instrument cluster JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 260 of 3039

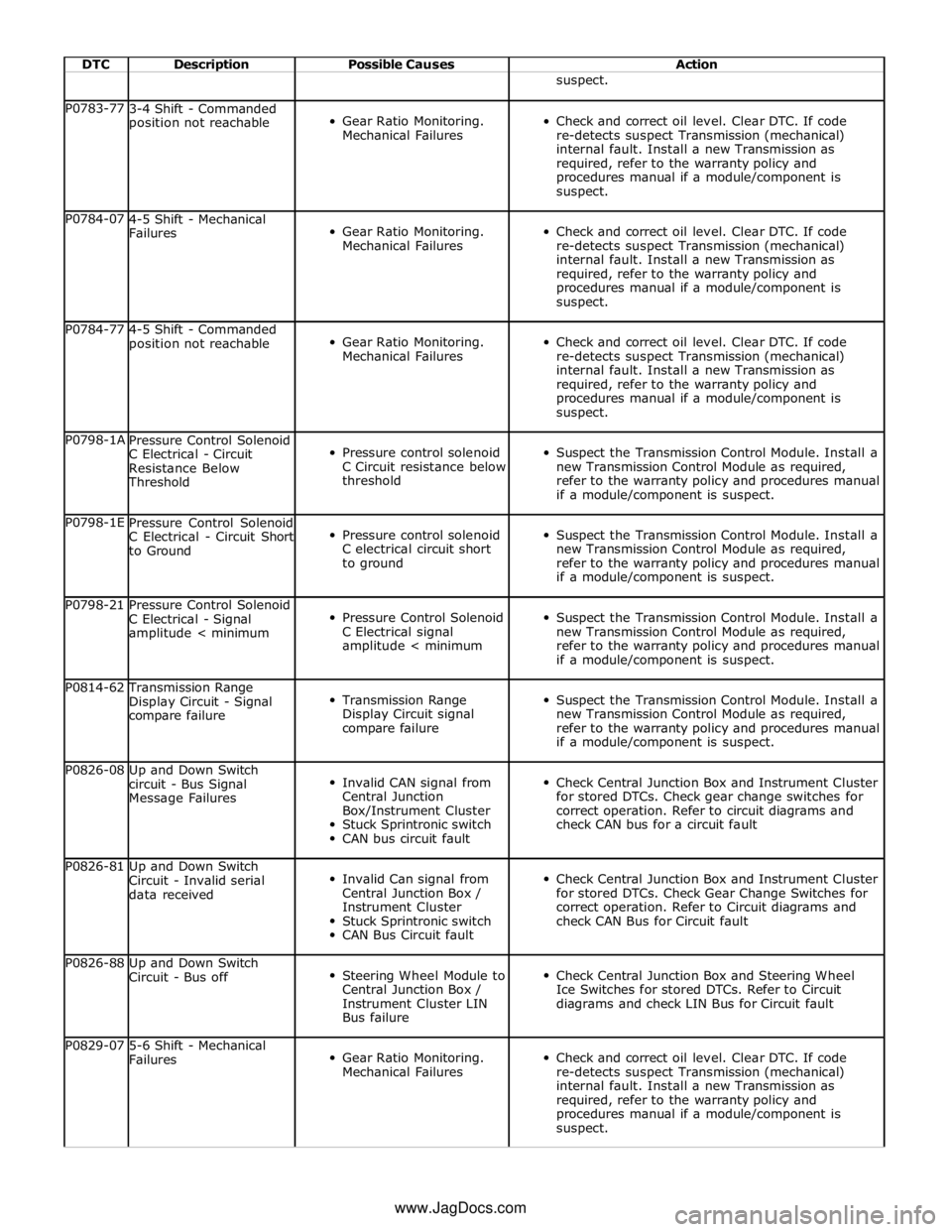

DTC Description Possible Causes Action suspect. P0783-77

3-4 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0784-07

4-5 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0784-77

4-5 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0798-1A

Pressure Control Solenoid

C Electrical - Circuit

Resistance Below Threshold

Pressure control solenoid

C Circuit resistance below

threshold

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0798-1E

Pressure Control Solenoid

C Electrical - Circuit Short

to Ground

Pressure control solenoid

C electrical circuit short

to ground

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0798-21

Pressure Control Solenoid

C Electrical - Signal

amplitude < minimum

Pressure Control Solenoid

C Electrical signal

amplitude < minimum

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0814-62 Transmission Range

Display Circuit - Signal

compare failure

Transmission Range

Display Circuit signal

compare failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0826-08

Up and Down Switch

circuit - Bus Signal

Message Failures

Invalid CAN signal from

Central Junction

Box/Instrument Cluster

Stuck Sprintronic switch

CAN bus circuit fault

Check Central Junction Box and Instrument Cluster

for stored DTCs. Check gear change switches for

correct operation. Refer to circuit diagrams and

check CAN bus for a circuit fault P0826-81

Up and Down Switch

Circuit - Invalid serial

data received

Invalid Can signal from

Central Junction Box /

Instrument Cluster

Stuck Sprintronic switch

CAN Bus Circuit fault

Check Central Junction Box and Instrument Cluster

for stored DTCs. Check Gear Change Switches for

correct operation. Refer to Circuit diagrams and

check CAN Bus for Circuit fault P0826-88

Up and Down Switch

Circuit - Bus off

Steering Wheel Module to

Central Junction Box /

Instrument Cluster LIN

Bus failure

Check Central Junction Box and Steering Wheel

Ice Switches for stored DTCs. Refer to Circuit

diagrams and check LIN Bus for Circuit fault P0829-07

5-6 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. www.JagDocs.com

Page 267 of 3039

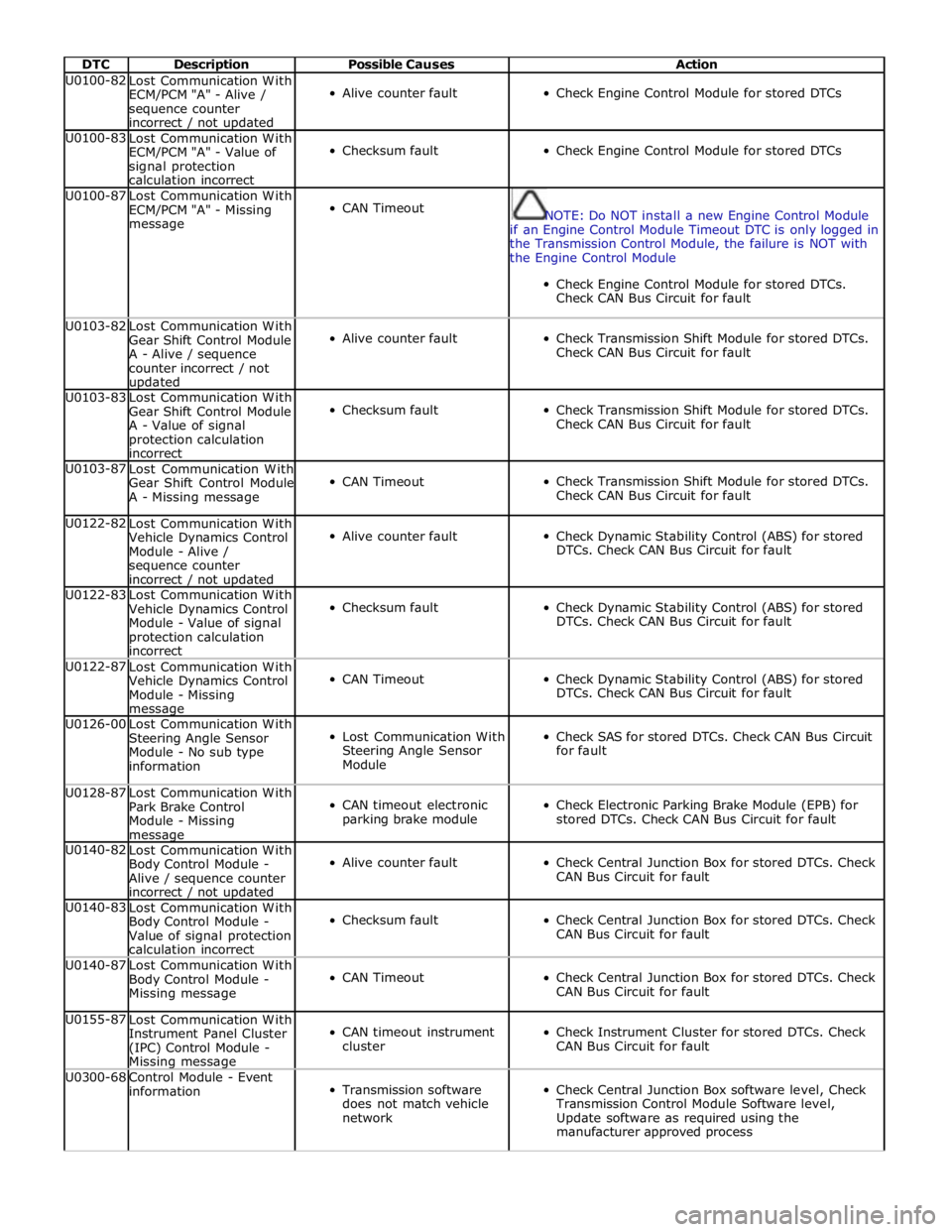

DTC Description Possible Causes Action U0100-82

Lost Communication With

ECM/PCM "A" - Alive /

sequence counter

incorrect / not updated

Alive counter fault

Check Engine Control Module for stored DTCs U0100-83

Lost Communication With

ECM/PCM "A" - Value of

signal protection

calculation incorrect

Checksum fault

Check Engine Control Module for stored DTCs U0100-87

Lost Communication With

ECM/PCM "A" - Missing

message

CAN Timeout

NOTE: Do NOT install a new Engine Control Module

if an Engine Control Module Timeout DTC is only logged in

the Transmission Control Module, the failure is NOT with

the Engine Control Module

Check Engine Control Module for stored DTCs.

Check CAN Bus Circuit for fault U0103-82

Lost Communication With

Gear Shift Control Module

A - Alive / sequence

counter incorrect / not updated

Alive counter fault

Check Transmission Shift Module for stored DTCs.

Check CAN Bus Circuit for fault U0103-83

Lost Communication With

Gear Shift Control Module

A - Value of signal

protection calculation

incorrect

Checksum fault

Check Transmission Shift Module for stored DTCs.

Check CAN Bus Circuit for fault U0103-87

Lost Communication With

Gear Shift Control Module

A - Missing message

CAN Timeout

Check Transmission Shift Module for stored DTCs.

Check CAN Bus Circuit for fault U0122-82

Lost Communication With

Vehicle Dynamics Control

Module - Alive /

sequence counter

incorrect / not updated

Alive counter fault

Check Dynamic Stability Control (ABS) for stored

DTCs. Check CAN Bus Circuit for fault U0122-83

Lost Communication With

Vehicle Dynamics Control

Module - Value of signal

protection calculation

incorrect

Checksum fault

Check Dynamic Stability Control (ABS) for stored

DTCs. Check CAN Bus Circuit for fault U0122-87

Lost Communication With

Vehicle Dynamics Control

Module - Missing message

CAN Timeout

Check Dynamic Stability Control (ABS) for stored

DTCs. Check CAN Bus Circuit for fault U0126-00

Lost Communication With

Steering Angle Sensor

Module - No sub type

information

Lost Communication With

Steering Angle Sensor

Module

Check SAS for stored DTCs. Check CAN Bus Circuit

for fault U0128-87

Lost Communication With

Park Brake Control

Module - Missing message

CAN timeout electronic

parking brake module

Check Electronic Parking Brake Module (EPB) for

stored DTCs. Check CAN Bus Circuit for fault U0140-82

Lost Communication With

Body Control Module -

Alive / sequence counter

incorrect / not updated

Alive counter fault

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U0140-83

Lost Communication With

Body Control Module -

Value of signal protection

calculation incorrect

Checksum fault

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U0140-87

Lost Communication With

Body Control Module -

Missing message

CAN Timeout

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U0155-87

Lost Communication With

Instrument Panel Cluster

(IPC) Control Module - Missing message

CAN timeout instrument

cluster

Check Instrument Cluster for stored DTCs. Check

CAN Bus Circuit for fault U0300-68

Control Module - Event

information

Transmission software

does not match vehicle

network

Check Central Junction Box software level, Check

Transmission Control Module Software level,

Update software as required using the

manufacturer approved process

Page 276 of 3039

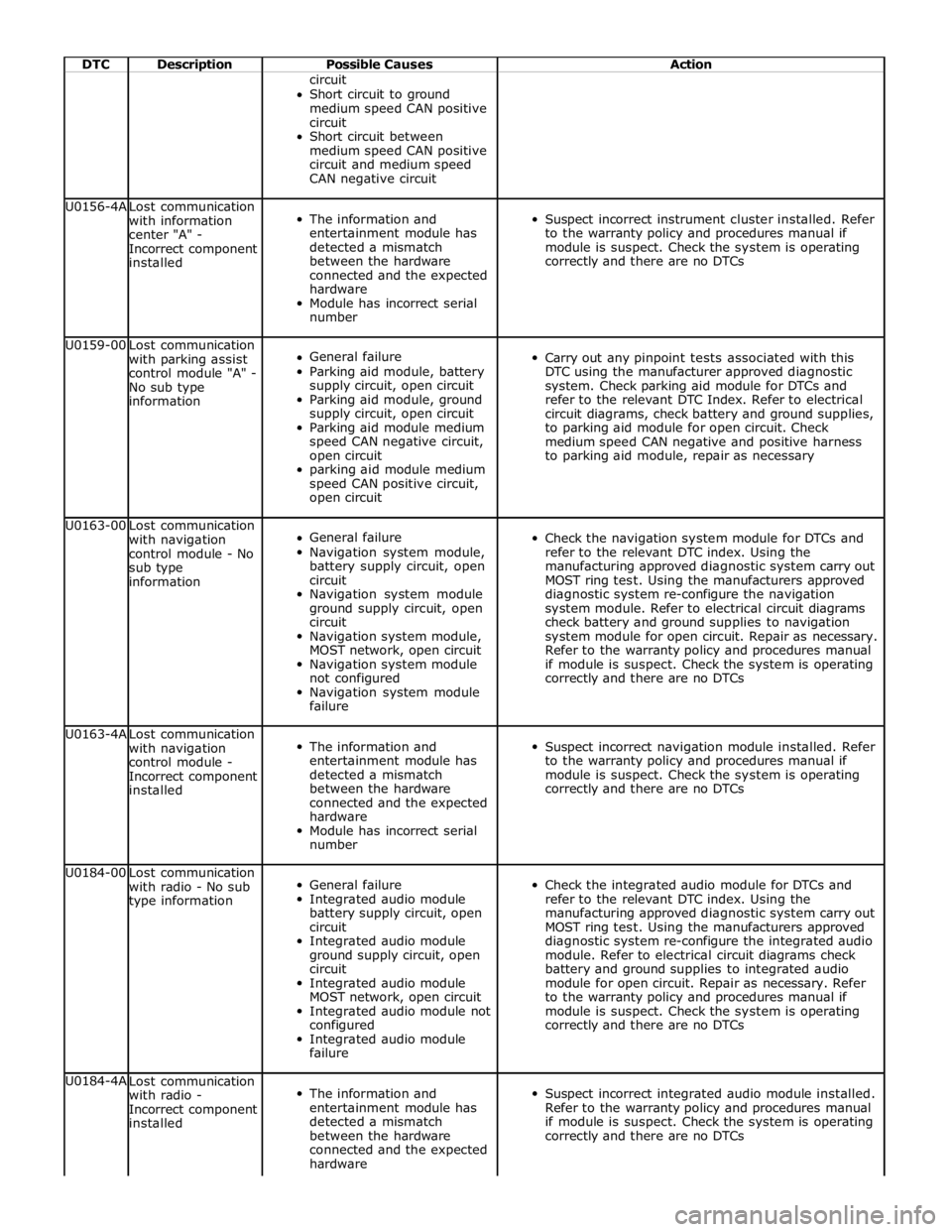

DTC Description Possible Causes Action circuit

Short circuit to ground

medium speed CAN positive

circuit

Short circuit between

medium speed CAN positive

circuit and medium speed

CAN negative circuit U0156-4A

Lost communication

with information

center "A" -

Incorrect component

installed

The information and

entertainment module has

detected a mismatch

between the hardware

connected and the expected

hardware

Module has incorrect serial

number

Suspect incorrect instrument cluster installed. Refer

to the warranty policy and procedures manual if

module is suspect. Check the system is operating

correctly and there are no DTCs U0159-00

Lost communication

with parking assist

control module "A" -

No sub type

information

General failure

Parking aid module, battery

supply circuit, open circuit

Parking aid module, ground

supply circuit, open circuit

Parking aid module medium

speed CAN negative circuit,

open circuit

parking aid module medium

speed CAN positive circuit,

open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check parking aid module for DTCs and

refer to the relevant DTC Index. Refer to electrical

circuit diagrams, check battery and ground supplies,

to parking aid module for open circuit. Check

medium speed CAN negative and positive harness

to parking aid module, repair as necessary U0163-00

Lost communication

with navigation

control module - No

sub type

information

General failure

Navigation system module,

battery supply circuit, open

circuit

Navigation system module

ground supply circuit, open

circuit

Navigation system module,

MOST network, open circuit

Navigation system module

not configured

Navigation system module

failure

Check the navigation system module for DTCs and

refer to the relevant DTC index. Using the

manufacturing approved diagnostic system carry out

MOST ring test. Using the manufacturers approved

diagnostic system re-configure the navigation

system module. Refer to electrical circuit diagrams

check battery and ground supplies to navigation

system module for open circuit. Repair as necessary.

Refer to the warranty policy and procedures manual

if module is suspect. Check the system is operating

correctly and there are no DTCs U0163-4A

Lost communication

with navigation

control module -

Incorrect component

installed

The information and

entertainment module has

detected a mismatch

between the hardware

connected and the expected

hardware

Module has incorrect serial

number

Suspect incorrect navigation module installed. Refer

to the warranty policy and procedures manual if

module is suspect. Check the system is operating

correctly and there are no DTCs U0184-00

Lost communication

with radio - No sub

type information

General failure

Integrated audio module

battery supply circuit, open

circuit

Integrated audio module

ground supply circuit, open

circuit

Integrated audio module

MOST network, open circuit

Integrated audio module not

configured

Integrated audio module

failure

Check the integrated audio module for DTCs and

refer to the relevant DTC index. Using the

manufacturing approved diagnostic system carry out

MOST ring test. Using the manufacturers approved

diagnostic system re-configure the integrated audio

module. Refer to electrical circuit diagrams check

battery and ground supplies to integrated audio

module for open circuit. Repair as necessary. Refer

to the warranty policy and procedures manual if

module is suspect. Check the system is operating

correctly and there are no DTCs U0184-4A

Lost communication

with radio -

Incorrect component

installed

The information and

entertainment module has

detected a mismatch

between the hardware

connected and the expected

hardware

Suspect incorrect integrated audio module installed.

Refer to the warranty policy and procedures manual

if module is suspect. Check the system is operating

correctly and there are no DTCs

Page 443 of 3039

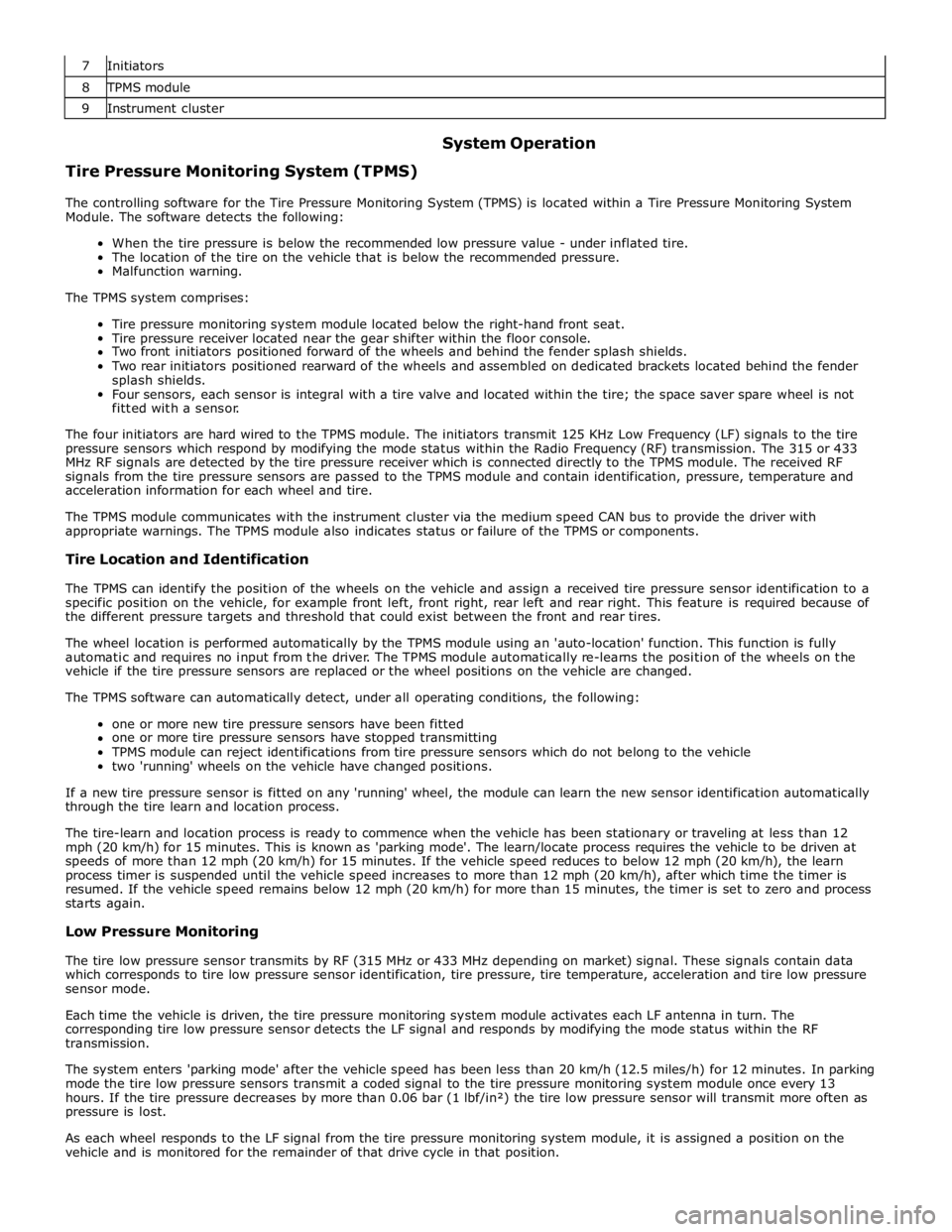

7 Initiators 8 TPMS module 9 Instrument cluster

Tire Pressure Monitoring System (TPMS) System Operation

The controlling software for the Tire Pressure Monitoring System (TPMS) is located within a Tire Pressure Monitoring System

Module. The software detects the following:

When the tire pressure is below the recommended low pressure value - under inflated tire.

The location of the tire on the vehicle that is below the recommended pressure.

Malfunction warning.

The TPMS system comprises:

Tire pressure monitoring system module located below the right-hand front seat.

Tire pressure receiver located near the gear shifter within the floor console.

Two front initiators positioned forward of the wheels and behind the fender splash shields.

Two rear initiators positioned rearward of the wheels and assembled on dedicated brackets located behind the fender

splash shields.

Four sensors, each sensor is integral with a tire valve and located within the tire; the space saver spare wheel is not

fitted with a sensor.

The four initiators are hard wired to the TPMS module. The initiators transmit 125 KHz Low Frequency (LF) signals to the tire

pressure sensors which respond by modifying the mode status within the Radio Frequency (RF) transmission. The 315 or 433

MHz RF signals are detected by the tire pressure receiver which is connected directly to the TPMS module. The received RF

signals from the tire pressure sensors are passed to the TPMS module and contain identification, pressure, temperature and

acceleration information for each wheel and tire.

The TPMS module communicates with the instrument cluster via the medium speed CAN bus to provide the driver with

appropriate warnings. The TPMS module also indicates status or failure of the TPMS or components.

Tire Location and Identification

The TPMS can identify the position of the wheels on the vehicle and assign a received tire pressure sensor identification to a

specific position on the vehicle, for example front left, front right, rear left and rear right. This feature is required because of

the different pressure targets and threshold that could exist between the front and rear tires.

The wheel location is performed automatically by the TPMS module using an 'auto-location' function. This function is fully

automatic and requires no input from the driver. The TPMS module automatically re-learns the position of the wheels on the

vehicle if the tire pressure sensors are replaced or the wheel positions on the vehicle are changed.

The TPMS software can automatically detect, under all operating conditions, the following:

one or more new tire pressure sensors have been fitted

one or more tire pressure sensors have stopped transmitting

TPMS module can reject identifications from tire pressure sensors which do not belong to the vehicle

two 'running' wheels on the vehicle have changed positions.

If a new tire pressure sensor is fitted on any 'running' wheel, the module can learn the new sensor identification automatically

through the tire learn and location process.

The tire-learn and location process is ready to commence when the vehicle has been stationary or traveling at less than 12

mph (20 km/h) for 15 minutes. This is known as 'parking mode'. The learn/locate process requires the vehicle to be driven at

speeds of more than 12 mph (20 km/h) for 15 minutes. If the vehicle speed reduces to below 12 mph (20 km/h), the learn

process timer is suspended until the vehicle speed increases to more than 12 mph (20 km/h), after which time the timer is

resumed. If the vehicle speed remains below 12 mph (20 km/h) for more than 15 minutes, the timer is set to zero and process

starts again.

Low Pressure Monitoring

The tire low pressure sensor transmits by RF (315 MHz or 433 MHz depending on market) signal. These signals contain data

which corresponds to tire low pressure sensor identification, tire pressure, tire temperature, acceleration and tire low pressure

sensor mode.

Each time the vehicle is driven, the tire pressure monitoring system module activates each LF antenna in turn. The

corresponding tire low pressure sensor detects the LF signal and responds by modifying the mode status within the RF

transmission.

The system enters 'parking mode' after the vehicle speed has been less than 20 km/h (12.5 miles/h) for 12 minutes. In parking

mode the tire low pressure sensors transmit a coded signal to the tire pressure monitoring system module once every 13

hours. If the tire pressure decreases by more than 0.06 bar (1 lbf/in²) the tire low pressure sensor will transmit more often as

pressure is lost.

As each wheel responds to the LF signal from the tire pressure monitoring system module, it is assigned a position on the

vehicle and is monitored for the remainder of that drive cycle in that position.

Page 445 of 3039

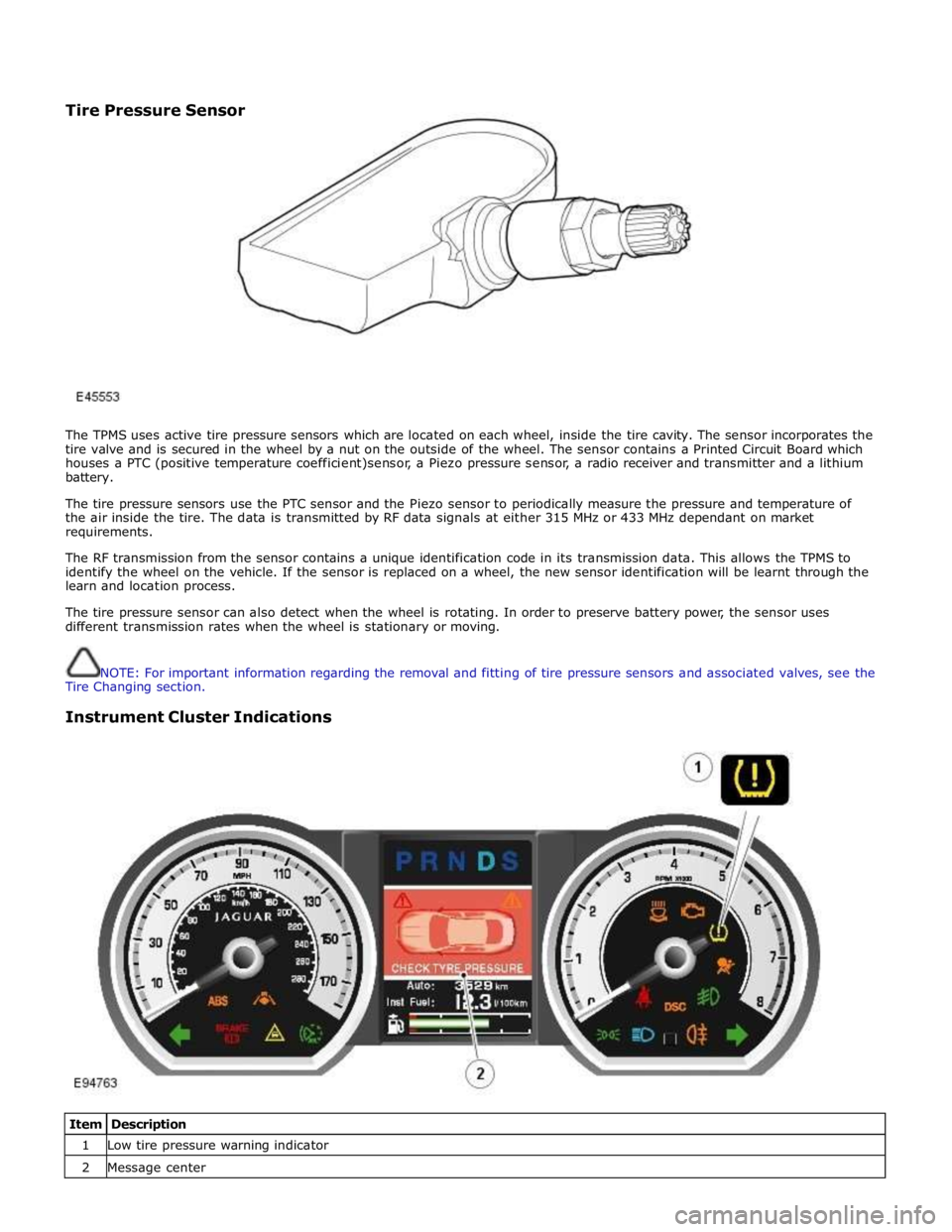

The TPMS uses active tire pressure sensors which are located on each wheel, inside the tire cavity. The sensor incorporates the

tire valve and is secured in the wheel by a nut on the outside of the wheel. The sensor contains a Printed Circuit Board which

houses a PTC (positive temperature coefficient)sensor, a Piezo pressure sensor, a radio receiver and transmitter and a lithium

battery.

The tire pressure sensors use the PTC sensor and the Piezo sensor to periodically measure the pressure and temperature of

the air inside the tire. The data is transmitted by RF data signals at either 315 MHz or 433 MHz dependant on market

requirements.

The RF transmission from the sensor contains a unique identification code in its transmission data. This allows the TPMS to

identify the wheel on the vehicle. If the sensor is replaced on a wheel, the new sensor identification will be learnt through the

learn and location process.

The tire pressure sensor can also detect when the wheel is rotating. In order to preserve battery power, the sensor uses

different transmission rates when the wheel is stationary or moving.

NOTE: For important information regarding the removal and fitting of tire pressure sensors and associated valves, see the

Tire Changing section.

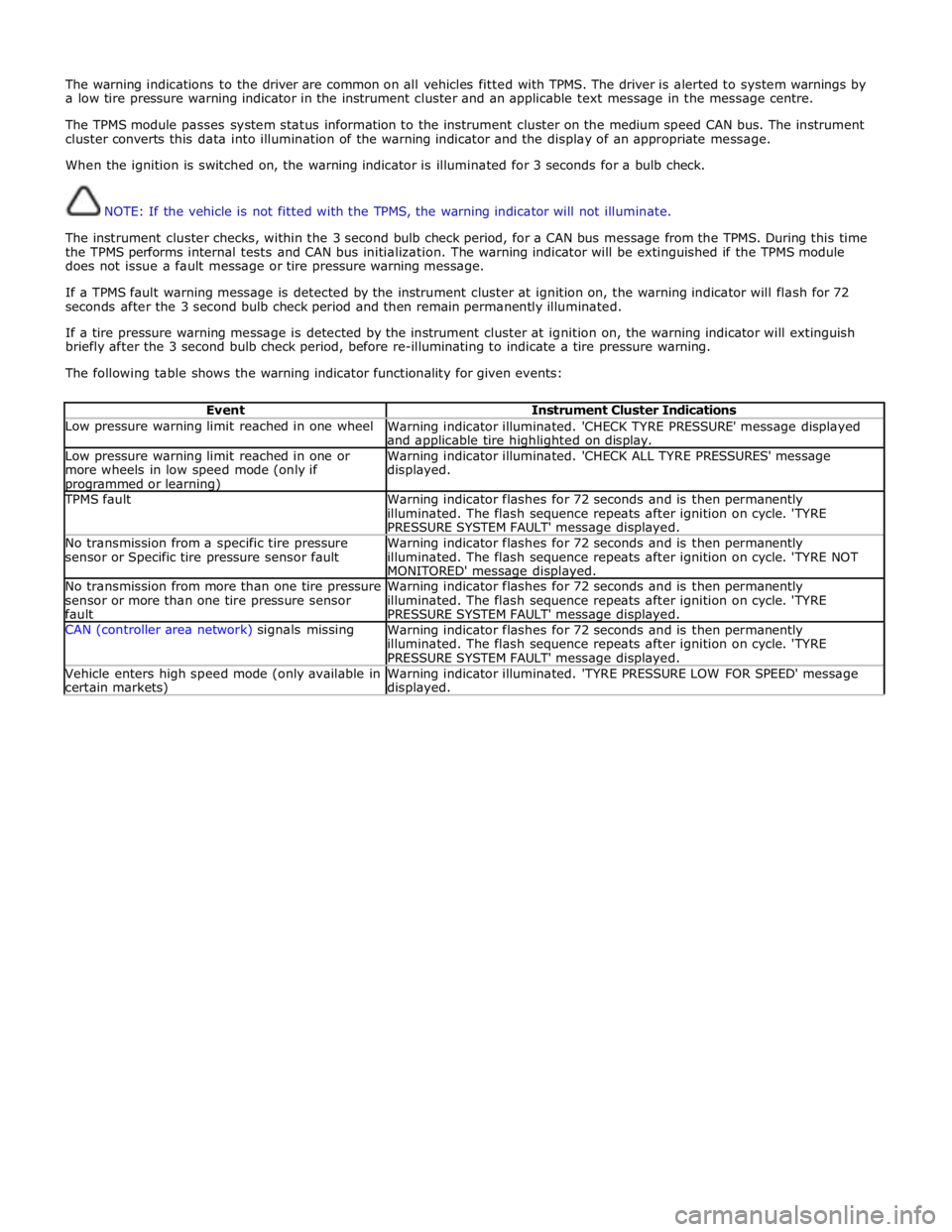

Instrument Cluster Indications

Item Description 1 Low tire pressure warning indicator 2 Message center Tire Pressure Sensor

Page 446 of 3039

The warning indications to the driver are common on all vehicles fitted with TPMS. The driver is alerted to system warnings by

a low tire pressure warning indicator in the instrument cluster and an applicable text message in the message centre.

The TPMS module passes system status information to the instrument cluster on the medium speed CAN bus. The instrument

cluster converts this data into illumination of the warning indicator and the display of an appropriate message.

When the ignition is switched on, the warning indicator is illuminated for 3 seconds for a bulb check.

NOTE: If the vehicle is not fitted with the TPMS, the warning indicator will not illuminate.

The instrument cluster checks, within the 3 second bulb check period, for a CAN bus message from the TPMS. During this time

the TPMS performs internal tests and CAN bus initialization. The warning indicator will be extinguished if the TPMS module

does not issue a fault message or tire pressure warning message.

If a TPMS fault warning message is detected by the instrument cluster at ignition on, the warning indicator will flash for 72

seconds after the 3 second bulb check period and then remain permanently illuminated.

If a tire pressure warning message is detected by the instrument cluster at ignition on, the warning indicator will extinguish

briefly after the 3 second bulb check period, before re-illuminating to indicate a tire pressure warning.

The following table shows the warning indicator functionality for given events:

Event Instrument Cluster Indications Low pressure warning limit reached in one wheel

Warning indicator illuminated. 'CHECK TYRE PRESSURE' message displayed

and applicable tire highlighted on display. Low pressure warning limit reached in one or

more wheels in low speed mode (only if programmed or learning) Warning indicator illuminated. 'CHECK ALL TYRE PRESSURES' message

displayed. TPMS fault

Warning indicator flashes for 72 seconds and is then permanently

illuminated. The flash sequence repeats after ignition on cycle. 'TYRE

PRESSURE SYSTEM FAULT' message displayed. No transmission from a specific tire pressure

sensor or Specific tire pressure sensor fault Warning indicator flashes for 72 seconds and is then permanently

illuminated. The flash sequence repeats after ignition on cycle. 'TYRE NOT

MONITORED' message displayed. No transmission from more than one tire pressure

sensor or more than one tire pressure sensor

fault Warning indicator flashes for 72 seconds and is then permanently

illuminated. The flash sequence repeats after ignition on cycle. 'TYRE

PRESSURE SYSTEM FAULT' message displayed. CAN (controller area network) signals missing

Warning indicator flashes for 72 seconds and is then permanently

illuminated. The flash sequence repeats after ignition on cycle. 'TYRE

PRESSURE SYSTEM FAULT' message displayed. Vehicle enters high speed mode (only available in

certain markets) Warning indicator illuminated. 'TYRE PRESSURE LOW FOR SPEED' message displayed.

Page 451 of 3039

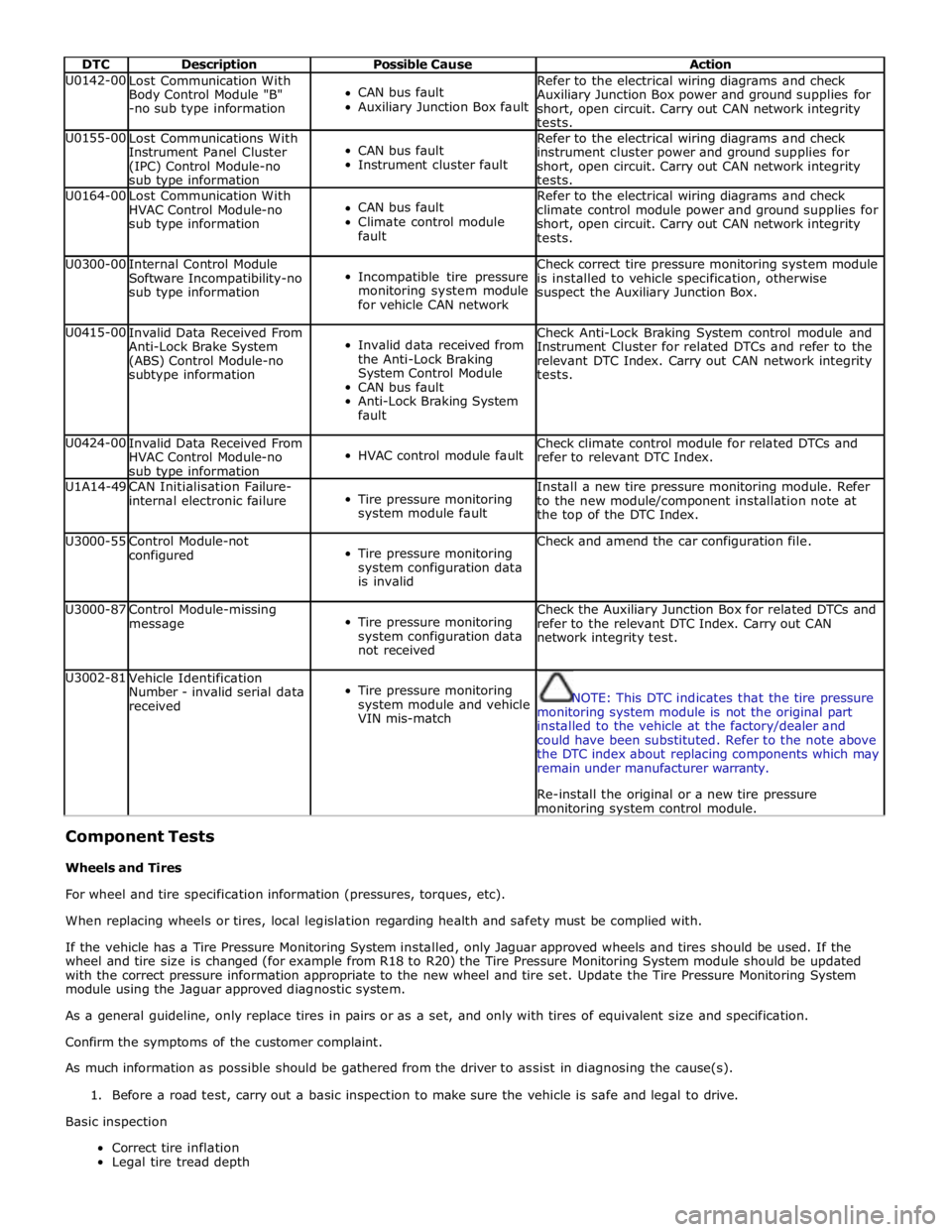

DTC Description Possible Cause Action U0142-00

Lost Communication With

Body Control Module "B"

-no sub type information

CAN bus fault

Auxiliary Junction Box fault Refer to the electrical wiring diagrams and check

Auxiliary Junction Box power and ground supplies for

short, open circuit. Carry out CAN network integrity

tests. U0155-00

Lost Communications With

Instrument Panel Cluster

(IPC) Control Module-no

sub type information

CAN bus fault

Instrument cluster fault Refer to the electrical wiring diagrams and check

instrument cluster power and ground supplies for

short, open circuit. Carry out CAN network integrity

tests. U0164-00

Lost Communication With

HVAC Control Module-no

sub type information

CAN bus fault

Climate control module

fault Refer to the electrical wiring diagrams and check

climate control module power and ground supplies for

short, open circuit. Carry out CAN network integrity

tests. U0300-00

Internal Control Module

Software Incompatibility-no

sub type information

Incompatible tire pressure

monitoring system module

for vehicle CAN network Check correct tire pressure monitoring system module

is installed to vehicle specification, otherwise

suspect the Auxiliary Junction Box. U0415-00

Invalid Data Received From

Anti-Lock Brake System

(ABS) Control Module-no

subtype information

Invalid data received from

the Anti-Lock Braking

System Control Module

CAN bus fault

Anti-Lock Braking System

fault Check Anti-Lock Braking System control module and

Instrument Cluster for related DTCs and refer to the

relevant DTC Index. Carry out CAN network integrity

tests. U0424-00

Invalid Data Received From

HVAC Control Module-no

sub type information

HVAC control module fault Check climate control module for related DTCs and

refer to relevant DTC Index. U1A14-49

CAN Initialisation Failure-

internal electronic failure

Tire pressure monitoring

system module fault Install a new tire pressure monitoring module. Refer

to the new module/component installation note at

the top of the DTC Index. U3000-55

Control Module-not

configured

Tire pressure monitoring

system configuration data

is invalid Check and amend the car configuration file. U3000-87

Control Module-missing

message

Tire pressure monitoring

system configuration data

not received Check the Auxiliary Junction Box for related DTCs and

refer to the relevant DTC Index. Carry out CAN

network integrity test. U3002-81

Vehicle Identification

Number - invalid serial data

received

Tire pressure monitoring

system module and vehicle

VIN mis-match

NOTE: This DTC indicates that the tire pressure

monitoring system module is not the original part

installed to the vehicle at the factory/dealer and

could have been substituted. Refer to the note above

the DTC index about replacing components which may

remain under manufacturer warranty.

Re-install the original or a new tire pressure monitoring system control module.

Component Tests

Wheels and Tires

For wheel and tire specification information (pressures, torques, etc).

When replacing wheels or tires, local legislation regarding health and safety must be complied with.

If the vehicle has a Tire Pressure Monitoring System installed, only Jaguar approved wheels and tires should be used. If the

wheel and tire size is changed (for example from R18 to R20) the Tire Pressure Monitoring System module should be updated

with the correct pressure information appropriate to the new wheel and tire set. Update the Tire Pressure Monitoring System

module using the Jaguar approved diagnostic system.

As a general guideline, only replace tires in pairs or as a set, and only with tires of equivalent size and specification.

Confirm the symptoms of the customer complaint.

As much information as possible should be gathered from the driver to assist in diagnosing the cause(s).

1. Before a road test, carry out a basic inspection to make sure the vehicle is safe and legal to drive.

Basic inspection

Correct tire inflation

Legal tire tread depth

Page 466 of 3039

1 Check for additional DTCs: C1A5631, C1A5831, C1A6031 or C1A6231 Is a C1A5631, C1A5831, C1A6031 or C1A6231 DTC also logged?

Yes

Refer to the DTC Index and remedial actions.

No

GO to G3. G3: CHECK INITIATOR INSTALLATION 1 Check for correct installation of Initiator. REFER to: (204-04 Wheels and Tires) Tire Pressure Monitoring System (TPMS) Front Antenna (Removal and Installation), Tire Pressure Monitoring System (TPMS) Rear Antenna (Removal and Installation). Is the Initiator correctly installed?

Yes

GO to G4. No

Rectify as required. REFER to: (204-04 Wheels and Tires)

Tire Pressure Monitoring System (TPMS) Front Antenna (Removal and Installation), Tire Pressure Monitoring System (TPMS) Rear Antenna (Removal and Installation). G4: CHECK FOR SHORT CIRCUIT IN INITIATOR HARNESS 1 Locate and remove module blue connector L. 2 Measure the resistance across the relevant initiator circuits within the blue connector. Is the resistance less than 1 Ohm?

Yes

A value of less than 1 Ohm indicates a short circuit, rectify the short circuit as required.

No

Install the correct tire low pressure sensor, of correct frequency, in accordance with that defined in the

manufacturer approved diagnostic system new tire low pressure sensor application, to the position

identified by the logged DTC.

REFER to: Tire Low Pressure Sensor (204-04 Wheels and Tires, Removal and Installation).

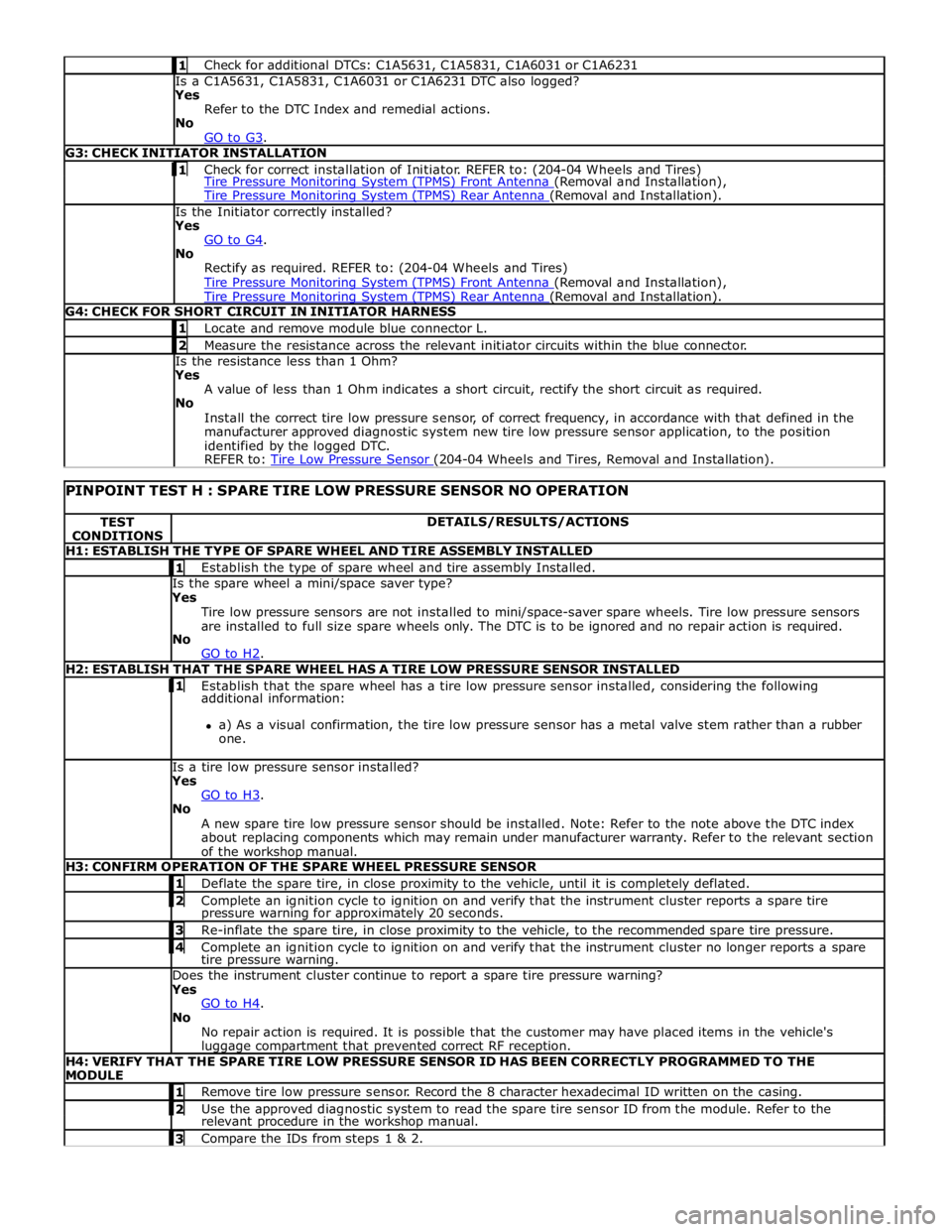

PINPOINT TEST H : SPARE TIRE LOW PRESSURE SENSOR NO OPERATION TEST

CONDITIONS DETAILS/RESULTS/ACTIONS H1: ESTABLISH THE TYPE OF SPARE WHEEL AND TIRE ASSEMBLY INSTALLED 1 Establish the type of spare wheel and tire assembly Installed. Is the spare wheel a mini/space saver type? Yes

Tire low pressure sensors are not installed to mini/space-saver spare wheels. Tire low pressure sensors

are installed to full size spare wheels only. The DTC is to be ignored and no repair action is required.

No

GO to H2. H2: ESTABLISH THAT THE SPARE WHEEL HAS A TIRE LOW PRESSURE SENSOR INSTALLED 1 Establish that the spare wheel has a tire low pressure sensor installed, considering the following additional information:

a) As a visual confirmation, the tire low pressure sensor has a metal valve stem rather than a rubber

one. Is a tire low pressure sensor installed? Yes

GO to H3. No

A new spare tire low pressure sensor should be installed. Note: Refer to the note above the DTC index

about replacing components which may remain under manufacturer warranty. Refer to the relevant section

of the workshop manual. H3: CONFIRM OPERATION OF THE SPARE WHEEL PRESSURE SENSOR 1 Deflate the spare tire, in close proximity to the vehicle, until it is completely deflated. 2 Complete an ignition cycle to ignition on and verify that the instrument cluster reports a spare tire pressure warning for approximately 20 seconds. 3 Re-inflate the spare tire, in close proximity to the vehicle, to the recommended spare tire pressure. 4 Complete an ignition cycle to ignition on and verify that the instrument cluster no longer reports a spare tire pressure warning. Does the instrument cluster continue to report a spare tire pressure warning? Yes

GO to H4. No

No repair action is required. It is possible that the customer may have placed items in the vehicle's luggage compartment that prevented correct RF reception. H4: VERIFY THAT THE SPARE TIRE LOW PRESSURE SENSOR ID HAS BEEN CORRECTLY PROGRAMMED TO THE

MODULE 1 Remove tire low pressure sensor. Record the 8 character hexadecimal ID written on the casing. 2 Use the approved diagnostic system to read the spare tire sensor ID from the module. Refer to the relevant procedure in the workshop manual. 3 Compare the IDs from steps 1 & 2.

Page 483 of 3039

7 Rear accelerometer 8 Instrument cluster 9 JaguarDrive selector module 10 ABS (anti-lock brake system) module 11 TCM (transmission control module) 12 ECM (engine control module) 13 RH (right-hand) rear damper 14 RH front damper 15 LH (left-hand) front damper 16 LH rear damper 17 LH rear suspension height sensor 18 RH rear suspension height sensor 19 LH front suspension height sensor 20 RH front accelerometer 21 RH front suspension height sensor 22 Adaptive damping module 23 LH front accelerometer

PRINCIPLES OF OPERATION System Operation

The adaptive damping module uses a combination of information from other system modules and data from the accelerometers

and suspension height sensors to measure the vehicle and suspension states and driver inputs. Using this information, the

adaptive damping module applies algorithms to control the dampers for the current driving conditions.

The adaptive damping module receives signals on the high speed CAN bus from the following system components: Brake Pressure - ABS module. Brake Pressure Quality Factor - ABS module. Car Configuration Parameters - AJB. Center Differential Range Actual - ECM. Engine Speed - ECM. Engine Speed Quality Factor - ECM. Engine Torque Flywheel Actual - ECM. Engine Torque Flywheel Actual Quality Factor - ECM. Gear Position Target - TCM. Lateral Acceleration - ABS module. Power Mode (Ignition Signal) - CJB. Power Mode Quality Factor - CJB. Roll Stability Control Mode - ABS module. Steering Wheel Angle - ABS module. Steering Wheel Angle Speed - ABS module. Steering Wheel Angle Status - ABS module. Terrain Mode Requested - JaguarDrive selector.

Torque Converter Slip - TCM. Vehicle Information Parameters HS - AJB Vehicle Speed - ABS module. Vehicle Speed Quality Factor - ABS module. Front Left Wheel Speed - ABS module. Front Left Wheel Speed Quality Factor - ABS module. Front Right Wheel Speed - ABS module. Front Right Wheel Speed Quality Factor - ABS module. Rear Left Wheel Speed - ABS module. Rear Left Wheel Speed Quality Factor - ABS module. Rear Right Wheel Speed Quality Factor - ABS module. Rear Right Wheel Speed - ABS module. The adaptive damping module also outputs information on the high speed CAN bus for use by other systems as follows: Fault Message - instrument cluster.

Terrain Mode Change Status - JaguarDrive selector.

Terrain Mode - JaguarDrive selector.

The adaptive damping module monitors the input signals and operates the damper solenoids. The input signals are used in

control modes and a force required for each damper for that mode is calculated. An arbitration mode monitors the force

requirements from each mode and apportions a force to a damper. The force is converted to the appropriate current and sent to

the damper.

The control modes are as follows:

Page 487 of 3039

System Fault Message

The adaptive damping module has a high speed CAN connection to the instrument cluster. If a fault is detected by the adaptive damping module, a message is sent to the instrument cluster and the message 'ADAPTIVE DYNAMICS FAULT' is

displayed. The adaptive damping module also logs an appropriate DTC. The adaptive damping module can be interrogated using an approved Jaguar diagnostic system.

When a fault is detected, the adaptive damping module implements a strategy based on the type of fault. If there is an

electrical power fault, or the adaptive damping module cannot control the dampers, they default to the firm condition. If a

sensor fails that only affects one or more control modes then an intermediate damper setting is used as the lower threshold

and the remaining working modes can demand higher damping as required.