JAGUAR XJ6 1994 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 201 of 521

@ Steering

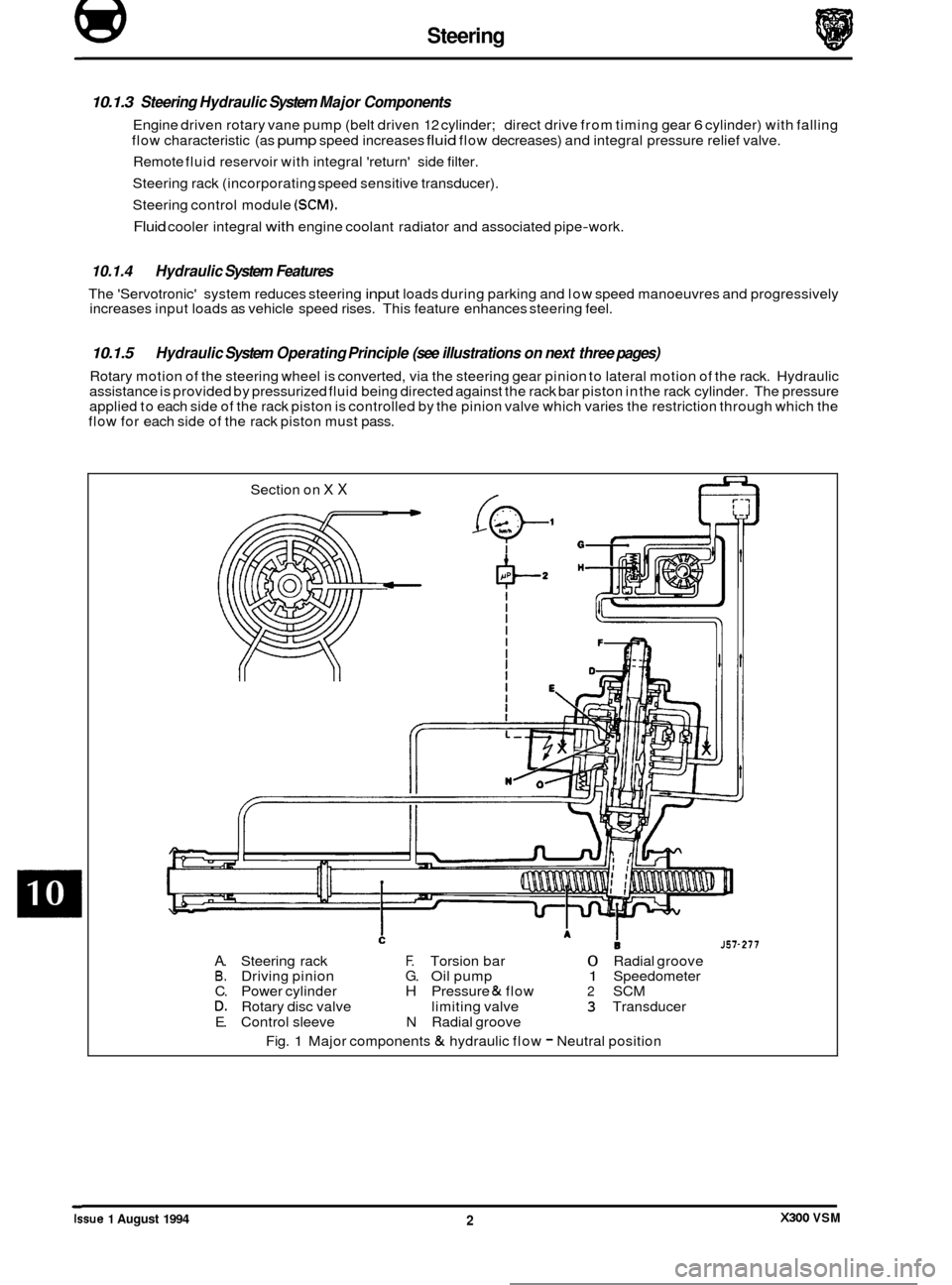

10.1.3 Steering Hydraulic System Major Components

Engine driven rotary vane pump (belt driven 12 cylinder; direct drive from timing gear 6 cylinder) with falling

flow characteristic (as

pump speed increases fluid flow decreases) and integral pressure relief valve.

Remote fluid reservoir with integral 'return' side filter.

Steering rack (incorporating speed sensitive transducer).

Steering control module

(SCM).

Fluid cooler integral with engine coolant radiator and associated pipe-work.

10.1.4 Hydraulic System Features

The 'Servotronic' system reduces steering input loads during parking and low speed manoeuvres and progressively

increases input loads as vehicle speed rises. This feature enhances steering feel.

10.1.5

Rotary motion of the steering wheel is converted, via the steering gear pinion to lateral motion of the rack. Hydraulic

assistance is provided by pressurized fluid being directed against the rack bar piston in the rack cylinder. The pressure

applied to each side of the rack piston is controlled by the pinion valve which varies the restriction through which the

flow for each side of the rack piston must pass.

Hydraulic System Operating Principle (see illustrations on next three pages)

Section on X X

J57-277

A. Steering rack F. Torsion bar 0 Radial groove B. Driving pinion G. Oil pump 1 Speedometer

C. Power cylinder H Pressure & flow 2 SCM D. Rotary disc valve limiting valve 3 Transducer

E. Control sleeve N Radial groove

Fig.

1 Major components & hydraulic flow - Neutral position ~

Issue 1 August 1994 X300 VSM 2

Page 202 of 521

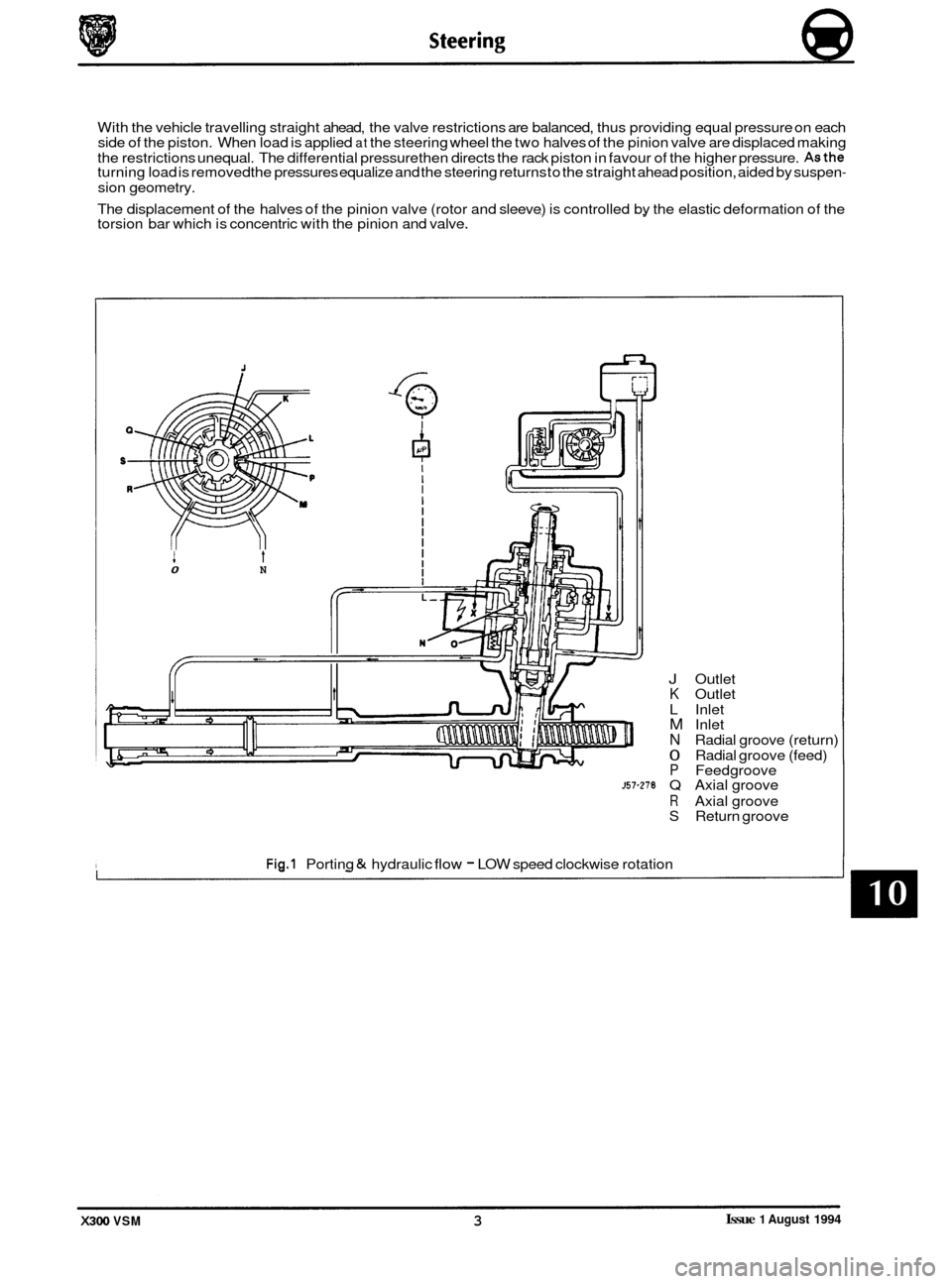

With the vehicle travelling straight ahead, the valve restrictions are balanced, thus providing equal pressure on each

side of the piston. When load is applied at the steering wheel the two halves of the pinion valve are displaced making

the restrictions unequal. The differential pressure then directs the rack piston in favour of the higher pressure.

Asthe turning load is removed the pressures equalize and the steering returns to the straight ahead position, aided by suspen-

sion geometry.

The displacement

of the halves of the pinion valve (rotor and sleeve) is controlled by the elastic deformation of the

torsion bar which is concentric with the pinion and valve.

0 N

J Outlet K Outlet

L Inlet

M Inlet

N Radial groove (return)

0 Radial groove (feed) P Feedgroove ~57-278 Q Axial groove

R Axial groove S Return groove

Fig.1 Porting & hydraulic flow - LOW speed clockwise rotation

Issue 1 August 1994 X300 VSM 3

Page 203 of 521

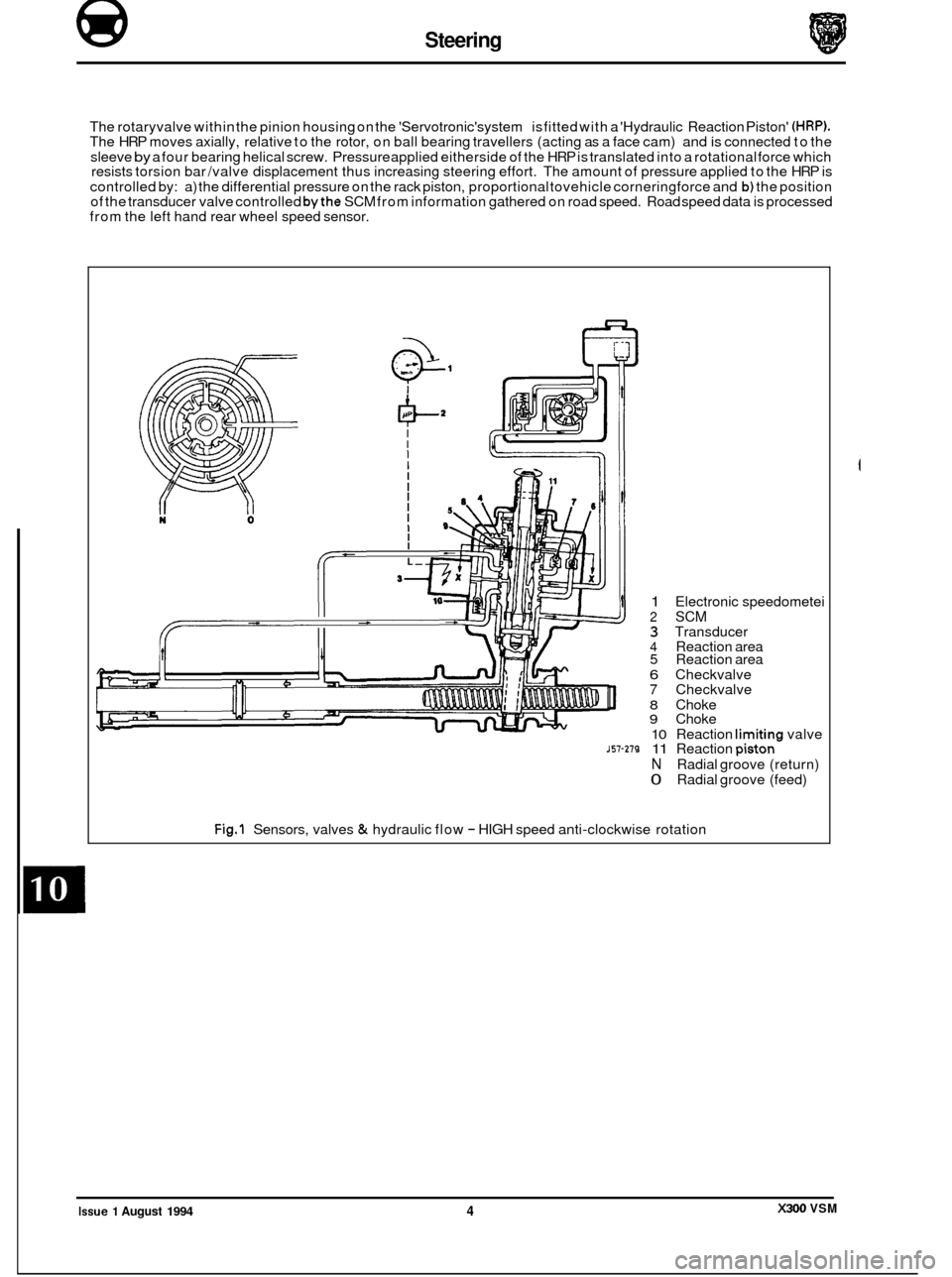

@ Steering

The rotaryvalve within the pinion housing on the 'Servotronic'system is fitted with a 'Hydraulic Reaction Piston' (HRP). The HRP moves axially, relative to the rotor, on ball bearing travellers (acting as a face cam) and is connected to the

sleeve

by a four bearing helical screw. Pressure applied eitherside of the HRP is translated into a rotational force which

resists torsion bar /valve displacement thus increasing steering effort. The amount of pressure applied to the HRP is

controlled by: a) the differential pressure on the rack piston, proportional tovehicle corneringforce and

b) the position

of the transducer valve controlled bythe SCM from information gathered on road speed. Road speed data is processed

from the left hand rear wheel speed sensor.

1 Electronic speedometei

2 SCM 3 Transducer 4 Reaction area 5 Reaction area

6 Checkvalve 7 Checkvalve

8 Choke 9 Choke

10 Reaction limitina valve 157-279 11 Reaction piston-

N Radial groove (return)

0 Radial groove (feed)

Fig.1 Sensors, valves & hydraulic flow - HIGH speed anti-clockwise rotation

X300 VSM Issue 1 August 1994 4

Page 204 of 521

10.2 SERVICE

PROCEDURES - SAFETY RELATED

10.2.1

Airbag

The electrically activated driver's side airbag is attached to the steering wheel hub and is fed by two wires from the

column stalk assembly. Electrical input to the column stalk assembly for the airbag is provided by a dedicated harness

which is encased in a yellow sleeve. A mechanism in the stalk assembly called the 'cable reel cassette' provides conti

-

nuity from the static column to the steering wheel. The 'cable reel cassette' is driven by a tang which locates in the

steering wheel. Because the connection is by wires, and the cassette assembly is only capable of approximately five

(5) full turns,

it is critically important that initial positioning is correct, see Section 15. It is equally important that fitting of the steering wheel, connection of the column, lower shaft and steering rackshould

ONLY be made with the steering rack in the center of its travel.

WARNING: DO NOT REMOVE THE STEERING COLUMN FROM THE VEHICLE WITH THE STEERING WHEEL AT- TACHED UNLESS THE STEERING IS CENTERED AND THE COLUMN LOCK IS ENGAGED. IF THE LOCK

BARREL

IS TO BE RENEWED, 'LOCK-WIRE THE ASSEMBLY TO PREVENT ROTATION. FAILURE TO OB- SERVE THIS AND CONSEQUENT DAMAGE TO THE 'CABLE REEL CASSETTE MAY RESULT IN AN INOP- ERATIVE AIRBAG SYSTEM. SEE LABEL ON STEERING WHEEL HUB.

10.3 SERVICE PROCEDURES

10.3.1 Working Practices

It is not recommended that either the steering rack or engine driven pump assemblies are repaired in any way other

than in accordance with the repair procedures described in this manual. The fluid reservoir and filter is a disposable

assembly and no attempt should be made to clean it internally. Genuine replacement units must be fitted following

routine service or diagnostic confirmation of the failure of any component.

The importance of cleanliness cannot be over

-stressed, not only with new parts but also those which may havefailed.

In-service contamination of the hydraulic system is a major cause of failures and may be avoided with good working

practices and care. All new units and pipes must be supplied with suitable blanks in every orifice. Should a unit not

have blanks fitted, do not use

it - return it to the supplier with an appropriate reason for your action.

To help the manufacturer diagnose problems and avoid post-removal contamination; provide full details of the fault

and plug all connections as soon as they are released. All suspect units must be returned to Jaguar Cars complete

with relevant documentation.

CAUTION: It is imperative that the power steering system does not become contaminated in any way. Always de- cant fluid from afresh sealed container and clean the area around the reservoir neck both before and after topping-up. Never return drained fluid to the system.

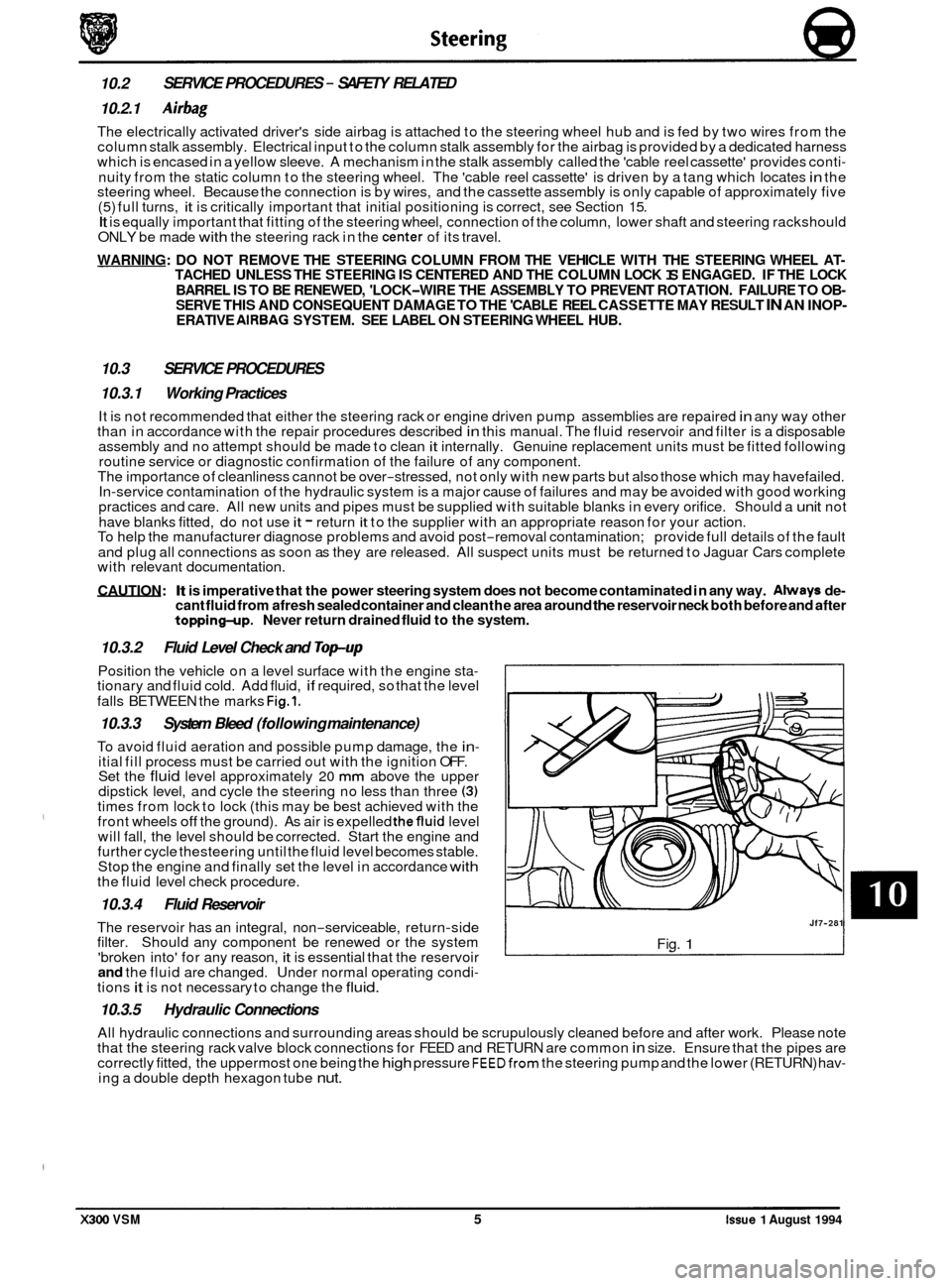

10.3.2

Position the vehicle on a level surface with the engine sta- tionary and fluid cold. Add fluid, if required, so that the level

falls BETWEEN the marks

Fig.1.

10.3.3 System Bleed (following maintenance)

To avoid fluid aeration and possible pump damage, the in- itial fill process must be carried out with the ignition OFF.

Set the fluid level approximately 20 mm above the upper

dipstick level, and cycle the steering no less than three (3) times from lock to lock (this may be best achieved with the

front wheels off the ground). As air is expelled thefluid level

will fall, the level should be corrected. Start the engine and

further cycle thesteering until the fluid level becomes stable.

Stop the engine and finally set the level in accordance

with the fluid level check procedure.

10.3.4 Fluid Reservoir

The reservoir has an integral, non-serviceable, return-side

filter. Should any component be renewed or the system

'broken into' for any reason,

it is essential that the reservoir and the fluid are changed. Under normal operating condi- tions it is not necessary to change the fluid.

10.3.5 Hydraulic Connections

Fluid

Level Check and

Top-up

Jf7-281

Fig. 1

All hydraulic connections and surrounding areas should be scrupulously cleaned before and after work. Please note

that the steering rack valve block connections for FEED and RETURN are common in size. Ensure that the pipes are

correctly fitted, the uppermost one being the high pressure FEEDfrom the steering pump and the lower (RETURN) hav- ing a double depth hexagon tube nut.

X300 VSM 5 issue 1 August 1994

Page 205 of 521

@ Steering

Cause

Fluid level low?

Drive belt slack

(V12)

Pump drive loose (6cyl)

center pressures low

Air in system due to loose connection

Pump shaft seal faulty (fluid loss)

Delivery pressure or flow too low

Return flow restricted by blocked reser

-

voir filter

Both check valves blocked

Rack damper too

tight

Lower column incorrectly set

Excessive upper column friction

Faulty rotary valve or seal

Drive belt slack

(VI217

Engine idle speed too low

Pump drive loose

(6cyl)

Air in system due to loose connection

Pump shaft seal faulty (fluid

loss)

Delivery pressure or flow too low

Fluid level low?

tire pressures

high

Air in system due to loose connection

Stiff or seized steering joint

Rack damper too tight

Castor or tracking error

Lower column over extended

Fluid level low?

Air

in system due to loose connection

Pump shaft seal faulty (fluid

loss)

Rack damper loose

Pinion bearing faulty

Rack or column fixings loose

Rack mounting bracket loose

Rack mounting bush loose

Free play in column assembly

10.4 DIAGNOSTIC PROCEDURE

10.4.1 Introduction

The following diagnostic procedures are provided to rapidly pin-point mechanical faults which are not interrogated

by electrical means. Diagnostic procedures which require dedicated electrically operated equipment are dealt with in the 'Electrical Diagnostic Manual' (EDM) but may be mentioned here for reference.

10.4.2 Preliminary Action

Before any problem solving is undertaken it is essential that the fluid level and where applicable, belt tension, is

checked and if required corrected.

CAUTION: It is imperative that the power steering system does not become contaminated in any way. Always de cant fluid from a fresh sealed container and clean the area around the reservoir neck both before and after

topping-up. Never return drained fluid to the system.

10.4.2 Diagnostic Chart 1

Remedy

Rectify fluid loss and or top up

Re

-tension belt

Renew pump

Set to specification

Secure connection and bleed air out

Renew pump

Renew pump

Renew reservoir

Renew rack

Renew rack

Set to specification

Renew upper column

Renew rack

Retension belt

Reset idle speed

Renew

pump

Secure connection and bleed air out

Renew

pump

Renew pump

Rectify

fluid loss and or top up

Set to specification

Secure connection and bleed air out

Test and renew faulty joint

Renew rack

Check geometry and rectify

if required

Set to specification

Rectify fluid

loss and or top up

Secure connection and bleed air out

Renew pump

Renew rack

Renew rack

Tighten to specification

Renew rack

Renew rack

Check and rectify as required

Trouble

Heavy on both sides

Heavy on one side

Heavy when steering

rapidly

Vague feel about center

Knocking

1 vibration felt

at steering wheel

0

0

0

0

Issue 1 August 1994 6 X300 VSM

Page 206 of 521

10.4.3 Diagnostic chart 2

0 Trouble

'lay at steering wheel

ieavy when stationary

Excessively heavy when

hiving, stationary effort

3K

Too easy when driving,

itationary effort OK

fffort not equal side to

;ide from center

dariation from heavy to

?asy when driving

:yclic load variation at steering wheel - 2 per

.evolution

:losely spaced cyclic

oad variation at steering

Nheel

Cause

Rack damper loose

Pinion bearing loose

Worn intermediate shaft joint

Worn suspension joint

Loose lower column 'pinch' bolt

Transducer not closed

Transducer not closed

- ground short

Transducer not closed

- no feed voltage

Transducer not closed

- defective cable

SCM defective

Delivery pressure or flow too low

Internal rack leakage

tire pressures low

Transducer open too early

Transducer open too early, incorrect SCM

h/Pe

Transducer open too early, incorrect

speedometer signal

Rack 'reaction limitation valve' CLOSED

or setting incorrect

Transducer not open (no oil flow)

Transducer not open, SCM faulty

Transducer not open, incorrect speedom

-

eter signal

Rack 'reaction limiting valve' OPEN or

setting incorrect

Low pressure pipe 'flattened' or re

-

stricted

Blocked reservoir filter

tire pressure high

Rack check valve leak

Rotary valve blockage Incorrect lower column assembly, see

'Cyclic load variations'

Incorrect speedometer signal

Transducer cable

/ connection faulty or

grounded

Lower column universal joint fitting error

Rack damper too tight

Remedy

Renew rack

Renew rack

Renew joint

Renew joint

Tighten to specification

Inspect and check for debris

Renew transducer*

Investigate and repair

Renew cable

Renew module*

Renew pump

Renew rack

Set to specification

Renew transducer*

Renew

SCM*

Renew speedometer transmitter*

Renew rack

Inspect and check for debris

Renew

SCM*

Renew speedometer transmitter*

Renew rack

Renew pipe

Renew filter

Set to specification

Renew rack

Renew rack

Rectify as required

Renew speedometer transmitter*

Investigate and repair

Verify that the lower column assembly is

correct for that drive.

RH and LH assem- blies MUST NOT be interchanged due to

joint phase differences

Renew rack

W: Items marked * should be validated using EDM test procedures.

X300 VSM 7 Issue 1 August 1994

Page 207 of 521

@ Steering

10.4.4 Diagnostic chart 3

Trouble

Hydraulic noise when

turning lock to lock

Continuous pressure

relief valve operation

Continuous noise

Cause

Fluid level low?

Air ingress at connections

Air ingress through feed hose lining

or

skin

Air ingress at pump front seal

Water contamination caused by fractured

cooler pipe within engine coolant radi

-

ator

Pump starvation or cavitation caused by

twisted or trapped feed hose

Pump starvation caused by blocked filter

Worn

pump

High pressure hose (pump to rack) dam-

aged or restricted

Fluid level low?

Drive belt loose

(12 cyl only)

Drive pulley loose

Steering pump mounting

(4 loose

Drive 'dog' loose, slipping or incorrectly

fitted

(6 cyl only)-

Hose or pipe fretting on body or chassis

structure

Hose twisted or restricted

Remedy

Rectify fluid loss and or top up

Check and tighten all connections to spec

-

ification

Renew faulty

'0' rings or Dowty washers

Renew porous

1 damaged hoses

Renew

pump

Renew radiator. Flush and drain steering

system twice

minimum, check for noise

and system performance (Pump is most

susceptible to damage due to

loss of lu-

brication and may have to be renewed)

Reroute or relieve pressure

Renew reservoir

Renew pump

Renew hose

Rectify

fluid loss and or top up

Inspect for damage and renew as required

Tighten pulley to specification

Tighten to specification

Investigate

& rectify as required

Rectify routing

Rectify routing

Issue 1 August 1994 8 X300 VSM

Page 208 of 521

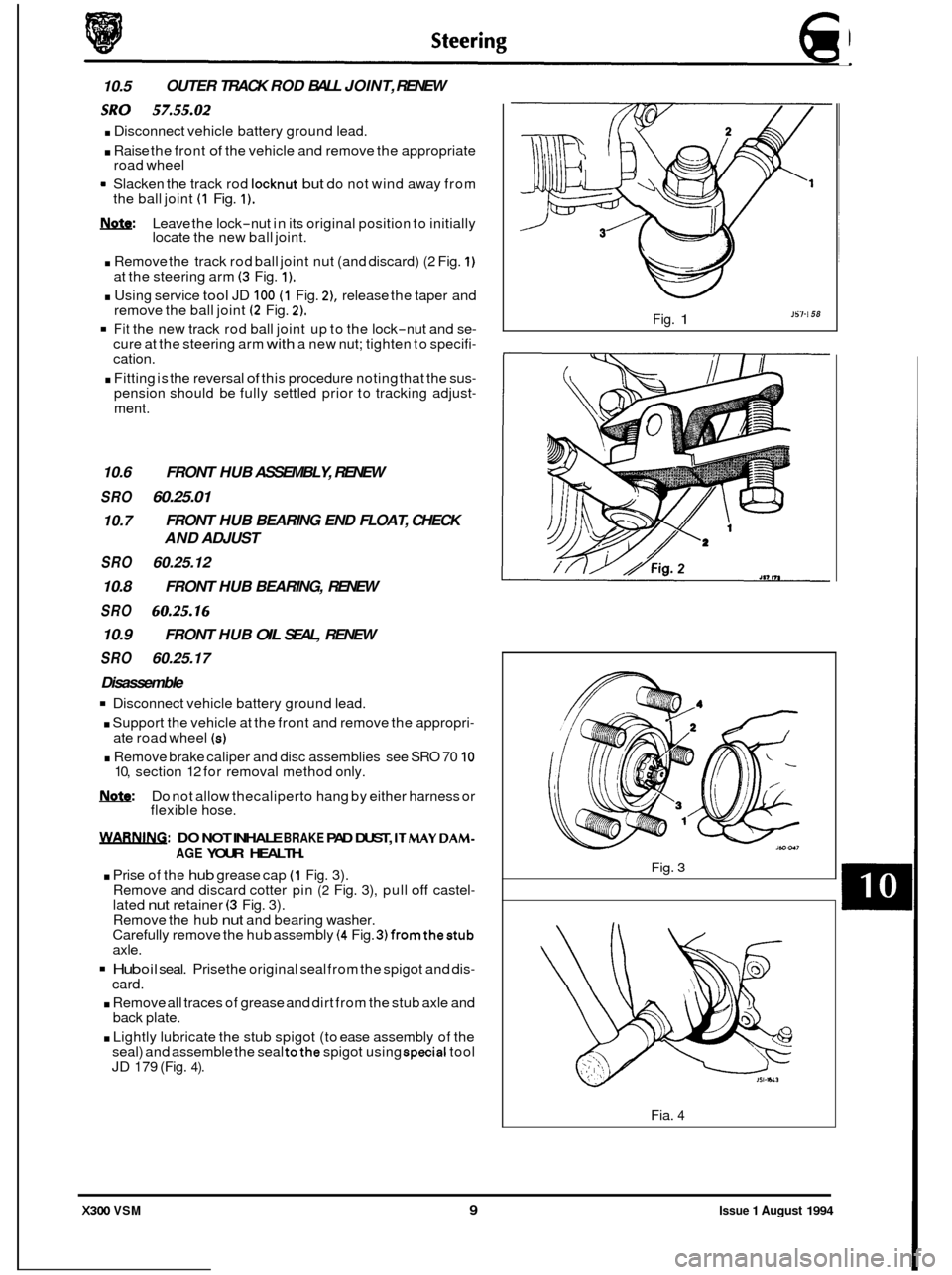

10.5 OUTER

TRACK ROD BALL JOINT, RENEW

sRo . Disconnect 57.55.02 vehicle battery ground lead.

. Raise the front of the vehicle and remove the appropriate

road wheel

Slacken the track rod

locknut but do not wind away from

the ball joint (1 Fig. 1).

m: Leave the lock-nut in its original position to initially

locate the new ball joint.

. Remove the track rod ball joint nut (and discard) (2 Fig. 1)

at the steering arm (3 Fig. 1).

. Using service tool JD 100 (1 Fig. 2), release the taper and

remove the ball joint (2 Fig. 2).

Fit the new track rod ball joint up to the lock-nut and se- cure at the steering arm with a new nut; tighten to specifi- cation.

. Fitting is the reversal of this procedure noting that the sus- pension should be fully settled prior to tracking adjust-

ment.

0 10.6 FRONT HUB ASSEMBLY, RENEW

SRO 60.25.01

10.7

SRO 60.25.12

10.8 FRONT HUB BEARING, RENEW

SRO 60.25.16

10.9

SRO 60.25.17

Disassemble

Disconnect vehicle battery ground lead.

. Support the vehicle at the front and remove the appropri-

. Remove brake caliper and disc assemblies see SRO 70 10

IWQ: Do not allow thecaliperto hang by either harness or

flexible hose.

FRONT HUB BEARING END FLOAT, CHECK

AND ADJUST

FRONT HUB

OIL SEAL, RENEW

ate road wheel (s)

10, section 12 for removal method only.

WARNIM: DO NOT INHALE BRAKE PAD DUST, ITMAY DAM-

0

AGE YOUR HEALTH.

. Prise of the hub grease cap (1 Fig. 3).

Remove and discard cotter pin (2 Fig. 3), pull off castel- lated nut retainer (3 Fig. 3).

Remove the hub nut and bearing washer.

Carefully remove the hub assembly (4 Fig. 3)fromthestub axle.

Hub oil seal. Prise the original seal from the spigot and dis-

card.

. Remove all traces of grease and dirt from the stub axle and

back plate.

. Lightly lubricate the stub spigot (to ease assembly of the

seal) and assemble the seal tothe spigot using special tool JD 179 (Fig. 4).

JS7-i 58 Fig. 1

Fig. 3

Fia.

4

X300 VSM 9 Issue 1 August 1994

Page 209 of 521

@ Steering

. Pack the annular gaps of the oil seal lips with grease.

. Bearing. Wash the hub assembly thoroughly and 'drift' the affected bearing cup(s) from the hub.

!&!$Q:

rn Hub. At this point the hub may be renewed if required.

Assembly

. Bearing. Assemble the inner bearing track to the hub using service tool 18G 134 and adaptor JD 550 - 5 / 1.

Ensure that the hub inner seal diameter is free of debris or damage and is lightly lubricated prior to assembly.

Only replace complete bearings, never cup or race in isolation.

Assemble the outer bearing cup to the hub using service tool

18G 134 and adaptor JD 550 - 5 / 2. Pack each race with approximately 4 ml of grease and position the inner race onto the stub axle.

Apply a smear of grease to hub inner surfaces and bearing cups. Assemble the hub to the stub axle followed by

outer race, bearing washer and hub nut.

It is not necessary to fill the hub cavity with grease, merely protect from corrosion with a coat of IubricanL'Seat'the bear-

ings by slightly tightening the hub nut whilst rotating the hub. Do not apply load without rotation. m:

. End float. Set a Dial Test Indicator (DTI) as shown in Fig. 1 and adjust the hub nut to achieve the correct end float.

As the adjustment is made, continually load the hub axial-

ly in both directions.

. Without disturbing the end float setting, fit the castellated

nut retainer so that it aligns with both hub nut and stub

axle drilling.

. Secure nut retainer using a new cotter pin.

9 Assembly and fitting is the reversal of this procedure not- ing that; all fixings MUST be tightened to specification

and operation of the braking system verified.

Fig. 1

Issue 1 August 1994 10 X300 VSM

Page 210 of 521

Suspension Systems

. .

SECTION CON TENTS

Subsection Tjf/e

.

SRO

I to IV ........... Preliminary Pages ................................................................... i

11.1 ............. Introduction ........................................................................\

. 1

11.2 ............. Front Suspension. Description ......................................... ..

Page

11.3 ............. Rearsuspension. Description .......................................................... 2

11.4.1

............ Diagnosis & Testing. Tire Wear ......................................................... 3

11.4.2

............ Diagnosis & Testing. Vibration & Roughness .............................................. 3

11.4.3

............ Diagnosis & Testing. Front End Inspection ................................................ 4

11.4.4 ............ Diagnosis & Testing. Upper/Lower Ball Joint Inspection ................................... 4

11.4.5

............ Diagnosis & Testing. Damper Inspection ................................................. 4

11.4.6

............ Diagnosis & Testing. Rear Suspension Inspection .......................................... 5

11.4.7. ........... Diagnosis & Testing. Vehicle Inspection .................................................. 5

11.4 ............. Diagnosis & Testing .................................................................. 3

. 1 1.4.8 ............ Diagnosis & Testing. Diagnostic Procedure Chart ............ ...

. .

........ .....

-

I X300 VSM i Issue 1 August 1994

.

............. 1

............. 6