fuse JAGUAR XFR 2010 1.G Manual Online

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2017 of 3039

Is the USB extension cable securely pushed into the USB connection port on the audio input control module

Yes

Replace the USB extension cable

No

Secure connections and retest B4: CHECK THE CAPACITY OF THE MEMORY STICK/STORAGE DEVICE

NOTE: The higher the capacity of the memory stick is the longer it takes to register with the audio input control module

and power up. The maximum permitted capacity is 8 Gigabytes 1 Check the storage capacity of the memory stick/storage device does not exceed 8 Gigabytes Is the storage capacity of the memory stick/storage device 8 Gigabytes or less?

Yes

High capacity devices may require longer to register and should be allowed up to two minutes to power up

following connection to the USB port. If memory stick fails to power up after two minutes, suspect a

faulty memory stick GO to B2. or USB extension cable GO to B3. No

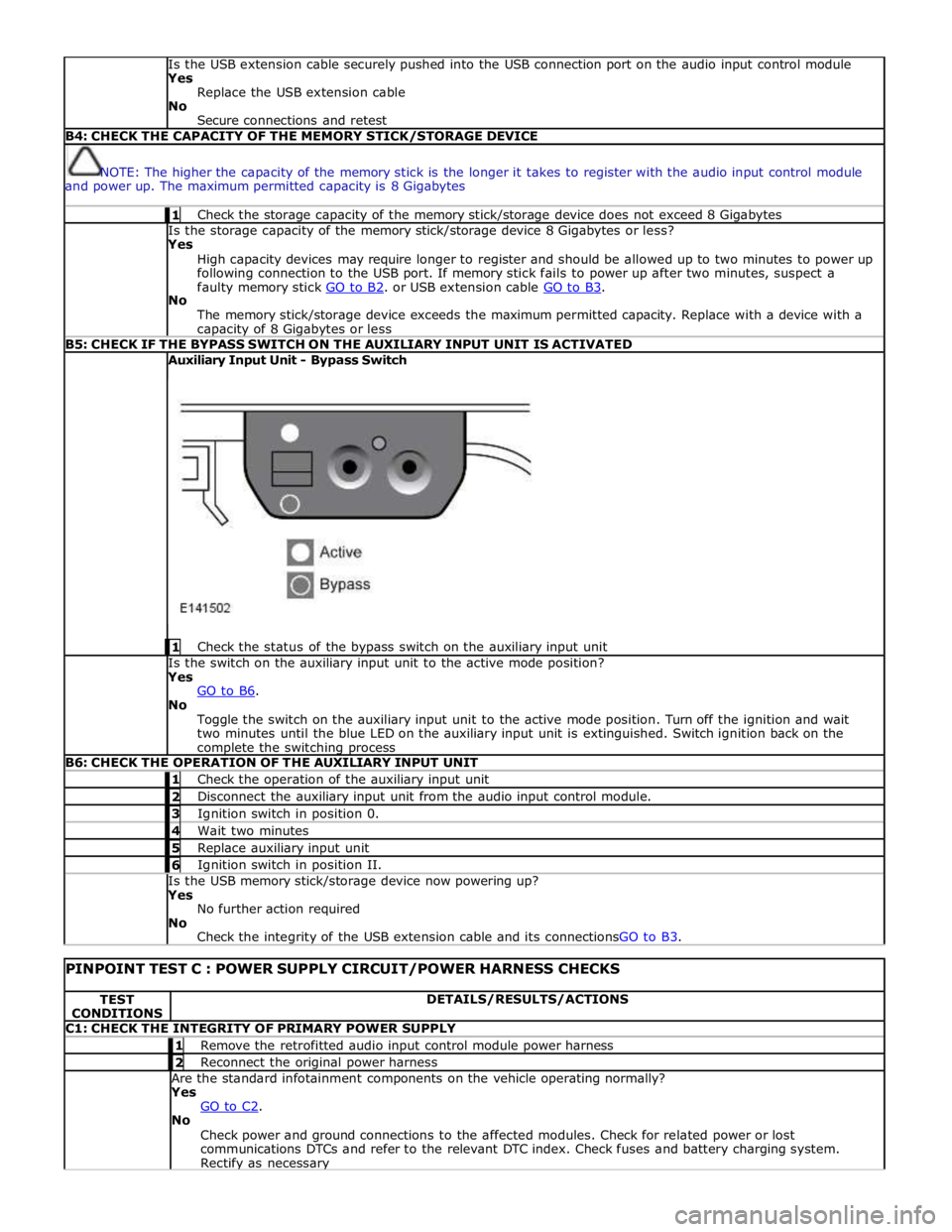

The memory stick/storage device exceeds the maximum permitted capacity. Replace with a device with a capacity of 8 Gigabytes or less B5: CHECK IF THE BYPASS SWITCH ON THE AUXILIARY INPUT UNIT IS ACTIVATED Auxiliary Input Unit - Bypass Switch

1 Check the status of the bypass switch on the auxiliary input unit Is the switch on the auxiliary input unit to the active mode position?

Yes

GO to B6. No

Toggle the switch on the auxiliary input unit to the active mode position. Turn off the ignition and wait

two minutes until the blue LED on the auxiliary input unit is extinguished. Switch ignition back on the complete the switching process B6: CHECK THE OPERATION OF THE AUXILIARY INPUT UNIT 1 Check the operation of the auxiliary input unit 2 Disconnect the auxiliary input unit from the audio input control module. 3 Ignition switch in position 0. 4 Wait two minutes 5 Replace auxiliary input unit 6 Ignition switch in position II. Is the USB memory stick/storage device now powering up?

Yes

No further action required

No

Check the integrity of the USB extension cable and its connectionsGO to B3.

PINPOINT TEST C : POWER SUPPLY CIRCUIT/POWER HARNESS CHECKS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: CHECK THE INTEGRITY OF PRIMARY POWER SUPPLY 1 Remove the retrofitted audio input control module power harness 2 Reconnect the original power harness Are the standard infotainment components on the vehicle operating normally?

Yes

GO to C2. No

Check power and ground connections to the affected modules. Check for related power or lost

communications DTCs and refer to the relevant DTC index. Check fuses and battery charging system. Rectify as necessary

Page 2025 of 3039

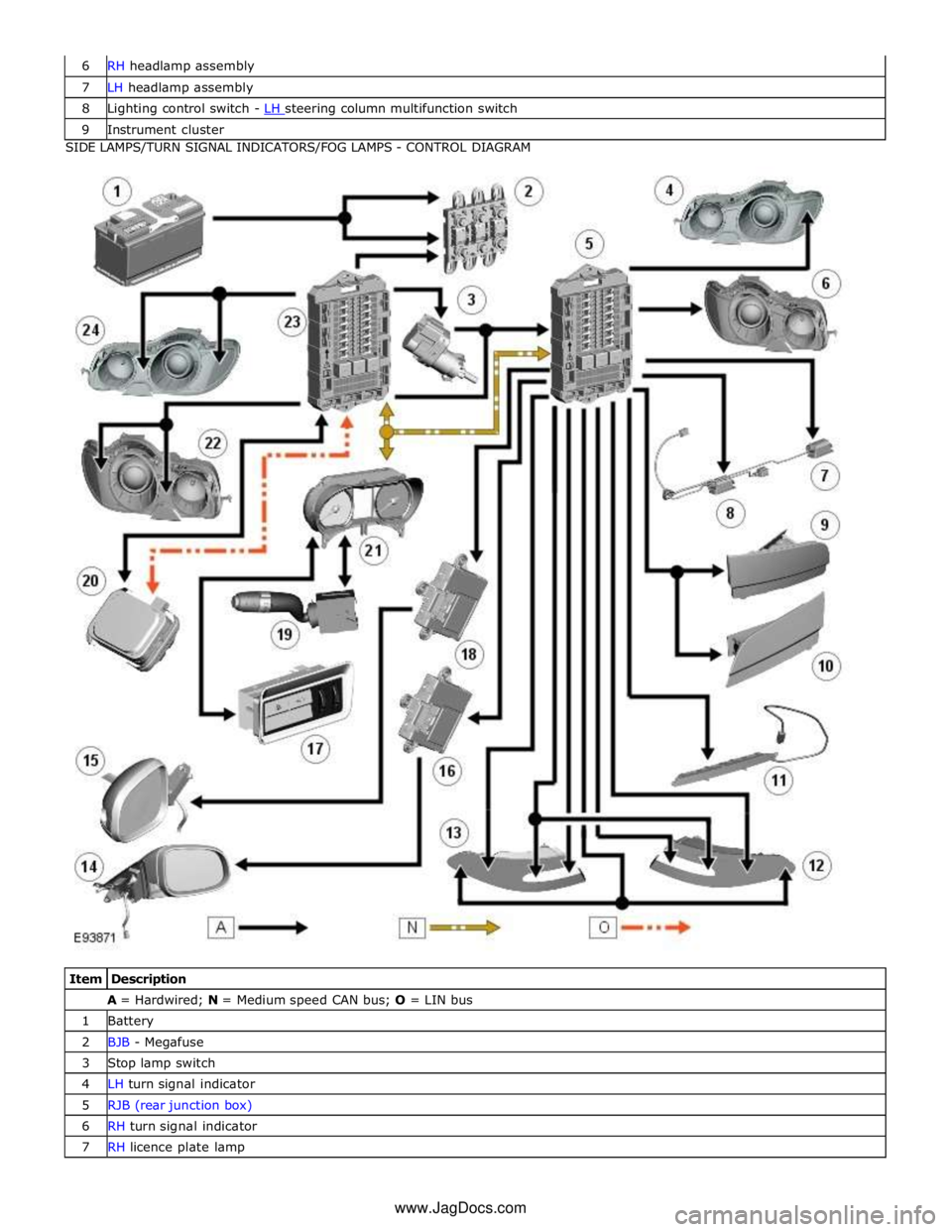

7 LH headlamp assembly 8 Lighting control switch - LH steering column multifunction switch 9 Instrument cluster SIDE LAMPS/TURN SIGNAL INDICATORS/FOG LAMPS - CONTROL DIAGRAM

Item Description A = Hardwired; N = Medium speed CAN bus; O = LIN bus 1 Battery 2 BJB - Megafuse 3 Stop lamp switch 4 LH turn signal indicator 5 RJB (rear junction box) 6 RH turn signal indicator 7 RH licence plate lamp www.JagDocs.com

Page 2027 of 3039

by Field Effect Transistors (FET's). The FET's can detect overloads and short circuits and respond to heat generated by

increased current flow caused by a short circuit.

On a normal conventionally protected circuit this would cause a fuse to blow. The FET's respond to the heat increase and

disconnect the power supply to the affected circuit. When the fault is rectified or the FET has cooled, the FET will reset and

operate the circuit normally. If the fault persists the FET will cycle, disconnecting and reconnecting the power supply.

The CJB and the RJB store fault codes which can be retrieved using a Jaguar approved diagnostic system. The fault code will identify that there is a fault on a particular output circuit which will assist with fault diagnosis and detection.

Alarm Indications

The exterior lighting system is used for alarm arm and disarm requests to show alarm system status.

When the driver locks and arms the vehicle, a visual indication of a successful lock and arm request is displayed to the driver

by a single flash of the hazard flashers. If the vehicle is superlocked, then the hazard flashers will flash a second time (200 ms

off and 200 ms on) to confirm the superlock request.

If the alarm is activated, the hazard flashers are operated for 10, 30 second cycles of 200 ms on and 200 ms off, with a 10

second delay between each cycle.

NOTE: On North American Specification (NAS) vehicles, the delay between the cycle when the alarm is activated is 60

seconds.

Lights on Warning

When the ignition is in the off power mode 0 or accessory power mode 4 and the lighting control switch is in the side lamp or

headlamp position, a warning chime will sound if the driver's door is opened. This indicates to the driver that the exterior

lights have been left switched on.

The chime is generated from the instrument cluster sounder on receipt of a lights on signal, a driver's door open signal and an

ignition off power mode 0 or accessory power mode 4 signal via a medium speed CAN bus signal from the CJB. Headlamp Timer

The RJB controls the headlamp timer function which allows the headlamps to remain on for a period of time after leaving the vehicle. This is a driver convenience feature which illuminates the driveway after leaving the vehicle.

To operate the timer function the lighting control switch must be in one of the three headlamp timer positions when the

ignition status is changed from ignition on power mode 6 to the off power mode 0. The timer function will then be initiated and

the low beam headlamps will be illuminated for the selected timer period.

NOTE: If the lighting switch is in the AUTO position, the headlamp timer will not function when the ignition is changed to

off power mode 0.

When the lighting control switch is in the autolamp exit delay position, the lighting control switch reference voltage flows

through 4 of the resistors. The returned signal voltage is detected by the instrument cluster which outputs a message on the

medium speed CAN bus to the RJB that autolamps has been selected.

Depending on the selected exit delay position, the reference voltage to the autolamp exit delay switch is routed through 3, 2

or 1 resistors which is detected by the instrument cluster. The cluster outputs a message on the medium speed CAN bus to the RJB that autolamp exit delay period has been selected at 30, 60 or 120 seconds respectively. Crash Signal Activation

When a crash signal is transmitted from the RCM (restraints control module), the RJB activates the hazard flashers. The hazard flashers continue to operate until the ignition is in the off power mode 0 or accessory power mode 6. Once this ignition state

has occurred, the RCM will cease to transmit the crash signal.

LIGHTING CONTROL SWITCH

The instrument cluster outputs 2 reference voltages to the rotary lighting control switch; one feed being supplied to the light

selection function of the switch and the second feed being supplied to the auto headlamp exit delay function. The switch

position is determined by instrument cluster by the change in returned signal voltage which is routed through up to 4 resistors

in series depending on the selection made.

OFF - When the lighting control switch is in the off position, the reference voltage flows through 1 of the resistors. The

returned signal voltage is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that no lighting selection is made. The reference voltage to the auto headlamp exit delay switch is routed through 4 resistors which is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that auto headlamp or exit delay has not been selected.

SIDE LAMPS - When the lighting control switch is in the side lamp position, the reference voltage flows through 2 of the

resistors. The returned signal voltage is detected by the instrument cluster which outputs a message on the medium speed

CAN bus to the CJB to activate the side lamps. The reference voltage to the autolamp exit delay switch is routed through 4 resistors which is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that auto headlamp or exit delay has not been selected.

HEADLAMPS - When the lighting control switch is in the headlamp position, the reference voltage flows through 3 of the

Page 2037 of 3039

Exterior Lighting - Headlamps

Diagnosis and Testing

Principles of Operation Published: 11-Jul-2014

For a detailed description of the exterior lighting system, refer to the relevant Description and Operation section in the

workshop manual. REFER to: (417-01 Exterior Lighting)

Exterior Lighting (Description and Operation), Exterior Lighting (Description and Operation), Exterior Lighting (Description and Operation).

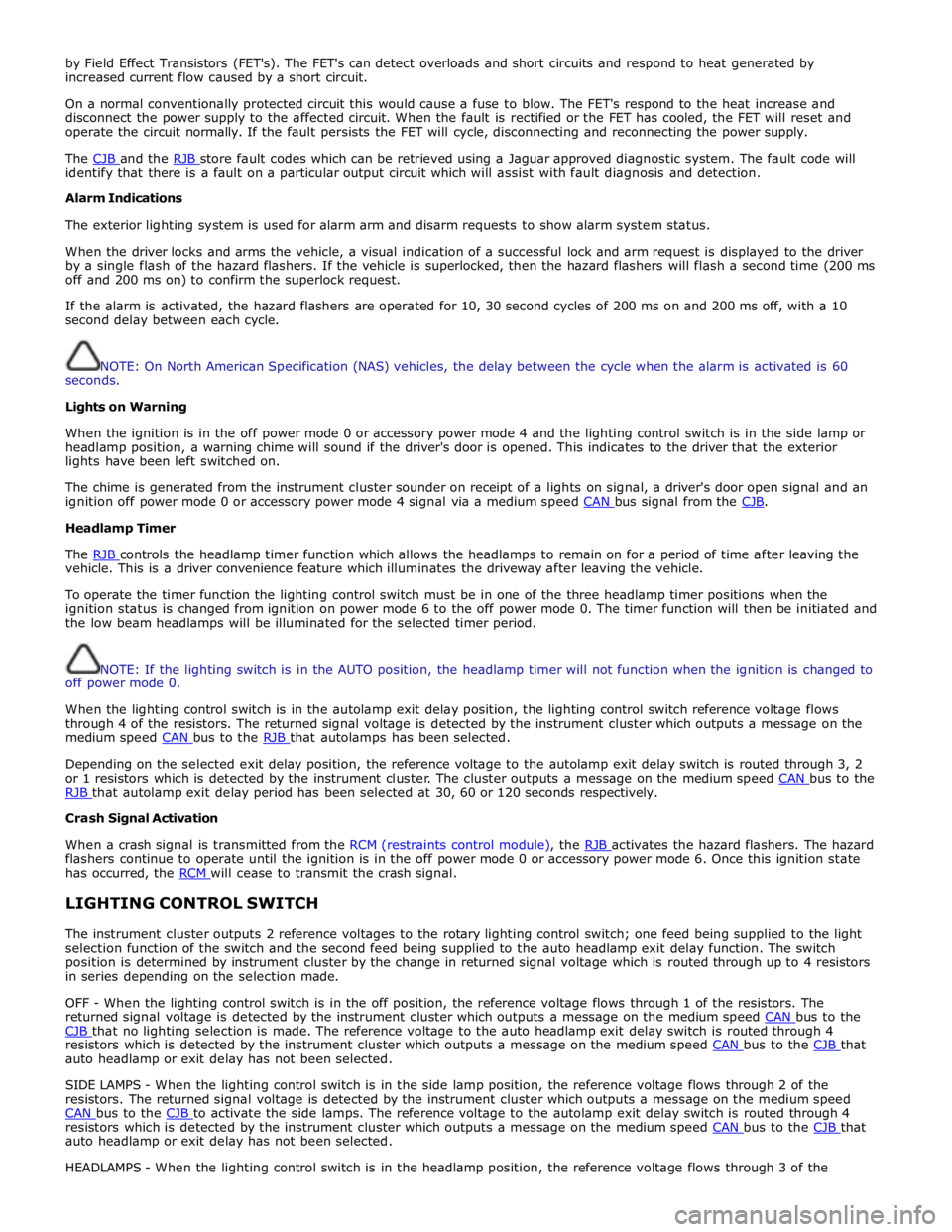

Safety Information

WARNINGS:

The Xenon Headlamp system generates up to 28,000 volts. Make sure that the headlamps are switched off before

working on the system. Failure to follow this instruction may lead to fatality.

The following safety precautions must be followed when working on the Xenon Headlamp system:

DO NOT attempt any procedures on the Xenon Headlamps or circuits when the system is energized.

Handling of the xenon bulb must be performed using suitable protective equipment, e.g. gloves and goggles. The glass

part of the bulb must not be touched.

Only operate the lamp in a mounted condition in the reflector.

All safety procedures and precautions must be followed to prevent personal injury.

CAUTION: Xenon bulbs must be disposed of as hazardous waste.

There are instructions on the correct procedures for Xenon Headlamp System repairs in the manual, refer to section 100-00 -

General Information, Standard Workshop Practices of the workshop manual.

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to DTC Index.

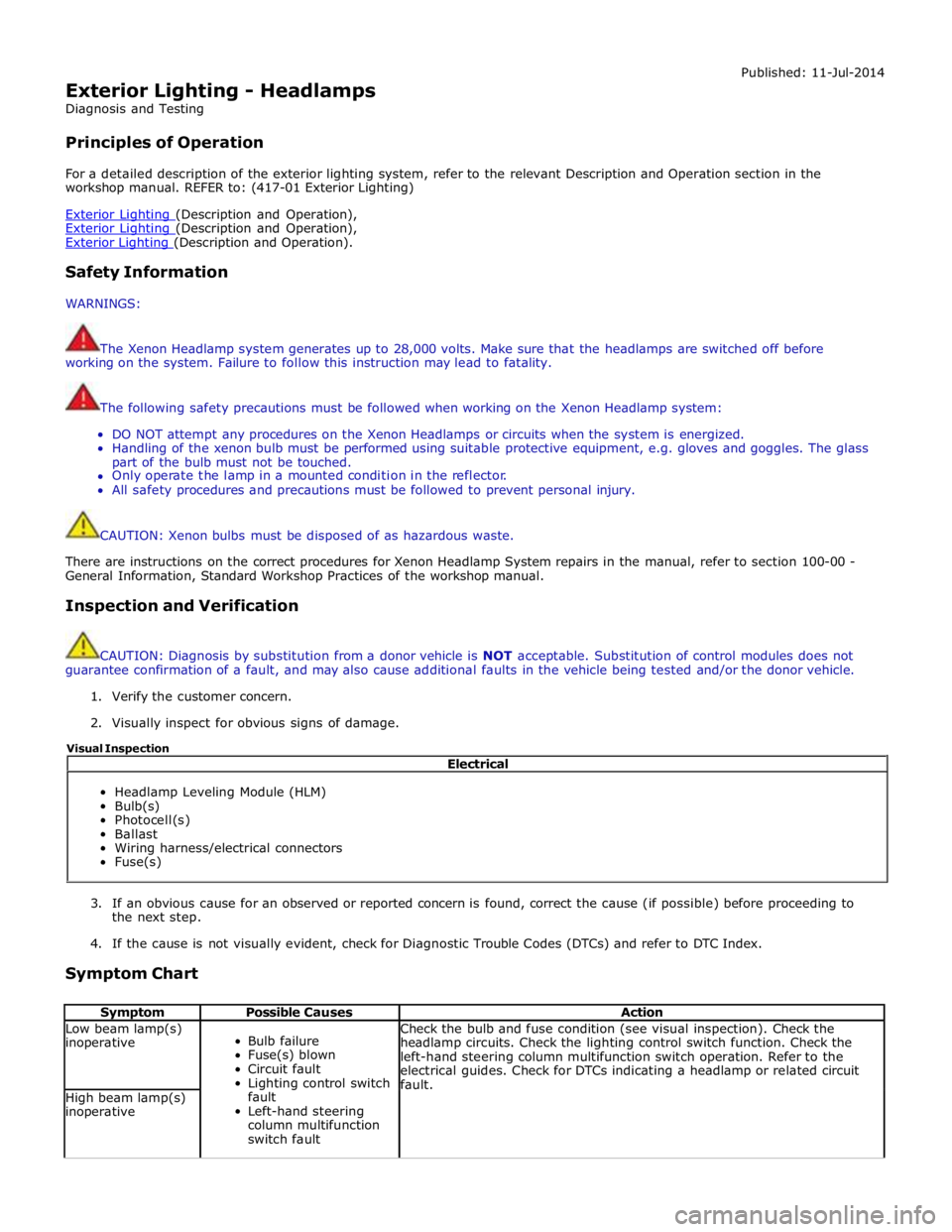

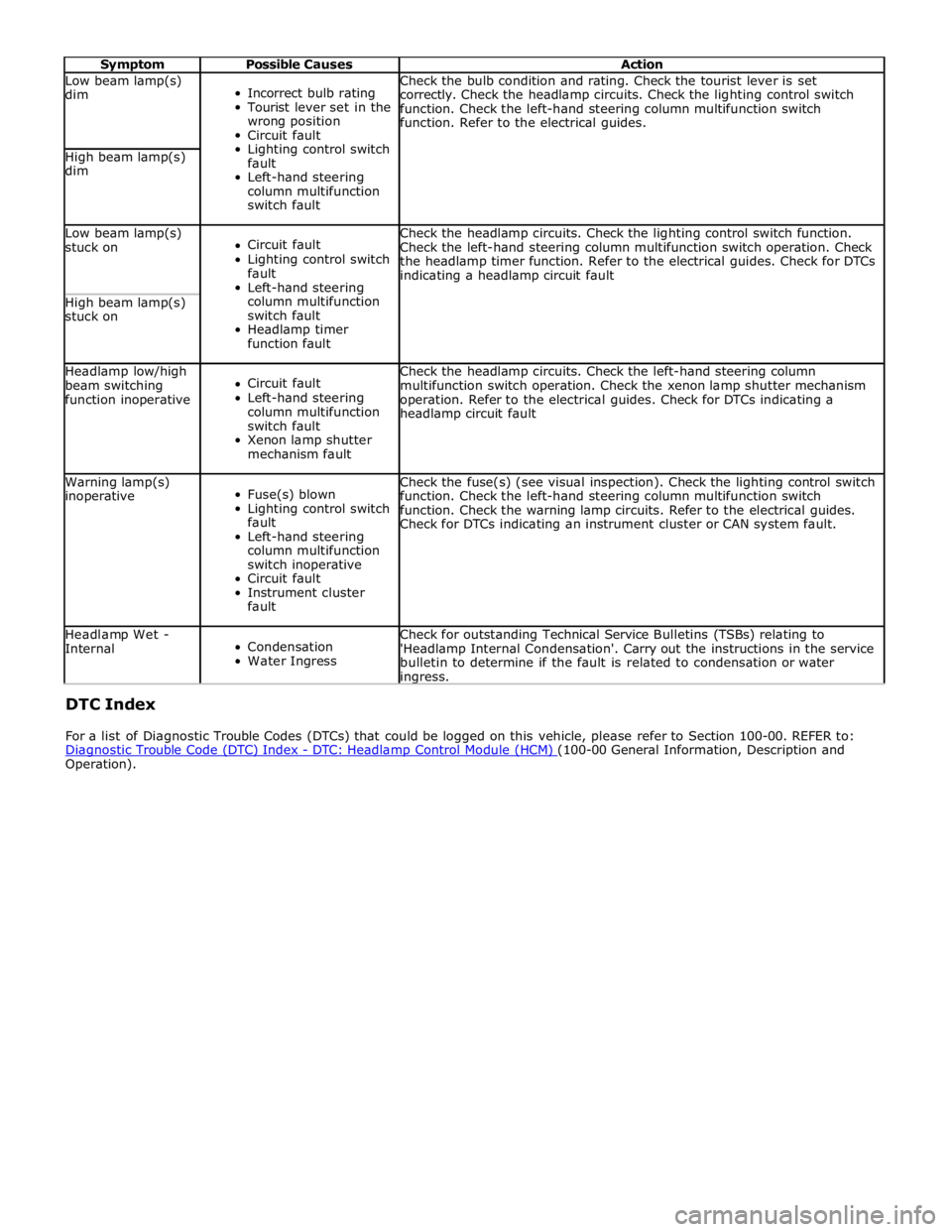

Symptom Chart

Symptom Possible Causes Action Low beam lamp(s)

inoperative

Bulb failure

Fuse(s) blown

Circuit fault

Lighting control switch

fault

Left-hand steering

column multifunction

switch fault Check the bulb and fuse condition (see visual inspection). Check the

headlamp circuits. Check the lighting control switch function. Check the

left-hand steering column multifunction switch operation. Refer to the

electrical guides. Check for DTCs indicating a headlamp or related circuit

fault. High beam lamp(s)

inoperative Electrical

Headlamp Leveling Module (HLM)

Bulb(s)

Photocell(s)

Ballast

Wiring harness/electrical connectors

Fuse(s) Visual Inspection

Page 2038 of 3039

Symptom Possible Causes Action Low beam lamp(s)

dim

Incorrect bulb rating

Tourist lever set in the

wrong position

Circuit fault

Lighting control switch

fault

Left-hand steering

column multifunction

switch fault Check the bulb condition and rating. Check the tourist lever is set

correctly. Check the headlamp circuits. Check the lighting control switch

function. Check the left-hand steering column multifunction switch

function. Refer to the electrical guides. High beam lamp(s)

dim Low beam lamp(s)

stuck on

Circuit fault

Lighting control switch

fault

Left-hand steering

column multifunction

switch fault

Headlamp timer

function fault Check the headlamp circuits. Check the lighting control switch function.

Check the left-hand steering column multifunction switch operation. Check

the headlamp timer function. Refer to the electrical guides. Check for DTCs

indicating a headlamp circuit fault High beam lamp(s)

stuck on Headlamp low/high

beam switching

function inoperative

Circuit fault

Left-hand steering

column multifunction

switch fault

Xenon lamp shutter

mechanism fault Check the headlamp circuits. Check the left-hand steering column

multifunction switch operation. Check the xenon lamp shutter mechanism

operation. Refer to the electrical guides. Check for DTCs indicating a

headlamp circuit fault Warning lamp(s)

inoperative

Fuse(s) blown

Lighting control switch

fault

Left-hand steering

column multifunction

switch inoperative

Circuit fault

Instrument cluster

fault Check the fuse(s) (see visual inspection). Check the lighting control switch

function. Check the left-hand steering column multifunction switch

function. Check the warning lamp circuits. Refer to the electrical guides.

Check for DTCs indicating an instrument cluster or CAN system fault. Headlamp Wet -

Internal

Condensation

Water Ingress Check for outstanding Technical Service Bulletins (TSBs) relating to

'Headlamp Internal Condensation'. Carry out the instructions in the service

bulletin to determine if the fault is related to condensation or water ingress. DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00. REFER to:

Diagnostic Trouble Code (DTC) Index - DTC: Headlamp Control Module (HCM) (100-00 General Information, Description and Operation).

Page 2056 of 3039

A = Hardwired; N = Medium speed CAN Bus 1 Battery 2 BJB (battery junction box) - Megafuse 3 BJB - Megafuse 4 RJB (rear junction box) 5 Driver's door mirror approach lamp 6 Driver's door module

Page 2057 of 3039

8 Passenger door module 9 LH (left-hand) rear door latch 10 RH (right-hand) rear door latch 11 LH front door latch 12 RH front door latch 13 CJB (central junction box) 14 LH front door handle LED (light emitting diode) illumination 15 RH front door handle LED illumination CONTROL DIAGRAM (SHEET 2 OF 2)

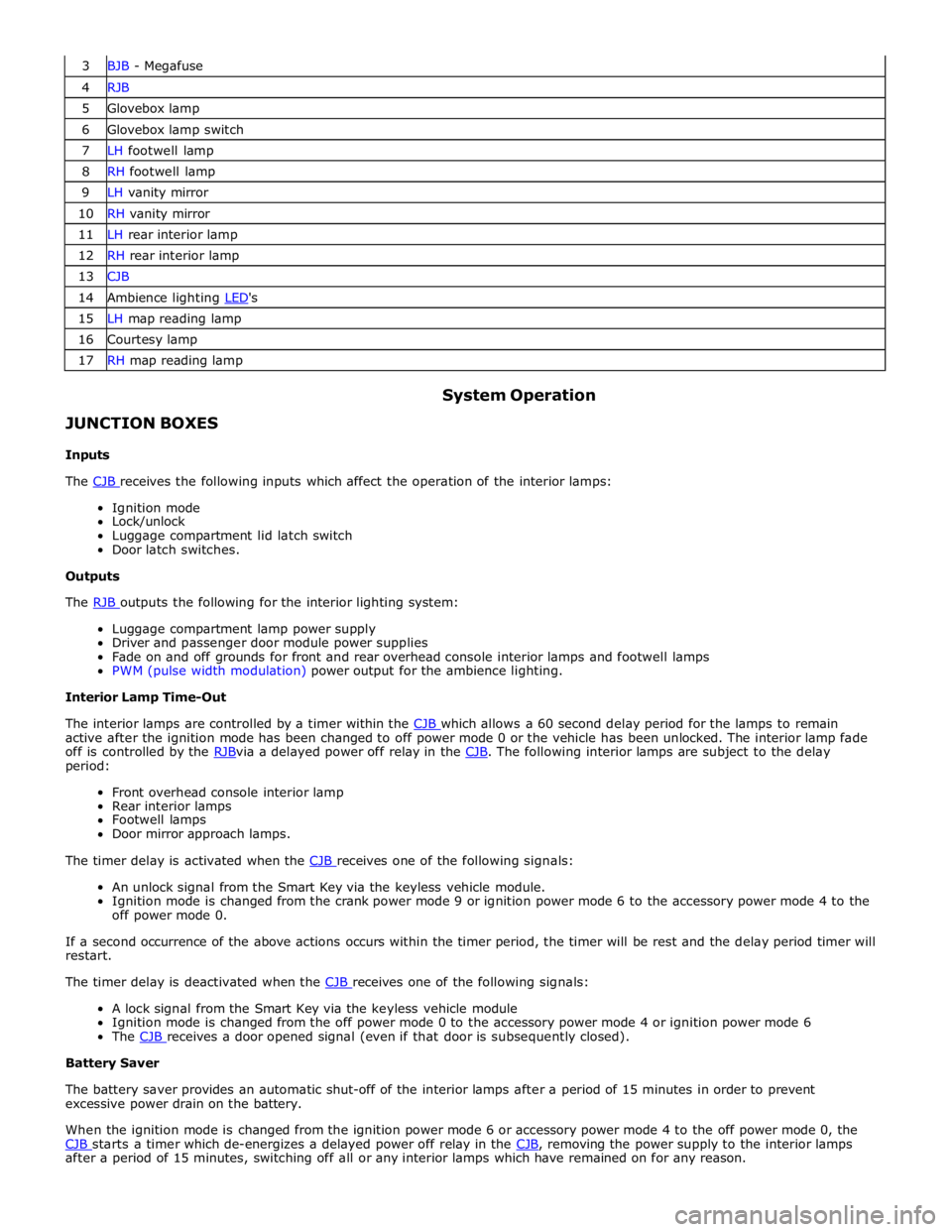

Item Description A = Hardwired 1 Battery 2 BJB - Megafuse

Page 2058 of 3039

3 BJB - Megafuse 4 RJB 5 Glovebox lamp 6 Glovebox lamp switch 7 LH footwell lamp 8 RH footwell lamp 9 LH vanity mirror 10 RH vanity mirror 11 LH rear interior lamp 12 RH rear interior lamp 13 CJB 14 Ambience lighting LED's 15 LH map reading lamp 16 Courtesy lamp 17 RH map reading lamp

JUNCTION BOXES

Inputs System Operation

The CJB receives the following inputs which affect the operation of the interior lamps: Ignition mode

Lock/unlock

Luggage compartment lid latch switch

Door latch switches.

Outputs

The RJB outputs the following for the interior lighting system: Luggage compartment lamp power supply

Driver and passenger door module power supplies

Fade on and off grounds for front and rear overhead console interior lamps and footwell lamps

PWM (pulse width modulation) power output for the ambience lighting.

Interior Lamp Time-Out

The interior lamps are controlled by a timer within the CJB which allows a 60 second delay period for the lamps to remain active after the ignition mode has been changed to off power mode 0 or the vehicle has been unlocked. The interior lamp fade

off is controlled by the RJBvia a delayed power off relay in the CJB. The following interior lamps are subject to the delay period:

Front overhead console interior lamp

Rear interior lamps

Footwell lamps

Door mirror approach lamps.

The timer delay is activated when the CJB receives one of the following signals: An unlock signal from the Smart Key via the keyless vehicle module.

Ignition mode is changed from the crank power mode 9 or ignition power mode 6 to the accessory power mode 4 to the

off power mode 0.

If a second occurrence of the above actions occurs within the timer period, the timer will be rest and the delay period timer will

restart.

The timer delay is deactivated when the CJB receives one of the following signals: A lock signal from the Smart Key via the keyless vehicle module

Ignition mode is changed from the off power mode 0 to the accessory power mode 4 or ignition power mode 6

The CJB receives a door opened signal (even if that door is subsequently closed). Battery Saver

The battery saver provides an automatic shut-off of the interior lamps after a period of 15 minutes in order to prevent

excessive power drain on the battery.

When the ignition mode is changed from the ignition power mode 6 or accessory power mode 4 to the off power mode 0, the

CJB starts a timer which de-energizes a delayed power off relay in the CJB, removing the power supply to the interior lamps after a period of 15 minutes, switching off all or any interior lamps which have remained on for any reason.

Page 2059 of 3039

Once the timer has expired and the lamps are off, any one of the following will 'wake up' the battery saver and the interior

lamps will function again. The timer will be restarted as soon as an input is received by the CJB from one of the following:

Ignition mode changed from off power mode 0 to accessory power mode 4, ignition power mode 6 or crank power mode

9.

Any door, including the luggage compartment lid is opened

An unlock request is received from the Smart Key via the keyless vehicle module

Overhead console interior lamp is switched on via the JaguarSense function.

INTERIOR LAMPS

When the interior lighting system switches the interior lamps on, the CJB ramps the lamps up to full power over a period of 1.3 seconds. When the system switches the lamps off, after the time-out period has expired, the CJB fades the lamps off over a period of 2.6 seconds.

The interior lighting system will illuminate the interior lamps when one of the following events occurs:

The CJB receives an unlock signal from the Smart Key via the keyless vehicle module Any door is opened including the luggage compartment lid

The ignition mode is changed from ignition power mode 6 or accessory power mode 4 to off power mode 0.

The interior lighting system will turn off the interior lamps when one of the following events occurs:

Once the time-out timer delay has expired since the lamps were either activated or the last door is closed and the

vehicle is not locked

The ignition is in off power mode 0 and an external lock is requested (using either the door lock buttons or the Smart

Key) with all doors closed

The ignition mode is changed from the off power mode 0 or the accessory power mode 4 to the ignition power mode 6

The last door is closed and the vehicle is externally locked, on receipt of an unlock request from the Smart Key or door

handle operation detected when the time-out timer is still active.

DELIVERY MODE

Delivery mode is set at the factory on vehicles to minimize battery drain. The mode enables the switching off of non-critical

electrical components, including the interior lighting system. The delivery mode feature is cancelled by the dealer during the

Pre-Delivery Inspection using an approved Jaguar diagnostic system.

CRASH ILLUMINATION

When a crash signal is received from the RCM (restraints control module), the CJB activates the interior lamps once the vehicle speed has reduced to 5 km/h (3.1 mph). The hazard flashers are also activated and the doors are prevented from being locked.

The lamps remain on until the crash signal is removed, they cannot be switched off using the JaguarSense feature. The crash

signal is removed by completing one ignition on and off cycle.

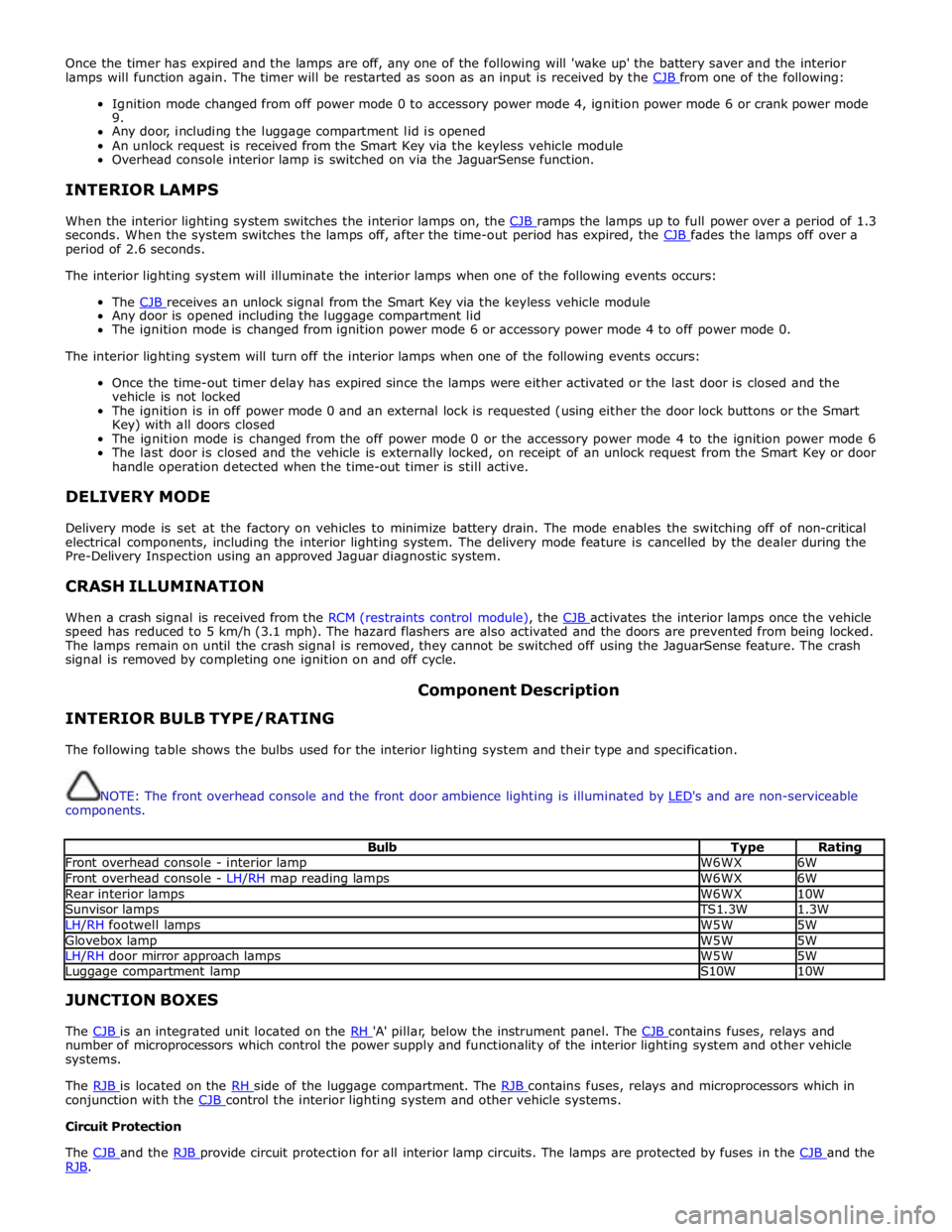

INTERIOR BULB TYPE/RATING Component Description

The following table shows the bulbs used for the interior lighting system and their type and specification.

NOTE: The front overhead console and the front door ambience lighting is illuminated by LED's and are non-serviceable components.

Bulb Type Rating Front overhead console - interior lamp W6WX 6W Front overhead console - LH/RH map reading lamps W6WX 6W Rear interior lamps W6WX 10W Sunvisor lamps TS1.3W 1.3W LH/RH footwell lamps W5W 5W Glovebox lamp W5W 5W LH/RH door mirror approach lamps W5W 5W Luggage compartment lamp S10W 10W JUNCTION BOXES

The CJB is an integrated unit located on the RH 'A' pillar, below the instrument panel. The CJB contains fuses, relays and number of microprocessors which control the power supply and functionality of the interior lighting system and other vehicle

systems.

The RJB is located on the RH side of the luggage compartment. The RJB contains fuses, relays and microprocessors which in conjunction with the CJB control the interior lighting system and other vehicle systems. Circuit Protection

The CJB and the RJB provide circuit protection for all interior lamp circuits. The lamps are protected by fuses in the CJB and the RJB.

Page 2063 of 3039

Interior Lighting - Interior Lighting

Diagnosis and Testing

Principles of Operation Published: 11-May-2011

For a detailed description of the interior lighting system, refer to the relevant Description and Operation sections in the

workshop manual. REFER to: (417-02 Interior Lighting)

Interior Lighting (Description and Operation), Interior Lighting (Description and Operation), Interior Lighting (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Bulbs

Fuses/relays (refer to electrical guide)

Wiring harness

Correct engagement of electrical connectors

Loose or corroded connections

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give extra information read by

the manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places and

with a current calibration certificate. When testing resistance, always take the resistance of the DMM leads into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B116511

Left Front

Puddle Lamp

Output

Left front puddle lamp

control circuit - short to

ground Refer to the electrical circuit diagrams and test left front puddle

lamp control circuit for short to ground