door lock JAGUAR XJ6 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 24 of 521

0

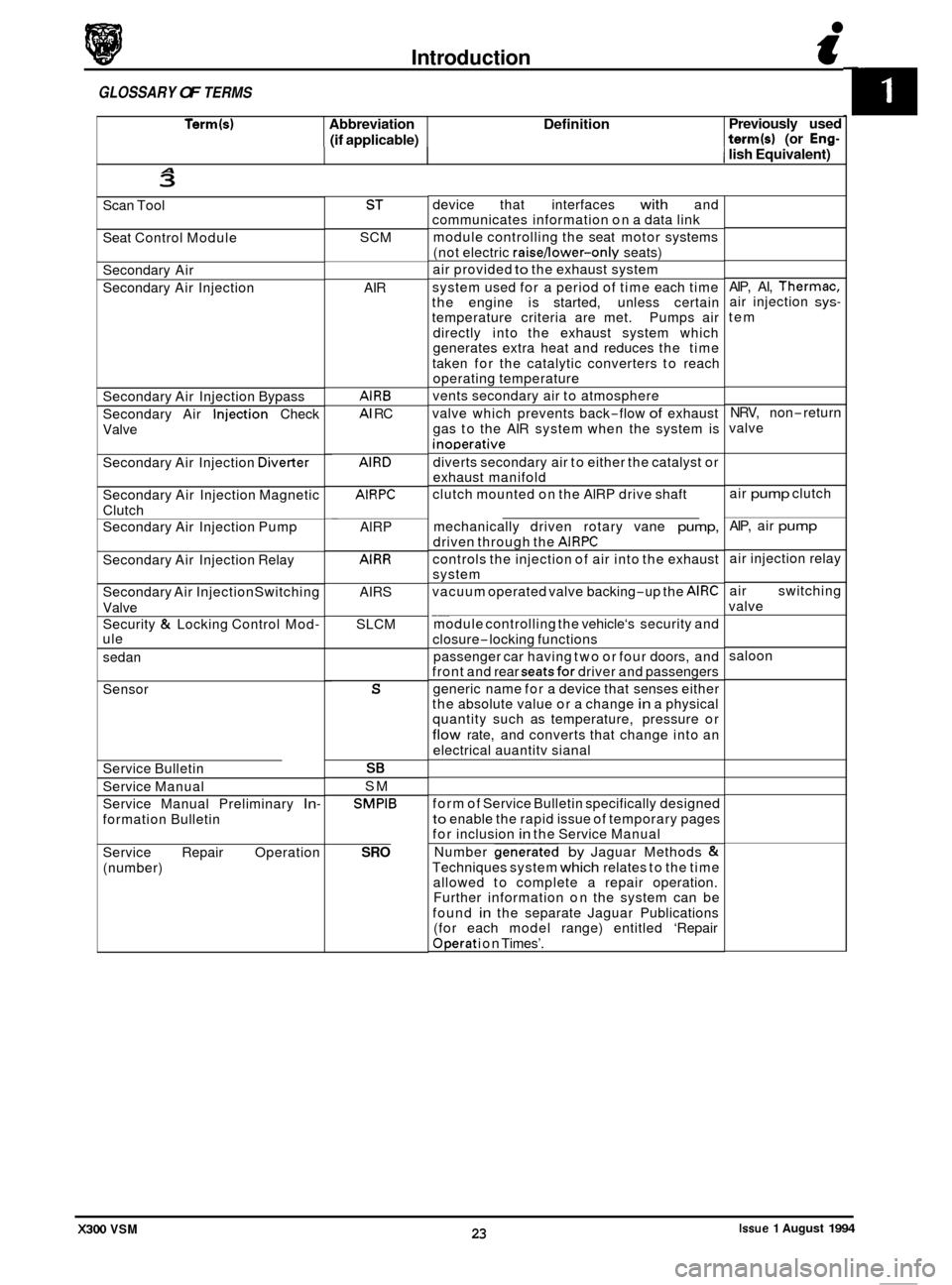

Term(s) Abbreviation Definition

(if applicable)

Introduction i

Previously used term(s) (or Eng-

GLOSSARY OF TERMS

I lish Equivalent) A 3

Scan Tool

Seat Control Module

Secondary Air

Secondary Air Injection

Secondary Air Injection Bypass

..

Secondary Air -Injection Check

Valve

Secondary Air Injection

Diverter

Secondary Air Injection Magnetic

Clutch

Secondary Air Injection Pump

Secondary Air Injection Relay

Secondary Air Injection Switching

Valve

Security

& Locking Control Mod- ule

sedan

Sensor

Service Bulletin

Service Manual

Service Manual Preliminary

In-

formation Bulletin

Service Repair Operation

(number)

ST

SCM

AIR

AlRB

AI RC

AlRD

AIRPC

AlRP

AlRR

AIRS

SLCM

-

S

SE

SM

SMPlB

SRO

device that interfaces with and

communicates information on a data link

module controlling the seat motor systems

(not electric

raisejower-only seats)

air provided

to the exhaust system

system used for a period of time each time

the engine is started, unless certain

temperature criteria are met. Pumps air

directly into the exhaust system which

generates extra heat and reduces the time

taken for the catalytic converters to reach

operating temperature

vents secondary air to atmosphere

valve which prevents back

-flow of exhaust

gas to the AIR system when the system is

inoDerative

diverts secondary air to either the catalyst or

exhaust manifold

clutch mounted on the AlRP drive shaft

mechanically driven rotary vane

pump,

driven through the AIRPC

controls the injection of air into the exhaust

system

vacuum operated valve backing

-up the AlRC

module controlling the vehicle‘s security and

closure

-locking functions

passenger car having two or four doors, and

front and rear

seatsfor driver and passengers

generic name for a device that senses either

the absolute value or a change

in a physical

quantity such as temperature, pressure or

flow rate, and converts that change into an

electrical auantitv sianal

__

form of Service Bulletin specifically designed

to enable the rapid issue of temporary pages

for inclusion in the Service Manual

Number

generated by Jaguar Methods &

Techniques system which relates to the time

allowed to complete a repair operation.

Further information on the system can be

found

in the separate Jaguar Publications

(for each model range) entitled ‘Repair

Operat ion Times’. AIP,

AI,

Thermac, air injection sys-

tem

NRV, non-return

valve

air

pump clutch

AIP, air

pump

air injection relay

air switching

valve

saloon

Issue 1 August 1994 23 X300 VSM

Page 250 of 521

Body Components & Trim .

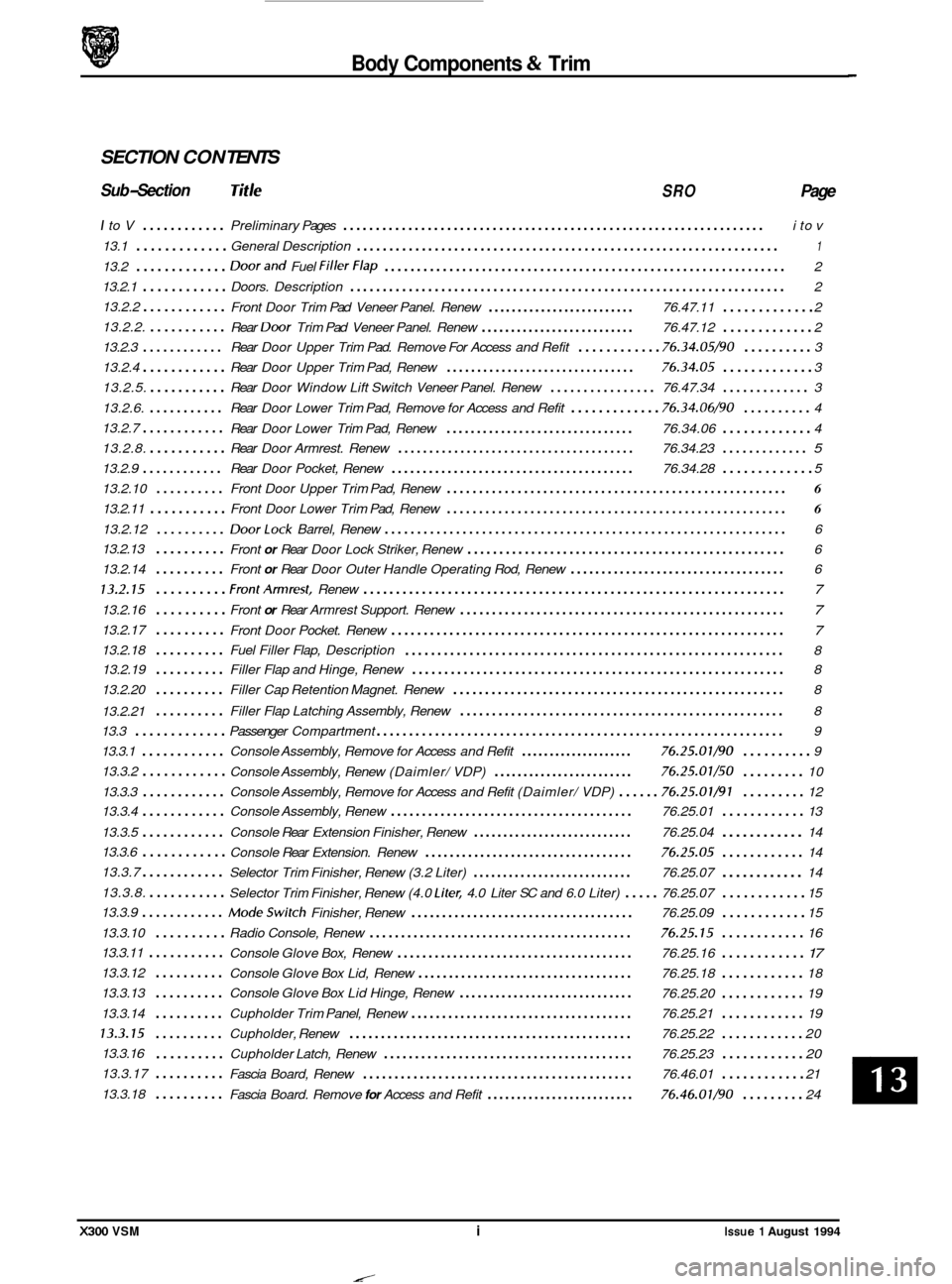

SECTION CON TENTS

Sub-Section Tit /e SRO Page

I to V ............ Preliminary Pages ................................................................. i to v

13.1

............. General Description ................................................................. 1

13.2 ............. Doorand Fuel FillerFlap .............................................................. 2

13.2.1

............ Doors. Description ................................................................... 2

13.2.2

............ Front Door Trim Pad Veneer Panel. Renew ......................... 76.47.11 ............. 2

13.2.2.

...........

13.2.3 ............ Rear Door Upper Trim Pad. Remove For Access and Refit ............ 76.34.05/90 .......... 3

13.2.5.

........... Rear Door Window Lift Switch Veneer Panel. Renew ................ 76.47.34 ............. 3

13.2.6.

........... Rear Door Lower Trim Pad, Remove for Access and Refit ............. 76.34.06/90 .......... 4

13.2.7

............ Rear Door Lower Trim Pad, Renew ............................... 76.34.06 ............. 4

13.2.8.

........... Rear Door Armrest. Renew ...................................... 76.34.23 ............. 5

13.2.9 ............ Rear Door Pocket, Renew ....................................... 76.34.28 ............. 5

13.2.10 .......... Front Door Upper Trim Pad, Renew ..................................................... 6

13.2.11 ........... Front Door Lower Trim Pad, Renew ..................................................... 6

13.2.12 .......... DoorLock Barrel, Renew .............................................................. 6

13.2.13 Front

or Rear Door Lock Striker, Renew .................................................. 6

13.2.14

.......... Front or Rear Door Outer Handle Operating Rod, Renew ................................... 6

13.2.15 .......... FrontArmrest, Renew ................................................................. 7

13.2.16 .......... Front or Rear Armrest Support. Renew ................................................... 7

13.2.17 .......... Front Door Pocket. Renew ............................................................. 7

........................................................... 8

Rear

Door Trim

Pad Veneer Panel. Renew .......................... 76.47.12 ............. 2

13.2.4

............ Rear Door Upper Trim Pad, Renew ............................... 76.34.05 ............. 3

..........

13.2.18 .......... Fuel Filler Flap, Description

13.2.19

.......... Filler Flap and Hinge, Renew .......................................................... 8

13.2.20

.......... Filler Cap Retention Magnet. Renew .................................................... 8

.......... Filler Flap Latching Assembly, Renew ................................................... 8

13.2.21

13.3

............. Passenger Compartment ............................................................... 9

13.3.1

............ Console Assembly, Remove for Access and Refit .................... 76.25.01/90 .......... 9

13.3.2

............ Console Assembly, Renew (Daimler/ VDP) ........................ 76.25.07/50 ......... 10

13.3.3

............ Console Assembly, Remove for Access and Refit (Daimler/ VDP) ...... 76.25.01/91 ......... 12

13.3.4

............ Console Assembly, Renew ....................................... 76.25.01 ............ 13

13.3.5

............ Console Rear Extension Finisher, Renew ........................... 76.25.04 14

Selector Trim Finisher, Renew (3.2 Liter)

........................... 76.25.07 ............ 14

Modeswitch Finisher, Renew .................................... 76.25.09 ............ 15

13.3.10

.......... Radio Console, Renew .......................................... 76.25.15 ............ 16

Console Glove Box, Renew

...................................... 76.25.16 ............ 17

Console Glove Box Lid, Renew ................................... 76.25.18 ............ 18

.......... Console Glove Box Lid Hinge, Renew ............................. 76.25.20 ............ 19

13.3.14

.......... Cupholder Trim Panel, Renew .................................... 76.25.21 ............ 19

13.3.15 .......... Cupholder, Renew ............................................. 76.25.22 ............ 20

.......... Cupholder Latch, Renew ........................................ 76.25.23 ............ 20

Fascia Board, Renew ........................................... 76.46.01 ............ 21

13.3.6

............ Console

Rear Extension. Renew .................................. 76.25.05 ............ 14

13.3.7

............

13.3.8. ........... Selector Trim Finisher, Renew (4.0 Liter, 4.0 Liter SC and 6.0 Liter) ..... 76.25.07 ............ 15

13.3.9

............

............

13.3.11 ...........

13.3.12

13.3.13 ..........

13.3.16

13.3.17

..........

13.3.18 .......... Fascia Board. Remove for Access and Refit ......................... 76.46.01/90 ......... 24

X300 VSM i Issue 1 August 1994

Page 253 of 521

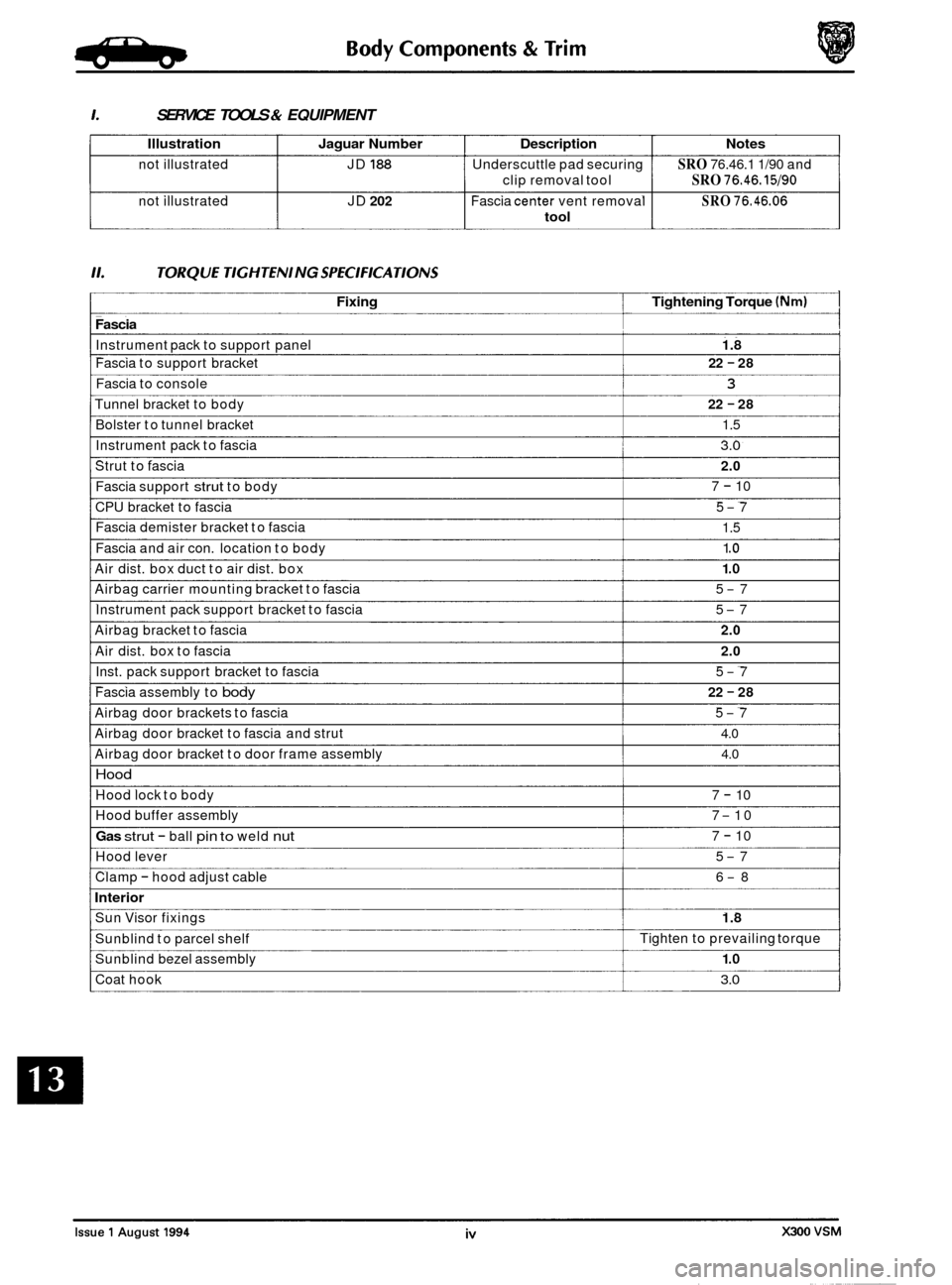

1. SERVICE TOOLS & EQUIPMENT

Illustration Jaguar Number Description Notes

not illustrated JD 188 Underscuttle pad securing SRO 76.46.1 1/90 and

not illustrated JD

202 Fascia center vent removal SRO 76.46.06

clip removal tool SRO 76.46.15190

tool

11. TORO U€ TIGHTEN1 NG SPEC1 FlCA TlONS

Fixing Tightening Torque (Nm) 1

Fascia I I

Instrument pack to support panel I 1.8 I

Fascia to support bracket

Fascia to console

3

Tunnel bracket to body

22 - 28

22

- 28

Bolster to tunnel bracket 1.5

Instrument pack to fascia

3.0

Strut to fascia 2.0

Fascia support strut to body 7 - 10

CPU bracket to fascia 5

-7

Fascia demister bracket to fascia

1.5

1 .o

1 .o

5-7

5

-7

Fascia

and air con. location to body

Air dist. box duct to air dist. box

Airbag carrier mounting bracket to fascia

Instrument pack support bracket to fascia

Airbag bracket to fascia

2.0

Air dist. box to fascia 2.0

Inst. pack support bracket to fascia 5-7

22 - 28 Fascia assembly to body

Airbag door brackets to fascia 5-7

4.0

4.0

Airbag door bracket to fascia and strut

Airbag door bracket to door frame assembly

Hood

Hood lock to body

Hood buffer assembly 7

-10

Gas strut - ball pin to weld nut

7 - 10

7

- 10

Hood lever 5

-7

Clamp

- hood adjust cable 6-8

Interior

Sun Visor fixings 1.8

Sunblind to parcel shelf

Sunblind bezel assembly

1 .o

Coat hook 3.0

Tighten to prevailing torque

Page 256 of 521

Body Components & Trim

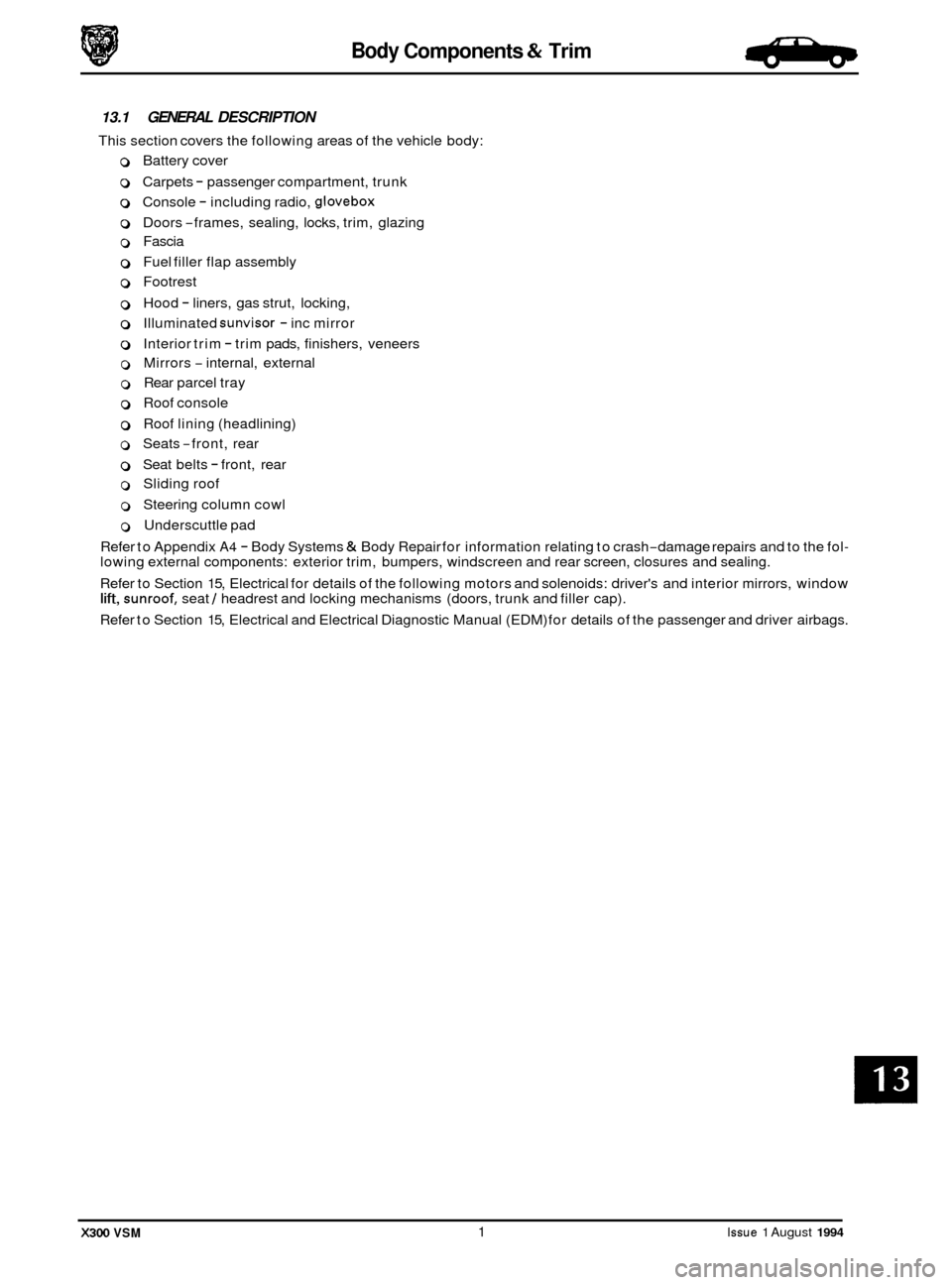

13.1 GENERAL DESCRIPTION

This section covers the following areas of the vehicle body:

0 Battery cover

0 Carpets - passenger compartment, trunk

0 Console - including radio, glovebox

0 Doors -frames, sealing, locks, trim, glazing

0 Fascia

0 Fuel filler flap assembly

0 Footrest

0 Hood - liners, gas strut, locking,

0 Illuminated sunvisor - inc mirror

0 Interior trim - trim pads, finishers, veneers

0 Mirrors - internal, external

0 Rear parcel tray

0 Roof console

0 Roof lining (headlining)

o Seats -front, rear -

0 Seat belts - front, rear

0 Sliding roof

0 Steering column cowl

0 Underscuttle pad

Refer to Appendix

A4 - Body Systems & Body Repair for information relating to crash-damage repairs and to the fol- lowing external components: exterior trim, bumpers, windscreen and rear screen, closures and sealing.

Refer to Section 15, Electrical for details of the following motors and solenoids: driver's and interior mirrors, window

lift, sunroof, seat / headrest and locking mechanisms (doors, trunk and filler cap).

Refer to Section 15, Electrical and Electrical Diagnostic Manual (EDM) for details of the passenger and driver airbags.

X300 VSM 1 Issue 1 August 1994

Page 257 of 521

Body Components & Trim d-!P

13.2

13.2.1 Doors, Description

Doors are of welded, mild steel frames welded to the door panels; sponge rubber primary and secondary seals are

mounted on the doors. Internal insulation is provided by a foam water shedder attached to the door by press fitting and doublesided adhesive tape.

Front and rear door armrests are attached to supports riveted to each door frame; the attaching screws are fitted

with access covers. Upper and lower trim pads and a door pocket are attached to each of the doors by clips and screws. multi-plug connectors are used to provide a means of connecting the guard lamps, window lift switches and loud- speakers, external mirror and regulator (front doors only), which are housed within the doors.

Central locking is provided subject to market variations: Dead Locking for UK

/ Europe and Driver only unlock for N America. Door locks are eight disc, bayonet fixing, barrels with integral lock / unlock switches. Keys include ‘in-key’

transponders which are programmed to the vehicle via the Jaguar Diagnostic System also operate the engine immobi

- lisation system.

CAUTION: When removing the door panel water shedder, a foam membrane attached to each door panel by a com- bination of pressfitting (upper area) and bydouble-sided tape (bottom area), it is important that the shed- der is refitted correctly to maintain the water seal.

It is advisable not to disturb the bottom (taped) portion of the water shedder unless absolutely necessary

- it is possible to unclip the top of the shedder and bend it over to gain access to the inner panel.

If

it is necessary to disturb the bottom attachment, eg to remove the water shedder from the door panel,

the existing water shedder must be discarded and a new one fitted to ensure that the seal is maintained.

On refitting, the new water shedder should be pressed onto the door panel at the top and then the adhes- ive tape backing strip peeled off to enable the shedder to be pressed home at the bottom.

DOORS AND FUEL FILLER FLAP

13.2.2 front and Rear Door Trim Pad Veneer Panel,

Renew

SRO 76.47.11

76.47.12

. Reposition the inner door handle. See Fig. 1.

Remove the inner handle escutcheon plate blanking plate.

Undo and remove the inner handle escutcheon plate se-

. Remove the plate and gasket.

. Carefully Undo and remove the veneer panel.

Undo and remove the retaining clip securing screws.

. Remove the retaining clip assemblies.

9 Place the veneer panel aside.

Place the new veneer panel to the front.

Fit the retaining clip assemblies.

. Fit and tighten the retaining clip securing screws.

. Fit and fully seat the veneer panel to the door.

. Reposition the inner door handle.

. Fit the gasket and plate over the inner door handle.

. Fit and tighten the escutcheon plate securing screw.

. Refit the blanking plate.

curing

screw.

Fig.

1

0

0

0

0

Issue 1 August 1994 2 X300 VSM

Page 261 of 521

Body Components & Trim -

13.2.10 Front Door Upper Trim Pad, Renew

. Disconnect vehicle battery ground lead.

. Remove the front door veneer panel.

. Remove the upper trim pad securing clip and screws.

. Lift the trim pad to release it from the door and remove the

To refit, carry out reversal of the above procedure.

inner

waist rail seal.

13.2.1 1 Front Door lower Trim Pad, Renew

. Disconnect vehicle battery ground lead.

Remove armrest.

. From inside door pocket, release guard retainer, discon-

. Carefully prise the trim pad away from the door and re-

With the trim pad moved for access, disconnect loud-

. Feed guard lamp harness through aperture and place trim

. Remove front door pocket and trim pad retainers.

. To refit, carry out reversal of the above procedure. Check

the trim pad retainers for damage before refitting.

nect

multi

-plug and remove lamp.

lease from the upper retainer.

speaker and window

lift switch multi-plugs.

pad on a clean workbench.

13.2.12 Door lock Barrel, Renew

. Disconnect vehicle battery ground lead.

. Remove the door trim veneer, door upper trim pad, door

. Remove the handle assembly to a clean workbench.

. Remove the lock barrel from its bayonet type mounting.

. Carefully remove the barrel components noting the order

. To refit, carry out reversal of the above procedure, ensur-

lower trim pad and door handle.

and position if reassembly is required.

ing that the components are lightly greased.

13.2.13 Front or Rear Door Lock Striker, Renew

. Note position of striker before removal.

. Remove two screws attaching striker to pillar.

Remove striker from pillar.

. To refit, carry out reversal of the above procedure, ensur- ing that the striker is correctly aligned with the door lock

before final torque tightening.

13.2.14 Front or Rear Door Outer Handle Operating

Rod, Renew

. Disconnect vehicle battery ground lead.

. Remove the door trim veneer, door upper trim pad, door

lower trim pad.

. Disengage the handle operating rod retaining clip and free

the rod from the operating pivot.

. Allowthe latch levertocontact the release mechanism, re- position the operating rod and replace the retaining clip.

. Check that the setting is correct by operating the door

mechanism.

To refit, carry out reversal of the above procedure.

/ 2 176 -1053

1. Water shedder 2. Multi connector 3. Armrest support

Fig. 1 Door Interior Components

Issue 1 August 1994 6 X300 VSM

Page 298 of 521

Body Components & Trim

13.5.4 GasStrut, Renew

. Disconnect vehicle battery ground lead.

. Open the hood and fit fender protectors.

CAUTION: Ensure that the hood cover is adequately sup ported and that paint damage cannot occur.

. Release upper strut pivot retaining clip and detach the

. Repeat for the lower pivot and remove the gas strut.

To refit, carry out reversal of the above procedure.

strut from the pivot.

13.5.5 Hood

Lock RH or LH, Renew

Open the hood and disconnect the lock operating cable

from the lock.

. Remove the bolts securing the lock to the body and re- move the lock.

. To refit, carry out reversal of the above procedure. Align

the lock with the striker prior to tightening.

13.5.6 Hood Lock Control Cable RH or LH, Renew

Slacken theclamp bolt securing thecabletothe lockactua- tor.

= Disconnect the cable from the lock and from the mounting

clip.

Release the cable from the bulkhead mounting clips and

remove the tie wraps securing the cable to the pipes and

harnesses.

. Remove the cable from the remaining large tie wraps.

. Open the front door.

. Remove the underscuttle pad.

. Pull the release handle and disconnect the cable from the

release handle and bracket.

Pull the cable through the bulkhead grommet and discard.

To refit, carry out reversal of the above procedure.

13.5.7 Hood Striker Assembly, Renew

. ODen the hood, slacken the locknut and unscrew the

sthker.

. Renew any damaged components and reassemble. - . A distance of 62mm from the end of the striker to the lock-

Adjust the striker until the hood is flush with the fender.

nut may be used as an initial setting.

13.5.8

. With the hood raised: slacken the clamp bolt which se- cures the cable to the lock actuator. Repeat the procedure

for the other side.

Hood Lock Release Handle, Renew

Open the driver side door.

. Remove the underscuttle pad.

. Disconnect the inner cablesfrom the hood release handle.

. Remove the bolts securing the hood release handle to the

body, remove the cables from the handle and remove

from the vehicle.

To refit, carry out reversal of the above procedure.

X300 VSM 43 Issue 1 August 1994

Page 299 of 521

Body Components & Trim #ib

13.6 GLAZING (FIXED)

13.6.1 Glazing (Fixed), Description

The fixed glazing comprises internal and external driving mirrors, sunvisor mirror and rear quarter light glass; see Ap- pendix A4, Body Components and Trim for details of the windscreen and rear screen glazing.

13.6.2 Interior Mirror, Renew

. Disconnect vehicle battery ground lead.

. Rotate mirror stem approximately one quarter turn clock- wise to release stem from spring contact on windscreen

boss.

. Disconnect mirror harness.

To refit, locate mirror stem base on windscreen boss with

stem parallel to top of windscreen, ie one quarter turn dis- placed from normal position; apply firmly over boss and

turn anti-clockwise to lock stem on windscreen boss.

. Reconnect mirror harness.

13.6.3

. Disconnect vehicle battery ground lead.

. Lower the sunvisor.

. Raise the sunvisor cover and remove the lenses.

Remove the screws securing the mirror to the sunvisor

and remove the mirror.

. To refit, carry out reversal of the above procedure, taking

care to correctly locate switch and bulb holders priortose-

curing the mirror.

Sun Visor Mirror Assembly, Renew

13.6.4 Exterior Mirror, Renew

= Disconnect vehicle battery ground lead.

Remove door trim pad veneer panel and upper trim pad.

9 Remove the cheater by sliding off.

. Remove mirror fixings.

. Disconnect the mirror harness block connectors.

. Remove the mirror securing screws and remove the mir-

ror assembly.

. To refit, carry out reversal of the above procedure.

13.6.5 Exterior Mirror Glass, Renew

. Switch ignition on and position the mirrorto inboard posi-

. Disconnect vehicle battery ground lead.

. Slide assembly outboard and pull outwards.

. To refit, carry out reversal of the above procedure.

tion.

Issue 1 August 1994 44 X300 VSM

Page 321 of 521

Climate Control Systems

. Centre vent flap

Foot flap

Defrost flap

I I

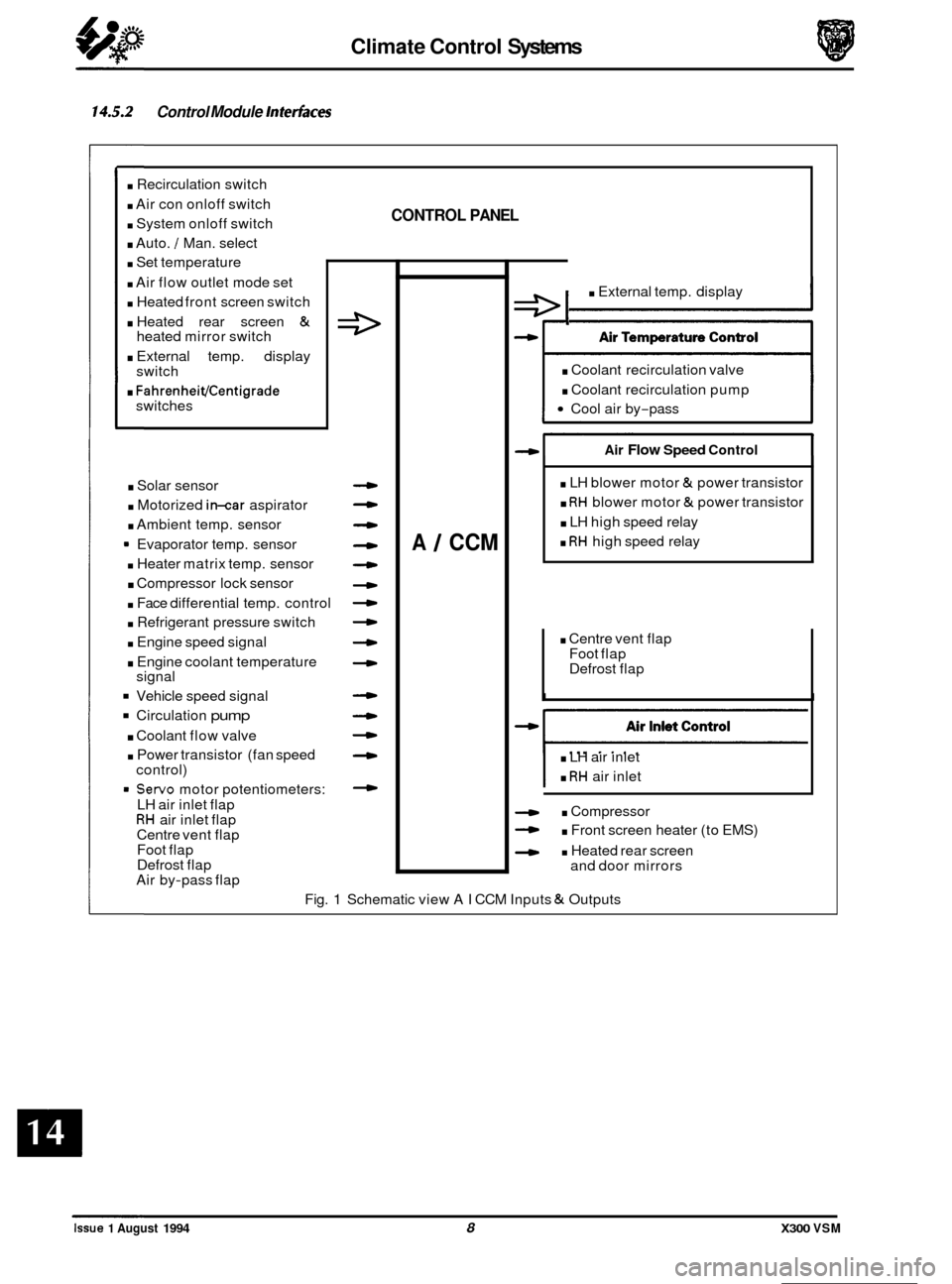

14.5.2 Control Module Interfaces

. Recirculation switch

. Air con onloff switch

. System onloff switch

. Auto. / Man. select

. Set temperature

. Air flow outlet mode set

. Heated front screen switch

. Heated rear screen &

. External temp. display

. FahrenheiVCentigrade

heated mirror switch

switch

switches

. Solar sensor

. Motorized in-car aspirator

. Ambient temp. sensor

9 Evaporator temp. sensor

. Heater matrix temp. sensor

. Compressor lock sensor

. Face differential temp. control

. Refrigerant pressure switch

. Engine speed signal

. Engine coolant temperature

Vehicle speed signal

Circulation pump

. Coolant flow valve

. Power transistor (fan speed

= Servo motor potentiometers:

signal

control)

LH air inlet flap

RH air inlet flap

Centre vent flap

Foot flap

Defrost flap

Air by

-pass flap

CONTROL PANEL

4

-

4

4

4

4

4

4

A 1 CCM

e I . External temp. display

. Coolant recirculation valve

. Coolant recirculation pump

Cool air by-pass

Air Flow Speed Control

. LH blower motor & power transistor

. RH blower motor & power transistor

. LH high speed relay

. RH high speed relay

. LH air inlet

. RH air inlet

. Compressor

- . Front screen heater (to EMS)

- . Heated rear screen

and door mirrors

Fig.

1 Schematic view AI CCM Inputs & Outputs

0

0

0

0

Issue 1 August 1994 8 X300 VSM

Page 350 of 521

31

30

29

28 27

26

4 26 24 21 23 22 7 20 19 18 18 17 8

a

10

11

12

13

14

1s

1M-137

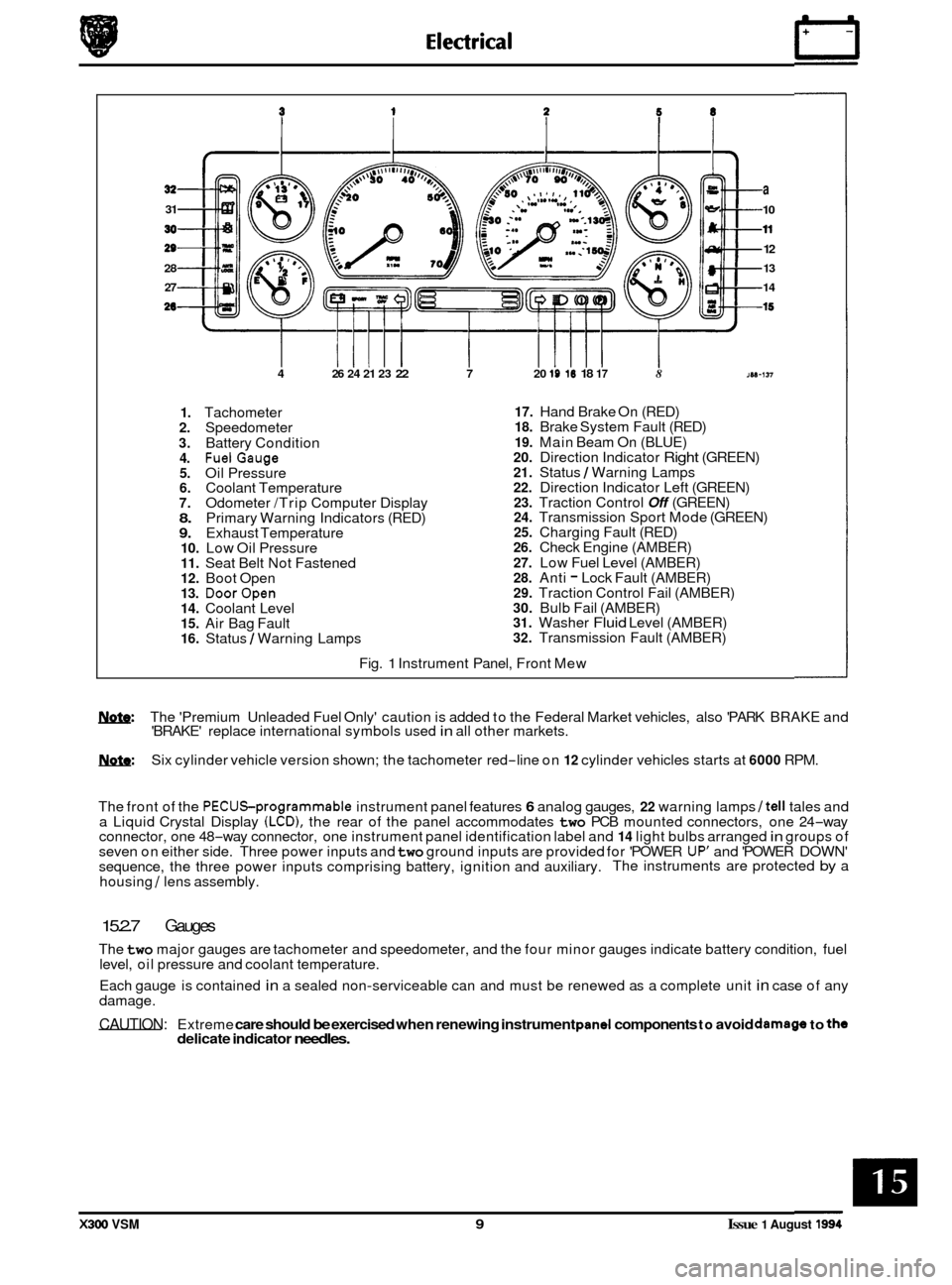

1. Tachometer 2. Speedometer

3. Battery Condition 4. FuelGauge 5. Oil Pressure 6. Coolant Temperature 7. Odometer /Trip Computer Display 8. Primary Warning Indicators (RED) 9. Exhaust Temperature 10. Low Oil Pressure 11. Seat Belt Not Fastened 12. Boot Open 13. DoorOpen 14. Coolant Level 15. Air Bag Fault 16. Status / Warning Lamps

17. Hand Brake On (RED) 18. Brake System Fault (RED)

19. Main Beam On (BLUE) 20. Direction Indicator Right (GREEN) 21. Status / Warning Lamps 22. Direction Indicator Left (GREEN) 23. Traction Control Off (GREEN) 24. Transmission Sport Mode (GREEN) 25. Charging Fault (RED) 26. Check Engine (AMBER)

27. Low Fuel Level (AMBER) 28. Anti - Lock Fault (AMBER) 29. Traction Control Fail (AMBER) 30. Bulb Fail (AMBER) 31. Washer Fluid Level (AMBER) 32. Transmission Fault (AMBER)

Fig.

1 Instrument Panel, Front Mew

w: The 'Premium Unleaded Fuel Only' caution is added to the Federal Market vehicles, also 'PARK BRAKE and

'BRAKE' replace international symbols used in all other markets.

m: Six cylinder vehicle version shown; the tachometer red-line on 12 cylinder vehicles starts at 6000 RPM.

The front of the

PECUSprogrammable instrument panel features 6 analog gauges, 22 warning lamps /tell tales and

a Liquid Crystal Display (LCD), the rear of the panel accommodates two PCB mounted connectors, one 24-way

connector, one 48-way connector, one instrument panel identification label and 14 light bulbs arranged in groups of

seven on either side. Three power inputs and two ground inputs are provided for 'POWER UP' and 'POWER DOWN'

sequence, the three power inputs comprising battery, ignition and auxiliary. The instruments are protected by a

housing

/ lens assembly.

15.2.7 Gauges

The two major gauges are tachometer and speedometer, and the four minor gauges indicate battery condition, fuel

level, oil pressure and coolant temperature.

Each gauge is contained

in a sealed non-serviceable can and must be renewed as a complete unit in case of any

damage.

CAUTION: Extreme care should be exercised when renewing instrument pand components to avoid damago to the delicate indicator needles.

X300 VSM 9 Issue 1 August 1994