warning JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2435 of 3039

Published: 11-May-2011

Glass, Frames and Mechanisms - Rear Door Window Regulator and Motor

Removal and Installation

Removal

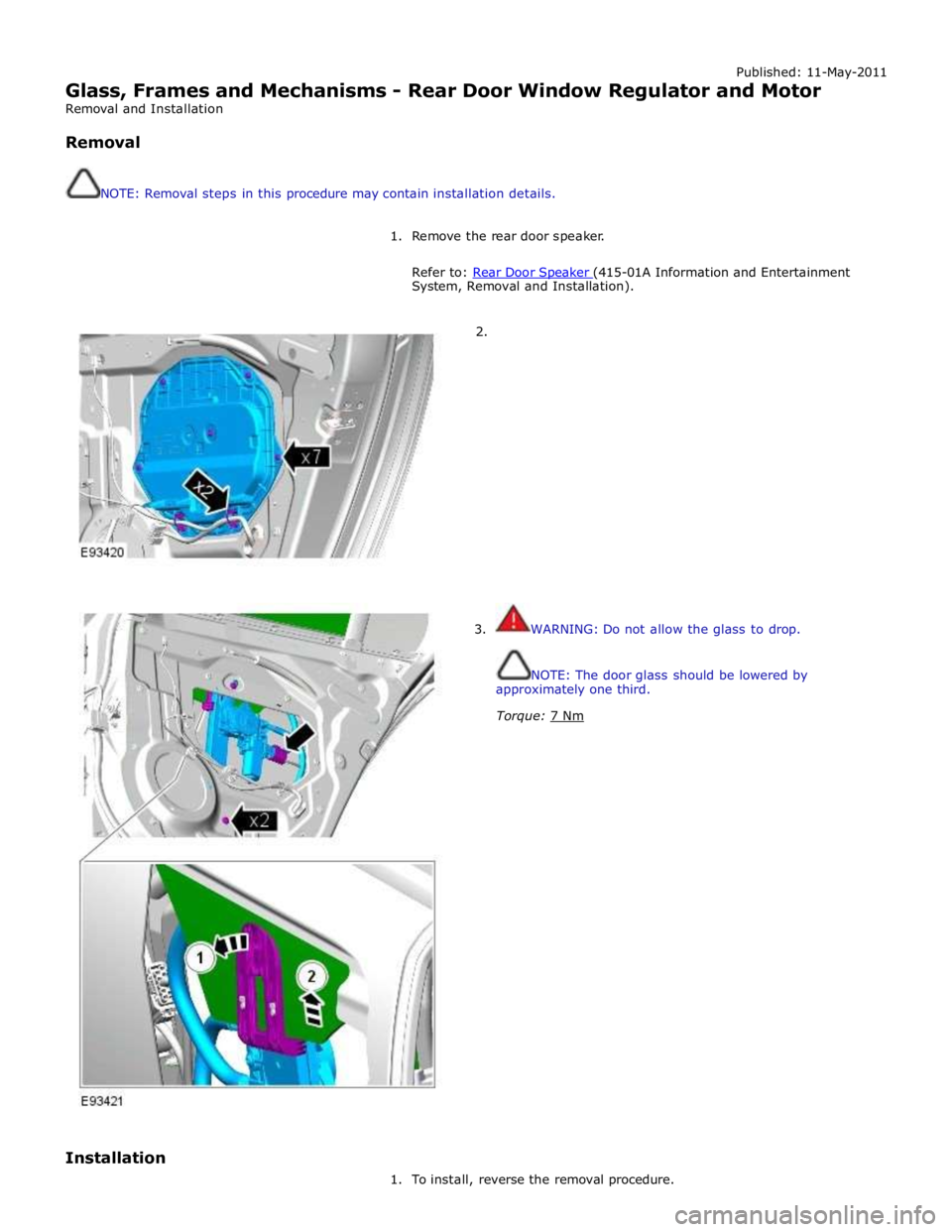

NOTE: Removal steps in this procedure may contain installation details.

1. Remove the rear door speaker.

Refer to: Rear Door Speaker (415-01A Information and Entertainment System, Removal and Installation).

2.

3. WARNING: Do not allow the glass to drop.

NOTE: The door glass should be lowered by

approximately one third.

Torque: 7 Nm

Installation

1. To install, reverse the removal procedure.

Page 2437 of 3039

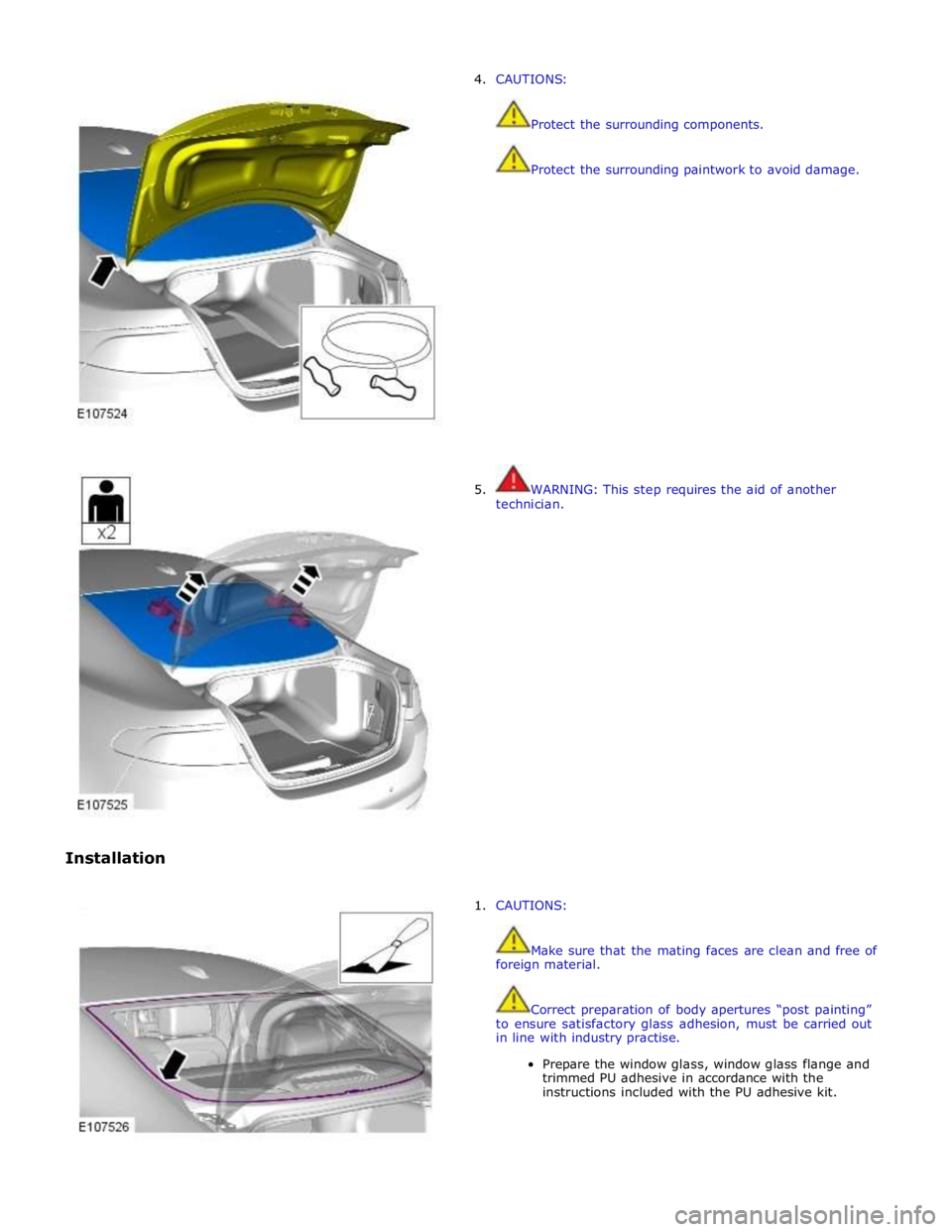

Installation 4. CAUTIONS:

Protect the surrounding components.

Protect the surrounding paintwork to avoid damage.

5. WARNING: This step requires the aid of another

technician.

1. CAUTIONS:

Make sure that the mating faces are clean and free of

foreign material.

Correct preparation of body apertures “post painting”

to ensure satisfactory glass adhesion, must be carried out

in line with industry practise.

Prepare the window glass, window glass flange and

trimmed PU adhesive in accordance with the

instructions included with the PU adhesive kit.

Page 2441 of 3039

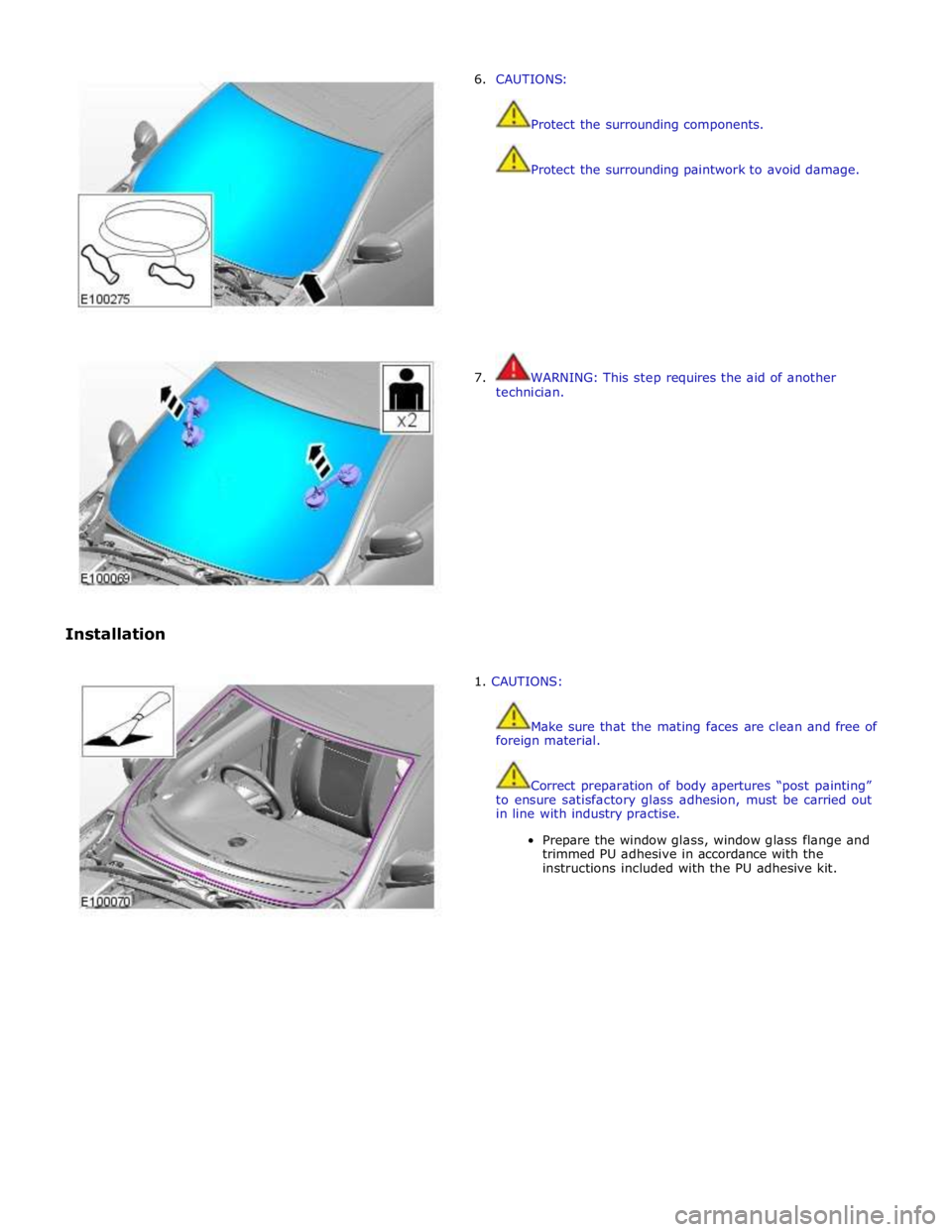

Installation 6. CAUTIONS:

Protect the surrounding components.

Protect the surrounding paintwork to avoid damage.

7. WARNING: This step requires the aid of another

technician.

1. CAUTIONS:

Make sure that the mating faces are clean and free of

foreign material.

Correct preparation of body apertures “post painting”

to ensure satisfactory glass adhesion, must be carried out

in line with industry practise.

Prepare the window glass, window glass flange and

trimmed PU adhesive in accordance with the

instructions included with the PU adhesive kit.

Page 2442 of 3039

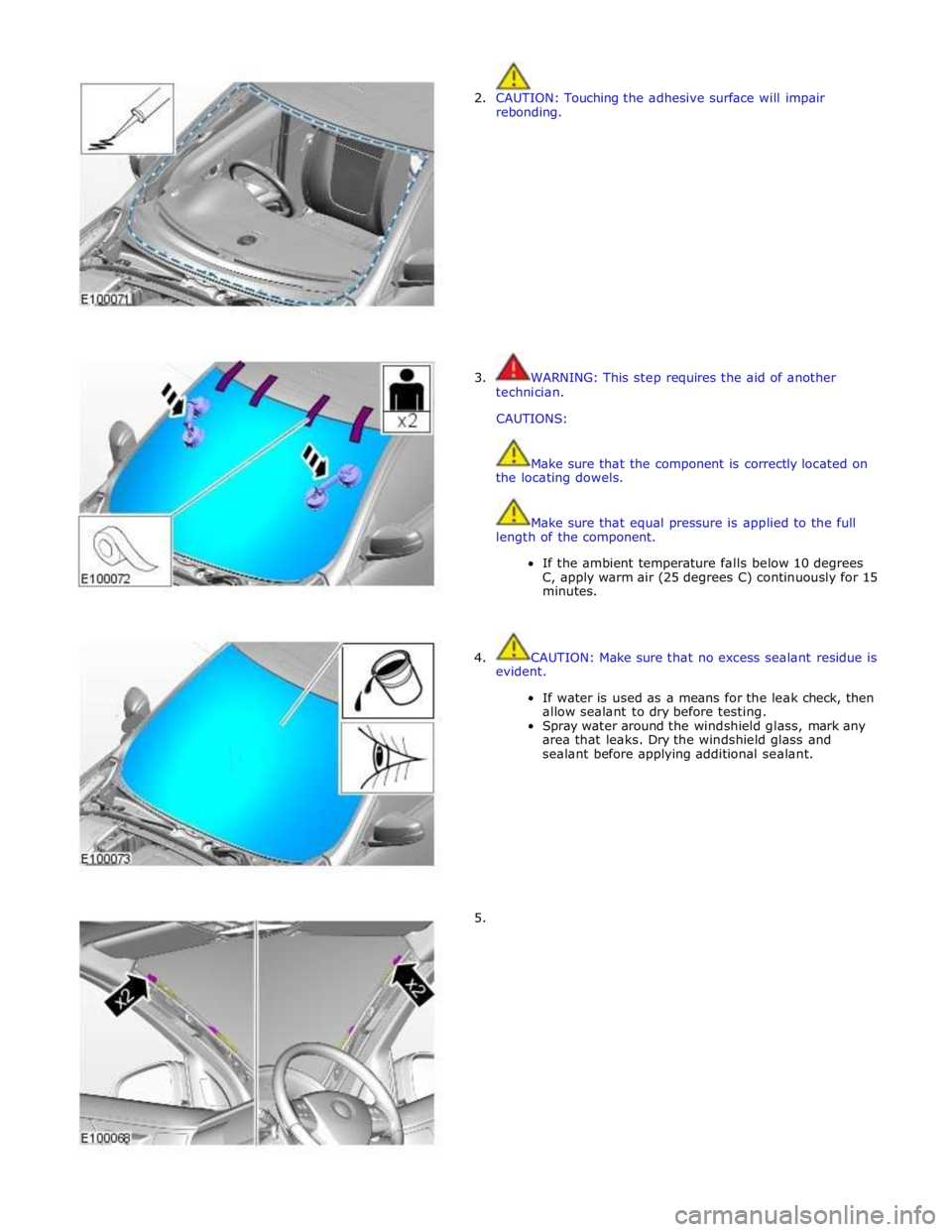

2. CAUTION: Touching the adhesive surface will impair

rebonding.

3. WARNING: This step requires the aid of another

technician.

CAUTIONS:

Make sure that the component is correctly located on

the locating dowels.

Make sure that equal pressure is applied to the full

length of the component.

If the ambient temperature falls below 10 degrees

C, apply warm air (25 degrees C) continuously for 15

minutes.

4. CAUTION: Make sure that no excess sealant residue is

evident.

If water is used as a means for the leak check, then

allow sealant to dry before testing.

Spray water around the windshield glass, mark any

area that leaks. Dry the windshield glass and

sealant before applying additional sealant.

5.

Page 2469 of 3039

Instrument Panel and Console - Instrument Panel Console

Removal and Installation Published: 11-May-2011

Removal

CAUTIONS:

Inspect the seals, replace if damaged.

Inspect the O-rings, replace if damaged.

NOTE: Removal steps in this procedure may contain installation details.

All vehicles

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

Vehicles with supercharger

3. Refer to: Cooling System Draining, Filling and Bleeding - V8 S/C 5.0L Petrol (303-03C Engine Cooling - V8 5.0L Petrol/V8 S/C 5.0L Petrol, General Procedures).

Vehicles without supercharger

4. Refer to: Cooling System Draining, Filling and Bleeding - V8 5.0L Petrol (303-03C Engine Cooling - V8 5.0L Petrol/V8 S/C 5.0L Petrol, General

Procedures).

Vehicles with diesel engine

5. Refer to: Cooling System Draining, Filling and Bleeding (303-03A Engine Cooling - TDV6 3.0L Diesel, General Procedures).

All vehicles

6. Refer to: Air Conditioning (A/C) System Recovery, Evacuation and Charging (412-00 Climate Control System - General Information, General Procedures).

7. Refer to: Secondary Bulkhead Center Panel (501-02 Front End Body Panels, Removal and Installation). 303-1496

Heater Hose Removal Tool Special Tool(s)

www.JagDocs.com

Page 2537 of 3039

7 Windshield washer pump 8 Wiper/Washer switch - RH (right-hand) steering column multifunction switch 9 Instrument cluster 10 CJB (central junction box) 11 BJB (battery junction box)

WINDSHIELD WIPERS System Operation

Operation of the wipers and washers is controlled by the CJB in response to driver inputs from the wiper control switch and signals from the rain/light sensor. The instrument cluster monitors the condition of the wiper/washer control switch and

transmits driver requests to the CJB over the medium speed CAN bus.

The wiper control switch is connected via hardwired connections to the instrument cluster. The instrument cluster outputs on 4

wires a reference voltage to the wash/wipe switch, the auto wiper switch, the wiper switch and the flick wipe switch. All the

switches are connected to the instrument cluster on a common ground. Each switch function is connected to ground via a

resistor or series of resistors and the instrument cluster monitors the ground signal and determines which function has been

selected. The instrument cluster then outputs the appropriate message on the medium speed CAN bus to the CJB which responds to the requested wiper function. The CJB then activates the appropriate function either directly or via relays in the EJB for the wipers and headlamp powerwashers. Speed Dependent Mode

When the wipers are operating, a vehicle speed signal received by the CJB on the high speed CAN bus is used to operate a speed dependent mode. If the wipers are in fast wipe and the vehicle speed decreases to below 2 km/h (1.2 mph), the wipers

will reduce to the normal wipe speed. When the vehicle speed increases to above 8 km/h (5 mph) the fast wiper speed

selection is restored. If slow speed is selected and the vehicle speed drops below 2km/h (1.2 mph), the wipers will operate in

the intermittent mode. When the vehicle speed increases to above 8 km/h (5 mph) the slow wiper speed selection is restored

– this feature is configurable by the dealer using the approved Jaguar diagnostic system.

Wiper Motor

The wiper motor is controlled by the CJB. The CJB is connected to a wiper motor normal/fast relay in the EJB on 2 wires. The CJB is also connected to a wiper run/park relay, also located in the EJB.

Driver requests are received by the CJB which energizes the wiper motor normal/fast relay in the appropriate mode (normal or fast wipe) and also energizes the run/park relay in the run mode by providing a ground for the relay coils. When wiper

operation is deselected by the driver, the CJB monitors a park switch which is integral with the wiper motor. On receipt of a signal from the park switch, the CJB de-energises the run/park relay, removing the power supply through the normal/fast relay, stopping the wipers in the park position on the windshield.

The wiper motor is a DC (direct current) motor which drives a gear wheel via a worm drive attached to the motor spindle. The

motor has 3 sets of brushes with one brush connected to ground. When the normal/fast relay is energized in the normal

position, a power feed is supplied to the brush directly opposite the ground brush and operates the motor at slow speed.

When the relay is energized in the fast position, a power feed is connected to the second motor brush, which is offset from the

ground brush and operates the motor at the fast speed. With power supplied through the offset brush, the current flows

through fewer motor coil windings. This results in a lower resistance to current flow to the ground brush and produces a higher

motor rotational speed.

WINDSHIELD WASHERS

The windshield washers are controlled by the CJB. A driver request for washer operation, via the wiper control switch, is passed to the instrument cluster on the LIN bus. The instrument cluster passes the message to the CJB on the medium speed CAN bus.

The CJB energizes the windshield washer pump during the up stroke of the first 2 wash/wipe cycles. This ensures that wiper fluid is pushed to the sides of the windshield and eliminates the trail of fluid which can occur if the fluid is pushed to the

bottom of the windshield. The wipers will continue for 3 more cycles, followed after a delay of 4 seconds, by a single dry wipe.

NOTE: The dry wipe feature is configurable using an approved Jaguar diagnostic system.

The operation of the washer pump on the wiper up stroke only is configurable using an approved Jaguar diagnostic system.

The washer button can be pressed and held and the wipers will operate continuously for up to 10 seconds. After this period

when the button is released, the wipers will continue for 3 more cycles, followed after a delay, by a single dry wipe. After this

period washing will be inhibited, the wipers will continue for 3 more cycles, followed after a delay, by a single dry wipe.

Reactivating the switch will recommence the wash/wipe cycle.

RESERVOIR LEVEL SWITCH

The level switch is connected directly to the CJB. The switch is operated by a float which closes contacts within the switch when the fluid level falls to below the switch level. When the contacts are closed a ground path is completed from the CJB through the switch. This is sensed by the CJB which issues a message to the instrument cluster which displays a low fluid level warning.

Page 2571 of 3039

6. WARNING: This step requires the aid of another

technician.

NOTE: Note the fitted position of the spacers.

Torque: 8 Nm

7. NOTE: Do not disassemble further if the component is

removed for access only.

Torque: 4 Nm

8.

Page 2580 of 3039

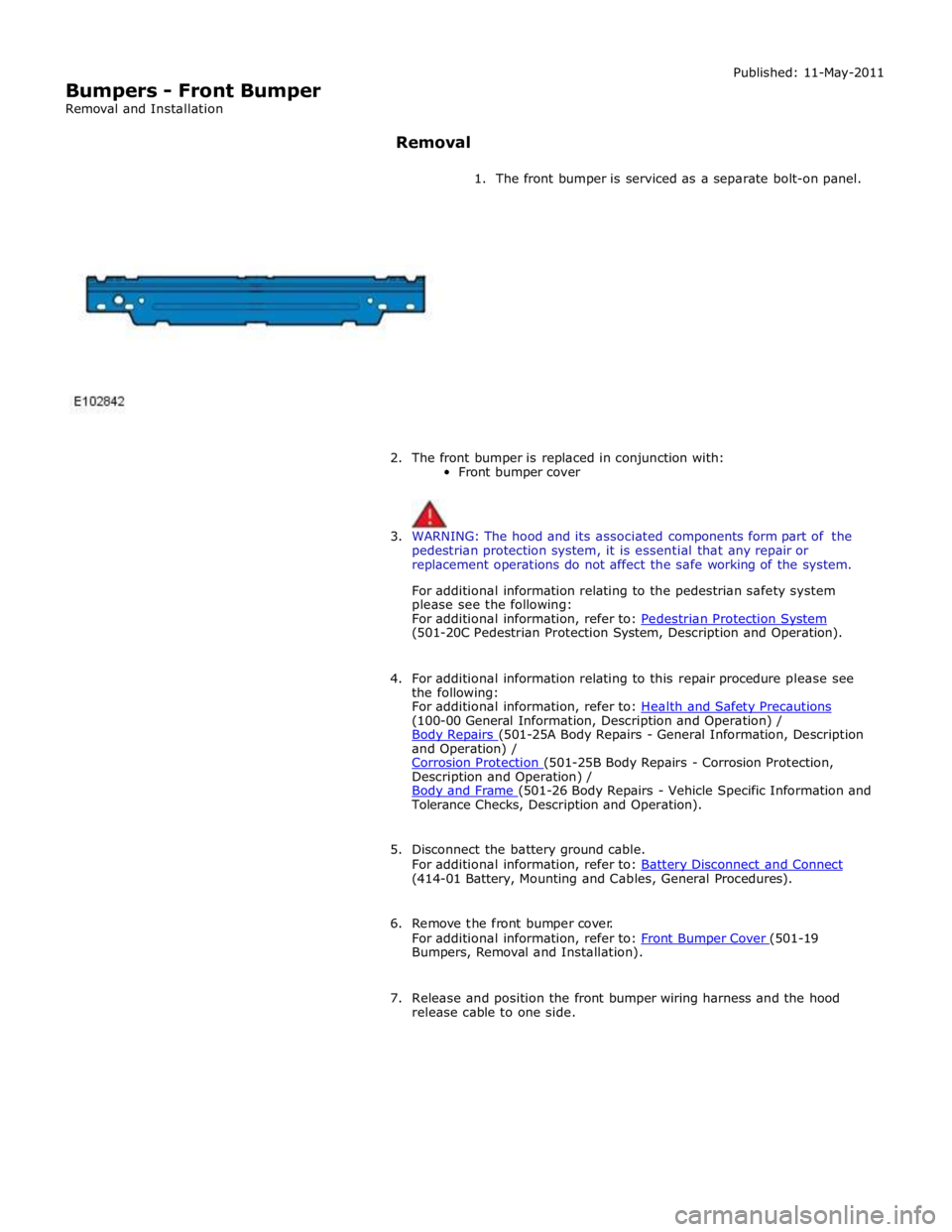

Bumpers - Front Bumper

Removal and Installation Published: 11-May-2011

Removal

1. The front bumper is serviced as a separate bolt-on panel.

2. The front bumper is replaced in conjunction with:

Front bumper cover

3. WARNING: The hood and its associated components form part of the

pedestrian protection system, it is essential that any repair or

replacement operations do not affect the safe working of the system.

For additional information relating to the pedestrian safety system

please see the following:

For additional information, refer to: Pedestrian Protection System (501-20C Pedestrian Protection System, Description and Operation).

4. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

5. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

6. Remove the front bumper cover.

For additional information, refer to: Front Bumper Cover (501-19 Bumpers, Removal and Installation).

7. Release and position the front bumper wiring harness and the hood

release cable to one side.

Page 2582 of 3039

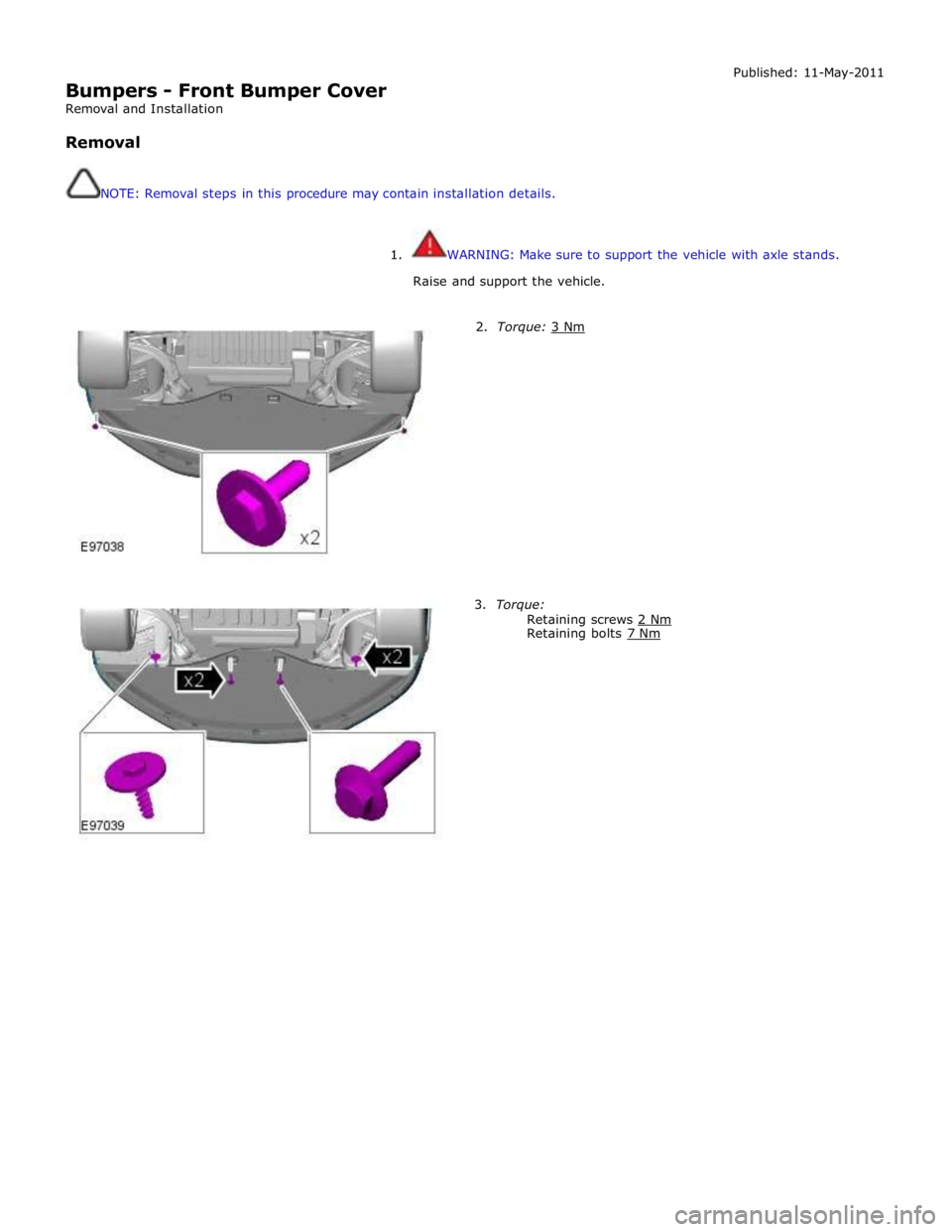

Bumpers - Front Bumper Cover

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Torque: 3 Nm 3. Torque:

Retaining screws 2 Nm Retaining bolts 7 Nm

Page 2593 of 3039

Safety Belt System - Safety Belt System - Overview

Description and Operation

Authoring Template

OVERVIEW Published: 11-May-2011

A three point safety belt is fitted to all seating positions. Each safety belt retractor incorporates an emergency locking feature.

The emergency locking retractor incorporates 2 mechanical inertia devices. One inertia device activates if the safety belt is

subjected to a sharp pull. The second inertia device activates if the vehicle is subject to a sudden deceleration or is on a

severe incline.

North American Specification (NAS) safety belt retractors also include an automatic locking feature. The Automatic Locking

Retractor (ALR) is fitted to all passenger seating positions and allows the safety belt to be tensioned to aid the safe fitment

of child or booster seats. For additional information, refer to the Owners Handbook.

NAS vehicles are also fitted with a belt tension sensor on the front passenger seat. The belt tension sensor is incorporated

into the seat belt lower anchorage and is attached to the seat frame by an M10 Torx head bolt. The belt tension sensor forms

part of the SRS (supplemental restraint system) occupancy detection and classification feature.

The center rear safety belt features a mini-buckle lower anchorage. The mini-buckle is disengaged by inserting a suitable tool

into the small aperture on the front face of the housing.

To aid the fitment of child seats, 3 tethers are located on the rear parcel shelf. Each tether is attached to the parcel shelf with

an M10 Torx head bolt.

A safety belt warning indicator is located in the instrument cluster to remind front seat passengers to fasten their safety belts.

The warning indicator will illuminate if the safety belt of an occupied front seat is not fastened.

Refer to: Instrument Cluster (413-01, Description and Operation).