Intake JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 13 of 3039

Throttle Body303-05D: Accessory Drive - V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

OverviewRemoval and InstallationAccessory Drive Belt

Accessory Drive Belt Idler Pulley

Accessory Drive Belt Tensioner

Supercharger Belt Idler Pulley

Supercharger Belt Tensioner303-06C: Starting System - V8 5.0L Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingStarting System

Starting System - Vehicles With: Smart KeyRemoval and InstallationStarter Motor303-07B: Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingEngine IgnitionRemoval and InstallationIgnition Coil-On-Plug - V8 S/C 5.0L Petrol303-08C: Engine Emission Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Description and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingEngine Emission Control303-12D: Intake Air Distribution and Filtering - V8 S/C 5.0L PetrolSpecification

Page 14 of 3039

Description and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingIntake Air Distribution and FilteringRemoval and InstallationAir Cleaner Element

Air Cleaner LH

Air Cleaner RH

Air Cleaner Outlet Pipe LH

Air Cleaner Outlet Pipe RH

Air Cleaner Outlet Pipe T-Connector

Charge Air Cooler

Supercharger

Supercharger Spring Isolator303-13B: Evaporative Emissions - V8 5.0L Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingEvaporative EmissionsRemoval and InstallationEvaporative Emission Canister

Evaporative Emission Canister Purge Valve - V8 S/C 5.0L Petrol303-14D: Electronic Engine Controls - V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingElectronic Engine ControlsGeneral ProceduresPowertrain Control Module (PCM) Long Drive Cycle Self-Test

Powertrain Control Module (PCM) Short Drive Cycle Self-TestRemoval and InstallationCamshaft Position (CMP) Sensor LH

Camshaft Position (CMP) Sensor RH

Catalyst Monitor Sensor LH

Page 54 of 3039

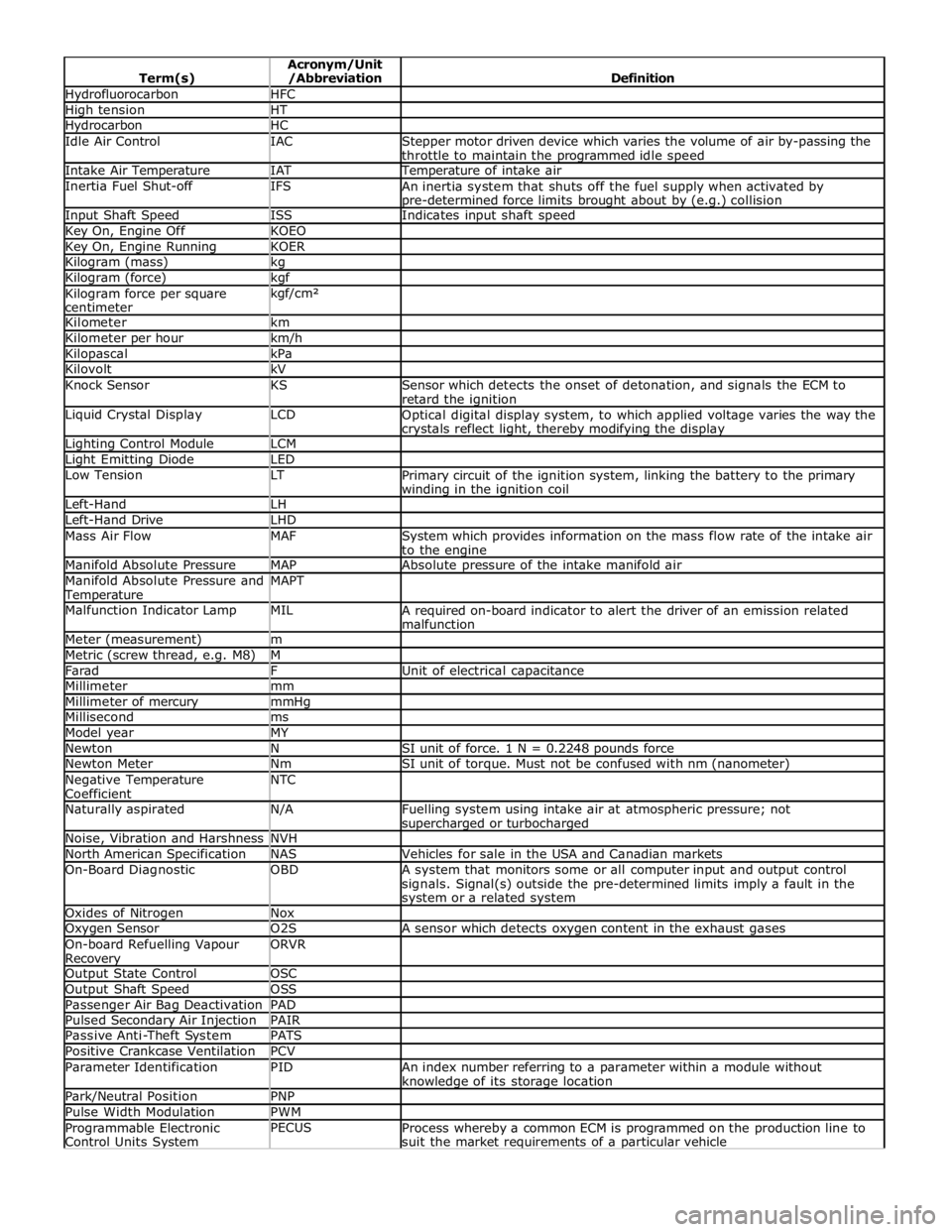

Hydrofluorocarbon HFC High tension HT Hydrocarbon HC Idle Air Control IAC

Stepper motor driven device which varies the volume of air by-passing the

throttle to maintain the programmed idle speed Intake Air Temperature IAT Temperature of intake air Inertia Fuel Shut-off IFS

An inertia system that shuts off the fuel supply when activated by pre-determined force limits brought about by (e.g.) collision Input Shaft Speed ISS Indicates input shaft speed Key On, Engine Off KOEO Key On, Engine Running KOER Kilogram (mass) kg Kilogram (force) kgf Kilogram force per square

centimeter kgf/cm²

Kilometer km Kilometer per hour km/h Kilopascal kPa Kilovolt kV Knock Sensor KS

Sensor which detects the onset of detonation, and signals the ECM to

retard the ignition Liquid Crystal Display LCD

Optical digital display system, to which applied voltage varies the way the crystals reflect light, thereby modifying the display Lighting Control Module LCM Light Emitting Diode LED Low Tension LT

Primary circuit of the ignition system, linking the battery to the primary winding in the ignition coil Left-Hand LH Left-Hand Drive LHD Mass Air Flow MAF

System which provides information on the mass flow rate of the intake air

to the engine Manifold Absolute Pressure MAP Absolute pressure of the intake manifold air Manifold Absolute Pressure and Temperature MAPT

Malfunction Indicator Lamp MIL

A required on-board indicator to alert the driver of an emission related

malfunction Meter (measurement) m Metric (screw thread, e.g. M8) M Farad F Unit of electrical capacitance Millimeter mm Millimeter of mercury mmHg Millisecond ms Model year MY Newton N SI unit of force. 1 N = 0.2248 pounds force Newton Meter Nm SI unit of torque. Must not be confused with nm (nanometer) Negative Temperature

Coefficient NTC

Naturally aspirated N/A

Fuelling system using intake air at atmospheric pressure; not supercharged or turbocharged Noise, Vibration and Harshness NVH North American Specification NAS Vehicles for sale in the USA and Canadian markets On-Board Diagnostic OBD

A system that monitors some or all computer input and output control

signals. Signal(s) outside the pre-determined limits imply a fault in the system or a related system Oxides of Nitrogen Nox Oxygen Sensor O2S A sensor which detects oxygen content in the exhaust gases On-board Refuelling Vapour Recovery ORVR

Output State Control OSC Output Shaft Speed OSS Passenger Air Bag Deactivation PAD Pulsed Secondary Air Injection PAIR Passive Anti-Theft System PATS Positive Crankcase Ventilation PCV Parameter Identification PID

An index number referring to a parameter within a module without knowledge of its storage location Park/Neutral Position PNP Pulse Width Modulation PWM Programmable Electronic

Control Units System PECUS

Process whereby a common ECM is programmed on the production line to

suit the market requirements of a particular vehicle

Page 55 of 3039

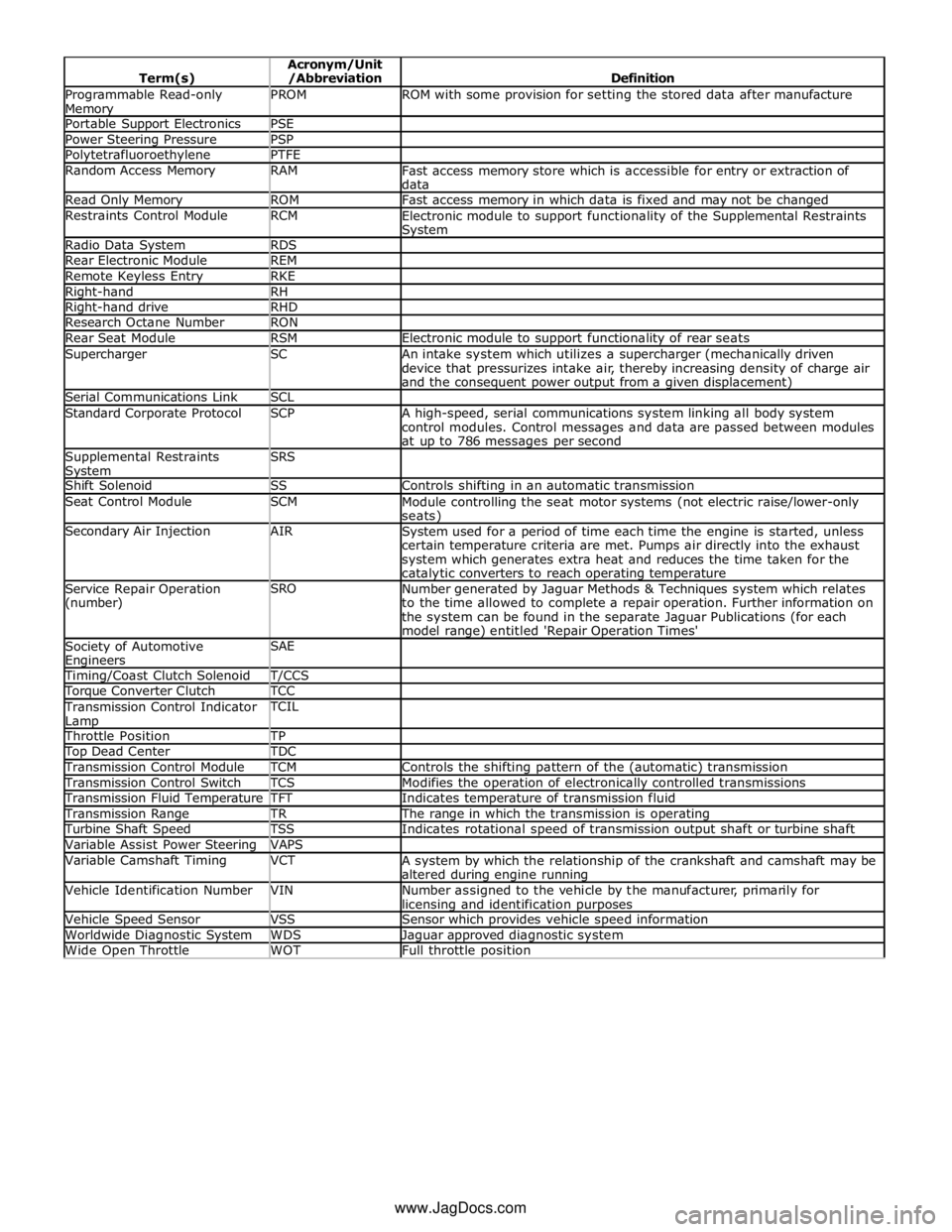

Programmable Read-only Memory PROM ROM with some provision for setting the stored data after manufacture Portable Support Electronics PSE Power Steering Pressure PSP Polytetrafluoroethylene PTFE Random Access Memory RAM

Fast access memory store which is accessible for entry or extraction of

data Read Only Memory ROM Fast access memory in which data is fixed and may not be changed Restraints Control Module RCM

Electronic module to support functionality of the Supplemental Restraints System Radio Data System RDS Rear Electronic Module REM Remote Keyless Entry RKE Right-hand RH Right-hand drive RHD Research Octane Number RON Rear Seat Module RSM Electronic module to support functionality of rear seats Supercharger SC

An intake system which utilizes a supercharger (mechanically driven

device that pressurizes intake air, thereby increasing density of charge air

and the consequent power output from a given displacement) Serial Communications Link SCL Standard Corporate Protocol SCP

A high-speed, serial communications system linking all body system

control modules. Control messages and data are passed between modules

at up to 786 messages per second Supplemental Restraints System SRS

Shift Solenoid SS Controls shifting in an automatic transmission Seat Control Module SCM

Module controlling the seat motor systems (not electric raise/lower-only seats) Secondary Air Injection AIR

System used for a period of time each time the engine is started, unless

certain temperature criteria are met. Pumps air directly into the exhaust

system which generates extra heat and reduces the time taken for the catalytic converters to reach operating temperature Service Repair Operation

(number) SRO

Number generated by Jaguar Methods & Techniques system which relates

to the time allowed to complete a repair operation. Further information on

the system can be found in the separate Jaguar Publications (for each

model range) entitled 'Repair Operation Times' Society of Automotive Engineers SAE

Timing/Coast Clutch Solenoid T/CCS Torque Converter Clutch TCC Transmission Control Indicator

Lamp TCIL

Throttle Position TP Top Dead Center TDC Transmission Control Module TCM Controls the shifting pattern of the (automatic) transmission Transmission Control Switch TCS Modifies the operation of electronically controlled transmissions Transmission Fluid Temperature TFT Indicates temperature of transmission fluid Transmission Range TR The range in which the transmission is operating Turbine Shaft Speed TSS Indicates rotational speed of transmission output shaft or turbine shaft Variable Assist Power Steering VAPS Variable Camshaft Timing VCT

A system by which the relationship of the crankshaft and camshaft may be

altered during engine running Vehicle Identification Number VIN

Number assigned to the vehicle by the manufacturer, primarily for licensing and identification purposes Vehicle Speed Sensor VSS Sensor which provides vehicle speed information Worldwide Diagnostic System WDS Jaguar approved diagnostic system Wide Open Throttle WOT Full throttle position www.JagDocs.com

Page 143 of 3039

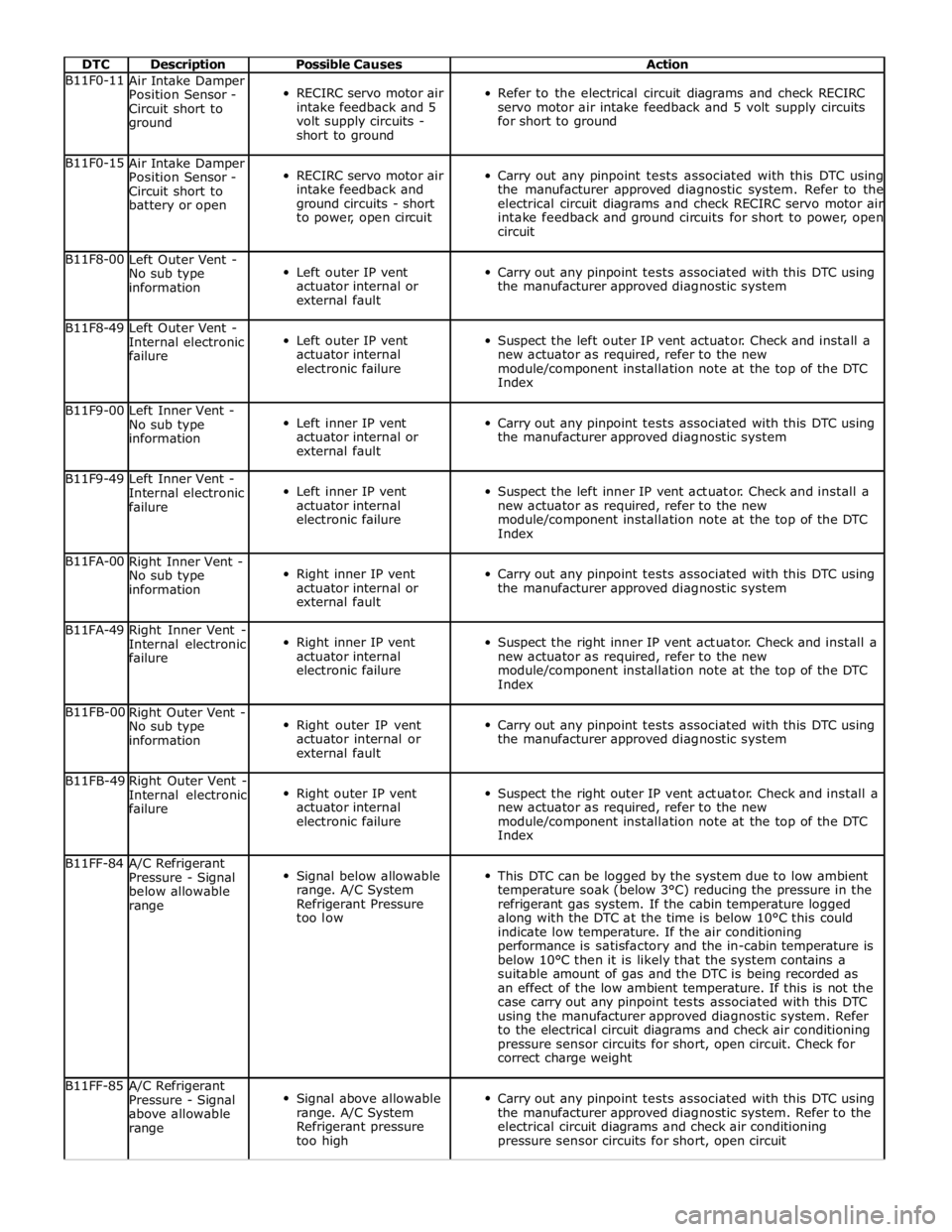

DTC Description Possible Causes Action B11F0-11

Air Intake Damper

Position Sensor -

Circuit short to

ground

RECIRC servo motor air

intake feedback and 5

volt supply circuits -

short to ground

Refer to the electrical circuit diagrams and check RECIRC

servo motor air intake feedback and 5 volt supply circuits

for short to ground B11F0-15

Air Intake Damper

Position Sensor -

Circuit short to

battery or open

RECIRC servo motor air

intake feedback and

ground circuits - short

to power, open circuit

Carry out any pinpoint tests associated with this DTC using the manufacturer approved diagnostic system. Refer to the electrical circuit diagrams and check RECIRC servo motor air intake feedback and ground circuits for short to power, open circuit B11F8-00

Left Outer Vent -

No sub type

information

Left outer IP vent

actuator internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11F8-49

Left Outer Vent -

Internal electronic

failure

Left outer IP vent

actuator internal

electronic failure

Suspect the left outer IP vent actuator. Check and install a

new actuator as required, refer to the new

module/component installation note at the top of the DTC

Index B11F9-00

Left Inner Vent -

No sub type

information

Left inner IP vent

actuator internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11F9-49

Left Inner Vent -

Internal electronic

failure

Left inner IP vent

actuator internal

electronic failure

Suspect the left inner IP vent actuator. Check and install a

new actuator as required, refer to the new

module/component installation note at the top of the DTC

Index B11FA-00

Right Inner Vent -

No sub type

information

Right inner IP vent

actuator internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11FA-49

Right Inner Vent -

Internal electronic

failure

Right inner IP vent

actuator internal

electronic failure

Suspect the right inner IP vent actuator. Check and install a

new actuator as required, refer to the new

module/component installation note at the top of the DTC

Index B11FB-00

Right Outer Vent -

No sub type

information

Right outer IP vent

actuator internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11FB-49

Right Outer Vent -

Internal electronic

failure

Right outer IP vent

actuator internal

electronic failure

Suspect the right outer IP vent actuator. Check and install a

new actuator as required, refer to the new

module/component installation note at the top of the DTC

Index B11FF-84

A/C Refrigerant

Pressure - Signal

below allowable

range

Signal below allowable

range. A/C System

Refrigerant Pressure

too low

This DTC can be logged by the system due to low ambient

temperature soak (below 3°C) reducing the pressure in the

refrigerant gas system. If the cabin temperature logged

along with the DTC at the time is below 10°C this could

indicate low temperature. If the air conditioning

performance is satisfactory and the in-cabin temperature is

below 10°C then it is likely that the system contains a

suitable amount of gas and the DTC is being recorded as

an effect of the low ambient temperature. If this is not the

case carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system. Refer

to the electrical circuit diagrams and check air conditioning

pressure sensor circuits for short, open circuit. Check for

correct charge weight B11FF-85

A/C Refrigerant

Pressure - Signal

above allowable

range

Signal above allowable

range. A/C System

Refrigerant pressure

too high

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check air conditioning

pressure sensor circuits for short, open circuit

Page 166 of 3039

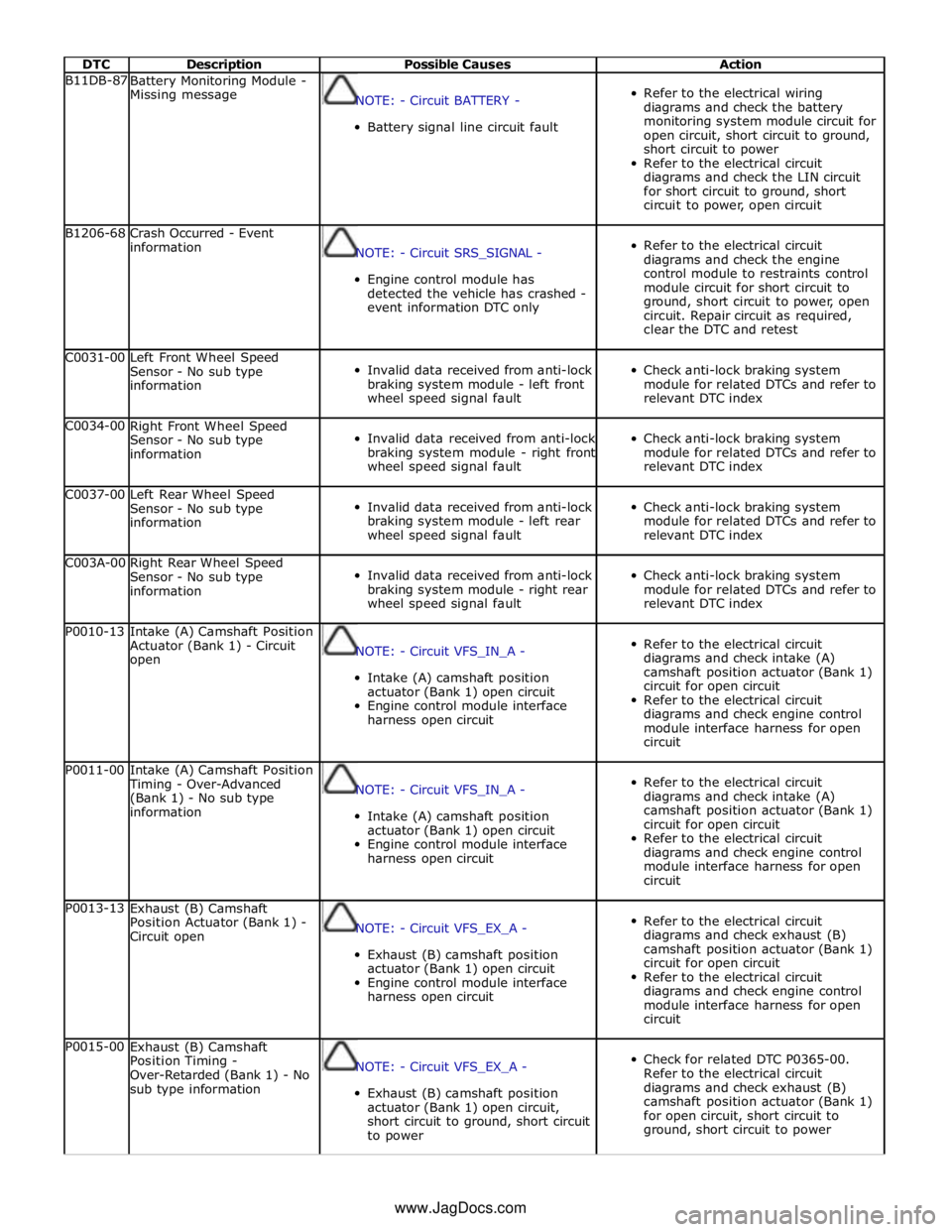

DTC Description Possible Causes Action B11DB-87

Battery Monitoring Module -

Missing message

NOTE: - Circuit BATTERY -

Battery signal line circuit fault

Refer to the electrical wiring

diagrams and check the battery

monitoring system module circuit for

open circuit, short circuit to ground,

short circuit to power

Refer to the electrical circuit

diagrams and check the LIN circuit

for short circuit to ground, short

circuit to power, open circuit B1206-68

Crash Occurred - Event

information

NOTE: - Circuit SRS_SIGNAL -

Engine control module has

detected the vehicle has crashed -

event information DTC only

Refer to the electrical circuit

diagrams and check the engine

control module to restraints control

module circuit for short circuit to

ground, short circuit to power, open

circuit. Repair circuit as required,

clear the DTC and retest C0031-00

Left Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0034-00

Right Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0037-00

Left Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C003A-00

Right Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index P0010-13

Intake (A) Camshaft Position

Actuator (Bank 1) - Circuit

open

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0011-00

Intake (A) Camshaft Position

Timing - Over-Advanced

(Bank 1) - No sub type

information

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0013-13

Exhaust (B) Camshaft

Position Actuator (Bank 1) -

Circuit open

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0015-00

Exhaust (B) Camshaft

Position Timing -

Over-Retarded (Bank 1) - No

sub type information

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit,

short circuit to ground, short circuit

to power

Check for related DTC P0365-00.

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

for open circuit, short circuit to

ground, short circuit to power www.JagDocs.com

Page 167 of 3039

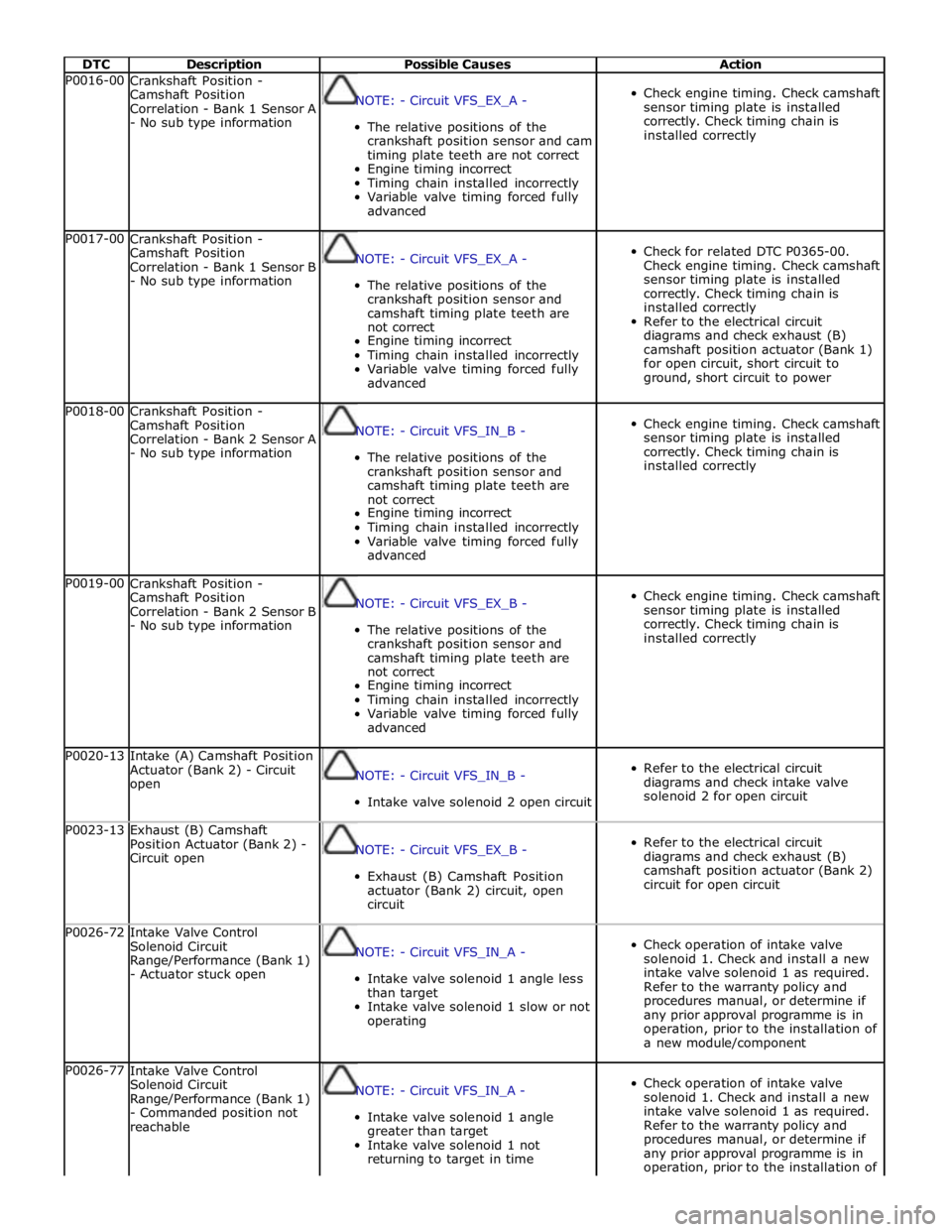

DTC Description Possible Causes Action P0016-00

Crankshaft Position -

Camshaft Position

Correlation - Bank 1 Sensor A

- No sub type information

NOTE: - Circuit VFS_EX_A -

The relative positions of the

crankshaft position sensor and cam

timing plate teeth are not correct

Engine timing incorrect

Timing chain installed incorrectly

Variable valve timing forced fully

advanced

Check engine timing. Check camshaft

sensor timing plate is installed

correctly. Check timing chain is

installed correctly P0017-00

Crankshaft Position -

Camshaft Position

Correlation - Bank 1 Sensor B

- No sub type information

NOTE: - Circuit VFS_EX_A -

The relative positions of the

crankshaft position sensor and

camshaft timing plate teeth are

not correct

Engine timing incorrect

Timing chain installed incorrectly

Variable valve timing forced fully

advanced

Check for related DTC P0365-00.

Check engine timing. Check camshaft

sensor timing plate is installed

correctly. Check timing chain is

installed correctly

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

for open circuit, short circuit to

ground, short circuit to power P0018-00

Crankshaft Position -

Camshaft Position

Correlation - Bank 2 Sensor A

- No sub type information

NOTE: - Circuit VFS_IN_B -

The relative positions of the

crankshaft position sensor and

camshaft timing plate teeth are

not correct

Engine timing incorrect

Timing chain installed incorrectly

Variable valve timing forced fully

advanced

Check engine timing. Check camshaft

sensor timing plate is installed

correctly. Check timing chain is

installed correctly P0019-00

Crankshaft Position -

Camshaft Position

Correlation - Bank 2 Sensor B

- No sub type information

NOTE: - Circuit VFS_EX_B -

The relative positions of the

crankshaft position sensor and

camshaft timing plate teeth are

not correct

Engine timing incorrect

Timing chain installed incorrectly

Variable valve timing forced fully

advanced

Check engine timing. Check camshaft

sensor timing plate is installed

correctly. Check timing chain is

installed correctly P0020-13

Intake (A) Camshaft Position

Actuator (Bank 2) - Circuit

open

NOTE: - Circuit VFS_IN_B -

Intake valve solenoid 2 open circuit

Refer to the electrical circuit

diagrams and check intake valve

solenoid 2 for open circuit P0023-13

Exhaust (B) Camshaft

Position Actuator (Bank 2) -

Circuit open

NOTE: - Circuit VFS_EX_B -

Exhaust (B) Camshaft Position

actuator (Bank 2) circuit, open

circuit

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 2)

circuit for open circuit P0026-72

Intake Valve Control

Solenoid Circuit

Range/Performance (Bank 1)

- Actuator stuck open

NOTE: - Circuit VFS_IN_A -

Intake valve solenoid 1 angle less

than target

Intake valve solenoid 1 slow or not

operating

Check operation of intake valve

solenoid 1. Check and install a new

intake valve solenoid 1 as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

a new module/component P0026-77

Intake Valve Control

Solenoid Circuit

Range/Performance (Bank 1)

- Commanded position not

reachable

NOTE: - Circuit VFS_IN_A -

Intake valve solenoid 1 angle

greater than target

Intake valve solenoid 1 not

returning to target in time

Check operation of intake valve

solenoid 1. Check and install a new

intake valve solenoid 1 as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

Page 168 of 3039

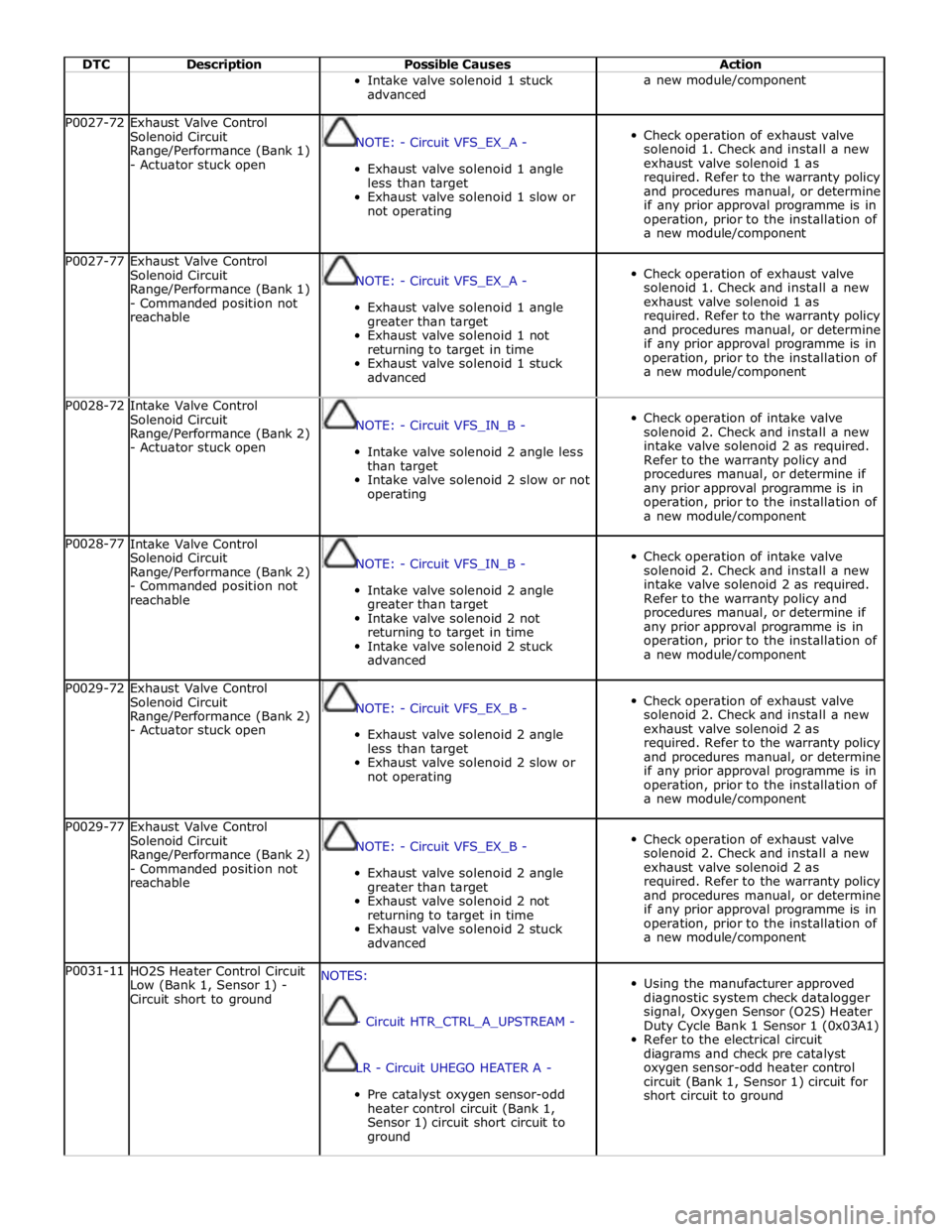

DTC Description Possible Causes Action Intake valve solenoid 1 stuck

advanced a new module/component P0027-72

Exhaust Valve Control

Solenoid Circuit

Range/Performance (Bank 1)

- Actuator stuck open

NOTE: - Circuit VFS_EX_A -

Exhaust valve solenoid 1 angle

less than target

Exhaust valve solenoid 1 slow or

not operating

Check operation of exhaust valve

solenoid 1. Check and install a new

exhaust valve solenoid 1 as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0027-77

Exhaust Valve Control

Solenoid Circuit

Range/Performance (Bank 1)

- Commanded position not

reachable

NOTE: - Circuit VFS_EX_A -

Exhaust valve solenoid 1 angle

greater than target

Exhaust valve solenoid 1 not

returning to target in time

Exhaust valve solenoid 1 stuck

advanced

Check operation of exhaust valve

solenoid 1. Check and install a new

exhaust valve solenoid 1 as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0028-72

Intake Valve Control

Solenoid Circuit

Range/Performance (Bank 2)

- Actuator stuck open

NOTE: - Circuit VFS_IN_B -

Intake valve solenoid 2 angle less

than target

Intake valve solenoid 2 slow or not

operating

Check operation of intake valve

solenoid 2. Check and install a new

intake valve solenoid 2 as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

a new module/component P0028-77

Intake Valve Control

Solenoid Circuit

Range/Performance (Bank 2)

- Commanded position not

reachable

NOTE: - Circuit VFS_IN_B -

Intake valve solenoid 2 angle

greater than target

Intake valve solenoid 2 not

returning to target in time

Intake valve solenoid 2 stuck

advanced

Check operation of intake valve

solenoid 2. Check and install a new

intake valve solenoid 2 as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

a new module/component P0029-72

Exhaust Valve Control

Solenoid Circuit

Range/Performance (Bank 2)

- Actuator stuck open

NOTE: - Circuit VFS_EX_B -

Exhaust valve solenoid 2 angle

less than target

Exhaust valve solenoid 2 slow or

not operating

Check operation of exhaust valve

solenoid 2. Check and install a new

exhaust valve solenoid 2 as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0029-77

Exhaust Valve Control

Solenoid Circuit

Range/Performance (Bank 2)

- Commanded position not

reachable

NOTE: - Circuit VFS_EX_B -

Exhaust valve solenoid 2 angle

greater than target

Exhaust valve solenoid 2 not

returning to target in time

Exhaust valve solenoid 2 stuck

advanced

Check operation of exhaust valve

solenoid 2. Check and install a new

exhaust valve solenoid 2 as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0031-11

HO2S Heater Control Circuit

Low (Bank 1, Sensor 1) -

Circuit short to ground NOTES:

- Circuit HTR_CTRL_A_UPSTREAM -

LR - Circuit UHEGO HEATER A -

Pre catalyst oxygen sensor-odd

heater control circuit (Bank 1,

Sensor 1) circuit short circuit to

ground

Using the manufacturer approved

diagnostic system check datalogger

signal, Oxygen Sensor (O2S) Heater

Duty Cycle Bank 1 Sensor 1 (0x03A1)

Refer to the electrical circuit

diagrams and check pre catalyst

oxygen sensor-odd heater control

circuit (Bank 1, Sensor 1) circuit for

short circuit to ground

Page 302 of 3039

and drive half shaft failure, which could cause serious personal injury and extensive vehicle damage. Failure to follow these

instructions may result in personal injury.

CAUTION: The suspension should not be allowed to hang free. When the CV joint is run at a very high angle, extra

vibration as well as damage to the seals and joints can occur.

The rear suspension lower arm should be supported as far outboard as possible. To bring the vehicle to its correct ride height,

the full weight of the vehicle should be supported in the rear by floor jacks. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

1. Raise and support the vehicle. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

2. Explore the speed range of interest using the Road Test Quick Checks as previously described.

3. Carry out a coast down in neutral. If the vehicle is free of vibration when operating at a steady indicated speed and

behaves very differently in drive and coast, a transmission concern is likely.

Note, however, that a test on the lift may produce different vibrations and noises than a road test because of the effect of the

lift. It is not unusual to find vibrations on the lift that were not found in the road test. If the condition found on the road can

be duplicated on the lift, carrying out experiments on the lift may save a great deal of time.

Exhaust Neutralization Procedure

1. Raise vehicle on lift and slacken all exhaust fixings.

2. With all fixings loose, neutralize the exhaust system.

3. Tighten all fixings to correct torque, starting at the rear-most point working towards the front of the vehicle.

Symptom Chart

Symptom Possible Cause Action High-speed shake

Wheel end vibration

Engine/transmission

Driveline GO to Pinpoint Test A. Tip-in moan

Air cleaner

Power steering

Powertrain

Engine mounts

Exhaust system GO to Pinpoint Test B. Idle boom/shake/vibration, or shudder

Cable(s)/hoses(s)

Intake air distribution and filtering system

Engine mounts

Exhaust system

Belt/pulleys GO to Pinpoint Test C. Wheel end vibration analysis

Suspension/rear drive halfshaft and CV joints

Tires/wheels

Wheel bearings

CV joint boots GO to Pinpoint Test D. Non-axle noise

Trim/mouldings

A/C system

Accessories GO to Pinpoint Test E. Pinpoint Tests

NOTE: These Pinpoint Tests are designed to take the technician through a step-by-step diagnosis procedure to determine

the cause of a condition. It may not always be necessary to follow the chart to its conclusion. Carry out only the Pinpoint Test

steps necessary to correct the condition. Then check operation of the system to make sure the condition is corrected.

After verifying that the condition has been corrected, make sure all components removed have been installed.

PINPOINT TEST A : HIGH-SPEED SHAKE TEST DETAILS/RESULTS/ACTIONS www.JagDocs.com

Page 367 of 3039

Suspension, Removal and Installation).

3. Remove the secondary bulkhead panel LH.

For additional information, refer to: Secondary Bulkhead Panel LH - 3.0L NA V6 - AJ27 (501-02 Front End Body Panels, Removal and Installation).

4. Remove the air cleaner.

For additional information, refer to: Air Cleaner (303-12A, Removal and

Installation) /

Air Cleaner (303-12B Intake Air Distribution and Filtering - V6 3.0L Petrol, Removal and Installation) /

Air Cleaner (303-12C, Removal and Installation) /

Air Cleaner LH (303-12D, Removal and Installation).

5. NOTE: Some variation in the illustrations may occur, but the

essential information is always correct.

Remove the upper arm retaining nut.

6. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

Remove the upper arm retaining nut.