electrical JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2350 of 3039

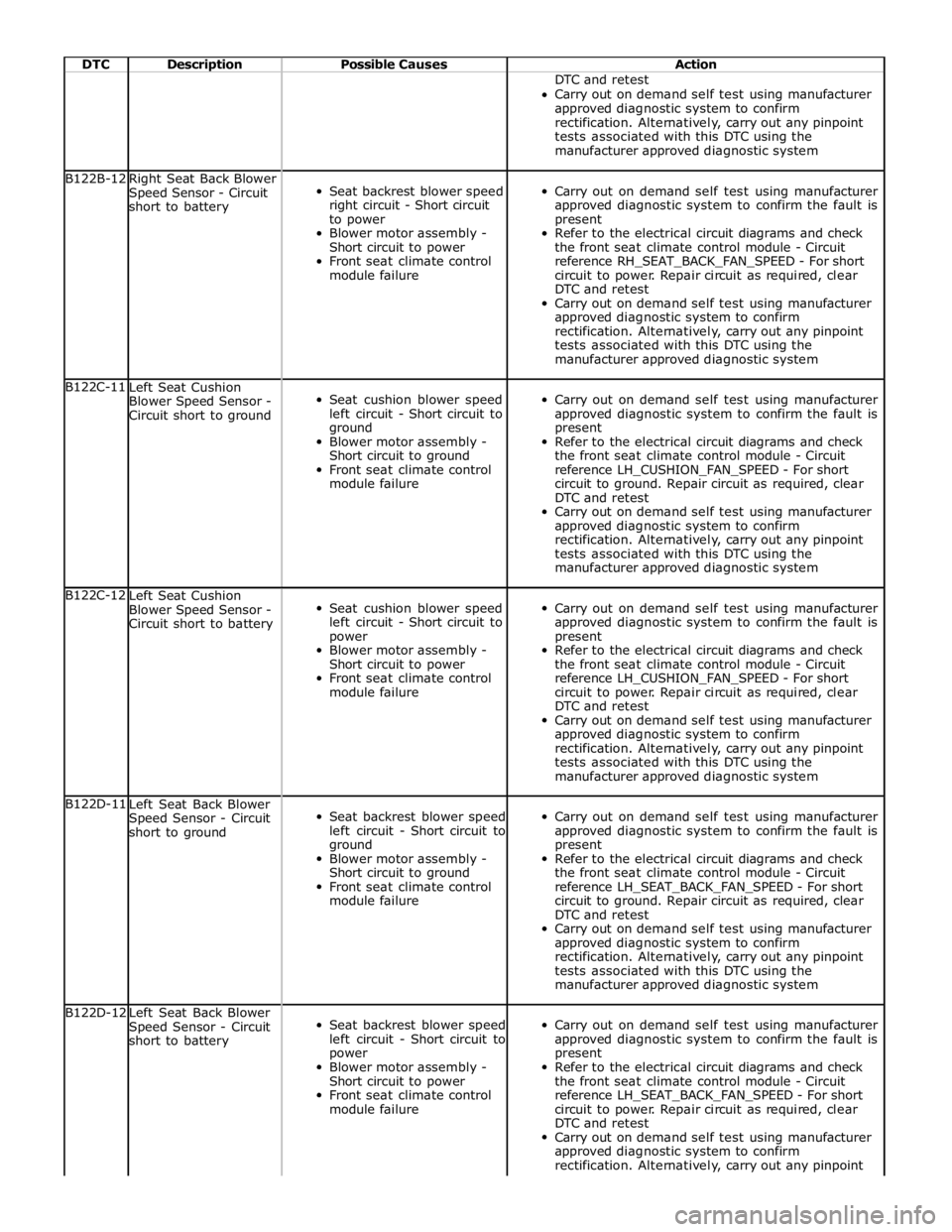

DTC Description Possible Causes Action DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122B-12

Right Seat Back Blower

Speed Sensor - Circuit

short to battery

Seat backrest blower speed

right circuit - Short circuit

to power

Blower motor assembly -

Short circuit to power

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference RH_SEAT_BACK_FAN_SPEED - For short

circuit to power. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122C-11

Left Seat Cushion

Blower Speed Sensor -

Circuit short to ground

Seat cushion blower speed

left circuit - Short circuit to

ground

Blower motor assembly -

Short circuit to ground

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_CUSHION_FAN_SPEED - For short

circuit to ground. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122C-12

Left Seat Cushion

Blower Speed Sensor -

Circuit short to battery

Seat cushion blower speed

left circuit - Short circuit to

power

Blower motor assembly -

Short circuit to power

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_CUSHION_FAN_SPEED - For short

circuit to power. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122D-11

Left Seat Back Blower

Speed Sensor - Circuit

short to ground

Seat backrest blower speed

left circuit - Short circuit to

ground

Blower motor assembly -

Short circuit to ground

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_SEAT_BACK_FAN_SPEED - For short

circuit to ground. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122D-12

Left Seat Back Blower

Speed Sensor - Circuit

short to battery

Seat backrest blower speed

left circuit - Short circuit to

power

Blower motor assembly -

Short circuit to power

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_SEAT_BACK_FAN_SPEED - For short

circuit to power. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

Page 2351 of 3039

DTC Description Possible Causes Action tests associated with this DTC using the

manufacturer approved diagnostic system B122E-98

Right Seat Cushion -

Component or system

over temperature

Blocked or restricted

thermal electric device fan

exhaust vent

Restricted thermal electric

device fan movement

Check for blockage or restriction in thermal electric

device fan exhaust vent

Check for restricted thermal electric device fan

movement

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122F-98

Right Seat Back -

Component or system

over temperature

Blocked or restricted

thermal electric device fan

exhaust vent

Restricted thermal electric

device fan movement

Check for blockage or restriction in thermal electric

device fan exhaust vent

Check for restricted thermal electric device fan

movement

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1230-98

Left Seat Back -

Component or system

over temperature

Blocked or restricted

thermal electric device fan

exhaust vent

Restricted thermal electric

device fan movement

Check for blockage or restriction in thermal electric

device fan exhaust vent

Check for restricted thermal electric device fan

movement

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1231-7A

Right Seat - Fluid leak

or seal failure

Seat backrest assembly -

Air path leaking

Seat cushion assembly -

Air path leaking

Seat assembly damaged

Check for blockage or restriction in seat

backrest/seat cushion thermal electric device fan

ducts

Check seat backrest/seat cushion thermal electric

device fan exhaust vent is clear

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1232-7A

Left Seat - Fluid leak or

seal failure

Seat backrest assembly -

Air path leaking

Seat cushion assembly -

Air path leaking

Seat assembly damaged

Check for blockage or restriction in seat

backrest/seat cushion thermal electric device fan

ducts

Check seat backrest/seat cushion thermal electric

device fan exhaust vent is clear

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1235-13

Left Seat Cushion Temperature Sensor -

Circuit open

Connectors disconnected or

connector pin damage

Seat cushion temperature

sensor left circuit - Open

circuit

Front seat climate control

module failure

Check for any disconnected connectors or damaged

connector pins

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_CUSHION_SENSOR, Circuit reference

LH_CUSHION_SENSOR_RTN - For open circuit.

Repair circuit as required, clear DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system

Page 2352 of 3039

DTC Description Possible Causes Action U0010-88

Medium Speed CAN

Communication Bus -

Bus off

Medium speed CAN

communication - Bus off

Refer to the electrical circuit diagrams and check

the power and ground connections to the module

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0140-00

Lost Communication

With Body Control

Module - No sub type

information

Lost communication with

central junction box

NOTE: This DTC may be stored even though no fault

condition is present and should be ignored unless the

customer has reported a climate seat concern. Clear the

DTC and retest. Verify the customer concern prior to

diagnosis

Refer to the electrical circuit diagrams and check

the power and ground connections to the module

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test

Refer to the electrical circuit diagrams and check

the CAN network between the front seat climate

control module and central junction box

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0142-00 Lost Communication

Lost communication with

Refer to the electrical circuit diagrams and check With Body Control Module "B" - No sub rear junction box the power and ground connections to the module type information Using the manufacturer approved diagnostic system, complete a CAN network integrity test Refer to the electrical circuit diagrams and check the CAN network between the front seat climate control module and rear junction box Carry out on demand self test using manufacturer approved diagnostic system to confirm rectification U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Lost communication with

instrument cluster

Refer to the electrical circuit diagrams and check

the power and ground connections to the module

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test

Refer to the electrical circuit diagrams and check

the CAN network between the front seat climate

control module and instrument cluster

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0156-00 Lost Communication

Lost communication with

Refer to the electrical circuit diagrams and check With Information Center "A" - No sub rear seat entertainment the power and ground connections to the module type information control module Using the manufacturer approved diagnostic system, complete a CAN network integrity test Refer to the electrical circuit diagrams and check the CAN network between the front seat climate control module and rear seat entertainment control module Carry out on demand self test using manufacturer approved diagnostic system to confirm rectification U0300-00

Internal Control Module

Software

Incompatibility - No

sub type information

Software stored in front

seat climate control

module is not compatible

with master configuration

Check the front seat climate control module is

configured correctly

Reconfigure the front seat climate control module

using the manufacturer approved diagnostic

system. Clear the DTC and retest the system

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0401-00

Invalid Data Received

From ECM/PCM - No

sub type information

The engine control module

has transmitted engine

speed quality factor CAN

signal at a specific value

for a greater than expected

time period

Check the engine control module for related DTCs

and refer to the relevant DTC index

On software levels previous to 8X23-14B663-AE

clear the DTC and take no further action if the

system is operating correctly

Page 2353 of 3039

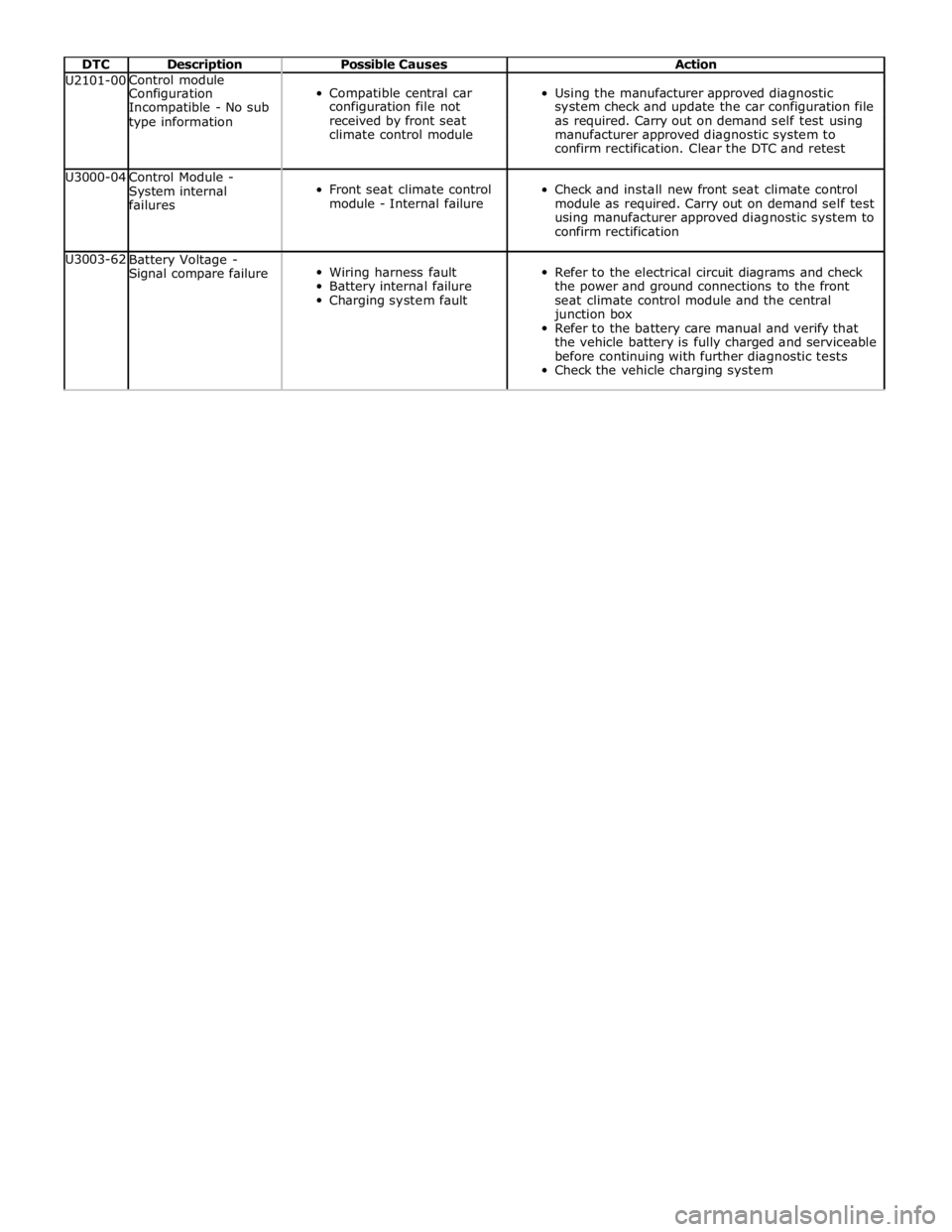

DTC Description Possible Causes Action U2101-00 Control module

Compatible central car

Using the manufacturer approved diagnostic Configuration Incompatible - No sub configuration file not system check and update the car configuration file type information received by front seat as required. Carry out on demand self test using climate control module manufacturer approved diagnostic system to confirm rectification. Clear the DTC and retest U3000-04

Control Module -

System internal

failures

Front seat climate control

module - Internal failure

Check and install new front seat climate control

module as required. Carry out on demand self test

using manufacturer approved diagnostic system to

confirm rectification U3003-62

Battery Voltage -

Signal compare failure

Wiring harness fault

Battery internal failure

Charging system fault

Refer to the electrical circuit diagrams and check

the power and ground connections to the front

seat climate control module and the central

junction box

Refer to the battery care manual and verify that

the vehicle battery is fully charged and serviceable

before continuing with further diagnostic tests

Check the vehicle charging system

Page 2354 of 3039

Seating - Seat Smoothing

General Procedures Published: 01-May-2014

WARNINGS: Check

Make sure that the steamer is in the OFF position before connecting or disconnecting from the electrical outlet.

Do not use another high wattage device on the same electrical circuit.

If the use of an extension cord is absolutely necessary, the cord must be rated at a minimum of 10 amps.

To avoid the risk of electrical shock, check the condition of the power cord and the steamer before use.

Make sure that the steamer is disconnected from the electrical outlet before filling or emptying the water reservoir.

The steamer must only be used and placed on its stand on a stable surface.

To prevent injury such as burns, take care whilst using the steamer. Avoid coming into contact with the hot surface of the

steamer and do not direct steam toward any persons.

The steamer must ALWAYS be switched off when not in use or left unattended.

Do not allow the power cord to come into contact with the hot surface of the steamer.

CAUTIONS:

Protect the surrounding paintwork to avoid damage.

Protect the paintwork during this operation.

Do not use any additives in the steamer. Damage to the steamer or the seat cover can result if used.

NOTE: Some variation in the illustrations may occur, but the essential information is always correct.

1. CAUTIONS:

Steam the leather cushions evenly and progressively. Do not use

excessive force.

Take care not to damage the leather whilst steaming into the

corners.

Do not hold the steamer in one place for longer than 10 seconds,

as this will burn the leather and damage the covers. www.JagDocs.com

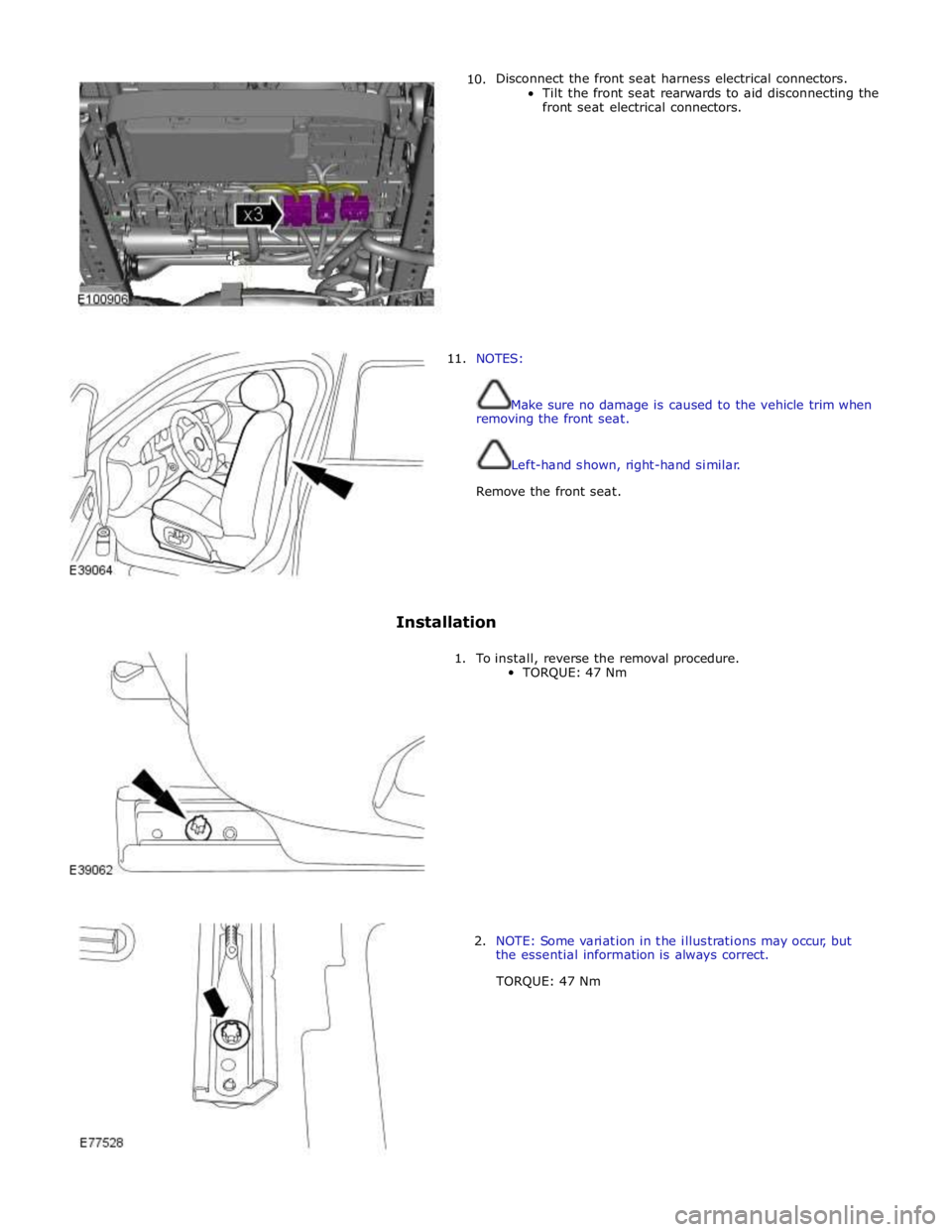

Page 2358 of 3039

10. Disconnect the front seat harness electrical connectors.

Tilt the front seat rearwards to aid disconnecting the

front seat electrical connectors.

11. NOTES:

Make sure no damage is caused to the vehicle trim when

removing the front seat.

Left-hand shown, right-hand similar.

Remove the front seat.

Installation

1. To install, reverse the removal procedure.

TORQUE: 47 Nm

2. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

TORQUE: 47 Nm

Page 2363 of 3039

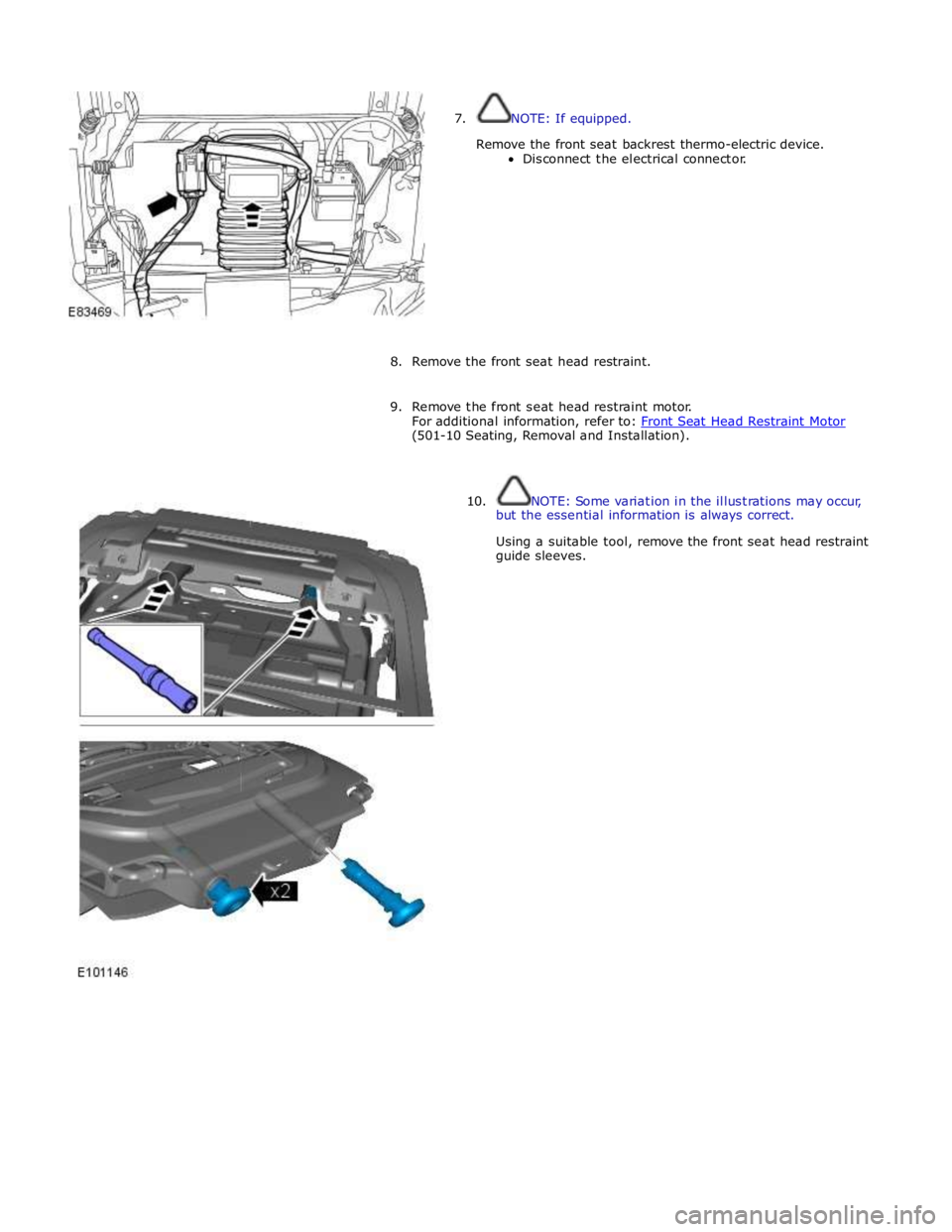

7. NOTE: If equipped.

Remove the front seat backrest thermo-electric device.

Disconnect the electrical connector.

8. Remove the front seat head restraint.

9. Remove the front seat head restraint motor.

For additional information, refer to: Front Seat Head Restraint Motor (501-10 Seating, Removal and Installation).

10. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Using a suitable tool, remove the front seat head restraint

guide sleeves.

Page 2376 of 3039

Seating - Seat Base

Removal and Installation

Removal

WARNINGS: Published: 11-May-2011

To avoid accidental deployment, the restraints control module backup power supply must be depleted. Wait at least one

minute after disconnecting the battery ground cable(s) before commencing any repair or adjustment to the supplemental

restraint system (SRS), or any component(s) adjacent to the SRS sensors. Failure to follow these instructions may result in

personal injury.

Always wear safety glasses when working on an air bag equipped vehicle and when handling an air bag module. Failure to

follow this instruction may result in personal injury.

To minimize the possibility of premature deployment, do not use radio key code savers when working on the

supplemental restraint system. Failure to follow this instruction may result in personal injury.

To minimize the possibility of injury in the event of premature deployment, always carry a live air bag module with the

bag and trim cover pointed away from the body. Failure to follow this instruction may result in personal injury.

To minimize the possibility of premature deployment, live air bag modules must only be placed on work benches which

have been ground bonded and with the trim cover facing up. Failure to follow these instructions may result in personal injury.

Never probe the electrical connectors of air bag modules or any other supplemental restraint system component. Failure

to follow this instruction may result in personal injury.

Painting over the driver air bag module trim cover or instrument panel could lead to deterioration of the trim cover and air

bags. Do not for any reason attempt to paint discolored or damaged air bag module trim covers or instrument panel. Install a

new component. Failure to follow this instruction may result in personal injury.

NOTES:

Some variation in the illustrations may occur, but the essential information is always correct.

Removal steps in this procedure may contain installation details.

1. Make the air bag supplemental restraint system (SRS) safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Refer to: Front Seat (501-10 Seating, Removal and Installation).

3. Refer to: Front Safety Belt Buckle (501-20A Safety Belt System, Removal and Installation).

4. Refer to: Front Seat Cushion Cover (501-10 Seating, Removal and Installation).

Page 2413 of 3039

Published: 11-May-2011

Glass, Frames and Mechanisms - Glass, Frames and Mechanisms - Overview

Description and Operation

Overview

The windshield is manufactured from laminated green-tinted glass with two variants of windshield being available: standard

and heated.

The rear window is manufactured from toughened green-tinted glass. The heated rear window grid-wire and antennas are

incorporated in the rear window. There are two variants of rear window dependant on the TV antenna specification.

The door windows are manufactured from green-tinted toughened glass. The driver and passenger windows are electrically

operated; the rear glass sections in the rear doors are fixed units. Door windows can be operated individually, or by the driver's

window control switch. An anti-trap function is included that stops the window's travel when an obstacle is detected in the in

the window's path.

Page 2416 of 3039

Rear Window

The rear window, manufactured from toughened 4mm green-tinted glass, is positioned to the vehicle's body by two locator

pins, one in each top corner of the windshield. This allows for the centralizing movement of the windshield across the car upon

fitment. The window is bonded and sealed to the vehicle body aperture using PU adhesive. The window finisher is a

three-sided extruded flip, taped onto the inner surface of the glass; this helps to centralize the glass in the aperture.

The heated rear window grid wire and antennas are incorporated in the rear window. There are two derivatives of rear window

dependant on the TV antenna specification.

Refer to: Video System (415-01, Description and Operation).

Door Windows

The door windows are manufactured from 4.85mm green-tinted toughened glass. The driver and passenger windows are

electrically operated, and are raised and lowered by a cable mechanism; the rear glass sections in the rear doors are fixed

units.

All windows can be operated individually, or by the driver's window control switch. The operation of the windows is proportional

to the switch activation. The driver window can be controlled by 'one touch' in an upward or downward direction. When the 'one

touch' operation is activated in the upwards direction an anti-trap sensor is automatically checked prior to the window closing.

If the anti-trap sensor is inoperative the window will not close. When the anti-trap sensor detects an obstacle in the window's

path, the upward travel of the window will automatically cease. Downward travel of the window will begin and then stop when a

preset time has elapsed.