JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 111 of 327

Electrical IT

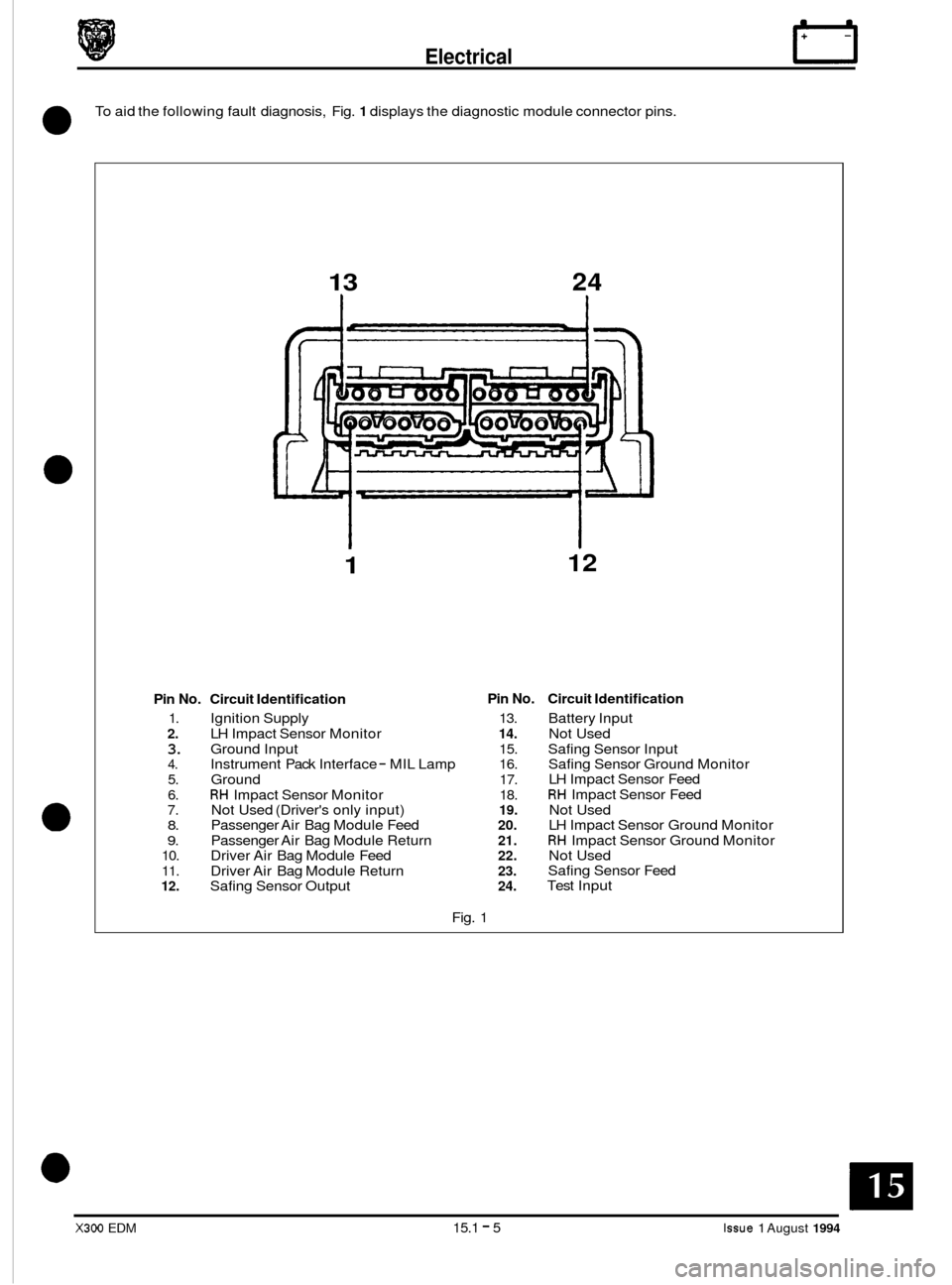

To aid the following fault diagnosis, Fig. 1 displays the diagnostic module connector pins.

0

13 24

1

Pin No. Circuit Identification

1. Ignition Supply

2. LH Impact Sensor Monitor

3. Ground Input 4.

5. Ground

6. RH Impact Sensor Monitor 7. 8.

9. 10.

11.

12. Safing Sensor Output

Instrument

Pack Interface

- MIL Lamp

Not Used (Driver's only input)

Passenger Air Bag Module Feed

Passenger Air Bag Module Return

Driver Air Bag Module Feed

Driver Air Bag Module Return

Fig.

1

Pin No.

13.

14.

15.

16. 17.

18.

19.

20.

21.

22.

23.

24.

12

Circuit Identification

Battery Input

Not Used

Safing Sensor Input

Safing Sensor Ground Monitor

LH Impact Sensor Feed

RH Impact Sensor Feed

Not Used

LH Impact Sensor Ground Monitor

RH Impact Sensor Ground Monitor

Not Used

Safing Sensor Feed

Test Input

X300 EDM 15.1 - 5 Issue 1 August 1994

Page 112 of 327

Electrical

0

NO AIR BAG MIl LAMP

Inoperative lamp Circuit or No Ignition to the Diagnostic Module

Normal Operation

The air bag MIL Lamp is designed to illuminate for approximately six seconds when the ignition is switched ‘on’; this

time has been allocated to prove the MIL Lamp operation.

The DM requires an ignition supply to Pin

1, to energize the air bag MIL Lamp circuit. If the MIL Lamp is open circuit

or the DM does not receive ignition voltage at Pin 1, the MII Lamp will not illuminate.

Open circuit in the

MII Lamp supply will cause the DM to emit five tones, or ‘beeps’ every 30 minutes while ignition

is on. Repair faulty circuitry before further diagnostics.

Possible Causes

0 Bulb blown or faulty wiring in the air bag MIL Lamp circuit.

0 Loss of ignition voltage at DM pin 1.

Fault Diagnosis

1. Ignition voltage -check

8 Disarm the SRS system.

8 Switch on the ignition.

8 Measure the voltage between pin 1 (+vel and pin 3 (-vel of the connector.

8 Battery voltage present, proceed with step 2.

8 Battery voltage not present; open circuit on R / W wire from RH fuse-box or faulty ground at pin 3.

8 Check fuse 17, RH fuse-box.

8 Check the fuse connectors and wiring.

8 Check the ground at pin 3 of the DM connector.

8 Arm and verify the SRS system.

2. MIL Lamp open circuit

8 Renew the DM.

8 Arm and verify the SRS system.

If the MIL Lamp is not illuminated, check the bulb, instrument pack and associated wiring.

Issue 1 August 1994 15.1 - 6 X300 EDM

Page 113 of 327

E I ect r ica I rl

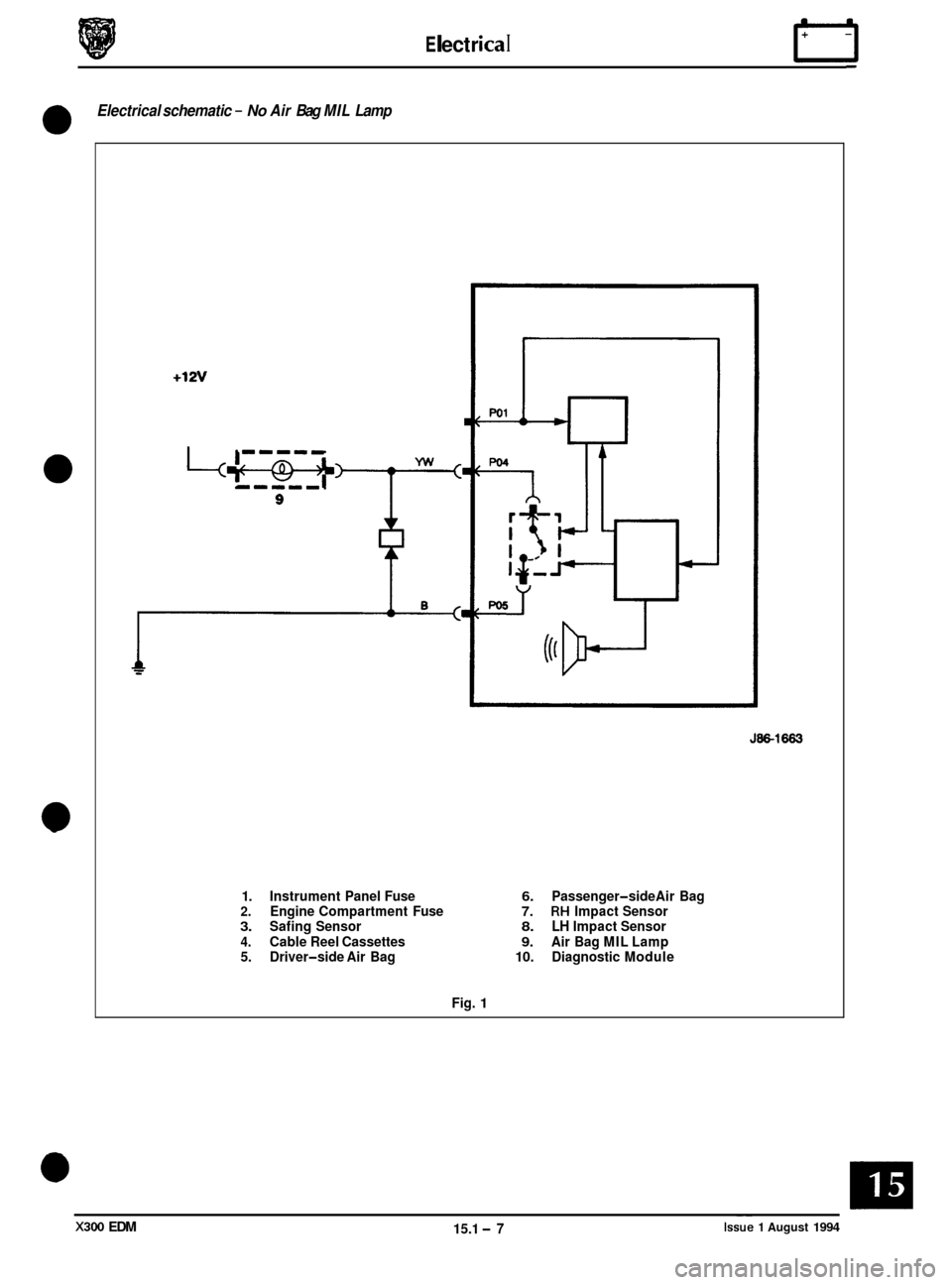

Electrical schematic - No Air Bag MIL Lamp

0

+12v

1. Instrument Panel Fuse 2. Engine Compartment Fuse 3. Safing Sensor

4. Cable Reel Cassettes

5. Driver-side Air Bag

Fig.

1

J86-1663

6. Passenger-side Air Bag 7. RH Impact Sensor 8. LH Impact Sensor

9. Air Bag MIL Lamp

10. Diagnostic Module

X300 EDM 15.1 -7 ~~ Issue 1 August 1994

Page 114 of 327

rl E I ect r ica I

CONTINUOUS AIR BAG MIL LAMP ILLUMINATION

Inoperative Lamp Circuit or No Ignition to the Diagnostic

Module

Normal Operation

The air bag MIL Lamp is designed to illuminate for approximately six seconds when the ignition is switched 'on'; this

time has been allocated to prove the MIL Lamp operation. If, after this proving period, the DM detects faults within

the system the MIL Lamp will illuminate and 'AIR BAG' will be displayed to the driver. If the MIL Lamp remains ON constantly, for over 8 seconds after ignition switch on, a fault is present within the indicator circuit.

Poor connection, or disconnection, of the indicator harness will cause

a short between pins 4 and 5, connecting the

circuit to ground and giving constant illumination of the MIL Lamp.

Faulty operation

ofthe DM internal logic may fail to turn off the indicator control circuit and cause constant illumination

of the MIL Lamp.

Fault Diagnosis

1. DM connectors

8 Disarm the SRS system.

8 Inspect the DM connectors.

2. MIL Lamp short circuit.

8 Disconnect the DM.

8 Remove the plastic locking wedge from the grey DM connector.

Switch on the ignition.

8 If the MIL Lamp is not illuminated, go to step 3.

If the MIL Lamp is illuminated; short circuit to ground between pin 45 instrument pack to pin 4 DM (Y / W). Rectify

8 Arm and verify the SRS system.

the short circuit.

3. Shorting

bar

Is the connector shorting bar operating correctly ?

Yes -

8 Renew the DM.

Reconnect, arm and verify the SRS system.

8 Renew the plastic locking wedge.

. Reconnect, arm and verify the SRS system.

NO -

15.1 -8 X300 EDM Issue 1 August 1994

Page 115 of 327

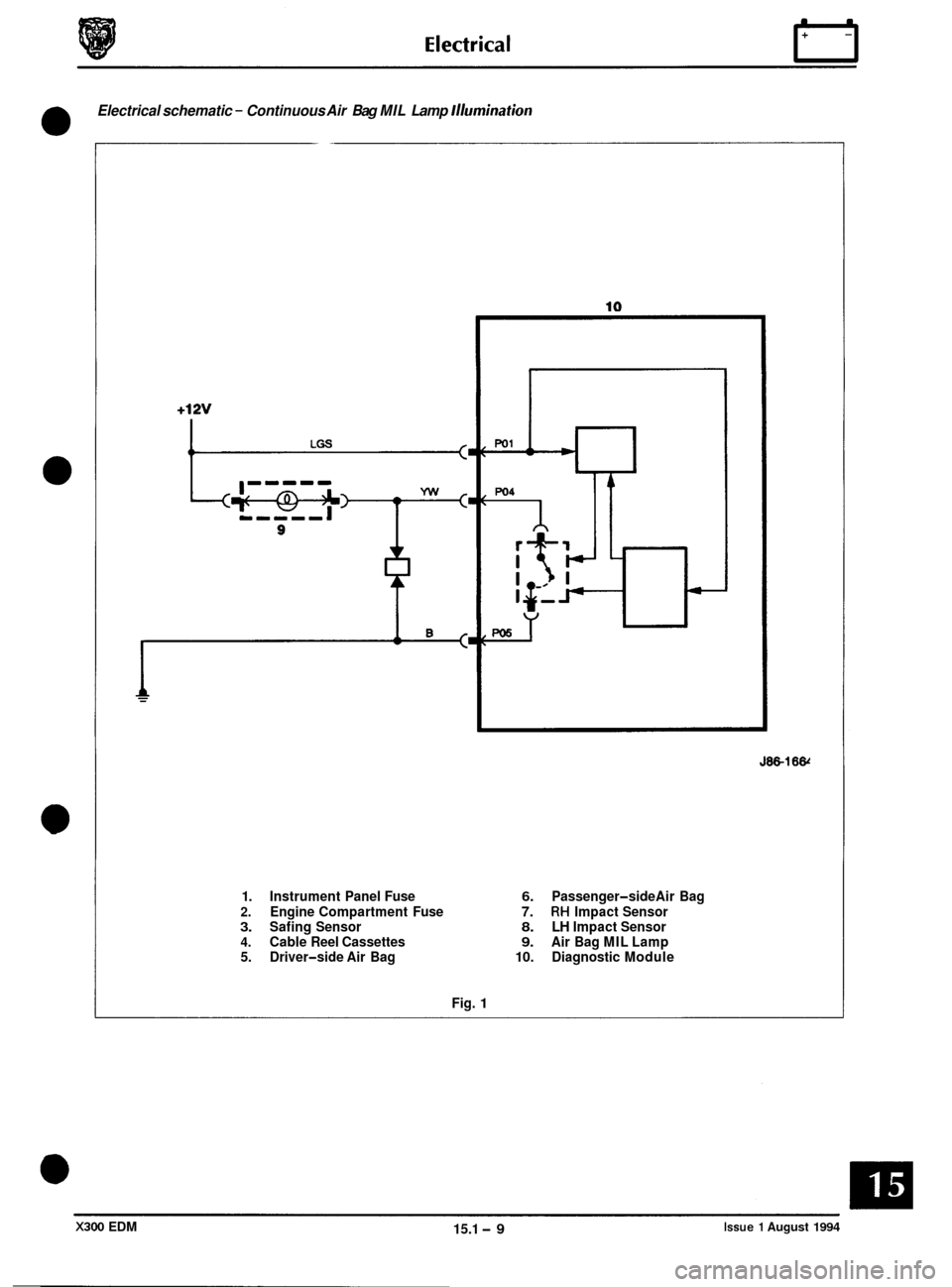

Electrical schematic - Continuous Air Bag MIL Lamp Illumination

0

J86-16&

1. Instrument Panel Fuse

2. Engine Compartment Fuse 3. Safing Sensor 4. Cable Reel Cassettes

5. Driver-side Air Bag

Fig.

1

6. Passenger-side Air Bag

7. RH Impact Sensor 8. LH Impact Sensor 9. Air Bag MIL Lamp

10. Diagnostic Module

X300 EDM 15.1 -9 Issue 1 August 1994

Page 116 of 327

n E I ectr ica I

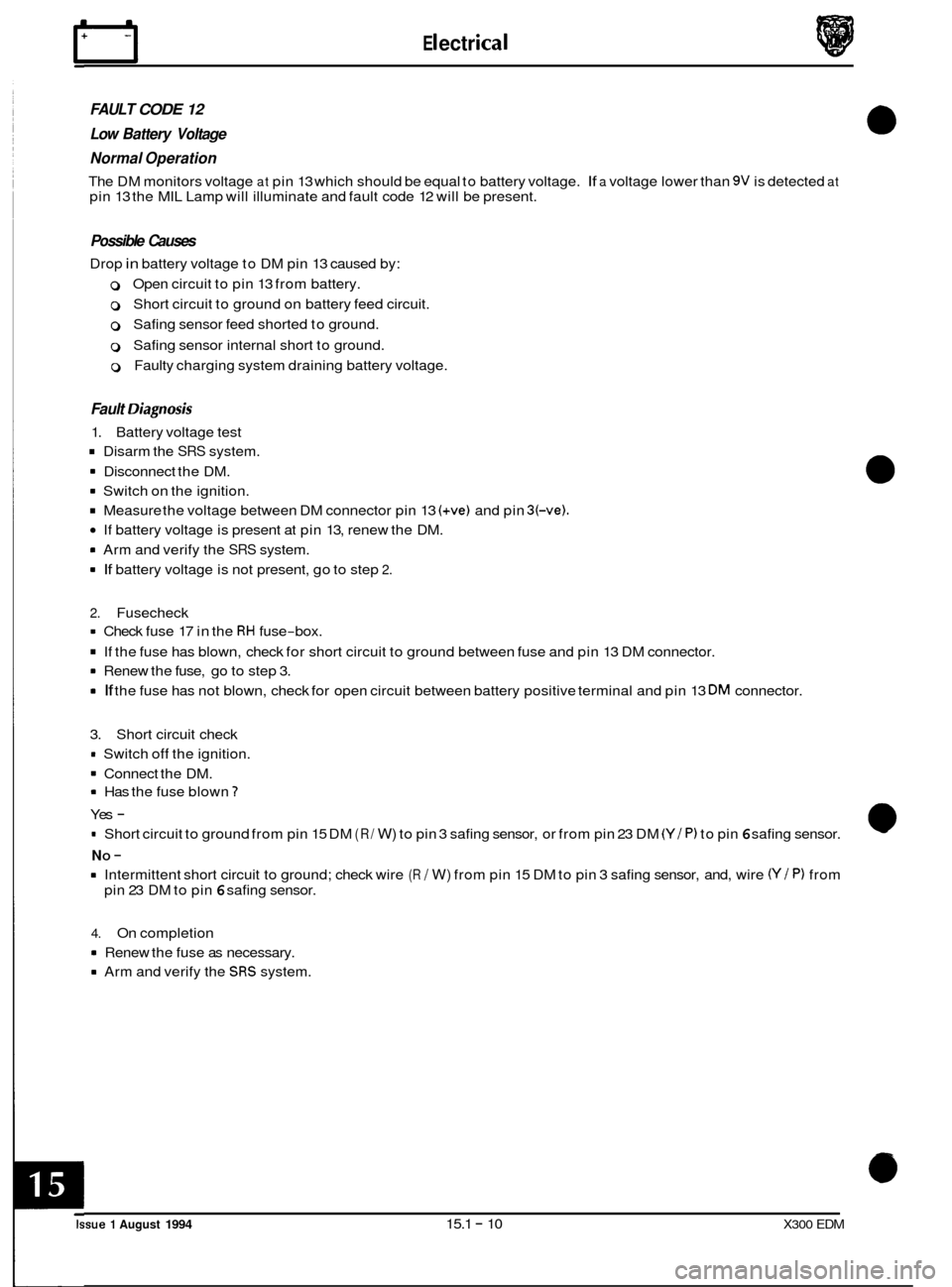

FAULT CODE 12

Low Battery Voltage

Normal Operation

The DM monitors voltage at pin 13 which should be equal to battery voltage. If a voltage lower than 9V is detected at pin 13 the MIL Lamp will illuminate and fault code 12 will be present.

Possible Causes

Drop in battery voltage to DM pin 13 caused by:

0 Open circuit to pin 13 from battery.

0 Short circuit to ground on battery feed circuit.

0 Safing sensor feed shorted to ground.

0 Safing sensor internal short to ground.

0 Faulty charging system draining battery voltage.

Fault Oiagnosis

1. Battery voltage test

Disarm the SRS system.

8 Disconnect the DM.

8 Switch on the ignition.

Measure the voltage between DM connector pin 13 (+ve) and pin 3(-ve).

If battery voltage is present at pin 13, renew the DM.

8 Arm and verify the SRS system.

8 If battery voltage is not present, go to step 2.

2.

Fusecheck

8 Check fuse 17 in the RH fuse-box.

If the fuse has blown, check for short circuit to ground between fuse and pin 13 DM connector.

8 Renew the fuse, go to step 3.

8 If the fuse has not blown, check for open circuit between battery positive terminal and pin 13 DM connector.

3. Short circuit check

* Switch off the ignition.

8 Connect the DM.

8 Has the fuse blown 1

Yes -

= Short circuit to ground from pin 15 DM (R/ W) to pin 3 safing sensor, or from pin 23 DM (Y / P) to pin 6 safing sensor.

8 Intermittent short circuit to ground; check wire (R / W) from pin 15 DM to pin 3 safing sensor, and, wire (Y/ P) from

NO -

pin 23 DM to pin 6 safing sensor.

4. On completion

8 Renew the fuse as necessary.

8 Arm and verify the SRS system.

Issue 1 August 1994 15.1 - 10 X300 EDM

Page 117 of 327

Electricalschematic - Fault Code 12

0

a

e

+12v

1 p=-+-

rn 4 rn

-

P15 !J23 P16

P12

P13

PO3 I

10

1. Instrument Panel Fuse 6. Passenger-side Air Bag 2. Engine Compartment Fuse 7. RH Impact Sensor 3. Safing Sensor 8. LH Impact Sensor

4. Cable Reel Cassettes 9. Air Bag MIL Lamp

5. Driver-side Air Bag 10. Diagnostic Module

Fig. 1

J86-1665

X300 EDM 15.1 - 11 Issue 1 August 1994

Page 118 of 327

rl Electrical

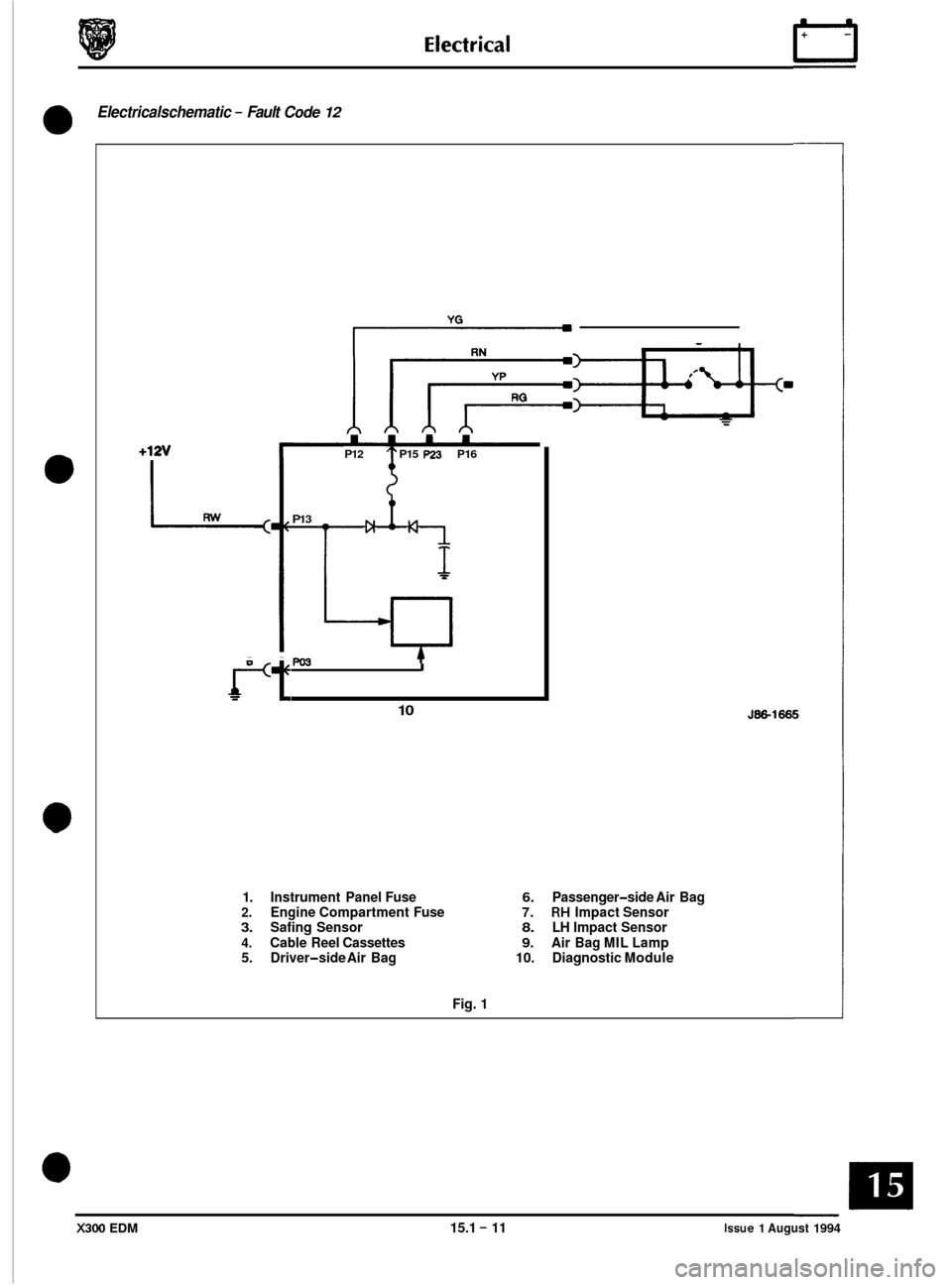

FAULTCODE 13

Air Bag Shorted to Ground

Normal Operation

The DM monitors voltage level at pins 11 and 12 which varies in accordance with charging voltage. If voltage measured

at these two pins falls below 2V the MIL Lamp will illuminate and fault code 13 will be present, indicating a possible

short to ground.

During the presence of fault code 13 the DM internal thermal fuse will blow, disabling the air bag deployment circuit.

If voltage to pins 11 and 12 is restored after the fuse has blown, fault code 51, open internal fuse,

will also be present.

Fault code 13 will be present only as long as the short to ground remains.

Possible Causes

Short to ground in any of the following circuits:

0 Air bag supply wiring.

0 Air bag internal.

0 Cable reel cassette internal.

0 Safing sensor supply wiring.

0 Safing sensor internal.

Fault Diagnosis

1. Air bag(s) -short circuit

. Disarm the SRS system.

. Disconnect both air bag modules multi-plug connector.

. Switch ignition ON.

. Is fault code 13 still present ?

Yes - Proceed to step 2.

No - Proceed to step 3.

2. Cable reel cassette

-short circuit

Examine wiring and connector where cable reel cassette mates to the main harness, below the steering column.

If a fault cannot be located, disconnect cable reel cassette from main harness.

. Connect air bag simulator to the main vehicle harness in place of the cable reel cassettes.

. Measure resistance between pin 11 DM and pin 3 (ground).

. Is pin 11 short circuit to ground ?

No - Proceed to fault code 51.

Yes

- Examine wiring and connections between DM, both air bags and safing sensor. Rectify faults as necessary.

If a fault is located, rectify and proceed to step 3.

3. Air bag modules

-check

. Ensure shorting bar is correctly installed to passenger-side air bag connector.

. Measure resistance between connector terminals and module casing.

If resistance value shows a short to ground, renew the module.

. If resistance shows open circuit, repeat test for driver-side module, renew as necessary.

Proceed to fault code 51 on successful diagnosis.

Issue 1 August 1994 15.1 - 12 X300 EDM

Page 119 of 327

E I ect r ical n

-

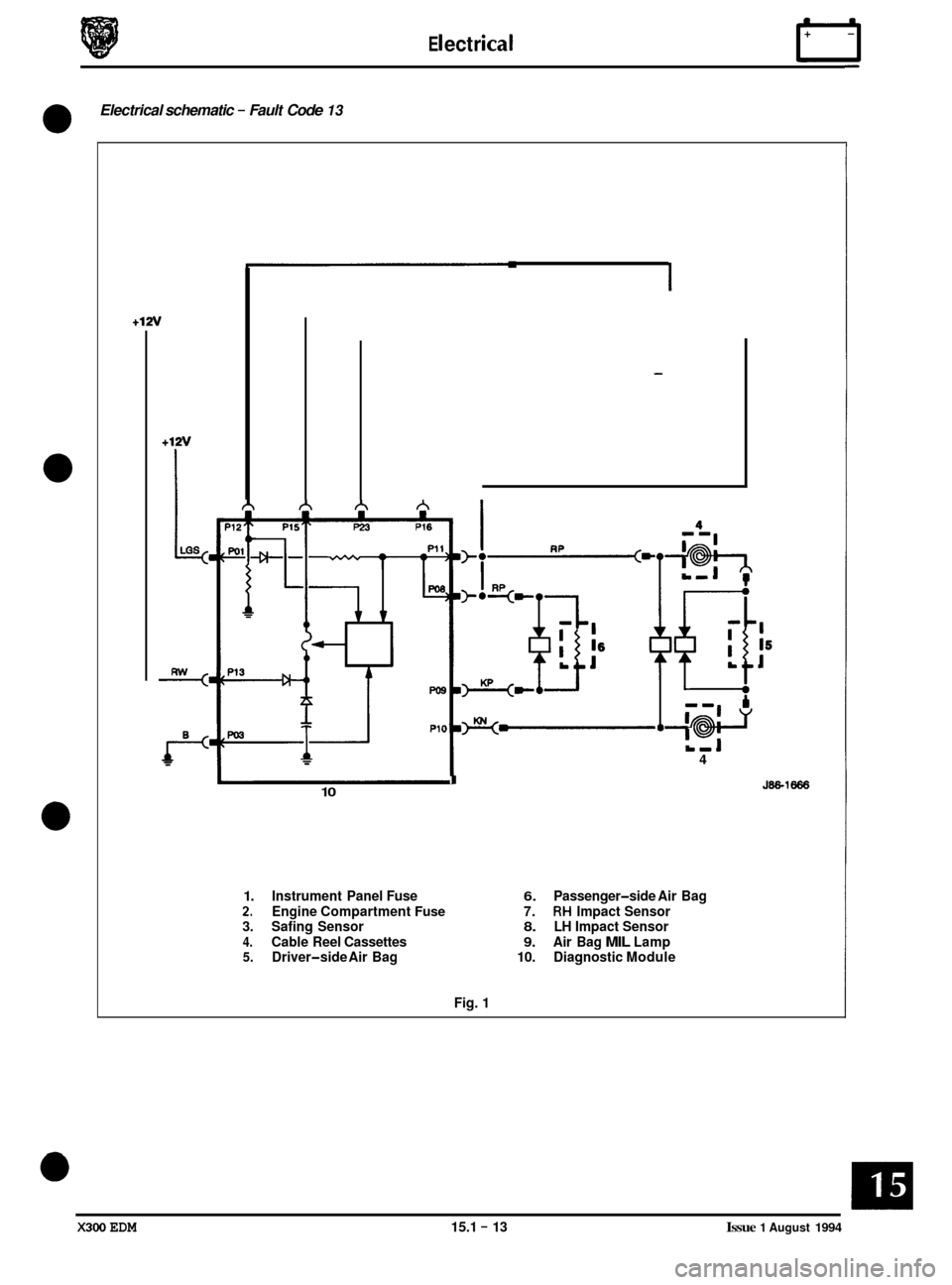

Electrical schematic - Fault Code 13

0

0

0

+12v

+12v

I_i

I 10

4

1. Instrument Panel Fuse 6. Passenger-side Air Bag

2. Engine Compartment Fuse 7. RH Impact Sensor

3. Safing Sensor 8. LH Impact Sensor

4. Cable Reel Cassettes 9. Air Bag MIL Lamp 5. Driver-side Air Bag 10. Diagnostic Module

Fig. 1

586-1668

X300 EDM 15.1 - 13 Issue 1 August 1994

Page 120 of 327

Electrical I3

FAULTCODE 14

Front Impact Sensor Circuit Shorted to Ground

Normal Operation

The DM monitors voltage level at pins 2 and 6. If this voltage falls to 5 volts, or less, the MIL Lamp will illuminate and

fault code 14 will be present, indicating a short circuit to ground on either of the two front impact sensorcircuits. During

the presence of fault code 14 the DM internal thermal fuse will blow, disabling the air bag deployment circuit. If voltage

to pins

2 and 6 is restored after the fuse has blown,fault code 51, open internal fuse will be present. Fault code 14 will

be present only as long as the short to ground remains.

Possible Causes

Short to ground in any of the following circuits:

0 Front impact sensor wiring.

0 Disconnection, or poor connection of harness.

0 Front impact sensors internal ground.

Fault Diagnosis

1. Sub-circuit identification

. Disarm SRS system.

. Remove plastic locking wedge from the grey DM connector.

. Measure resistance between connector pin 3 and all of the following pins; 2,6, 17 and 18.

9 Does any resistance reading indicate short circuit ?

Yes - Renew faulty sensor.

No - Examine sensor wiring harness, locate and rectify faults as necessary.

Proceed to fault code 51 on successful diagnosis.

rm

0

0

0

0

X300 EDM Issue 1 August 1994 15.1 - 14