coolant level JAGUAR XJ6 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 12 of 521

Introduction

Term(s) Abbreviation Definition

(if applicable) Previously

used term(s) (or Eng-

lish Equivalent)

downshift

draft _.

drivability

driveshaft

driveshaft tunnel

dry sleeve

Dual Overhead Cam

Data

Data Link Connector

Data Output Line

defogger, backlight defogger

degree (angle or temperature)

Department of Transportation

(US)

Department of Transport (UK)

Deutsche lnstitut fur

Normuna

diameter

Diagnostic Module

Diagnostic Test Mode

Diagnostic Trouble Code

differential housing

differentia

I pressure

Differential Pressure Feedback

EGR

dimmer switch DOHC

DLC

DOL

deg, O

DOT

DTP DIN dia

DM

DTM

DTC

DPFE longitudinal

shaft transmitting power from

transmission output to rear axle differential

tunnel

in floor above the driveshaft (propeller

shaft)

cylinder sleeve which is not in contact with

coolant

engine configuration with two camshafts

positioned above the valves

(US) Fact or group of facts.

connector providing access

andlor control of

the vehicle information, operating

conditions, and diagnostic information

circuit that sends certain information from

the PCM to the instrument cluster

German Standards regulation body

Supplemental Restraint System

(non-controlling) module for diagnostics

overview

a level of capability in an OBD system. May

include different functional states

to observe

signals, a base level to read

DTCs, a monitor

level which includes information on signal

levels,

bi-directional control with onloff board aids, and the ability to interface with

remote diagnosis

an

alphahumeric identifier for a fault

condition identified by the On

-Board

Diagnostic

(OBD) system

rotating housing

(in a bevel differential)

attached to the crownwheel, carrying the

final drive pinions

pressure difference between two regions e.g.

between intake manifold and atmospheric

pressures

an EGR system that monitors differential

EGR pressure across a remote orifice

to control EGR flow change

down

draught

driveability

propeller shaft

transmission

tunnel

dry liner

(English) Group

of facts (i.e. plural

of

datum)

HRW, rear screen

heater, demister

Self Test Mode

Self Test Code.

Fuel Fail code

differential cage

dip switch,

dipper switch

Issue 1 August 1994 11 X300 VSM

Page 14 of 521

Introduction c

GLOSSARY OF TERMS

Term(s) Abbreviation Definition Previously used (if applicable) term(s) (or Eng- lish Equivalent)

0

EGRT Sensor

EGR Vacuum Regulator

1 Read-only memory

I Electronic Engine Control

kronic Secondary Air Injection

Engine Control Module

Engine Coolant Level

ECT Sensor

Engine Speed

Engine Speed Sensor

1 Evaporative Emission Control

Va Ive

Exhaust Gas Recirculation

Solenoid Vacuum Valve

Exhaust Gas Recirculation

Temperature Sensor

Exhaust Gas Recirculation Valve

Extreme Pressure EGR

EGRT EVR

EVP

EDM

EEPROM EPROM EEC

EAlR

ECM ECL

ECT

ECTS

RPM

EPA

EVAP

EVAPP EGRS

EGRT Sensor

EGRV EP System

which reduces

NOx emissions by

adding exhaust gases to the incoming

fuel/air charae

Sensing EGR function based on temperature

change.

controls EGR flow by changing vacuum to

the EGR valve

an EGR system that directly monitors EGR

valve position to control EGR flow

Manual which deals with the diagnosis of

electrical faults (see also Vehicle Service

Manual and Unit Service Manual)

a system that provides electronic control of

enaine electronics

a pump

-driven system for providing

secondarv air usina an electric air Dump

thermistor which provides engine coolant

temperature signal to the PCME to trigger

enrichment circuits which increase injector

'on' time for cold start and warm-up

sensor fitted on flywheel of

VI2 engine;

provides engine speed information

system designed to prevent fuel vapor from

escaping into the atmosphere. Typically

includes a charcoal filled canister to absorb

fuel

vaoor

additives to drive axle lubricants. Designed

to protect the spiral bevel gears from wear

induced by their

slidingholling action EGR

EEPROM,

EPPROM

EPROM ECU

engine coolant level indicator

Coolant temp.

sensor, ECT

revlmin. RPM

purge valve

EGR solenoid

valve

EGR temperature

sensor

X300 VSM issue 1 August 1994 13

Page 56 of 521

Cooling System (AJl6) m

4.1.1 COOLING SYSTEM DESCRIPTION

4.1.1.1 Major Components

o Main engine crossflow radiator, incorporating a concentric tube cooler for the power steering fluid mounted in

the right

-hand radiator side tank. Vehicles with automatic transmission have a transmission fluid cooler

mounted in the left

-hand radiator side tank; for 4,O liter supercharged engines a six-plate cooler is fitted; other

vehicles have

a tube-type cooler. Adouble-action temperature switch, for controlling the radiator cooling fans,

is mounted in the left

-hand radiator side tank.

0 Two electrically operated radiator cooling fans, mounted behind the main radiator.

0 Coolant circulating pump, belt driven from the engine crankshaft.

0 Coolant header tank with pressure relief cap and coolant level probe.

o Engine thermostat.

4.1.1.2

0 Heater matrix.

o Electrically operated coolant circulating pump, mounted on the left-hand side of the engine bulkhead.

o Solenoid operated valve, located adjacent to the coolant circulating pump.

Components for Climate Control System

4.1.1.3 Components for Supercharged Engine

0 0 Supercharger crossflow radiator, mounted in front of the main radiator. The supercharger radiator is reverse- circuited, i.e. the coolant inlet is at the bottom of the radiator.

0 Electrically operated coolant circulating pump, located at the left-hand side of the main radiator.

4.1.1.4 Operation

The configuration of the cooling system for normally aspirated and supercharged (4,O liter) engines is shown in Sub- section 4.1.2.

The cooling system is pressurized, which allows the system to operate at a higher temperature without overheating.

The header tank is fitted with a pressure relief cap to protect the system against overpressure.

Under cold start conditions, coolant is forced by the engine driven water pump through the cylinder block and cylinder

head to the thermostat housing. The thermostat is closed to give rapid engine warm up, hence the coolant is returned

directly to the water pump inlet. When normal engine operating temperature is reached, the thermostat opens and

coolant is diverted through the radiator before returning to the water pump inlet. In vehicles fitted with

a supercharger,

coolant is circulated through the supercharger radiator and intercooler by the supercharger water pump. The super- charger cooling circuit uses the same coolant header tank as the main engine cooling system.

The radiator cooling fans operate in series and parallel under the control of the double

-action radiator mounted tem- perature switch. The fans are also controlled by the climate control system on vehicles fitted with air conditioning.

Under hot operating conditions, the fans may continue to operate after the engine has been switched off. The fans

stop automatically when the coolant temperature has been reduced sufficiently.

The system also provides the coolant supply for the climate control system, which is described in Section

14.

X300 VSM 1 Issue 1 August 1994

Page 58 of 521

area washed to remove all traces of coolant.

CAUTION: To prevent the possibility of damage to the heater circuit pump and supercharger pump (where fitted),

the pumps should be electrically isolated if the ignition has to be turned ON while the cooling system is

drained.

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI

- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL

ALL THE STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT WITH THE ENGINE HOT, PROTECT THE HANDS AGAINST CONTACT

WITH HOT COOLANT.

WARNING: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE RADIATOR COOLING

FANS. THE FANS COULD START WITHOUT WARNING EVEN IF THE ENGINE IS NOT RUNNING.

4.1.3.2 Working Practices

Whenfilling thesystem with coolant,ensurethatthevehicle isstanding on a level surfaceandthatthecoolant is poured

in slowly so that airlocks are not introduced into the system. Airlocks can seriously affect the operation of the climate

control system and can cause damage to the heater circuit pump (and supercharger circuit pump if fitted).

Cooling System (AJ16)

4.1.3 SERVICE PROCEDURES

4.1.3.1 Safety Precautions

The anti-freeze specified in Appendix AI must be used wherever possible. It is designed to afford the maximum cor- rosion protection to all metals found in the engine cooling system, as well as having the frost protection properties

necessary during the winter months.

Should

it not be available, then anti-freeze conforming to Ford Motor Company specification ESLbM97B49-A may be

used. To provide optimum temperature and corrosion protection, the specified anti-freeze concentration must always

be used.

Once coolant has been drained from the system,

it must be discarded and not reused. Anti-freeze is harmful to the

environment. Used coolant must be disposed of safely and never poured down a drain connected to the public sewer.

CAUTION: Never fill or topup the system with water only.

CAUTION : Anti-freeze is harmful to paintwork. Coolant spillages must be wiped up immediately and the affected

Hose clips should always be positioned so that there is proper access for tightening and that the clip does not foul or

interfere with the operation of any components.

Drive belts must always be tensioned to the specified value and the tension checked

at the correct point on the belt.

This information is given in Subsection IV in the preliminary pages.

0

When tightening components, the torque figures given in Sukection II in the preliminary pages should always be

used for the fastenings listed.

4.1.3.3 Coolant Change

The coolant must be changed at intervals of four years. The system should be drained from the radiator drain plug,

flushed and filled with fresh coolant. Flushing should be carried out thoroughly to remove all the old coolant from the

engineand heater matrix. (The heatervalve isopen withthe ignition OFF). AfterfiIling,checkthecoolant concentration

with a hydrometer. For the specified anti-freeze and coolant concentration, see Appendix AI.

X300 VSM 3 Issue 1 August 1994

Page 59 of 521

€3 Cooling System (AJ16)

4.1.4 DRAIN AND FILL PROCEDURES

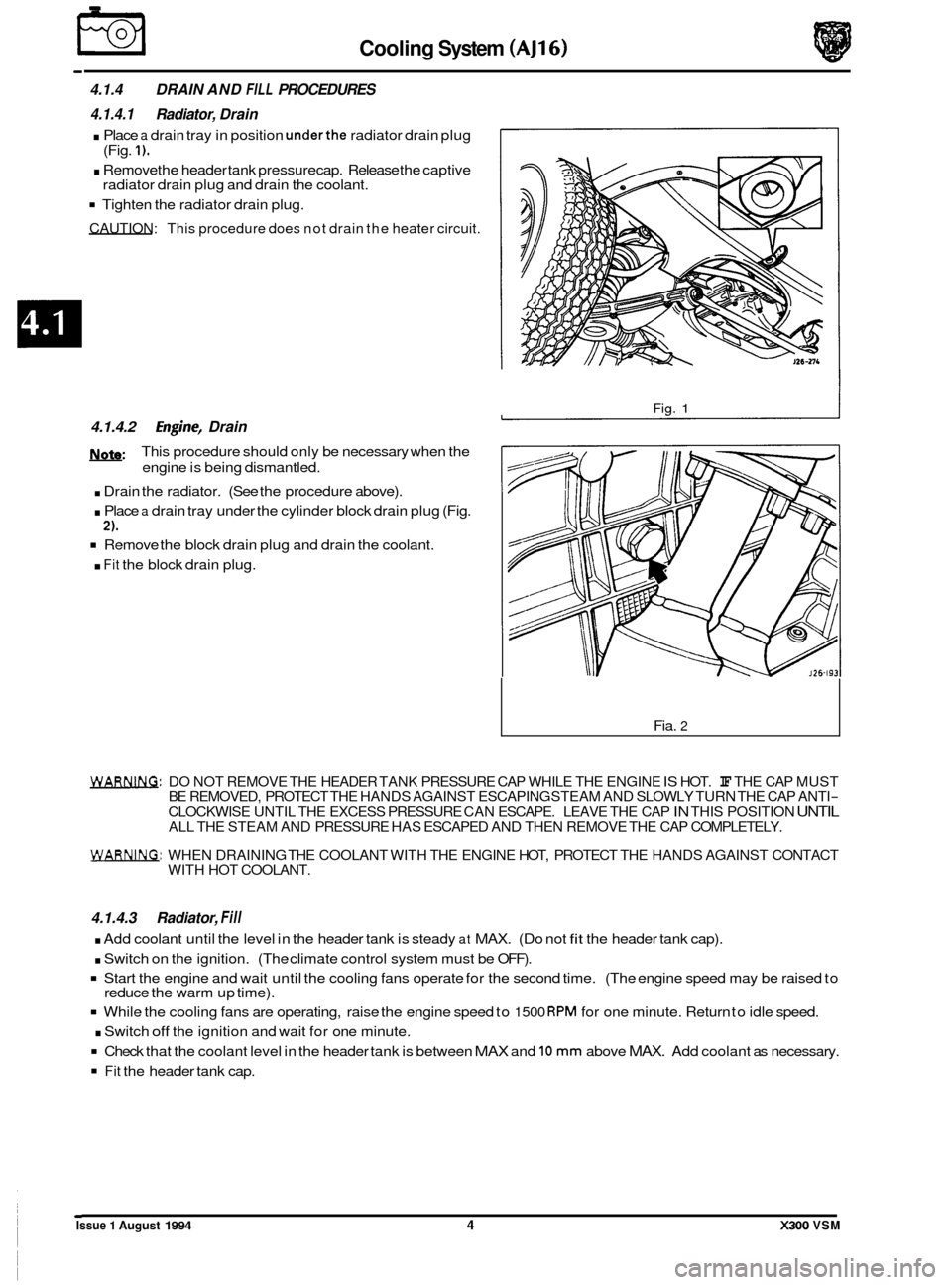

4.1.4.1 Radiator, Drain

. Place a drain tray in position underthe radiator drain plug

. Remove the header tank pressure cap. Release the captive

Tighten the radiator drain plug.

CAUTION: This procedure does not drain the heater circuit.

(Fig. 1).

radiator drain plug and drain the coolant.

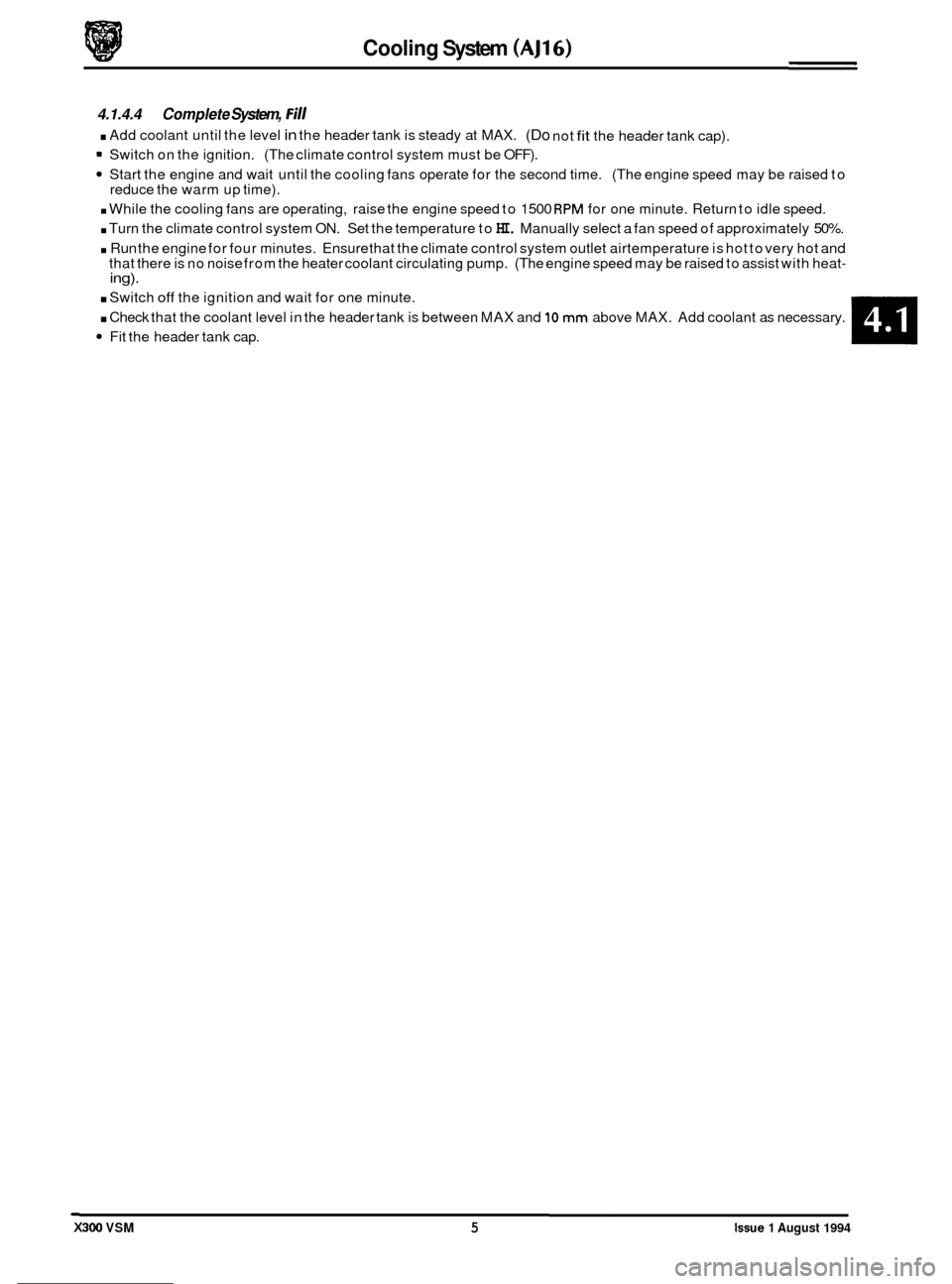

4.1.4.2 Engh-, Drain

m:

. Drain the radiator. (See the procedure above).

. Place a drain tray under the cylinder block drain plug (Fig.

Remove the block drain plug and drain the coolant.

. Fit the block drain plug.

This procedure

should only be necessary when the

engine is being dismantled.

2).

Fig. 1

Fia. 2

WAm. DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL ALL THE STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT WITH THE ENGINE HOT, PROTECT THE HANDS AGAINST CONTACT

WITH HOT COOLANT.

4.1.4.3 Radiator, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

. Switch on the ignition. (The climate control system must be OFF).

Start the engine and wait until the cooling fans operate for the second time. (The engine speed may be raised to

While the cooling fans are operating, raise the engine speed to 1500 RPM for one minute. Return to idle speed.

. Switch off the ignition and wait for one minute.

Check that the coolant level in the header tank is between MAX and 10 mm above MAX. Add coolant as necessary.

Fit the header tank cap.

reduce

the warm up time).

Issue 1 August 1994 4 X300 VSM

Page 60 of 521

.

0

0

Cooling System (AJ1

4.1.4.4 Complete System, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

m Switch on the ignition. (The climate control system must be OFF).

Start the engine and wait until the cooling fans operate for the second time. (The engine speed may be raised to

. While the cooling fans are operating, raise the engine speed to 1500 RPM for one minute. Return to idle speed.

. Turn the climate control system ON. Set the temperature to HI. Manually select a fan speed of approximately 50%.

. Run the engine for four minutes. Ensure that the climate control system outlet airtemperature is hot to very hot and

that there is no noise from the heater coolant circulating pump. (The engine speed may be raised to assist with heat- ing).

reduce the warm up time).

. Switch off the ignition and wait for one minute.

. Check that the coolant level in the header tank is between MAX and 10 mm above MAX. Add coolant as necessary.

Fit the header tank cap.

X300 VSM 5 Issue 1 August 1994

Page 61 of 521

4.1.5 FAULT DIAGNOSIS

4.1.5.1 Introduction

The following diagnostic procedures are provided to assist properly qualified persons to identify and rectify the faults

in the system which are most likely to be encountered. Reference is made to the Electrical Diagnostic Manual (EDM),

which should be consulted for all electrical faults. When investigating faults relating to temperature, the prevailing

ambient temperature conditions should be taken into account. The climate control system is dealt with in Section 14.

Possible Cause

Thermostat stuck closed

Incorrect thermostat rating

Faulty temperature gauge

Faulty temperature transmitter

4.1.5.2 Diagnostic Procedures

Check

Test thermostat

Check thermostat operating

temperature

Refer to EDM

Refer to EDM

Symptom

herheating

Cooling fan(s) not operating 3verheating at

dle

roo cold

Refer to EDM

Incorrect thermostat rating

Thermostat not fitted

Cooling

fan(s) operating con-

tinuously Faulty temperature gauge

Faulty temperature transmitter

Radiator

core blocked

Radiator grille obstructed

Check thermostat operating

temperature

Remove thermostat housing

and inspect

Refer to EDM

Refer to EDM

Refer to EDM

Concentration of

anti

-freeze too high

Drive belt slack

Drive belt broken

Water pump seized

Insufficient coolant

Internally collapsed hoses

Incorrect ignition timing

Fuel

/ air mixture too weak

Incorrect valve

timing

Cylinder head gasket leaking

Brakes binding Check

for

hotspots in radiator

Check grille for obstruction

Check strength of coolant

Check belt tension

Visual check

Slacken drive belt and turn

water

pump pulley by hand.

Check belt for damage

Check coolant level

Pressure test system and

check for deformation of hoses

Refer to EDM

Refer to EDM

Check valve

timing

Pressure-test system. (Check

for contamination of coolant

in header tank)

Check brake calipers for stick

-

ing pistons and seized brake

pad pins

Thermostat stuck open

I Test thermostat

Remedy

Renew thermostat

Renew thermostat

Renew gauge

Renew transmitter

Flush

or renew radiator

Remove obstruction from

grille

Drain and fill

with coolant of

correct concentration

Adjust belt to correct tension

or renew belt

if worn

Renew belt

Renew water pump. Renew

drive belt

if required

Top-up coolant

Renew hoses as required

Rectify

as required

Rectify

as required

Correct valve

timing

Renew head gasket

Rectify

as required

Rectify

as required

Renew thermostat

Renew thermostat

Fit thermostat

Rectify

as required

Renew gauge

Renew transmitter

0

e

0

0

Issue 1 August 1994 X300 VSM

Page 66 of 521

Cooling System (V12

4.2.1 COOLING SYSTEM DESCRIPTION I

4.2.1.1 Major Components

o Engine crossflow radiator, incorporating a concentric tube cooler for the power steering fluid mounted in the

left

-hand radiator side tank. Vehicles with automatic transmission have a six-plate transmission fluid cooler

mounted in the right

-hand radiator side tank. A double-action temperature switch, for controlling the electric

radiator cooling fans, is mounted in the left

-hand radiator side tank.

0 Engine driven, viscous-coupled, radiator cooling fan

0 Two electrically operated radiator cooling fans, mounted in front of the radiator.

o Coolant circulating pump, belt driven from the engine crankshaft.

0 Coolant header tank with pressure relief cap and coolant level probe.

0 Two engine thermostats, one in each cylinder bank.

4.2.1.2

0 Heater matrix.

0 Electrically operated coolant circulating pump, mounted on the left-hand side of the engine bulkhead.

o Solenoid operated valve, located adjacent to the coolant circulating pump.

Components for Climate Control System

1

4.2.1.3 Operation

The configuration of the cooling system is shown in Sub-section 4.2.2.

The cooling system is pressurized, which allows the system to operate at a higher temperature without overheating.

The header tank is fitted with a pressure relief cap to protect the system against overpressure.

Under cold start conditions, coolant is forced by the engine driven water pump through each cylinder block and cylin

- der head to the thermostat housings. The thermostats are closed to give rapid engine warm up, hence the coolant is

returned via the engine cross pipe to the water pump inlet. When normal engine operating temperature is reached,

the thermostats open and coolant is diverted through the radiator before returning to the water pump inlet.

If the engine driven fan is unable to provide sufficient cooling, the electrically operated fans operate in series and paral

-

lel underthe control of the radiator mounted temperature switch. Under hot operating conditions, the electric fans may

continue to operate after the engine has been switched off. The fans stop automatically when the coolant temperature

has been reduced sufficiently.

The system also provides the coolant supply for the climate control system, which is described in Section 14.

I

I X300 VSM 1 Issue 1 August 1994

Page 68 of 521

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL

ALL THE STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT WITH THE ENGINE HOT, PROTECT THE HANDS AGAINST CONTACT

WITH HOT COOLANT.

WARNING

: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE ENGINE DRIVEN RADI- ATOR COOLING FAN WHEN THE ENGINE IS RUNNING.

4.2.3.2 Working Practices

Whenfilling thesystem with coolant,ensurethatthevehicle isstanding on a level surfaceand thatthecoolant is poured

in slowly so that airlocks are not introduced into the system. Airlocks can seriously affect the operation of the climate

control system and can cause damage to the heater circuit pump.

Hose clips should always be positioned

so that there is proper access for tightening and that the clip does not foul or

interfere with the operation of any components.

4.2.3 SERVICE PROCEDURES

4.2.3.1 Safety Precautions

The anti-freeze specified in Appendix A1 must be used wherever possible. It is designed to afford the maximum cor- rosion protection to all metals found in the engine cooling system, as well as having the frost protection properties

necessary during the winter months. Should it not be available, then anti-freeze conforming to Ford Motor Company

specification

ESBM97B49-A may be used. To provide optimum temperature and corrosion protection, the specified

anti-freeze concentration must always be used. Once coolant has been drained from the system, it must be discarded

and not reused. Anti-freeze is harmful to the environment. Always dispose of used coolant safely and never pour it down a drain connected to the public sewer.

CAUTION: Never fill or topup the system with water only.

CAUTION

: Anti-freeze is harmful to paintwork. Coolant spillages must be wiped up immediately and the affected

area washed to remove all traces of coolant.

CAUTION: To prevent the possibility of damage to the heater circuit

pump, the pump should be electrically isolated if the ignition has to be turned ON while the cooling system is drained.

The drive belt must always be tensioned to the specified value and the tension checked at the correct point on the belt.

This information is given in Sub-section IV in the preliminary pages.

When tightening components, the torque figures given in Sub

-section II in the preliminary pages should always be

used for the fastenings listed.

When fitting a replacement thermostat, ensure that the jiggle-pin is to the top of the thermostat housing.

4.2.3.3 Coolant Change

The coolant must be changed at intervals of four years. The system should be drained from the radiator drain plug,

flushed and filled with fresh coolant. Flushing should be carried out thoroughly to remove all the old coolant from the

engine and heater matrix. (The heatervalve isopen with the ignition OFF). AfterfilIing,checkthecoolant concentration

with a hydrometer. For specified anti-freeze and coolant concentration, see in Appendix Al.

X300 VSM 3 Issue 1 August 1994

Page 69 of 521

€3 Cooling System (V12)

4.2.4 DRAIN AND FILL PROCEDURES

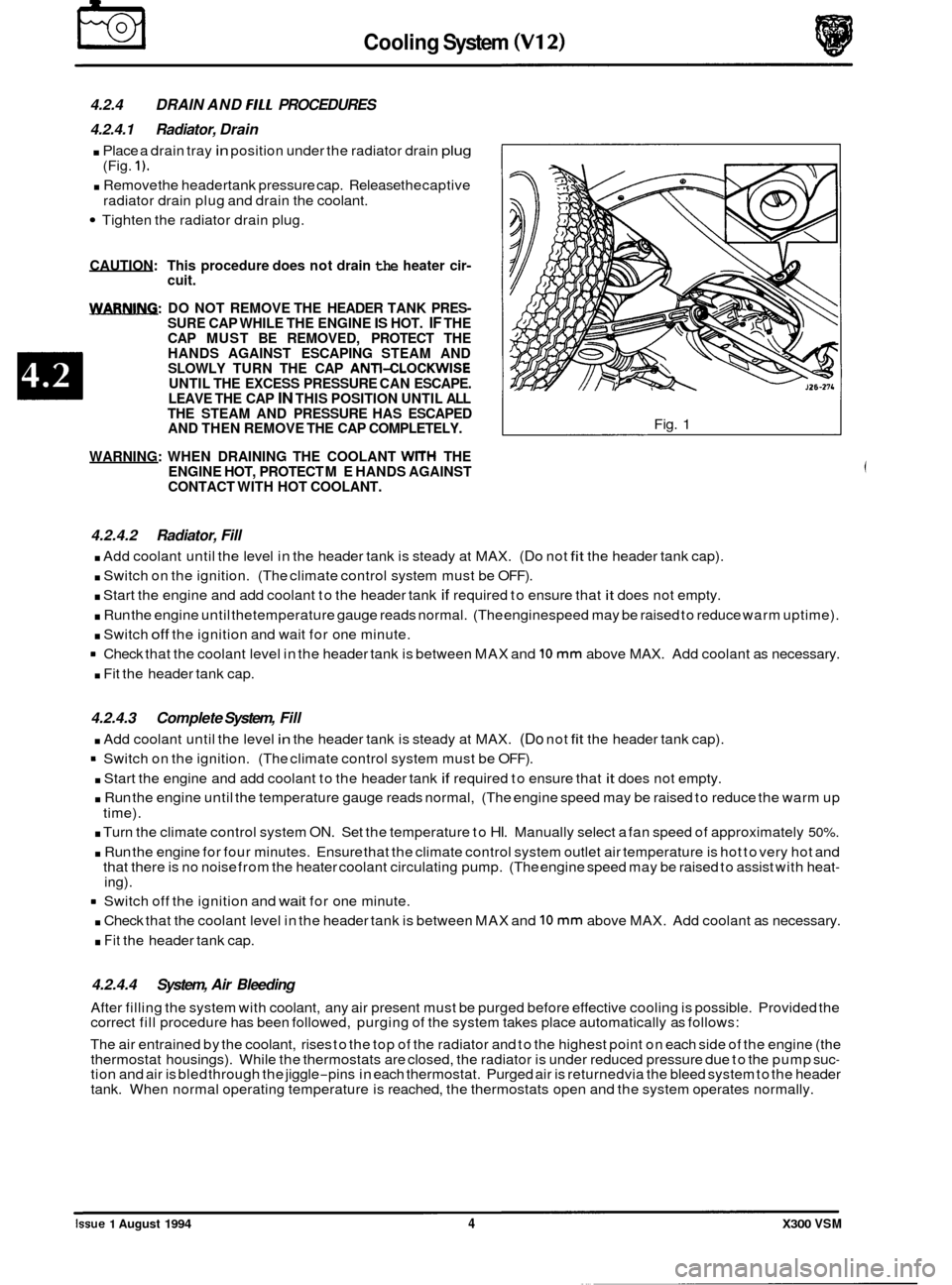

4.2.4.1 Radiator, Drain

. Place a drain tray in position under the radiator drain plug

. Remove the headertank pressure cap. Release thecaptive

Tighten the radiator drain plug.

(Fig.

1).

radiator drain

plug and drain the coolant.

CAUTION: This procedure does not drain the heater cir- cuit.

m: DO NOT REMOVE THE HEADER TANK PRES- SURE CAP WHILE THE ENGINE IS HOT. IF THE

CAP MUST BE REMOVED, PROTECT THE

HANDS AGAINST ESCAPING STEAM AND

SLOWLY TURN THE CAP

ANTI-CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE.

LEAVE THE CAP IN THIS POSITION UNTIL ALL

THE STEAM AND PRESSURE HAS ESCAPED

AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT

WITH THE

ENGINE HOT, PROTECT ME HANDS AGAINST

CONTACT WITH HOT COOLANT.

Fig. 1

4.2.4.2 Radiator, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

. Switch on the ignition. (The climate control system must be OFF).

. Start the engine and add coolant to the header tank if required to ensure that it does not empty.

. Run the engine until thetemperature gauge reads normal. (The enginespeed may be raised to reduce warm uptime).

. Switch off the ignition and wait for one minute.

Check that the coolant level in the header tank is between MAX and

10 mm above MAX. Add coolant as necessary.

. Fit the header tank cap.

4.2.4.3 Complete System, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

= Switch on the ignition. (The climate control system must be OFF).

. Start the engine and add coolant to the header tank if required to ensure that it does not empty.

. Run the engine until the temperature gauge reads normal, (The engine speed may be raised to reduce the warm up

. Turn the climate control system ON. Set the temperature to HI. Manually select a fan speed of approximately 50%.

. Run the engine for four minutes. Ensure that the climate control system outlet air temperature is hot to very hot and

that there is no noise from the heater coolant circulating pump. (The engine speed may be raised to assist with heat- ing).

time).

8 Switch

off the ignition and wait for one minute.

. Check that the coolant level in the header tank is between MAX and 10 mm above MAX. Add coolant as necessary.

. Fit the header tank cap.

4.2.4.4 System, Air Bleeding

After filling the system with coolant, any air present must be purged before effective cooling is possible. Provided the

correct fill procedure has been followed, purging of the system takes place automatically as follows:

The air entrained by the coolant, rises to the top of the radiator and to the highest point on each side of the engine (the

thermostat housings). While the thermostats are closed, the radiator is under reduced pressure due to the pump suc

- tion and air is bled through the jiggle-pins in each thermostat. Purged air is returnedvia the bleed system to the header

tank. When normal operating temperature is reached, the thermostats open and the system operates normally. ~~

Issue 1 August 1994 4 X300 VSM