warning JAGUAR XFR 2010 1.G Manual Online

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 539 of 3039

Rear Drive Axle/Differential - Differential Draining and Filling

General Procedures

Check Published: 11-May-2011

NOTE: Some variation in the illustrations may occur, but the essential information is always correct.

1. Refer to: Specifications - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-02 Rear Drive Axle/Differential, Specifications).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

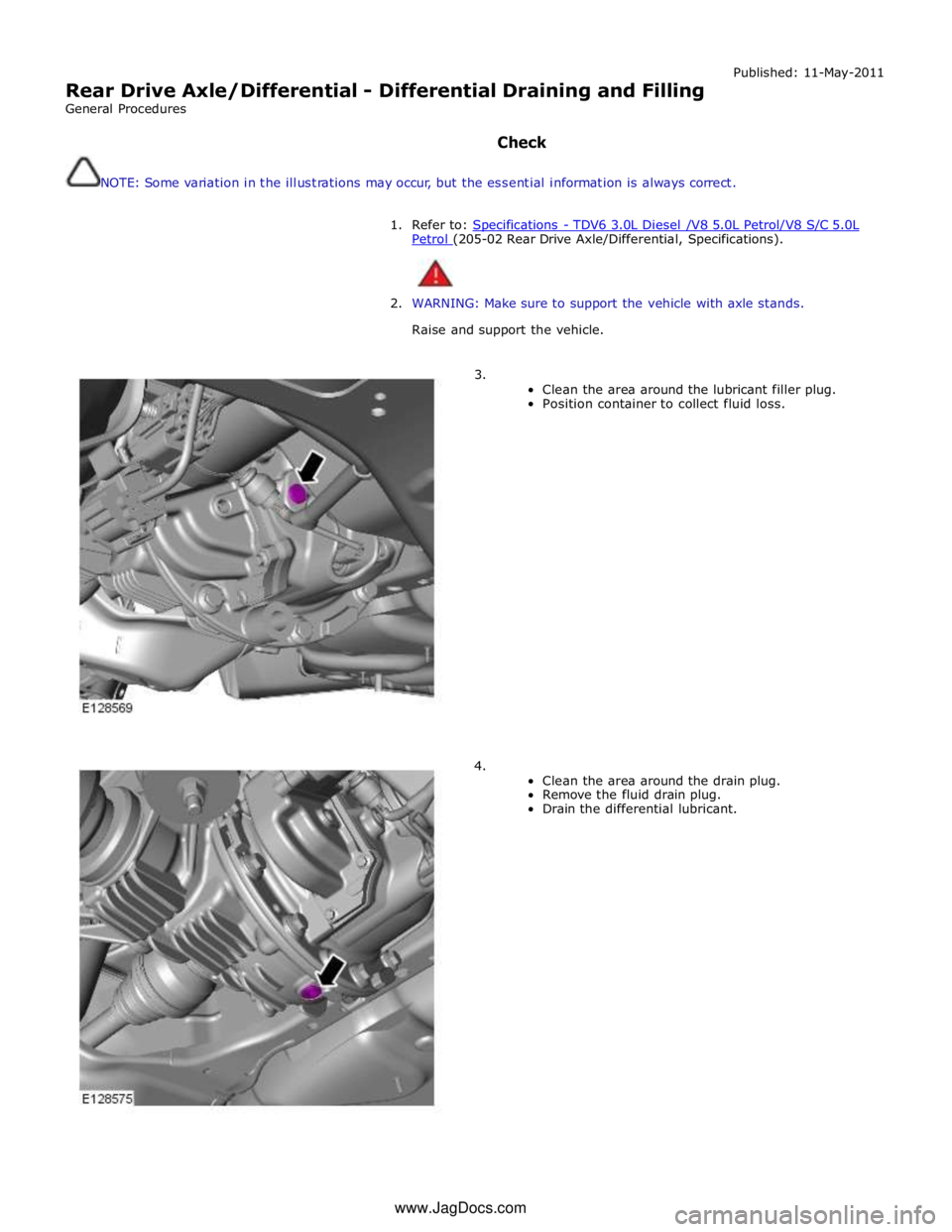

3.

Clean the area around the lubricant filler plug.

Position container to collect fluid loss.

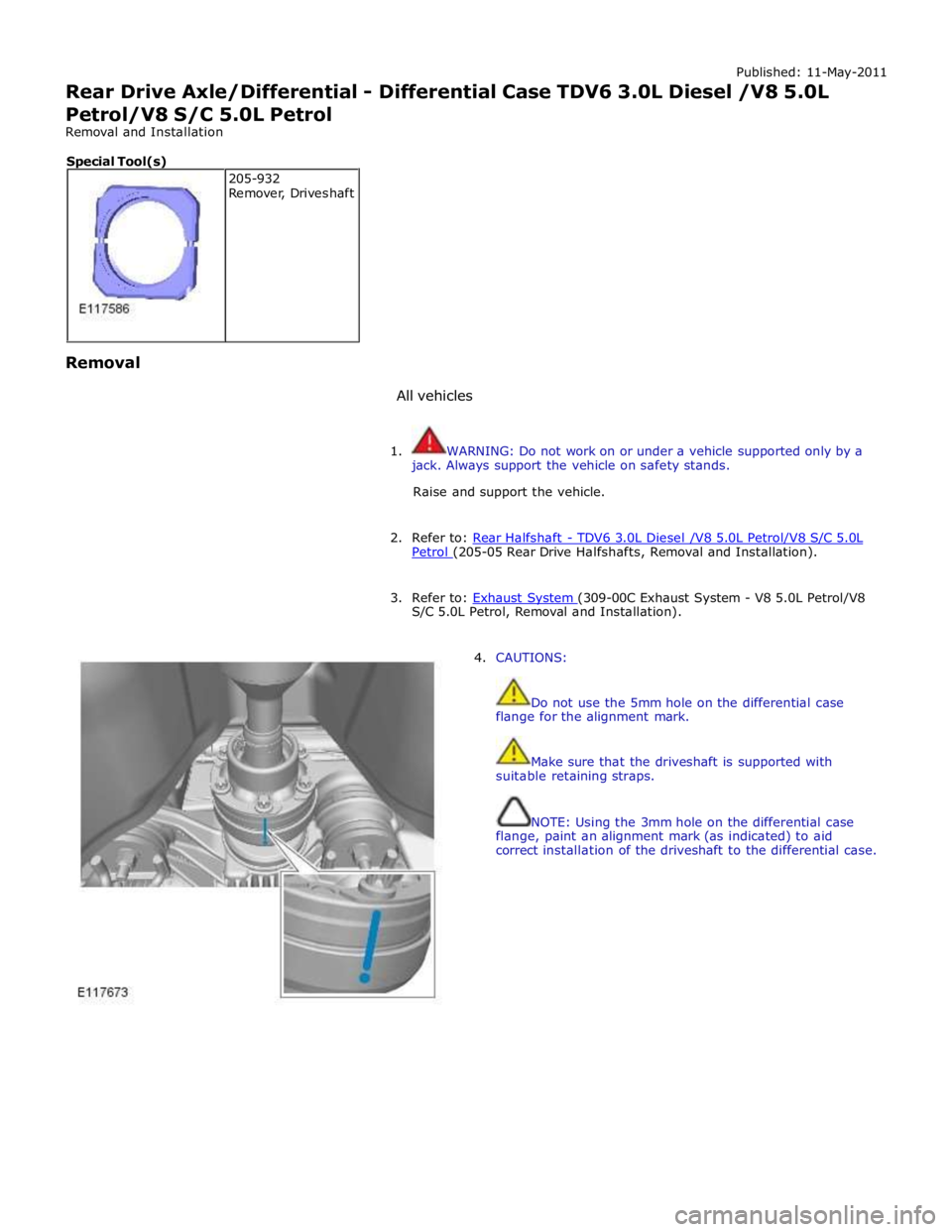

4.

Clean the area around the drain plug.

Remove the fluid drain plug.

Drain the differential lubricant. www.JagDocs.com

Page 542 of 3039

Published: 11-May-2011

Rear Drive Axle/Differential - Differential Case TDV6 3.0L Diesel /V8 5.0L

Petrol/V8 S/C 5.0L Petrol

Removal and Installation

Removal

All vehicles

1. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Rear Halfshaft - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-05 Rear Drive Halfshafts, Removal and Installation).

3. Refer to: Exhaust System (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

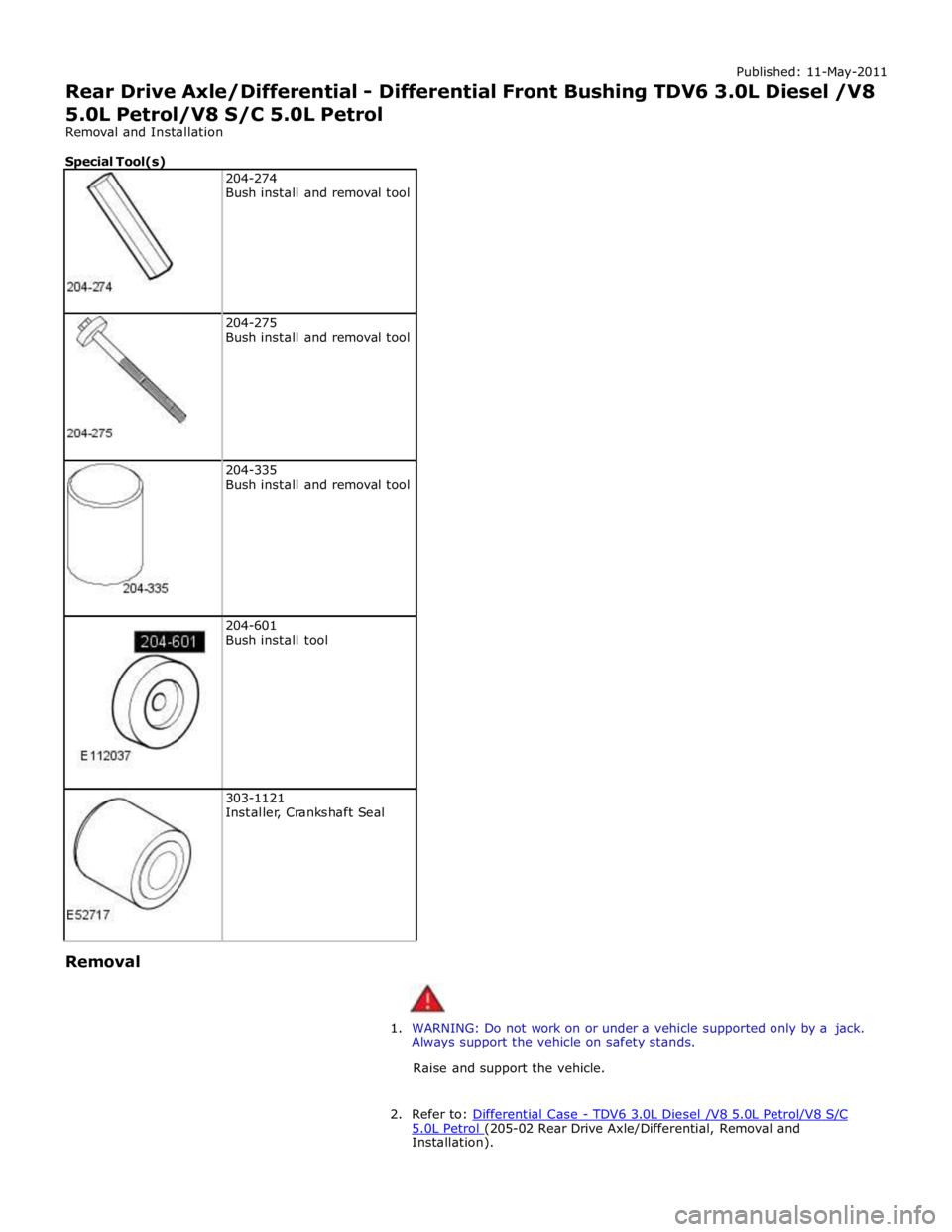

4. CAUTIONS:

Do not use the 5mm hole on the differential case

flange for the alignment mark.

Make sure that the driveshaft is supported with

suitable retaining straps.

NOTE: Using the 3mm hole on the differential case

flange, paint an alignment mark (as indicated) to aid

correct installation of the driveshaft to the differential case. 205-932

Remover, Driveshaft Special Tool(s)

Page 547 of 3039

Published: 11-May-2011

Rear Drive Axle/Differential - Differential Front Bushing TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

Removal and Installation

Special Tool(s)

204-274

Bush install and removal tool

204-275

Bush install and removal tool

204-335

Bush install and removal tool

204-601

Bush install tool

303-1121

Installer, Crankshaft Seal Removal

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Differential Case - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-02 Rear Drive Axle/Differential, Removal and Installation).

Page 550 of 3039

Removal

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Driveshaft - TD4 2.2L Diesel (205-01, Removal and

Installation).

Refer to: Driveshaft - V6 3.0L Petrol (205-01 Driveshaft, Removal and Installation).

Refer to: Driveshaft - V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-01 Driveshaft, Removal and Installation).

Refer to: Driveshaft - TDV6 3.0L Diesel (205-01 Driveshaft, Removal and Installation).

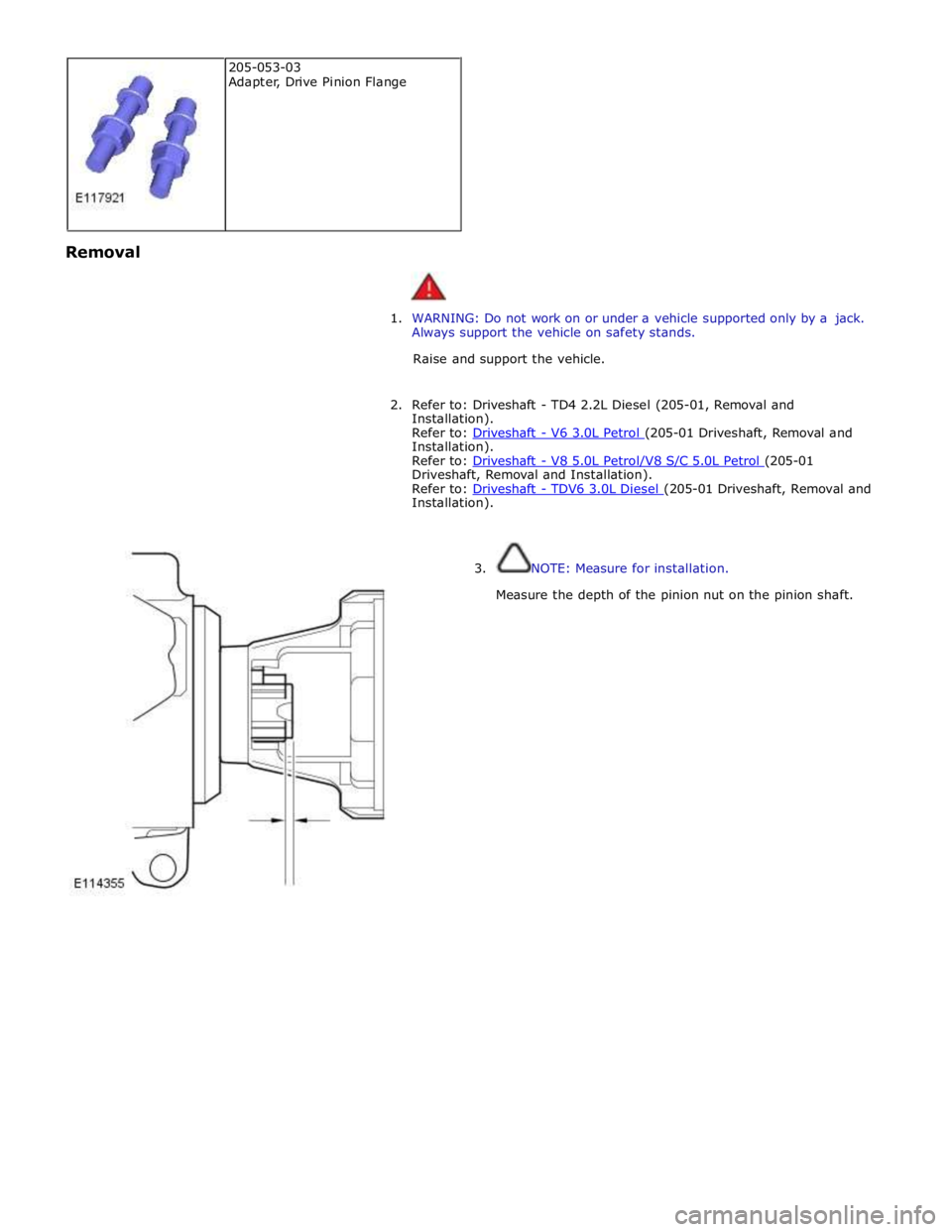

3. NOTE: Measure for installation.

Measure the depth of the pinion nut on the pinion shaft. 205-053-03

Adapter, Drive Pinion Flange

Page 566 of 3039

Removal

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the LH rear wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

3. With assistance, remove the halfshaft retaining nut, and

retain it for the install procedure.

4. Release the brake caliper. 308-621-2

Installer/Guide, Halfshaft Oil Seal

Page 575 of 3039

Rear Drive Halfshafts - Inner Constant Velocity (CV) Joint Boot

Removal and Installation

Removal Published: 11-May-2011

1. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the rear halfshaft.

For additional information, refer to: Rear Halfshaft - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-05 Rear Drive Halfshafts, Removal and Installation).

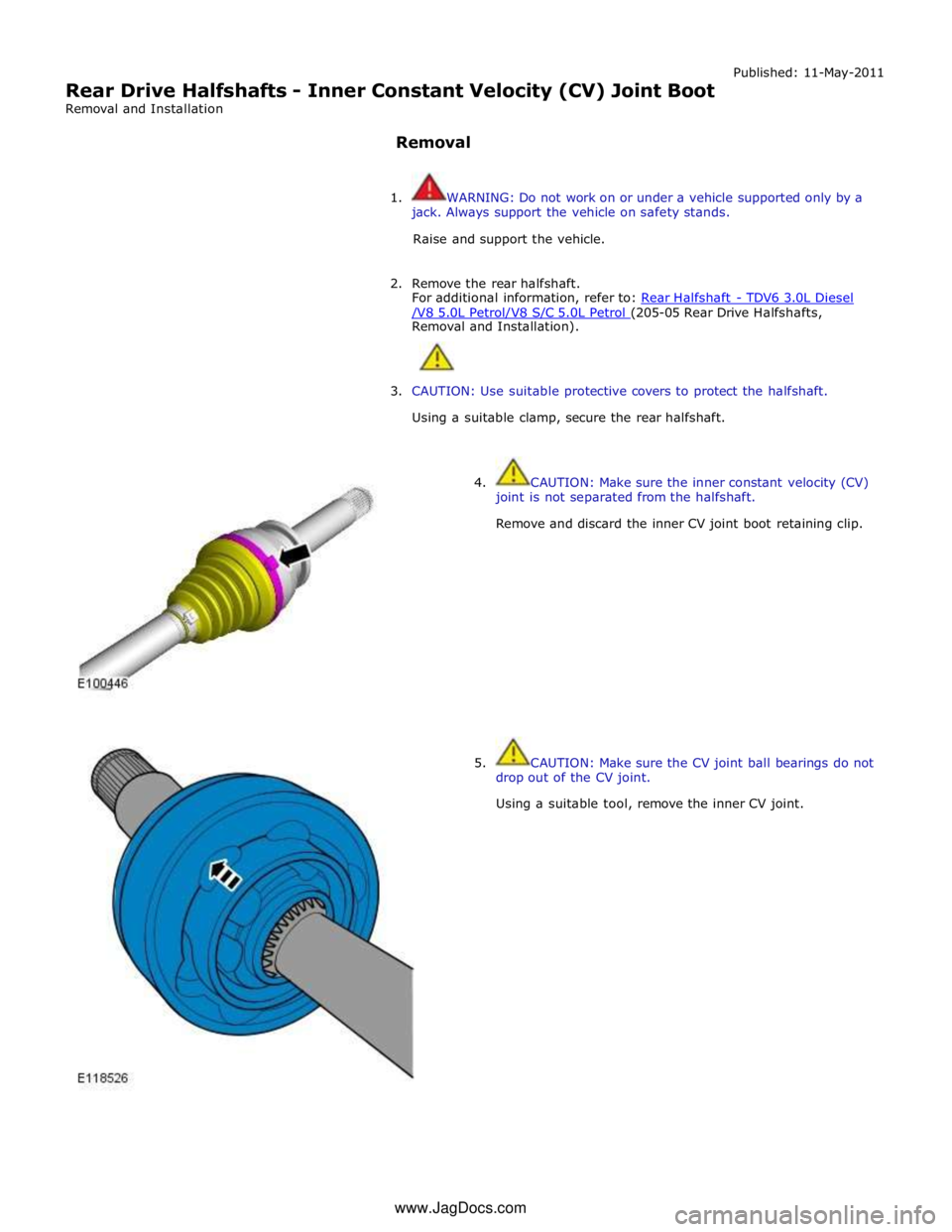

3. CAUTION: Use suitable protective covers to protect the halfshaft.

Using a suitable clamp, secure the rear halfshaft.

4. CAUTION: Make sure the inner constant velocity (CV)

joint is not separated from the halfshaft.

Remove and discard the inner CV joint boot retaining clip.

5. CAUTION: Make sure the CV joint ball bearings do not

drop out of the CV joint.

Using a suitable tool, remove the inner CV joint. www.JagDocs.com

Page 579 of 3039

Rear Drive Halfshafts - Outer Constant Velocity (CV) Joint Boot

Removal and Installation

Removal Published: 11-May-2011

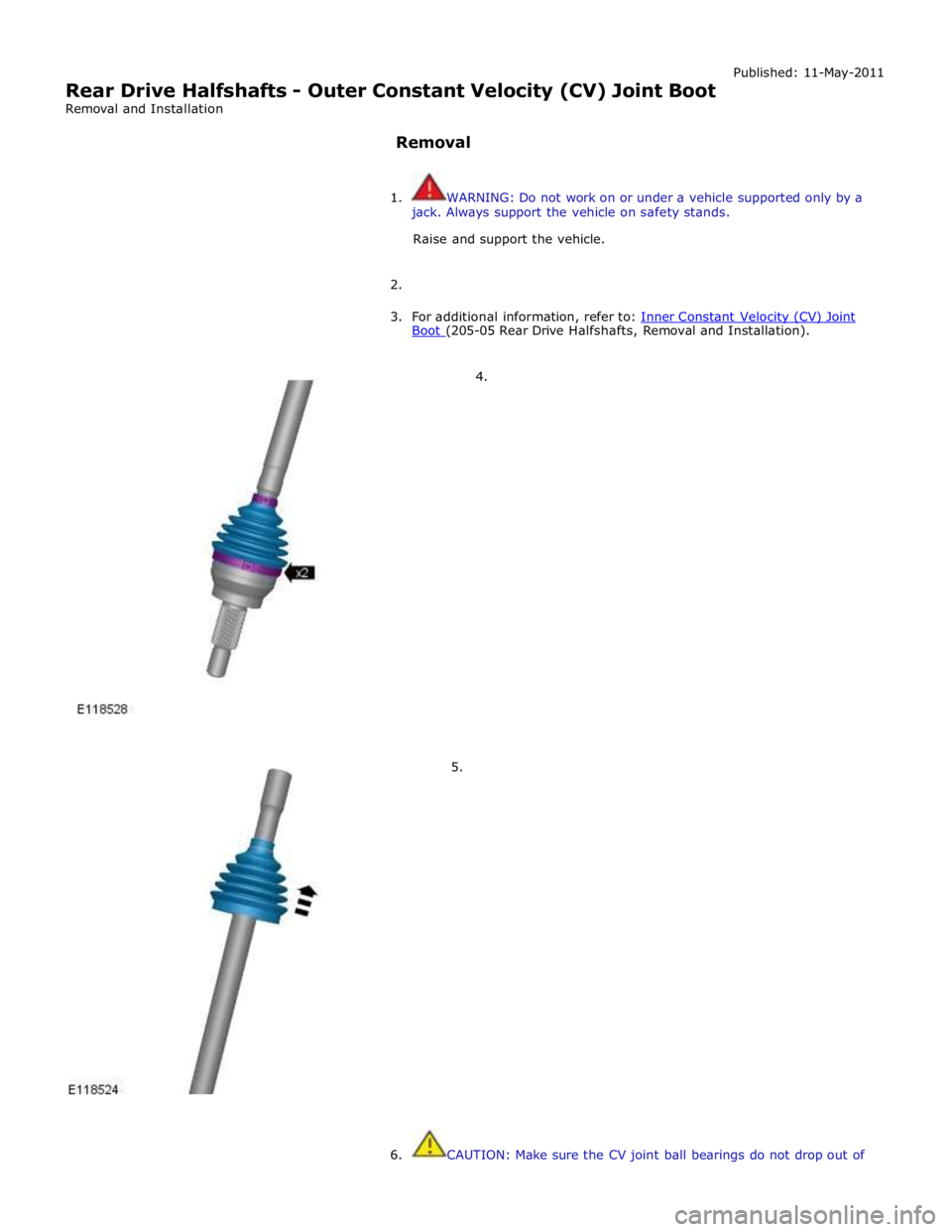

1. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2.

3. For additional information, refer to: Inner Constant Velocity (CV) Joint Boot (205-05 Rear Drive Halfshafts, Removal and Installation).

4.

5.

6. CAUTION: Make sure the CV joint ball bearings do not drop out of

Page 583 of 3039

If the concern becomes evident during this check, verify it fits the description given before the road test. If the concern is not

evident, attempt to duplicate the condition using the information from the description.

If a concern exists, use the Symptom Chart in order to isolate it to a specific sub-system and condition description. From this

description, a list of possible sources can be used to further narrow the cause to a specific component or condition.

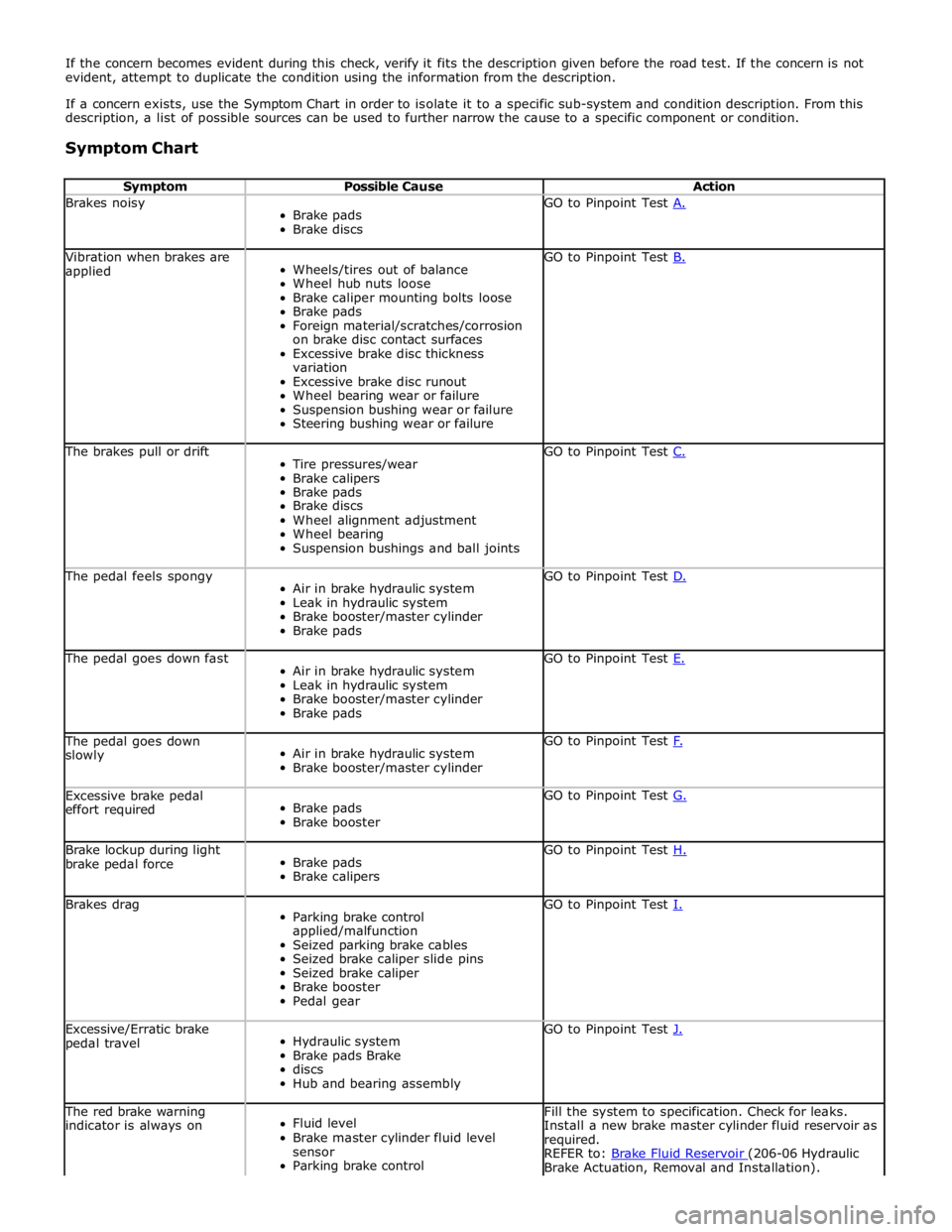

Symptom Chart

Symptom Possible Cause Action Brakes noisy

Brake pads

Brake discs GO to Pinpoint Test A. Vibration when brakes are

applied

Wheels/tires out of balance

Wheel hub nuts loose

Brake caliper mounting bolts loose

Brake pads

Foreign material/scratches/corrosion

on brake disc contact surfaces

Excessive brake disc thickness

variation

Excessive brake disc runout

Wheel bearing wear or failure

Suspension bushing wear or failure

Steering bushing wear or failure GO to Pinpoint Test B. The brakes pull or drift

Tire pressures/wear

Brake calipers

Brake pads

Brake discs

Wheel alignment adjustment

Wheel bearing

Suspension bushings and ball joints GO to Pinpoint Test C. The pedal feels spongy

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test D. The pedal goes down fast

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test E. The pedal goes down

slowly

Air in brake hydraulic system

Brake booster/master cylinder GO to Pinpoint Test F. Excessive brake pedal

effort required

Brake pads

Brake booster GO to Pinpoint Test G. Brake lockup during light

brake pedal force

Brake pads

Brake calipers GO to Pinpoint Test H. Brakes drag

Parking brake control

applied/malfunction

Seized parking brake cables

Seized brake caliper slide pins

Seized brake caliper

Brake booster

Pedal gear GO to Pinpoint Test I. Excessive/Erratic brake

pedal travel

Hydraulic system

Brake pads Brake

discs

Hub and bearing assembly GO to Pinpoint Test J. The red brake warning

indicator is always on

Fluid level

Brake master cylinder fluid level

sensor

Parking brake control Fill the system to specification. Check for leaks.

Install a new brake master cylinder fluid reservoir as

required.

REFER to: Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

Page 590 of 3039

Does the brake pedal return to its original position? Yes

No action required, vehicle is OK.

No

GO to K2. K2: CHECK FOR BRAKE PEDAL BINDING 1 Disconnect the brake booster from the brake pedal. Check the brake pedal to ensure free operation. Is the brake pedal operating freely? Yes

Install a new brake booster as required. REFER to:

Brake Booster (206-07 Power Brake Actuation, Removal and Installation), Brake Booster - RHD (206-07, Removal and Installation).

Re-test the system for normal operation.

No

Repair or install new brake pedal. Re-test the system for normal operation. Component Tests

Brake Booster

1. Check all hoses and connections. All unused vacuum connectors should be capped. Hoses and their connections should

be correctly secured and in good condition with no holes and no collapsed areas. Inspect the valve on the brake booster

for damage.

2. Check the hydraulic brake system for leaks or low fluid.

3. With the automatic transmission in PARK, stop the engine and apply the parking brake. Pump the brake pedal several

times to exhaust all vacuum in the system. With the engine switched off and all vacuum in the system exhausted,

apply the brake pedal and hold it down. Start the engine. If the vacuum system is operating, the brake pedal will tend

to move downward under constant foot pressure. If no motion is felt, the vacuum booster system is not functioning.

4. Remove the vacuum hose from the brake booster. Manifold vacuum should be available at the brake booster end of the

hose with the engine at idle speed and the automatic transmission in PARK. Make sure that all unused vacuum outlets

are correctly capped, hose connectors are correctly secured and vacuum hoses are in good condition. When it is

established that manifold vacuum is available to the brake booster, connect the vacuum hose to the brake booster and

repeat Step 3. If no downward movement of the brake pedal is felt, install a new brake booster.

5. Operate the engine for a minimum of 10 seconds at a fast idle. Stop the engine and allow the vehicle to stand for 10

minutes. Then, apply the brake pedal with approximately 89 N (20lb) of force. The pedal feel (brake application) should

be the same as that noted with the engine running. If the brake pedal feels hard (no power assist), install a new valve

and then repeat the test. If the brake pedal still feels hard, install a new brake booster. If the brake pedal movement

feels spongy, bleed the brake system.

REFER to: Brake System Bleeding (206-00 Brake System - General Information, General Procedures). Brake Master Cylinder

Usually, the first and strongest indicator of anything wrong in the brake system is a feeling through the brake pedal. In

diagnosing the condition of the brake master cylinder, check pedal feel as evidence of a brake concern. Check for brake warning

lamp illumination and the brake fluid level in the brake master cylinder reservoir.

Normal Conditions

The following conditions are considered normal and are not indications that the brake master cylinder is in need of repair.

Modern brake systems are designed to produce a pedal effort that is not as hard as in the past. Complaints of light

pedal efforts should be compared to the pedal efforts of another vehicle of the same model and year.

The fluid level will fall with brake pad wear.

Abnormal Conditions

Changes in the brake pedal feel or brake pedal travel are indicators that something could be wrong in the brake system. The

diagnostic procedure and techniques use brake pedal feel, warning indicator illumination and low brake fluid level as indicators

to diagnosing brake system concerns. The following conditions are considered abnormal and indicate that the brake master

cylinder is in need of repair:

NOTE: Prior to carrying out any diagnosis, make sure the brake system warning indicator is functional.

Brake pedal goes down fast. This could be caused by an external or internal leak.

Brake pedal goes down slowly. This could be caused by an internal or external leak.

Brake pedal is low or feels spongy. This condition may be caused by no fluid in the brake master cylinder, reservoir cap

vent holes clogged or air in the hydraulic system.

Brake pedal effort is excessive. This may be caused by a bind or obstruction in the pedal/linkage, a faulty non-return

valve, booster or insufficient booster vacuum.

Rear brakes lock up during light pedal force. This may be caused by damaged brake pads, a partially applied parking

brake, a damaged ABS sensor or bearing failure.

Brake pedal effort erratic. This condition could be caused by the brake booster or incorrectly installed brake pads.

Brake warning indicator is on. This may be caused by low fluid level or float assembly damaged. www.JagDocs.com

Page 594 of 3039

Brake System - General Information - Brake System Bleeding

General Procedures

CAUTIONS:

The brake fluid reservoir must remain full with new, clean brake fluid at all times during bleeding. Published: 11-May-2011

Brake fluid will damage paint finished surfaces. If spilled, immediately remove the fluid and clean the area with water.

NOTE:

All vehicles

1. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Check that the brake fluid lines are secure and that there are no signs of

a brake fluid leak. If a brake fluid leak is detected, investigate and

rectify the cause of the leak before bleeding the brakes.

3. Remove the brake master cylinder cover.

Carefully release the clip.

4. WARNING: Do not allow dirt or foreign liquids to enter

the reservoir. Use only new brake fluid of the correct

specification from airtight containers. Do not mix brands of

brake fluid as they may not be compatible.

CAUTION: Brake fluid will damage paint finished

surfaces. If spilled, immediately remove the fluid and clean

the area with water.

Remove the brake fluid reservoir cap.