power steering fluid JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 415 of 521

General Fitting Instructions

Pressordrifttheseal in tothefull depthofthe housing ifthe housing is shouldered,orflush withthefaceofthe housing

where no shoulder is provided.

Note: Careless fitting of oil seals, which can result in damage to the seal and sealing surfaces, accounts for most

cases of failure of seals. Care in fitting is essential

if good results are to be obtained.

A3.2.7 joints And joint Faces

Remove all traces of old jointing materials prior to reassembly. Inspect joint faces for scratches or burrs and remove

with a fine file or oilstone; do not allow swarf or dirt to enter tapped holes or enclosed parts. Blow out any pipes, chan- nels or crevices with compressed air, refitting or renewing any 0-rings or seals which have been displaced by the com- pressed air.

Always use the specified gaskets. Use jointing compound only when recommended, otherwise fit joints dry. When

jointing compound is used, apply in

a thin film to metal surfaces; take great care to prevent it from entering oilways, pipes or blind tapped holes.

A3.2.8

Before removing a hose from the brake or power steering systems, thoroughly clean the end fittings and the area sur- rounding them. Obtain blanking caps beforedetaching hosefittings,sothat portscan becovered to excludedirt. Clean

the hose externally and blow through with compressed air. Examine the hose carefully for cracks, separation of plies,

security of end fittings and external damage. Reject any hose found to be faulty. When refitting the hose, ensure that

no unnecessary bends are introduced and that the hose is not twisted before or during tightening of union nuts.

Do not store hydraulic fluid in an unsealed container because it will absorb water. Fluid in this condition would be dan- gerous to use due to a lowering of its boiling point. Do not allow hydraulic fluid to be contaminated with mineral oil,

or use a container which has previously contained mineral oil.

Do not re-use fluid bled from the system. Always use clean brake fluid, or a recommended alternative, to clean the

hydraulic components. Fit a blanking cap to the hydraulic union and

a plug to its mating socket, after removal from

the vehicle, to prevent ingress of dirt. Absolute cleanliness must be observed with hydraulic components at all times.

After any work has been performed on hydraulicsystems, inspect carefully for leaks underneath the car while a second

operator applies maximum pressure to the brakes (with the engine running) and operates the steering.

Hydraulic Flexible Pipes And Hoses

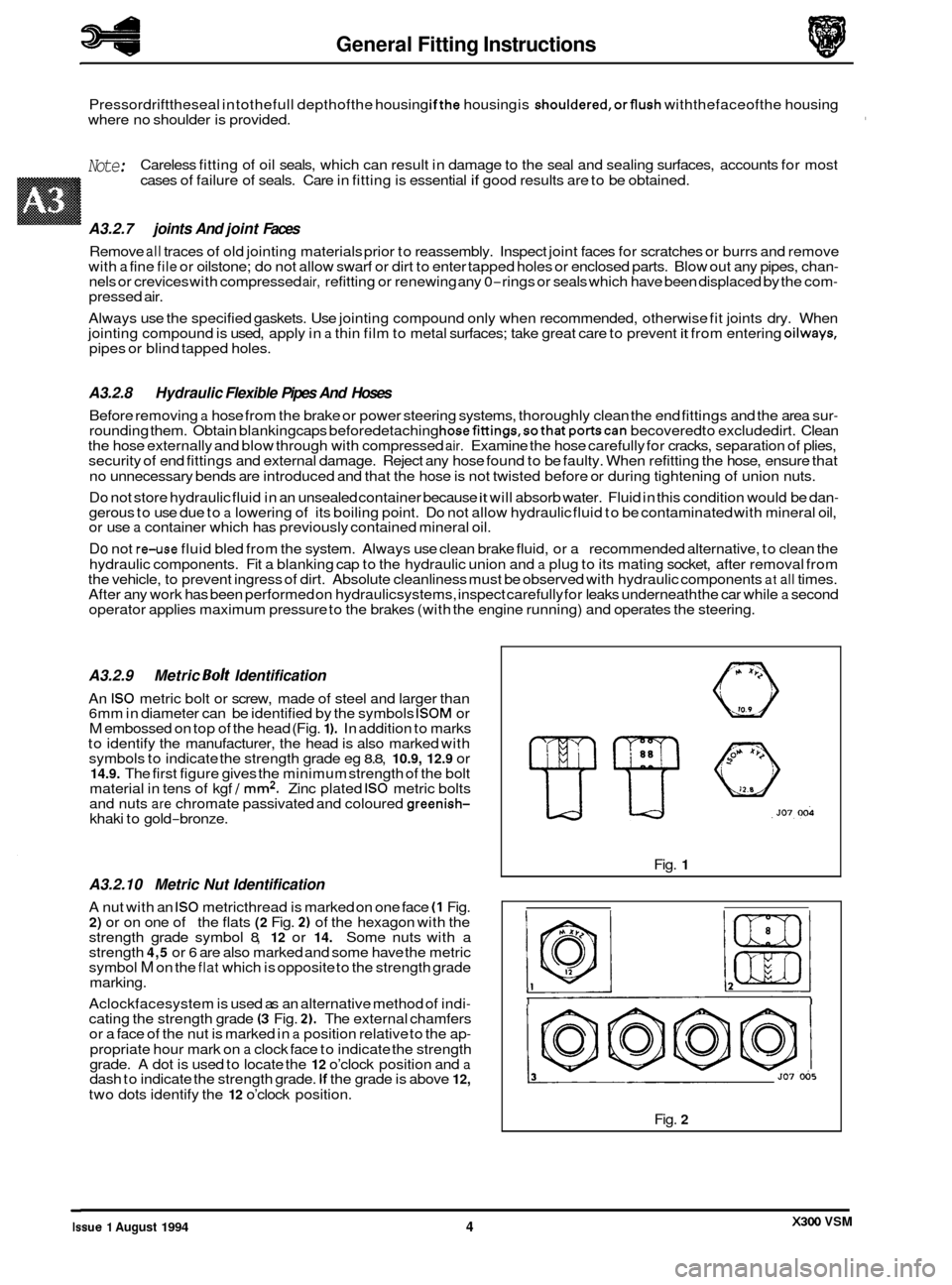

A3.2.9 Metric

Bolt Identification

An IS0 metric bolt or screw, made of steel and larger than

6mm in diameter can be identified by the symbols ISOM or M embossed on top of the head (Fig. 1 ). In addition to marks

to identify the manufacturer, the head is also marked with

symbols to indicate the strength grade eg

8.8, 10.9, 12.9 or 14.9. The first figure gives the minimum strength of the bolt

material in tens of kgf / mm2. Zinc plated IS0 metric bolts

and nuts are chromate passivated and coloured greenish- khaki to gold-bronze.

A3.2.10 Metric Nut Identification

A nut with an IS0 metricthread is marked on one face (1 Fig. 2) or on one of the flats (2 Fig. 2) of the hexagon with the

strength grade symbol 8, 12 or 14. Some nuts with a

strength 4,5 or 6 are also marked and some have the metric

symbol M on the flat which is opposite to the strength grade

marking.

Aclockfacesystem is used as an alternative method of indi

- cating the strength grade (3 Fig. 2). The external chamfers

or a face of the nut is marked in a position relative to the ap-

propriate hour mark on a clock face to indicate the strength

grade. A dot is used to locate the 12 o’clock position and a dash to indicate the strength grade. If the grade is above 12,

two dots identify the 12 o’clock position. Fig.

1

I I

Fig. 2

X300 VSM Issue 1 August 1994 4

Page 459 of 521

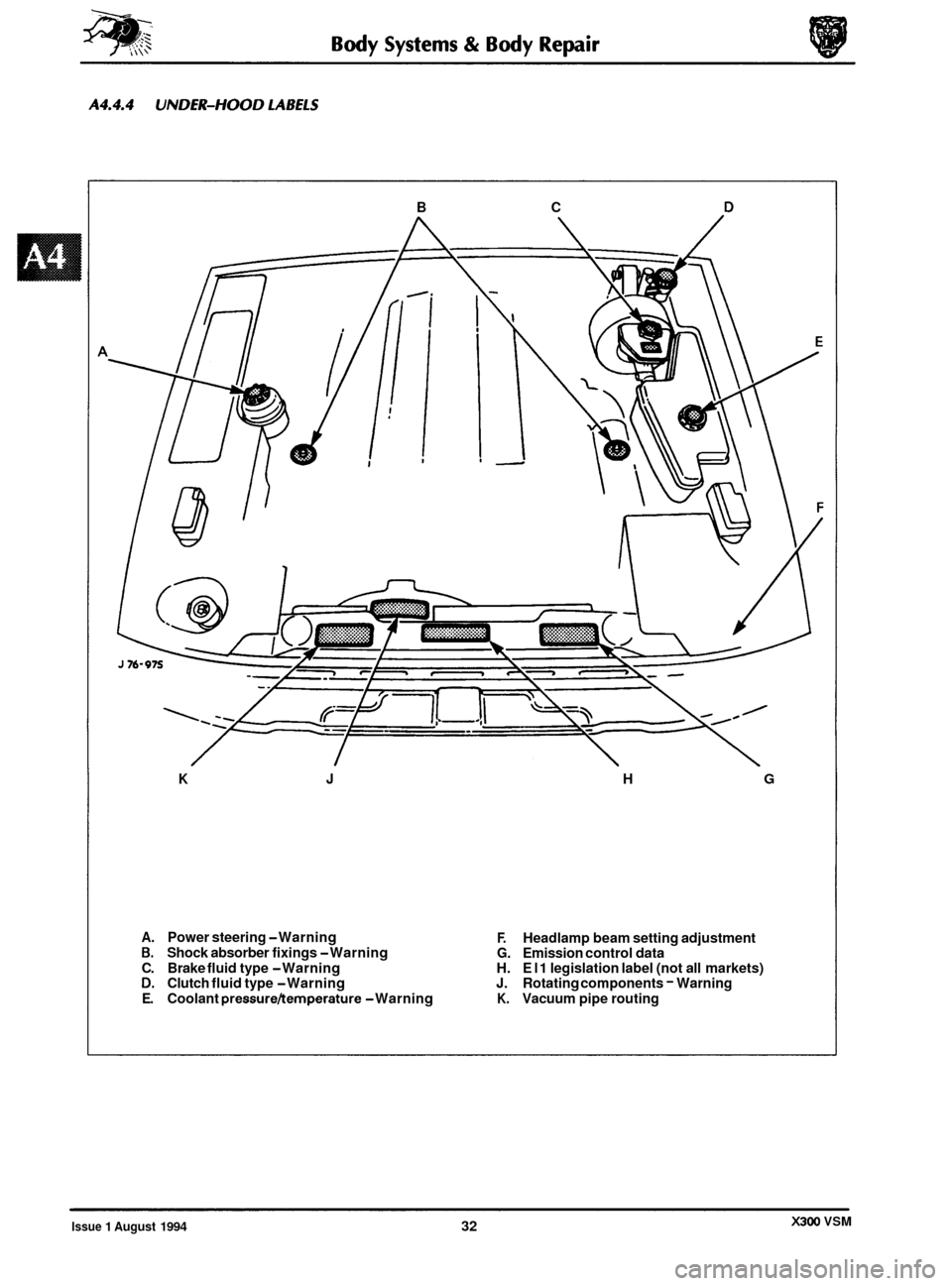

B C D

K J H G

A. Power steering -Warning F. Headlamp beam setting adjustment B. Shock absorber fixings -Warning G. Emission control data

C. Brake fluid type -Warning H. El 1 legislation label (not all markets) D. Clutch fluid type -Warning J. Rotating components - Warning

E. Coolant pressureltemperature -Warning K. Vacuum pipe routing

0

0

X300 VSM Issue 1 August 1994 32