Exhaust JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 3 of 3039

Diagnostic Trouble Code (DTC) IndexDTC: Occupant Classification System (OCS)

Diagnostic Trouble Code (DTC) IndexDTC: Parking Aid Module (PAM)

Diagnostic Trouble Code (DTC) IndexDTC: Pedestrian Protection System Control Module (PPSCM)

Diagnostic Trouble Code (DTC) IndexDTC: Rear Differential Control Module (RDCM)

Diagnostic Trouble Code (DTC) IndexDTC: Rear Junction Box (RJB)

Diagnostic Trouble Code (DTC) IndexDTC: Remote Keyless Entry Module (RFA)

Diagnostic Trouble Code (DTC) IndexDTC: Restraints Control Module (RCM)

Diagnostic Trouble Code (DTC) IndexDTC: Satellite Digital Audio Radio System Module (SARM)

Diagnostic Trouble Code (DTC) IndexDTC: Speed Control Module (CCM)

Diagnostic Trouble Code (DTC) IndexDTC: Steering Column Lock Module (VIM)

Diagnostic Trouble Code (DTC) IndexDTC: Television Module (TVM)

Diagnostic Trouble Code (DTC) IndexDTC: Tire Pressure Monitoring System Module (TPM)

Diagnostic Trouble Code (DTC) IndexDTC: Touch Screen Display (FCDIM)

Diagnostic Trouble Code (DTC) IndexVehicles With: 6HP28 6-Speed Automatic Transmission, DTC:

Transmission Control Module (TCM)

Diagnostic Trouble Code (DTC) IndexDTC: Transmission Shift Module (GSM)

Diagnostic Trouble Code (DTC) IndexDTC: Portable Audio Interface Control Module (PAICM)

Diagnostic Trouble Code (DTC) IndexDTC: Hybrid Digital Radio Control Module (HDRCM)

Diagnostic Trouble Code (DTC) IndexDTC: Infotainment Control Module (ICM)

Diagnostic Trouble Code (DTC) IndexDTC: Telephone Module (TEL)100-01: Identification Codes

Description and OperationIdentification Codes100-02: Jacking and Lifting

Description and OperationJacking

Lifting100-04: Noise, Vibration and Harshness

Description and OperationNoise, Vibration and Harshness (NVH)Diagnosis and TestingNoise, Vibration and Harshness (NVH)General ProceduresExhaust System Neutralizing2: Chassis

204: Suspension

204-00: Suspension System - General InformationSpecificationDiagnosis and TestingSuspension SystemGeneral ProceduresCamber and Caster Adjustment

Page 10 of 3039

211-05: Steering Column Switches

Description and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingSteering Column SwitchesRemoval and InstallationHazard Flasher Switch

Steering Column Multifunction Switch LH

Steering Column Multifunction Switch RH

Steering Column Lock Actuator3: Powertrain

303: Engine

303-00: Engine System - General Information

Diagnosis and TestingEngine - 5.0LGeneral ProceduresBearing Inspection

Camshaft Bearing Journal Diameter

Camshaft End Play

Camshaft Lobe Lift

Camshaft Surface Inspection

Connecting Rod Cleaning

Connecting Rod Large End Bore

Crankshaft End Play

Cylinder Bore Out-of-Round

Exhaust Manifold Cleaning and Inspection

Leakage Test Using Smoke Test Equipment

Piston Inspection

Piston Pin Diameter

Piston Pin to Bore Diameter

Piston Ring End Gap

Piston Ring-to-Groove Clearance

Valve Spring Free Length

Valve Stem Diameter

Cylinder Head Distortion

Cylinder Compression Test - V8 S/C 5.0L Petrol303-01D: Engine - V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Page 11 of 3039

Overview

System Operation and Component DescriptionDiagnosis and TestingEngineGeneral ProceduresEngine Oil Draining and Filling

Engine Oil Vacuum Draining and Filling

Fuel Pump Camshaft Timing Check

Fuel Pump Camshaft Timing Adjustment

Valve Clearance Check

Valve Clearance AdjustmentRemoval and InstallationCamshaft LH

Camshaft RH

Crankshaft Front Seal

Crankshaft Pulley

Crankshaft Rear Seal

Cylinder Head LH

Cylinder Head RH

Engine Mount LH

Engine Mount RH

Exhaust Manifold LH

Exhaust Manifold RH

Flexplate

Oil Cooler

Oil Filter Element

Oil Pan

Oil Pan Extension

Oil Pump

Timing Cover

Timing Drive Components

Valve Cover LH

Valve Cover RH

Cylinder Block Oil Gallery Plug

Fuel Pump Camshaft - Assembly Part Number: INA Timing Drive

Fuel Pump Camshaft - Assembly Part Number: Tsubaki Timing Drive

Lower Timing Cover

ValvesRemovalEngineInstallationEngine

Page 16 of 3039

307-02B: Transmission/Transaxle Cooling - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingTransmission CoolingRemoval and InstallationTransmission Fluid Cooler - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Transmission Fluid Cooler Tubes - V8 5.0L Petrol/V8 S/C 5.0L Petrol307-05B: Automatic Transmission/Transaxle External Controls - TDV6 3.0L Diesel /V8 5.0L

Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingExternal ControlsRemoval and InstallationTransmission Control Switch (TCS)

Transmission Control Switch (TCS) Knob

Emergency Park Position Release Lever

Upshift

Paddle Switch

Downshift Paddle Switch309: Exhaust System

309-00C: Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingExhaust SystemRemoval and InstallationCatalytic Converter LH

Catalytic Converter RH

Exhaust Sound Enhancement Valve

Exhaust System

Front Muffler

Rear Muffler

Page 51 of 3039

Always reduce the engine speed to idle before disconnecting the jump leads.

Before removing the jump leads, switch on the heater blower (high) or the heated rear screen, to reduce the voltage peak

when the leads are removed.

Always disconnect the jump leads in the reverse order to the connecting sequence and take great care not to short the ends of

the leads.

Do not rely on the generator to restore a discharged battery. For a generator to recharge a battery, it would take in excess of 8

hours continuous driving with no additional loads placed on the battery.

Component Cleaning

To prevent ingress of dirt, accumulations of loose dirt and greasy deposits should be removed before disconnecting or

dismantling components or assemblies.

Components should be thoroughly cleaned before inspection prior to reassembly.

Cleaning Methods:

Dry Cleaning

Removal of loose dirt with soft or wire brushes

Scraping dirt off with a piece of metal or wood

Wiping off with a rag

CAUTION: Compressed air is sometimes wet so use with caution, especially on hydraulic systems.

Blowing dirt off with compressed air (Eye protection should be worn when using this method)

Removal of dry dust using vacuum equipment. This method should always be used to remove friction lining material

dust (asbestos particles)

Steam Cleaning

Calibration of Essential Measuring Equipment

WARNING: Failure to comply may result in personal injury or damage to components.

It is of fundamental importance that certain essential equipment e.g. torque wrenches, multimeters, exhaust gas analysers,

rolling roads etc., are regularly calibrated in accordance with the manufacturers instructions.

Use of Control Modules

Control modules may only be used on the vehicle to which they were originally installed. Do not attempt to use or test a

control module on any other vehicle.

Functional Test

On completion of a maintenance procedure, a thorough test should be carried out, to ensure the relevant vehicle systems are

working correctly.

Preparation

Before disassembly, clean the surrounding area as thoroughly as possible. When components have been removed, blank off

any exposed openings using grease-proof paper and masking tape. Immediately seal fuel, oil and hydraulic lines when

separated, using plastic caps or plugs, to prevent loss of fluid and the entry of dirt. Close the open ends of oil ways, exposed

by component removal, with tapered hardwood plugs or readily visible plastic plugs. Immediately a component is removed,

place it in a suitable container; use a separate container for each component and its associated parts. Before dismantling a

component, clean it thoroughly with a recommended cleaning agent; check that the agent will not damage any of the materials

within the component. Clean the bench and obtain marking materials, labels, containers and locking wire before dismantling a

component.

Dismantling

Observe scrupulous cleanliness when dismantling components, particularly when parts of the brake, fuel or hydraulic systems

are being worked on. A particle of dirt or a fragment of cloth could cause a dangerous malfunction if trapped in these systems.

Clean all tapped holes, crevices, oil ways and fluid passages with compressed air.

WARNING: Do not permit compressed air to enter an open wound. Always use eye protection when using compressed air.

Make sure that any O-rings used for sealing are correctly reinstalled or renewed if disturbed. Mark mating parts to make sure

that they are replaced as dismantled. Whenever possible use marking materials which avoid the possibilities of causing

distortion or the initiation of cracks, which could occur if a center punch or scriber were used. Wire together mating parts where

necessary to prevent accidental interchange (e.g roller bearing components). Tie labels on to all parts to be renewed and to

parts requiring further inspection before being passed for reassembly. Place labelled parts and other parts for rebuild in

separate containers. Do not discard a part which is due for renewal until it has been compared with the new part, to make sure

Page 53 of 3039

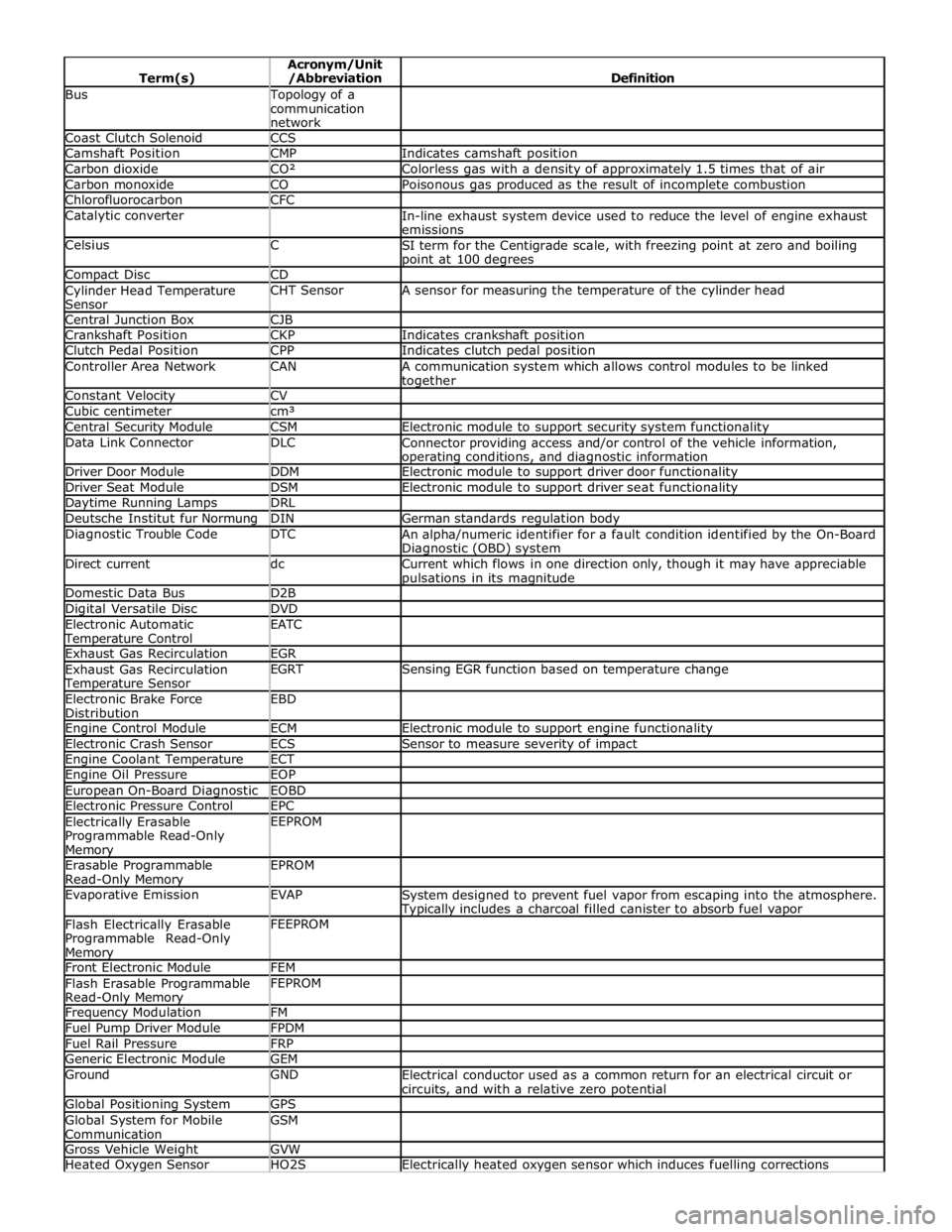

Bus Topology of a

communication

network Coast Clutch Solenoid CCS Camshaft Position CMP Indicates camshaft position Carbon dioxide CO² Colorless gas with a density of approximately 1.5 times that of air Carbon monoxide CO Poisonous gas produced as the result of incomplete combustion Chlorofluorocarbon CFC Catalytic converter

In-line exhaust system device used to reduce the level of engine exhaust

emissions Celsius C

SI term for the Centigrade scale, with freezing point at zero and boiling point at 100 degrees Compact Disc CD Cylinder Head Temperature

Sensor CHT Sensor A sensor for measuring the temperature of the cylinder head Central Junction Box CJB Crankshaft Position CKP Indicates crankshaft position Clutch Pedal Position CPP Indicates clutch pedal position Controller Area Network CAN

A communication system which allows control modules to be linked together Constant Velocity CV Cubic centimeter cm³ Central Security Module CSM Electronic module to support security system functionality Data Link Connector DLC

Connector providing access and/or control of the vehicle information, operating conditions, and diagnostic information Driver Door Module DDM Electronic module to support driver door functionality Driver Seat Module DSM Electronic module to support driver seat functionality Daytime Running Lamps DRL Deutsche Institut fur Normung DIN German standards regulation body Diagnostic Trouble Code DTC

An alpha/numeric identifier for a fault condition identified by the On-Board Diagnostic (OBD) system Direct current dc

Current which flows in one direction only, though it may have appreciable pulsations in its magnitude Domestic Data Bus D2B Digital Versatile Disc DVD Electronic Automatic Temperature Control EATC

Exhaust Gas Recirculation EGR Exhaust Gas Recirculation Temperature Sensor EGRT Sensing EGR function based on temperature change Electronic Brake Force

Distribution EBD

Engine Control Module ECM Electronic module to support engine functionality Electronic Crash Sensor ECS Sensor to measure severity of impact Engine Coolant Temperature ECT Engine Oil Pressure EOP European On-Board Diagnostic EOBD Electronic Pressure Control EPC Electrically Erasable

Programmable Read-Only Memory EEPROM

Erasable Programmable

Read-Only Memory EPROM

Evaporative Emission EVAP

System designed to prevent fuel vapor from escaping into the atmosphere. Typically includes a charcoal filled canister to absorb fuel vapor Flash Electrically Erasable

Programmable Read-Only Memory FEEPROM

Front Electronic Module FEM Flash Erasable Programmable

Read-Only Memory FEPROM

Frequency Modulation FM Fuel Pump Driver Module FPDM Fuel Rail Pressure FRP Generic Electronic Module GEM Ground GND

Electrical conductor used as a common return for an electrical circuit or

circuits, and with a relative zero potential Global Positioning System GPS Global System for Mobile

Communication GSM

Gross Vehicle Weight GVW Heated Oxygen Sensor HO2S Electrically heated oxygen sensor which induces fuelling corrections

Page 54 of 3039

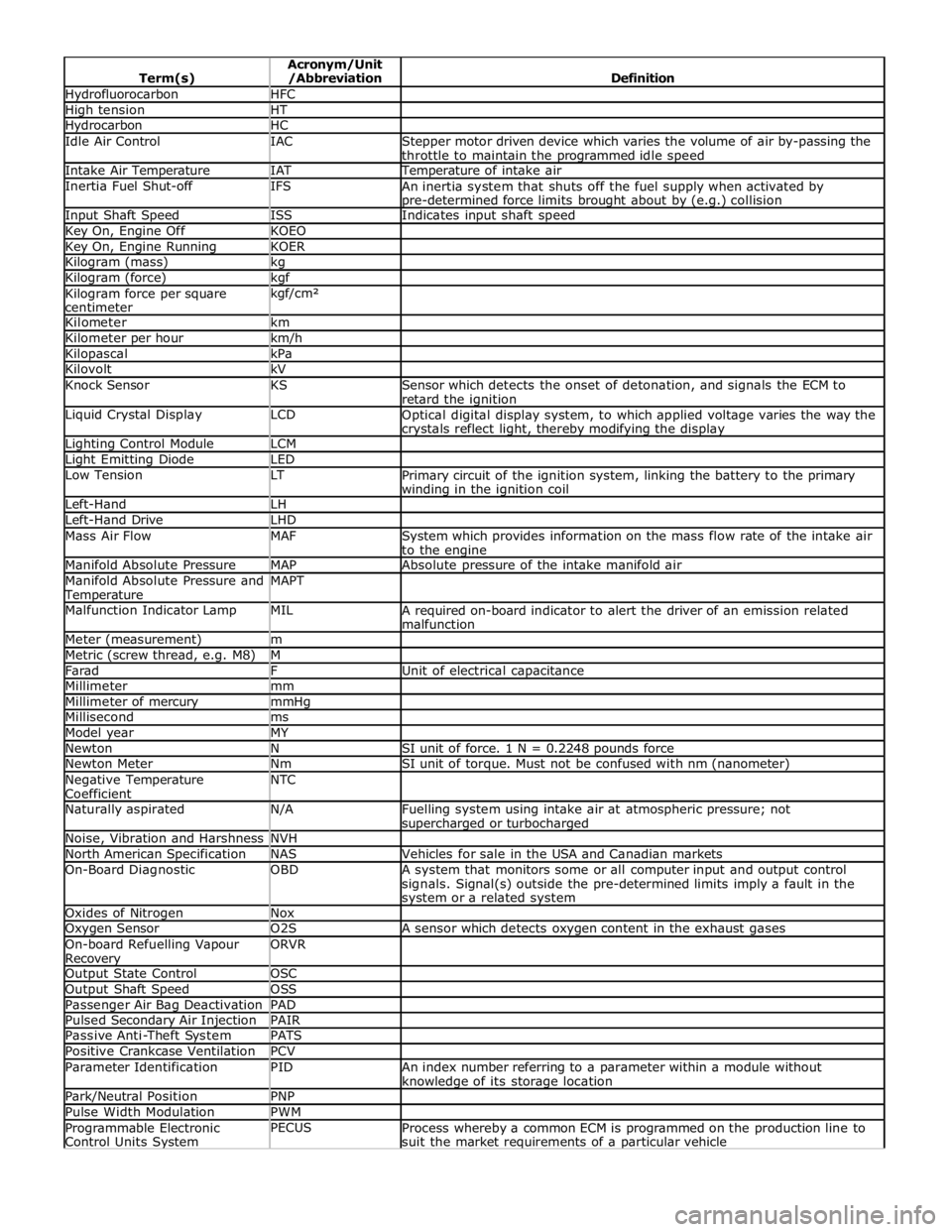

Hydrofluorocarbon HFC High tension HT Hydrocarbon HC Idle Air Control IAC

Stepper motor driven device which varies the volume of air by-passing the

throttle to maintain the programmed idle speed Intake Air Temperature IAT Temperature of intake air Inertia Fuel Shut-off IFS

An inertia system that shuts off the fuel supply when activated by pre-determined force limits brought about by (e.g.) collision Input Shaft Speed ISS Indicates input shaft speed Key On, Engine Off KOEO Key On, Engine Running KOER Kilogram (mass) kg Kilogram (force) kgf Kilogram force per square

centimeter kgf/cm²

Kilometer km Kilometer per hour km/h Kilopascal kPa Kilovolt kV Knock Sensor KS

Sensor which detects the onset of detonation, and signals the ECM to

retard the ignition Liquid Crystal Display LCD

Optical digital display system, to which applied voltage varies the way the crystals reflect light, thereby modifying the display Lighting Control Module LCM Light Emitting Diode LED Low Tension LT

Primary circuit of the ignition system, linking the battery to the primary winding in the ignition coil Left-Hand LH Left-Hand Drive LHD Mass Air Flow MAF

System which provides information on the mass flow rate of the intake air

to the engine Manifold Absolute Pressure MAP Absolute pressure of the intake manifold air Manifold Absolute Pressure and Temperature MAPT

Malfunction Indicator Lamp MIL

A required on-board indicator to alert the driver of an emission related

malfunction Meter (measurement) m Metric (screw thread, e.g. M8) M Farad F Unit of electrical capacitance Millimeter mm Millimeter of mercury mmHg Millisecond ms Model year MY Newton N SI unit of force. 1 N = 0.2248 pounds force Newton Meter Nm SI unit of torque. Must not be confused with nm (nanometer) Negative Temperature

Coefficient NTC

Naturally aspirated N/A

Fuelling system using intake air at atmospheric pressure; not supercharged or turbocharged Noise, Vibration and Harshness NVH North American Specification NAS Vehicles for sale in the USA and Canadian markets On-Board Diagnostic OBD

A system that monitors some or all computer input and output control

signals. Signal(s) outside the pre-determined limits imply a fault in the system or a related system Oxides of Nitrogen Nox Oxygen Sensor O2S A sensor which detects oxygen content in the exhaust gases On-board Refuelling Vapour Recovery ORVR

Output State Control OSC Output Shaft Speed OSS Passenger Air Bag Deactivation PAD Pulsed Secondary Air Injection PAIR Passive Anti-Theft System PATS Positive Crankcase Ventilation PCV Parameter Identification PID

An index number referring to a parameter within a module without knowledge of its storage location Park/Neutral Position PNP Pulse Width Modulation PWM Programmable Electronic

Control Units System PECUS

Process whereby a common ECM is programmed on the production line to

suit the market requirements of a particular vehicle

Page 55 of 3039

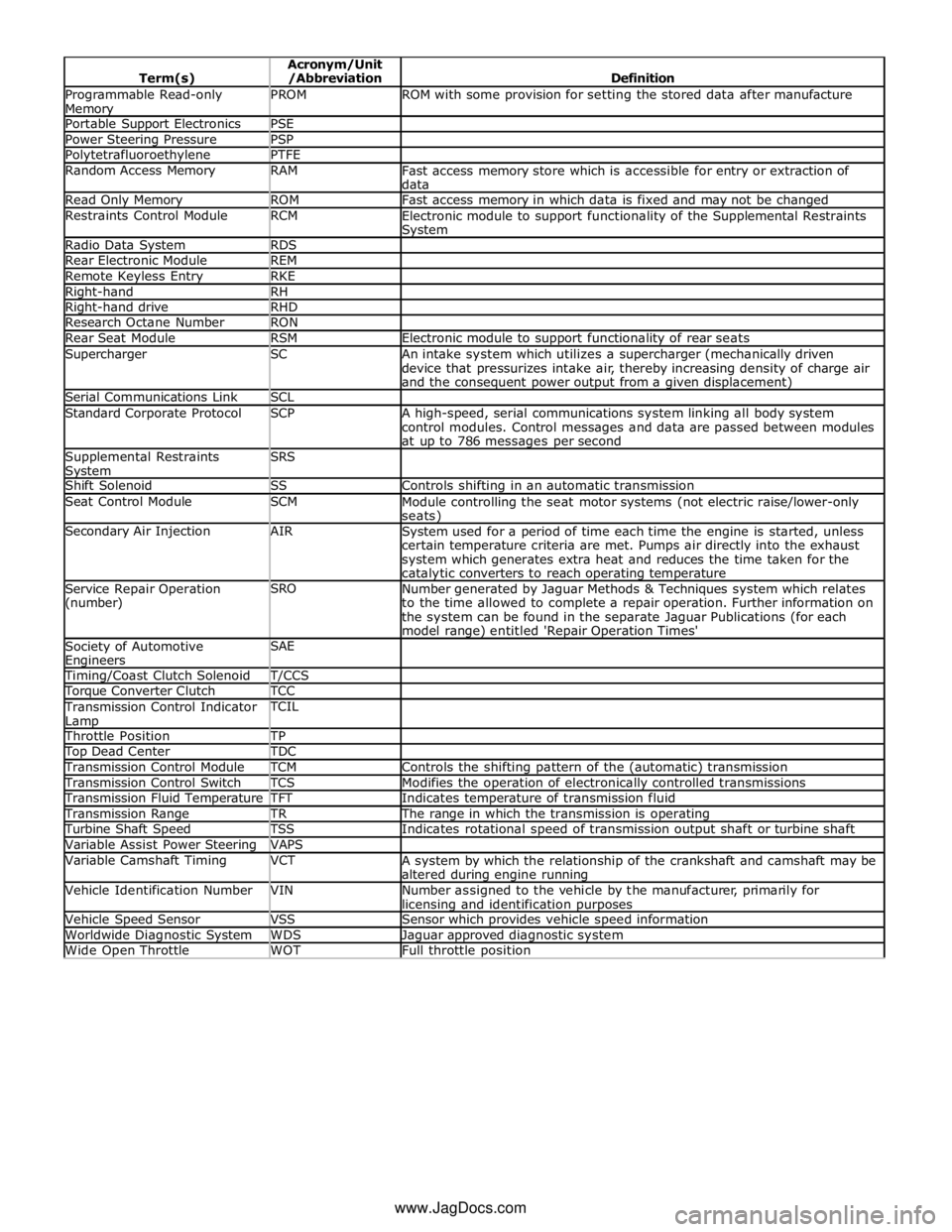

Programmable Read-only Memory PROM ROM with some provision for setting the stored data after manufacture Portable Support Electronics PSE Power Steering Pressure PSP Polytetrafluoroethylene PTFE Random Access Memory RAM

Fast access memory store which is accessible for entry or extraction of

data Read Only Memory ROM Fast access memory in which data is fixed and may not be changed Restraints Control Module RCM

Electronic module to support functionality of the Supplemental Restraints System Radio Data System RDS Rear Electronic Module REM Remote Keyless Entry RKE Right-hand RH Right-hand drive RHD Research Octane Number RON Rear Seat Module RSM Electronic module to support functionality of rear seats Supercharger SC

An intake system which utilizes a supercharger (mechanically driven

device that pressurizes intake air, thereby increasing density of charge air

and the consequent power output from a given displacement) Serial Communications Link SCL Standard Corporate Protocol SCP

A high-speed, serial communications system linking all body system

control modules. Control messages and data are passed between modules

at up to 786 messages per second Supplemental Restraints System SRS

Shift Solenoid SS Controls shifting in an automatic transmission Seat Control Module SCM

Module controlling the seat motor systems (not electric raise/lower-only seats) Secondary Air Injection AIR

System used for a period of time each time the engine is started, unless

certain temperature criteria are met. Pumps air directly into the exhaust

system which generates extra heat and reduces the time taken for the catalytic converters to reach operating temperature Service Repair Operation

(number) SRO

Number generated by Jaguar Methods & Techniques system which relates

to the time allowed to complete a repair operation. Further information on

the system can be found in the separate Jaguar Publications (for each

model range) entitled 'Repair Operation Times' Society of Automotive Engineers SAE

Timing/Coast Clutch Solenoid T/CCS Torque Converter Clutch TCC Transmission Control Indicator

Lamp TCIL

Throttle Position TP Top Dead Center TDC Transmission Control Module TCM Controls the shifting pattern of the (automatic) transmission Transmission Control Switch TCS Modifies the operation of electronically controlled transmissions Transmission Fluid Temperature TFT Indicates temperature of transmission fluid Transmission Range TR The range in which the transmission is operating Turbine Shaft Speed TSS Indicates rotational speed of transmission output shaft or turbine shaft Variable Assist Power Steering VAPS Variable Camshaft Timing VCT

A system by which the relationship of the crankshaft and camshaft may be

altered during engine running Vehicle Identification Number VIN

Number assigned to the vehicle by the manufacturer, primarily for licensing and identification purposes Vehicle Speed Sensor VSS Sensor which provides vehicle speed information Worldwide Diagnostic System WDS Jaguar approved diagnostic system Wide Open Throttle WOT Full throttle position www.JagDocs.com

Page 71 of 3039

General Information - Solvents, Sealants and Adhesives

Description and Operation Published: 11-May-2011

WARNING: Always handle all solvents, sealers and adhesives with extreme care. Some contain chemicals or give off

fumes which can be dangerous to health. Always follow the manufacturers instructions. If in doubt about any substance,

particularly a solvent, DO NOT use it.

CAUTION: If in doubt about the suitability of any proprietary solvent or sealer for a particular application, contact the

manufacturer of the product for information regarding storage, handling and application.

The Solvents, Sealers and Adhesives subsection refers to some commonly used chemicals and materials, hazards associated

with their use, and safety measures to be taken.

Adhesives and Sealers

Highly flammable, flammable, combustible – observe No Smoking policy.

Generally should be stored in No Smoking' areas. Cleanliness and tidiness in use should be observed e.g. disposable paper

covering benches; should be dispensed from applicators where possible; containers, including secondary containers, should be

labelled appropriately.

Solvent - based Adhesives/Sealers - See Solvents

Follow manufacturer's instructions.

Water - based Adhesives/Sealers

Those based on polymer emulsions and rubber latexes may contain small amounts of volatile toxic and harmful chemicals. Skin

and eye contact should be avoided and adequate ventilation provided during use.

Hot Melt Adhesives

In the solid state, they are safe. In the molten state they may cause burns and health hazards may arise from the inhalation

of toxic fumes.

Use appropriate protective clothing and a thermostatically controlled heater with a thermal cut - out and adequate extraction.

Resin - based Adhesives/Sealers e.g. Epoxide and Formaldehyde Resin - based

Mixing should be carried out in well ventilated areas, as harmful or toxic volatile chemicals may be released.

Skin contact with uncured resins and hardeners can result in irritation, dermatitis, and absorption of toxic or harmful chemicals

through the skin. Splashes can damage the eyes.

Provide adequate ventilation and avoid skin and eye contact.

Anaerobic, Cyanoacrylate (Super - glues) and other Acrylic Adhesives Many are irritant, sensitizing or harmful to the skin and/or respiratory tract. Some are eye irritants.

Skin and eye contact should be avoided and the manufacturer's instructions followed.

Cyanoacrylate adhesives (super-glues) MUST NOT contact the skin or eyes. If skin or eye tissue is bonded, cover with a clean

moist pad and seek immediate medical attention. Do not attempt to pull tissue apart. Use in well ventilated areas as vapors

can cause irritation to the nose and eyes.

For two - pack systems see Resin - based and Isocyanate Adhesives/Sealers.

Isocyanate (Polyurethane) Adhesives/Sealers

See also Resin - based Adhesives

Individuals suffering from asthma or respiratory allergies should not work with or near these materials as sensitivity reactions

can occur.

Over exposure is irritating to the eyes and respiratory system. Excessive concentrations may produce effects on the nervous

system including drowsiness. In extreme cases, loss of consciousness may result. Long term exposure to vapor concentrations

may result in adverse health effects.

Prolonged contact with the skin may lead to skin irritation and, in some cases, dermatitis.

Splashes entering the eye will cause discomfort and possible damage.

Any spraying should preferably be carried out in exhaust ventilated booths removing vapors and spray droplets from the

breathing zone.

Wear appropriate gloves, eye and respiratory protection.

Page 72 of 3039

General Information - Standard Workshop Practices

Description and Operation

Protecting the Vehicle Published: 04-Jul-2014

Always install covers to protect the fenders before commencing work in the engine compartment. Always install the interior

protection kit, wear clean overalls and wash hands or wear gloves before working inside the vehicle. Avoid spilling hydraulic

fluid, antifreeze or battery acid on the paintwork. In the event of spillage, wash off with water immediately. Use polythene

sheets in the luggage compartment to protect carpets. Always use the recommended service tool, or a satisfactory equivalent,

where specified. Protect temporarily exposed screw threads by replacing nuts or installing caps.

Vehicle in Workshop

When working on a vehicle in the workshop always make sure that:

The parking brake is applied or the wheels are securely chocked to prevent the vehicle moving forwards or backwards

If the engine is to be run, there is adequate ventilation, or an extraction hose to remove exhaust fumes is installed

There is adequate room to jack up the vehicle and remove the wheels, if necessary

Fender covers are always installed if any work is to be carried out in the engine compartment

The battery is disconnected if working on the engine, underneath the vehicle, or if the vehicle is jacked up

CAUTION: When electric arc welding on a vehicle, always disconnect the generator wiring to prevent the possibility of a

surge of current causing damage to the internal components of the generator.

If using welding equipment on the vehicle, ensure a suitable fire extinguisher is readily available.

Screw Threads

Damaged nuts, bolts and screws must always be discarded. Attempting to recut or repair damaged threads with a tap

or die impairs the strength and fit of the threads and is not recommended.

NOTES:

During certain repair operations, it may be necessary to remove traces of thread locking agents using a tap. Where this

is necessary, the instruction to do so will appear in the relevant operation and it is essential that a tap of the correct size and

thread is used.

New Taptite bolts when used cut their own threads on the first application.

Some bolts are coated with a thread locking agent and unless stated otherwise, they must not be reused. New bolts

having the same part number as the original must always be installed. When nuts or bolts are to be discarded, the

repair operation and relevant torque chart will include an instruction to that effect. Do not use proprietary thread

locking agents as they may not meet the specification required. See also Encapsulated ('Patched') Bolts and Screws.

Always make sure that replacement nuts and bolts are at least equal in strength to those that they are replacing.

Castellated nuts must not be loosened to accept a split pin except in recommended cases when this forms part of an

adjustment.

Do not allow oil or grease to enter blind holes, the hydraulic action resulting from tightening the bolt or stud can split

the housing and also give a false torque reading.

Always tighten a nut, bolt or screw to the specified torque figure, damaged or corroded threads can give a false torque

reading.

Nut and bolt loosening and tightening sequences, where given, must ALWAYS be followed. Distortion of components or

faulty sealing of joints will result if the sequences are not followed. Where an instruction is given to tighten in stages,

these stages must be adhered to; do not attempt to combine stages particularly where certain stages involve

tightening by degrees.

To check or re-tighten a fixing to a specified torque, first loosen a quarter of a turn, then retighten to the specified

torque figure.

Unless instructed otherwise, do not lubricate bolt or nut threads prior to installing.

Where it is stated that bolts and screws may be reused, the following procedures must be carried out:

Check that threads are undamaged.

Remove all traces of locking agent from the threads.

CAUTION: DO NOT use a wire brush; take care that threads are not damaged.

Make sure that threads are clean and free from oil or grease.

Apply the specified locking agent to the bolt threads.