list JAGUAR XFR 2010 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 488 of 3039

Vehicle Dynamic Suspension - Vehicle Dynamic Suspension

Diagnosis and Testing

Principle of Operation Published: 09-Jul-2014

For a detailed description of the adaptive damping system operation, refer to the relevant Description and Operation section of

the workshop manual. REFER to: (204-05 Vehicle Dynamic Suspension)

Vehicle Dynamic Suspension - V8 5.0L Petrol/V8 S/C 5.0L Petrol (Description and Operation),

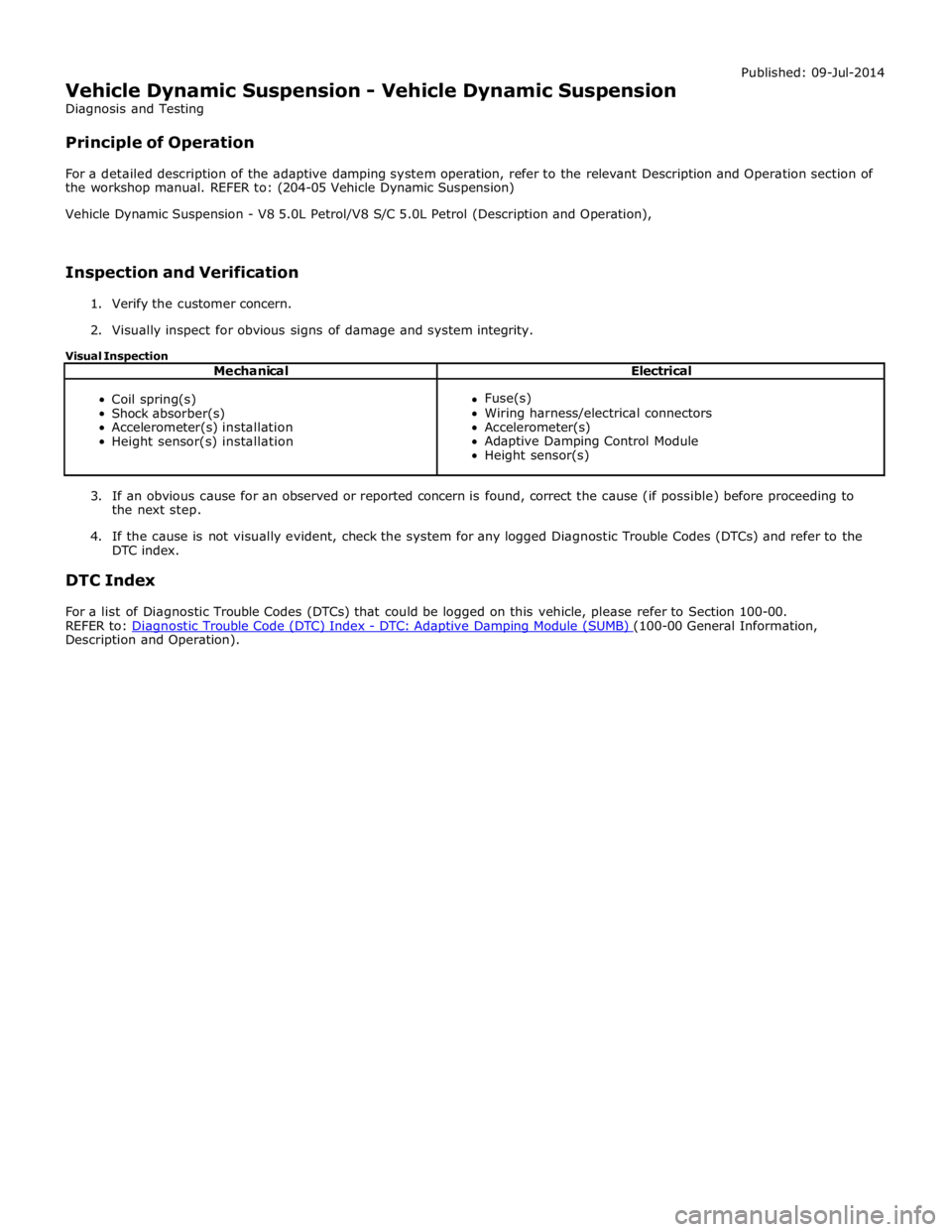

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Coil spring(s)

Shock absorber(s)

Accelerometer(s) installation

Height sensor(s) installation

Fuse(s)

Wiring harness/electrical connectors

Accelerometer(s)

Adaptive Damping Control Module

Height sensor(s)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check the system for any logged Diagnostic Trouble Codes (DTCs) and refer to the

DTC index.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Adaptive Damping Module (SUMB) (100-00 General Information, Description and Operation).

Page 538 of 3039

Rear Drive Axle/Differential - Rear Drive Axle and Differential

Diagnosis and Testing

Principle of Operation Published: 12-May-2014

For a detailed description of the Rear Drive Axle and Differential, refer to the relevant Description and Operation section in the

workshop manual. REFER to: Rear Drive Axle and Differential (205-02 Rear Drive Axle/Differential, Description and Operation).

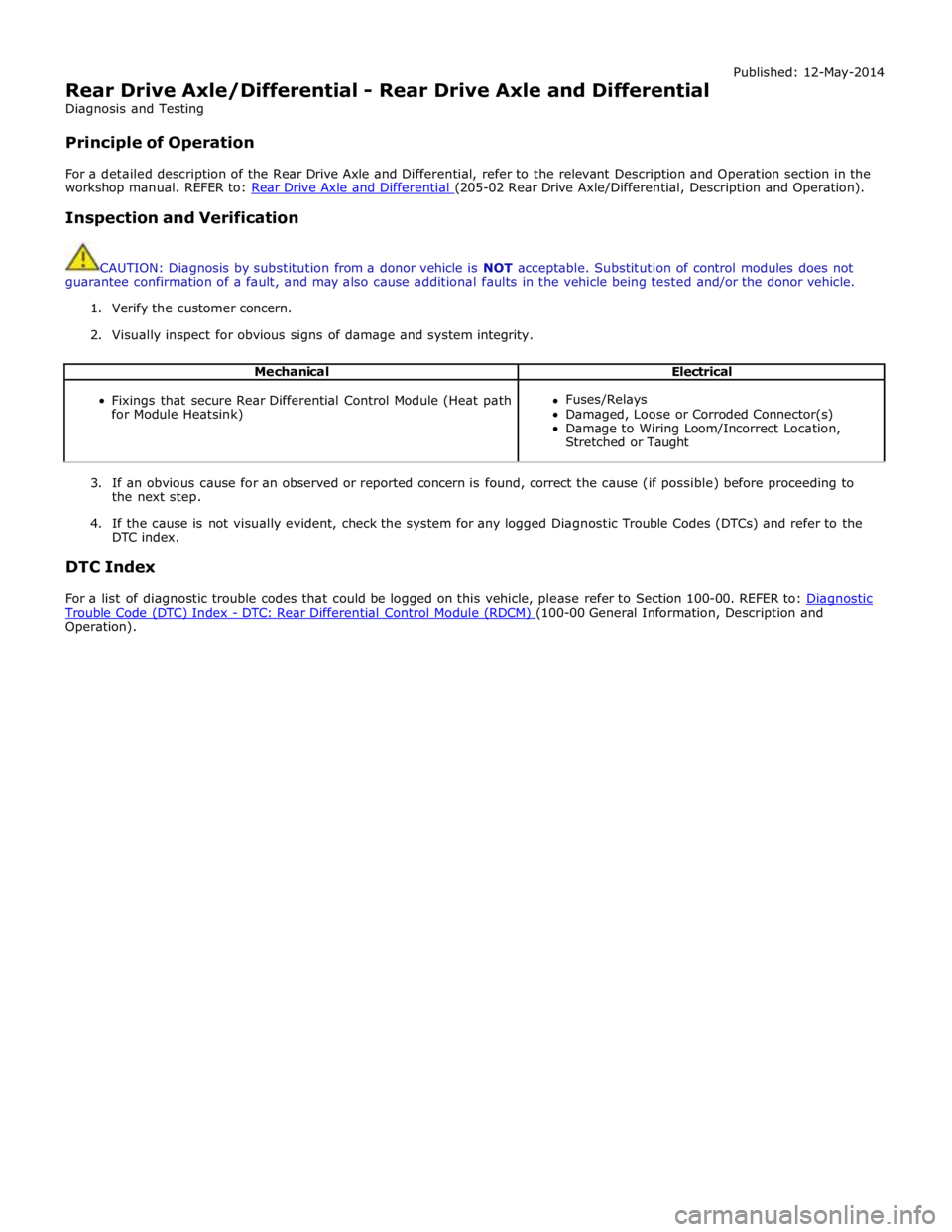

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Mechanical Electrical

Fixings that secure Rear Differential Control Module (Heat path

for Module Heatsink)

Fuses/Relays

Damaged, Loose or Corroded Connector(s)

Damage to Wiring Loom/Incorrect Location,

Stretched or Taught

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check the system for any logged Diagnostic Trouble Codes (DTCs) and refer to the

DTC index.

DTC Index

For a list of diagnostic trouble codes that could be logged on this vehicle, please refer to Section 100-00. REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Rear Differential Control Module (RDCM) (100-00 General Information, Description and Operation).

Page 583 of 3039

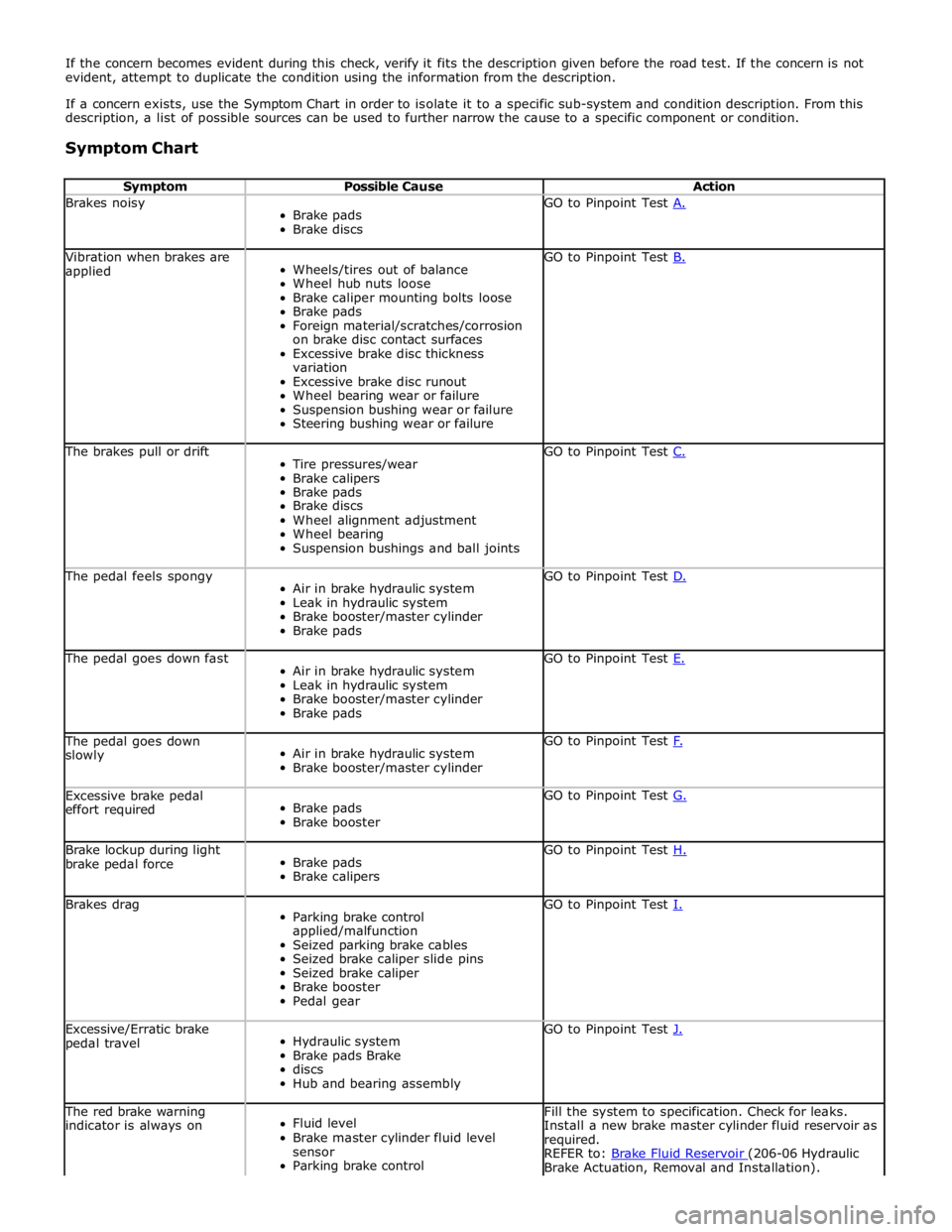

If the concern becomes evident during this check, verify it fits the description given before the road test. If the concern is not

evident, attempt to duplicate the condition using the information from the description.

If a concern exists, use the Symptom Chart in order to isolate it to a specific sub-system and condition description. From this

description, a list of possible sources can be used to further narrow the cause to a specific component or condition.

Symptom Chart

Symptom Possible Cause Action Brakes noisy

Brake pads

Brake discs GO to Pinpoint Test A. Vibration when brakes are

applied

Wheels/tires out of balance

Wheel hub nuts loose

Brake caliper mounting bolts loose

Brake pads

Foreign material/scratches/corrosion

on brake disc contact surfaces

Excessive brake disc thickness

variation

Excessive brake disc runout

Wheel bearing wear or failure

Suspension bushing wear or failure

Steering bushing wear or failure GO to Pinpoint Test B. The brakes pull or drift

Tire pressures/wear

Brake calipers

Brake pads

Brake discs

Wheel alignment adjustment

Wheel bearing

Suspension bushings and ball joints GO to Pinpoint Test C. The pedal feels spongy

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test D. The pedal goes down fast

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test E. The pedal goes down

slowly

Air in brake hydraulic system

Brake booster/master cylinder GO to Pinpoint Test F. Excessive brake pedal

effort required

Brake pads

Brake booster GO to Pinpoint Test G. Brake lockup during light

brake pedal force

Brake pads

Brake calipers GO to Pinpoint Test H. Brakes drag

Parking brake control

applied/malfunction

Seized parking brake cables

Seized brake caliper slide pins

Seized brake caliper

Brake booster

Pedal gear GO to Pinpoint Test I. Excessive/Erratic brake

pedal travel

Hydraulic system

Brake pads Brake

discs

Hub and bearing assembly GO to Pinpoint Test J. The red brake warning

indicator is always on

Fluid level

Brake master cylinder fluid level

sensor

Parking brake control Fill the system to specification. Check for leaks.

Install a new brake master cylinder fluid reservoir as

required.

REFER to: Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

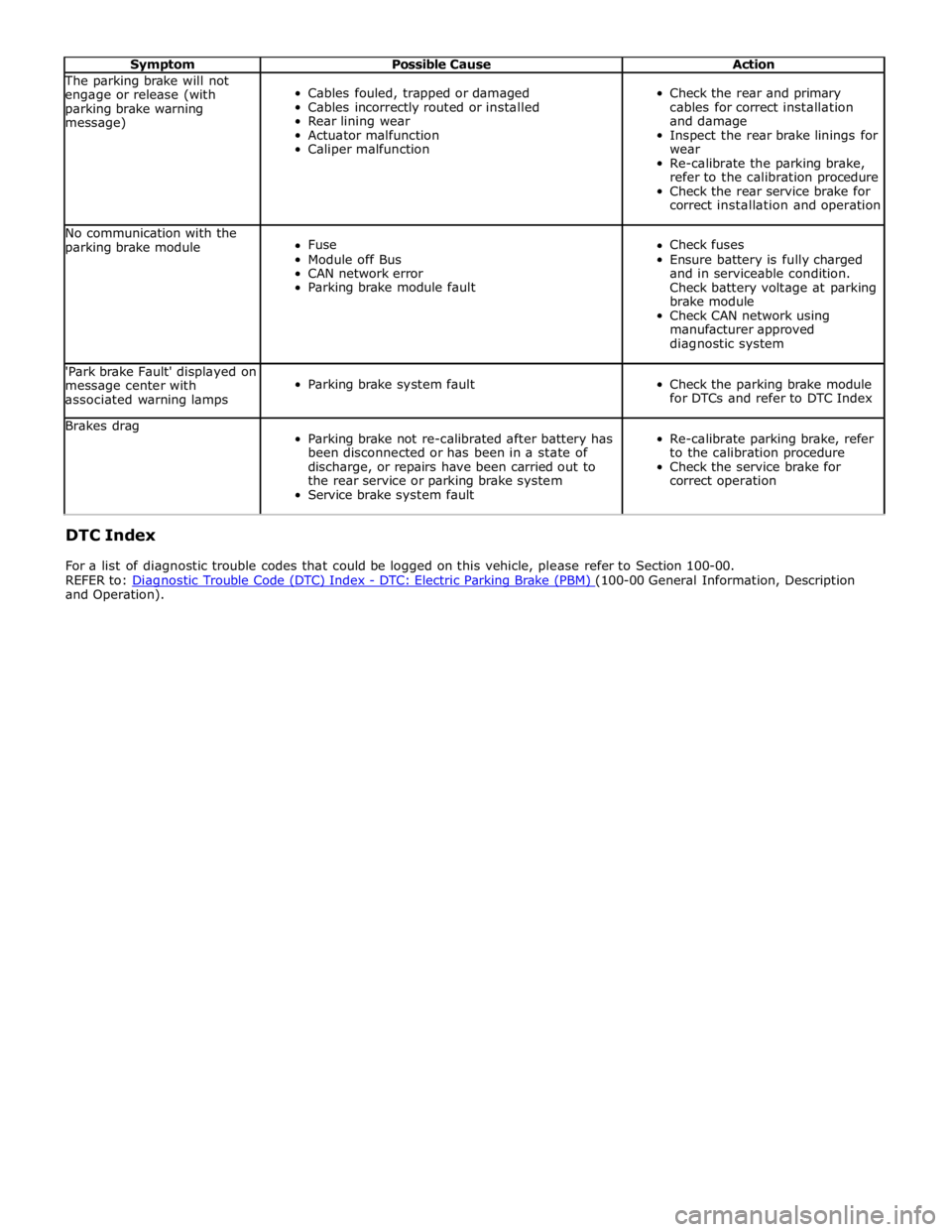

Page 654 of 3039

Symptom Possible Cause Action The parking brake will not

engage or release (with

parking brake warning

message)

Cables fouled, trapped or damaged

Cables incorrectly routed or installed

Rear lining wear

Actuator malfunction

Caliper malfunction

Check the rear and primary

cables for correct installation

and damage

Inspect the rear brake linings for

wear

Re-calibrate the parking brake,

refer to the calibration procedure

Check the rear service brake for

correct installation and operation No communication with the

parking brake module

Fuse

Module off Bus

CAN network error

Parking brake module fault

Check fuses

Ensure battery is fully charged

and in serviceable condition.

Check battery voltage at parking

brake module

Check CAN network using

manufacturer approved

diagnostic system 'Park brake Fault' displayed on

message center with

associated warning lamps

Parking brake system fault

Check the parking brake module

for DTCs and refer to DTC Index Brakes drag

Parking brake not re-calibrated after battery has

been disconnected or has been in a state of

discharge, or repairs have been carried out to

the rear service or parking brake system

Service brake system fault

Re-calibrate parking brake, refer

to the calibration procedure

Check the service brake for

correct operation DTC Index

For a list of diagnostic trouble codes that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Electric Parking Brake (PBM) (100-00 General Information, Description and Operation).

Page 692 of 3039

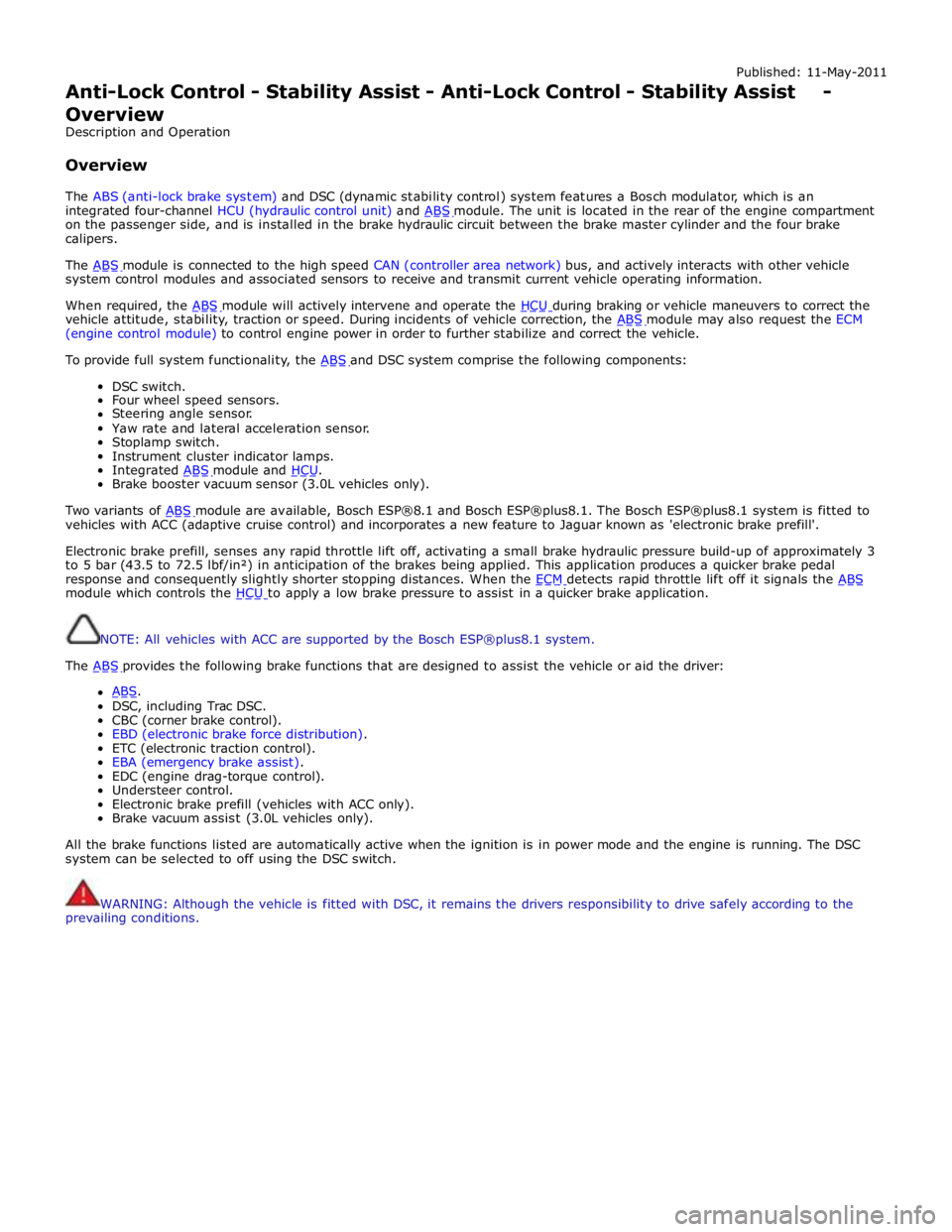

Published: 11-May-2011

Anti-Lock Control - Stability Assist - Anti-Lock Control - Stability Assist - Overview

Description and Operation

Overview

The ABS (anti-lock brake system) and DSC (dynamic stability control) system features a Bosch modulator, which is an

integrated four-channel HCU (hydraulic control unit) and ABS module. The unit is located in the rear of the engine compartment on the passenger side, and is installed in the brake hydraulic circuit between the brake master cylinder and the four brake

calipers.

The ABS module is connected to the high speed CAN (controller area network) bus, and actively interacts with other vehicle system control modules and associated sensors to receive and transmit current vehicle operating information.

When required, the ABS module will actively intervene and operate the HCU during braking or vehicle maneuvers to correct the vehicle attitude, stability, traction or speed. During incidents of vehicle correction, the ABS module may also request the ECM (engine control module) to control engine power in order to further stabilize and correct the vehicle.

To provide full system functionality, the ABS and DSC system comprise the following components: DSC switch.

Four wheel speed sensors.

Steering angle sensor.

Yaw rate and lateral acceleration sensor.

Stoplamp switch.

Instrument cluster indicator lamps.

Integrated ABS module and HCU. Brake booster vacuum sensor (3.0L vehicles only).

Two variants of ABS module are available, Bosch ESP®8.1 and Bosch ESP®plus8.1. The Bosch ESP®plus8.1 system is fitted to vehicles with ACC (adaptive cruise control) and incorporates a new feature to Jaguar known as 'electronic brake prefill'.

Electronic brake prefill, senses any rapid throttle lift off, activating a small brake hydraulic pressure build-up of approximately 3

to 5 bar (43.5 to 72.5 lbf/in²) in anticipation of the brakes being applied. This application produces a quicker brake pedal

response and consequently slightly shorter stopping distances. When the ECM detects rapid throttle lift off it signals the ABS module which controls the HCU to apply a low brake pressure to assist in a quicker brake application.

NOTE: All vehicles with ACC are supported by the Bosch ESP®plus8.1 system.

The ABS provides the following brake functions that are designed to assist the vehicle or aid the driver: ABS. DSC, including Trac DSC.

CBC (corner brake control).

EBD (electronic brake force distribution).

ETC (electronic traction control).

EBA (emergency brake assist).

EDC (engine drag-torque control).

Understeer control.

Electronic brake prefill (vehicles with ACC only).

Brake vacuum assist (3.0L vehicles only).

All the brake functions listed are automatically active when the ignition is in power mode and the engine is running. The DSC

system can be selected to off using the DSC switch.

WARNING: Although the vehicle is fitted with DSC, it remains the drivers responsibility to drive safely according to the

prevailing conditions.

Page 703 of 3039

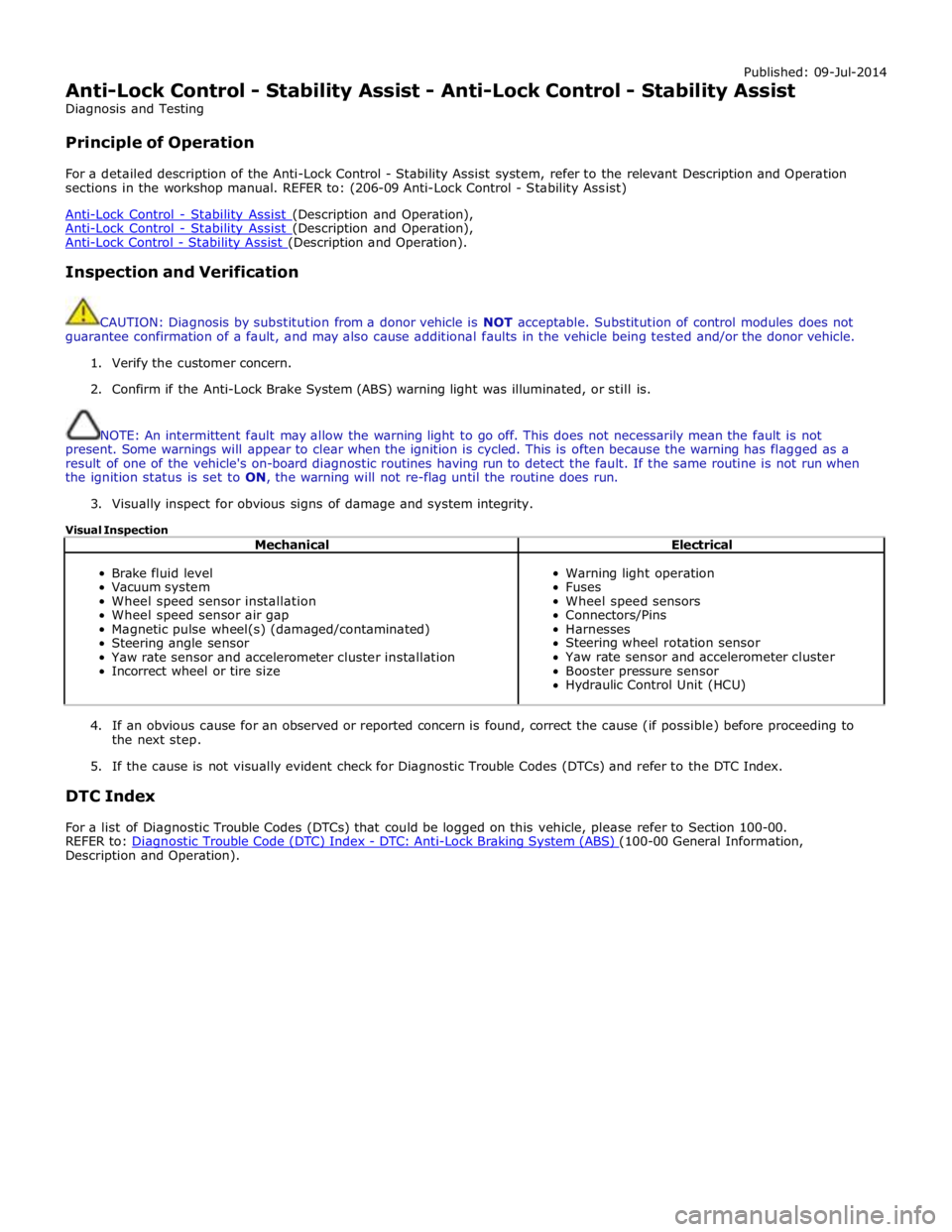

Published: 09-Jul-2014

Anti-Lock Control - Stability Assist - Anti-Lock Control - Stability Assist

Diagnosis and Testing

Principle of Operation

For a detailed description of the Anti-Lock Control - Stability Assist system, refer to the relevant Description and Operation

sections in the workshop manual. REFER to: (206-09 Anti-Lock Control - Stability Assist)

Anti-Lock Control - Stability Assist (Description and Operation), Anti-Lock Control - Stability Assist (Description and Operation), Anti-Lock Control - Stability Assist (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Confirm if the Anti-Lock Brake System (ABS) warning light was illuminated, or still is.

NOTE: An intermittent fault may allow the warning light to go off. This does not necessarily mean the fault is not

present. Some warnings will appear to clear when the ignition is cycled. This is often because the warning has flagged as a

result of one of the vehicle's on-board diagnostic routines having run to detect the fault. If the same routine is not run when

the ignition status is set to ON, the warning will not re-flag until the routine does run.

3. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Brake fluid level

Vacuum system

Wheel speed sensor installation

Wheel speed sensor air gap

Magnetic pulse wheel(s) (damaged/contaminated)

Steering angle sensor

Yaw rate sensor and accelerometer cluster installation

Incorrect wheel or tire size

Warning light operation

Fuses

Wheel speed sensors

Connectors/Pins

Harnesses

Steering wheel rotation sensor

Yaw rate sensor and accelerometer cluster

Booster pressure sensor

Hydraulic Control Unit (HCU)

4. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

5. If the cause is not visually evident check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Anti-Lock Braking System (ABS) (100-00 General Information, Description and Operation).

Page 804 of 3039

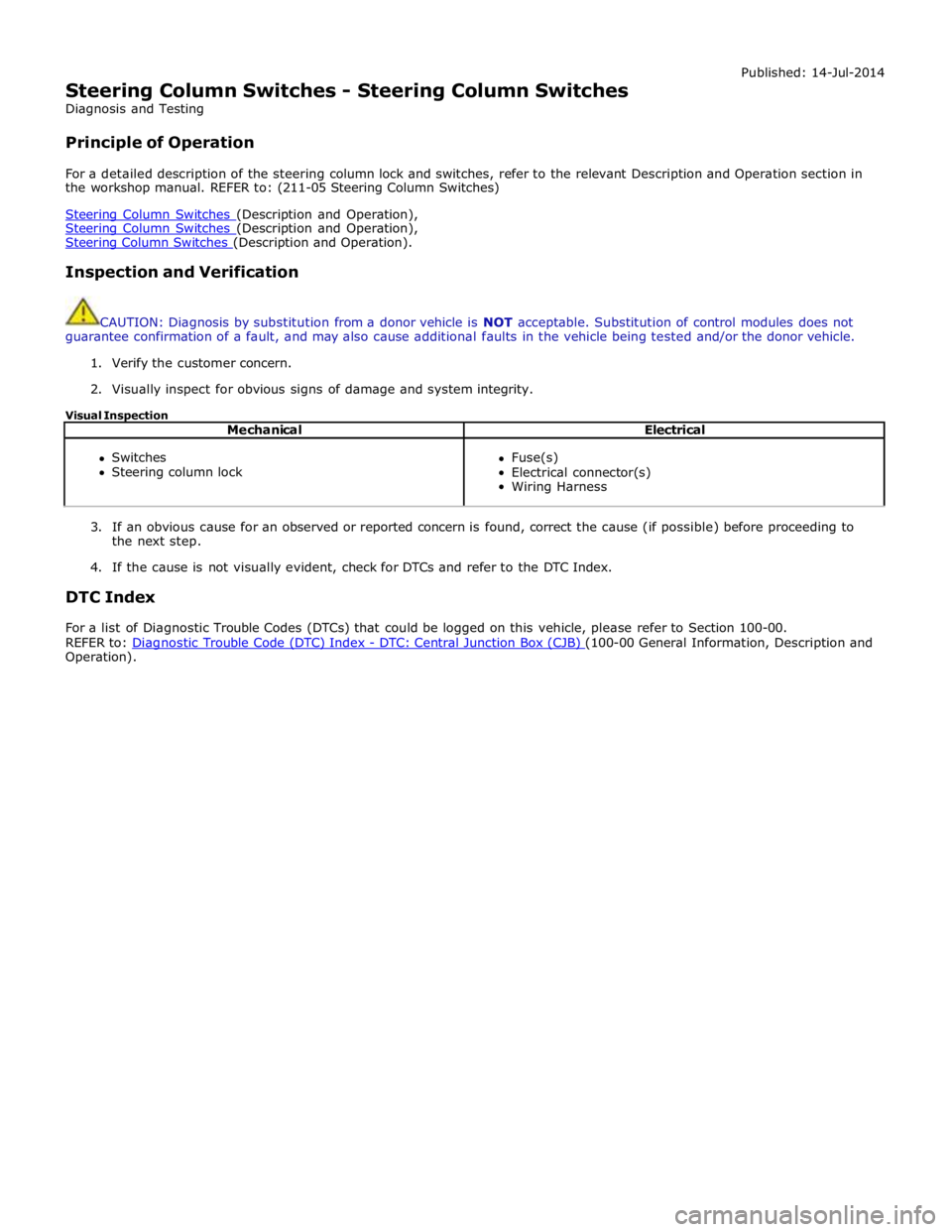

Steering Column Switches - Steering Column Switches

Diagnosis and Testing

Principle of Operation Published: 14-Jul-2014

For a detailed description of the steering column lock and switches, refer to the relevant Description and Operation section in

the workshop manual. REFER to: (211-05 Steering Column Switches)

Steering Column Switches (Description and Operation), Steering Column Switches (Description and Operation), Steering Column Switches (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Switches

Steering column lock

Fuse(s)

Electrical connector(s)

Wiring Harness

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for DTCs and refer to the DTC Index.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Central Junction Box (CJB) (100-00 General Information, Description and Operation).

Page 812 of 3039

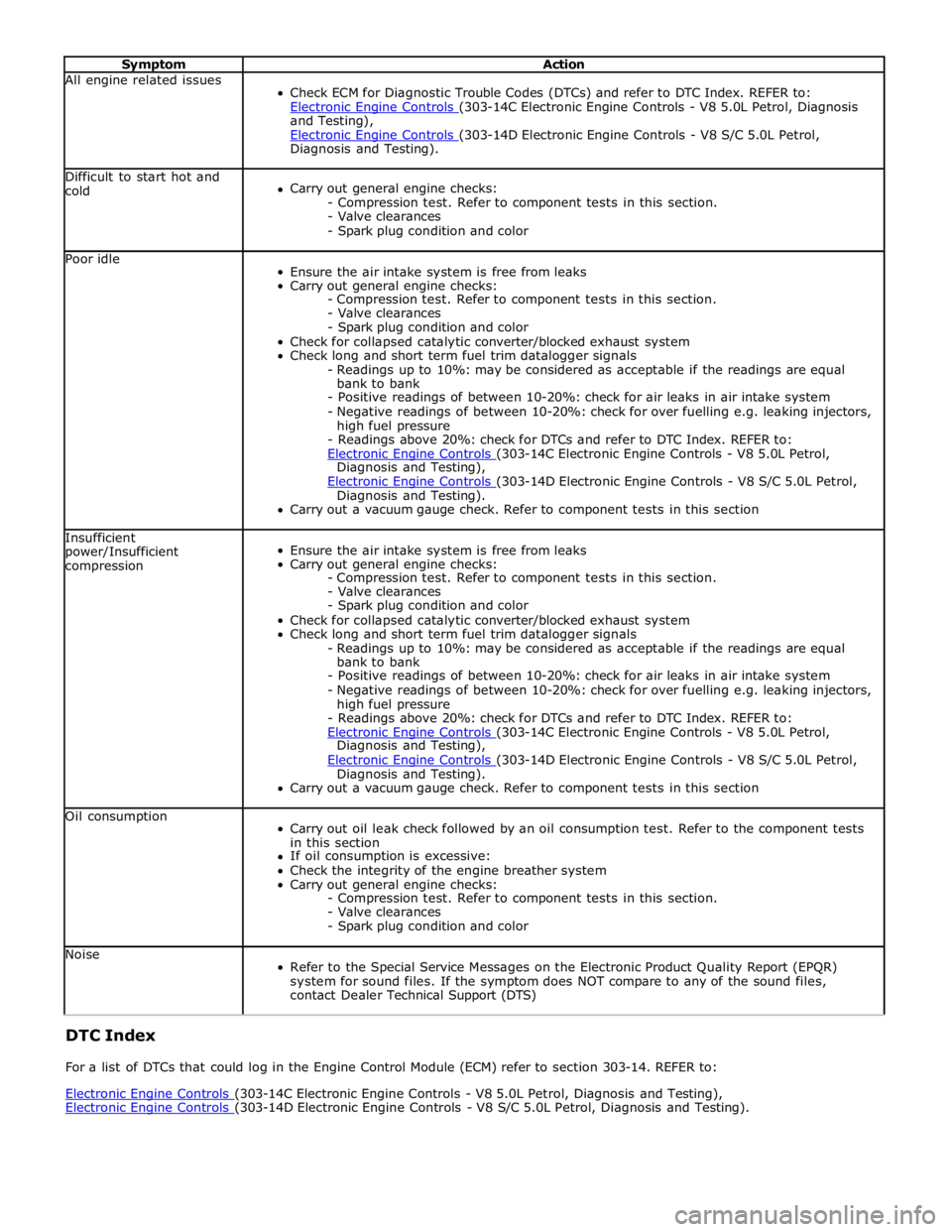

Symptom Action All engine related issues

Check ECM for Diagnostic Trouble Codes (DTCs) and refer to DTC Index. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing),

Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing). Difficult to start hot and

cold

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color Poor idle

Ensure the air intake system is free from leaks

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color

Check for collapsed catalytic converter/blocked exhaust system

Check long and short term fuel trim datalogger signals

- Readings up to 10%: may be considered as acceptable if the readings are equal

bank to bank

- Positive readings of between 10-20%: check for air leaks in air intake system

- Negative readings of between 10-20%: check for over fuelling e.g. leaking injectors,

high fuel pressure

- Readings above 20%: check for DTCs and refer to DTC Index. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing),

Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Carry out a vacuum gauge check. Refer to component tests in this section Insufficient

power/Insufficient

compression

Ensure the air intake system is free from leaks

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color

Check for collapsed catalytic converter/blocked exhaust system

Check long and short term fuel trim datalogger signals

- Readings up to 10%: may be considered as acceptable if the readings are equal

bank to bank

- Positive readings of between 10-20%: check for air leaks in air intake system

- Negative readings of between 10-20%: check for over fuelling e.g. leaking injectors,

high fuel pressure

- Readings above 20%: check for DTCs and refer to DTC Index. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing),

Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Carry out a vacuum gauge check. Refer to component tests in this section Oil consumption

Carry out oil leak check followed by an oil consumption test. Refer to the component tests

in this section

If oil consumption is excessive:

Check the integrity of the engine breather system

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color Noise

Refer to the Special Service Messages on the Electronic Product Quality Report (EPQR)

system for sound files. If the symptom does NOT compare to any of the sound files,

contact Dealer Technical Support (DTS) DTC Index

For a list of DTCs that could log in the Engine Control Module (ECM) refer to section 303-14. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing), Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Page 1123 of 3039

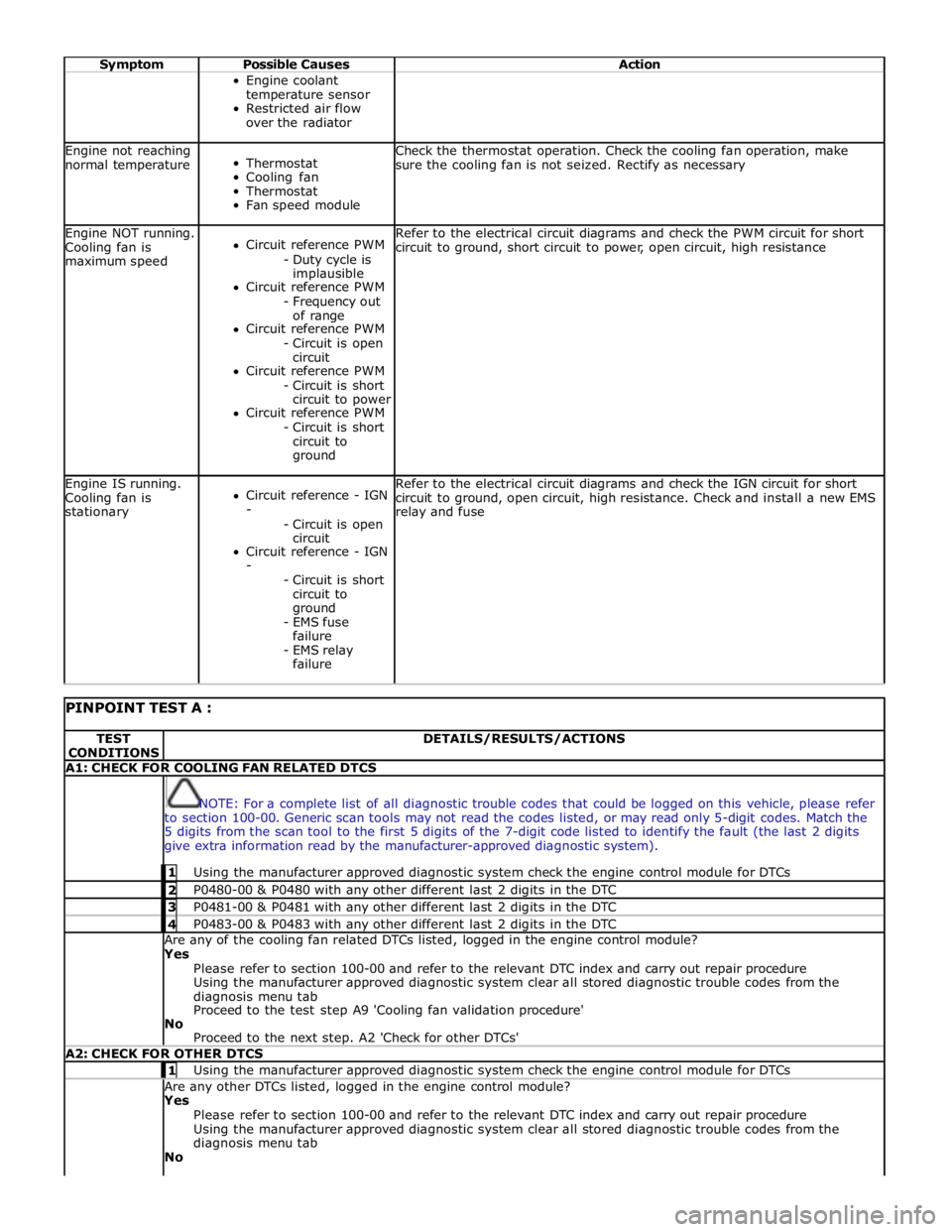

Symptom Possible Causes Action Engine coolant

temperature sensor

Restricted air flow

over the radiator Engine not reaching

normal temperature

Thermostat

Cooling fan

Thermostat

Fan speed module Check the thermostat operation. Check the cooling fan operation, make

sure the cooling fan is not seized. Rectify as necessary Engine NOT running.

Cooling fan is

maximum speed

Circuit reference PWM

- Duty cycle is

implausible

Circuit reference PWM

- Frequency out

of range

Circuit reference PWM

- Circuit is open

circuit

Circuit reference PWM

- Circuit is short

circuit to power

Circuit reference PWM

- Circuit is short

circuit to

ground Refer to the electrical circuit diagrams and check the PWM circuit for short

circuit to ground, short circuit to power, open circuit, high resistance Engine IS running.

Cooling fan is

stationary

Circuit reference - IGN

-

- Circuit is open

circuit

Circuit reference - IGN

-

- Circuit is short

circuit to

ground

- EMS fuse

failure

- EMS relay

failure Refer to the electrical circuit diagrams and check the IGN circuit for short

circuit to ground, open circuit, high resistance. Check and install a new EMS

relay and fuse

PINPOINT TEST A : TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK FOR COOLING FAN RELATED DTCS

NOTE: For a complete list of all diagnostic trouble codes that could be logged on this vehicle, please refer

to section 100-00. Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the

5 digits from the scan tool to the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits

give extra information read by the manufacturer-approved diagnostic system). 1 Using the manufacturer approved diagnostic system check the engine control module for DTCs 2 P0480-00 & P0480 with any other different last 2 digits in the DTC 3 P0481-00 & P0481 with any other different last 2 digits in the DTC 4 P0483-00 & P0483 with any other different last 2 digits in the DTC Are any of the cooling fan related DTCs listed, logged in the engine control module?

Yes

Please refer to section 100-00 and refer to the relevant DTC index and carry out repair procedure

Using the manufacturer approved diagnostic system clear all stored diagnostic trouble codes from the

diagnosis menu tab

Proceed to the test step A9 'Cooling fan validation procedure'

No

Proceed to the next step. A2 'Check for other DTCs' A2: CHECK FOR OTHER DTCS 1 Using the manufacturer approved diagnostic system check the engine control module for DTCs Are any other DTCs listed, logged in the engine control module?

Yes

Please refer to section 100-00 and refer to the relevant DTC index and carry out repair procedure

Using the manufacturer approved diagnostic system clear all stored diagnostic trouble codes from the

diagnosis menu tab

No

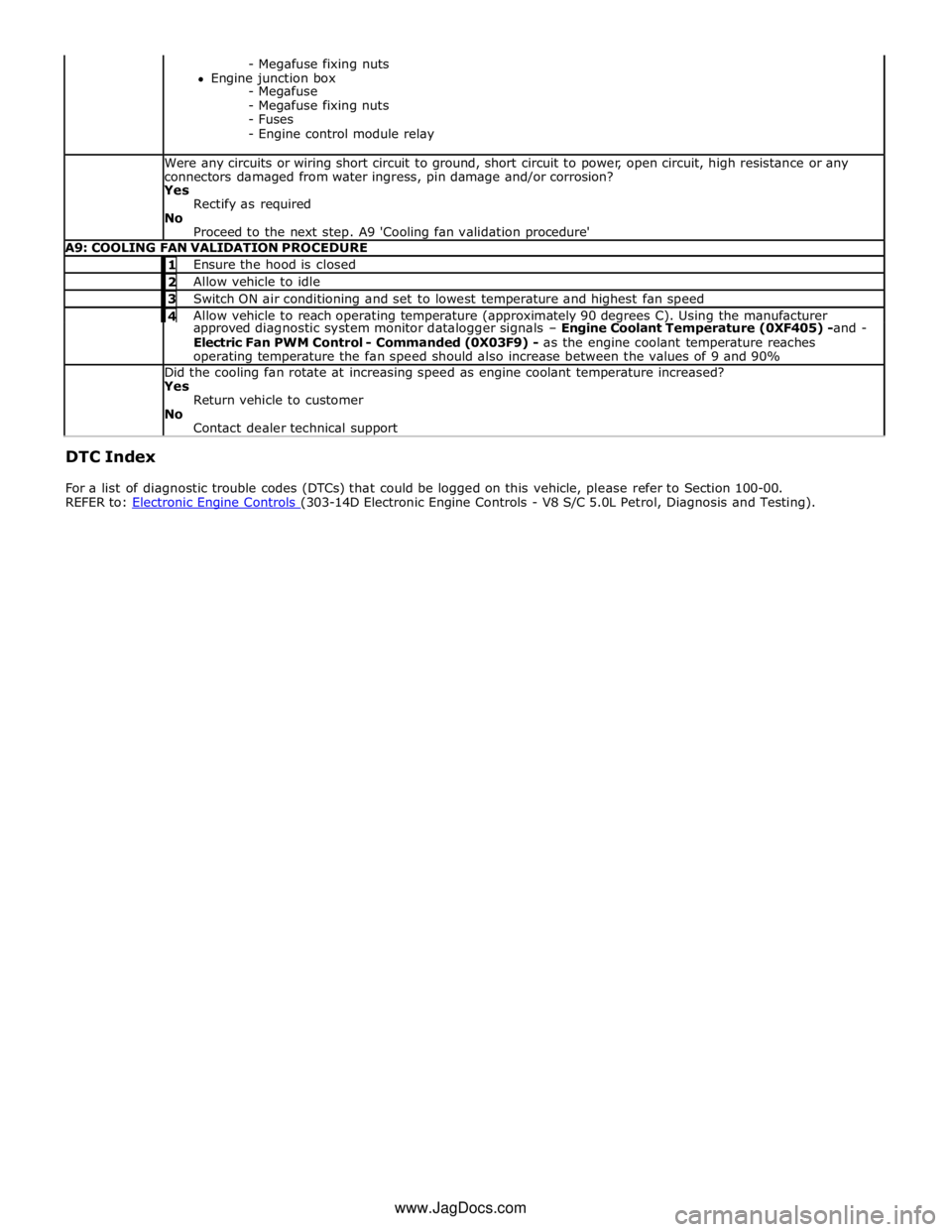

Page 1125 of 3039

- Megafuse fixing nuts

Engine junction box

- Megafuse

- Megafuse fixing nuts

- Fuses

- Engine control module relay Were any circuits or wiring short circuit to ground, short circuit to power, open circuit, high resistance or any

connectors damaged from water ingress, pin damage and/or corrosion?

Yes

Rectify as required

No

Proceed to the next step. A9 'Cooling fan validation procedure' A9: COOLING FAN VALIDATION PROCEDURE 1 Ensure the hood is closed 2 Allow vehicle to idle 3 Switch ON air conditioning and set to lowest temperature and highest fan speed 4 Allow vehicle to reach operating temperature (approximately 90 degrees C). Using the manufacturer approved diagnostic system monitor datalogger signals – Engine Coolant Temperature (0XF405) -and -

Electric Fan PWM Control - Commanded (0X03F9) - as the engine coolant temperature reaches

operating temperature the fan speed should also increase between the values of 9 and 90% Did the cooling fan rotate at increasing speed as engine coolant temperature increased?

Yes

Return vehicle to customer

No

Contact dealer technical support DTC Index

For a list of diagnostic trouble codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing). www.JagDocs.com