brake sensor JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 691 of 3039

Published: 02-Sep-2011

Anti-Lock Control - Stability Assist - Anti-Lock Control - Stability Assist - Component Location

Description and Operation

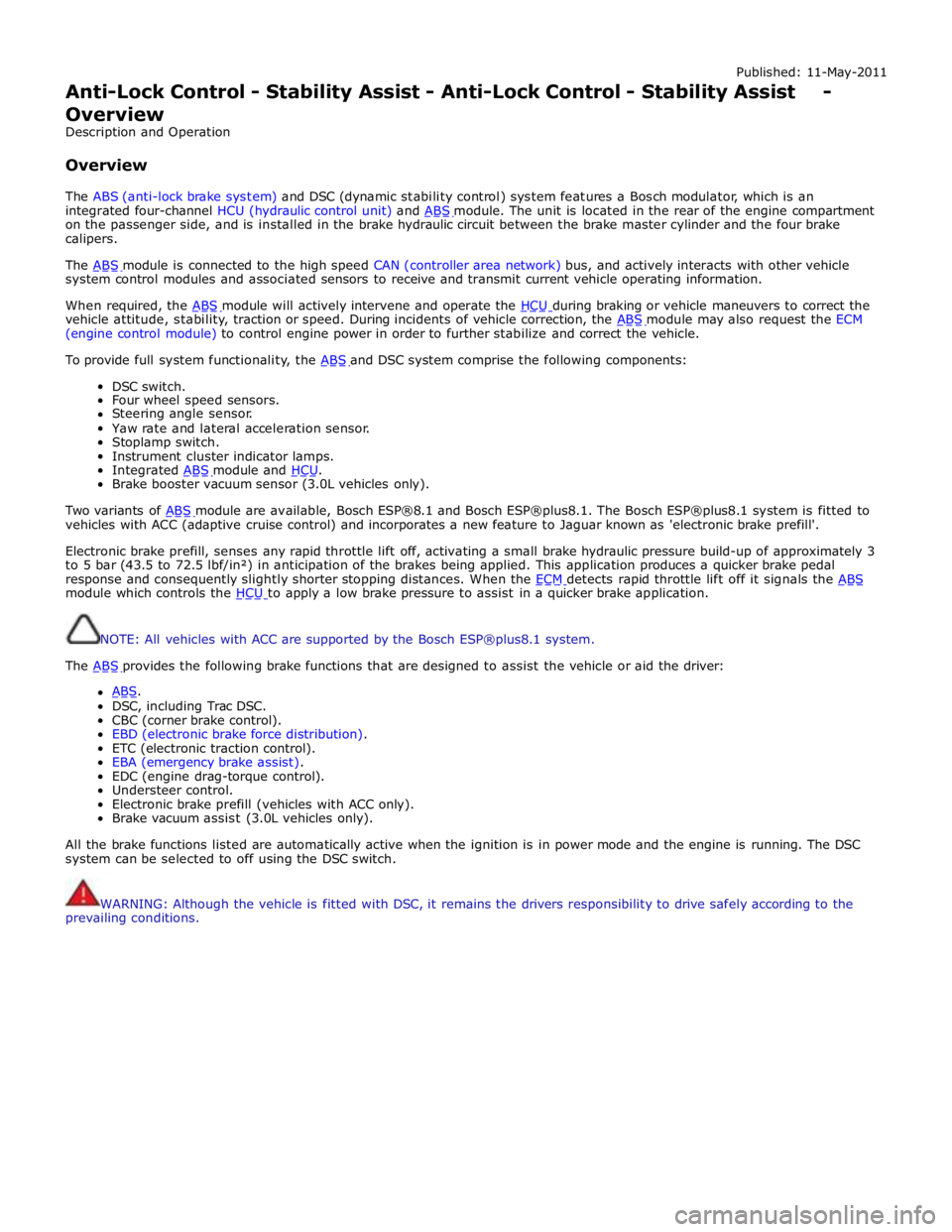

NOTE: RHD (right-hand drive) installation shown, LHD (left-hand drive) installation similar.

Component Location

Item Description 1 ABS (anti-lock brake system) module 2 RH (right-hand) front wheel speed sensor 3 Instrument cluster 4 Steering angle sensor 5 Yaw rate and lateral acceleration sensor 6 RH rear wheel speed sensor 7 LH (left-hand) rear wheel speed sensor 8 LH front wheel speed sensor

Page 692 of 3039

Published: 11-May-2011

Anti-Lock Control - Stability Assist - Anti-Lock Control - Stability Assist - Overview

Description and Operation

Overview

The ABS (anti-lock brake system) and DSC (dynamic stability control) system features a Bosch modulator, which is an

integrated four-channel HCU (hydraulic control unit) and ABS module. The unit is located in the rear of the engine compartment on the passenger side, and is installed in the brake hydraulic circuit between the brake master cylinder and the four brake

calipers.

The ABS module is connected to the high speed CAN (controller area network) bus, and actively interacts with other vehicle system control modules and associated sensors to receive and transmit current vehicle operating information.

When required, the ABS module will actively intervene and operate the HCU during braking or vehicle maneuvers to correct the vehicle attitude, stability, traction or speed. During incidents of vehicle correction, the ABS module may also request the ECM (engine control module) to control engine power in order to further stabilize and correct the vehicle.

To provide full system functionality, the ABS and DSC system comprise the following components: DSC switch.

Four wheel speed sensors.

Steering angle sensor.

Yaw rate and lateral acceleration sensor.

Stoplamp switch.

Instrument cluster indicator lamps.

Integrated ABS module and HCU. Brake booster vacuum sensor (3.0L vehicles only).

Two variants of ABS module are available, Bosch ESP®8.1 and Bosch ESP®plus8.1. The Bosch ESP®plus8.1 system is fitted to vehicles with ACC (adaptive cruise control) and incorporates a new feature to Jaguar known as 'electronic brake prefill'.

Electronic brake prefill, senses any rapid throttle lift off, activating a small brake hydraulic pressure build-up of approximately 3

to 5 bar (43.5 to 72.5 lbf/in²) in anticipation of the brakes being applied. This application produces a quicker brake pedal

response and consequently slightly shorter stopping distances. When the ECM detects rapid throttle lift off it signals the ABS module which controls the HCU to apply a low brake pressure to assist in a quicker brake application.

NOTE: All vehicles with ACC are supported by the Bosch ESP®plus8.1 system.

The ABS provides the following brake functions that are designed to assist the vehicle or aid the driver: ABS. DSC, including Trac DSC.

CBC (corner brake control).

EBD (electronic brake force distribution).

ETC (electronic traction control).

EBA (emergency brake assist).

EDC (engine drag-torque control).

Understeer control.

Electronic brake prefill (vehicles with ACC only).

Brake vacuum assist (3.0L vehicles only).

All the brake functions listed are automatically active when the ignition is in power mode and the engine is running. The DSC

system can be selected to off using the DSC switch.

WARNING: Although the vehicle is fitted with DSC, it remains the drivers responsibility to drive safely according to the

prevailing conditions.

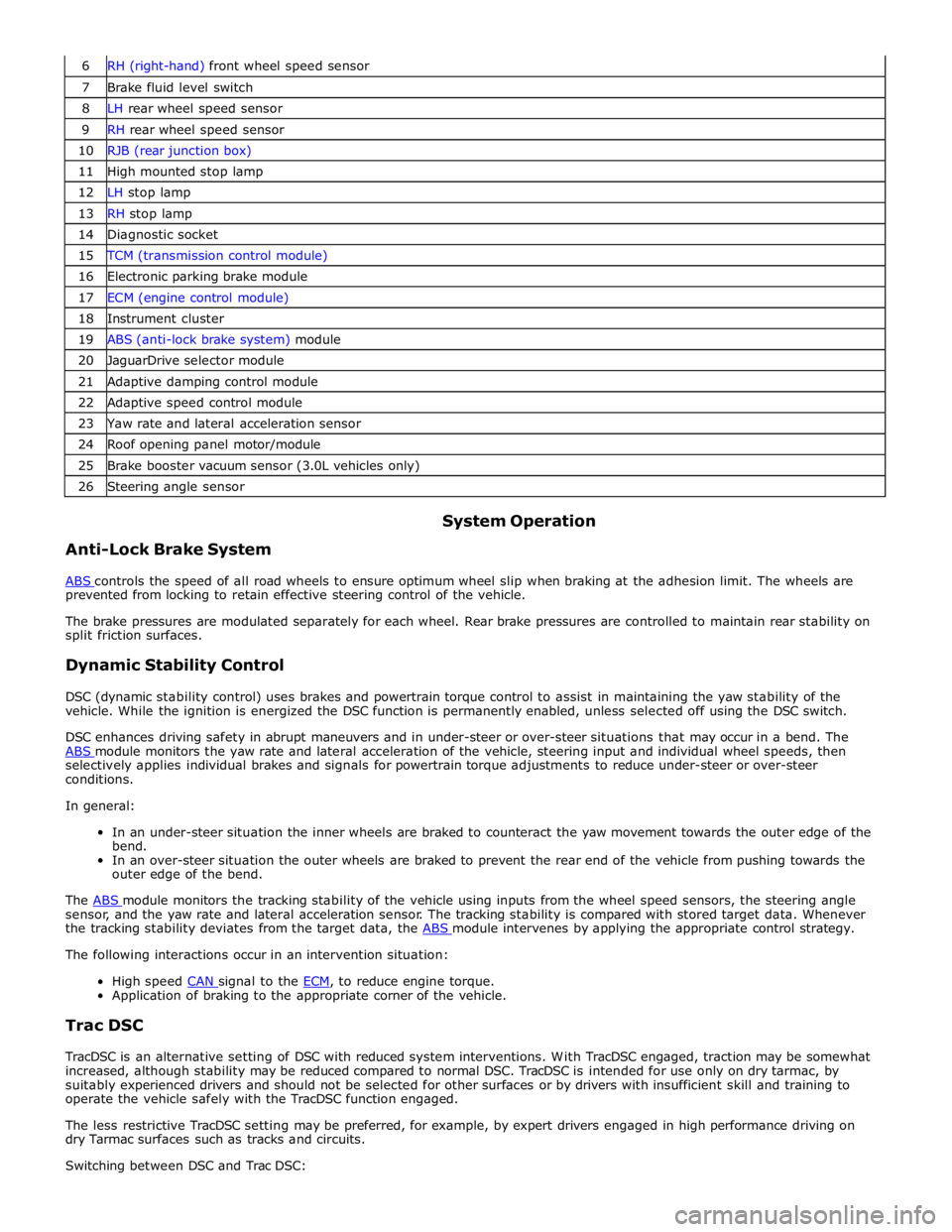

Page 694 of 3039

7 Brake fluid level switch 8 LH rear wheel speed sensor 9 RH rear wheel speed sensor 10 RJB (rear junction box) 11 High mounted stop lamp 12 LH stop lamp 13 RH stop lamp 14 Diagnostic socket 15 TCM (transmission control module) 16 Electronic parking brake module 17 ECM (engine control module) 18 Instrument cluster 19 ABS (anti-lock brake system) module 20 JaguarDrive selector module 21 Adaptive damping control module 22 Adaptive speed control module 23 Yaw rate and lateral acceleration sensor 24 Roof opening panel motor/module 25 Brake booster vacuum sensor (3.0L vehicles only) 26 Steering angle sensor

Anti-Lock Brake System System Operation

ABS controls the speed of all road wheels to ensure optimum wheel slip when braking at the adhesion limit. The wheels are prevented from locking to retain effective steering control of the vehicle.

The brake pressures are modulated separately for each wheel. Rear brake pressures are controlled to maintain rear stability on

split friction surfaces.

Dynamic Stability Control

DSC (dynamic stability control) uses brakes and powertrain torque control to assist in maintaining the yaw stability of the

vehicle. While the ignition is energized the DSC function is permanently enabled, unless selected off using the DSC switch.

DSC enhances driving safety in abrupt maneuvers and in under-steer or over-steer situations that may occur in a bend. The

ABS module monitors the yaw rate and lateral acceleration of the vehicle, steering input and individual wheel speeds, then selectively applies individual brakes and signals for powertrain torque adjustments to reduce under-steer or over-steer

conditions.

In general:

In an under-steer situation the inner wheels are braked to counteract the yaw movement towards the outer edge of the

bend.

In an over-steer situation the outer wheels are braked to prevent the rear end of the vehicle from pushing towards the

outer edge of the bend.

The ABS module monitors the tracking stability of the vehicle using inputs from the wheel speed sensors, the steering angle sensor, and the yaw rate and lateral acceleration sensor. The tracking stability is compared with stored target data. Whenever

the tracking stability deviates from the target data, the ABS module intervenes by applying the appropriate control strategy. The following interactions occur in an intervention situation:

High speed CAN signal to the ECM, to reduce engine torque. Application of braking to the appropriate corner of the vehicle.

Trac DSC

TracDSC is an alternative setting of DSC with reduced system interventions. With TracDSC engaged, traction may be somewhat

increased, although stability may be reduced compared to normal DSC. TracDSC is intended for use only on dry tarmac, by

suitably experienced drivers and should not be selected for other surfaces or by drivers with insufficient skill and training to

operate the vehicle safely with the TracDSC function engaged.

The less restrictive TracDSC setting may be preferred, for example, by expert drivers engaged in high performance driving on

dry Tarmac surfaces such as tracks and circuits.

Switching between DSC and Trac DSC:

Page 695 of 3039

Press and hold the DSC switch for less than 10 seconds.

The message center will temporarily display either Trac DSC or DSC ON.

The warning indicator in the instrument panel will illuminate while Trac DSC is selected.

The warning indicator will flash when DSC or Trac DSC is active.

NOTE: If cruise control is engaged, it will automatically disengage if DSC activates.

Refer to: Speed Control (310-03 Speed Control - 2.7L V6 - TdV6, Description and Operation).

Corner Brake Control

CBC (corner brake control) influences the brake pressures, below and within DSC and ABS thresholds, to counteract the yawing moment produced when braking in a corner. CBC produces a correction torque by limiting the brake pressure on one side of the

vehicle.

Electronic Brake Force Distribution

EBD (electronic brake force distribution) limits the brake pressure applied to the rear wheels. When the brakes are applied, the

weight of the vehicle transfers forwards, reducing the ability of the rear wheels to transfer braking effort to the road surface.

This may cause the rear wheels to slip and make the vehicle unstable.

EBD uses the ABS braking hardware to automatically optimize the pressure to the rear brakes, below the point where ABS is normally invoked.

NOTE: Only the rear brakes are controlled by the EBD function.

Electronic Traction Control

ETC (electronic traction control) attempts to optimize forward traction by reducing engine torque, or by applying the brake of a

spinning wheel until traction is regained.

ETC is activated if an individual wheel speed is above that of the vehicle reference speed (positive slip) and the brake pedal is

not pressed. The brake is applied to the spinning wheel, allowing the excess torque to be transmitted to the non-spinning

wheel through the drive line. If necessary, the ABS module also sends a high speed CAN bus message to the ECM to request a reduction in engine torque.

When the DSC function is selected off using the DSC switch, the braking and engine torque reduction features are both

disabled, except when the JaguarDrive control is in winter mode. When the JaguarDrive control is in winter mode, selecting the

DSC function off retains the braking and engine torque reduction features, but reduces intervention levels compared to DSC

and Trac DSC modes.

Emergency Brake Assist

EBA (emergency brake assist) assists the driver in emergency braking situations by automatically increasing the applied

braking effort. The ABS module invokes EBA when: The brake pedal is rapidly pressed.

The brake pedal is pressed hard enough to bring the front brakes into ABS operation.

When the brake pedal is rapidly pressed, the ABS module increases the hydraulic pressure to all of the brakes until the threshold for ABS operation is reached. This action applies the maximum braking effort for the available traction. The ABS module monitors for the sudden application of the brakes, using inputs from the brake pedal switch and from the pressure

sensor within the HCU (hydraulic control unit). With the brake pedal pressed, if the rate of increase of hydraulic pressure

exceeds the predetermined limit, the ABS module invokes emergency braking.

When the brake pedal is pressed hard enough to bring the front brakes into ABS operation, the ABS module increases the hydraulic pressure to the rear brakes up to the ABS threshold.

EBA operation continues until the driver releases the brake pedal, sufficiently for the hydraulic pressure in the HCU to drop below a threshold value stored in the ABS module.

Engine Drag-Torque Control

EDC (engine drag-torque control) prevents wheel slip caused by any of the following: A

sudden decrease in engine torque when the accelerator is suddenly released.

A downshift using the Jaguar sequential shift function on automatic transmission vehicles.

When the ABS module detects the onset of wheel slip without the brakes being applied, the ABS module signals the ECM via the high speed CAN bus to request a momentary increase in engine torque.

Understeer Control

Understeer Logic Control is a proactive system which monitors the vehicle for understeer by comparing signals from the yaw

rate and lateral acceleration sensor with signals from the steering angle sensor and wheel speed sensors. www.JagDocs.com

Page 696 of 3039

a decrease in engine torque. At the same time the ABS module will control the HCU to apply brake pressure to the relevant wheels to correct the understeer.

Electronic Brake Prefill (Vehicles With ACC Only)

Electronic brake prefill (Bosch ESP®plus8.1), senses any rapid throttle lift off, activating a small brake hydraulic pressure

build-up of approximately 3 to 5 bar (43.5 to 72.5 lbf/in²) in anticipation of the brakes being applied.

This application produces a quicker brake pedal response and consequently slightly shorter stopping distances. The system

supports vehicles with ACC (adaptive cruise control).

When the ABS module detects rapid throttle lift off (from the signals received from the ECM over the high speed CAN bus), it controls the HCU to apply a low brake pressure to assist in a quicker brake application.

Brake Vacuum Assist (3.0L Vehicles Only)

Operation of Brake Vacuum Assist generally occurs at the beginning of an ignition cycle when brake booster vacuum levels are

low; refer to Brake Booster Vacuum sensor, below.

Brake vacuum assist operation will be recognized by the driver experiencing a vibrating brake pedal and slight modulator noise.

This will be similar to that experienced when ABS system is operating.

As the engine warms up, Brake Vacuum Assist operation will become less frequent. However, it can be become more active

when vacuum levels are low due to driving at high-altitudes, or during frequent heavy-braking.

Noise levels during Brake Vacuum Assist may vary with initial system activity being the loudest observed. In some

circumstances initial activity may be interpreted as a 'thump' noise, particularly if there is no immediate and significant Brake

Vacuum Assist functionality.

In this circumstance system behavior is normal and should not be a cause for fault investigation.

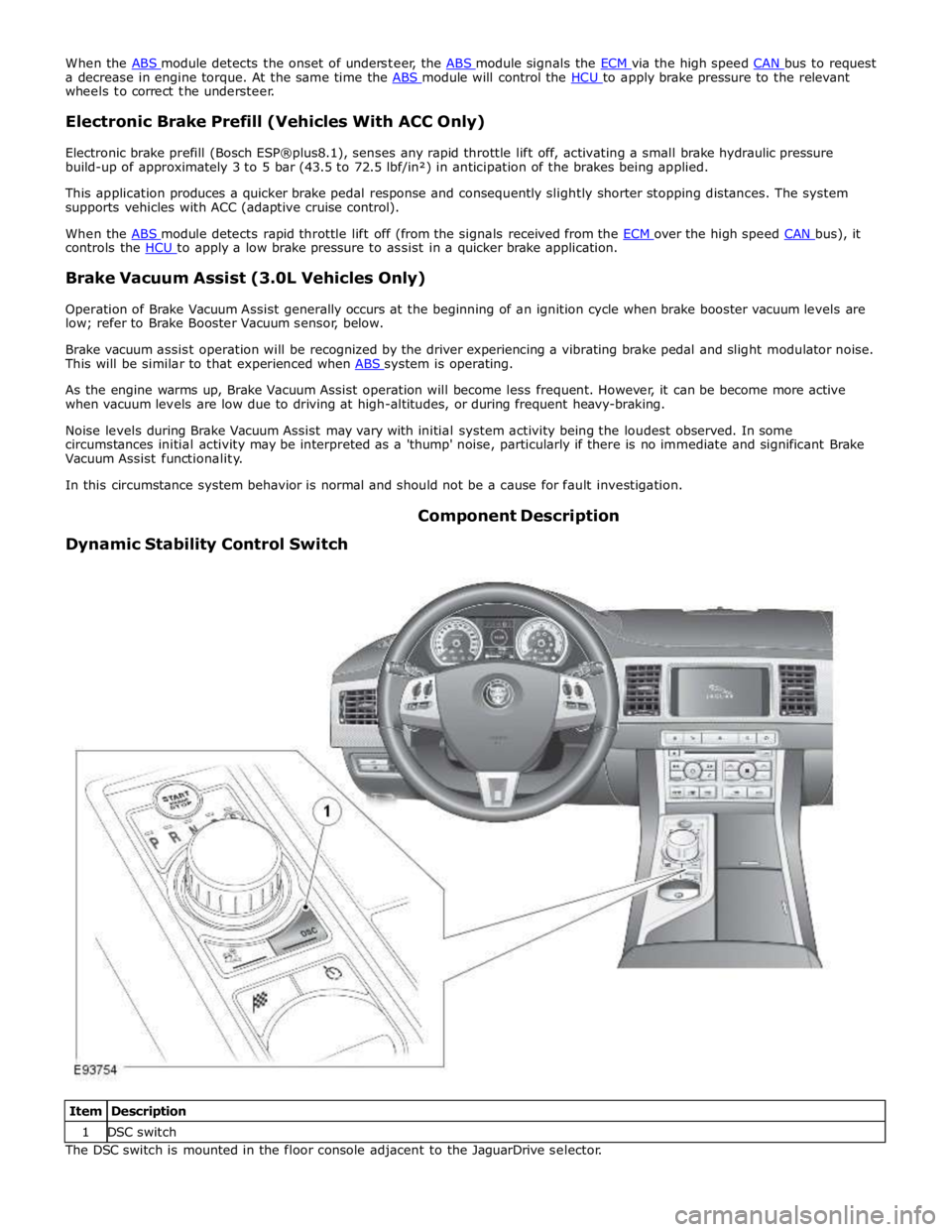

Dynamic Stability Control Switch Component Description

Item Description 1 DSC switch The DSC switch is mounted in the floor console adjacent to the JaguarDrive selector.

Page 703 of 3039

Published: 09-Jul-2014

Anti-Lock Control - Stability Assist - Anti-Lock Control - Stability Assist

Diagnosis and Testing

Principle of Operation

For a detailed description of the Anti-Lock Control - Stability Assist system, refer to the relevant Description and Operation

sections in the workshop manual. REFER to: (206-09 Anti-Lock Control - Stability Assist)

Anti-Lock Control - Stability Assist (Description and Operation), Anti-Lock Control - Stability Assist (Description and Operation), Anti-Lock Control - Stability Assist (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Confirm if the Anti-Lock Brake System (ABS) warning light was illuminated, or still is.

NOTE: An intermittent fault may allow the warning light to go off. This does not necessarily mean the fault is not

present. Some warnings will appear to clear when the ignition is cycled. This is often because the warning has flagged as a

result of one of the vehicle's on-board diagnostic routines having run to detect the fault. If the same routine is not run when

the ignition status is set to ON, the warning will not re-flag until the routine does run.

3. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Brake fluid level

Vacuum system

Wheel speed sensor installation

Wheel speed sensor air gap

Magnetic pulse wheel(s) (damaged/contaminated)

Steering angle sensor

Yaw rate sensor and accelerometer cluster installation

Incorrect wheel or tire size

Warning light operation

Fuses

Wheel speed sensors

Connectors/Pins

Harnesses

Steering wheel rotation sensor

Yaw rate sensor and accelerometer cluster

Booster pressure sensor

Hydraulic Control Unit (HCU)

4. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

5. If the cause is not visually evident check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Anti-Lock Braking System (ABS) (100-00 General Information, Description and Operation).

Page 782 of 3039

16 Ball (12 off) 17 Distance keeper 18 Crash tube The column comprises a cast magnesium mounting bracket which provides the attachment to the cross-beam. Attached to the

mounting bracket is a rake lever which is attached to the mounting bracket at the lower end with two pivot bearings. The

bearings allow the rake lever to rotate upwards or downward to adjust the column rake.

The rake lever also provides for the attachment of the rake housing which can slide within the lever to provide the reach

adjustment. Within the rake housing is the axial housing which is supported on each side with 6 ball bearings which allow the

rake housing to move forward or backwards. The bearings on each side are arranged in groups of 3 bearings and are separated

by a distance keeper which allows the housing to supported on bearings along its length. Within the axial housing is a tube

which is supported at the upper end of the column on the upper bearing. The tube has a central splined hole which provides for

the fitment of the splined shaft. The splined shaft can slide within the tube on the splines when the column reach is adjusted

or the column collapses in a crash condition. The splined shaft also passes rotary motion from the steering wheel through the

length of the column to the outer clamping yoke which is supported on the lower bearing.

The electric steering column lock is attached to the top of the rake lever. A lock bolt within the steering column lock engages in

one of 8 slots in the locking sleeve located at the lower end of the column preventing rotation of the steering wheel. The

locking sleeve is retained by a tolerance ring which in turn is located on the outer diameter of the tube yoke. The tolerance

ring allows a specified amount of torque to be applied to the splined shaft before it slips, preventing damage to the column

lock due to excessive force being applied to the steering wheel when the lock is engaged. The tolerance ring is designed to

slip on the splined shaft when the applied torque exceeds the fitted slip load of 200 Nm minimum. Repeated rotation of the

lock collar will reduce its slipping torque to 100 Nm minimum. The lock is controlled by the CJB.

A steering angle sensor is located at the upper end of the steering column and is attached to the crash adaptor. The sensor

measures steering rotation via a toothed wheel located on the splined tube at the upper end of the column. The sensor

receives a power supply from the CJB and supplies 2 signals (A and B) relating to the steering rotation to the ABS (anti-lock brake system) module. The module transmits this data on the high speed CAN bus for use by other vehicle systems. Refer to: Anti-Lock Control - Stability Assist (206-09 Anti-Lock Control - Stability Assist, Description and Operation).

The steering column is adjustable electrically, for reach and rake. The adjustment mechanism comprises an electric adjustment

motor, a lead screw, a rake solenoid, a reach solenoid, a reach clutch and a rake clutch. The column adjustment is controlled

manually using a joystick switch located on the LH (left-hand) side of the column lower cowl. The joystick can be moved

forward and backward to adjust the column reach in and out and moved up and down to adjust the rake. The switch selection

energizes the adjustment motor in the applicable direction and also engages the applicable solenoid and clutch.

When the joystick switch is rotated to the 'auto' position, the steering column will adjust to the uppermost rake position when

the ignition is switched off. It will re-adjust to the position corresponding to the memory position for the remote handset when

the ignition is switched on.

The memory function of the electric column is linked to and controlled by the driver's seat module. The module provides for the

storage of three separate memory positions which are stored against 3 individual remote handsets.

Refer to: Seats (501-10 Seating, Description and Operation).

The steering wheel locates on a splined shaft in the upper column assembly and is secured with a bolt. The steering wheel

houses the driver's airbag and switches for the audio system, gear change and speed control. A clockspring is used to connect

the steering wheel electrical components to the vehicle harness.

Two plastic shrouds are fitted to the upper column assembly. The lower shroud is fitted with an energy absorbing foam pad to

minimize leg injury in the event of an accident.

www.JagDocs.com

Page 1295 of 3039

13 Bypass valve 14 SC 15 Gasket 16 RH intake manifold 17 M08 x 30 mm crew (3 off) 18 M08 x 50 mm screw 19 N.H. pad 20 M6 x 15 mm screw (4 off) 21 M08 x 45 mm screw (4 off) 22 RH charge air cooler 23 M08 x 150 mm screw Supercharger

The SC is a Roots blower with high angle helix rotors driven at 2.1 x engine speed by the secondary belt of the accessory drive.

The two rotors of the SC are contained in a housing. The ends of the rotors are supported in bearings in the front cover and the bearing plate. A rear cover seals the bearing plate and incorporates a filler/level plug for lubricant. A pulley transfers power

from the accessory drive to the shaft of one of the rotors.

A pneumatic actuator on the front cover is attached to a by-pass valve in the housing. The bypass valve regulates a flow of air

from the outlet of the SC back to the inlet side of the rotors, to control the outlet pressure of the SC. Hoses connect the pneumatic actuator to the throttle T-piece of the air ducts, upstream of the electric throttle, and to the front cover, downstream

of the electric throttle. A lever connects the actuating rod of the pneumatic actuator to the shaft of the bypass

valve. A screw in the front cover limits movement of the lever in the closed direction to allow calibration of the SC output. The front cover also incorporates:

The SC air inlet and mounting face for the electric throttle. A connector stub for the part load breather.

A MAP (manifold absolute pressure) sensor.

A connector stub for a hose from the EVAP (evaporative emission) canister purge valve.

Intake Manifolds

Each intake manifold is attached to the SC with three screws and a bolt. Two dowels ensure correct alignment of each intake manifold. The RHD (right-hand drive) intake manifold incorporates a connection port for the noise feedback system. The LH intake manifold incorporates:

A connector stub for the brake vacuum system.

A MAPT (manifold absolute pressure and temperature) sensor.

Page 1422 of 3039

1 Transmission selected gear status 2 MIL (malfunction indicator lamp) 3 Message center The instrument cluster is connected to the TCM via the high speed CAN bus. Transmission status is transmitted by the TCM and displayed to the driver in one of two displays in the instrument cluster. For additional information, refer to 413-01

Instrument Cluster.

Malfunction Indicator Lamp

The MIL (malfunction indicator lamp) is located in the tachometer in the instrument cluster. Transmission related faults which

may affect the vehicle emissions output will illuminate the MIL.

The MIL is illuminated by the ECM (engine control module) on receipt of a relevant fault message from the TCM on the high speed CAN. The nature of the fault can be diagnosed using a Jaguar approved diagnostic system which reads the fault codes stored in the TCM memory.

Transmission Status Display

The transmission status display is located in a LCD (liquid crystal display) at the top of the instrument cluster, between the

speedometer and the tachometer. The LCD shows the JaguarDrive selector position or the selected gear when in manual 'Jaguar Sequential Shift' mode.

The following table shows the displays and their descriptions.

Symbol Description P Park selected R Reverse selected N Neutral selected D Drive selected S Sport mode selected 1 1st gear selected (manual Jaguar sequential shift mode) 2 2nd gear selected (manual Jaguar sequential shift mode) 3 3rd gear selected (manual Jaguar sequential shift mode) 4 4th gear selected (manual Jaguar sequential shift mode) 5 5th gear selected (manual Jaguar sequential shift mode) 6 6th gear selected (manual Jaguar sequential shift mode) The message center is located in the lower center of the instrument cluster. The message center is a LCD to relay vehicle status and operating information to the driver and can display messages relating to a number of the vehicle systems. If a

transmission fault occurs, the message center will display the message 'GEARBOX FAULT'.

TRANSMISSION CONTROL MODULE

The TCM outputs signals to control the shift control solenoid valve and the EPRS (electronic pressure regulating solenoid) to control the hydraulic operation of the transmission.

The TCM processes signals from the transmission speed and temperature sensors, the ECM and other vehicle systems. From the received signal inputs and pre-programmed data, the module calculates the correct gear, torque converter clutch setting

and optimum pressure settings for gear shift and lock-up clutch control.

The ECM supplies the engine management data over the high speed CAN bus. The TCM requires engine data to efficiently control the transmission operation, for example; flywheel torque, engine speed, accelerator pedal angle, engine temperature.

The steering angle sensor and the ABS (anti-lock brake system) module also supply data to the TCM on the high speed CAN bus. The TCM uses data from these systems to suspend gear changes when the vehicle is cornering and/or the ABS module is controlling braking or traction control.

Using the signal inputs and the memorized data, the TCM control program computes the correct gear and torque converter lock-up clutch setting and the optimum pressure settings for gear shift and lock-up clutch control. Special output-side modules

(power output stages, current regulator circuits), allow the TCM to control the solenoid valves and pressure regulators and consequently precisely control the hydraulics of the automatic transmission. In addition, the amount and duration of engine

interventions are supplied to the engine management by way of the CAN bus.

The transmission has a fully electronic JaguarDrive selector with no Bowden cable connection to the transmission. The

transmission selections are made using a rotary JaguarDrive selector which rises from the floor console once the engine is

running. Rotation of the JaguarDrive selector to any of the five positions is sensed by the TCM via the high speed CAN bus. The TCM then reacts according to the selected position. The 'S' (sport) position selection allows the TCM to operate the transmission using the semi-automatic 'Jaguar Sequential Shift'.

Gear selections are sensed by the TCM when the driver operates the steering wheel paddle switches. Once the JaguarDrive selector position is confirmed, the TCM outputs appropriate information on the high speed CAN bus.

If the JaguarDrive selector is in 'D', 'Jaguar Sequential Shift' is temporary and will cancel after a time period or can be cancelled

by pressing and holding the + paddle for approximately 2 seconds.

If the JaguarDrive selector is in 'S', 'Jaguar Sequential Shift' is permanent and can only be cancelled by pressing and holding

the + paddle for approximately 2 seconds or by moving the JaguarDrive selector to the 'D' position.

www.JagDocs.com

Page 1423 of 3039

The TCM can be reprogrammed using a Jaguar approved diagnostic system using a flash code. The TCM processor has a 440 kb internal flash memory. Of this capacity, approximately 370 kb are used by the basic transmission program. The remainder,

approximately 70 kb is used to store vehicle-specific application data.

Engine Stall

If the vehicle stalls it will coast down in gear, with the transmission providing drive to the engine. A restart can be attempted

at this point and the engine may start and the driver can continue.

If the coast down speed reduces such that the speed of the engine is less than 600 rev/min, the transmission will go to

neutral, D illumination will flash in the instrument cluster. The driver needs to select neutral or park and then press the brake

pedal to restart the engine.

If the start/stop button is pressed when driving, the message ENGINE STOP BUTTON PRESSED is displayed in the message

center but there will be no change to the ignition state. If the driver requires to switch off the engine, the start/stop button

must be pressed for a second time. The engine will be stopped and will be back driven by the transmission as the vehicle

coasts down. When the engine speed is less than 600 rev/min the transmission engages neutral (flashing D illumination in the

instrument cluster). When vehicle speed is less than 2 km/h (1.2 mph) Park is engaged. The JaguarDrive selector automatically

rotates back to its lowered P position and the vehicle ignition is switched off.

The park engagement is prevented in a stall case as the ignition power is on and D was the last selected gear. The park

engagement speed at ignition off is from the least value of the wheel speeds (CAN signal) and transmission output speed (internal signal).

TRANSMISSION Component Description

The transmission comprises the main casing which houses all of the transmission components. The main casing also

incorporates an integral bell housing.

A fluid pan is attached to the lower face of the main casing and is secured with bolts. The fluid pan is sealed to the main

casing with a gasket. Removal of the fluid pan allows access to the Mechatronic valve block. The fluid pan has a magnet

located around the drain plug which collects any metallic particles present in the transmission fluid.

A fluid filter is located inside the fluid pan. If the transmission fluid becomes contaminated or after any service work, the fluid

pan with integral filter must be replaced.

The integral bell housing provides protection for the torque converter assembly and also provides the attachment for the

gearbox to the engine cylinder block. The torque converter is a non-serviceable assembly which also contains the lock-up clutch

mechanism. The torque converter drives a crescent type pump via drive tangs. The fluid pump is located in the main casing,

behind the torque converter.

The main casing contains the following major components:

Input shaft

Output shaft

Mechatronic valve block which contains the solenoids, speed sensors and the TCM Three rotating multiplate drive clutches

Two fixed multiplate brake clutches

A single planetary gear train and a double planetary gear train.