heater JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 68 of 521

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL

ALL THE STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT WITH THE ENGINE HOT, PROTECT THE HANDS AGAINST CONTACT

WITH HOT COOLANT.

WARNING

: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE ENGINE DRIVEN RADI- ATOR COOLING FAN WHEN THE ENGINE IS RUNNING.

4.2.3.2 Working Practices

Whenfilling thesystem with coolant,ensurethatthevehicle isstanding on a level surfaceand thatthecoolant is poured

in slowly so that airlocks are not introduced into the system. Airlocks can seriously affect the operation of the climate

control system and can cause damage to the heater circuit pump.

Hose clips should always be positioned

so that there is proper access for tightening and that the clip does not foul or

interfere with the operation of any components.

4.2.3 SERVICE PROCEDURES

4.2.3.1 Safety Precautions

The anti-freeze specified in Appendix A1 must be used wherever possible. It is designed to afford the maximum cor- rosion protection to all metals found in the engine cooling system, as well as having the frost protection properties

necessary during the winter months. Should it not be available, then anti-freeze conforming to Ford Motor Company

specification

ESBM97B49-A may be used. To provide optimum temperature and corrosion protection, the specified

anti-freeze concentration must always be used. Once coolant has been drained from the system, it must be discarded

and not reused. Anti-freeze is harmful to the environment. Always dispose of used coolant safely and never pour it down a drain connected to the public sewer.

CAUTION: Never fill or topup the system with water only.

CAUTION

: Anti-freeze is harmful to paintwork. Coolant spillages must be wiped up immediately and the affected

area washed to remove all traces of coolant.

CAUTION: To prevent the possibility of damage to the heater circuit

pump, the pump should be electrically isolated if the ignition has to be turned ON while the cooling system is drained.

The drive belt must always be tensioned to the specified value and the tension checked at the correct point on the belt.

This information is given in Sub-section IV in the preliminary pages.

When tightening components, the torque figures given in Sub

-section II in the preliminary pages should always be

used for the fastenings listed.

When fitting a replacement thermostat, ensure that the jiggle-pin is to the top of the thermostat housing.

4.2.3.3 Coolant Change

The coolant must be changed at intervals of four years. The system should be drained from the radiator drain plug,

flushed and filled with fresh coolant. Flushing should be carried out thoroughly to remove all the old coolant from the

engine and heater matrix. (The heatervalve isopen with the ignition OFF). AfterfilIing,checkthecoolant concentration

with a hydrometer. For specified anti-freeze and coolant concentration, see in Appendix Al.

X300 VSM 3 Issue 1 August 1994

Page 69 of 521

€3 Cooling System (V12)

4.2.4 DRAIN AND FILL PROCEDURES

4.2.4.1 Radiator, Drain

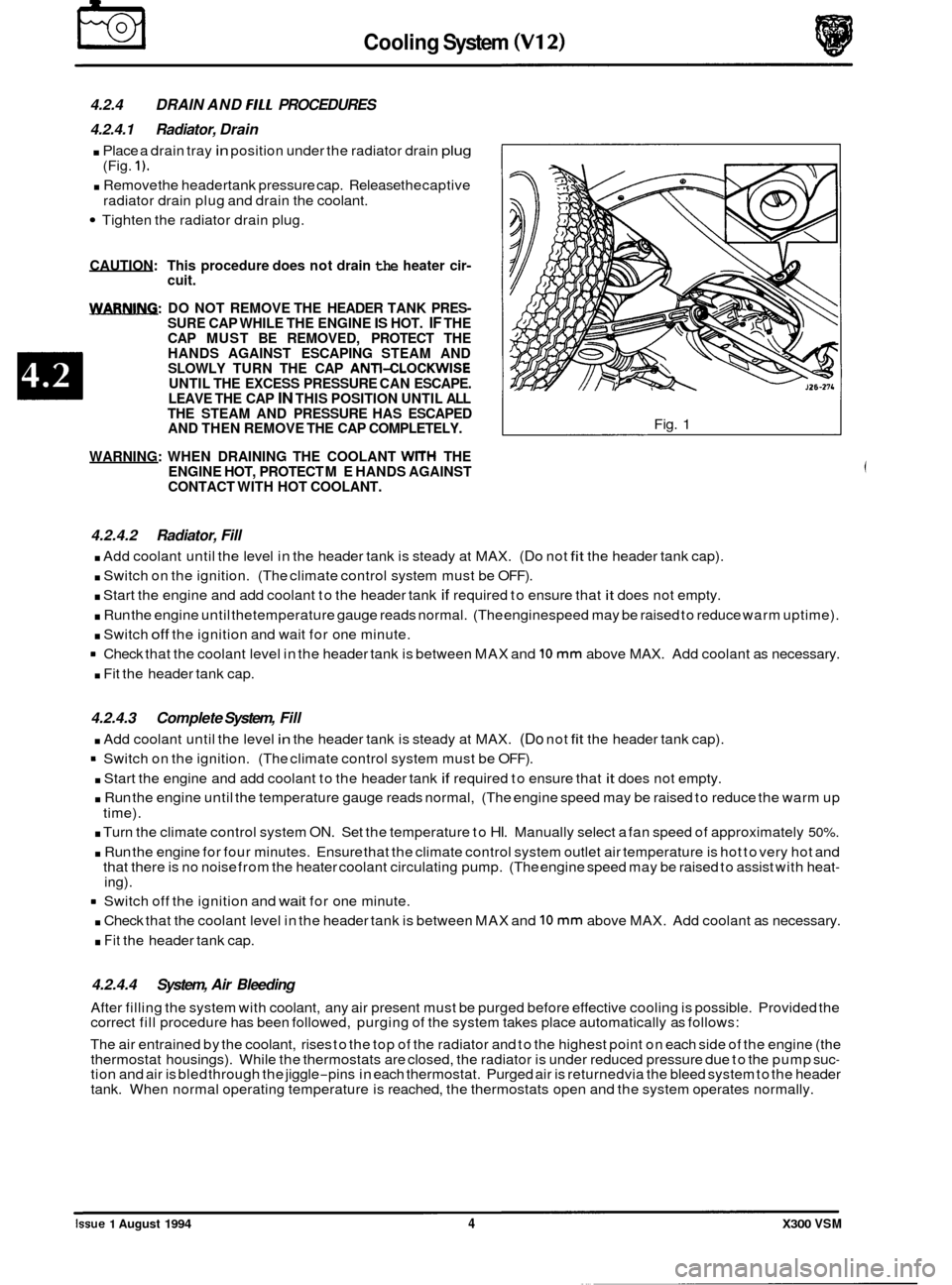

. Place a drain tray in position under the radiator drain plug

. Remove the headertank pressure cap. Release thecaptive

Tighten the radiator drain plug.

(Fig.

1).

radiator drain

plug and drain the coolant.

CAUTION: This procedure does not drain the heater cir- cuit.

m: DO NOT REMOVE THE HEADER TANK PRES- SURE CAP WHILE THE ENGINE IS HOT. IF THE

CAP MUST BE REMOVED, PROTECT THE

HANDS AGAINST ESCAPING STEAM AND

SLOWLY TURN THE CAP

ANTI-CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE.

LEAVE THE CAP IN THIS POSITION UNTIL ALL

THE STEAM AND PRESSURE HAS ESCAPED

AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT

WITH THE

ENGINE HOT, PROTECT ME HANDS AGAINST

CONTACT WITH HOT COOLANT.

Fig. 1

4.2.4.2 Radiator, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

. Switch on the ignition. (The climate control system must be OFF).

. Start the engine and add coolant to the header tank if required to ensure that it does not empty.

. Run the engine until thetemperature gauge reads normal. (The enginespeed may be raised to reduce warm uptime).

. Switch off the ignition and wait for one minute.

Check that the coolant level in the header tank is between MAX and

10 mm above MAX. Add coolant as necessary.

. Fit the header tank cap.

4.2.4.3 Complete System, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

= Switch on the ignition. (The climate control system must be OFF).

. Start the engine and add coolant to the header tank if required to ensure that it does not empty.

. Run the engine until the temperature gauge reads normal, (The engine speed may be raised to reduce the warm up

. Turn the climate control system ON. Set the temperature to HI. Manually select a fan speed of approximately 50%.

. Run the engine for four minutes. Ensure that the climate control system outlet air temperature is hot to very hot and

that there is no noise from the heater coolant circulating pump. (The engine speed may be raised to assist with heat- ing).

time).

8 Switch

off the ignition and wait for one minute.

. Check that the coolant level in the header tank is between MAX and 10 mm above MAX. Add coolant as necessary.

. Fit the header tank cap.

4.2.4.4 System, Air Bleeding

After filling the system with coolant, any air present must be purged before effective cooling is possible. Provided the

correct fill procedure has been followed, purging of the system takes place automatically as follows:

The air entrained by the coolant, rises to the top of the radiator and to the highest point on each side of the engine (the

thermostat housings). While the thermostats are closed, the radiator is under reduced pressure due to the pump suc

- tion and air is bled through the jiggle-pins in each thermostat. Purged air is returnedvia the bleed system to the header

tank. When normal operating temperature is reached, the thermostats open and the system operates normally. ~~

Issue 1 August 1994 4 X300 VSM

Page 85 of 521

Fuel, Emission Control & Engine Management (AJ16)

5.1.8

SRO

SRO IDLE

SPEED CONTROL VALVE/ GASKETS (NORMALLY ASPIRATED), RENEW

18.30.74 IDLE SPEED CONTROL VALVE

18.30.77 IDLE SPEED CONTROL VALVE GASKET

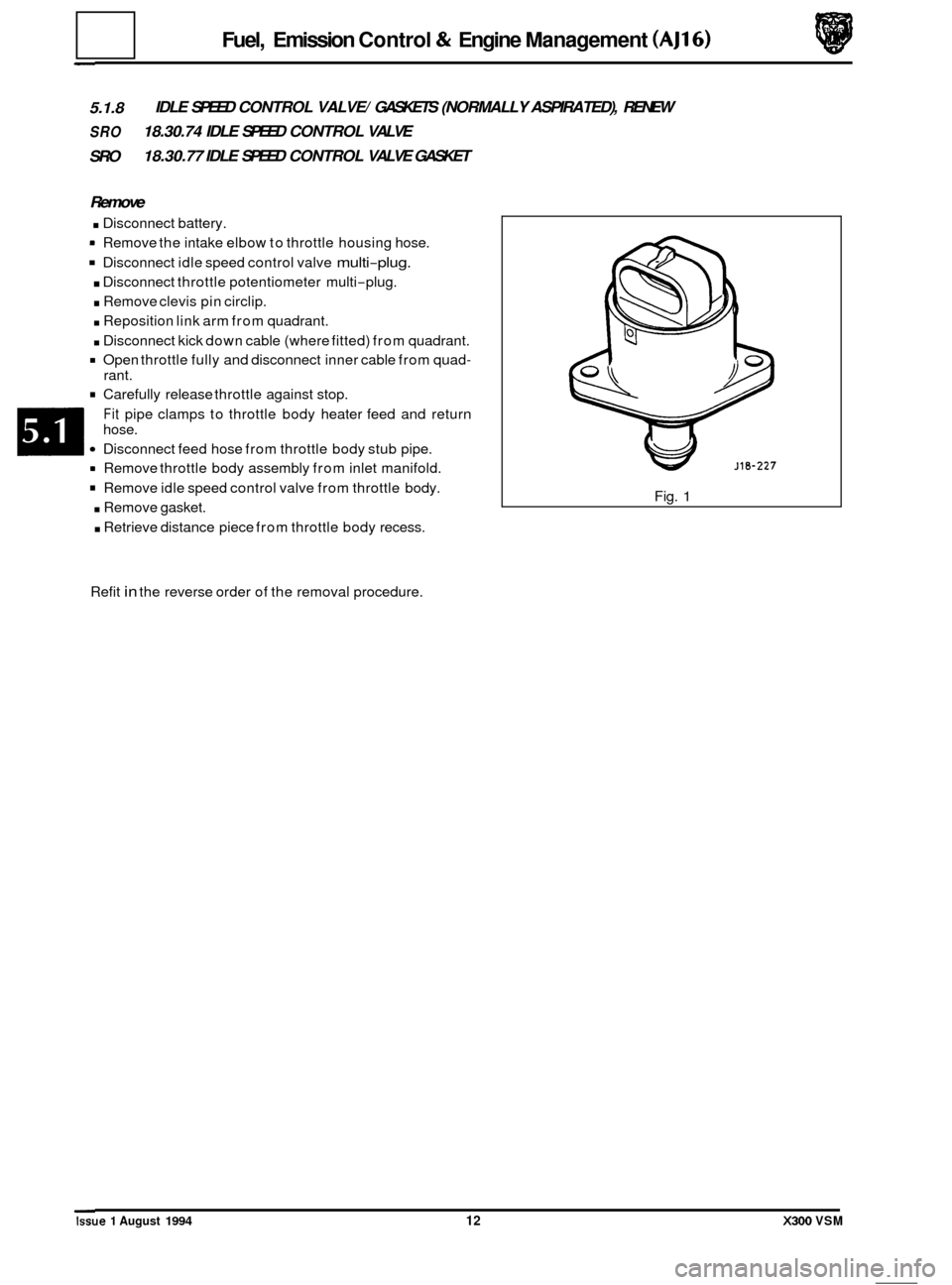

Remove

. Disconnect battery.

9 Remove the intake elbow to throttle housing hose.

Disconnect idle speed control valve multi-plug.

. Disconnect throttle potentiometer multi-plug.

. Remove clevis pin circlip.

. Reposition link arm from quadrant.

. Disconnect kick down cable (where fitted) from quadrant.

Open throttle fully and disconnect inner cable from quad-

Carefully release throttle against stop.

rant.

Fit pipe clamps

to throttle body heater feed and return

hose.

Disconnect feed hose from throttle body stub pipe.

rn Remove throttle body assembly from inlet manifold.

Remove idle speed control valve from throttle body.

. Remove gasket.

. Retrieve distance piece from throttle body recess. Fig.

1

Refit in the

reverse order of the removal procedure.

0

0

0

0

Issue 1 August 1994 12 X300 VSM

Page 299 of 521

Body Components & Trim #ib

13.6 GLAZING (FIXED)

13.6.1 Glazing (Fixed), Description

The fixed glazing comprises internal and external driving mirrors, sunvisor mirror and rear quarter light glass; see Ap- pendix A4, Body Components and Trim for details of the windscreen and rear screen glazing.

13.6.2 Interior Mirror, Renew

. Disconnect vehicle battery ground lead.

. Rotate mirror stem approximately one quarter turn clock- wise to release stem from spring contact on windscreen

boss.

. Disconnect mirror harness.

To refit, locate mirror stem base on windscreen boss with

stem parallel to top of windscreen, ie one quarter turn dis- placed from normal position; apply firmly over boss and

turn anti-clockwise to lock stem on windscreen boss.

. Reconnect mirror harness.

13.6.3

. Disconnect vehicle battery ground lead.

. Lower the sunvisor.

. Raise the sunvisor cover and remove the lenses.

Remove the screws securing the mirror to the sunvisor

and remove the mirror.

. To refit, carry out reversal of the above procedure, taking

care to correctly locate switch and bulb holders priortose-

curing the mirror.

Sun Visor Mirror Assembly, Renew

13.6.4 Exterior Mirror, Renew

= Disconnect vehicle battery ground lead.

Remove door trim pad veneer panel and upper trim pad.

9 Remove the cheater by sliding off.

. Remove mirror fixings.

. Disconnect the mirror harness block connectors.

. Remove the mirror securing screws and remove the mir-

ror assembly.

. To refit, carry out reversal of the above procedure.

13.6.5 Exterior Mirror Glass, Renew

. Switch ignition on and position the mirrorto inboard posi-

. Disconnect vehicle battery ground lead.

. Slide assembly outboard and pull outwards.

. To refit, carry out reversal of the above procedure.

tion.

Issue 1 August 1994 44 X300 VSM

Page 311 of 521

Climate Control Systems

Illustration 1 JaguarNumber I Deription Not-

not i II ustrated

11. TORQUE TIGHTEN1 NG SPEC1 FICATIONS

Recovery 1 Recycling 1 Recharging

station See

standards

fixing

Blower assembly to body

Condenser to receiver

1 drier (tube nut)

lightening Torque

I (Nm)

4-7

14

- 18

Hoses to evaporator plate

Liquid line to receiver

1 drier (tube nut)

I Discharge hose to condenser (tube nut) I 22 - 28 I

7 - 10

14- 18

I Heater 1 cooler case to body I 5-7 I

I Hoses to compressor I 7-10 I

I Mountina strut to heater / cooler case I 5-7 I

X300 VSM Issue 1 August 1994 ii

Page 316 of 521

Climate Control Systems

CL /MATE CONTROL SYSTEM 0 14*2 14.2.1 Description

The climate control system in the 1995 model year saloon has a centre mounted heater / cooler unit with separate

blower assemblies, one LH and one RH. Heating temperature control is effected by means of a coolant flow valve and

circulation pump.

For models fitted with air conditioning, cooling is provide by passing air through the evaporator, which is situated im

- mediately behind the heater / cooler case inlet ducts.

Electric motors with integral potentiometers are used to position

all flaps.

W: There are no vacuum operated components in the system.

14.2.2 Features

o Self diagnostic control system with error codes.

0 Actuator 'self check'.

0 Display element check.

m: These features will be helpful for initial trouble shooting and where Jaguar Diagnostic Equipment (JDE) is not

available.

0 'Soft touch' logic controls. 0

0 Serial link from panel to control module (NCCM).

0 LCD display for temperature, status and fan speed.

0 Variable fan speed, whether in automatic or manual mode.

0 Manual air flow distribution over-rides.

0 Compensated air flow with regard to vehicle speed.

0 Rear footwell outlets.

0 Rear face outlets.

0 Scavenge system closed circuit temperature control.

0 Heated front screen (where fitted).

x300 VSM 3

Page 319 of 521

Climate Control Systems

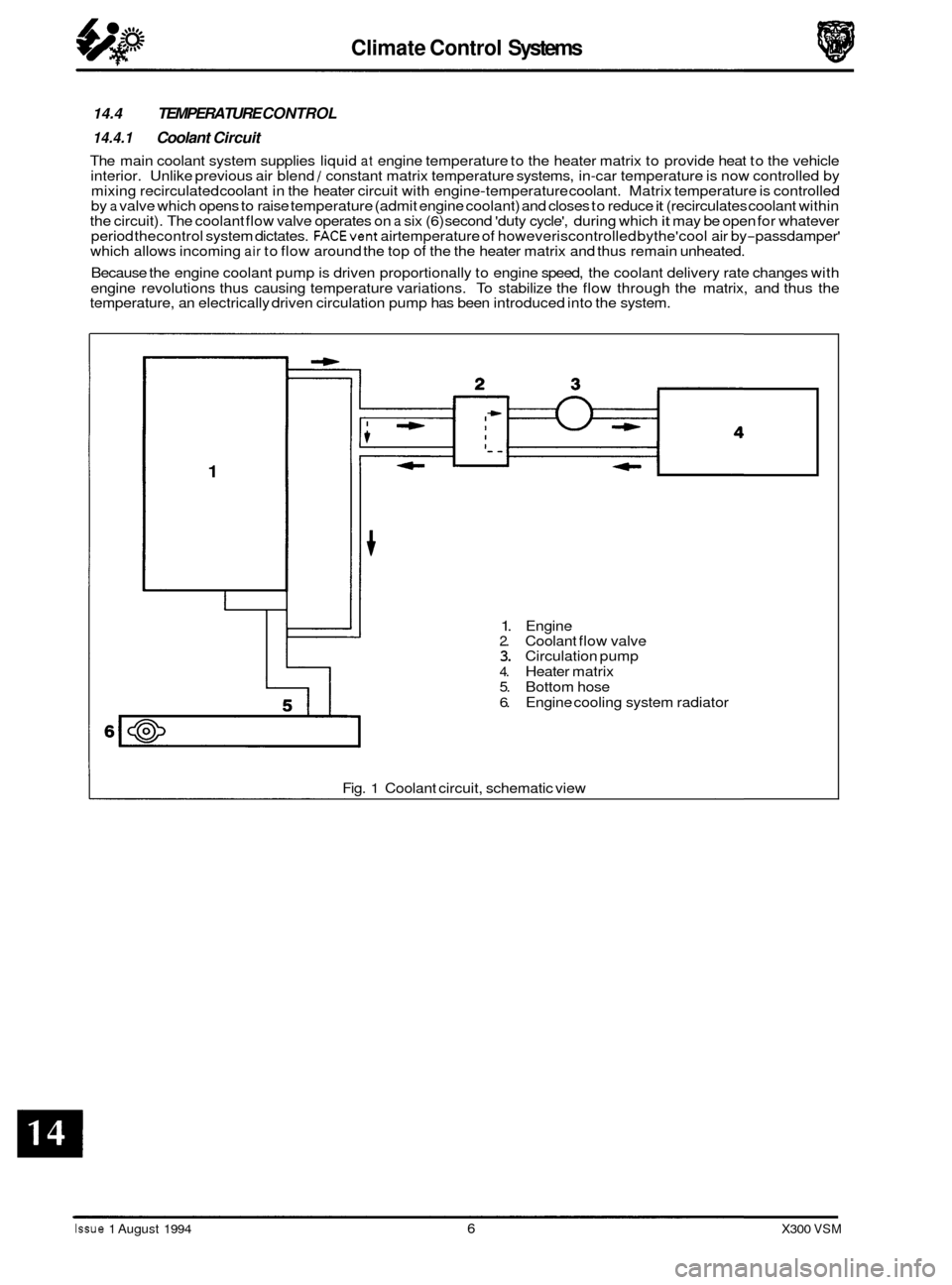

14.4 TEMPERATURE CONTROL

14.4.1 Coolant Circuit

The main coolant system supplies liquid at engine temperature to the heater matrix to provide heat to the vehicle

interior. Unlike previous air blend / constant matrix temperature systems, in-car temperature is now controlled by

mixing recirculated coolant in the heater circuit with engine-temperature coolant. Matrix temperature is controlled

by a valve which opens to raise temperature (admit engine coolant) and closes to reduce it (recirculates coolant within

the circuit). The coolant flow valve operates on a six (6) second 'duty cycle', during which it may be open for whatever

period thecontrol system dictates. FACEvent airtemperature of howeveriscontrolled bythe'cool air by-passdamper'

which allows incoming air to flow around the top of the the heater matrix and thus remain unheated.

Because the engine coolant pump is driven proportionally to engine speed, the coolant delivery rate changes with

engine revolutions thus causing temperature variations. To stabilize the flow through the matrix, and thus the

temperature, an electrically driven circulation pump has been introduced into the system.

1

1. Engine 2. Coolant flow valve 3. Circulation pump

4. Heater matrix

5. Bottom hose

6. Engine cooling system radiator

Fig.

1 Coolant circuit, schematic view

Issue 1 August 1994 6 X300 VSM

Page 320 of 521

Climate Control Systems

Manual Inputs

Automatic inputs

outputs

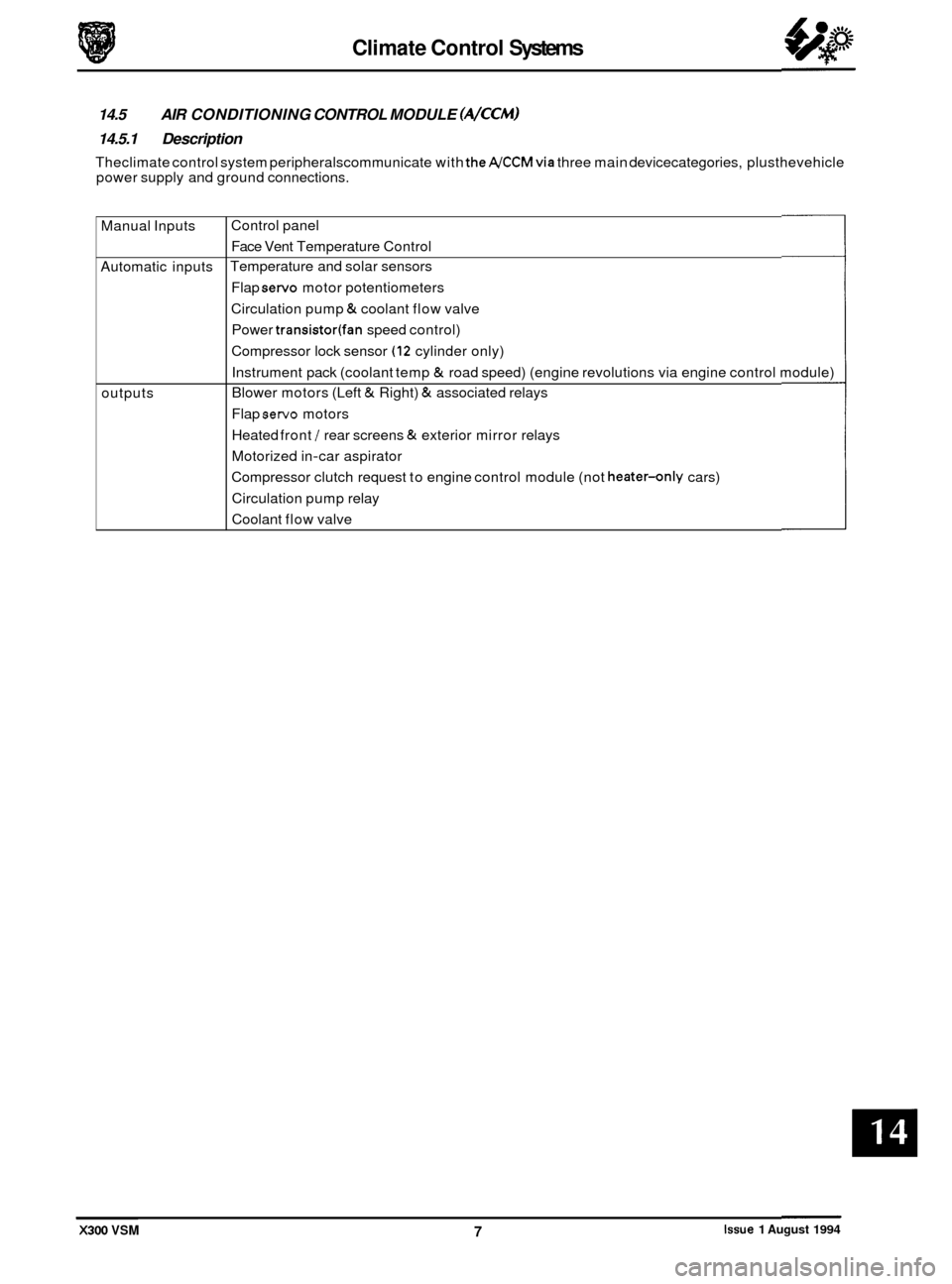

14.5 AIR CONDITIONING CONTROL MODULE (A/CCM)

14.5.1 Description

Theclimate control system peripheralscommunicate with theA/CCMvia three main devicecategories, plusthevehicle

power supply and ground connections.

Control panel Face Vent Temperature Control

Temperature and solar sensors

Flap

servo motor potentiometers

Circulation pump

& coolant flow valve

Power

transistor(fan speed control)

Compressor lock sensor

(12 cylinder only)

Instrument pack (coolant temp

& road speed) (engine revolutions via engine control module)

Blower motors (Left

& Right) & associated relays

Flap

servo motors

Heated front

/ rear screens & exterior mirror relays

Motorized in

-car aspirator

Compressor clutch request to engine control module (not

heater-only cars)

Circulation pump relay

Coolant flow valve

X300 VSM Issue 1 August 1994 7

Page 321 of 521

Climate Control Systems

. Centre vent flap

Foot flap

Defrost flap

I I

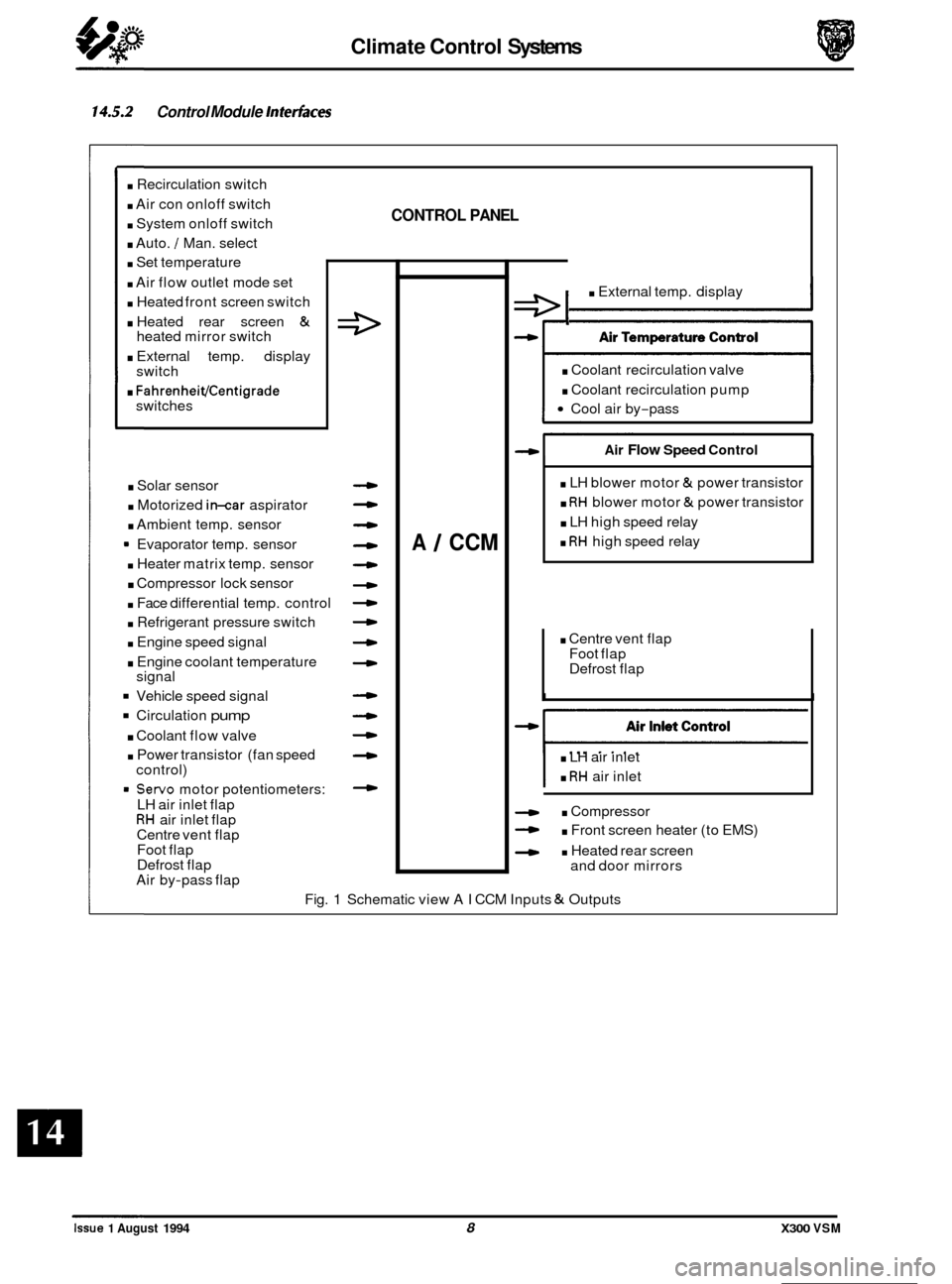

14.5.2 Control Module Interfaces

. Recirculation switch

. Air con onloff switch

. System onloff switch

. Auto. / Man. select

. Set temperature

. Air flow outlet mode set

. Heated front screen switch

. Heated rear screen &

. External temp. display

. FahrenheiVCentigrade

heated mirror switch

switch

switches

. Solar sensor

. Motorized in-car aspirator

. Ambient temp. sensor

9 Evaporator temp. sensor

. Heater matrix temp. sensor

. Compressor lock sensor

. Face differential temp. control

. Refrigerant pressure switch

. Engine speed signal

. Engine coolant temperature

Vehicle speed signal

Circulation pump

. Coolant flow valve

. Power transistor (fan speed

= Servo motor potentiometers:

signal

control)

LH air inlet flap

RH air inlet flap

Centre vent flap

Foot flap

Defrost flap

Air by

-pass flap

CONTROL PANEL

4

-

4

4

4

4

4

4

A 1 CCM

e I . External temp. display

. Coolant recirculation valve

. Coolant recirculation pump

Cool air by-pass

Air Flow Speed Control

. LH blower motor & power transistor

. RH blower motor & power transistor

. LH high speed relay

. RH high speed relay

. LH air inlet

. RH air inlet

. Compressor

- . Front screen heater (to EMS)

- . Heated rear screen

and door mirrors

Fig.

1 Schematic view AI CCM Inputs & Outputs

0

0

0

0

Issue 1 August 1994 8 X300 VSM

Page 323 of 521

Climate Control Systems

14.7 AIR DlSTRlBUTlON

(Refer to illustrations on this and next page)

Air is drawn from the plenum chamber into the heater/cooler case at the lower front right and left hand sides. All air must first pass through the evaporator (not fitted to heater only cars) and then through the heater matrix for in-car distribution.

When cooler air than that available from the other outlets is desired at the FACE vents, air by

-passes the matrix via

the 'cool air by-pass damper' within the range cold to hot.

The flaps for FOOT, COOL AIR, CENTRE VENT, RH & LH RECIRCULATION and DEFROST are electrically driven by indi- vidual motor / potentiometer units.

1. Face outlet

2. Defrost outlet

3. End-of-dash outlet 4. Cool air by-pass damper

5. Evaporator

6. Air in 7. Foot outlet (front)

8. Foot outlet (rear)

9. Rear face outlet 10. Heater matrix

J82-49L

Fig. 1

\d J82-495 \d J82-L96

(Solid arrow = Hot, Line arrow = Cold)

Fig. 2

0

0

0

0

Issue 1 August 1994 10 X300 VSM