sensor JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 178 of 3039

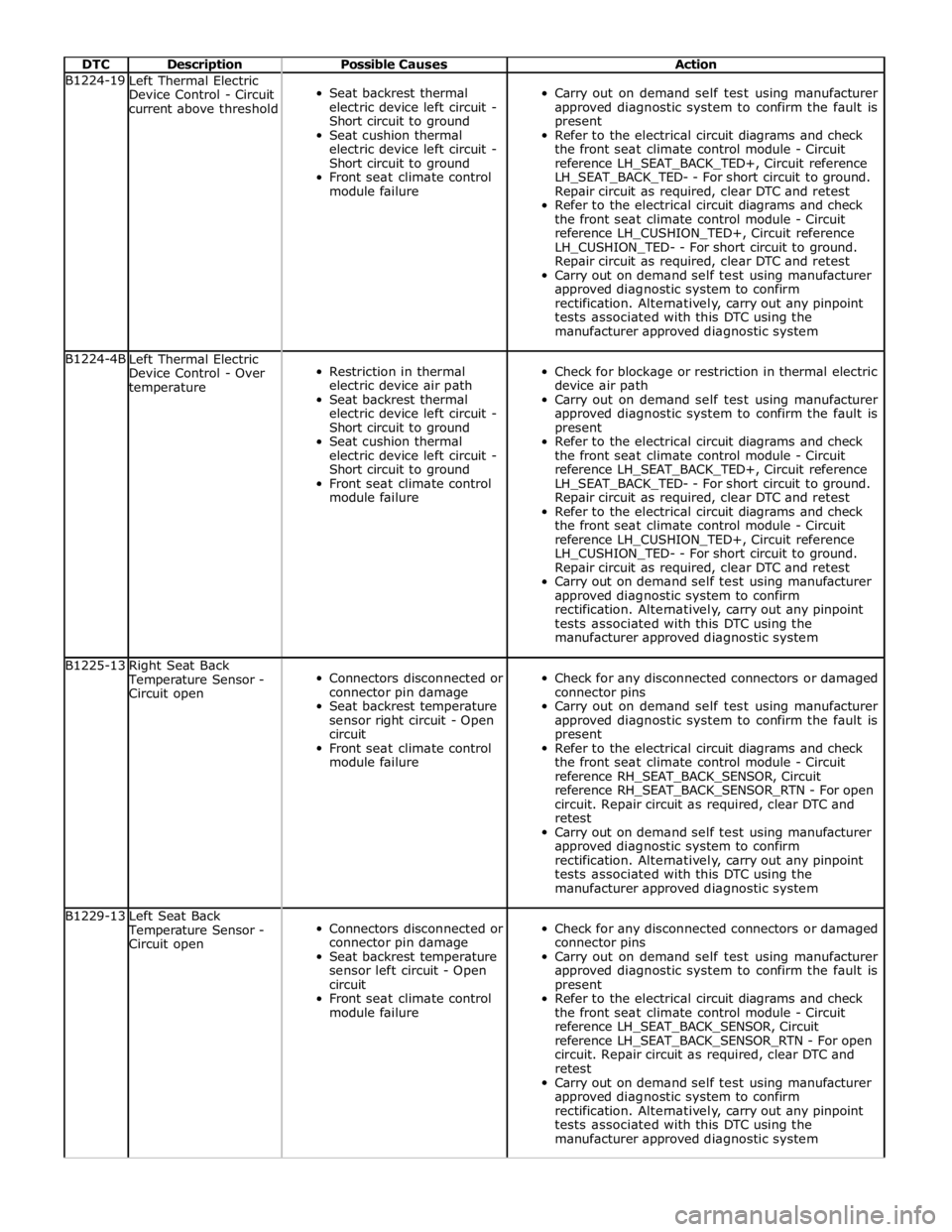

DTC Description Possible Causes Action B1224-19

Left Thermal Electric

Device Control - Circuit

current above threshold

Seat backrest thermal

electric device left circuit -

Short circuit to ground

Seat cushion thermal

electric device left circuit -

Short circuit to ground

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_SEAT_BACK_TED+, Circuit reference

LH_SEAT_BACK_TED- - For short circuit to ground.

Repair circuit as required, clear DTC and retest

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_CUSHION_TED+, Circuit reference

LH_CUSHION_TED- - For short circuit to ground.

Repair circuit as required, clear DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1224-4B

Left Thermal Electric

Device Control - Over

temperature

Restriction in thermal

electric device air path

Seat backrest thermal

electric device left circuit -

Short circuit to ground

Seat cushion thermal

electric device left circuit -

Short circuit to ground

Front seat climate control

module failure

Check for blockage or restriction in thermal electric

device air path

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_SEAT_BACK_TED+, Circuit reference

LH_SEAT_BACK_TED- - For short circuit to ground.

Repair circuit as required, clear DTC and retest

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_CUSHION_TED+, Circuit reference

LH_CUSHION_TED- - For short circuit to ground.

Repair circuit as required, clear DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1225-13

Right Seat Back Temperature Sensor -

Circuit open

Connectors disconnected or

connector pin damage

Seat backrest temperature

sensor right circuit - Open

circuit

Front seat climate control

module failure

Check for any disconnected connectors or damaged

connector pins

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference RH_SEAT_BACK_SENSOR, Circuit

reference RH_SEAT_BACK_SENSOR_RTN - For open

circuit. Repair circuit as required, clear DTC and

retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1229-13

Left Seat Back Temperature Sensor -

Circuit open

Connectors disconnected or

connector pin damage

Seat backrest temperature

sensor left circuit - Open

circuit

Front seat climate control

module failure

Check for any disconnected connectors or damaged

connector pins

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_SEAT_BACK_SENSOR, Circuit

reference LH_SEAT_BACK_SENSOR_RTN - For open

circuit. Repair circuit as required, clear DTC and

retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system

Page 179 of 3039

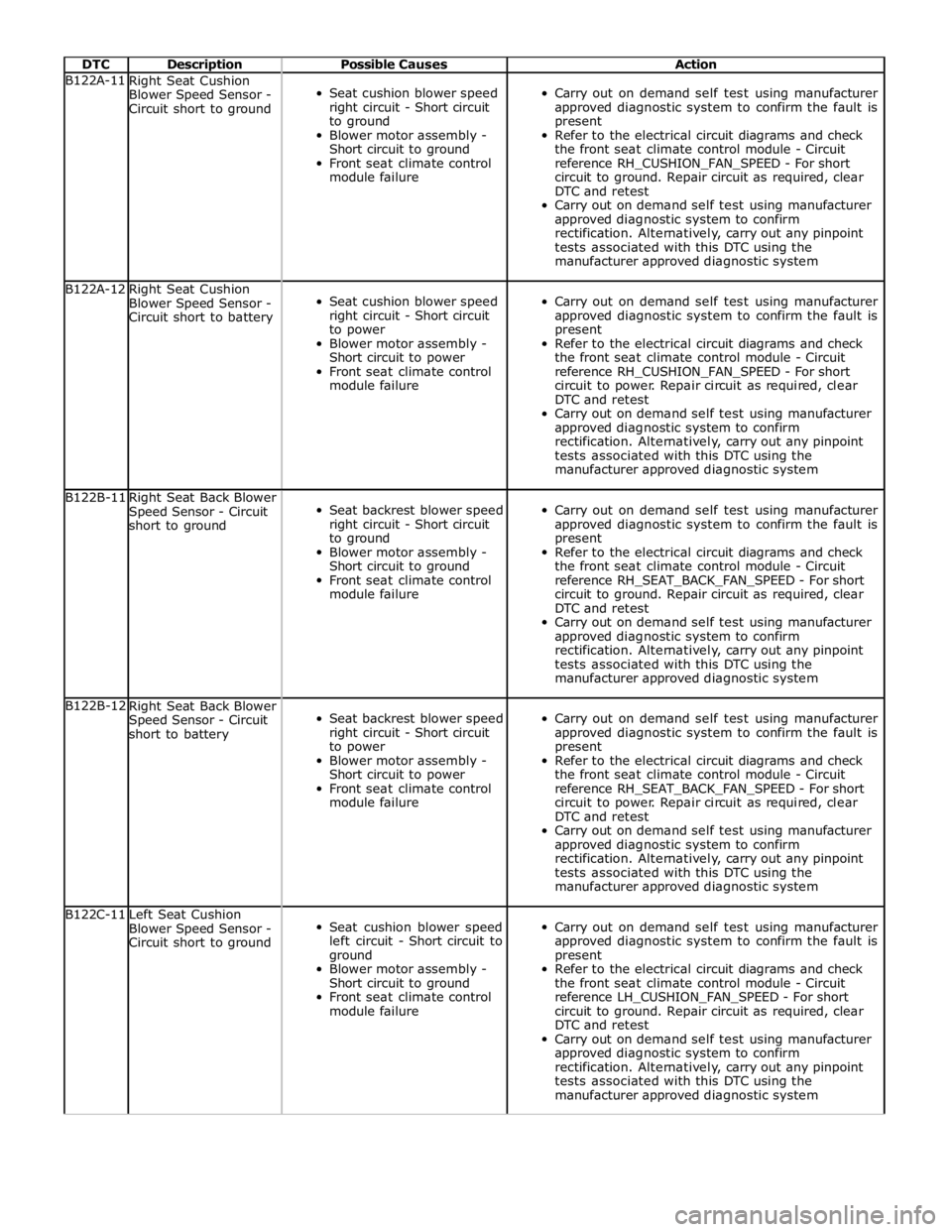

DTC Description Possible Causes Action B122A-11

Right Seat Cushion

Blower Speed Sensor -

Circuit short to ground

Seat cushion blower speed

right circuit - Short circuit

to ground

Blower motor assembly -

Short circuit to ground

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference RH_CUSHION_FAN_SPEED - For short

circuit to ground. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122A-12

Right Seat Cushion

Blower Speed Sensor -

Circuit short to battery

Seat cushion blower speed

right circuit - Short circuit

to power

Blower motor assembly -

Short circuit to power

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference RH_CUSHION_FAN_SPEED - For short

circuit to power. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122B-11

Right Seat Back Blower

Speed Sensor - Circuit

short to ground

Seat backrest blower speed

right circuit - Short circuit

to ground

Blower motor assembly -

Short circuit to ground

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference RH_SEAT_BACK_FAN_SPEED - For short

circuit to ground. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122B-12

Right Seat Back Blower

Speed Sensor - Circuit

short to battery

Seat backrest blower speed

right circuit - Short circuit

to power

Blower motor assembly -

Short circuit to power

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference RH_SEAT_BACK_FAN_SPEED - For short

circuit to power. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122C-11

Left Seat Cushion

Blower Speed Sensor -

Circuit short to ground

Seat cushion blower speed

left circuit - Short circuit to

ground

Blower motor assembly -

Short circuit to ground

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_CUSHION_FAN_SPEED - For short

circuit to ground. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system

Page 180 of 3039

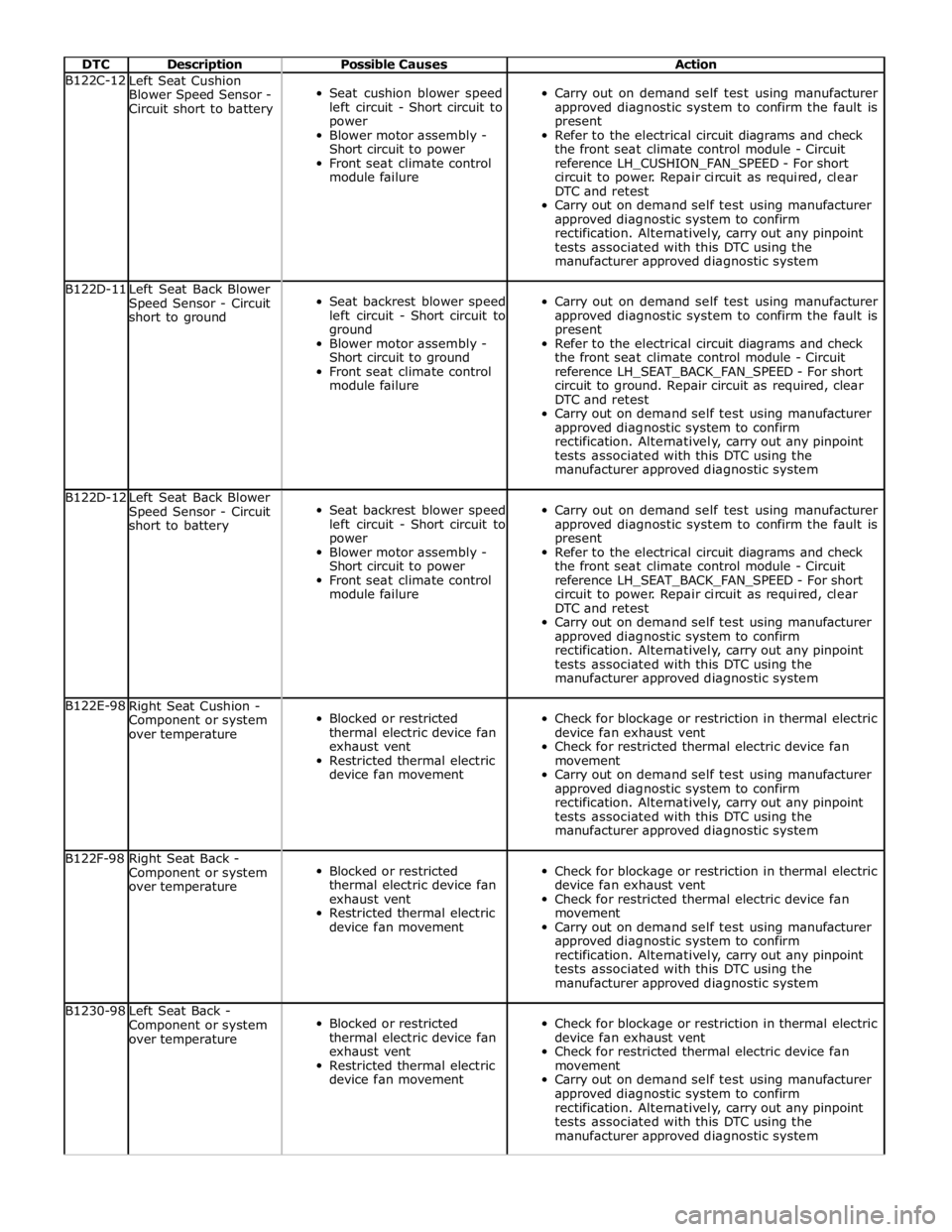

DTC Description Possible Causes Action B122C-12

Left Seat Cushion

Blower Speed Sensor -

Circuit short to battery

Seat cushion blower speed

left circuit - Short circuit to

power

Blower motor assembly -

Short circuit to power

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_CUSHION_FAN_SPEED - For short

circuit to power. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122D-11

Left Seat Back Blower

Speed Sensor - Circuit

short to ground

Seat backrest blower speed

left circuit - Short circuit to

ground

Blower motor assembly -

Short circuit to ground

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_SEAT_BACK_FAN_SPEED - For short

circuit to ground. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122D-12

Left Seat Back Blower

Speed Sensor - Circuit

short to battery

Seat backrest blower speed

left circuit - Short circuit to

power

Blower motor assembly -

Short circuit to power

Front seat climate control

module failure

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_SEAT_BACK_FAN_SPEED - For short

circuit to power. Repair circuit as required, clear

DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122E-98

Right Seat Cushion -

Component or system

over temperature

Blocked or restricted

thermal electric device fan

exhaust vent

Restricted thermal electric

device fan movement

Check for blockage or restriction in thermal electric

device fan exhaust vent

Check for restricted thermal electric device fan

movement

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B122F-98

Right Seat Back -

Component or system

over temperature

Blocked or restricted

thermal electric device fan

exhaust vent

Restricted thermal electric

device fan movement

Check for blockage or restriction in thermal electric

device fan exhaust vent

Check for restricted thermal electric device fan

movement

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1230-98

Left Seat Back -

Component or system

over temperature

Blocked or restricted

thermal electric device fan

exhaust vent

Restricted thermal electric

device fan movement

Check for blockage or restriction in thermal electric

device fan exhaust vent

Check for restricted thermal electric device fan

movement

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system

Page 181 of 3039

DTC Description Possible Causes Action B1231-7A

Right Seat - Fluid leak

or seal failure

Seat backrest assembly -

Air path leaking

Seat cushion assembly -

Air path leaking

Seat assembly damaged

Check for blockage or restriction in seat

backrest/seat cushion thermal electric device fan

ducts

Check seat backrest/seat cushion thermal electric

device fan exhaust vent is clear

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1232-7A

Left Seat - Fluid leak or

seal failure

Seat backrest assembly -

Air path leaking

Seat cushion assembly -

Air path leaking

Seat assembly damaged

Check for blockage or restriction in seat

backrest/seat cushion thermal electric device fan

ducts

Check seat backrest/seat cushion thermal electric

device fan exhaust vent is clear

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system B1235-13

Left Seat Cushion Temperature Sensor -

Circuit open

Connectors disconnected or

connector pin damage

Seat cushion temperature

sensor left circuit - Open

circuit

Front seat climate control

module failure

Check for any disconnected connectors or damaged

connector pins

Carry out on demand self test using manufacturer

approved diagnostic system to confirm the fault is

present

Refer to the electrical circuit diagrams and check

the front seat climate control module - Circuit

reference LH_CUSHION_SENSOR, Circuit reference

LH_CUSHION_SENSOR_RTN - For open circuit.

Repair circuit as required, clear DTC and retest

Carry out on demand self test using manufacturer

approved diagnostic system to confirm

rectification. Alternatively, carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system U0010-88

Medium Speed CAN

Communication Bus -

Bus off

Medium speed CAN

communication - Bus off

Refer to the electrical circuit diagrams and check

the power and ground connections to the module

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0140-00

Lost Communication

With Body Control

Module - No sub type

information

Lost communication with

central junction box

NOTE: This DTC may be stored even though no fault

condition is present and should be ignored unless the

customer has reported a climate seat concern. Clear the

DTC and retest. Verify the customer concern prior to

diagnosis

Refer to the electrical circuit diagrams and check

the power and ground connections to the module

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test

Refer to the electrical circuit diagrams and check

the CAN network between the front seat climate

control module and central junction box

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0142-00 Lost Communication

Lost communication with

Refer to the electrical circuit diagrams and check With Body Control Module "B" - No sub rear junction box the power and ground connections to the module type information Using the manufacturer approved diagnostic system, complete a CAN network integrity test Refer to the electrical circuit diagrams and check the CAN network between the front seat climate control module and rear junction box Carry out on demand self test using manufacturer approved diagnostic system to confirm rectification www.JagDocs.com

Page 183 of 3039

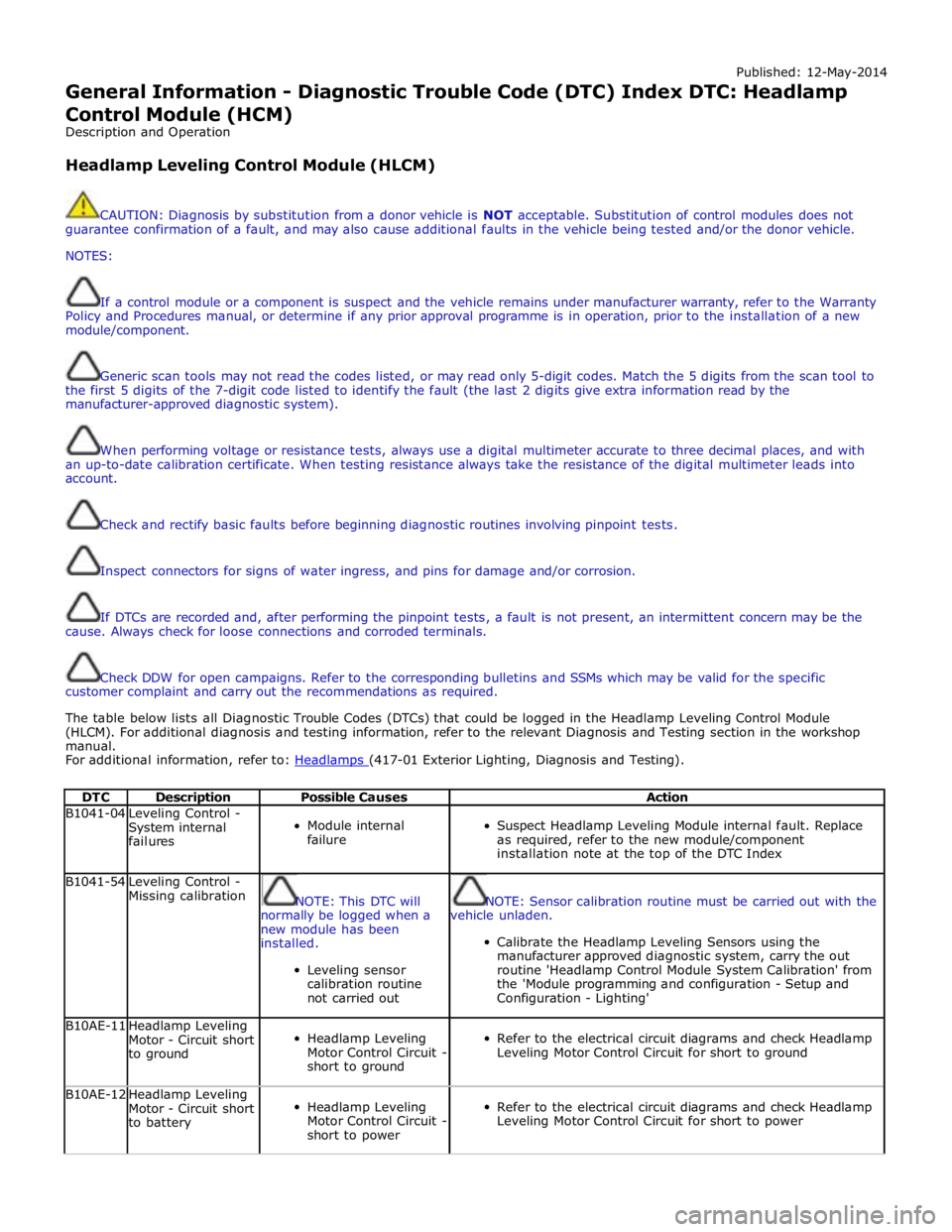

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Headlamp

Control Module (HCM)

Description and Operation

Headlamp Leveling Control Module (HLCM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Headlamp Leveling Control Module

(HLCM). For additional diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop

manual.

For additional information, refer to: Headlamps (417-01 Exterior Lighting, Diagnosis and Testing).

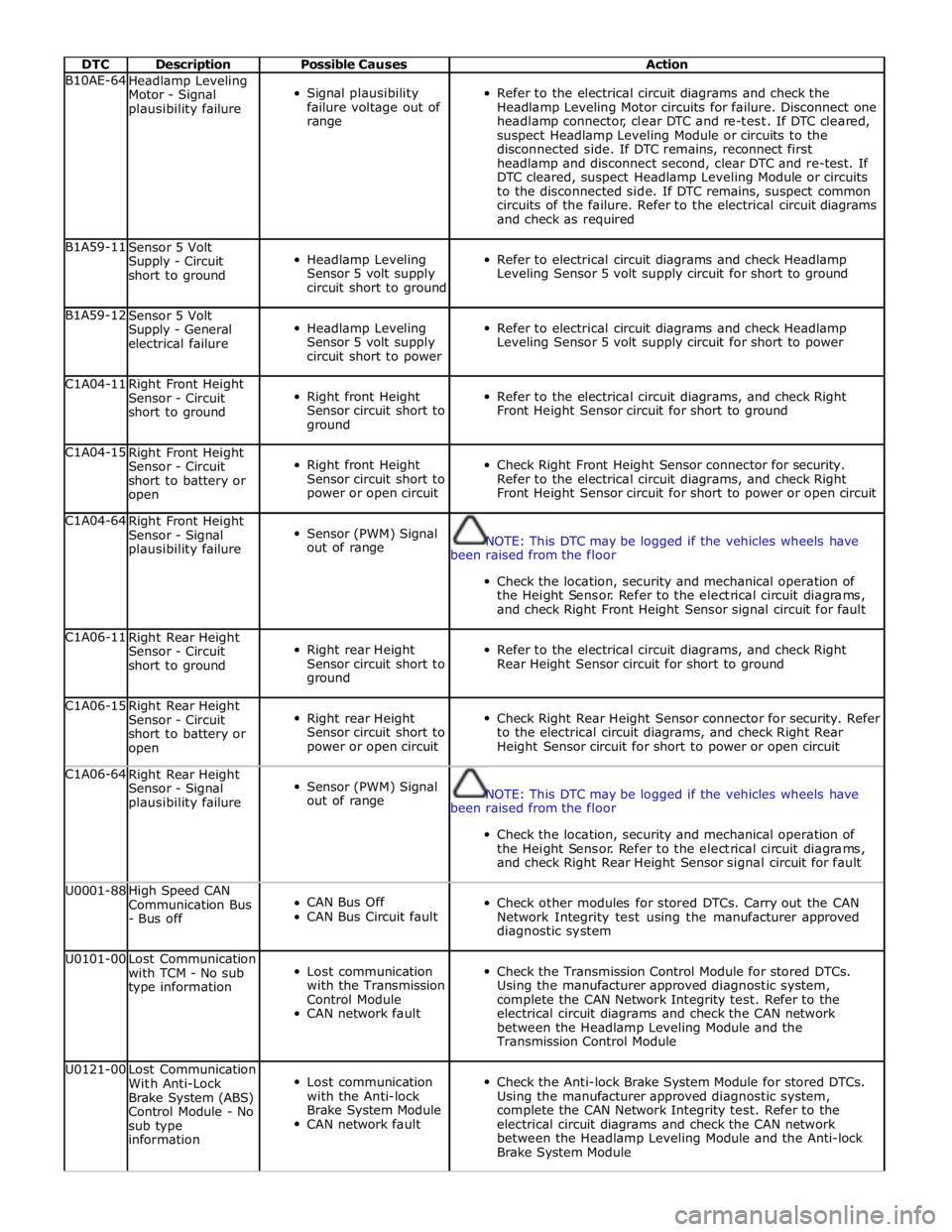

DTC Description Possible Causes Action B1041-04

Leveling Control -

System internal

failures

Module internal

failure

Suspect Headlamp Leveling Module internal fault. Replace

as required, refer to the new module/component

installation note at the top of the DTC Index B1041-54

Leveling Control -

Missing calibration

NOTE: This DTC will

normally be logged when a

new module has been

installed.

Leveling sensor

calibration routine

not carried out

NOTE: Sensor calibration routine must be carried out with the

vehicle unladen.

Calibrate the Headlamp Leveling Sensors using the

manufacturer approved diagnostic system, carry the out

routine 'Headlamp Control Module System Calibration' from

the 'Module programming and configuration - Setup and

Configuration - Lighting' B10AE-11

Headlamp Leveling

Motor - Circuit short

to ground

Headlamp Leveling

Motor Control Circuit -

short to ground

Refer to the electrical circuit diagrams and check Headlamp

Leveling Motor Control Circuit for short to ground B10AE-12

Headlamp Leveling

Motor - Circuit short

to battery

Headlamp Leveling

Motor Control Circuit -

short to power

Refer to the electrical circuit diagrams and check Headlamp

Leveling Motor Control Circuit for short to power

Page 184 of 3039

DTC Description Possible Causes Action B10AE-64

Headlamp Leveling

Motor - Signal

plausibility failure

Signal plausibility

failure voltage out of

range

Refer to the electrical circuit diagrams and check the

Headlamp Leveling Motor circuits for failure. Disconnect one

headlamp connector, clear DTC and re-test. If DTC cleared,

suspect Headlamp Leveling Module or circuits to the

disconnected side. If DTC remains, reconnect first

headlamp and disconnect second, clear DTC and re-test. If

DTC cleared, suspect Headlamp Leveling Module or circuits

to the disconnected side. If DTC remains, suspect common

circuits of the failure. Refer to the electrical circuit diagrams

and check as required B1A59-11

Sensor 5 Volt

Supply - Circuit

short to ground

Headlamp Leveling

Sensor 5 volt supply

circuit short to ground

Refer to electrical circuit diagrams and check Headlamp

Leveling Sensor 5 volt supply circuit for short to ground B1A59-12

Sensor 5 Volt

Supply - General

electrical failure

Headlamp Leveling

Sensor 5 volt supply

circuit short to power

Refer to electrical circuit diagrams and check Headlamp

Leveling Sensor 5 volt supply circuit for short to power C1A04-11

Right Front Height

Sensor - Circuit

short to ground

Right front Height

Sensor circuit short to

ground

Refer to the electrical circuit diagrams, and check Right

Front Height Sensor circuit for short to ground C1A04-15

Right Front Height

Sensor - Circuit

short to battery or

open

Right front Height

Sensor circuit short to

power or open circuit

Check Right Front Height Sensor connector for security.

Refer to the electrical circuit diagrams, and check Right

Front Height Sensor circuit for short to power or open circuit C1A04-64

Right Front Height

Sensor - Signal

plausibility failure

Sensor (PWM) Signal

out of range

NOTE: This DTC may be logged if the vehicles wheels have

been raised from the floor

Check the location, security and mechanical operation of

the Height Sensor. Refer to the electrical circuit diagrams,

and check Right Front Height Sensor signal circuit for fault C1A06-11

Right Rear Height

Sensor - Circuit

short to ground

Right rear Height

Sensor circuit short to

ground

Refer to the electrical circuit diagrams, and check Right

Rear Height Sensor circuit for short to ground C1A06-15

Right Rear Height

Sensor - Circuit

short to battery or

open

Right rear Height

Sensor circuit short to

power or open circuit

Check Right Rear Height Sensor connector for security. Refer

to the electrical circuit diagrams, and check Right Rear

Height Sensor circuit for short to power or open circuit C1A06-64

Right Rear Height

Sensor - Signal

plausibility failure

Sensor (PWM) Signal

out of range

NOTE: This DTC may be logged if the vehicles wheels have

been raised from the floor

Check the location, security and mechanical operation of

the Height Sensor. Refer to the electrical circuit diagrams,

and check Right Rear Height Sensor signal circuit for fault U0001-88

High Speed CAN

Communication Bus

- Bus off

CAN Bus Off

CAN Bus Circuit fault

Check other modules for stored DTCs. Carry out the CAN

Network Integrity test using the manufacturer approved

diagnostic system U0101-00

Lost Communication

with TCM - No sub

type information

Lost communication

with the Transmission

Control Module

CAN network fault

Check the Transmission Control Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the

Transmission Control Module U0121-00

Lost Communication

With Anti-Lock

Brake System (ABS)

Control Module - No

sub type

information

Lost communication

with the Anti-lock

Brake System Module

CAN network fault

Check the Anti-lock Brake System Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the Anti-lock

Brake System Module

Page 185 of 3039

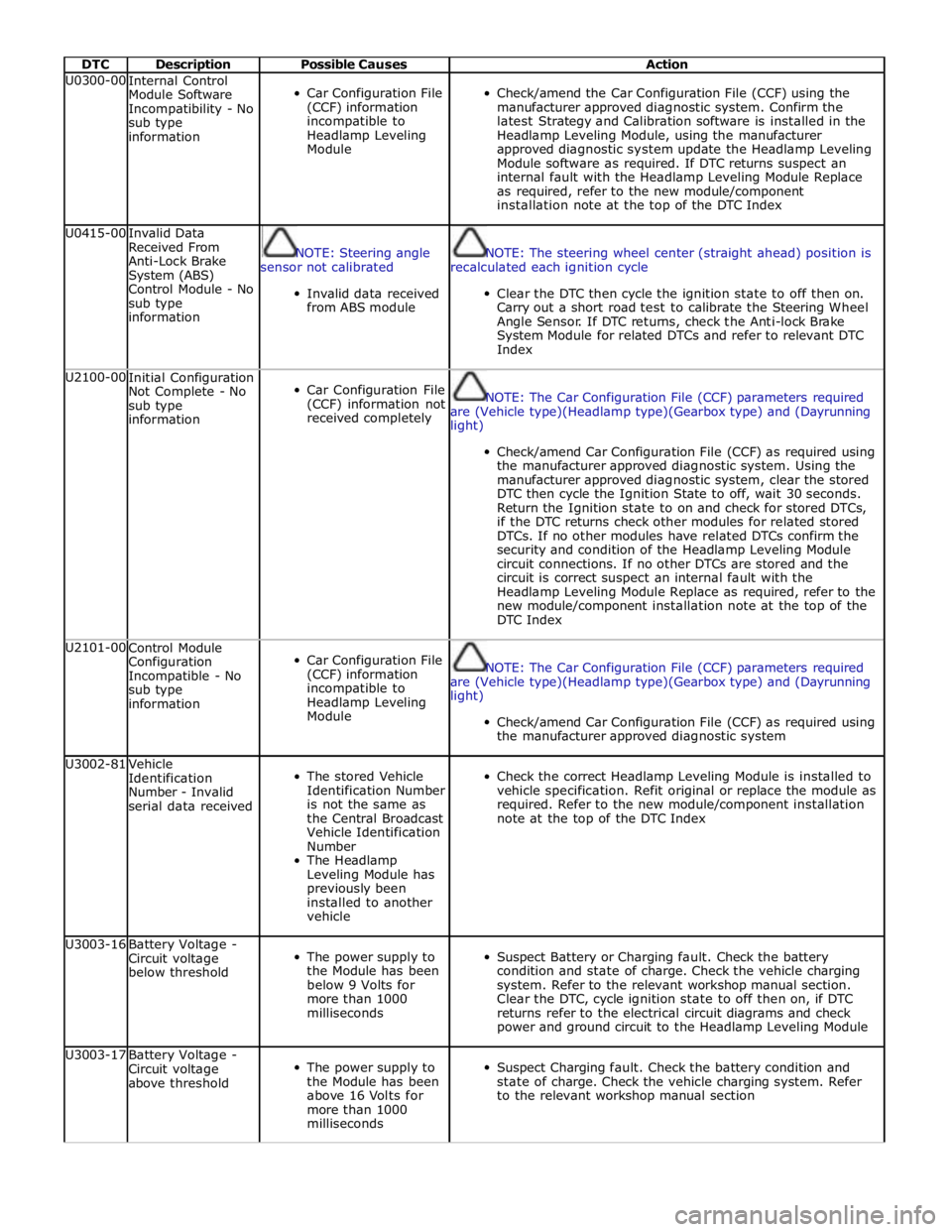

DTC Description Possible Causes Action U0300-00

Internal Control

Module Software

Incompatibility - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

Check/amend the Car Configuration File (CCF) using the

manufacturer approved diagnostic system. Confirm the

latest Strategy and Calibration software is installed in the

Headlamp Leveling Module, using the manufacturer

approved diagnostic system update the Headlamp Leveling

Module software as required. If DTC returns suspect an

internal fault with the Headlamp Leveling Module Replace

as required, refer to the new module/component

installation note at the top of the DTC Index U0415-00

Invalid Data

Received From

Anti-Lock Brake

System (ABS)

Control Module - No

sub type

information

NOTE: Steering angle

sensor not calibrated

Invalid data received

from ABS module

NOTE: The steering wheel center (straight ahead) position is

recalculated each ignition cycle

Clear the DTC then cycle the ignition state to off then on.

Carry out a short road test to calibrate the Steering Wheel

Angle Sensor. If DTC returns, check the Anti-lock Brake

System Module for related DTCs and refer to relevant DTC

Index U2100-00

Initial Configuration

Not Complete - No

sub type

information

Car Configuration File

(CCF) information not

received completely

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system. Using the

manufacturer approved diagnostic system, clear the stored

DTC then cycle the Ignition State to off, wait 30 seconds.

Return the Ignition state to on and check for stored DTCs,

if the DTC returns check other modules for related stored

DTCs. If no other modules have related DTCs confirm the

security and condition of the Headlamp Leveling Module

circuit connections. If no other DTCs are stored and the

circuit is correct suspect an internal fault with the

Headlamp Leveling Module Replace as required, refer to the

new module/component installation note at the top of the

DTC Index U2101-00

Control Module

Configuration

Incompatible - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system U3002-81

Vehicle

Identification

Number - Invalid

serial data received

The stored Vehicle

Identification Number

is not the same as

the Central Broadcast

Vehicle Identification

Number

The Headlamp

Leveling Module has

previously been

installed to another

vehicle

Check the correct Headlamp Leveling Module is installed to

vehicle specification. Refit original or replace the module as

required. Refer to the new module/component installation

note at the top of the DTC Index U3003-16

Battery Voltage -

Circuit voltage

below threshold

The power supply to

the Module has been

below 9 Volts for

more than 1000

milliseconds

Suspect Battery or Charging fault. Check the battery

condition and state of charge. Check the vehicle charging

system. Refer to the relevant workshop manual section.

Clear the DTC, cycle ignition state to off then on, if DTC

returns refer to the electrical circuit diagrams and check

power and ground circuit to the Headlamp Leveling Module U3003-17

Battery Voltage -

Circuit voltage

above threshold

The power supply to

the Module has been

above 16 Volts for

more than 1000

milliseconds

Suspect Charging fault. Check the battery condition and

state of charge. Check the vehicle charging system. Refer

to the relevant workshop manual section

Page 186 of 3039

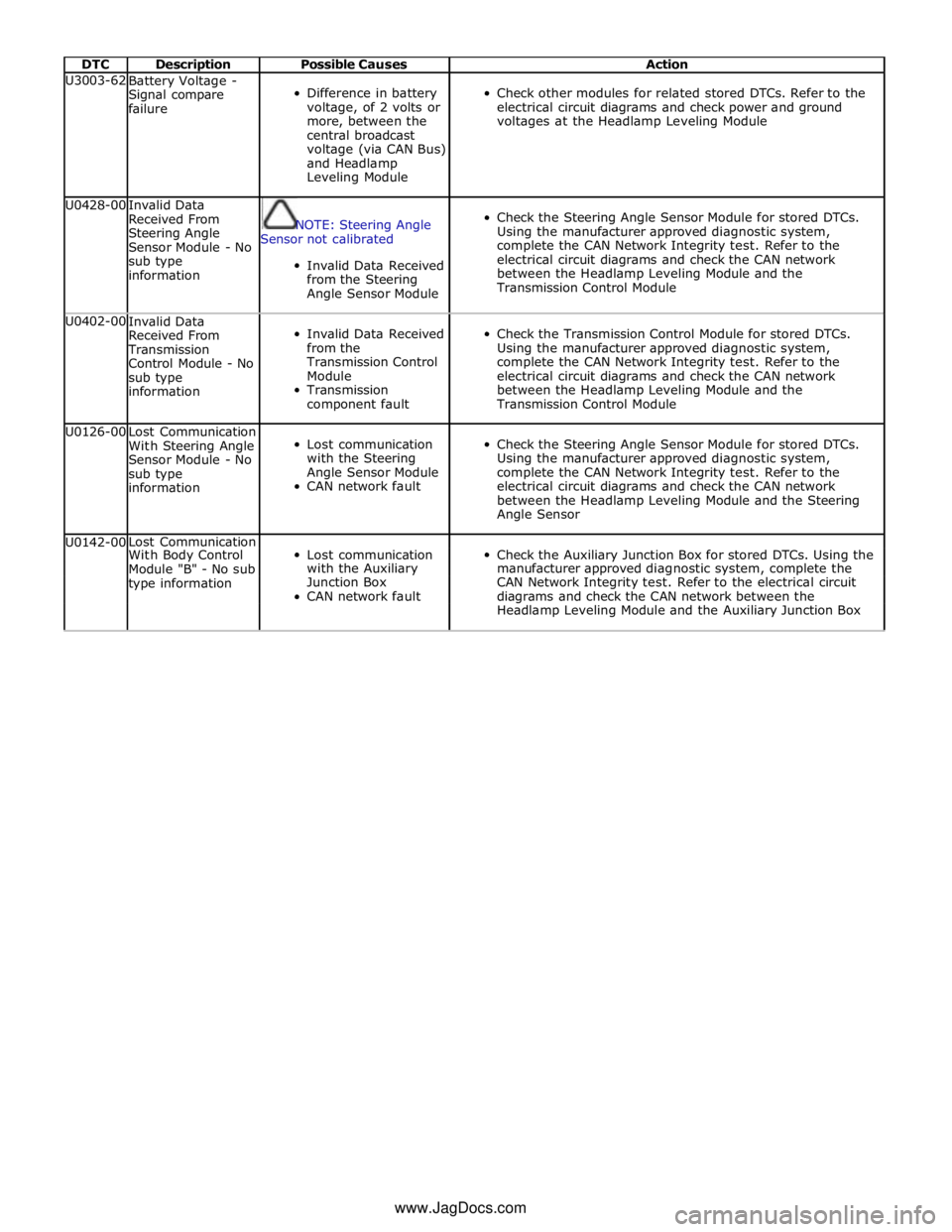

DTC Description Possible Causes Action U3003-62

Battery Voltage -

Signal compare

failure

Difference in battery

voltage, of 2 volts or

more, between the

central broadcast

voltage (via CAN Bus)

and Headlamp

Leveling Module

Check other modules for related stored DTCs. Refer to the

electrical circuit diagrams and check power and ground

voltages at the Headlamp Leveling Module U0428-00

Invalid Data

Received From

Steering Angle

Sensor Module - No

sub type

information

NOTE: Steering Angle

Sensor not calibrated

Invalid Data Received

from the Steering

Angle Sensor Module

Check the Steering Angle Sensor Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the

Transmission Control Module U0402-00

Invalid Data

Received From

Transmission

Control Module - No

sub type

information

Invalid Data Received

from the

Transmission Control

Module

Transmission

component fault

Check the Transmission Control Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the

Transmission Control Module U0126-00

Lost Communication

With Steering Angle

Sensor Module - No

sub type

information

Lost communication

with the Steering

Angle Sensor Module

CAN network fault

Check the Steering Angle Sensor Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the Steering

Angle Sensor U0142-00 Lost Communication

Lost communication

Check the Auxiliary Junction Box for stored DTCs. Using the With Body Control Module "B" - No sub with the Auxiliary manufacturer approved diagnostic system, complete the type information Junction Box CAN Network Integrity test. Refer to the electrical circuit CAN network fault diagrams and check the CAN network between the Headlamp Leveling Module and the Auxiliary Junction Box www.JagDocs.com

Page 191 of 3039

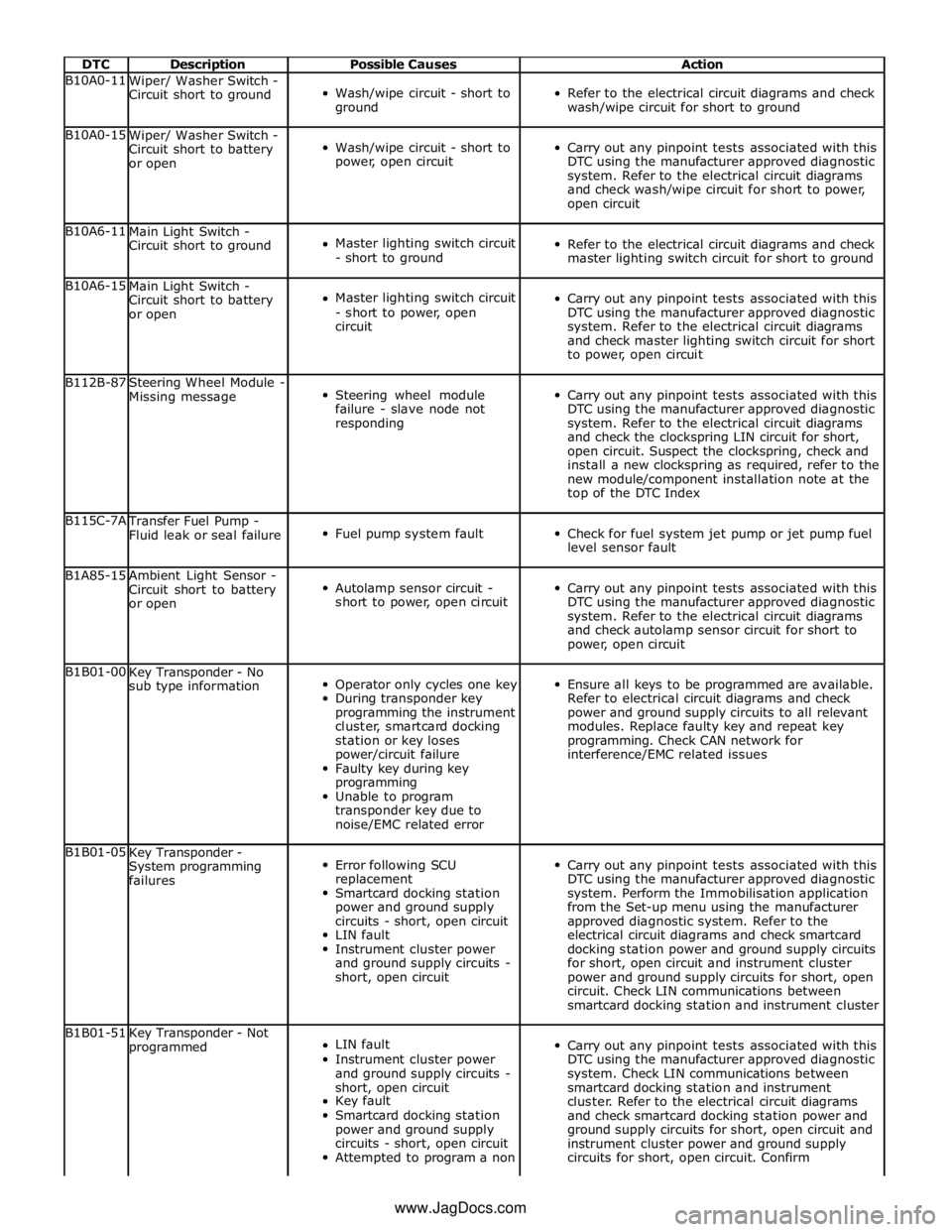

DTC Description Possible Causes Action B10A0-11

Wiper/ Washer Switch -

Circuit short to ground

Wash/wipe circuit - short to

ground

Refer to the electrical circuit diagrams and check

wash/wipe circuit for short to ground B10A0-15

Wiper/ Washer Switch -

Circuit short to battery

or open

Wash/wipe circuit - short to

power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check wash/wipe circuit for short to power,

open circuit B10A6-11

Main Light Switch -

Circuit short to ground

Master lighting switch circuit

- short to ground

Refer to the electrical circuit diagrams and check

master lighting switch circuit for short to ground B10A6-15

Main Light Switch -

Circuit short to battery

or open

Master lighting switch circuit

- short to power, open

circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check master lighting switch circuit for short

to power, open circuit B112B-87

Steering Wheel Module -

Missing message

Steering wheel module

failure - slave node not

responding

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check the clockspring LIN circuit for short,

open circuit. Suspect the clockspring, check and

install a new clockspring as required, refer to the

new module/component installation note at the

top of the DTC Index B115C-7A Transfer Fuel Pump -

Fluid leak or seal failure

Fuel pump system fault

Check for fuel system jet pump or jet pump fuel

level sensor fault B1A85-15

Ambient Light Sensor -

Circuit short to battery

or open

Autolamp sensor circuit -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check autolamp sensor circuit for short to

power, open circuit B1B01-00

Key Transponder - No

sub type information

Operator only cycles one key

During transponder key

programming the instrument

cluster, smartcard docking

station or key loses

power/circuit failure

Faulty key during key

programming

Unable to program

transponder key due to

noise/EMC related error

Ensure all keys to be programmed are available.

Refer to electrical circuit diagrams and check

power and ground supply circuits to all relevant

modules. Replace faulty key and repeat key

programming. Check CAN network for

interference/EMC related issues B1B01-05

Key Transponder -

System programming

failures

Error following SCU

replacement

Smartcard docking station

power and ground supply

circuits - short, open circuit

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Perform the Immobilisation application

from the Set-up menu using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check smartcard

docking station power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check LIN communications between

smartcard docking station and instrument cluster B1B01-51

Key Transponder - Not

programmed

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Key fault

Smartcard docking station

power and ground supply

circuits - short, open circuit

Attempted to program a non

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check LIN communications between

smartcard docking station and instrument

cluster. Refer to the electrical circuit diagrams

and check smartcard docking station power and

ground supply circuits for short, open circuit and

instrument cluster power and ground supply

circuits for short, open circuit. Confirm www.JagDocs.com

Page 203 of 3039

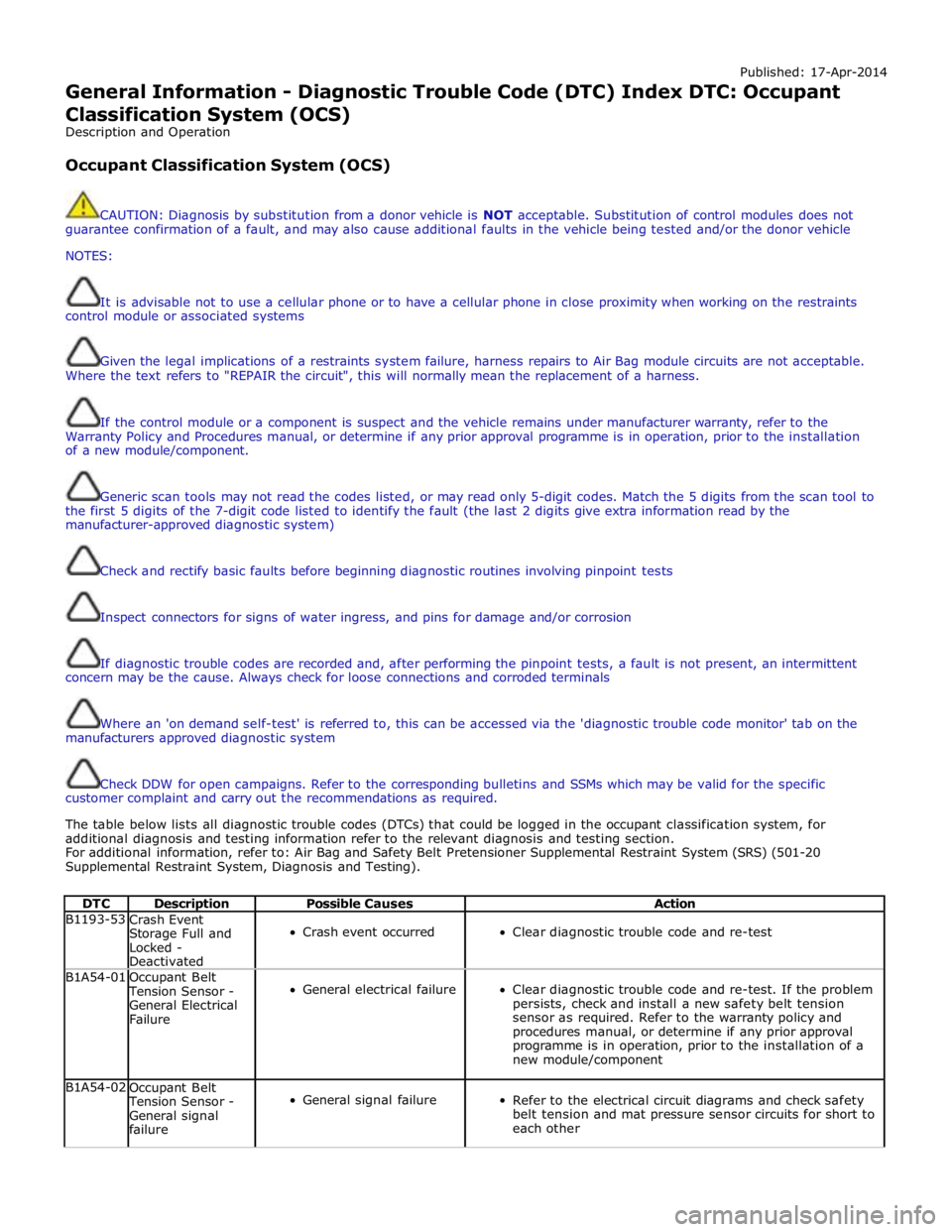

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Occupant Classification System (OCS)

Description and Operation

Occupant Classification System (OCS)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

It is advisable not to use a cellular phone or to have a cellular phone in close proximity when working on the restraints

control module or associated systems

Given the legal implications of a restraints system failure, harness repairs to Air Bag module circuits are not acceptable.

Where the text refers to "REPAIR the circuit", this will normally mean the replacement of a harness.

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the occupant classification system, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS) (501-20

Supplemental Restraint System, Diagnosis and Testing).

DTC Description Possible Causes Action B1193-53

Crash Event

Storage Full and

Locked -

Deactivated

Crash event occurred

Clear diagnostic trouble code and re-test B1A54-01

Occupant Belt Tension Sensor -

General Electrical

Failure

General electrical failure

Clear diagnostic trouble code and re-test. If the problem

persists, check and install a new safety belt tension

sensor as required. Refer to the warranty policy and

procedures manual, or determine if any prior approval

programme is in operation, prior to the installation of a

new module/component B1A54-02

Occupant Belt Tension Sensor -

General signal

failure

General signal failure

Refer to the electrical circuit diagrams and check safety

belt tension and mat pressure sensor circuits for short to

each other