sensor JAGUAR XFR 2010 1.G Manual Online

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 219 of 3039

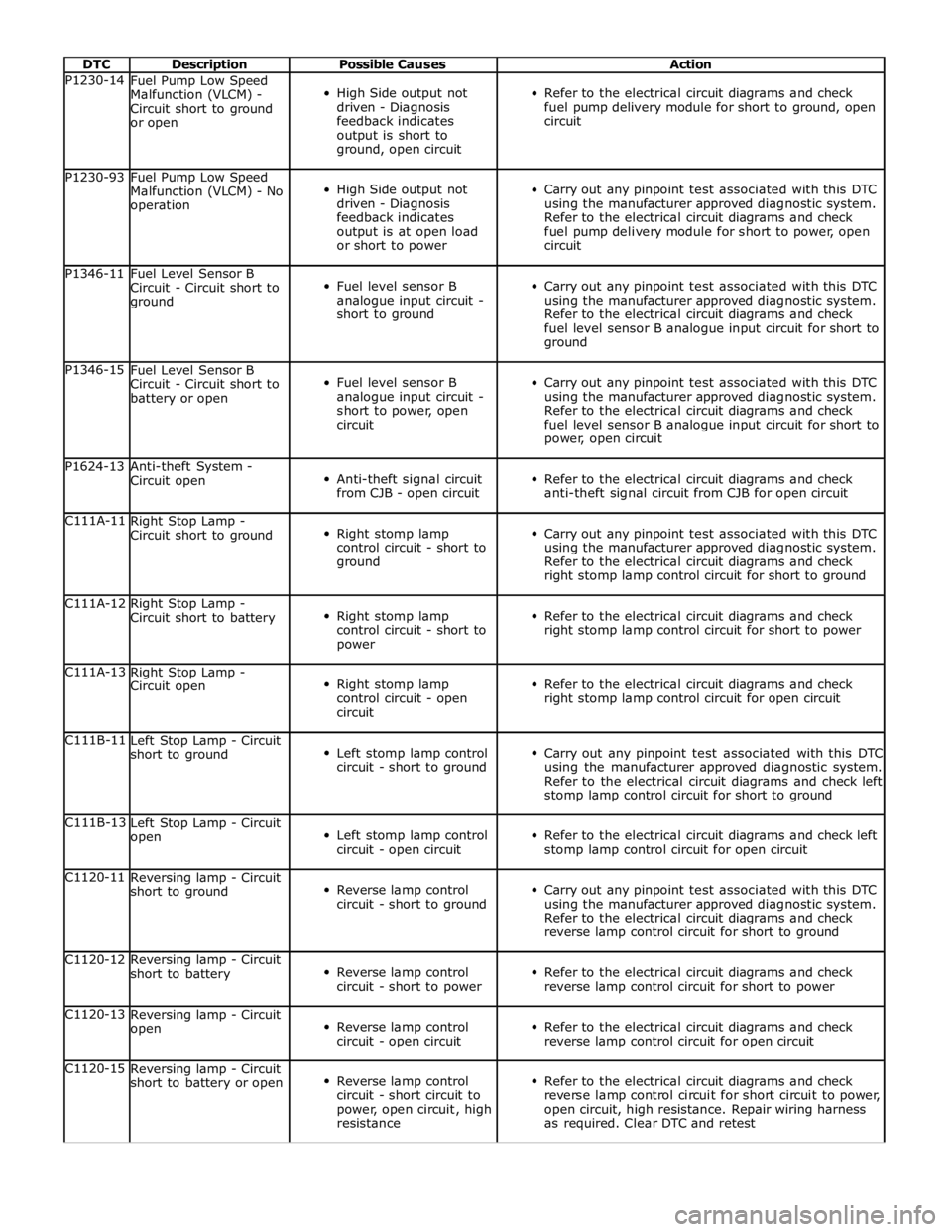

DTC Description Possible Causes Action P1230-14

Fuel Pump Low Speed

Malfunction (VLCM) -

Circuit short to ground

or open

High Side output not

driven - Diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

fuel pump delivery module for short to ground, open

circuit P1230-93

Fuel Pump Low Speed

Malfunction (VLCM) - No

operation

High Side output not

driven - Diagnosis

feedback indicates

output is at open load

or short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel pump delivery module for short to power, open

circuit P1346-11

Fuel Level Sensor B

Circuit - Circuit short to

ground

Fuel level sensor B

analogue input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor B analogue input circuit for short to

ground P1346-15

Fuel Level Sensor B

Circuit - Circuit short to

battery or open

Fuel level sensor B

analogue input circuit -

short to power, open

circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor B analogue input circuit for short to

power, open circuit P1624-13

Anti-theft System -

Circuit open

Anti-theft signal circuit

from CJB - open circuit

Refer to the electrical circuit diagrams and check

anti-theft signal circuit from CJB for open circuit C111A-11

Right Stop Lamp -

Circuit short to ground

Right stomp lamp

control circuit - short to

ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

right stomp lamp control circuit for short to ground C111A-12

Right Stop Lamp -

Circuit short to battery

Right stomp lamp

control circuit - short to

power

Refer to the electrical circuit diagrams and check

right stomp lamp control circuit for short to power C111A-13

Right Stop Lamp -

Circuit open

Right stomp lamp

control circuit - open

circuit

Refer to the electrical circuit diagrams and check

right stomp lamp control circuit for open circuit C111B-11

Left Stop Lamp - Circuit

short to ground

Left stomp lamp control

circuit - short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check left

stomp lamp control circuit for short to ground C111B-13

Left Stop Lamp - Circuit

open

Left stomp lamp control

circuit - open circuit

Refer to the electrical circuit diagrams and check left

stomp lamp control circuit for open circuit C1120-11

Reversing lamp - Circuit

short to ground

Reverse lamp control

circuit - short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for short to ground C1120-12

Reversing lamp - Circuit

short to battery

Reverse lamp control

circuit - short to power

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for short to power C1120-13

Reversing lamp - Circuit

open

Reverse lamp control

circuit - open circuit

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for open circuit C1120-15

Reversing lamp - Circuit

short to battery or open

Reverse lamp control

circuit - short circuit to

power, open circuit, high

resistance

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for short circuit to power,

open circuit, high resistance. Repair wiring harness

as required. Clear DTC and retest

Page 235 of 3039

DTC Description Possible Causes Action B0029-09

Right Curtain Deployment

Control 1 - Component failures

Right curtain deployment

control 1 circuit - internal

driver failure

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system B0029-11

Right Curtain Deployment

Control 1 - Circuit short to

ground

Right curtain deployment

control 1 circuit - short to

ground

Refer to electrical circuit diagrams and

check right curtain deployment control 1

circuit for short to ground B0029-12

Right Curtain Deployment

Control 1 - Circuit short to

battery

Right curtain deployment

control 1 circuit - short to

power

Refer to electrical circuit diagrams and

check right curtain deployment control 1

circuit for short to power B0029-1A

Right Curtain Deployment

Control 1 - Circuit resistance

below threshold

Circuit resistance below

threshold

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system B0029-1B

Right Curtain Deployment

Control 1 - Circuit resistance

above threshold

Circuit resistance above

threshold

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system B0029-1C

Right Curtain Deployment

Control 1 - Circuit voltage out

of range

Right curtain deployment

control 1 circuit - high

resistance

Refer to electrical circuit diagrams and

test right curtain deployment control 1

circuit for high resistance B0029-56

Right Curtain Deployment

Control 1 - Invalid/incomplete

configuration

Incompatible configuration

Re-configure the RCM using the

manufacturer approved diagnostic

system B0029-95

Right Curtain Deployment

Control 1 - Incorrect assembly

Crosscoupling with other

firing loop

Refer to electrical circuit diagrams and

test right curtain deployment control 1

circuit for crosscoupling with other firing

loop B0050-11

Driver Safety Belt Sensor -

Circuit short to ground

Driver safety belt sensor

circuit - short to ground

Refer to the electrical circuit diagrams

and test driver safety belt sensor circuit

for short to ground B0050-12

Driver Safety Belt Sensor -

Circuit short to battery

Driver safety belt sensor

circuit - short to power

Refer to the electrical circuit diagrams

and test driver safety belt sensor circuit

for short to power B0050-13

Driver Safety Belt Sensor -

Circuit open

Driver safety belt sensor

circuit - open circuit

Refer to the electrical circuit diagrams

and test driver safety belt sensor circuit

for open circuit B0050-1E

Driver Safety Belt Sensor -

Circuit resistance out of range

Driver safety belt sensor

circuit - resistance out of

range

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system B0050-56

Driver Safety Belt Sensor -

Invalid/incomplete

configuration

Incompatible configuration

Re-configure the RCM using the

manufacturer approved diagnostic

system B0052-11

Passenger Safety Belt Sensor -

Circuit short to ground

Passenger safety belt sensor

circuit - short to ground

Refer to the electrical circuit diagrams

and test passenger safety belt sensor

circuit for short to ground B0052-12

Passenger Safety Belt Sensor -

Circuit short to battery

Passenger safety belt sensor

circuit - short to power

Refer to the electrical circuit diagrams

and test passenger safety belt sensor

circuit for short to power B0052-13

Passenger Safety Belt Sensor -

Circuit open

Passenger safety belt sensor

circuit - open circuit

Refer to the electrical circuit diagrams

and test passenger safety belt sensor

circuit for open circuit

Page 238 of 3039

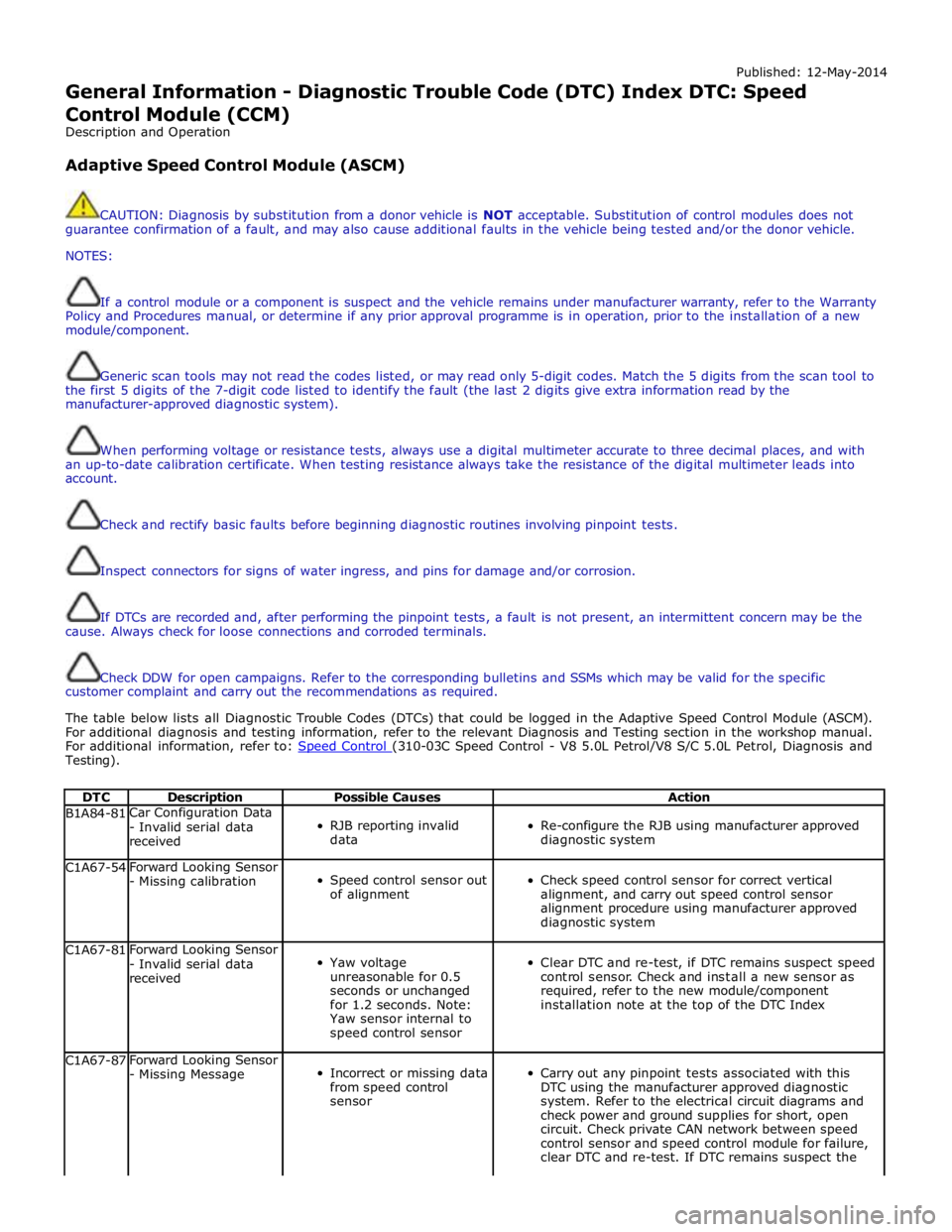

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Speed

Control Module (CCM)

Description and Operation

Adaptive Speed Control Module (ASCM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Adaptive Speed Control Module (ASCM).

For additional diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop manual.

For additional information, refer to: Speed Control (310-03C Speed Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Diagnosis and Testing).

DTC Description Possible Causes Action B1A84-81 Car Configuration Data

- Invalid serial data

received

RJB reporting invalid

data

Re-configure the RJB using manufacturer approved

diagnostic system C1A67-54 Forward Looking Sensor

- Missing calibration

Speed control sensor out

of alignment

Check speed control sensor for correct vertical

alignment, and carry out speed control sensor

alignment procedure using manufacturer approved

diagnostic system C1A67-81 Forward Looking Sensor

- Invalid serial data

received

Yaw voltage

unreasonable for 0.5

seconds or unchanged

for 1.2 seconds. Note:

Yaw sensor internal to

speed control sensor

Clear DTC and re-test, if DTC remains suspect speed

control sensor. Check and install a new sensor as

required, refer to the new module/component

installation note at the top of the DTC Index C1A67-87 Forward Looking Sensor

- Missing Message

Incorrect or missing data

from speed control

sensor

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check power and ground supplies for short, open

circuit. Check private CAN network between speed

control sensor and speed control module for failure,

clear DTC and re-test. If DTC remains suspect the

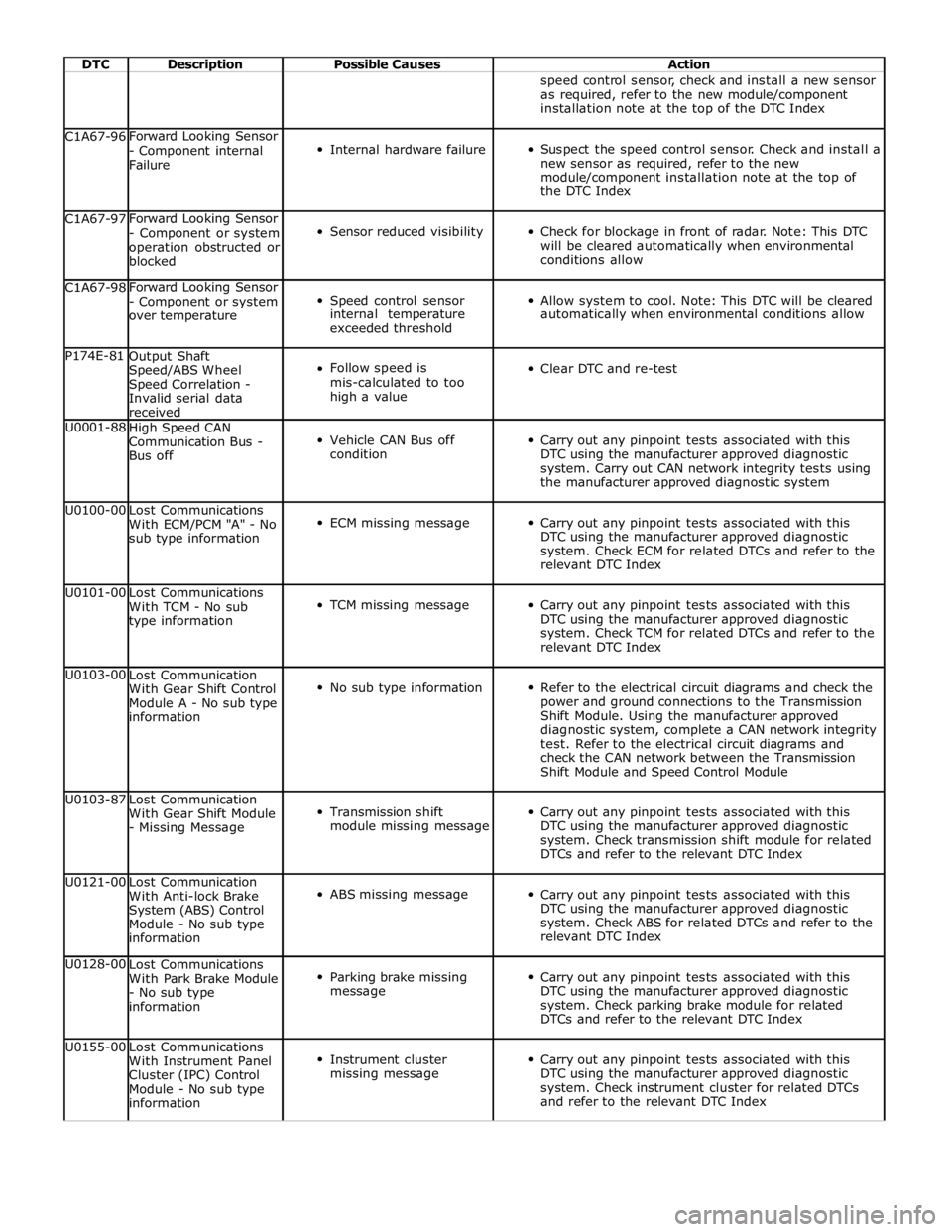

Page 239 of 3039

DTC Description Possible Causes Action speed control sensor, check and install a new sensor

as required, refer to the new module/component

installation note at the top of the DTC Index C1A67-96 Forward Looking Sensor

- Component internal

Failure

Internal hardware failure

Suspect the speed control sensor. Check and install a

new sensor as required, refer to the new

module/component installation note at the top of

the DTC Index C1A67-97 Forward Looking Sensor

- Component or system

operation obstructed or

blocked

Sensor reduced visibility

Check for blockage in front of radar. Note: This DTC

will be cleared automatically when environmental

conditions allow C1A67-98 Forward Looking Sensor

- Component or system

over temperature

Speed control sensor

internal temperature

exceeded threshold

Allow system to cool. Note: This DTC will be cleared

automatically when environmental conditions allow P174E-81

Output Shaft

Speed/ABS Wheel

Speed Correlation -

Invalid serial data

received

Follow speed is

mis-calculated to too

high a value

Clear DTC and re-test U0001-88

High Speed CAN

Communication Bus -

Bus off

Vehicle CAN Bus off

condition

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity tests using

the manufacturer approved diagnostic system U0100-00

Lost Communications

With ECM/PCM "A" - No

sub type information

ECM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ECM for related DTCs and refer to the

relevant DTC Index U0101-00

Lost Communications

With TCM - No sub

type information

TCM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check TCM for related DTCs and refer to the

relevant DTC Index U0103-00

Lost Communication

With Gear Shift Control

Module A - No sub type

information

No sub type information

Refer to the electrical circuit diagrams and check the

power and ground connections to the Transmission

Shift Module. Using the manufacturer approved

diagnostic system, complete a CAN network integrity

test. Refer to the electrical circuit diagrams and

check the CAN network between the Transmission

Shift Module and Speed Control Module U0103-87

Lost Communication

With Gear Shift Module

- Missing Message

Transmission shift

module missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check transmission shift module for related

DTCs and refer to the relevant DTC Index U0121-00

Lost Communication

With Anti-lock Brake

System (ABS) Control

Module - No sub type

information

ABS missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ABS for related DTCs and refer to the

relevant DTC Index U0128-00

Lost Communications

With Park Brake Module

- No sub type

information

Parking brake missing

message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check parking brake module for related

DTCs and refer to the relevant DTC Index U0155-00

Lost Communications

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Instrument cluster

missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check instrument cluster for related DTCs

and refer to the relevant DTC Index

Page 246 of 3039

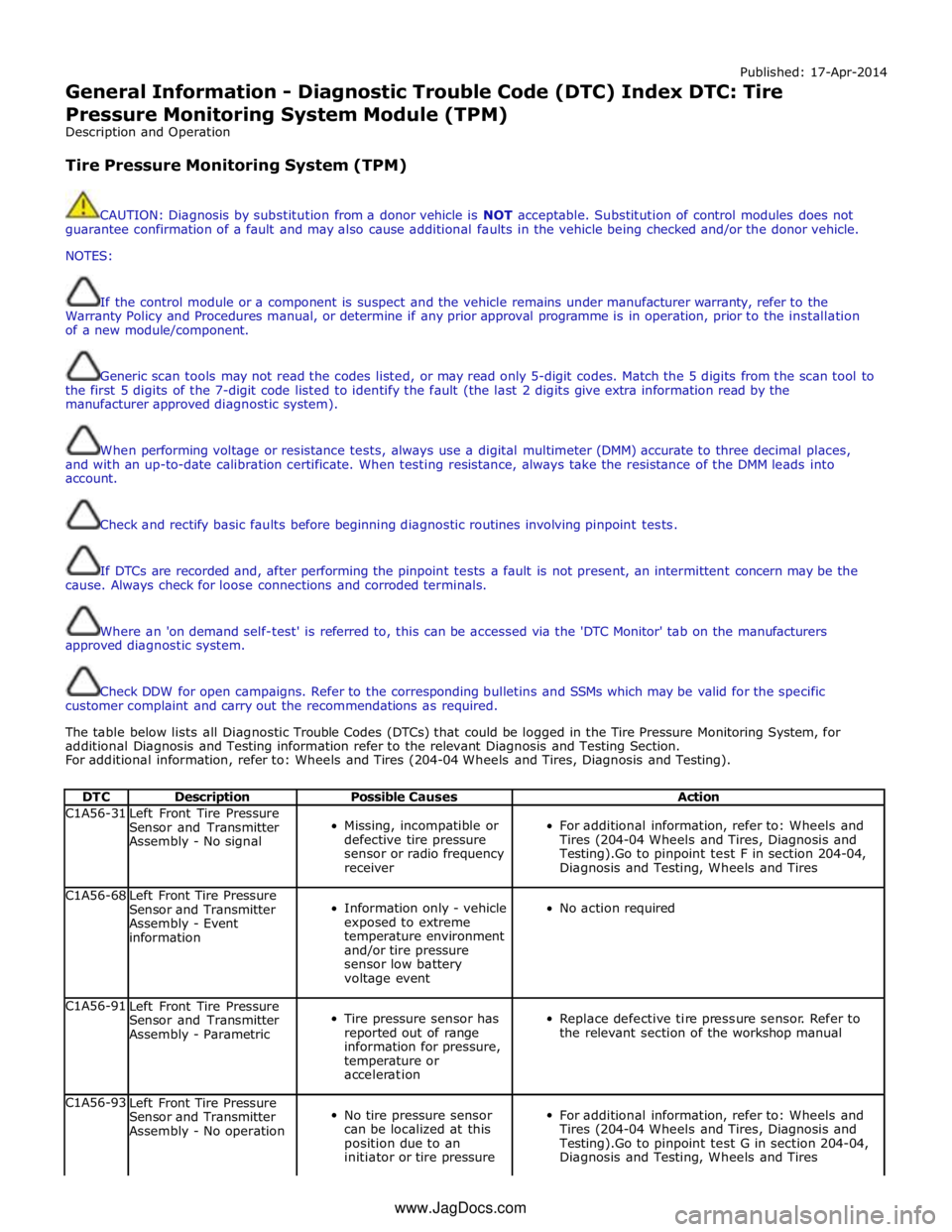

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Tire

Pressure Monitoring System Module (TPM)

Description and Operation

Tire Pressure Monitoring System (TPM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Where an 'on demand self-test' is referred to, this can be accessed via the 'DTC Monitor' tab on the manufacturers

approved diagnostic system.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Tire Pressure Monitoring System, for

additional Diagnosis and Testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Wheels and Tires (204-04 Wheels and Tires, Diagnosis and Testing).

DTC Description Possible Causes Action C1A56-31

Left Front Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A56-68

Left Front Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A56-91

Left Front Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor. Refer to

the relevant section of the workshop manual C1A56-93

Left Front Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires www.JagDocs.com

Page 247 of 3039

DTC Description Possible Causes Action sensor malfunction

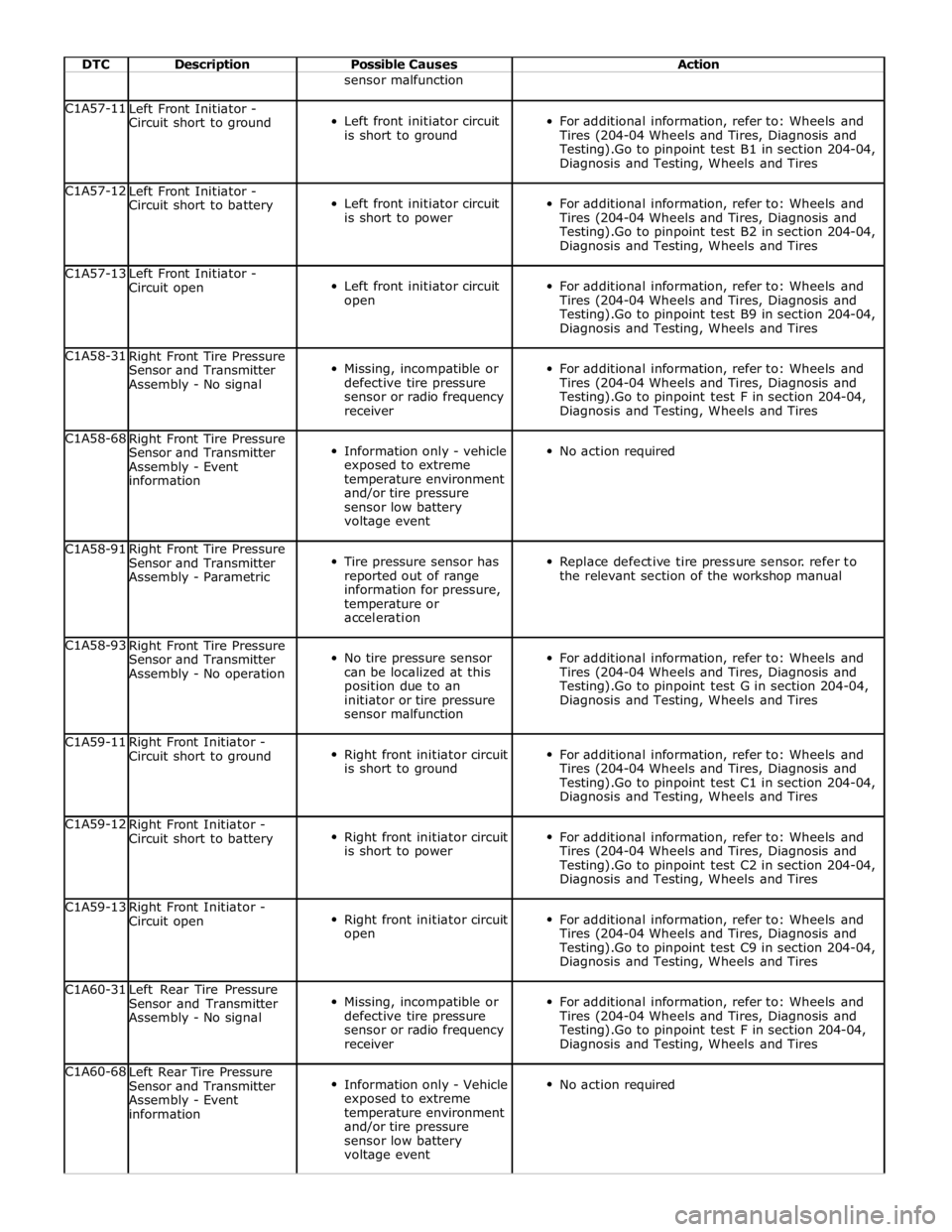

C1A57-11

Left Front Initiator -

Circuit short to ground

Left front initiator circuit

is short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test B1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A57-12

Left Front Initiator -

Circuit short to battery

Left front initiator circuit

is short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test B2 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A57-13

Left Front Initiator -

Circuit open

Left front initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test B9 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A58-31

Right Front Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A58-68

Right Front Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A58-91

Right Front Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor. refer to

the relevant section of the workshop manual C1A58-93

Right Front Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

sensor malfunction

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A59-11

Right Front Initiator -

Circuit short to ground

Right front initiator circuit

is short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test C1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A59-12

Right Front Initiator -

Circuit short to battery

Right front initiator circuit

is short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test C2 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A59-13

Right Front Initiator -

Circuit open

Right front initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test C9 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A60-31

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A60-68

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - Vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required

Page 248 of 3039

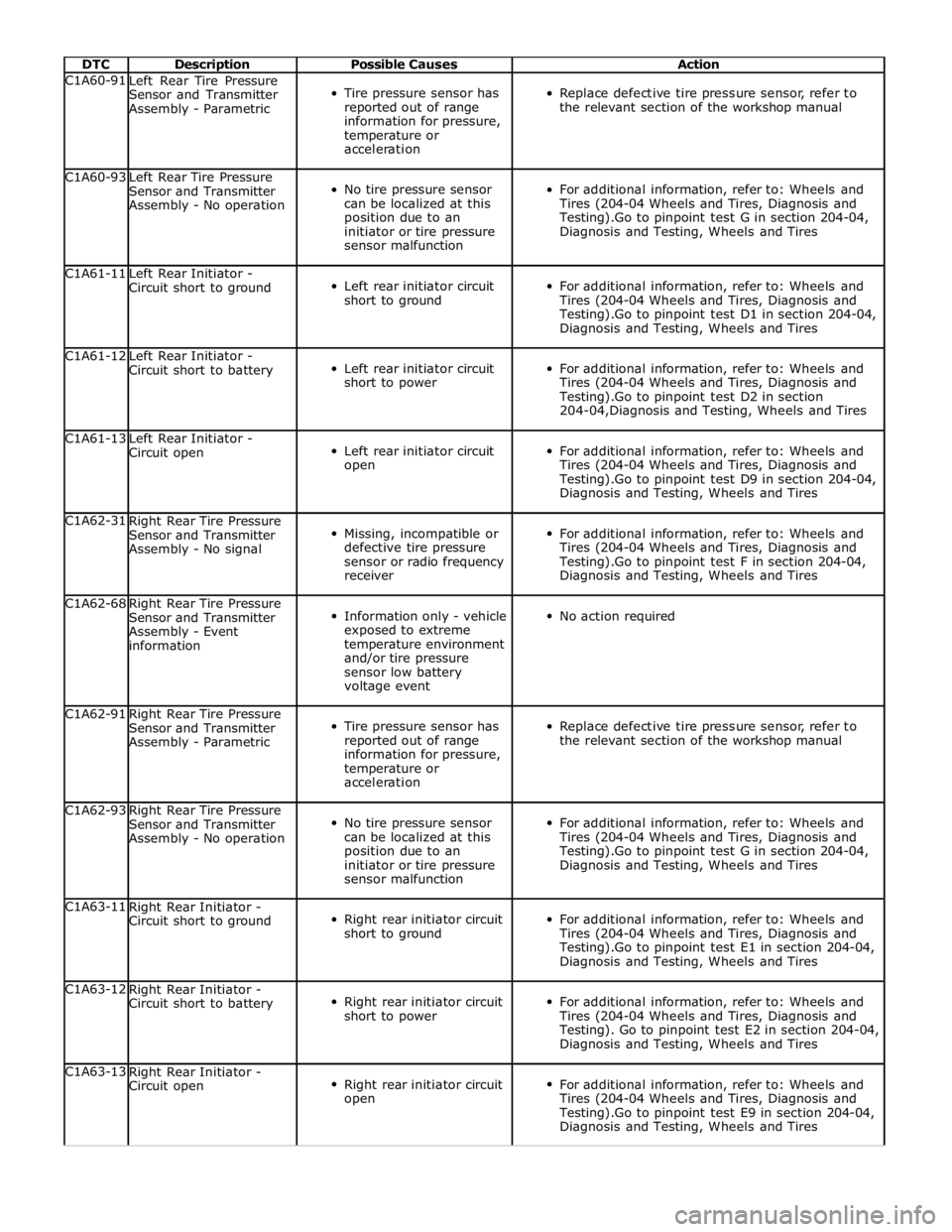

DTC Description Possible Causes Action C1A60-91

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A60-93

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

sensor malfunction

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A61-11

Left Rear Initiator -

Circuit short to ground

Left rear initiator circuit

short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test D1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A61-12

Left Rear Initiator -

Circuit short to battery

Left rear initiator circuit

short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test D2 in section

204-04,Diagnosis and Testing, Wheels and Tires C1A61-13

Left Rear Initiator -

Circuit open

Left rear initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test D9 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A62-31

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A62-68

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A62-91

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A62-93

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

sensor malfunction

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A63-11

Right Rear Initiator -

Circuit short to ground

Right rear initiator circuit

short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test E1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A63-12

Right Rear Initiator -

Circuit short to battery

Right rear initiator circuit

short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing). Go to pinpoint test E2 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A63-13

Right Rear Initiator -

Circuit open

Right rear initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test E9 in section 204-04,

Diagnosis and Testing, Wheels and Tires

Page 249 of 3039

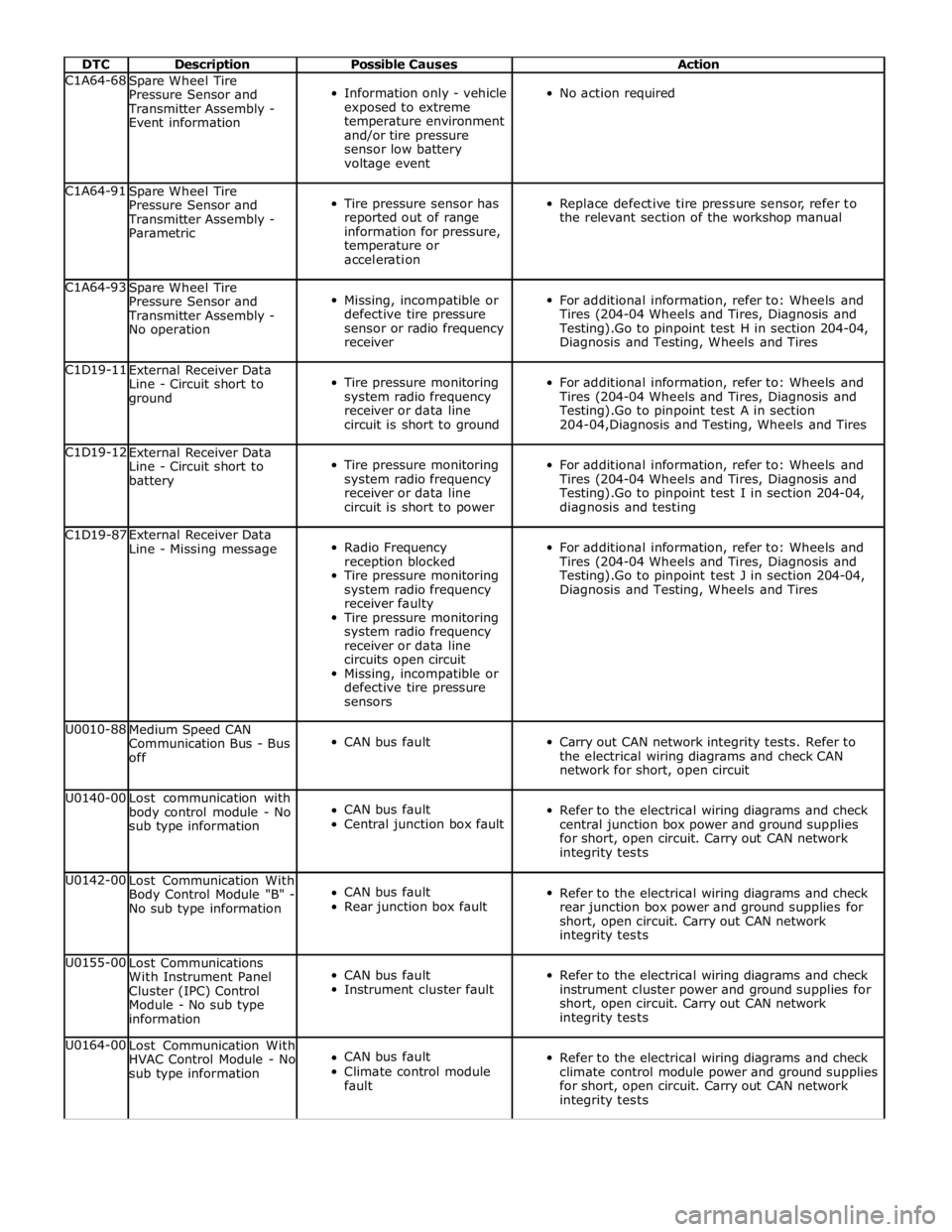

DTC Description Possible Causes Action C1A64-68

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

Event information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A64-91

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A64-93

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

No operation

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test H in section 204-04,

Diagnosis and Testing, Wheels and Tires C1D19-11

External Receiver Data

Line - Circuit short to

ground

Tire pressure monitoring

system radio frequency

receiver or data line

circuit is short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test A in section

204-04,Diagnosis and Testing, Wheels and Tires C1D19-12

External Receiver Data

Line - Circuit short to

battery

Tire pressure monitoring

system radio frequency

receiver or data line

circuit is short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test I in section 204-04,

diagnosis and testing C1D19-87

External Receiver Data

Line - Missing message

Radio Frequency

reception blocked

Tire pressure monitoring

system radio frequency

receiver faulty

Tire pressure monitoring

system radio frequency

receiver or data line

circuits open circuit

Missing, incompatible or

defective tire pressure

sensors

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test J in section 204-04,

Diagnosis and Testing, Wheels and Tires U0010-88

Medium Speed CAN

Communication Bus - Bus

off

CAN bus fault

Carry out CAN network integrity tests. Refer to

the electrical wiring diagrams and check CAN

network for short, open circuit U0140-00

Lost communication with

body control module - No

sub type information

CAN bus fault

Central junction box fault

Refer to the electrical wiring diagrams and check

central junction box power and ground supplies

for short, open circuit. Carry out CAN network

integrity tests U0142-00

Lost Communication With

Body Control Module "B" -

No sub type information

CAN bus fault

Rear junction box fault

Refer to the electrical wiring diagrams and check

rear junction box power and ground supplies for

short, open circuit. Carry out CAN network

integrity tests U0155-00

Lost Communications

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

CAN bus fault

Instrument cluster fault

Refer to the electrical wiring diagrams and check

instrument cluster power and ground supplies for

short, open circuit. Carry out CAN network

integrity tests U0164-00

Lost Communication With

HVAC Control Module - No

sub type information

CAN bus fault

Climate control module

fault

Refer to the electrical wiring diagrams and check

climate control module power and ground supplies

for short, open circuit. Carry out CAN network

integrity tests

Page 253 of 3039

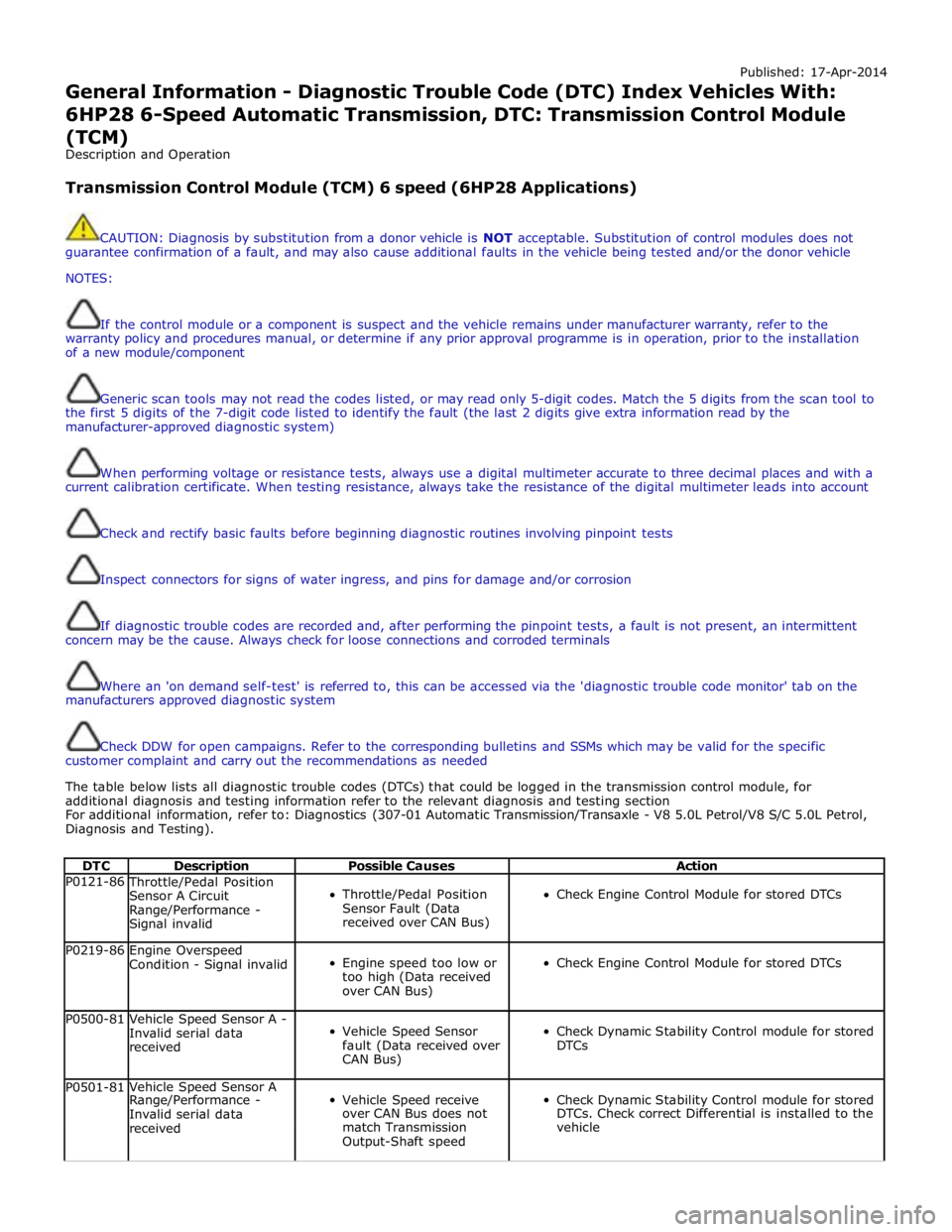

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index Vehicles With:

6HP28 6-Speed Automatic Transmission, DTC: Transmission Control Module

(TCM)

Description and Operation

Transmission Control Module (TCM) 6 speed (6HP28 Applications)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as needed

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the transmission control module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section

For additional information, refer to: Diagnostics (307-01 Automatic Transmission/Transaxle - V8 5.0L Petrol/V8 S/C 5.0L Petrol,

Diagnosis and Testing).

DTC Description Possible Causes Action P0121-86 Throttle/Pedal Position

Sensor A Circuit

Range/Performance -

Signal invalid

Throttle/Pedal Position

Sensor Fault (Data

received over CAN Bus)

Check Engine Control Module for stored DTCs P0219-86

Engine Overspeed

Condition - Signal invalid

Engine speed too low or

too high (Data received

over CAN Bus)

Check Engine Control Module for stored DTCs P0500-81

Vehicle Speed Sensor A -

Invalid serial data

received

Vehicle Speed Sensor

fault (Data received over

CAN Bus)

Check Dynamic Stability Control module for stored

DTCs P0501-81 Vehicle Speed Sensor A

Vehicle Speed receive

Check Dynamic Stability Control module for stored Range/Performance - Invalid serial data over CAN Bus does not DTCs. Check correct Differential is installed to the received match Transmission vehicle Output-Shaft speed

Page 255 of 3039

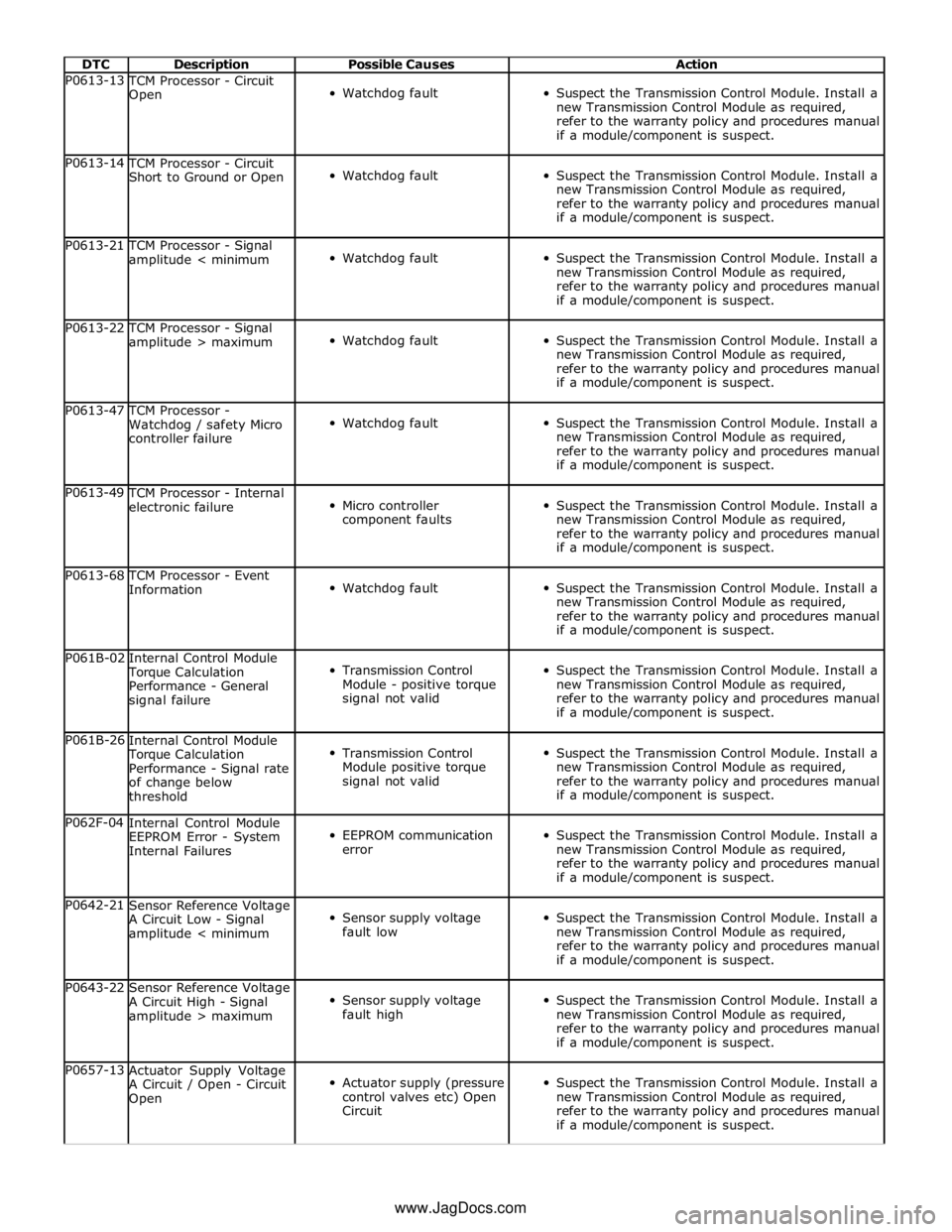

DTC Description Possible Causes Action P0613-13 TCM Processor - Circuit

Open

Watchdog fault

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0613-14 TCM Processor - Circuit

Short to Ground or Open

Watchdog fault

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0613-21 TCM Processor - Signal

amplitude < minimum

Watchdog fault

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0613-22 TCM Processor - Signal

amplitude > maximum

Watchdog fault

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0613-47 TCM Processor -

Watchdog / safety Micro

controller failure

Watchdog fault

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0613-49 TCM Processor - Internal

electronic failure

Micro controller

component faults

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0613-68 TCM Processor - Event

Information

Watchdog fault

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P061B-02

Internal Control Module Torque Calculation

Performance - General

signal failure

Transmission Control

Module - positive torque

signal not valid

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P061B-26

Internal Control Module Torque Calculation

Performance - Signal rate

of change below

threshold

Transmission Control

Module positive torque

signal not valid

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P062F-04

Internal Control Module

EEPROM Error - System

Internal Failures

EEPROM communication

error

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0642-21

Sensor Reference Voltage

A Circuit Low - Signal

amplitude < minimum

Sensor supply voltage

fault low

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0643-22

Sensor Reference Voltage

A Circuit High - Signal

amplitude > maximum

Sensor supply voltage

fault high

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0657-13

Actuator Supply Voltage

A Circuit / Open - Circuit

Open

Actuator supply (pressure

control valves etc) Open

Circuit

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. www.JagDocs.com