lock JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 258 of 3039

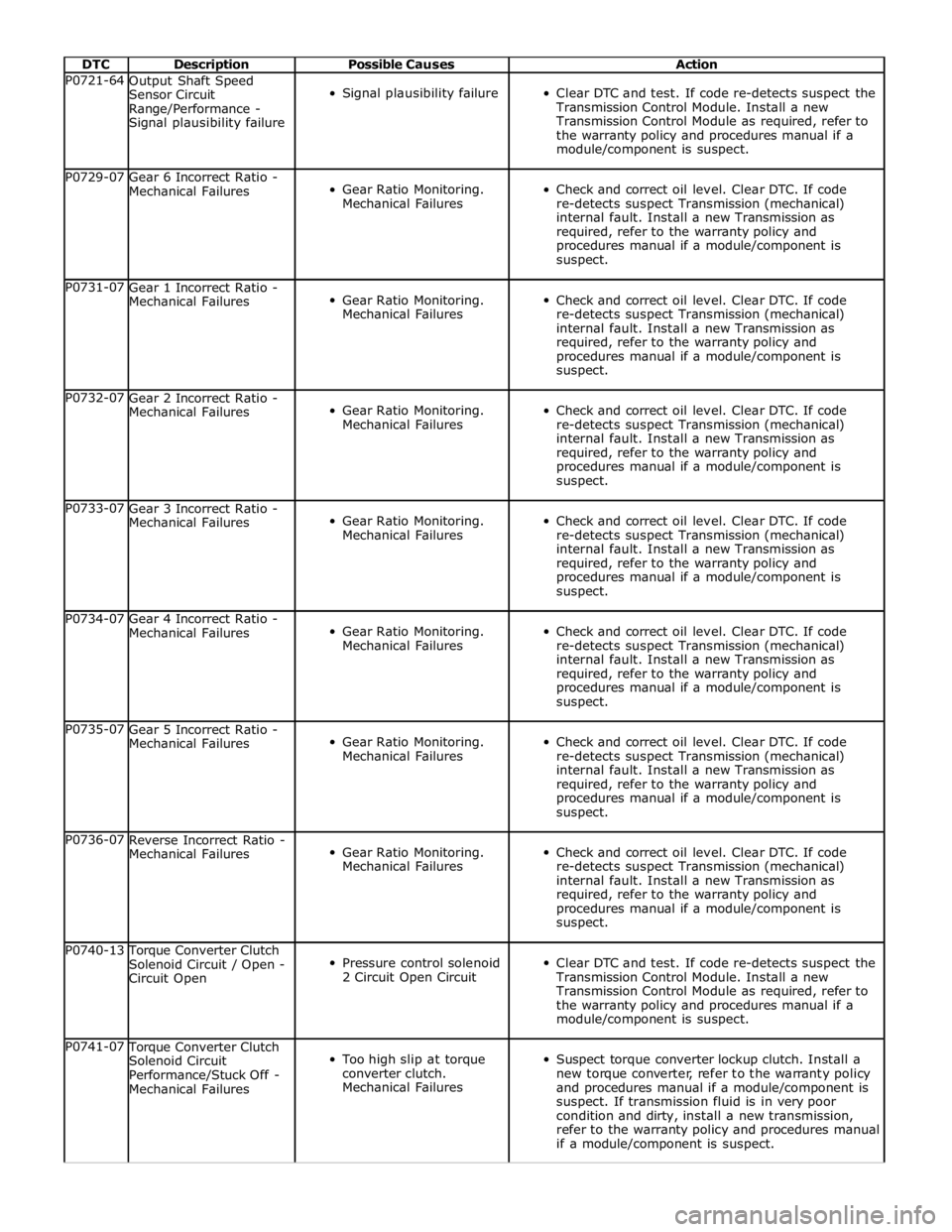

DTC Description Possible Causes Action P0721-64

Output Shaft Speed

Sensor Circuit

Range/Performance -

Signal plausibility failure

Signal plausibility failure

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0729-07

Gear 6 Incorrect Ratio -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0731-07

Gear 1 Incorrect Ratio -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0732-07

Gear 2 Incorrect Ratio -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0733-07

Gear 3 Incorrect Ratio -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0734-07

Gear 4 Incorrect Ratio -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0735-07

Gear 5 Incorrect Ratio -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0736-07

Reverse Incorrect Ratio -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0740-13 Torque Converter Clutch

Solenoid Circuit / Open -

Circuit Open

Pressure control solenoid

2 Circuit Open Circuit

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0741-07 Torque Converter Clutch

Solenoid Circuit

Performance/Stuck Off -

Mechanical Failures

Too high slip at torque

converter clutch.

Mechanical Failures

Suspect torque converter lockup clutch. Install a

new torque converter, refer to the warranty policy

and procedures manual if a module/component is

suspect. If transmission fluid is in very poor

condition and dirty, install a new transmission,

refer to the warranty policy and procedures manual

if a module/component is suspect.

Page 261 of 3039

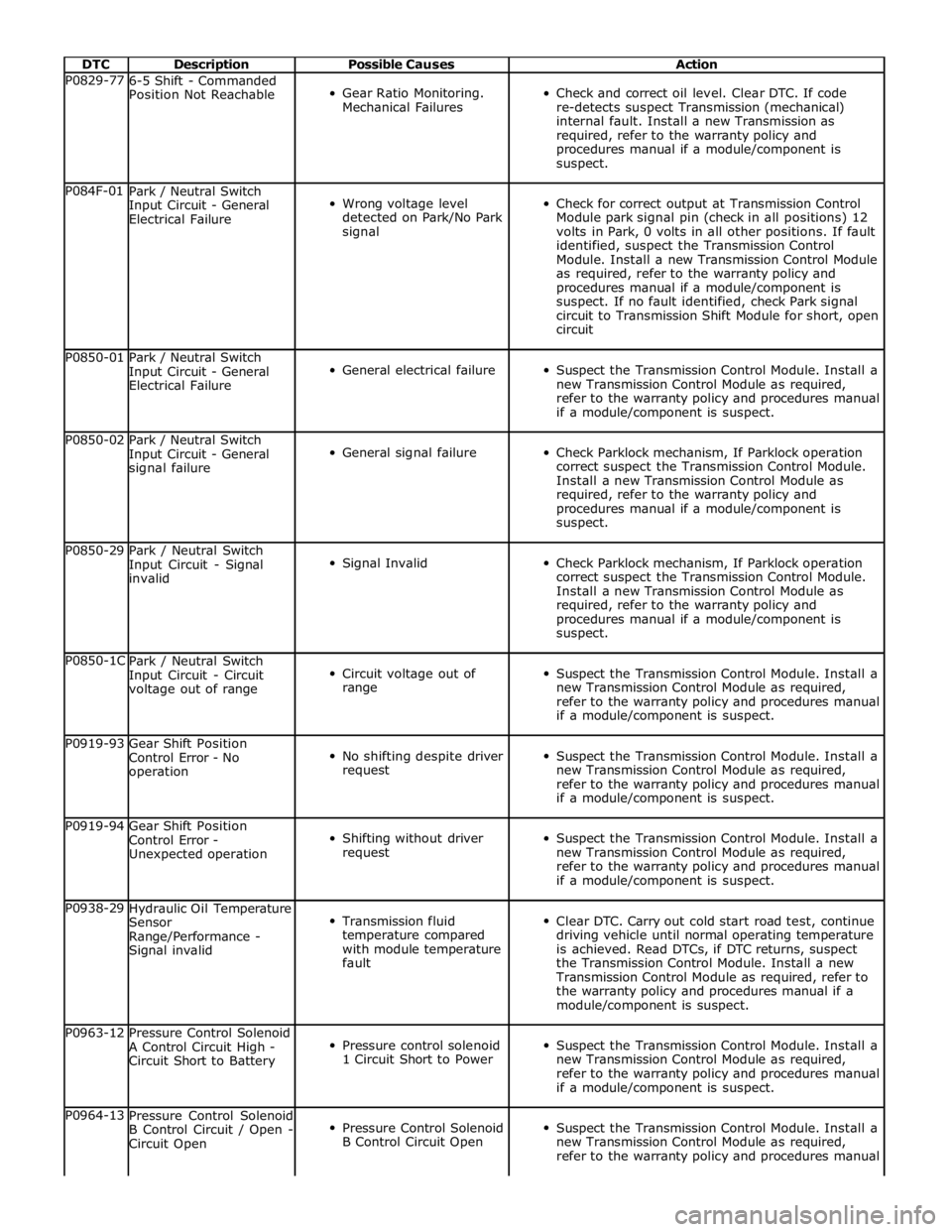

DTC Description Possible Causes Action P0829-77

6-5 Shift - Commanded

Position Not Reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P084F-01

Park / Neutral Switch

Input Circuit - General

Electrical Failure

Wrong voltage level

detected on Park/No Park

signal

Check for correct output at Transmission Control

Module park signal pin (check in all positions) 12

volts in Park, 0 volts in all other positions. If fault

identified, suspect the Transmission Control

Module. Install a new Transmission Control Module

as required, refer to the warranty policy and

procedures manual if a module/component is

suspect. If no fault identified, check Park signal

circuit to Transmission Shift Module for short, open

circuit P0850-01

Park / Neutral Switch

Input Circuit - General

Electrical Failure

General electrical failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0850-02

Park / Neutral Switch

Input Circuit - General

signal failure

General signal failure

Check Parklock mechanism, If Parklock operation

correct suspect the Transmission Control Module.

Install a new Transmission Control Module as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0850-29

Park / Neutral Switch

Input Circuit - Signal

invalid

Signal Invalid

Check Parklock mechanism, If Parklock operation

correct suspect the Transmission Control Module.

Install a new Transmission Control Module as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0850-1C

Park / Neutral Switch

Input Circuit - Circuit

voltage out of range

Circuit voltage out of

range

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0919-93

Gear Shift Position

Control Error - No

operation

No shifting despite driver

request

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0919-94

Gear Shift Position

Control Error -

Unexpected operation

Shifting without driver

request

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0938-29

Hydraulic Oil Temperature

Sensor

Range/Performance -

Signal invalid

Transmission fluid

temperature compared

with module temperature

fault

Clear DTC. Carry out cold start road test, continue

driving vehicle until normal operating temperature

is achieved. Read DTCs, if DTC returns, suspect

the Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0963-12

Pressure Control Solenoid

A Control Circuit High -

Circuit Short to Battery

Pressure control solenoid

1 Circuit Short to Power

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0964-13

Pressure Control Solenoid

B Control Circuit / Open -

Circuit Open

Pressure Control Solenoid

B Control Circuit Open

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

Page 263 of 3039

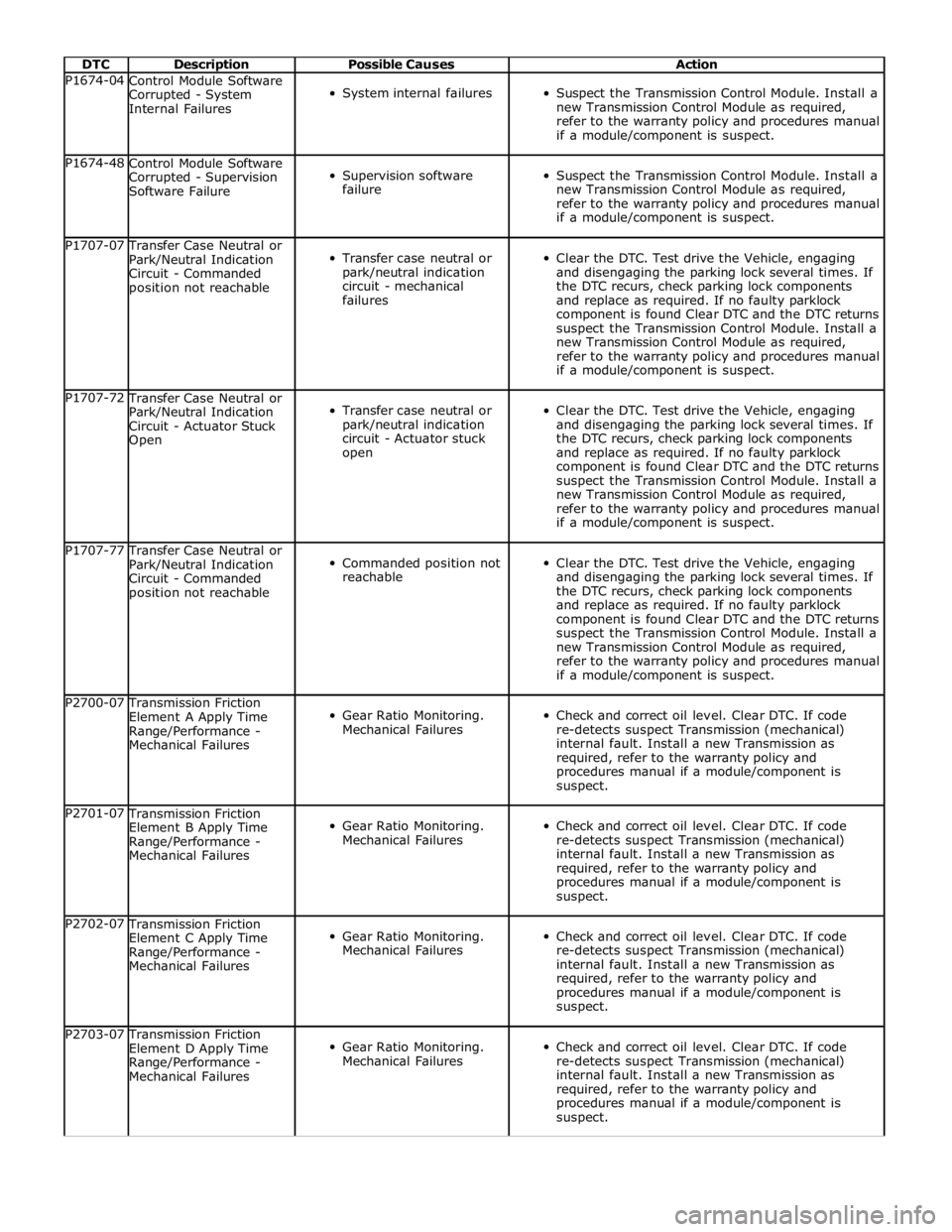

DTC Description Possible Causes Action P1674-04

Control Module Software

Corrupted - System

Internal Failures

System internal failures

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P1674-48

Control Module Software

Corrupted - Supervision

Software Failure

Supervision software

failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P1707-07 Transfer Case Neutral or

Park/Neutral Indication

Circuit - Commanded

position not reachable

Transfer case neutral or

park/neutral indication

circuit - mechanical

failures

Clear the DTC. Test drive the Vehicle, engaging

and disengaging the parking lock several times. If

the DTC recurs, check parking lock components

and replace as required. If no faulty parklock

component is found Clear DTC and the DTC returns

suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P1707-72 Transfer Case Neutral or

Park/Neutral Indication

Circuit - Actuator Stuck

Open

Transfer case neutral or

park/neutral indication

circuit - Actuator stuck

open

Clear the DTC. Test drive the Vehicle, engaging

and disengaging the parking lock several times. If

the DTC recurs, check parking lock components

and replace as required. If no faulty parklock

component is found Clear DTC and the DTC returns

suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P1707-77 Transfer Case Neutral or

Park/Neutral Indication

Circuit - Commanded

position not reachable

Commanded position not

reachable

Clear the DTC. Test drive the Vehicle, engaging

and disengaging the parking lock several times. If

the DTC recurs, check parking lock components

and replace as required. If no faulty parklock

component is found Clear DTC and the DTC returns

suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2700-07 Transmission Friction

Element A Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P2701-07 Transmission Friction

Element B Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P2702-07 Transmission Friction

Element C Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P2703-07 Transmission Friction

Element D Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect.

Page 268 of 3039

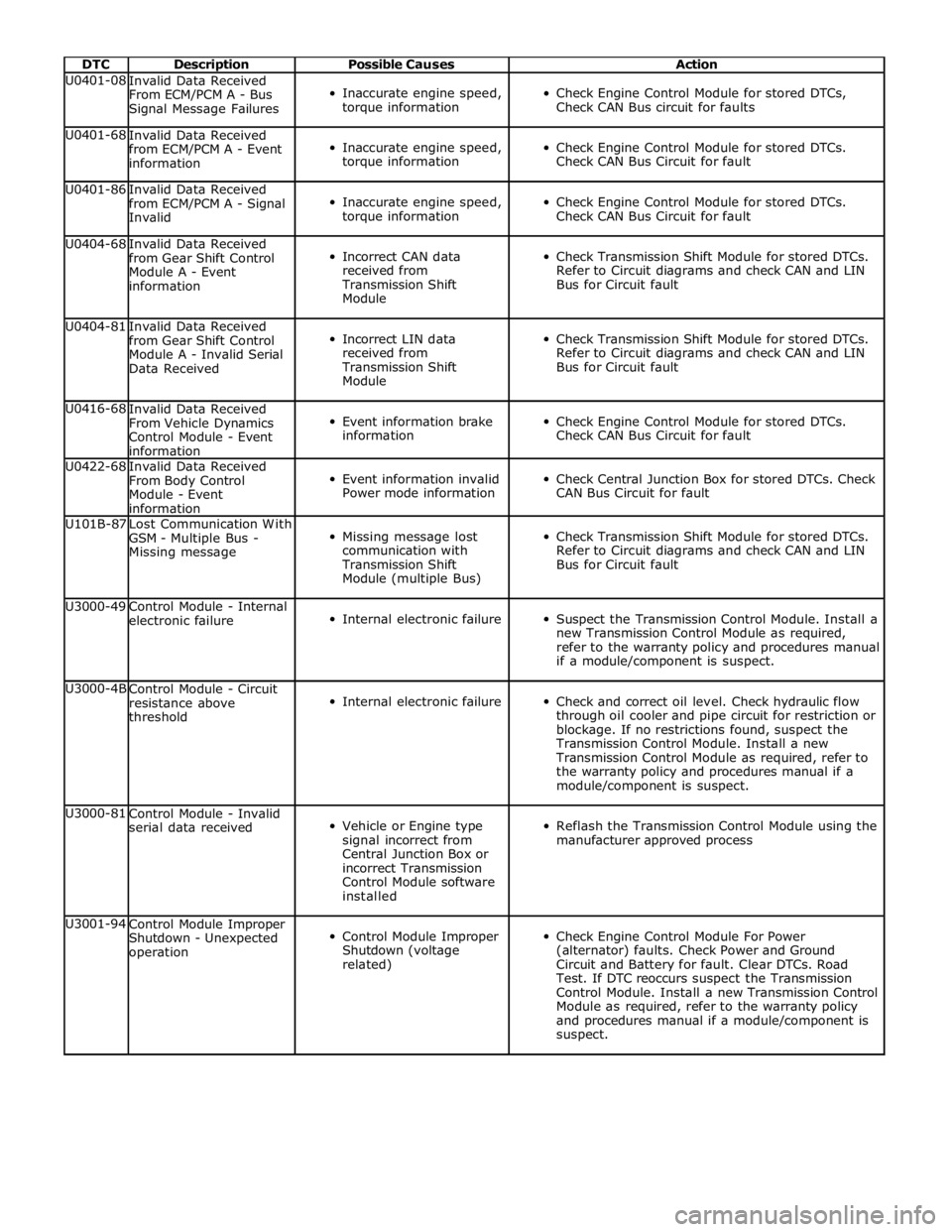

DTC Description Possible Causes Action U0401-08

Invalid Data Received

From ECM/PCM A - Bus

Signal Message Failures

Inaccurate engine speed,

torque information

Check Engine Control Module for stored DTCs,

Check CAN Bus circuit for faults U0401-68

Invalid Data Received

from ECM/PCM A - Event

information

Inaccurate engine speed,

torque information

Check Engine Control Module for stored DTCs.

Check CAN Bus Circuit for fault U0401-86

Invalid Data Received

from ECM/PCM A - Signal

Invalid

Inaccurate engine speed,

torque information

Check Engine Control Module for stored DTCs.

Check CAN Bus Circuit for fault U0404-68

Invalid Data Received

from Gear Shift Control

Module A - Event

information

Incorrect CAN data

received from

Transmission Shift

Module

Check Transmission Shift Module for stored DTCs.

Refer to Circuit diagrams and check CAN and LIN

Bus for Circuit fault U0404-81

Invalid Data Received

from Gear Shift Control

Module A - Invalid Serial

Data Received

Incorrect LIN data

received from

Transmission Shift

Module

Check Transmission Shift Module for stored DTCs.

Refer to Circuit diagrams and check CAN and LIN

Bus for Circuit fault U0416-68

Invalid Data Received

From Vehicle Dynamics

Control Module - Event

information

Event information brake

information

Check Engine Control Module for stored DTCs.

Check CAN Bus Circuit for fault U0422-68

Invalid Data Received

From Body Control

Module - Event

information

Event information invalid

Power mode information

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U101B-87

Lost Communication With

GSM - Multiple Bus -

Missing message

Missing message lost

communication with

Transmission Shift

Module (multiple Bus)

Check Transmission Shift Module for stored DTCs.

Refer to Circuit diagrams and check CAN and LIN

Bus for Circuit fault U3000-49

Control Module - Internal

electronic failure

Internal electronic failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. U3000-4B

Control Module - Circuit

resistance above

threshold

Internal electronic failure

Check and correct oil level. Check hydraulic flow

through oil cooler and pipe circuit for restriction or

blockage. If no restrictions found, suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. U3000-81

Control Module - Invalid

serial data received

Vehicle or Engine type

signal incorrect from

Central Junction Box or

incorrect Transmission

Control Module software

installed

Reflash the Transmission Control Module using the

manufacturer approved process U3001-94

Control Module Improper

Shutdown - Unexpected

operation

Control Module Improper

Shutdown (voltage

related)

Check Engine Control Module For Power

(alternator) faults. Check Power and Ground

Circuit and Battery for fault. Clear DTCs. Road

Test. If DTC reoccurs suspect the Transmission

Control Module. Install a new Transmission Control

Module as required, refer to the warranty policy

and procedures manual if a module/component is

suspect.

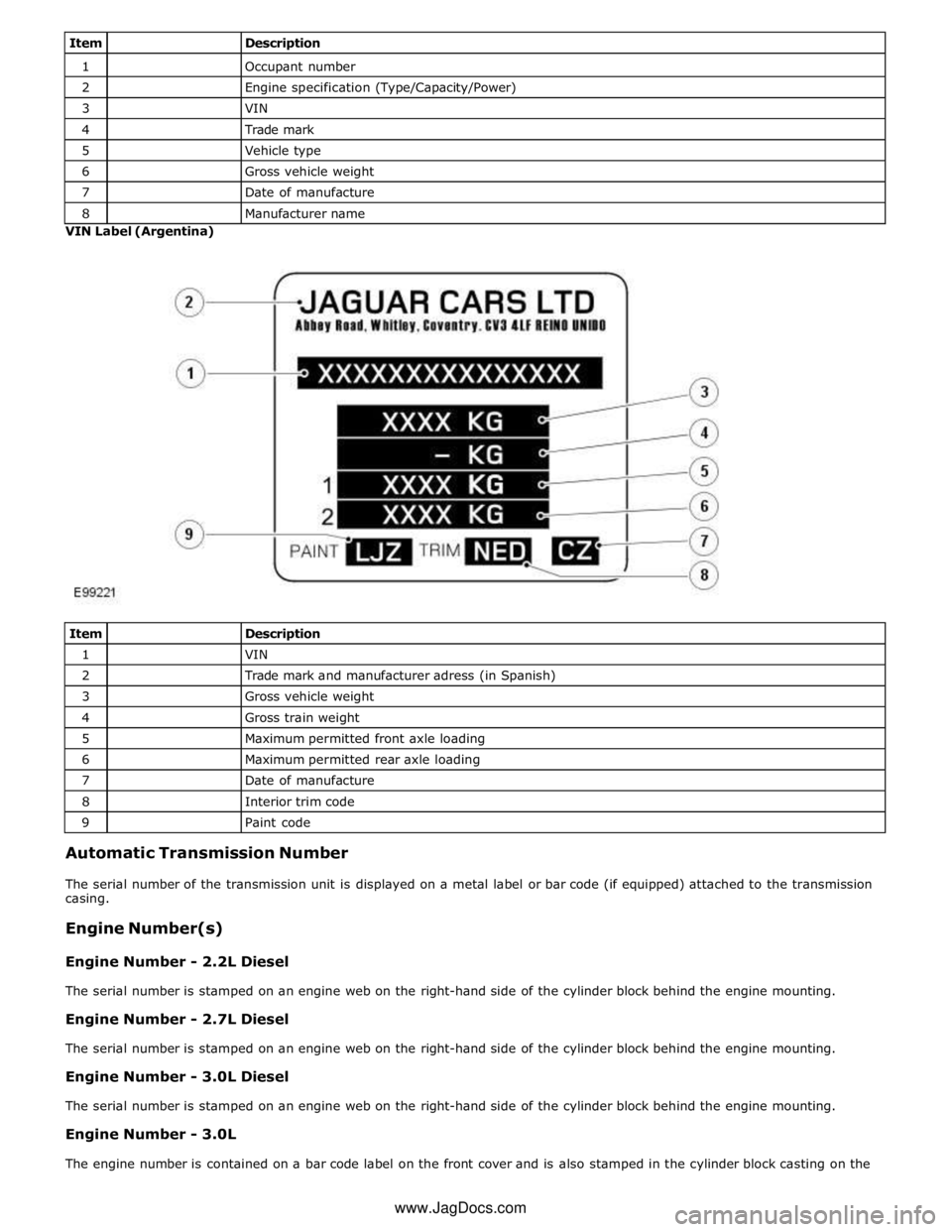

Page 292 of 3039

1

Occupant number 2

Engine specification (Type/Capacity/Power) 3

VIN 4

Trade mark 5

Vehicle type 6

Gross vehicle weight 7

Date of manufacture 8

Manufacturer name VIN Label (Argentina)

Item

Description 1

VIN 2

Trade mark and manufacturer adress (in Spanish) 3

Gross vehicle weight 4

Gross train weight 5

Maximum permitted front axle loading 6

Maximum permitted rear axle loading 7

Date of manufacture 8

Interior trim code 9

Paint code Automatic Transmission Number

The serial number of the transmission unit is displayed on a metal label or bar code (if equipped) attached to the transmission

casing.

Engine Number(s)

Engine Number - 2.2L Diesel

The serial number is stamped on an engine web on the right-hand side of the cylinder block behind the engine mounting.

Engine Number - 2.7L Diesel

The serial number is stamped on an engine web on the right-hand side of the cylinder block behind the engine mounting.

Engine Number - 3.0L Diesel

The serial number is stamped on an engine web on the right-hand side of the cylinder block behind the engine mounting.

Engine Number - 3.0L

The engine number is contained on a bar code label on the front cover and is also stamped in the cylinder block casting on the www.JagDocs.com

Page 293 of 3039

left-hand side of the engine below the engine mounting.

Engine Number - 4.2L and 4.2L Supercharged

The serial number is stamped on an engine web on the left-hand side of the cylinder block behind the engine mounting. The

emission code is also located here, on the transmission flange.

Engine Number - 5.0L and 5.0L Supercharged

The serial number is stamped on an engine web on the left-hand side of the cylinder block behind the engine mounting.

Page 296 of 3039

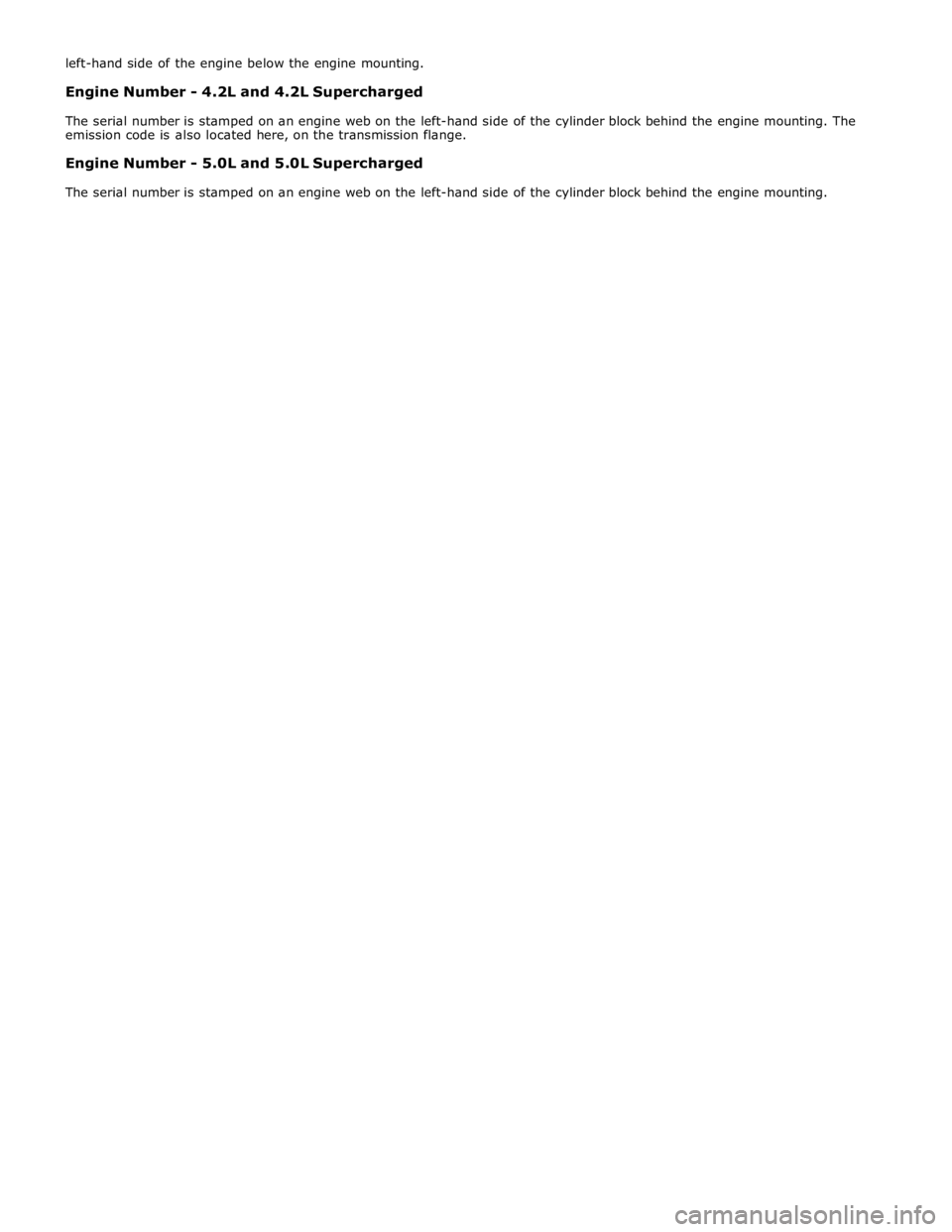

Vehicle Support Points

Vehicle Recovery

NOTE: Prior to vehicle recovery, make sure the vehicle keys are available and the security system is disarmed.

Vehicle recovery methods are:

By flat-bed transporter.

By rear suspended tow.

By rear suspended tow.

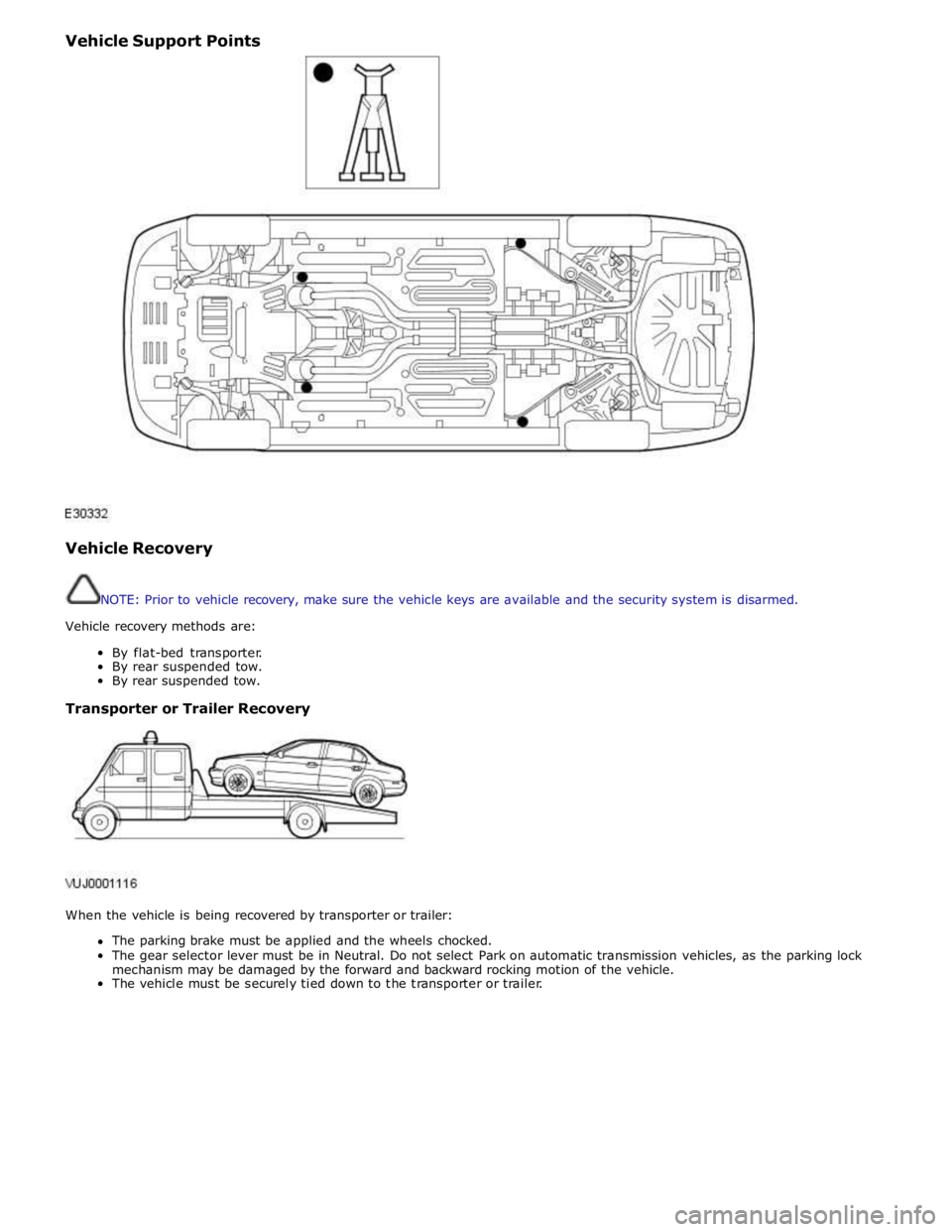

Transporter or Trailer Recovery

When the vehicle is being recovered by transporter or trailer:

The parking brake must be applied and the wheels chocked.

The gear selector lever must be in Neutral. Do not select Park on automatic transmission vehicles, as the parking lock

mechanism may be damaged by the forward and backward rocking motion of the vehicle.

The vehicle must be securely tied down to the transporter or trailer.

Page 297 of 3039

Rear Suspended Tow

When the vehicle is being recovered by rear suspended tow:

The ignition key must be removed from the ignition switch to lock the steering.

The rear wheels must be correctly positioned in the lifting cradle and securely tied down.

Emergency Towing

WARNING: If the engine is not running, the steering will become heavy and the force necessary to effectively apply the

brakes will be greatly increased.

CAUTION: A vehicle with a defective transmission must be towed by rear suspended tow.

When the vehicle is being towed on its own wheels:

Local regulations for the towing of vehicles must be followed. In some countries the registration number of the towing

vehicle and an 'On Tow' sign or warning triangle must be displayed at the rear of the towed vehicle.

The gear selector lever must be in Neutral.

The ignition switch must be in position II to release the steering lock and make the direction indicators, horn and stop

lamps operate.

A distance of 0,8 km (0.5 mile) must not be exceeded.

A speed of 48 km/h (30 mph) must not be exceeded.

The tow rope must be attached to the front towing eye. www.JagDocs.com

Page 307 of 3039

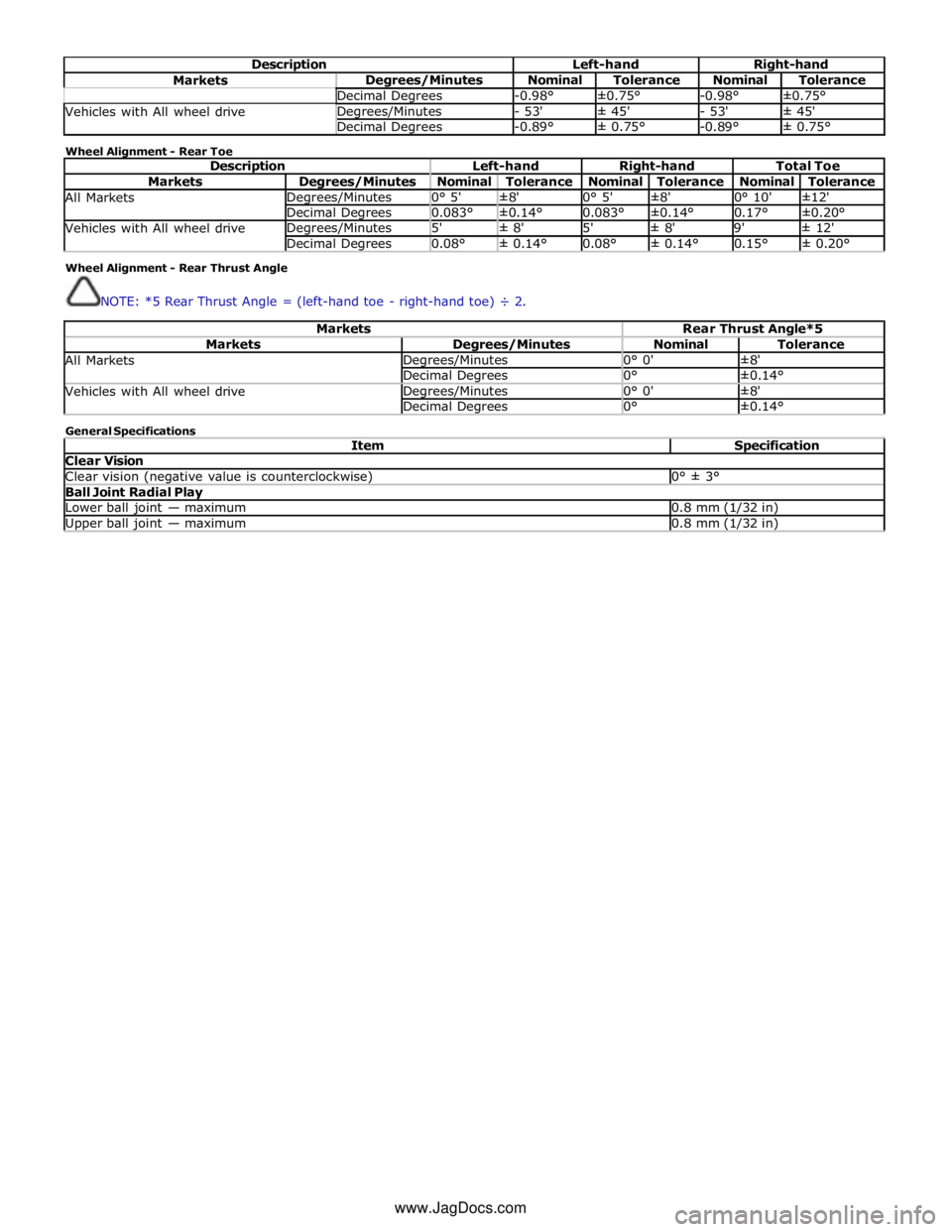

Description Left-hand Right-hand Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance Decimal Degrees -0.98° ±0.75° -0.98° ±0.75° Vehicles with All wheel drive Degrees/Minutes - 53' ± 45' - 53' ± 45' Decimal Degrees -0.89° ± 0.75° -0.89° ± 0.75° Wheel Alignment - Rear Toe

Description Left-hand Right-hand Total Toe Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance Nominal Tolerance All Markets Degrees/Minutes 0° 5' ±8' 0° 5' ±8' 0° 10' ±12' Decimal Degrees 0.083° ±0.14° 0.083° ±0.14° 0.17° ±0.20° Vehicles with All wheel drive Degrees/Minutes 5' ± 8' 5' ± 8' 9' ± 12' Decimal Degrees 0.08° ± 0.14° 0.08° ± 0.14° 0.15° ± 0.20° Wheel Alignment - Rear Thrust Angle

NOTE: *5 Rear Thrust Angle = (left-hand toe - right-hand toe) ÷ 2.

Markets Rear Thrust Angle*5 Markets Degrees/Minutes Nominal Tolerance All Markets Degrees/Minutes 0° 0' ±8' Decimal Degrees 0° ±0.14° Vehicles with All wheel drive Degrees/Minutes 0° 0' ±8' Decimal Degrees 0° ±0.14° General Specifications

Item Specification Clear Vision Clear vision (negative value is counterclockwise) 0° ± 3° Ball Joint Radial Play Lower ball joint — maximum 0.8 mm (1/32 in) Upper ball joint — maximum 0.8 mm (1/32 in) www.JagDocs.com

Page 313 of 3039

Published: 16-Oct-2013

Suspension System - General Information - Camber and Caster Adjustment

General Procedures

NOTES:

The camber and caster adjustment for the left-hand side is shown, the procedure for adjusting the right-hand side is

similar.

This procedure must be carried out using a 4-post ramp.

Adjustments to the camber will affect the toe settings. Therefore, the camber and toe may need to be adjusted at the

same time to achieve the correct settings.

Adjustments to the camber may affect the caster settings. Therefore, the caster will need to be checked, and adjusted as

necessary.

All vehicles

1. Vehicles with air suspension.

For additional information, refer to: Air Suspension Manual Tight

Tolerance Setting Mode (204-05, General Procedures).

2. Check the rear toe adjustment.

For additional information, refer to: Rear Toe Adjustment (204-00 Suspension System - General Information, General Procedures).

Adjust as necessary.

3. Check the front toe adjustment.

For additional information, refer to: Front Toe Adjustment (204-00 Suspension System - General Information, General Procedures).

Adjust as necessary.

4. Check the camber and caster settings. Follow the equipment

manufacturer's instructions.

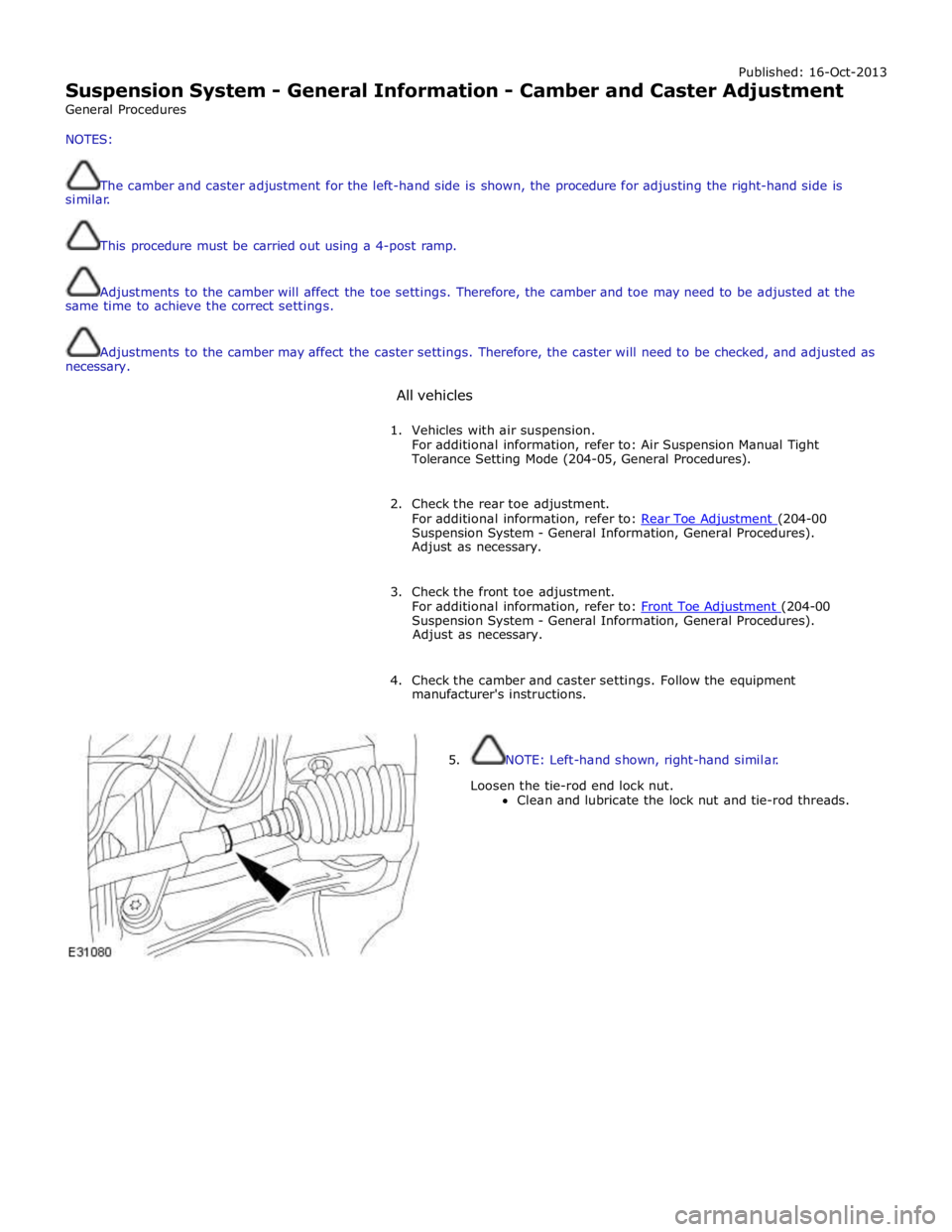

5. NOTE: Left-hand shown, right-hand similar.

Loosen the tie-rod end lock nut.

Clean and lubricate the lock nut and tie-rod threads.