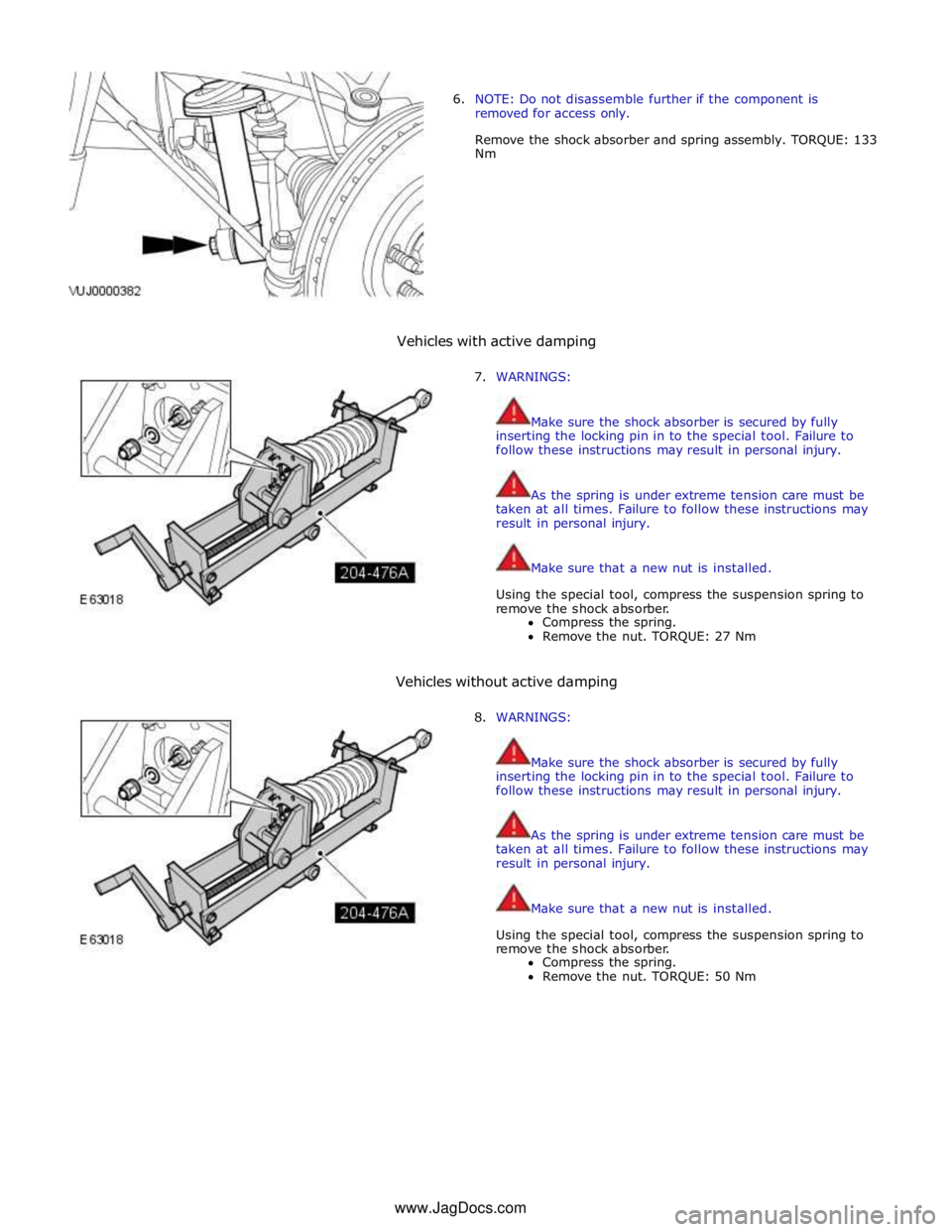

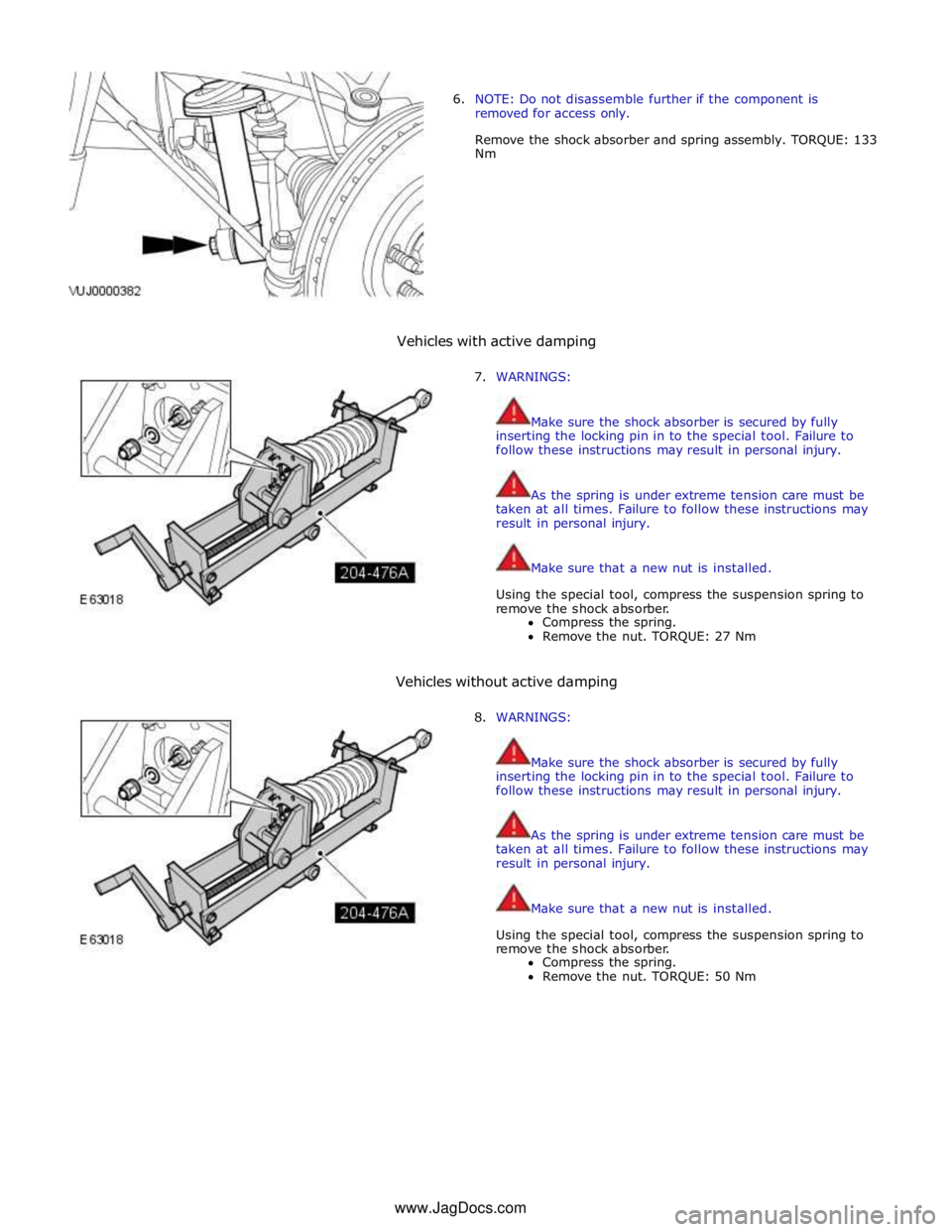

6. NOTE: Do not disassemble further if the component is

removed for access only.

Remove the shock absorber and spring assembly. TORQUE: 133

Nm

Vehicles with active damping

7. WARNINGS:

Make sure the shock absorber is secured by fully

inserting the locking pin in to the special tool. Failure to

follow these instructions may result in personal injury.

As the spring is under extreme tension care must be

taken at all times. Failure to follow these instructions may

result in personal injury.

Make sure that a new nut is installed.

Using the special tool, compress the suspension spring to

remove the shock absorber.

Compress the spring.

Remove the nut. TORQUE: 27 Nm

Vehicles without active damping

8. WARNINGS:

Make sure the shock absorber is secured by fully

inserting the locking pin in to the special tool. Failure to

follow these instructions may result in personal injury.

As the spring is under extreme tension care must be

taken at all times. Failure to follow these instructions may

result in personal injury.

Make sure that a new nut is installed.

Using the special tool, compress the suspension spring to

remove the shock absorber.

Compress the spring.

Remove the nut. TORQUE: 50 Nm

www.JagDocs.com

Page 428 of 3039

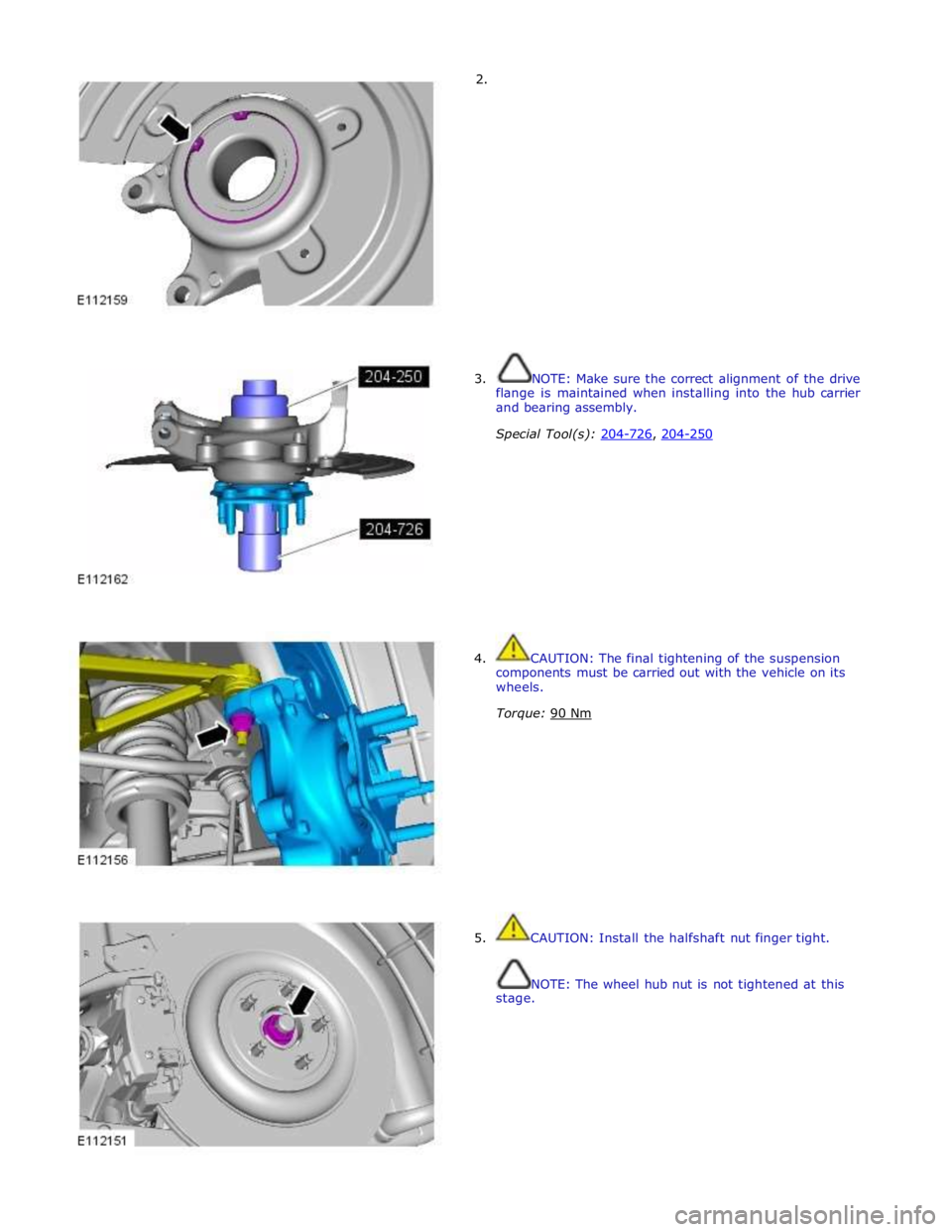

2.

3. NOTE: Make sure the correct alignment of the drive

flange is maintained when installing into the hub carrier

and bearing assembly.

Special Tool(s): 204-726, 204-250

4. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 90 Nm

5. CAUTION: Install the halfshaft nut finger tight.

NOTE: The wheel hub nut is not tightened at this

stage.

Page 429 of 3039

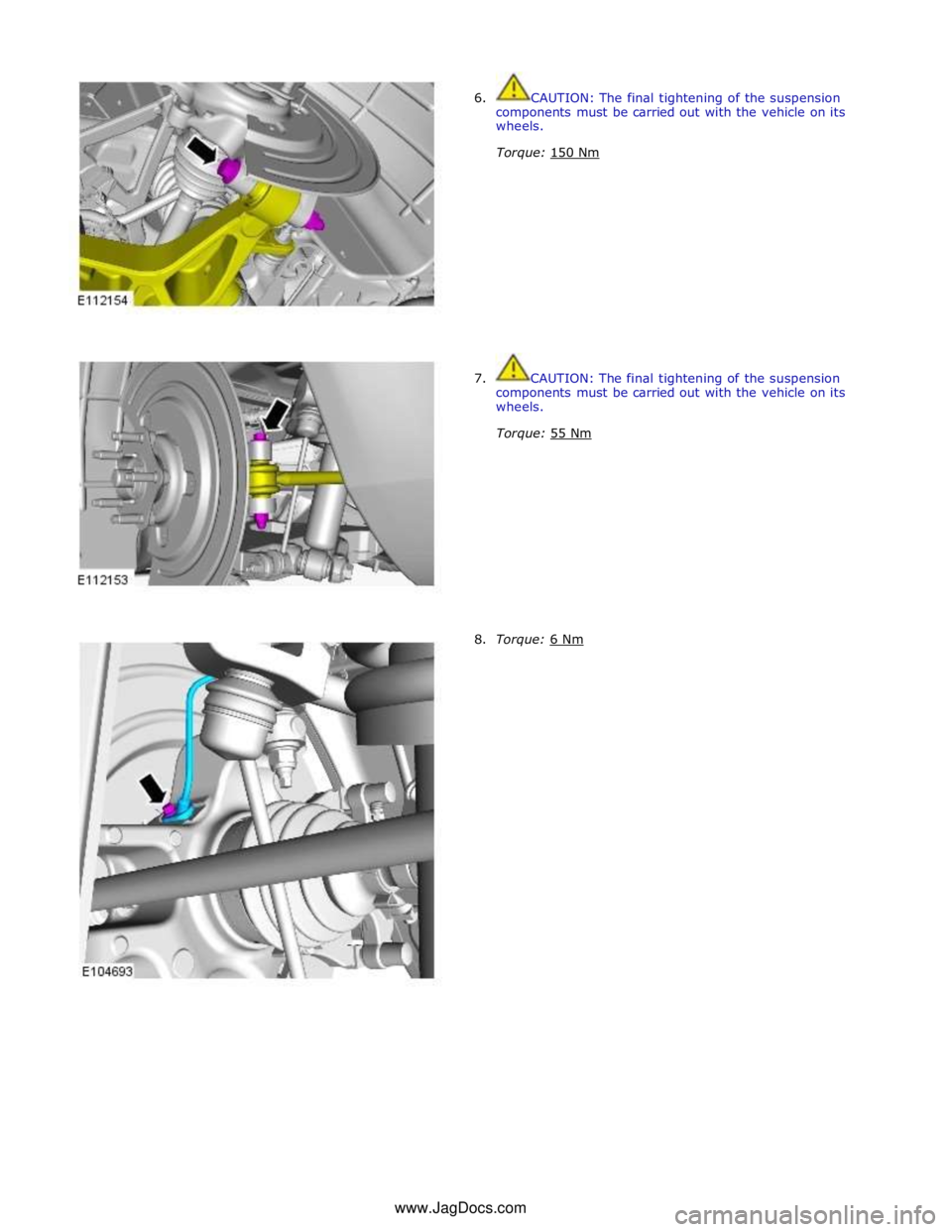

6. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 150 Nm

7. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 55 Nm

8. Torque: 6 Nm www.JagDocs.com

Page 430 of 3039

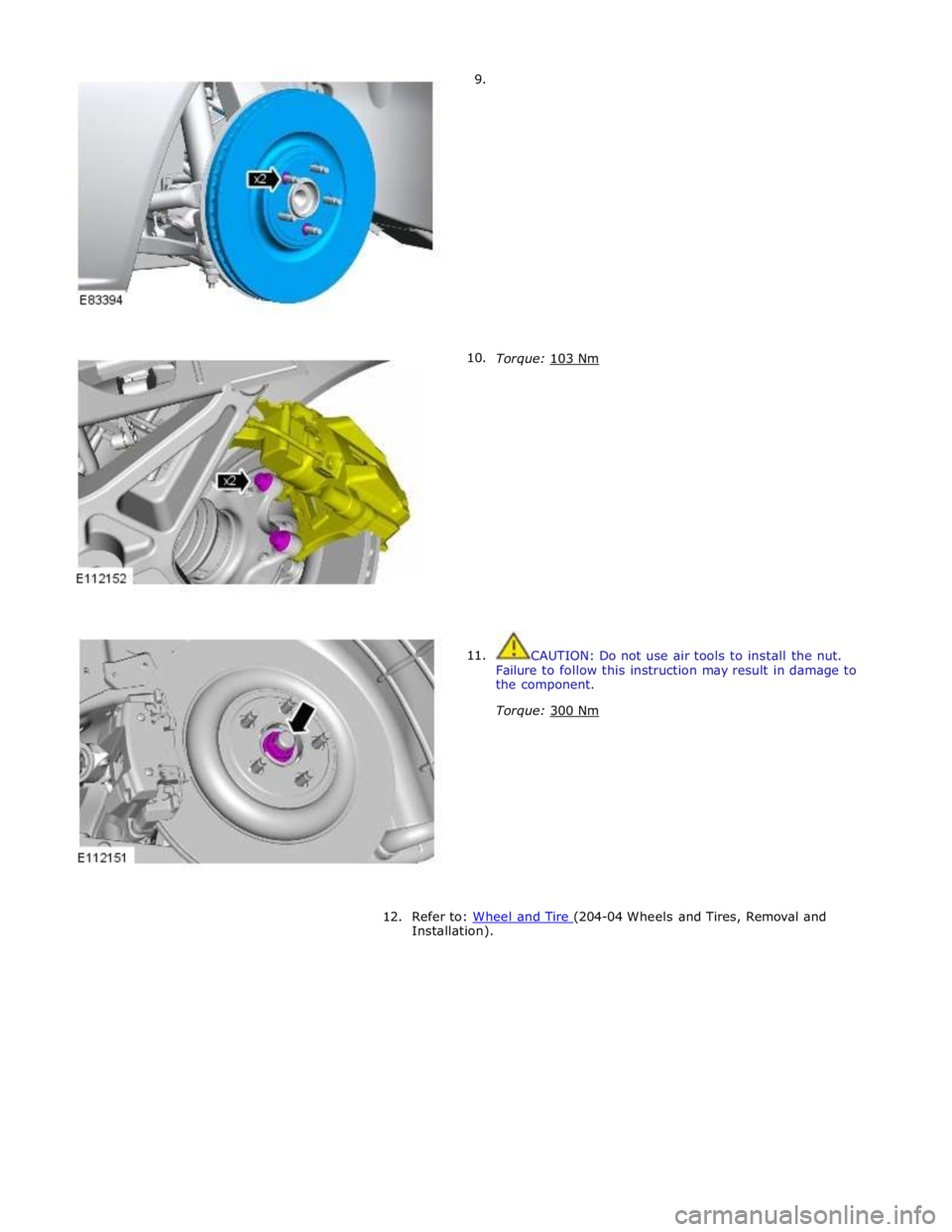

9.

10.

11.

Torque: 103 Nm

CAUTION: Do not use air tools to install the nut.

Failure to follow this instruction may result in damage to

the component.

Torque: 300 Nm

12. Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

Page 432 of 3039

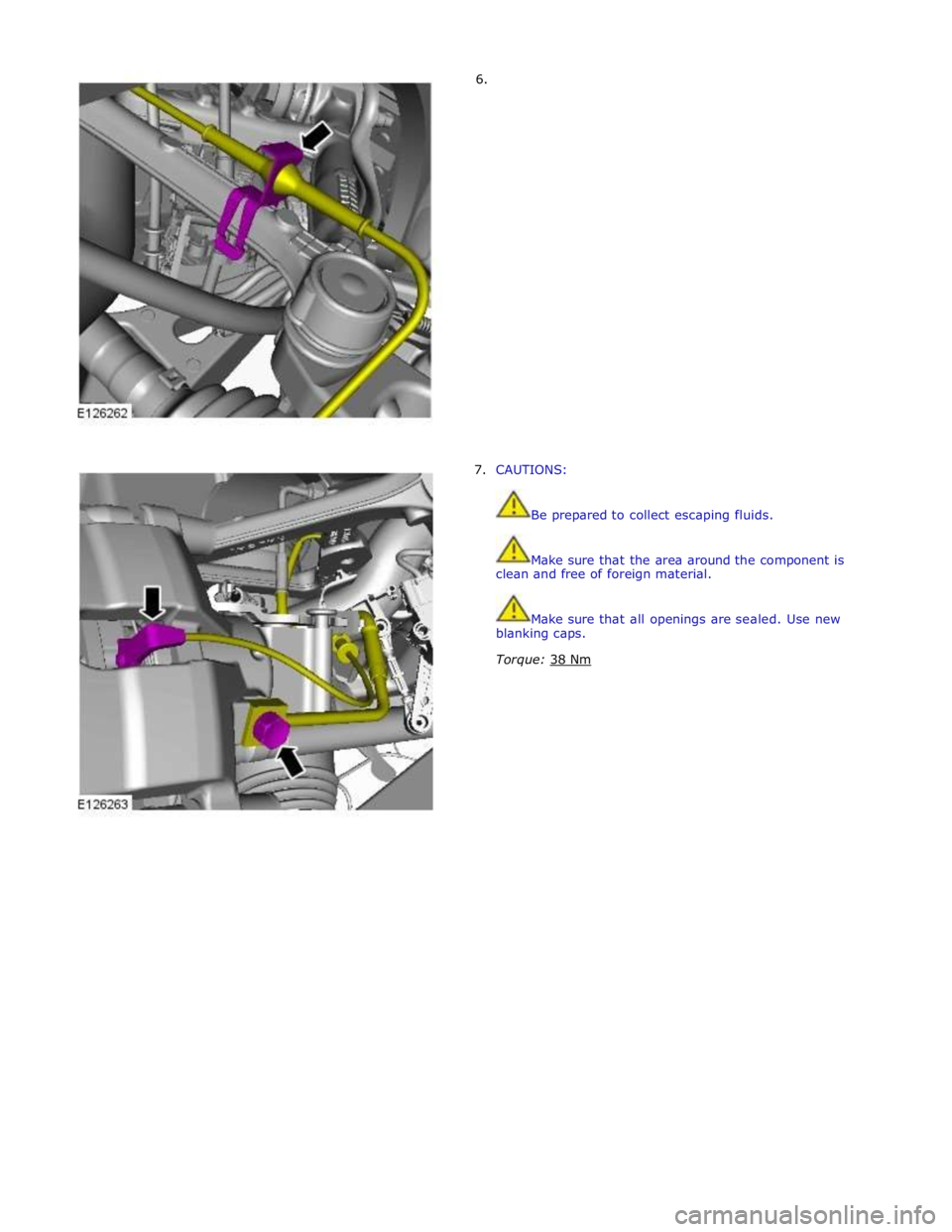

6.

7. CAUTIONS:

Be prepared to collect escaping fluids.

Make sure that the area around the component is

clean and free of foreign material.

Make sure that all openings are sealed. Use new

blanking caps.

Torque: 38 Nm

Page 433 of 3039

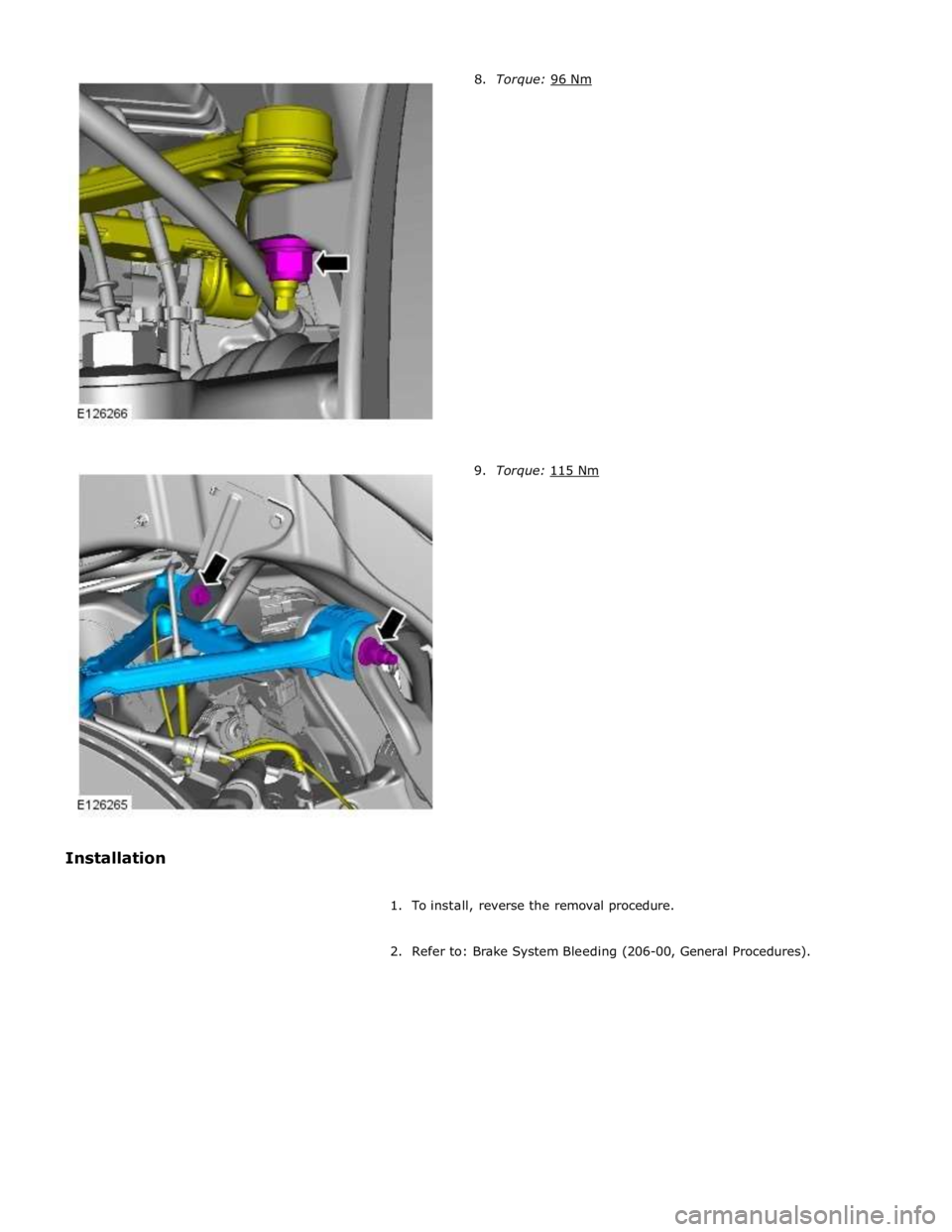

9. Torque: 115 Nm

1. To install, reverse the removal procedure.

2. Refer to: Brake System Bleeding (206-00, General Procedures).