warning JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 38 of 327

Automatic Transmission (V12) ~ Pow. rtrain

Engine

Torque Reduction and Malfunction Indication

This signal, to the ECM, has three modes of operation.

1. To indicate normal engine operation to the ECM.

2. During gearshifts, to request reduction of engine torque

3. During fault conditions, to inform the ECM.

During normal operation

theTCM outputs a constant duty cycle signal to the ECM. The signal is changed when torque

reduction is required to indicate to the ECM the degree of ignition retardation necessary. If a fault condition, relating

to OBD

II CARB legislation, occurs the TCM will transmit a signal to the ECM relating this event. The ECM will only

respond to this signal if its duration is 100 milli-seconds or longer.

If the signal from the torque reduction line is either HIGH or LOW for 2 or more seconds the EMS will recognise that

a fault may be present and transmit this information to the TCM.

If the signal from the torque reduction line lasts for 2 or more seconds the EMS will return to normal operation.

Sport Mode Indicator Lamp

The sport mode indicator lamp, mounted on the instrument panel, is illuminate when sport mode is selected and the

ignition switch is ON. Sport mode is selected at a two position switch mounted to the rear of the gear selector assembly.

Gearbox Failure Warning Lamp

The gearbox failure warning lamp, mounted on the instrument panel, is illuminated when afault is detected bytheTCM within the transmission electrical or mechanical systems.

Vehicle Speed (12 cylinder vehicles only)

This output signal is calculated from the transmission output speed and supplied to the ECM as an indication of vehicle

speed.

8.2.5 DIAGNOSTIC LINKS

Diagnostic

L line

One of a two wire interface used to activate stored diagnostic codes for reading by external equipment.

Diagnostic K Line

One of a two-wire interface used to communicate stored diagnostic codes for reading by external diagnostic equip- ment.

X300 EDM 7 Issue 1 August 1994

Page 52 of 327

Automatic Transmission (V12) Powertrain

Torque Reduction Signal Malfunction - P1780

Function:

ECM signal monitor.

Connections: TCM PI Harness ECM

CC048/007 P1063/008 P1044/006

Possible causes:

. Faulty harness wiring /connection.

. Faulty ECM signal.

Effects:

. Harsh gearshifts.

Remedy:

. Repair or renew harness / connector.

Examine ECM fault diagnosis (refer to EDM, section 5.2).

Transmission

warning lamp illuminated.

Engine Torque Signal Malfunction - P1781

Function:

ECM signal monitor.

Connections: TCM PI Harness

CC048/0 12 P1063/007

ECM

P1044/005

Possible causes:

. Faulty harness wiring /connection.

. Faulty ECM signal.

Effects:

. Transmission warning lamp illuminated.

. Harsh gearshifts.

Remedy:

Repair or renew harness / connector.

Examine ECM fault diagnosis (refer

to EDM, section 5.2).

X300 EDM 21 Issue 1 August 1994

Page 66 of 327

Brakes

12.2 SYSTEM DESCRIPTION

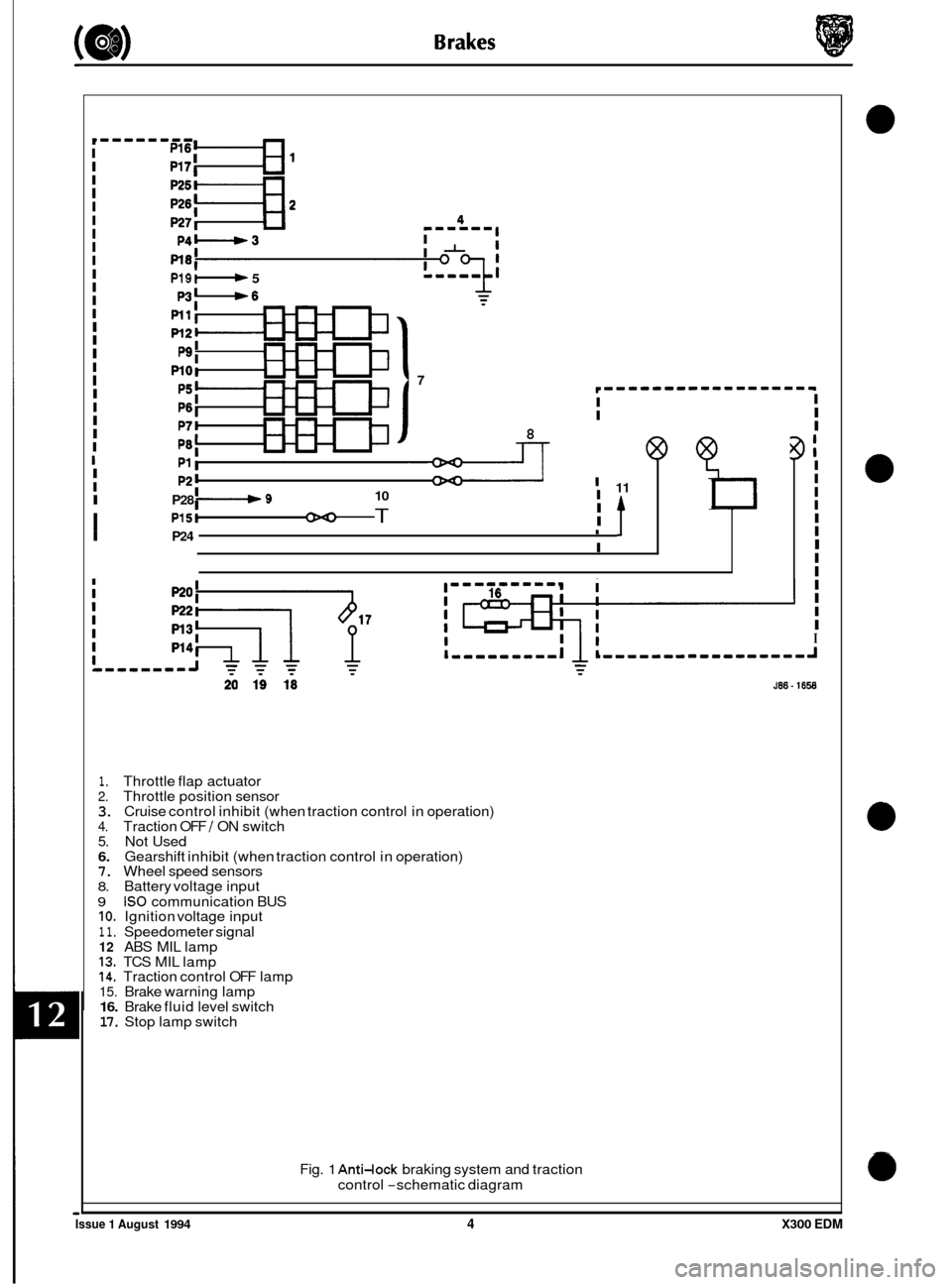

The anti-lock braking system (ABS) and traction control system CTC) comprise the following components:

0 Hydraulic module: incorporating a pump, motor, low pressure accumulator, valve block, and either an ABS Con-

trol Module (ABS CM) or an ABS / TC Control Module (ABS / TC CM).

U!&: Within the hydraulic module are contained the electro-hydraulic inlet and outlet valves which regulate brake

system pressure.

o Four wheel speed sensors; hub end mounted.

0 Three warning indicators plus a Brake Warning Lamp and a Traction OFF / ON switch; fascia mounted.

0 Throttle valve flap positioning mechanism; mounted adjacent to the hydraulic module.

0 Various auxiliary inputs; providing information to ABS / TC CM.

0 Diagnostic IS0 communication BUS input / output link.

The solenoid operated hydraulic valves

are activated by signals, from the ABS /TC CM, which are generated using in-

formation received from the wheel speed sensors.

For vehicles without traction control thevalves operate on threecircuits, two front and one rear, as necessaryto prevent

wheel locking during braking. Brake pressure is modulated individually

at the front wheels and collectively at the rear.

Rear wheel control operates

a 'select low' principle such that locking in either wheel is sensed, and controlled brake

pressure is applied to both wheels.

Vehicles with traction control fitted have

all four wheels individually controlled allowing selective regulation of tractive

and braking force to each wheel as necessary when traction control is in operation.

The ABS

/ TC system as a whole is monitored constantly by the ABS / TC CM and is disabled (switched off until fault

is rectified) automatically when certain failures are identified. In the event of

a failure being detected the ABS and TC

MIL lamps, located on the instrument panel will illuminate. Full boosted brake operation and normal acceleration con- trol is available when ABS /TC is disabled. The system will be disabled when the following conditions occur:

0 Valve failure.

0 Sensor failure.

0 Main driver failure (internal ABS / TC CM fault).

0 Redundancy error (internal ABS / TC CM fault).

0 Over-voltage.

0 Pump motor failure.

0 Throttle valve actuator motor failure.

In the event

of under-voltage both ABS and TC will be disabled and the ABS andTC MIL lamps on the instrument panel

will illuminate.

U!&: The TC MIL lamp will only illuminate providing a voltage is still present at pin 15 'IGN FEED'

Throttle potentiometer failure will disable the TC function only and illuminate the TC MIL lamp.

The

moduleABS/TC CM is activated when ignition is ON, after an initiation period of approximately 1.7 seconds. After

this time delay the control module is ready to process signals provided from the various input sources and, using the

software defined algorithm, control the electrical and hydraulic circuits.

The inductive sensors attached to each of the four wheels provide speed signals to the ABS

/ TC CM. These signals are processed by ABS/TC CM giving comparison between individual wheel speeds, controlling braking or traction as

necessary and generating a pulse to drive the speedometer. Each sensor is monitored for open and short circuit failure,

causing disabling of ABS / TC on detection of a fault condition.

Issue 1 August 1994 2 X300 EDM

Page 68 of 327

I I I I I I I I

I

I

I 11 I I

I

I

I I P24 1

I

I

I

I

I I I I I I I I

I

I

I

P19: 5

P3-6

7

8

I I I I P28 I-+ 9 10

I P15t T

I

I I I

I

,t I

I

I I I I I I I I

I

I I I

1. Throttle flap actuator 2. Throttle position sensor 3. Cruise control inhibit (when traction control in operation) 4. Traction OFF / ON switch 5. Not Used 6. Gearshift inhibit (when traction control in operation) 7. Wheel speed sensors 8. Battery voltage input

9 IS0 communication BUS IO. Ignition voltage input

1 1. Speedometer signal 12 ABS MIL lamp 13. TCS MIL lamp 14. Traction control OFF lamp 15. Brake warning lamp 16. Brake fluid level switch 17. Stop lamp switch

Fig.

1 Anti-lock braking system and traction

control

-schematic diagram

0

0

Issue 1 August 1994 4 X300 EDM

Page 70 of 327

Brakes

12.4 SYSTEM FAULT INDICATION

Fault Indication:

ABS MIL lamp is still illuminated after ignition switch on and instrument pack self test.

h:

Possible causes

Fuses blown.

Faulty wheel speed sensor or harness.

Faulty wiring.

Faulty ABS

/ TC CM.

It is likely that theTC MIL lamp and Traction OFF lamp will also illuminate on vehicles with traction control fitted.

Fault Diagnosis

On the first ignition cycle after afault has been sucessfully diagnosed and corrected the vehicle must bedriven to a speed above 20kph (12.5 mile/ h) before warning lamps will extinguish. If lamps remain on after this exer- cise repeat fault diagnosis.

. Check fuses (F7) in battery feed lines and (F16) in ignition line. Battery fuses are located in the left and right hand

. Unbolt 28 way multi-plug connector from ABS / TC CM.

. Measure resistance across each wheel speed sensor.

No - Unplug sensor flying lead and re-measure sensor resistance.

N&:

heelboard fuse boxes. The ignition supply fuse is located in the left hand heelboard fuse box.

Is value measured 1 10052, f 50%?

Rear sensor connectors are located beneath the rear seat. Seat must be removed to gain access to connector.

Forward sensor connectors are located adjacent to the hood catch bracket.

Is value now within range?

Yes

- Examine harness between ABS I TC CM and sensor.

No - Renew sensor.

= Check continuity to ground from ABS 1 TC CM harness connections 13 and 14. If value is much greater than 0.152

renew harness.

. With the ignition switch ON, measure voltage between ABS /TC CM harness connection 14 and connections 1 and 2 respectively. If value is not approximately equivalent to battery voltage renew harness.

. With the ignition switch ON, measure voltage between ABSITC CM harness connections14 and 15. If value is not

approximately equivalent to battery voltage renew harness.

Renew ABS /TC CM if fault is not located during the above procedures.

fault Indication:

ABS MIL lamp illuminates at 20 kph.

m:

Possible Causes

Fuses blown.

Faulty hydraulic module pump

/ motor unit or circuitry.

Faulty ABS

/ TC CM.

Fault Diagnosis

Check fuses.

. Disconnect pump / motor unit and measure resistance across two pin connector. Measured value should be in the

. Unbolt 28-way connector from ABS /TC CM and measure voltage between harness connections1 and 14. If value

. Renew ABS 1 TC CM if fault is not located during the above procedures.

It is IikelythattheTCMILlampandTraction OFFlampwill also illuminateonvehicleswithtractioncontrolfitted.

region of 0.852. Renew unit if excessive resistance or short circuit is recorded.

is not approximately equal to battery volts renew harness.

Issue 1 August 1994 X300 EDM

Page 102 of 327

Electrical IT

SECTION CONTENTS

Sub

-Section 15.2 lnsfrumenfs

Subsection Title SRO Page

15.2 ............. Instruments .................................................................... 15.2-1

15.2.1

............ Introduction .................................................................... 15.2-1

15.2.2

............ Instrument Pack Connectors - Pin Locations ......................................... 15.2-3

15.2.3

............ Component Description .......................................................... 15.24

15.2.3.1 .......... Speedometer ................................................................... 15.24

15.2.3.2 .......... Tachometer .................................................................... 15.24

15.2.3.3

.......... Engine Oil Pressure and Warning Lamp ............................................. 15.24

15.2.3.4 .......... Engine Coolant Temperature ...................................................... 15.24

15.2.3.5 .......... Fuel Tank Level Gauge and Warning Lamp .......................................... 15.24

15.2.3.6

.......... Battery Voltage Gauge and Warning Lamp .......................................... 15.24

15.2.3.7

.......... Liquid Crystal Display ........................................................... 15.24

15.2.3.8 .......... Trip Computer .................................................................. 15.2-5

15.2.4

............ Primary Warning Lamps (Illuminated Red) .......................................... 15.2-5

15.2.4.1

.......... Exhaust Temperature ............................................................ 15.2-5

15.2.4.2

.......... Low Oil Pressure ................................................................ 15.2-5

15.2.4.3

.......... Seat Belt ....................................................................... \

15.2-5

15.2.4.4

.......... Trunk Lid Open ................................................................. 15.2-5

15.2.4.5

.......... DoorAjar ...................................................................... 15.2-5

15.2.4.6

.......... Engine Coolant LeveL ............................................................ 15.24

15.2.4.7

.......... SRS Airbag Fault ................................................................ 15.24

15.2.4.8 .......... Charging Fault .................................................................. 15.24

15.2.4.9 .......... Brake System Fault .............................................................. 15.24

15.2.4.10 ......... Bark Brake ..................................................................... 15.24

15.2.5. ........... Secondary Warning Lamps (Illuminated Amber) ...................................... 15.2-7

15.2.5.1

.......... Transmission Fault ............................................................... 15.2-7

15.2.5.2

.......... Washer Fluid Level .............................................................. 15.2-7

15.2.5.3

.......... Bulb Fail ....................................................................... \

15.2-7

15.2.5.4

.......... Traction Control Fail ............................................................. 15.2-7

15.2.5.5

.......... Anti-lock Fail .................................................................. 15.2-7

15.2.5.6

.......... Low Fuel Level ................................................................. 15.2-7

15.2.5.7

.......... Check Engine ................................................................... 15.2-7

15.2.6.1

.......... Transmission Sport Mode ......................................................... 15.2-8

15.2.6.2

.......... Traction Control OFF ............................................................ 15.2-8

15.2.6.3

.......... Direction Indicators ............................................................. 15.2-8

15.2.6.4

.......... Main Beam .................................................................... 15.2-8

15.2.6

............ Status

and Warning Lamps ........................................................ 15.2-8

m

a

0

e

0

X300 EDM ii Issue 1 August 1994

Page 103 of 327

Electrical IT

SECTION CON TENTS

Subsection 15.2 Instruments (continued)

Sub-Section Title SRO Page

15.2.7 ............ Fault Diagnosis ................................................................. 15.2-9

15.2.7.1

.......... Active High /Low Inputs ......................................................... 15.2-9

15.2.8.

........... Instrument Pack Pin-point Tests .................................................. 15.2-1 0

15.2.8.1 .......... Oil Pressure, Battery Condition, Coolant Temperature and Fuel Gauges ................. 15.2-1 0

75.2.8.2

.......... Speedometer .................................................................. 15.2-10

15.2.8.4

.......... Liquid Crystal Display .......................................................... 15.2-17

15.2.8.6

.......... Door Open Warning Lamp ...................................................... 15.2-12

15.2.8.7

.......... Exhaust Temperature Warning Lamp .............................................. 15.2-1 3

15.2.8.8 .......... Luggage Compartment Warning Lamp ............................................. 15.2-14

15.2.8.9

.......... Seat Belt Warning Indicator ...................................................... 15.2-1 5

15.2.8.3

.......... Tachometer ................................................................... 15.2-11

15.2.8.5

.......... Trip Computer ................................................................. 15.2-11

15.2.8.70

......... Park Brake Indicator ............................................................ 15.2-16

15.2.8.71

......... Main Beam Indicator ........................................................... 15.2-17

75.2.8.12

......... Direction Indicator Tell Tales ..................................................... 15.2-18

15.2.8.14

......... Washer Fluid Level Indicator ..................................................... 15.2-20

15.2.8.16

......... Brake Fluid Level Indicator ...................................................... 15.2-22

75.2.8.17

......... General Bulb Failure Indicator ................................................... 15.2-23

15.2.8.18

.........

75.2.8.19 .........

15.2.8.20 ......... Traction Control OFF Tell-tale .................................................... 15.2-24

0

75.2.8.13 ......... Generator IND Voltage Indicator ................................................. 15.2-19

7 5.2.8.15 ......... Engine Coolant Level indicator ................................................... 15.2-2 1

Transmission Sport mode Indicator ................................................ 75.2-24

Traction Control Failure Warning Lamp

............................................ 15.2-24

15.2.8.21

......... Anti-lock Failure Warning Lamp .................................................. 15.2-24

15.2.8.22

......... Check Engine Warning Lamp .................................................... 75.2-24

Issue 1 August 1994 iii X300 EDM

Page 109 of 327

Electrical rl

15.1.3 AIR BAG DISARMING/ ARMING PROCEDURE

warnings and cautions

WARNING: DISARM SRS BEFORE SERVICING ANY SRS OR STEERING COLUMN COMPONENT.

ALLOW A MINIMUM OF ONE MINUTE TIME DELAY FOR THE BACK

-UP POWER SUPPLY TO DISCHARGE,

AFTER THE BATTERY GROUND LEAD HAS BEEN DISCONNECTED.

THE SYSTEM COMPONENTS ARE NON

-SERVICEABLE, IF FAULTS ARE SUSPECTED, CHANGE COMPO- NENTS FOR NEW ITEMS ONLY.

NEVER PROBE THE CONNECTORS OF AN AIR BAG MODULE.

FAILURE TO OBSERVE THE ABOVE PROCEDURES MAY RESULT

IN ACCIDENTAL DEPLOYMENT OF AIR

BAG.

ALWAYS WEAR SAFETY GLASSES WHEN WORKING ON AIR BAG EQUIPPED VEHICLES.

PERSONNEL CARRYING AN AIR BAG MODULE MUST ENSURE THAT THE MODULE AND TRIM COVER

ARE POINTED AWAY FROM THE BODY. WHEN POSITIONED ON A BENCH

OR WORK SURFACE ENSURE

THAT THE AIR BAG MODULE AND TRIM COVER FACE UPWARDS, LIMITING MOTION ON ACCIDENTAL

DEPLOYMENT.

ALWAYS WEAR GLOVES WHEN HANDLING DEPLOYED AIR BAG MODULE, DEPOSITS OF SODIUM HY

- DROXIDE MAY BE PRESENT ON THE MODULE SURFACE. IF SODIUM HYDROXIDE CONTACTS ANY

AREA OF SKIN, WASH THE AFFECTED AREA IMMEDIATELY WITH MILD SOAP AND WATER. DISPOSE OF

THE DEPLOYED AIR BAG USING THE CORRECT PROCEDURES, REFER TO SECTION

15 OF THE VSM.

CAUTION:

When scrapping vehicles ensure air bags have been deployed.

If

a component has been renewed and the fault does not clear, refit original item and repeat diagnostic

procedure.

After servicing repeat diagnostic procedures to ensure correct system operation.

Renew air bag module if surrounding trim panels are damaged.

Do not attempt to repaint trim covers as paint may damage cover material.

Disarming

. Allow a minimum 1 minute time delay before attempting to diagnose or renew any component in the SRS system.

Remove driver-side air bag module and connect air bag simulator to cable reel cassette multi-plug.

. Remove passenger-side air bag module and connect air bag simulator to harness.

. Re-connect battery ground lead.

Disconnect

the battery ground lead.

This delay allows the DM back

-up power supply to discharge, preventing accidental firing of the air bag.

0

Arming

Disconnect the battery ground lead.

. Remove air bag simulators and install driver and passenger-side air bag modules. Ensure fasteners are tightened

. Re-connect battery ground lead.

Switch ignition 'on' and ensure air bag MIL Lamp extinguishes.

to specified torque.

X300 EDM 15.1 -3 Issue 1 August 1994

Page 154 of 327

Electrical n

15.2 INSTRUMENTS

15.2.1 Introduction

The instrument pack is a self-contained, removable unit, which incorporates all the main display gauges and warning

indicators that are used to present vehicle condition information. The instrument pack is programmed during vehicle

build, to match the vehicle's individual requirements using 'Programmable Electronic Control Units System'

(PECUS). This is achieved via the diagnostic communication line, and therefore, should be renewed like-for-like. The primary

function of the instrument display is to provide the driver with information usual to normal driving requirements. The

secondary function is to display trip computer information.

The trip computer functions are selected via the steering column stalk switch

(LH). The messages are displayed in the

following order:

Odometer

- Distance - Range - Fuel Used -Average Fuel -Average Speed - Instant Fuel - Odometer (return).

Two trip computer switches, 'Reset' and 'Odo', are incorporated into the facia switch panel.

Instrument pack information is received from sensors positioned

at various locations about the vehicle (Fig. 1, follow-

ing page) via one of the two multi-pin sockets located at the rear of the instrument pack.

Information concerning vehicle condition and operation is displayed in one of three ways:

0 Information necessary to confirm normal vehicle operation: road speed, engine speed, oil pressure, battery

condition, fuel level, coolant temperature. This information is displayed using analogue gauges.

0 Information indicating the presence of a hazard/fault condition (low oil pressure/door open etc.) or operational

action (indicator flashing / headlamp full beam 'on' etc.). This information is provided by twenty two warning

lampsltell-tales, arranged in four groups; two groups of seven at the left and right sides of the instrument pack

and two groups of four

at the bottom of the instrument pack.

0 A Liquid Crystal Display (LCD) is located at the bottom-centre of the instrument pack and is normally used to

display the odometer reading, but it can also be used to display SRS fault conditions and trip computer informa-

tion such as vehicle speed, fuel usage and distance travelled.

0

X300 EDM 15.2 - 1 Issue 1 August 1994

Page 157 of 327

E I ect r ical

15.2.3 COMPONENT DESCRIPTION

15.2.3.1 Speedometer

The speed indication input signal, sent as a pulse rate, is generated by an open collectortransistor within the ABS con- trol module. The instrument pack converts the frequency of this signal to drive the speedometer and to provide two

road speed outputs:

Speed output

1 (pin 2,48 way connector)

This output is connected to the radio head unit, security control module and the power steering module.

Speed output 2 (pin

3,48 way connector)

This output is connected to the body processor unit, cruise control control module, air conditioning control module

and the engine management system.

15.2.3.2 Tachometer

The tachometer input, all engine variants, is provided by the engine management control module. When the engine

is running the control module generates three high state pulses per engine revolution.

15.2.3.3

This signal comes direct from the variable resistance type oil pressure sensor, mounted on the engine. The sensor

resistance values range from 75Q (8 Bar) to 330Q (0 Bar).

When the gauge reaches

a pre-determined reading the instrument pack illuminates the warning light.

Engine Oil Pressure and Warning lamp

15.2.3.4 Engine Coolant Temperature

This signal comes direct from the coolant temperature sensor (variable resistance type), mounted on the engine. The

sensor resistance values range from 34Q (hot) to 241Q (cold), when disconnected from the vehicle.

Note: The coolant temperature gauge is calibrated to indicate at approximately 'Normal' for a wide range of normal

engine operating temperatures.

15.2.3.5 Fuel Tank level Gauge and Warning lamp

This signal (pin 20,24-way connector) comes direct from the variable resistor type fuel level sensor. The sensor resis- tance values range from 80 ohms (full tank) to 900 ohms (empty tank).

When the gauge reaches a pre

-determined reading, the instrument pack illuminates the warning lamp.

15.2.3.6

Battery voltage is displayed on the gauge by measuring the ignition voltage.

The red charge warning lamp will illuminate if either the voltage is too low (below

10.5V) or too high (above 15.5V). In addition, the generator provides a low signal to the instrument pack (pin 9,48-way connector) when battery charging

is unsatisfactory.

Battery Voltage Gauge and Warning lamp

15.2.3.7 Liquid Crystal Display

A single line, six digit, 7 segment display with six trip function flags used for odometer, trip computer and driver mess- ages.

!Y,Q&: If the instrument pack has not been PECUS programmed, the back illumination of the LCD will not switch on.

Check that a PECUS label is attached to the back of the pack.

Issue 1 August 1994 15.2 - 4 X300 EDM