differential JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 203 of 521

@ Steering

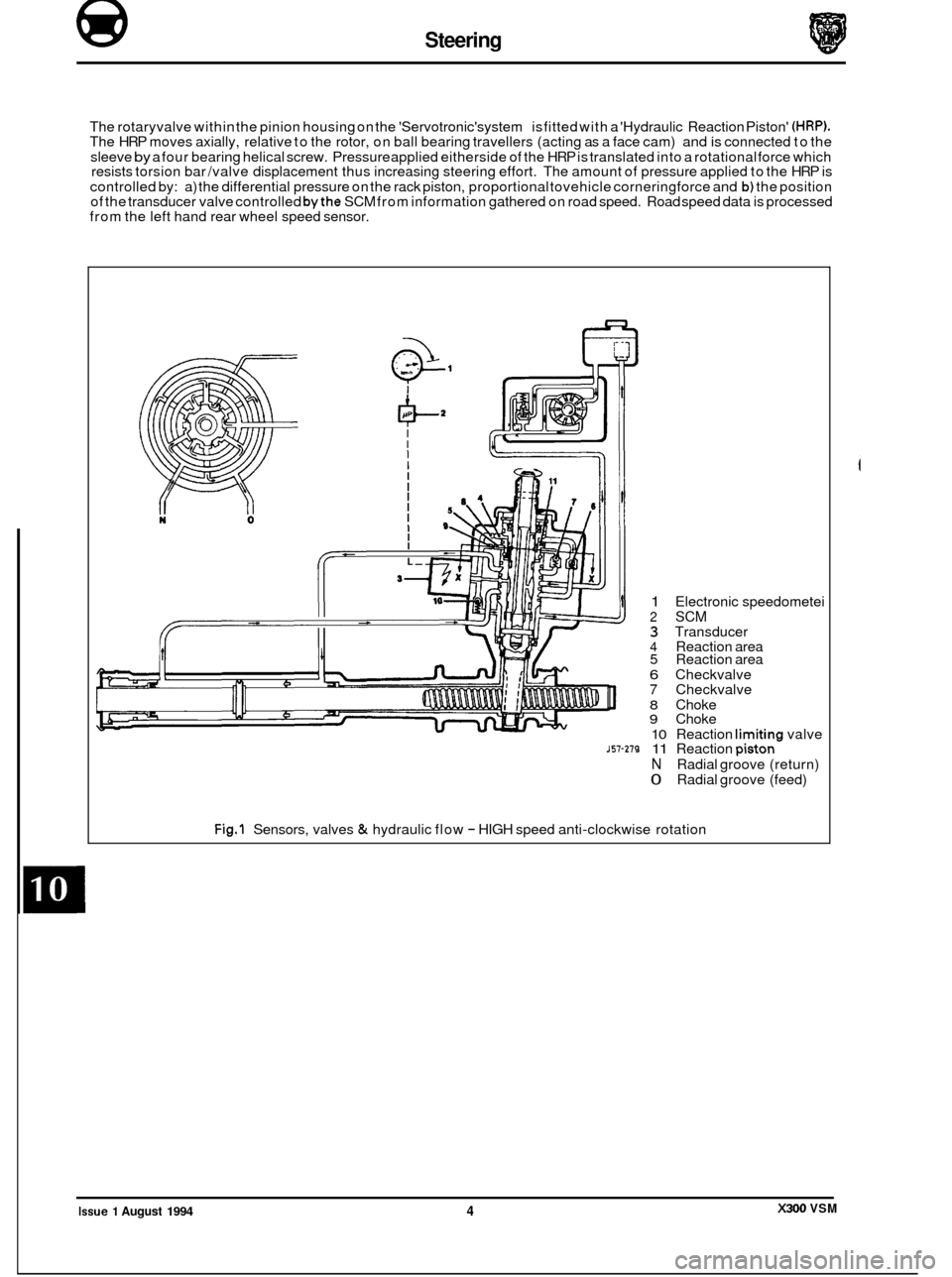

The rotaryvalve within the pinion housing on the 'Servotronic'system is fitted with a 'Hydraulic Reaction Piston' (HRP). The HRP moves axially, relative to the rotor, on ball bearing travellers (acting as a face cam) and is connected to the

sleeve

by a four bearing helical screw. Pressure applied eitherside of the HRP is translated into a rotational force which

resists torsion bar /valve displacement thus increasing steering effort. The amount of pressure applied to the HRP is

controlled by: a) the differential pressure on the rack piston, proportional tovehicle corneringforce and

b) the position

of the transducer valve controlled bythe SCM from information gathered on road speed. Road speed data is processed

from the left hand rear wheel speed sensor.

1 Electronic speedometei

2 SCM 3 Transducer 4 Reaction area 5 Reaction area

6 Checkvalve 7 Checkvalve

8 Choke 9 Choke

10 Reaction limitina valve 157-279 11 Reaction piston-

N Radial groove (return)

0 Radial groove (feed)

Fig.1 Sensors, valves & hydraulic flow - HIGH speed anti-clockwise rotation

X300 VSM Issue 1 August 1994 4

Page 215 of 521

Suspension Systems

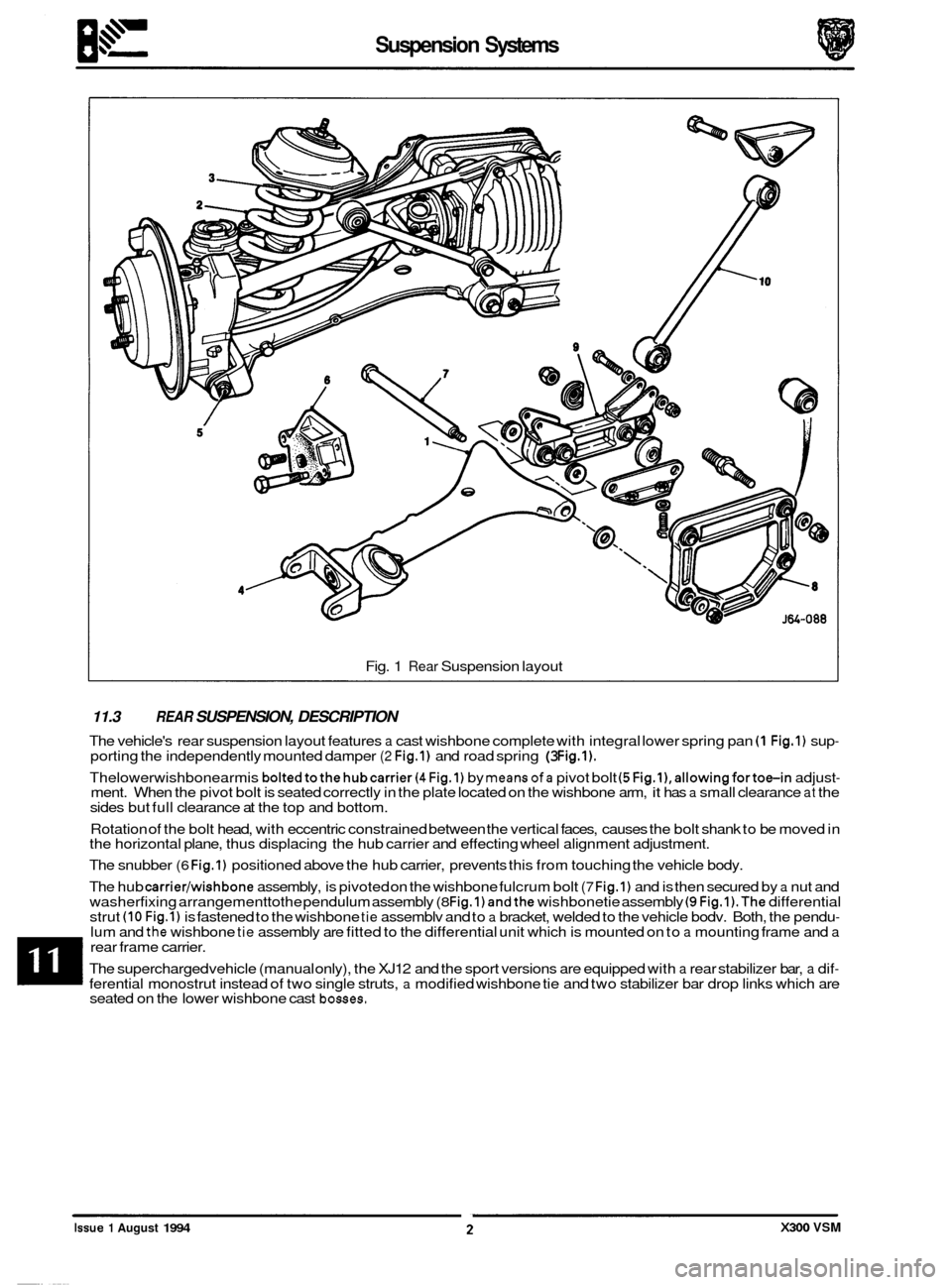

Fig. 1 Rear Suspension layout

11.3 REAR SUSPENSION, DESCRIPTION

The vehicle's rear suspension layout features a cast wishbone complete with integral lower spring pan (1 Fig.1) sup- porting the independently mounted damper (2 Fig.1) and road spring (3 Fig.1).

Thelowerwishbonearmis boltedtothehubcarrier(4 Fig.1) by meansofa pivot bolt (5Fig.l),allowingfortoe-in adjust- ment. When the pivot bolt is seated correctly in the plate located on the wishbone arm, it has a small clearance at the

sides but full clearance at the top and bottom.

Rotation of the bolt head, with eccentric constrained between the vertical faces, causes the bolt shank to be moved in

the horizontal plane, thus displacing the hub carrier and effecting wheel alignment adjustment.

The snubber

(6 Fig.1) positioned above the hub carrier, prevents this from touching the vehicle body.

The hub

carrier/wishbone assembly, is pivoted on the wishbone fulcrum bolt (7 Fig.1) and is then secured by a nut and

washerfixing arrangementtothe pendulum assembly (8 Fig.1) andthe wishbonetie assembly (9 Fig.l).The differential

strut (10 Fia.1) is fastened to the wishbone tie assemblv and to a bracket, welded to the vehicle bodv. Both, the pendu- lum and the wishbone tie assembly are fitted to the differential unit which is mounted on to a mounting frame and a rear frame carrier.

The supercharged vehicle (manual only), the XJ12 and the sport versions are equipped with

a rear stabilizer bar, a dif- ferential monostrut instead of two single struts, a modified wishbone tie and two stabilizer bar drop links which are

seated on the lower wishbone cast bosses.

0

0

e

Issue 1 August 1994 X300 VSM

Page 276 of 521

Body Components & Trim ~

issue 1 August 1994 X300 VSM 21

13.3.17 Fascia Board, Renew

SRO 76.46.01

. Remove

the battery cover and disconnect the battery.

Remove the drivers side and passenger side underscuttle

pads, see sub

-sections 13.3.19 and 13.3.20.

. Remove the drivers airbag module, see section 15.5.

Remove the steering wheel, section 10.

Remove the drivers side and passenger side fascia closing

. Remove the fascia center veneer panel, see subsection

Remove the fascia board for access, see subsection

. Disconnect the air conditioning differential potentiometer

Remove the differential potentiometer assembly.

. Displace and reposition the through panel connectors

from the fascia assembly.

. Displace the fascia vent motor / gearbox assemblies har- ness multi-plug from the mounting bracket.

. Disconnect and reposition the fascia harness to console

harness

multi-plug from the mounting bracket.

. Disconnect the BPU harness multi-plugs.

Remove the tiestraps securing the harness to the fascia.

. Reposition the fascia on a bench.

= Displace and reposition the solar sensor assembly from

Disconnect the solar sensor harness multi-plug.

Remove the solar sensor assembly.

= Undo and remove the defrost vents securing screws.

Displace and reposition the defrost vent assemblies.

. Disconnect the tweeter speaker harness multi-plugs.

. Remove the defrost vent assemblies.

. Displace the fascia harness grommet from the fascia.

. Route the harness through the aperture.

Remove the fascia harness assembly.

. Undo and remove passenger airbag deployment door to

fascia securing bolts ( one bolt is removed with the fascia).

. Displace and remove the deployment door assembly.

. Undo and remove the passenger airbag module to fascia

. Displace and remove the airbag module assembly.

. Undo and remove the airbag module I BPU mounting

bracket assembly to fascia securing nuts 1 bolts.

= Displace and remove the mounting bracket assembly.

. Retrieve the spacing washers.

. Displace and remove the side vent outlets from the fascia.

. Displace and remove the side vent ducts securing clips.

. Displace and remove the side vent ducts.

. Undo and remove the center vent flap assembly to fascia

. Displace and remove the center vent flap assembly.

Undo and remove fascia location bracket securing nuts.

Displace and remove the location bracket.

panels, see

sub

-sections 13.3.22 and 13.3.21.

13.3.23. 13.3.17.

harness multi

-plug.

the fascia.

securing bolts.

securing nuts.

Page 278 of 521

Body Components & Trim

. Reposition and fit the motor/gearbox assemblies harness

. Fully seat the through panel connectors to the fascia.

. Place the air conditioning differential potentiometer to the

fascia and route the differential potentiometer harness

through the vent aperture.

. Reconnect the differential potentiometer harness multi-

Plug.

Refit the fascia board.

. Refit the center veneer panel.

. Refit the fascia closing panels.

. Refit the steering wheel.

. Refit the drivers airbag module.

. Refit the underscuttle pads.

. Reconnect the battery and refit the battery cover.

multi

-plug

to the mounting bracket.

X300 VSM 23 Issue 1 August 1994

Page 283 of 521

Body Components & Trim -

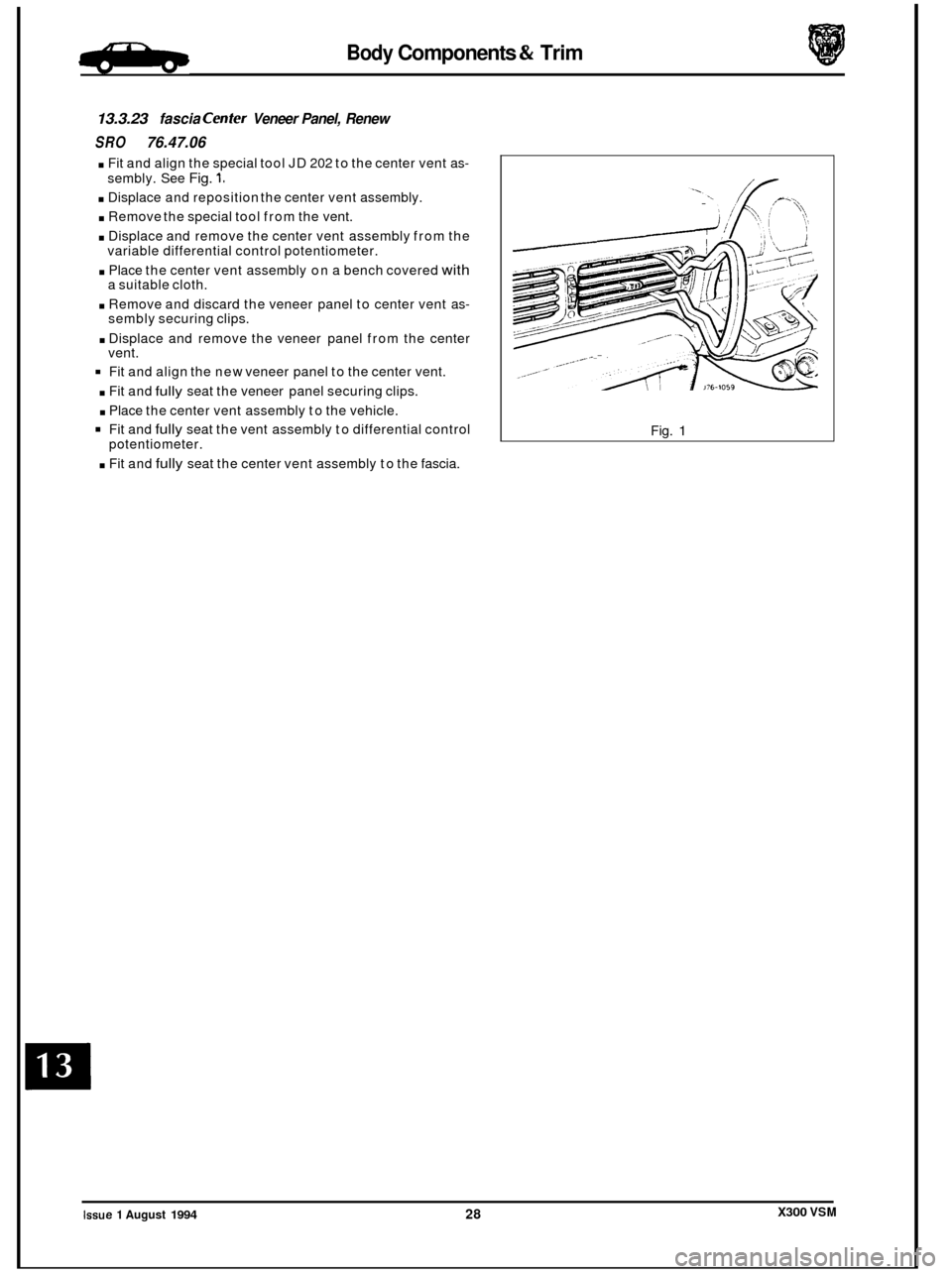

13.3.23 fascia Cenfer Veneer Panel, Renew

SRO 76.47.06

. Fit and align the special tool JD 202 to the center vent as-

. Displace and reposition the center vent assembly.

. Remove the special tool from the vent.

. Displace and remove the center vent assembly from the

. Place the center vent assembly on a bench covered with

. Remove and discard the veneer panel to center vent as-

. Displace and remove the veneer panel from the center

Fit and align the new veneer panel to the center vent.

. Fit and fully seat the veneer panel securing clips.

. Place the center vent assembly to the vehicle.

Fit and fully seat the vent assembly to differential control

. Fit and fully seat the center vent assembly to the fascia.

sembly.

See

Fig. 1.

variable differential control potentiometer.

a suitable cloth.

sembly securing clips.

vent.

potentiometer.

._-

Fig. 1

X300 VSM Issue 1 August 1994 28

Page 321 of 521

Climate Control Systems

. Centre vent flap

Foot flap

Defrost flap

I I

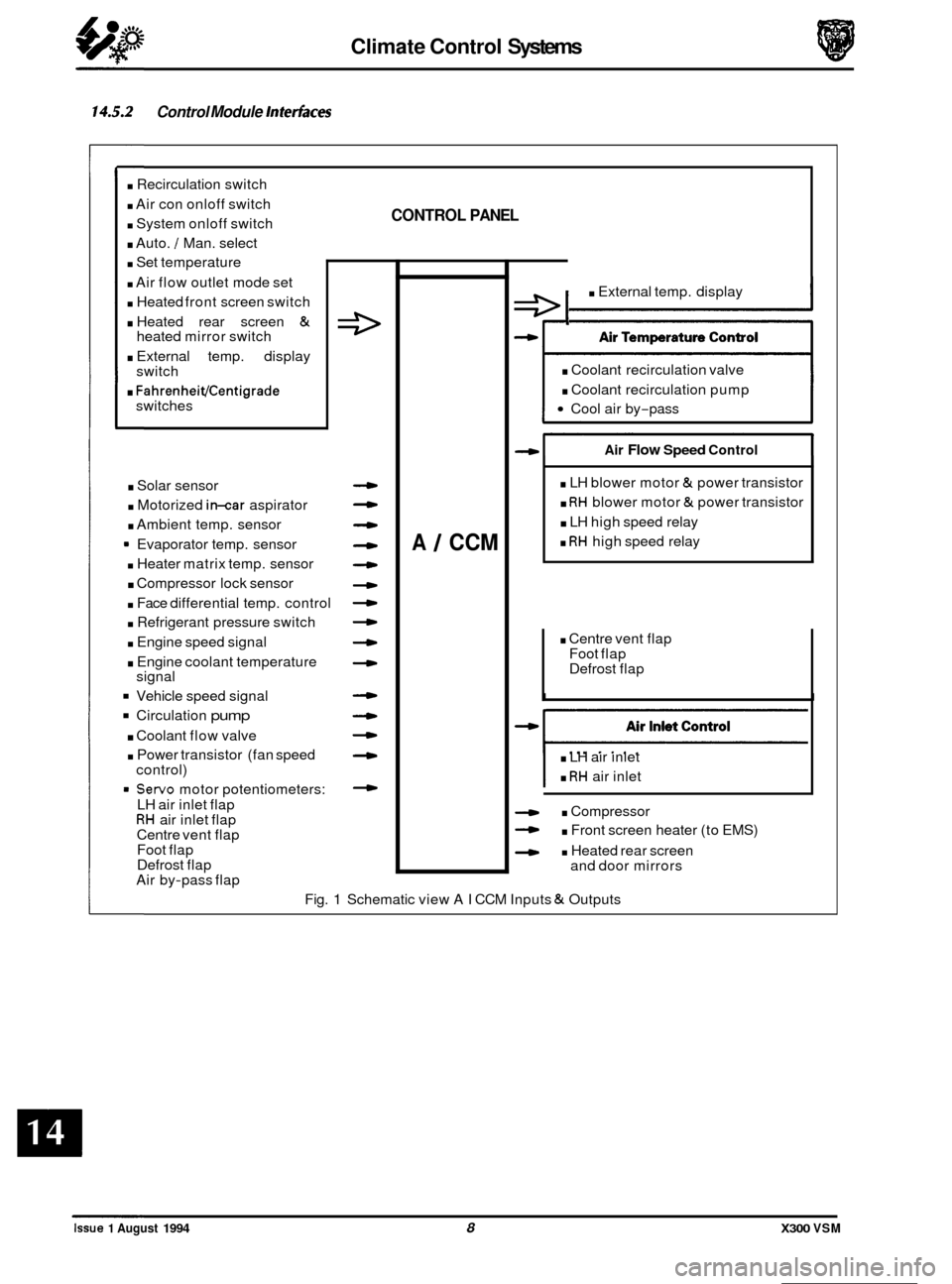

14.5.2 Control Module Interfaces

. Recirculation switch

. Air con onloff switch

. System onloff switch

. Auto. / Man. select

. Set temperature

. Air flow outlet mode set

. Heated front screen switch

. Heated rear screen &

. External temp. display

. FahrenheiVCentigrade

heated mirror switch

switch

switches

. Solar sensor

. Motorized in-car aspirator

. Ambient temp. sensor

9 Evaporator temp. sensor

. Heater matrix temp. sensor

. Compressor lock sensor

. Face differential temp. control

. Refrigerant pressure switch

. Engine speed signal

. Engine coolant temperature

Vehicle speed signal

Circulation pump

. Coolant flow valve

. Power transistor (fan speed

= Servo motor potentiometers:

signal

control)

LH air inlet flap

RH air inlet flap

Centre vent flap

Foot flap

Defrost flap

Air by

-pass flap

CONTROL PANEL

4

-

4

4

4

4

4

4

A 1 CCM

e I . External temp. display

. Coolant recirculation valve

. Coolant recirculation pump

Cool air by-pass

Air Flow Speed Control

. LH blower motor & power transistor

. RH blower motor & power transistor

. LH high speed relay

. RH high speed relay

. LH air inlet

. RH air inlet

. Compressor

- . Front screen heater (to EMS)

- . Heated rear screen

and door mirrors

Fig.

1 Schematic view AI CCM Inputs & Outputs

0

0

0

0

Issue 1 August 1994 8 X300 VSM

Page 322 of 521

Climate Control Systems

CONTROL MODULE FAULT & CONDITION SELF-ANALYSIS

0 14.6 14.6.1 System Health

The climate control system has a 'self-test' facility, accessible from the control panel. The self test sequence has two

basic modes:

0 System error information is stored in the A/CCM up to a maximum of five faults. Should a fault occur there will

be an audible 'beep' and the message 'Er' will be displayed on the control panel LCD for approximately five (5)

seconds after ignition on. Please note that this will happen only once in any ignition switch cycle. The error

source may be accessed by the procedure described in 'Self Test System Diagnosis', this section.

0 Panel communication check may be initiated by following the instruction in 'Self Test System Diagnosis', this

section.

Nsfe: Displayed error codes are NOT directly related to Jaguar Diagnostic Equipment (JDE) but more detailed fault

related information may be accessed using Portable Diagnostic Unit (PDU).

14.6.2 System Protection

Power to the compressor clutch may be cut should either the engine management or air conditioning control systems

detect certain conditions; these conditions may be caused by Fault or Demand and can be classified thus:

0 Engine coolant overheat,

0 Refrigerant excessive pressure.

0 Refrigerant, insufficient pressure or low charge weight.

0 Speed differential between compressor and crankshaft caused by belt slippage or compressor seizure (indi-

cated by A/C state lamp flashing once per second) - 12 cylinder engine only. This feature, 'lock sensing' is fully

explained

in the EDM.

Demand

0 Engine maximum power requirement

0 Electrical system drain at engine idle.

X300 VSM 9 Issue 1 August 1994

Page 325 of 521

Climate Control Systems

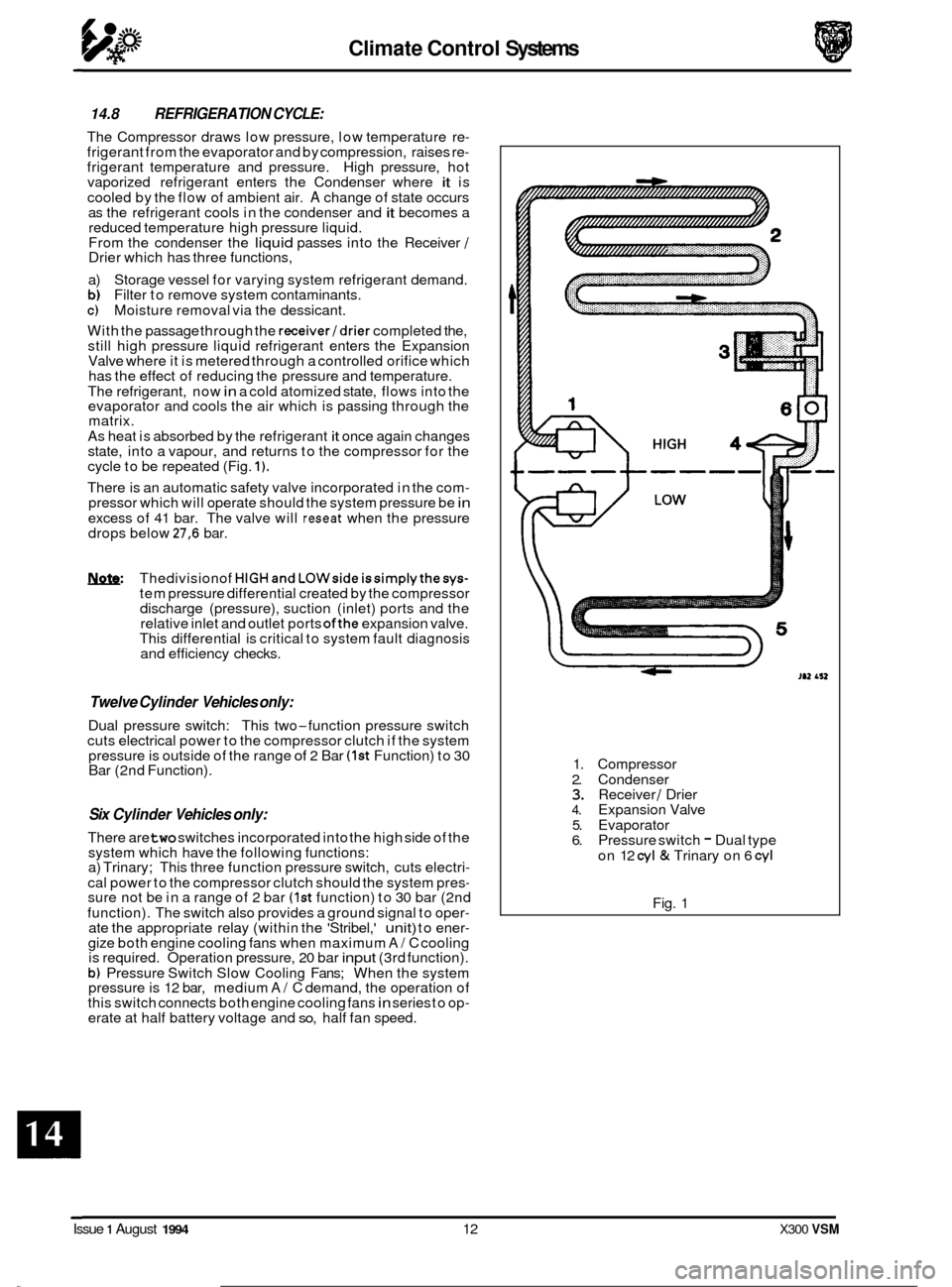

14.8 REFRIGERATION CYCLE:

The Compressor draws low pressure, low temperature re- frigerant from the evaporator and by compression, raises re- frigerant temperature and pressure. High pressure, hot

vaporized refrigerant enters the Condenser where it is

cooled by the flow of ambient air.

A change of state occurs

as the refrigerant cools in the condenser and it becomes a

reduced temperature high pressure liquid.

From the condenser the

liquid passes into the Receiver / Drier which has three functions,

a) Storage vessel for varying system refrigerant demand.

b) Filter to remove system contaminants. c) Moisture removal via the dessicant.

With the passage through the

receiver/drier completed the,

still high pressure liquid refrigerant enters the Expansion

Valve where it is metered through a controlled orifice which

has the effect of reducing the pressure and temperature.

The refrigerant, now

in a cold atomized state, flows into the

evaporator and cools the air which is passing through the

matrix.

As heat is absorbed by the refrigerant

it once again changes

state, into a vapour, and returns to the compressor for the

cycle to be repeated (Fig.

1).

There is an automatic safety valve incorporated in the com- pressor which will operate should the system pressure be in

excess of 41 bar. The valve will reseat when the pressure

drops below 27,6 bar.

W Thedivisionof HIGHandLOWsideissimplythesys- tem pressure differential created by the compressor

discharge (pressure), suction (inlet) ports and the

relative inlet and outlet ports

ofthe expansion valve.

This differential is critical to system fault diagnosis

and efficiency checks.

Twelve Cylinder Vehicles only:

Dual pressure switch: This two-function pressure switch

cuts electrical power to the compressor clutch if the system

pressure is outside of the range

of 2 Bar (1st Function) to 30

Bar (2nd Function).

Six Cylinder Vehicles only:

There are two switches incorporated into the high side of the

system which have the following functions:

a) Trinary; This three function pressure switch, cuts electri

-

cal power to the compressor clutch should the system pres- sure not be in a range of 2 bar (1st function) to 30 bar (2nd

function). The switch also provides a ground signal to oper

- ate the appropriate relay (within the 'Stribel,' unit) to ener- gize both engine cooling fans when maximum A/ C cooling

is required. Operation pressure, 20 bar input (3rd function).

b) Pressure Switch Slow Cooling Fans; When the system

pressure is 12 bar, medium A/ C demand, the operation of

this switch connects both engine cooling fans in series to op- erate at half battery voltage and so, half fan speed. 1.

Compressor

2. Condenser

3. Receiver / Drier 4. Expansion Valve

5. Evaporator

6. Pressure switch - Dual type

on 12

cyl & Trinary on 6 cyl

Fig. 1

0

0

Issue 1 August 1994 12 X300 VSM

Page 437 of 521

Body Systems & Body Repair

Location

Centre line of the front crossmember rear mounting, at the

main floor

RH longitudinal

A4.2.2.1 Datum location, Example

The FRONT MASTER DATUM (front crossmember rear mounting at the inner face ofthe main floor RH longitudi- nal) is nominally 359,5mm to the right-hand side of the body center line. The LH side front datum is measured 717,0/ 721,Omm from the RH. Please refer to the illustration on the following page.

Expressed as

a true position in three planes, the front master datum is:

Position

X 300,O

Y 359.5 Z -50.0

0

Datum

Front Master Datum

Plan

A4.2.2.2 Key, Plan View

Please refer to the illustration on the opposite page.

Key Location

1

2

3

4

5 Driveshaft centre bearing fixings

6

7

8

9

10 Front

face body

- bumper strut / mounting point

Rearmost hole, Vee

-mount to crush tube

Front Master Datum Plan, centre line

of the front crossmember rear mounting at the main floor RH longi-

tudinal

Rearmost hole, transmission mounting

at the main floor RH longitudinal

Rear Master Datum Plan, rear longitudinal

Tapped boss, rear suspension

'A' frame mounting bush

Rear suspension spring

-pan damper mounting

Rear suspension differential strut mounting

Rear face body

- bumper strut / mounting point

X300 VSM Issue 1 August 1994 10

Page 439 of 521

E 12

Rear face bodv - bumDer strut / mountina Doint

Body Systems

I

& Body

side vww

the illustration on the opposite page.

Repair

Location

Front face body - bumper strut / mounting point

Front Master Datum Vertical. centre line of the front crossmember rear mountina

Front

face body - bumper strut / mounting point

Front Master Datum Vertical, centre line of the front crossmember rear mounting

Transmission mountings

at the main floor longitudinal

Driveshaft centre bearing fixings

Rear Master Datum

Vertical, rear longitudinal

Tapped boss, rear suspension

'A' frame mounting bush

Rear suspension spring

-pan damper mounting

Rear suspension differential strut mounting

Rear face body

- bumper strut / mounting point

Transmission

mountings

at the main floor longitudinal

Driveshaft centre bearing fixings

Rear Master Datum

Vertical, rear longitudinal

Tapped boss, rear suspension

'A' frame mounting bush

Rear suspension spring

-pan damper mounting

Rear

susoension differential strut mounting

Wheel centre to

bummr cover face I

Wheel base I

Wheel centre to bumper cover face

Body Systems & Body Repair

A4.2.2.3 Key, Side Vww

Please refer to the illustration on the opposite page.

0

0

0

X300 VSM Issue 1 August 1994 12