lock JAGUAR XJ6 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 497 of 521

Security System - RESTRICTED ISSUE

A5.7.7 Central Locking

W

With the ignition switch in either position 'I' or 'll', press the central locking switch and check that all the doors and the

luggage compartment lock, if they are unlocked.

Hold down the switch for

3 seconds and check any open windows or the sliding roof close, if open.

Check that

a further press on the central locking switch after 3 seconds will unlock the doors and the luggage compart- ment.

If the switch is pressed when ignition switch is not in position I or II, tilt and intrusion sensing will be disabled until the

next arming action. The active indicator, mounted in the switch housing, will flash to confirm this action.

To disarm

a passively armed vehicle the ignition key or key-ring transmitter can be used as follows:

Ensure

all doors

are fully closed before commencing lock operations.

0 Ignition key - Switch to position '11'.

0 Key-ring transmitter - Refer to A5.3.5 Unlocking.

A5.7.8 Passive Arming

Passive arming is a dealer option on variants 1 and 3 only.

With the ignition switch in the OFF position, check that passive arming of the vehicle takes place

30 seconds after the last closure of the doors, trunk lid, hood or sliding roof.

Ensurethat when passive arming occurs, the direction indicators flash once and the security active indicator in the cen

- tral locking switch lights for 2 seconds then flashes once when vehicle arming is complete.

W There is no audible indication when passive arming occurs.

A5.7.9 Trunk Release

Check that the the trunk lid can be released in the following ways:

0 From the vehicle interior by pressing the trunk release switch mounted on the facia.

0 By using the ignition key in the trunk lid if the vehicle is disarmed. If not disarmed the the alarm system will be

activated and can be switched off by ignition key or key-ring transmitter.

0 Remotely (as part of the unlocking procedure) by the key-ring transmitter.

A5.7.10 Trunk Valet Isolate

Check that valet switch operation prevents unauthorized entry into the luggagecompartment by inhibiting the luggage

compartment remote release switch and the green headed valet key can be used to park and lock the vehicle but does

not unlock the luggage compartment.

A5.7.11 Flush Sill Buttons

Variants 1 and 3 (except Japanese market) are fitted with flush sill buttons mounted in the door trim panel. Check but- ton operation as follows:

To lock the door from the interior press the sill button down, flush with the door trim panel. To unlock the door pull the

door lever out.

X300 VSM Issue 1 August 1994 20

Page 498 of 521

Remedy: Fault:

Possible causes:

1. No power supply to lock relays.

Door lock/ unlock relays faulty.

Door locking / unlocking facility inoperative or faulty

2.

3. Door actuators faulty.

4. Keylock switches faulty.

5. Deadlock circuitry faulty.

6. Wiring harness or connectors faulty.

Remedy: 1.

2. Renew faulty relay.

3.

4.

5. See Deadlock fault Sub-Routine.

6.

Check fuse F1 in RH 'A' post base fusebox.

Renew door lock assembly complete.

Renew door lock assembly complete.

Examine and repair or renew faulty harness.

Fault Deadlocking facility inoperative or faulty (not NAS)

Possible causes: 1. No power supply to deadlock relays.

2. Deadlock relays faulty.

3. Deadlock status micro-switch faulty.

Remedy: 1.

2. Renew faulty relay.

3. Renew doorlock assembly complete.

Check

fuse

F1 in RH 'A' post base fusebox.

Page 499 of 521

Security System - RESTRICTED lSSUE

Fault:

Possible causes:

Remedy: Fault:

Fault:

Possible causes:

Remedy:

Fault:

Possible causes:

Remedy: Intrusion

sensing inoperative

1. Faulty sensor.

2. Harness wiring or connectors faulty.

1. Renew sensor.

2. Examine and repair or renew faulty harness.

Inclination sensing inoperative

1. Faulty sensor.

2. Harness wiring or connectors faulty.

1. Renew sensor.

2. Examine and repair or renew faulty harness.

1.

2.

3.

4.

1.

2.

3.

4.

Fuel filler cap locking / unlocking faulty

No power to actuator relay.

Wiring harness or connectors faulty

Relay faulty

Actuator faulty.

Check fuse

F1 in RH 'A' post fuse box.

Examine and repair or renew faulty harness.

Renew relay.

Renew actuator.

Pan.; feature inoperative

1. Transmitter battery inoperative.

2. Rear screen aerial cable damaged / disconnected.

1. Renew battery.

2. Identify and repair aerial fault.

Fault: Central locking switch inoperative

Possible causes:

1. Harness wiring or connectors faulty.

2. Switch faulty.

Remedy: 1.

2. Renew switch.

Examine

and repair

or renew damaged harness.

X3OO VSM Issue 1 August 1994 22

Page 501 of 521

Security System - RESTRICTED ISSUE 84

eb

Description

Security / Locking Control Module

Central locking switch

Front passenger door ajar switch

RH rear passenger door ajar switch

LH rear passenger door ajar switch

Driver's door ajar switch

Driver's door lock switch

Passenger's door lock switch

Driver's door unlock relay (NAS only)

Non

-deadlock shorting links (NAS only)

Front left

/ rear right deadlock relay

Front right

/ rear left deadlock relay

Door lock relay

Door unlock relay

LH Rear door actuator and switch

RH Rear door actuator and switch

Front door actuator lock

/ deadlock status

switches

Driver's door actuator lock

/ deadlock status

switches

Driver's door unlock shorting link

RH 'A' post base fuse-box

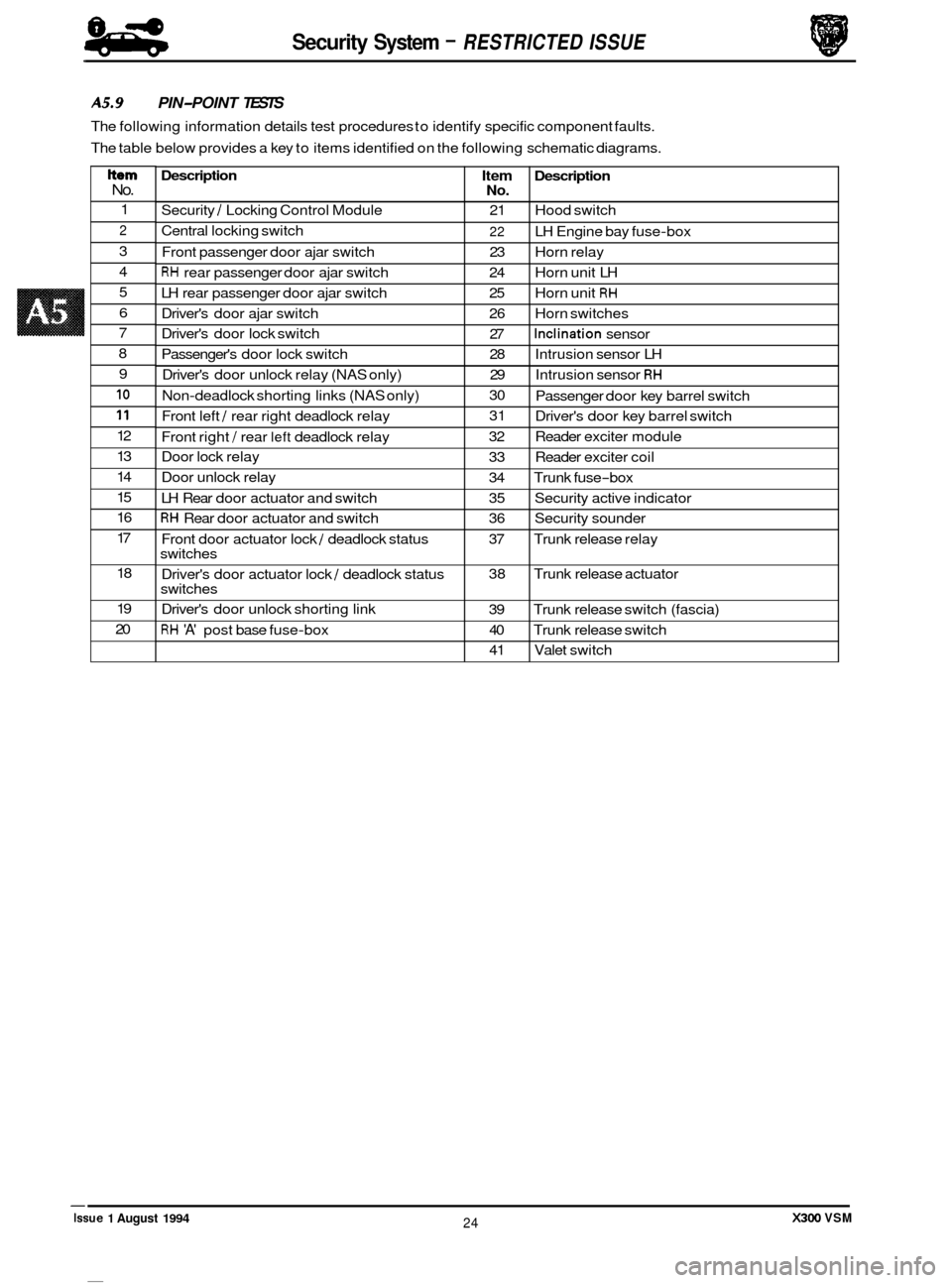

A5.9 PIN-POINT TESTS

The following information details test procedures to identify specific component faults.

The table below provides a key to items identified on the following schematic diagrams.

Item Description No.

21 Hood switch

22 LH Engine bay fuse-box

23 Horn relay

24 Horn unit LH

25 Horn unit

RH

26 Horn switches

27

Inclination sensor

28 Intrusion sensor LH

29 Intrusion sensor

RH

30

31

32 Reader exciter module

33 Reader exciter coil

34 Trunk fuse

-box

35 Security active indicator

36 Security sounder

37 Trunk release relay

38 Trunk release actuator

39 Trunk release switch (fascia)

40 Trunk release switch

41 Valet switch

Passenger

door key barrel switch

Driver's door key barrel switch

Item No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

X300 VSM 24 Issue 1 August 1994

Page 502 of 521

I

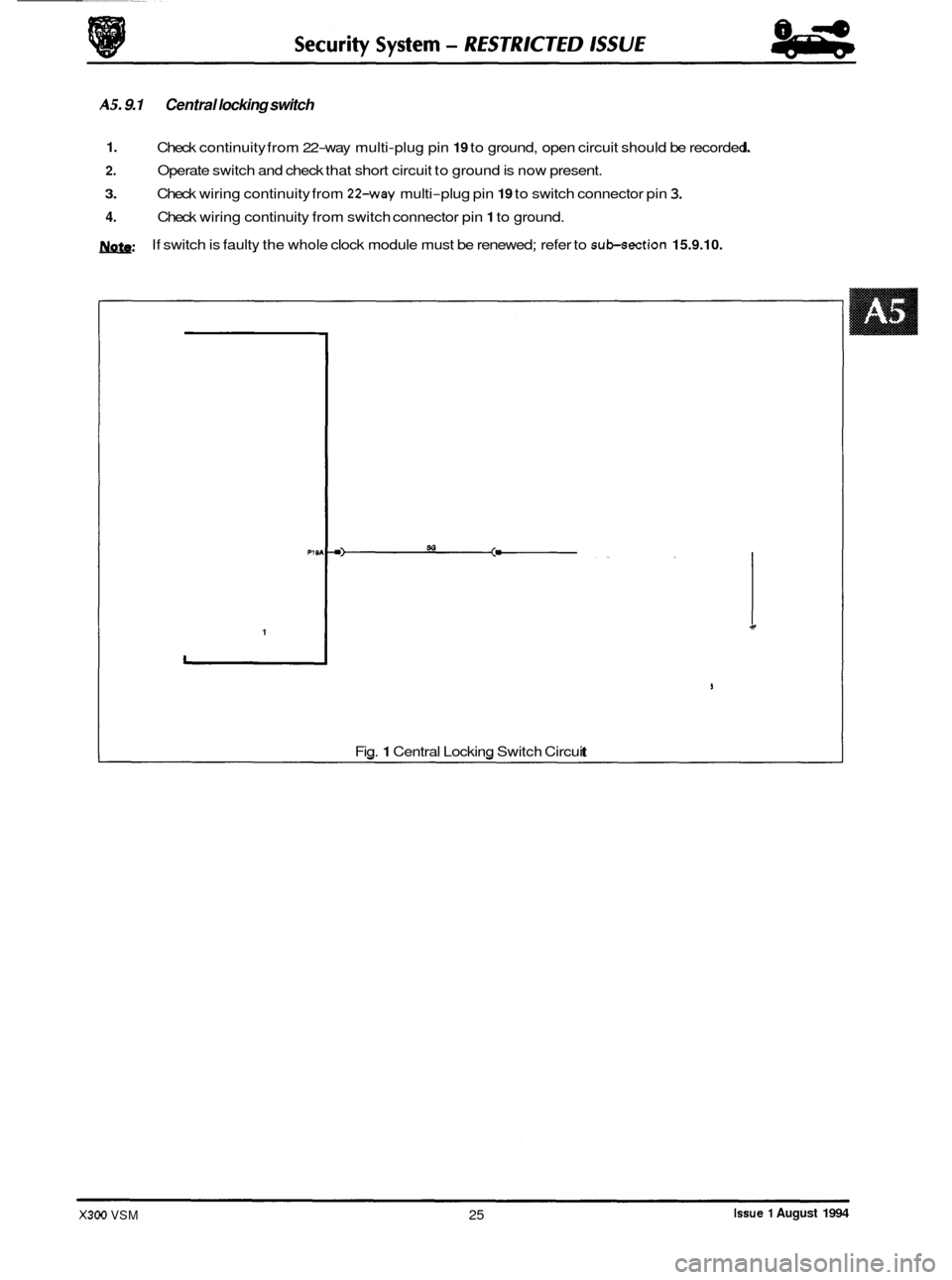

AS. 9.1 Central locking switch

1.

2.

3.

4.

Check continuity from 22-way multi-plug pin 19 to ground, open circuit should be recorded.

Operate switch and check that short circuit to ground is now present.

Check wiring continuity from

224vay multi-plug pin 19 to switch connector pin 3.

Check wiring continuity from switch connector pin 1 to ground.

If switch is faulty the whole clock module must be renewed; refer to

sub-section 15.9.10. m:

PI 9

1

Fig. 1 Central Locking Switch Circuit

Issue 1 August 1994 X300 VSM 25

Page 504 of 521

0

1

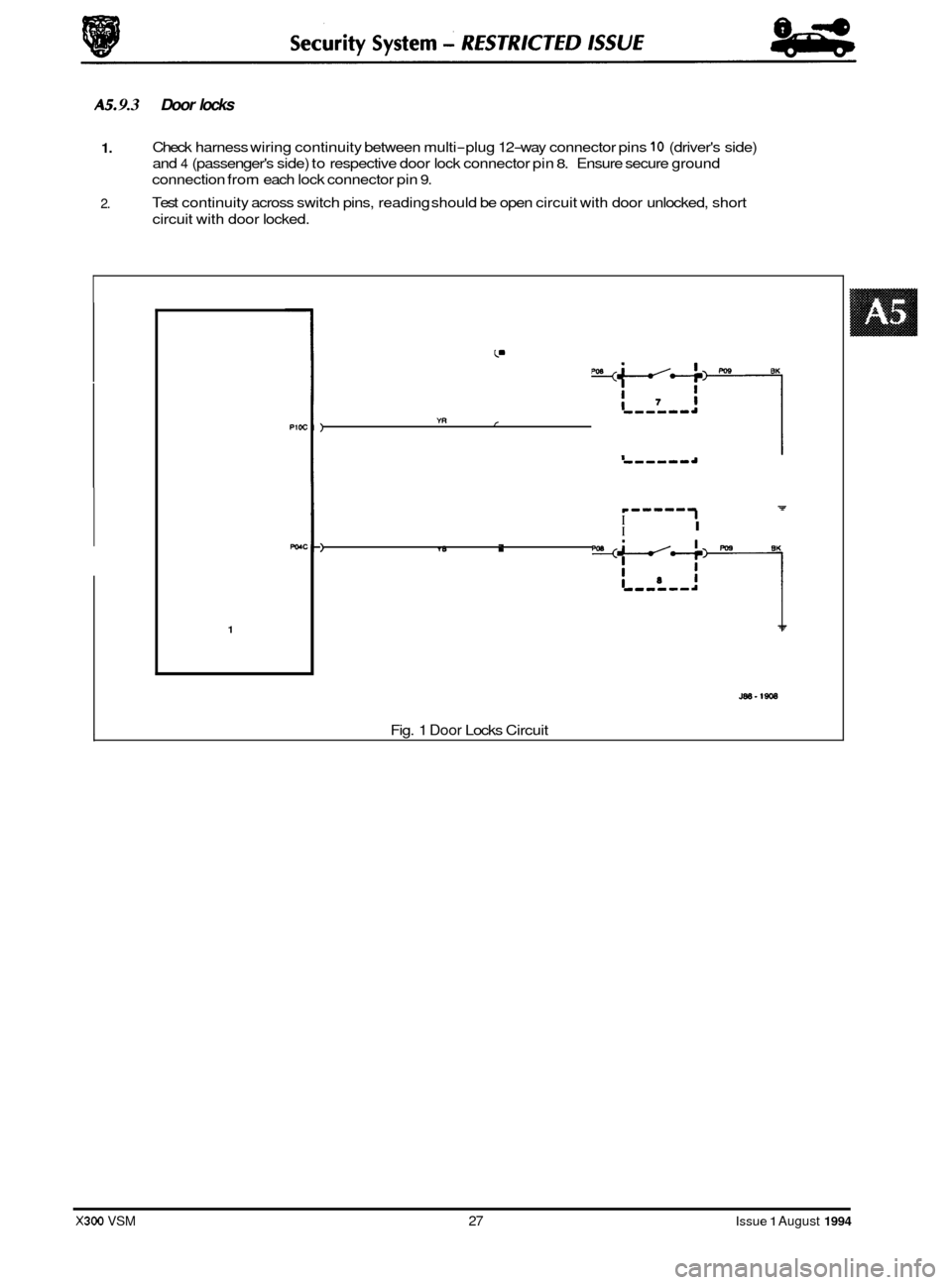

AS. 9.3 Door locks

U 1. Check harness wiring continuity between multi-plug 12-way connector pins 10 (driver's side)

and

4 (passenger's side) to respective door lock connector pin 8. Ensure secure ground

connection from each lock connector pin

9.

Test continuity across switch pins, reading should be open circuit with door unlocked, short

circuit with door locked. 2.

7 e-----

I I I

1 r

I-, -a

.-

mT

YB .

mcE?-l

YR

7 7 p-ww--

I I I

) ,

1

JBB-1908

I Fig. 1 Door Locks Circuit

9 J

3

X300 VSM 27 Issue 1 August 1994

Page 505 of 521

Security System - RESTRICTED ISSUE 84

4b

A5.9.4 Door lock actuators and switch

1.

2.

3.

Examine fuse F1 in right hand 'A' post base fusebox, if blown determine reason for rupture and

renew.

Check continuity of harness wiring as shown on Fig.

1 below. Ensure secure ground connection

from lock/ unlock and deadlock (not N.A.S.) relay pins

4 and 9.

Remove the left hand rear seat hell board, gaining access to lock/ unlock and deadlock (not

N.A.S.) relays. Operate lock/ unlock and deadlock checking for audible relay operation. renew

suspect relays.

Release door lock and measure resistance between actuator unit pins

2 and 3, a value of

approximately

8Q should be recorded. Operate door lock and check that circuit between pins 2

and 3 is opened. Resistance across pins 1 and 3 should now be approximately 88.

4.

SI

+

SR SI I I sa VI II

I 1

J8S-1909

Fig. 1 Door Lock Actuator Circuit

*I N.A.S. only

*2 Not N.A.S.

X300 VSM Issue 1 August 1994 28

Page 508 of 521

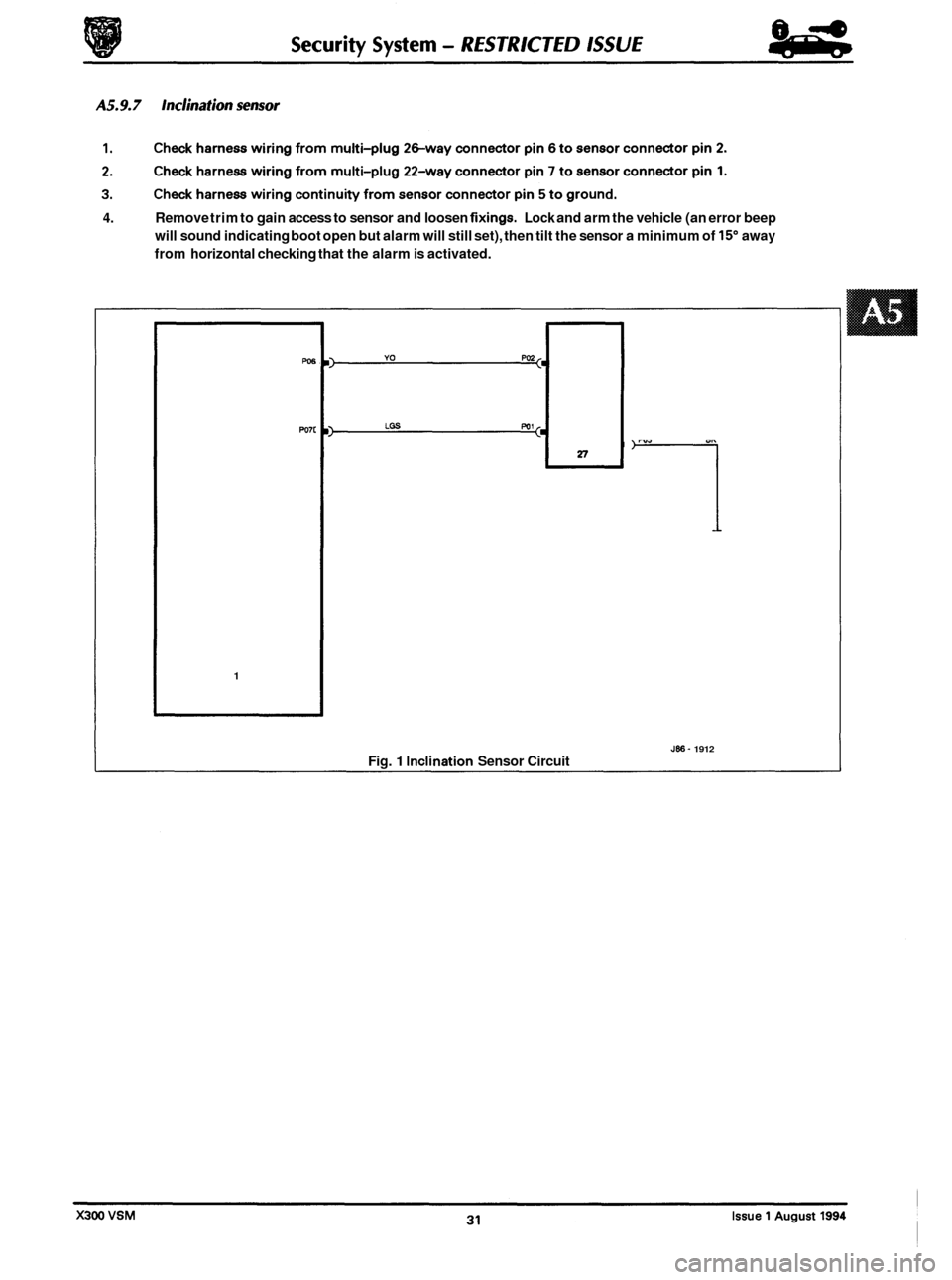

4. Remove trim to gain access to sensor and loosen fixings. Lock and arm the vehicle (an error beep

will sound indicating boot open but alarm will still set), then tilt the sensor a minimum of

15" away

from horizontal checking that the alarm is activated.

w6

Po7c

1

Fig. 1 Inclination Sensor Circuit

1

Jffi- 1912

Page 509 of 521

Security System - RESTRICTED ISSUE 84

-

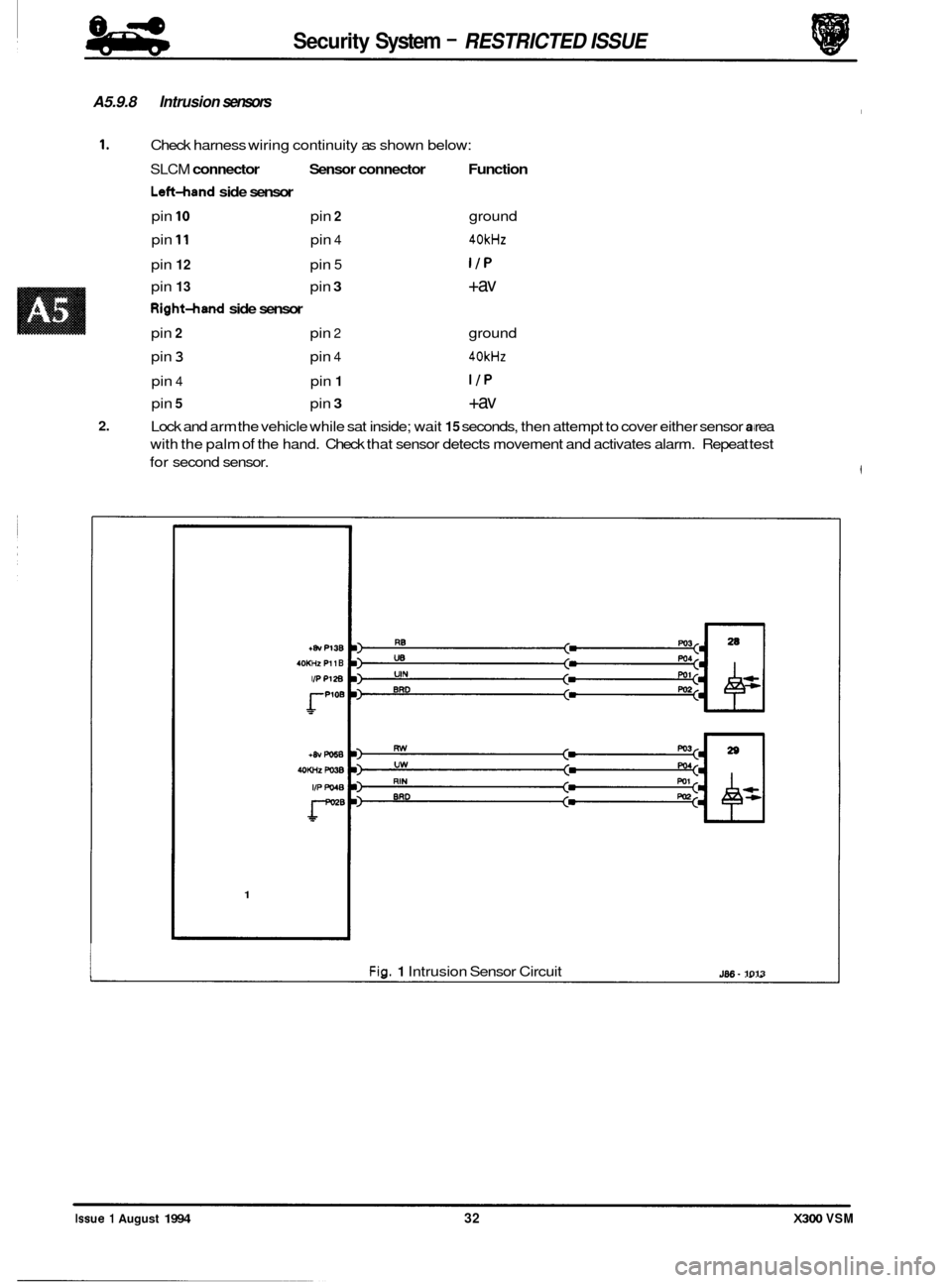

A5.9.8 Intrusion sensors

1. Check harness wiring continuity as shown below:

SLCM connector Sensor connector Function

Lsft-hand side sensor

pin 10 pin 2 ground

pin

11 pin 4 40kHz

pin 12 pin 5 I/P

pin 13 pin 3 +av

RightAand side sensor

pin 2 pin 2 ground

pin

3 pin 4 40kHz

pin 4 pin 1 I/P

pin 5 pin 3 +av

2. Lock and arm the vehicle while sat inside; wait 15 seconds, then attempt to cover either sensor rea

with the palm

of the hand. Check that sensor detects movement and activates alarm. Repeat test

for second sensor.

+8v P13B

40KHz P11 B

IPP128

rPloB

1

Fig. 1 Intrusion Sensor Circuit J86- 1013

Issue 1 August 1994 32 X300 VSM

Page 510 of 521

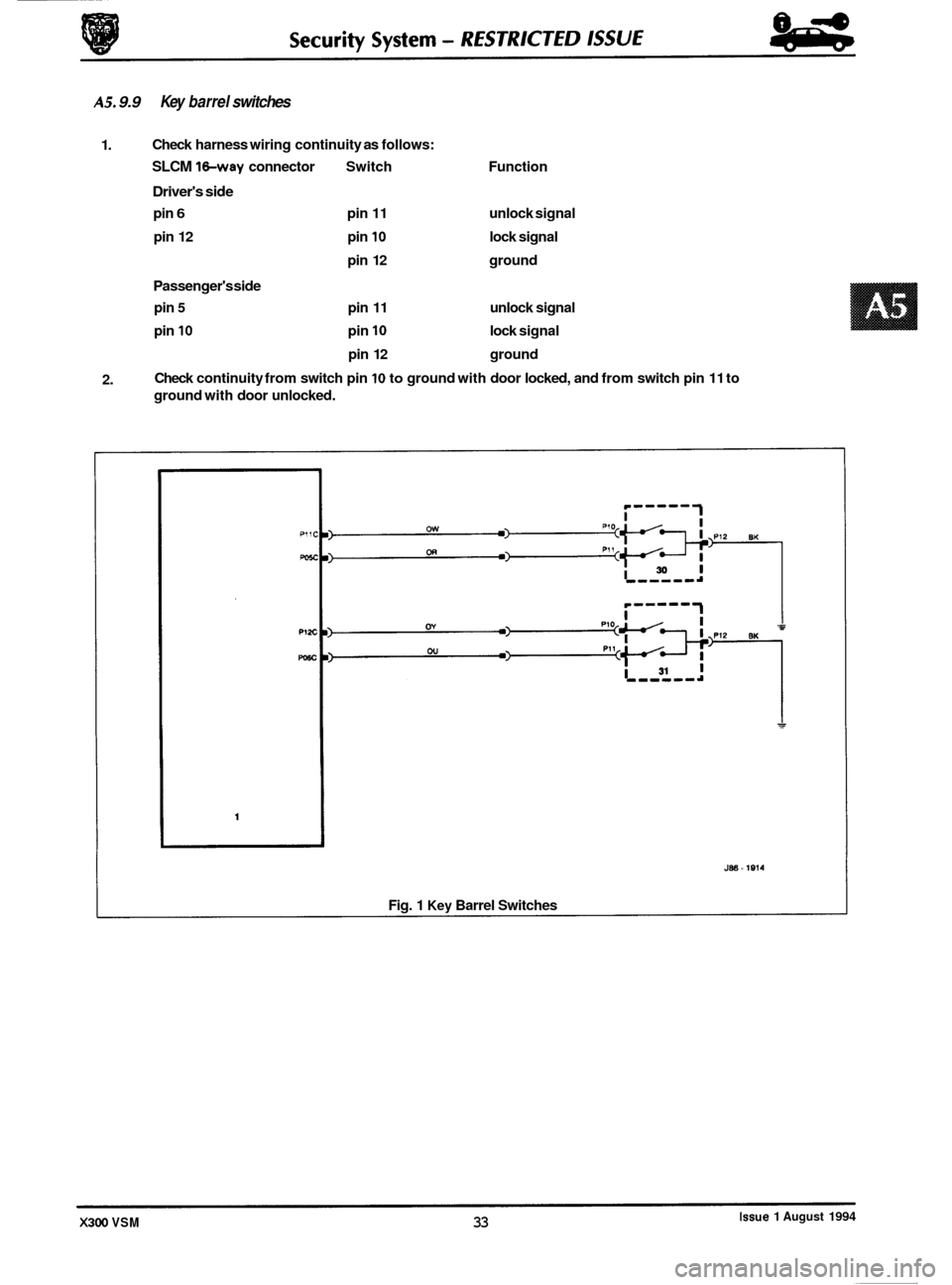

AS. 9.9 Key barrel switches

1. Check

harness wiring continuity as follows:

SLCM 1hay connector Switch Function

Driver's side

pin 6 pin 11 unlock signal

pin 12 pin

10 lock signal

pin 12 ground

Passenger's side

pin 5 pin 11 unlock signal

pin

10 pin 10 lock signal

pin 12 ground

Check continuity from switch pin

10 to ground with door locked, and from switch pin 11 to

ground with door unlocked.

2.

J88 - 1814

Fig. 1 Key Barrel Switches

Issue 1 August 1994 X300 VSM 33