front seat JAGUAR XJ6 1997 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 74 of 227

3261 Jaguar XJ6

3

Chapter 3

Cooling, heating and air conditioning systems

General

Radiator cap pressure rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.5 to 117.5 psi

Thermostat rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 to 207° F

Torque wrench settingsNm lbf ft

Coolant pipe to block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Fan assembly-to-drive hub nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Fan clutch-to-fan blade bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Thermostat cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Thermostat housing-to-block bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Water pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21 Air conditioning and heating system - check and maintenance . . . . 13

Air conditioning compressor - removal and refitting . . . . . . . . . . . . . 15

Air conditioning condenser - removal and refitting . . . . . . . . . . . . . . 16

Air conditioning evaporator and expansion valve - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Air conditioning receiver/drier - removal and refitting . . . . . . . . . . . . 14

Antifreeze/coolant - general information . . . . . . . . . . . . . . . . . . . . . . 2

Coolant level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Coolant temperature sender unit - check and renewal . . . . . . . . . . . .9

Cooling system check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Cooling system draining, flushing and refilling . . . . . . . . See Chapter 1

Drivebelt check, adjustment and renewal . . . . . . . . . . . See Chapter 1

Engine cooling fans - check and renewal . . . . . . . . . . . . . . . . . . . . . 4Engine oil cooler - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Heater and air conditioning blower motors -circuit check

and component renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Heater and air conditioning control assembly -

check, removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Heater core - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Radiator, expansion tank and coolant reservoir -

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Thermostat - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Underbonnet hose check and renewal . . . . . . . . . . . . . . See Chapter 1

Water pump - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Water pump and pipes - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

Engine cooling system

All vehicles covered by this manual employ a

pressurised engine cooling system with

thermostatically-controlled coolant circulation.

An impeller type water pump mounted on the

front of the block pumps coolant through the

engine. The coolant flows around each cylinder

and toward the rear of the engine. Cast-in

coolant passages direct coolant around the

intake and exhaust ports, near the spark plug

areas and in proximity to the exhaust valve

guides.A wax-pellet type thermostat is located in

the thermostat housing at the front of the

engine. During warm up, the closed

thermostat prevents coolant from circulating

through the radiator. When the engine

reaches normal operating temperature, the

thermostat opens and allows hot coolant to

travel through the radiator, where it is cooled

before returning to the engine.

The cooling system is sealed by a pressure-

type radiator cap. This raises the boiling point

of the coolant, and the higher boiling point of

the coolant increases the cooling efficiency

of the radiator. If the system pressure exceeds

the cap pressure-relief value, the excess

pressure in the system forces the spring-

loaded valve inside the cap off its seat and

allows the coolant to escape through the

overflow tube into a coolant reservoir. Whenthe system cools, the excess coolant is

automatically drawn from the reservoir back

into the radiator. This type of cooling system is

known as a closed design because coolant

that escapes past the pressure cap is saved

and reused.

The Jaguar cooling system on 1988 and

1989 models has both a manifold tank and a

coolant recovery tank. The manifold tank is the

highest point in the cooling system and is the

location of the “radiator” cap (the cap is not on

the radiator). The recovery tank down in the

passenger’s footwell collects heated coolant

as described above. Models from 1990 to

1994 do not have a coolant recovery tank, but

have an enlarged manifold tank. In all models,

the recovery tank has a sensor in it to detect a

low coolant level, and the instrument panel has

a warning light to that effect.

Page 107 of 227

Refitting

7Insert the distributor into the engine in

exactly the same relationship to the block that

it was in when removed.

8If the distributor does not seat completely,

recheck the alignment marks between the

distributor base and the block to verify that

the distributor is in the same position it was in

before removal. Also check the rotor to see if

it’s aligned with the mark you made on the

edge of the distributor base.

9Refit the distributor hold-down bolt(s).

10The remainder of refitting is the reverse of

removal.

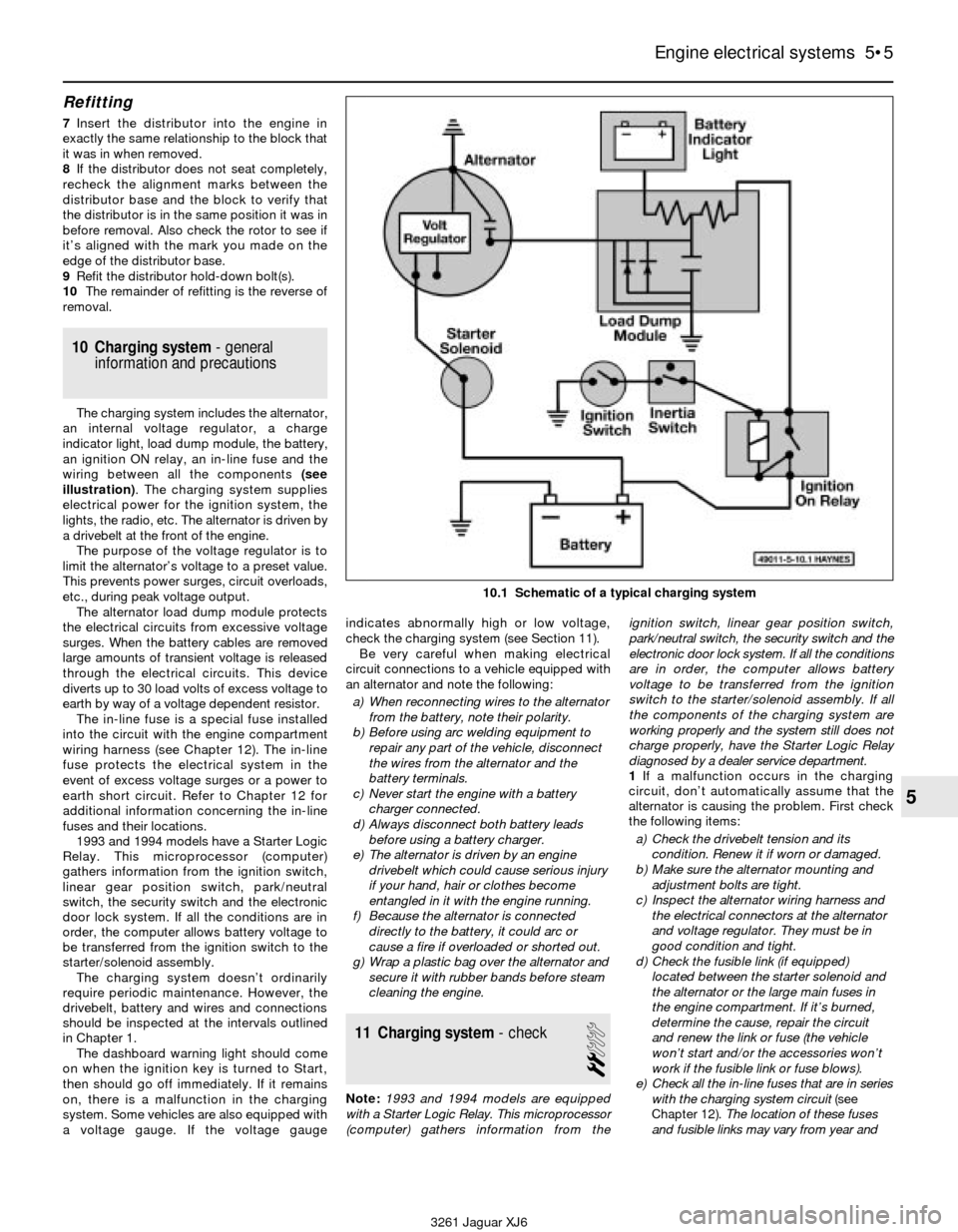

10 Charging system- general

information and precautions

The charging system includes the alternator,

an internal voltage regulator, a charge

indicator light, load dump module, the battery,

an ignition ON relay, an in-line fuse and the

wiring between all the components (see

illustration). The charging system supplies

electrical power for the ignition system, the

lights, the radio, etc. The alternator is driven by

a drivebelt at the front of the engine.

The purpose of the voltage regulator is to

limit the alternator’s voltage to a preset value.

This prevents power surges, circuit overloads,

etc., during peak voltage output.

The alternator load dump module protects

the electrical circuits from excessive voltage

surges. When the battery cables are removed

large amounts of transient voltage is released

through the electrical circuits. This device

diverts up to 30 load volts of excess voltage to

earth by way of a voltage dependent resistor.

The in-line fuse is a special fuse installed

into the circuit with the engine compartment

wiring harness (see Chapter 12). The in-line

fuse protects the electrical system in the

event of excess voltage surges or a power to

earth short circuit. Refer to Chapter 12 for

additional information concerning the in-line

fuses and their locations.

1993 and 1994 models have a Starter Logic

Relay. This microprocessor (computer)

gathers information from the ignition switch,

linear gear position switch, park/neutral

switch, the security switch and the electronic

door lock system. If all the conditions are in

order, the computer allows battery voltage to

be transferred from the ignition switch to the

starter/solenoid assembly.

The charging system doesn’t ordinarily

require periodic maintenance. However, the

drivebelt, battery and wires and connections

should be inspected at the intervals outlined

in Chapter 1.

The dashboard warning light should come

on when the ignition key is turned to Start,

then should go off immediately. If it remains

on, there is a malfunction in the charging

system. Some vehicles are also equipped with

a voltage gauge. If the voltage gaugeindicates abnormally high or low voltage,

check the charging system (see Section 11).

Be very careful when making electrical

circuit connections to a vehicle equipped with

an alternator and note the following:

a) When reconnecting wires to the alternator

from the battery, note their polarity.

b) Before using arc welding equipment to

repair any part of the vehicle, disconnect

the wires from the alternator and the

battery terminals.

c) Never start the engine with a battery

charger connected.

d) Always disconnect both battery leads

before using a battery charger.

e) The alternator is driven by an engine

drivebelt which could cause serious injury

if your hand, hair or clothes become

entangled in it with the engine running.

f) Because the alternator is connected

directly to the battery, it could arc or

cause a fire if overloaded or shorted out.

g) Wrap a plastic bag over the alternator and

secure it with rubber bands before steam

cleaning the engine.

11 Charging system- check

2

Note:1993 and 1994 models are equipped

with a Starter Logic Relay. This microprocessor

(computer) gathers information from theignition switch, linear gear position switch,

park/neutral switch, the security switch and the

electronic door lock system. If all the conditions

are in order, the computer allows battery

voltage to be transferred from the ignition

switch to the starter/solenoid assembly. If all

the components of the charging system are

working properly and the system still does not

charge properly, have the Starter Logic Relay

diagnosed by a dealer service department.

1If a malfunction occurs in the charging

circuit, don’t automatically assume that the

alternator is causing the problem. First check

the following items:

a) Check the drivebelt tension and its

condition. Renew it if worn or damaged.

b) Make sure the alternator mounting and

adjustment bolts are tight.

c) Inspect the alternator wiring harness and

the electrical connectors at the alternator

and voltage regulator. They must be in

good condition and tight.

d) Check the fusible link (if equipped)

located between the starter solenoid and

the alternator or the large main fuses in

the engine compartment. If it’s burned,

determine the cause, repair the circuit

and renew the link or fuse (the vehicle

won’t start and/or the accessories won’t

work if the fusible link or fuse blows).

e) Check all the in-line fuses that are in series

with the charging system circuit (see

Chapter 12).The location of these fuses

and fusible links may vary from year and

Engine electrical systems 5•5

5

10.1 Schematic of a typical charging system

3261 Jaguar XJ6

Page 126 of 227

necessary to detach the brake line. If you’re

removing the caliper for overhaul, detach the

hose from the metal line at the frame bracket

(see Section 8), then disconnect the brake line

from the caliper with a flare-nut spanner to

protect the fitting (see illustration). Plug the

metal line to keep contaminants out of the

brake system and to prevent losing brake

fluid.

3Refer to illustration 3.5c and unbolt the

front or rear caliper.

Overhaul

4Before you remove the piston, place a

wood block between the piston and caliper to

prevent damage as it is removed.

5To remove the piston from the caliper,

apply compressed air to the brake fluid hose

connection on the caliper body (see

illustration). Use only enough pressure to

ease the piston out of its bore. Remove the

dust boot.

Warning: Be careful not to place

your fingers between the piston

and the caliper as the piston

may come out with some force.

Be sure to wear eye protection when using

compressed air.

6Inspect the mating surfaces of the piston

and caliper bore wall. If there is any scoring,

rust, pitting or bright areas, renew the

complete caliper unit with a new one.

7If these components are in good condition,

remove the piston seal from the caliper bore

using a wooden or plastic tool (see

illustration). Metal tools may damage the

cylinder bore.

8Remove the caliper guide pins and the

rubber dust boots from the caliper bracket.

9Wash all the components in brake system

cleaner.

10Using the correct rebuild kit for your

vehicle, reassemble the caliper as follows.11Submerge the new rubber seal in clean

brake fluid and refit it in the lower groove in

the caliper bore, making sure it isn’t twisted.

12Coat the piston with clean brake fluid and

stretch the new dust boot over the bottom of

the piston. Hold the piston over the caliper

bore and insert the rubber flange of the dust

boot into the upper groove in the bore. Start

with the side farthest from you and work your

way around toward the front until it is

completely seated. Push the piston into the

caliper bore until it is bottomed in the bore,

then seat the top of the dust boot in the

groove in the piston.

13Lubricate the sliding surfaces of the guide

pins with silicone-based grease (usually

supplied in the kit), then refit the new dust

boots and pins into the caliper bracket.

Refitting

14Refit the caliper by reversing the removal

procedure (see Section 3).

15If the brake hose was disconnected from

the caliper, bleed the brake system (see

Section 9).

5 Brake disc- inspection,

removal and refitting

2

Note:The following procedure applies to both

the front and rear brake discs.

Inspection

1Loosen the wheel nuts, raise the vehicle

and support it securely on axle stands.

Remove the wheel and refit three nuts to hold

the disc in place. If the rear brake disc is being

worked on, release the handbrake.

2Remove the brake caliper as outlined in

Section 4. It is not necessary to disconnect

the brake hose. After removing the caliper,

suspend it out of the way with a piece of wire.

3Visually inspect the disc surface for scoring

or damage. Light scratches and shallow

grooves are normal after use and may not

always be detrimental to brake operation, but

deep scoring - over 0.015 inch - requires disc

removal and refinishing by an automotive

machine shop. Be sure to check both sides of

the disc (see illustration). If pulsating has

9•4 Braking system

4.7 Remove the piston seal from the

caliper bore using a wooden or plastic tool

(metal tools may damage the

cylinder bore)5.3 The brake pads on this vehicle were

obviously neglected, as they wore down to

the rivets and cut deep grooves into the

disc - this disc must be replaced

3261 Jaguar XJ6 4.2 Use a flare-nut spanner to protect the brake hose fitting when

unscrewing it from the caliper

4.5 With the caliper padded to catch the piston, use compressed

air to force the piston out of its bore - make sure your fingers are

not between the piston and the caliper

Page 139 of 227

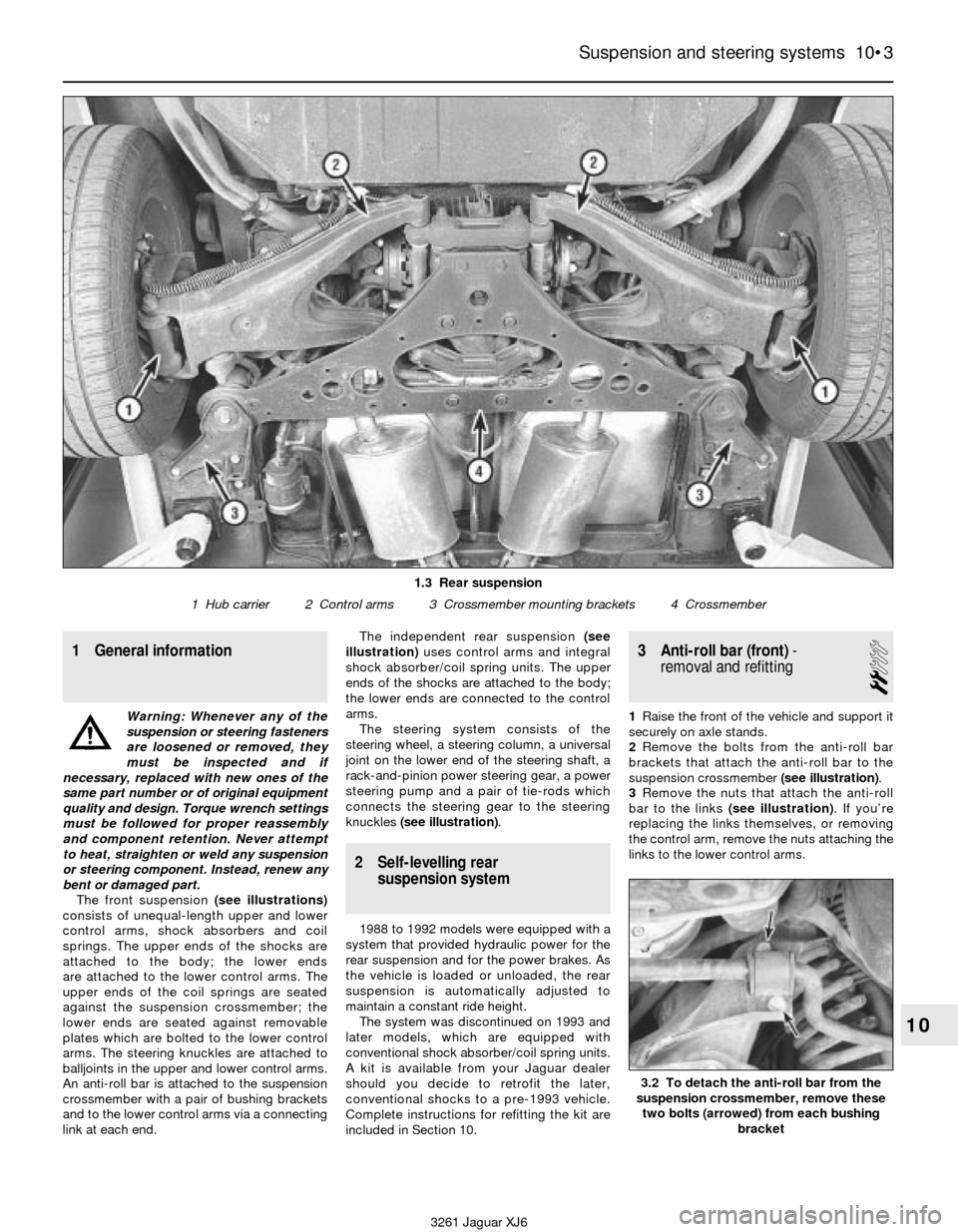

1 General information

Warning: Whenever any of the

suspension or steering fasteners

are loosened or removed, they

must be inspected and if

necessary, replaced with new ones of the

same part number or of original equipment

quality and design. Torque wrench settings

must be followed for proper reassembly

and component retention. Never attempt

to heat, straighten or weld any suspension

or steering component. Instead, renew any

bent or damaged part.

The front suspension (see illustrations)

consists of unequal-length upper and lower

control arms, shock absorbers and coil

springs. The upper ends of the shocks are

attached to the body; the lower ends

are attached to the lower control arms. The

upper ends of the coil springs are seated

against the suspension crossmember; the

lower ends are seated against removable

plates which are bolted to the lower control

arms. The steering knuckles are attached to

balljoints in the upper and lower control arms.

An anti-roll bar is attached to the suspension

crossmember with a pair of bushing brackets

and to the lower control arms via a connecting

link at each end.The independent rear suspension (see

illustration)uses control arms and integral

shock absorber/coil spring units. The upper

ends of the shocks are attached to the body;

the lower ends are connected to the control

arms.

The steering system consists of the

steering wheel, a steering column, a universal

joint on the lower end of the steering shaft, a

rack-and-pinion power steering gear, a power

steering pump and a pair of tie-rods which

connects the steering gear to the steering

knuckles (see illustration).

2 Self-levelling rear

suspension system

1988 to 1992 models were equipped with a

system that provided hydraulic power for the

rear suspension and for the power brakes. As

the vehicle is loaded or unloaded, the rear

suspension is automatically adjusted to

maintain a constant ride height.

The system was discontinued on 1993 and

later models, which are equipped with

conventional shock absorber/coil spring units.

A kit is available from your Jaguar dealer

should you decide to retrofit the later,

conventional shocks to a pre-1993 vehicle.

Complete instructions for refitting the kit are

included in Section 10.

3 Anti-roll bar (front)-

removal and refitting

2

1Raise the front of the vehicle and support it

securely on axle stands.

2Remove the bolts from the anti-roll bar

brackets that attach the anti-roll bar to the

suspension crossmember (see illustration).

3Remove the nuts that attach the anti-roll

bar to the links (see illustration). If you’re

replacing the links themselves, or removing

the control arm, remove the nuts attaching the

links to the lower control arms.

Suspension and steering systems 10•3

10

1.3 Rear suspension

1 Hub carrier 2 Control arms 3 Crossmember mounting brackets 4 Crossmember

3.2 To detach the anti-roll bar from the

suspension crossmember, remove these

two bolts (arrowed) from each bushing

bracket

3261 Jaguar XJ6

Page 149 of 227

3261 Jaguar XJ6

11

Chapter 11

Bodywork and fittings

Body - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Body repair - major damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Body repair - minor damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bonnet - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . 10

Bonnet and boot lid support struts - removal and refitting . . . . . . . . 9

Bonnet release latch and cable - removal and refitting . . . . . . . . . . . 11

Boot lid - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . 16

Boot lid latch and lock cylinder - removal and refitting . . . . . . . . . . . 17

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 24

Cowl cover - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Dashboard trim panels - removal and refitting . . . . . . . . . . . . . . . . . 26

Door - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . 19

Door latch, lock cylinder and handles - removal and refitting . . . . . . 20

Door trim panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 18Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . . 22

Door window glass regulator - removal and refitting . . . . . . . . . . . . . 21

Front spoiler - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 13

Front wing - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hinges and locks - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Instrument cluster housing - removal and refitting . . . . . . . . . . . . . . 25

Outside mirrors - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 23

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 12

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Steering column cover - removal and refitting . . . . . . . . . . . . . . . . . 27

Upholstery and carpets - maintenance . . . . . . . . . . . . . . . . . . . . . . . 4

Vinyl trim - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Windscreen and fixed glass - replacement . . . . . . . . . . . . . . . . . . . . 8

11•1

Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

These models feature a “unibody”

construction, using a floor pan with front and

rear frame side rails which support the body

components, front and rear suspension

systems and other mechanical components.

Certain components are particularly vulnerable

to accident damage and can be unbolted and

repaired or replaced. Among these parts are

the body mouldings, bumpers, front wings,

bonnet and boot lids and all glass.

Only general body maintenance practices

and body panel repair procedures within the

scope of the do-it-yourselfer are included in

this Chapter.

2 Body- maintenance

1

1The condition of your vehicle’s body is very

important, because the resale value depends

a great deal on it. It’s much more difficult to

repair a neglected or damaged body than it is

to repair mechanical components. The hidden

areas of the body, such as the wheel wells,

the frame and the engine compartment, areequally important, although they don’t require

as frequent attention as the rest of the body.

2Once a year, or every 12,000 miles, it’s a

good idea to have the underside of the body

steam cleaned. All traces of dirt and oil will be

removed and the area can then be inspected

carefully for rust, damaged brake lines, frayed

electrical wires, damaged cables and other

problems. The front suspension components

should be greased after completion of this job.

3At the same time, clean the engine and the

engine compartment with a steam cleaner or

water soluble degreaser.

4The wheel wells should be given close

attention, since undercoating can peel away

and stones and dirt thrown up by the tyres

can cause the paint to chip and flake, allowing

rust to set in. If rust is found, clean down to

the bare metal and apply an anti-rust paint.

5The body should be washed about once a

week. Wet the vehicle thoroughly to soften the

dirt, then wash it down with a soft sponge and

plenty of clean soapy water. If the surplus dirt

is not washed off very carefully, it can wear

down the paint.

6Spots of tar or asphalt thrown up from the

road should be removed with a cloth soaked

in solvent.

7Once every six months, wax the body and

chrome trim. If a chrome cleaner is used to

remove rust from any of the vehicle’s plated

parts, remember that the cleaner also removes

part of the chrome, so use it sparingly.

3 Vinyl trim- maintenance

1

Don’t clean vinyl trim with detergents,

caustic soap or petroleum-based cleaners.

Plain soap and water works just fine, with a

soft brush to clean dirt that may be ingrained.

Wash the vinyl as frequently as the rest of the

vehicle.

After cleaning, application of a high quality

rubber and vinyl protectant will help prevent

oxidation and cracks. The protectant can also

be applied to weather-stripping, vacuum lines

and rubber hoses (which often fail as a result

of chemical degradation) and to the tyres.

4 Upholstery and carpets-

maintenance

1

1Every three months remove the carpets or

mats and clean the interior of the vehicle

(more frequently if necessary). Vacuum the

upholstery and carpets to remove loose dirt

and dust.

2Leather upholstery requires special care.

Stains should be removed with warm water

and a very mild soap solution. Use a clean,

damp cloth to remove the soap, then wipe

Page 153 of 227

7Attach a piece of thin wire or string to the

end of the cables to help aid the refitting

process.

8Working in the engine compartment, pull

the cables and grommet out of the bulkhead

until you can see the wire or string. Ensure

that the new cable has a grommet attached

then remove the old cable from the wire or

string and replace it with the new cable.

9Working from passenger compartment pull

the wire or string back through the bulkhead.

10Refitting is the reverse of removal.Note:

Push on the grommet with your fingers from

the engine compartment to seat the grommet

in the bulkhead.

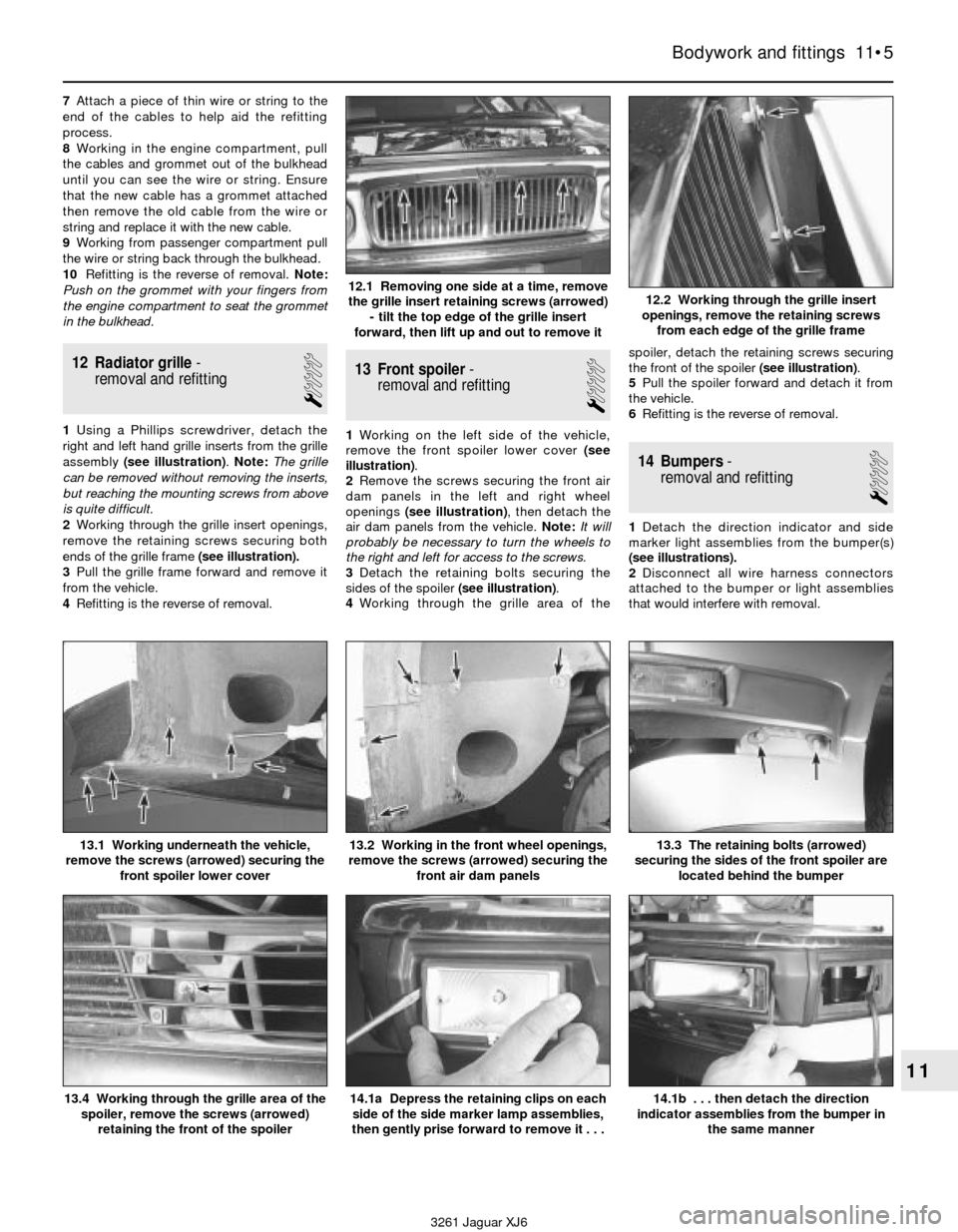

12 Radiator grille-

removal and refitting

1

1Using a Phillips screwdriver, detach the

right and left hand grille inserts from the grille

assembly (see illustration).Note: The grille

can be removed without removing the inserts,

but reaching the mounting screws from above

is quite difficult.

2Working through the grille insert openings,

remove the retaining screws securing both

ends of the grille frame (see illustration).

3Pull the grille frame forward and remove it

from the vehicle.

4Refitting is the reverse of removal.

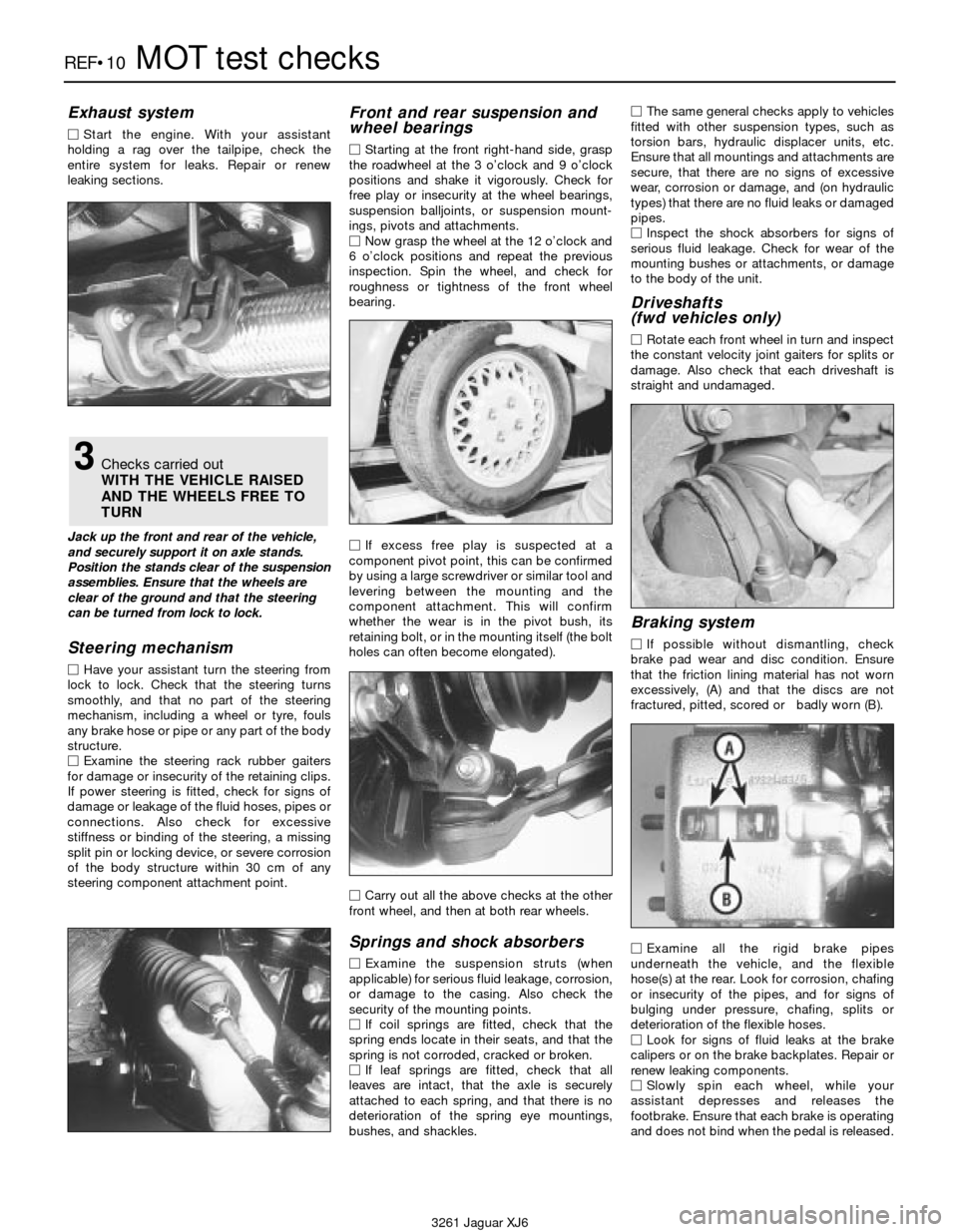

13 Front spoiler-

removal and refitting

1

1Working on the left side of the vehicle,

remove the front spoiler lower cover (see

illustration).

2Remove the screws securing the front air

dam panels in the left and right wheel

openings (see illustration), then detach the

air dam panels from the vehicle. Note:It will

probably be necessary to turn the wheels to

the right and left for access to the screws.

3Detach the retaining bolts securing the

sides of the spoiler (see illustration).

4Working through the grille area of thespoiler, detach the retaining screws securing

the front of the spoiler (see illustration).

5Pull the spoiler forward and detach it from

the vehicle.

6Refitting is the reverse of removal.

14 Bumpers-

removal and refitting

1

1Detach the direction indicator and side

marker light assemblies from the bumper(s)

(see illustrations).

2Disconnect all wire harness connectors

attached to the bumper or light assemblies

that would interfere with removal.

Bodywork and fittings 11•5

11

12.1 Removing one side at a time, remove

the grille insert retaining screws (arrowed)

- tilt the top edge of the grille insert

forward, then lift up and out to remove it12.2 Working through the grille insert

openings, remove the retaining screws

from each edge of the grille frame

13.4 Working through the grille area of the

spoiler, remove the screws (arrowed)

retaining the front of the spoiler14.1a Depress the retaining clips on each

side of the side marker lamp assemblies,

then gently prise forward to remove it . . .14.1b . . . then detach the direction

indicator assemblies from the bumper in

the same manner

13.1 Working underneath the vehicle,

remove the screws (arrowed) securing the

front spoiler lower cover13.2 Working in the front wheel openings,

remove the screws (arrowed) securing the

front air dam panels13.3 The retaining bolts (arrowed)

securing the sides of the front spoiler are

located behind the bumper

3261 Jaguar XJ6

Page 162 of 227

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering column or instrument panel. The

manufacturer recommends that, on airbag

equipped models, the following procedure

should be left to a dealer service

department or other repair workshop

because of the special tools and techniques

required to disable the airbag system.

1Remove the steering wheel (Chapter 10)

2Remove the knob from the rheostat

(dimmer) for the instrument panel lights (see

illustration).

3Remove the lower steering column cover

screws (see illustration), then detach the

lower cover.

4Working through the lower cover opening,

remove the four screws securing the upper

half of the cover, then pull the cover forward

and out to remove it (see illustration).

5Refitting is the reverse of removal.

28 Cowl cover-

removal and refitting

2

1Remove the windscreen wiper arms (see

Chapter 12).2Remove the retaining screws located along

the top of the cowl cover (see illustration).

3Lift the cowl cover up slightly, then detach

the electrical connectors and the spray nozzle

hoses from the backside of the cowl cover.

4Detach the cowl cover from the vehicle.

5Refitting is the reverse of removal.

29 Seats- removal and refitting

2

Front seat

1Position the seat all the way forward or all

the way to the rear to access the front seat

retaining bolts.

2Detach any bolt trim covers and remove the

retaining bolts (see illustration).

3Tilt the seat upward to access the

underneath, then unplug any electrical

connectors and lift the seat from the vehicle.

4Refitting is the reverse of removal.

Rear seat

5Remove retaining screws at the lower edge

of the seat cushion (see illustration). Then lift

up on the front edge and remove the cushion

from the vehicle.

6Detach the retaining bolts at the lower edge

of the seat back.

7Lift up on the lower edge of the seat back to

release the clips securing the top. Then

remove it from the vehicle.

8Refitting is the reverse of removal.

11•14 Bodywork and fittings

27.4 Remove the four screws securing the

upper half of the steering column cover

28.2 Remove the screws (arrowed)

located along the top of the cowl cover29.2 Use a Torx bit to remove the front

seat retaining bolts (arrowed)

3261 Jaguar XJ6 27.2 Pull off the knob from the instrument panel light rheostat

27.3 Remove the lower steering column cover screws

29.5 Detach the screws (arrowed) along

the lower edge of the seat cove

Page 210 of 227

3261 Jaguar XJ6

MOT test checksREF•9

Seat belts and seats

Note: The following checks are applicable to

all seat belts, front and rear.

MExamine the webbing of all the belts

(including rear belts if fitted) for cuts, serious

fraying or deterioration. Fasten and unfasten

each belt to check the buckles. If applicable,

check the retracting mechanism. Check the

security of all seat belt mountings accessible

from inside the vehicle.

MThe front seats themselves must be

securely attached and the backrests must

lock in the upright position.

Doors

MBoth front doors must be able to be opened

and closed from outside and inside, and must

latch securely when closed.

Vehicle identification

MNumber plates must be in good condition,

secure and legible, with letters and numbers

correctly spaced – spacing at (A) should be

twice that at (B).

MThe VIN plate and/or homologation plate

must be legible.

Electrical equipment

MSwitch on the ignition and check the

operation of the horn.

MCheck the windscreen washers and wipers,

examining the wiper blades; renew damaged

or perished blades. Also check the operation

of the stop-lights.

MCheck the operation of the sidelights and

number plate lights. The lenses and reflectors

must be secure, clean and undamaged.

MCheck the operation and alignment of the

headlights. The headlight reflectors must not

be tarnished and the lenses must be

undamaged.

MSwitch on the ignition and check the

operation of the direction indicators (including

the instrument panel tell-tale) and the hazard

warning lights. Operation of the sidelights and

stop-lights must not affect the indicators - if it

does, the cause is usually a bad earth at the

rear light cluster.

MCheck the operation of the rear foglight(s),

including the warning light on the instrument

panel or in the switch.

Footbrake

MExamine the master cylinder, brake pipes

and servo unit for leaks, loose mountings,

corrosion or other damage.

MThe fluid reservoir must be secure and the

fluid level must be between the upper (A) and

lower (B) markings.MInspect both front brake flexible hoses for

cracks or deterioration of the rubber. Turn the

steering from lock to lock, and ensure that the

hoses do not contact the wheel, tyre, or any

part of the steering or suspension mechanism.

With the brake pedal firmly depressed, check

the hoses for bulges or leaks under pressure.

Steering and suspension

MHave your assistant turn the steering wheel

from side to side slightly, up to the point where

the steering gear just begins to transmit this

movement to the roadwheels. Check for

excessive free play between the steering

wheel and the steering gear, indicating wear or

insecurity of the steering column joints, the

column-to-steering gear coupling, or the

steering gear itself.

MHave your assistant turn the steering wheel

more vigorously in each direction, so that the

roadwheels just begin to turn. As this is done,

examine all the steering joints, linkages,

fittings and attachments. Renew any

component that shows signs of wear or

damage. On vehicles with power steering,

check the security and condition of the

steering pump, drivebelt and hoses.

MCheck that the vehicle is standing level,

and at approximately the correct ride height.

Shock absorbers

MDepress each corner of the vehicle in turn,

then release it. The vehicle should rise and

then settle in its normal position. If the vehicle

continues to rise and fall, the shock absorber

is defective. A shock absorber which has

seized will also cause the vehicle to fail.

2Checks carried out

WITH THE VEHICLE ON THE

GROUND

Page 211 of 227

3261 Jaguar XJ6

REF•10MOT test checks

Exhaust system

MStart the engine. With your assistant

holding a rag over the tailpipe, check the

entire system for leaks. Repair or renew

leaking sections.

Jack up the front and rear of the vehicle,

and securely support it on axle stands.

Position the stands clear of the suspension

assemblies. Ensure that the wheels are

clear of the ground and that the steering

can be turned from lock to lock.

Steering mechanism

MHave your assistant turn the steering from

lock to lock. Check that the steering turns

smoothly, and that no part of the steering

mechanism, including a wheel or tyre, fouls

any brake hose or pipe or any part of the body

structure.

MExamine the steering rack rubber gaiters

for damage or insecurity of the retaining clips.

If power steering is fitted, check for signs of

damage or leakage of the fluid hoses, pipes or

connections. Also check for excessive

stiffness or binding of the steering, a missing

split pin or locking device, or severe corrosion

of the body structure within 30 cm of any

steering component attachment point.

Front and rear suspension and

wheel bearings

MStarting at the front right-hand side, grasp

the roadwheel at the 3 o’clock and 9 o’clock

positions and shake it vigorously. Check for

free play or insecurity at the wheel bearings,

suspension balljoints, or suspension mount-

ings, pivots and attachments.

MNow grasp the wheel at the 12 o’clock and

6 o’clock positions and repeat the previous

inspection. Spin the wheel, and check for

roughness or tightness of the front wheel

bearing.

MIf excess free play is suspected at a

component pivot point, this can be confirmed

by using a large screwdriver or similar tool and

levering between the mounting and the

component attachment. This will confirm

whether the wear is in the pivot bush, its

retaining bolt, or in the mounting itself (the bolt

holes can often become elongated).

MCarry out all the above checks at the other

front wheel, and then at both rear wheels.

Springs and shock absorbers

MExamine the suspension struts (when

applicable) for serious fluid leakage, corrosion,

or damage to the casing. Also check the

security of the mounting points.

MIf coil springs are fitted, check that the

spring ends locate in their seats, and that the

spring is not corroded, cracked or broken.

MIf leaf springs are fitted, check that all

leaves are intact, that the axle is securely

attached to each spring, and that there is no

deterioration of the spring eye mountings,

bushes, and shackles.MThe same general checks apply to vehicles

fitted with other suspension types, such as

torsion bars, hydraulic displacer units, etc.

Ensure that all mountings and attachments are

secure, that there are no signs of excessive

wear, corrosion or damage, and (on hydraulic

types) that there are no fluid leaks or damaged

pipes.

MInspect the shock absorbers for signs of

serious fluid leakage. Check for wear of the

mounting bushes or attachments, or damage

to the body of the unit.

Driveshafts

(fwd vehicles only)

MRotate each front wheel in turn and inspect

the constant velocity joint gaiters for splits or

damage. Also check that each driveshaft is

straight and undamaged.

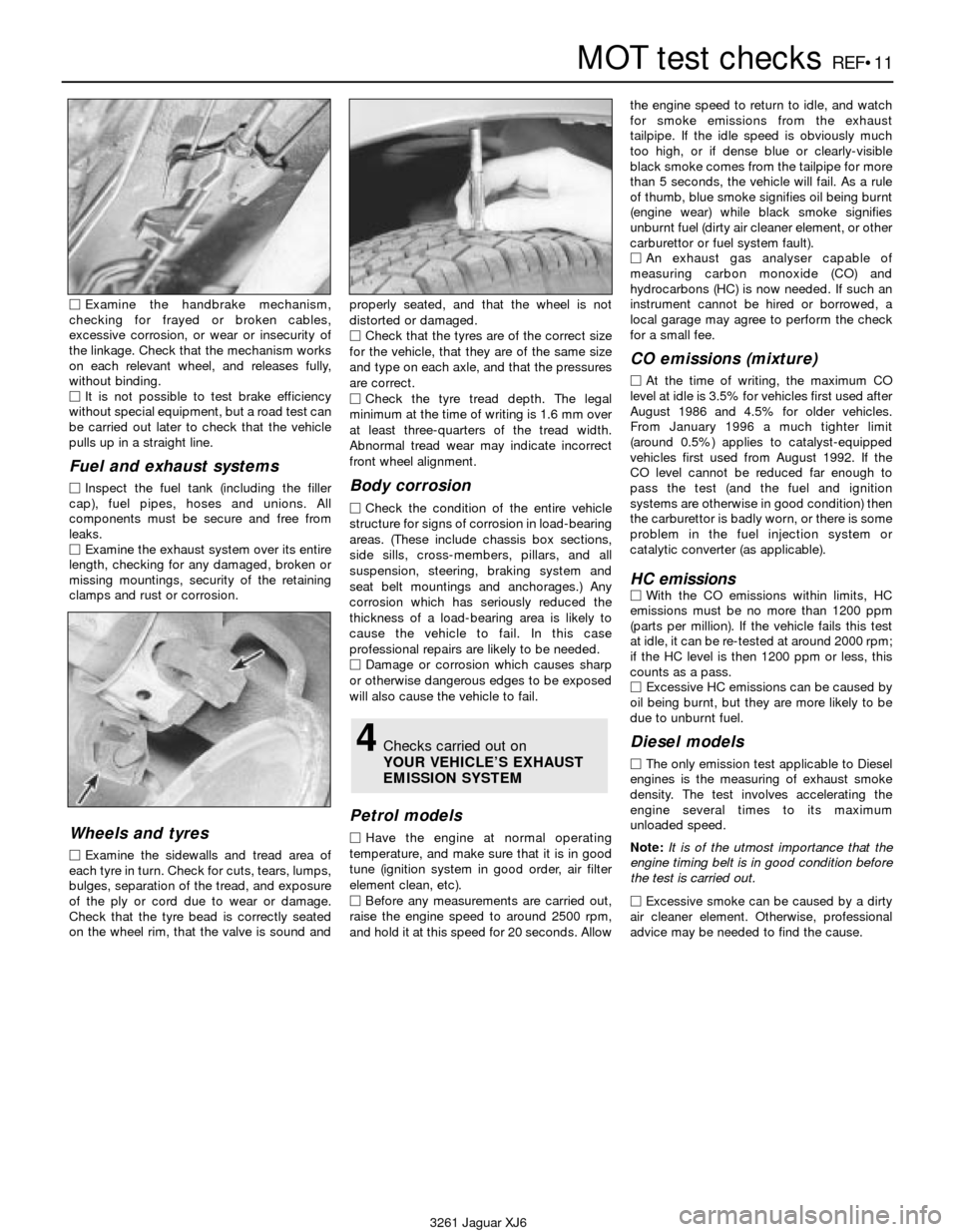

Braking system

MIf possible without dismantling, check

brake pad wear and disc condition. Ensure

that the friction lining material has not worn

excessively, (A) and that the discs are not

fractured, pitted, scored or badly worn (B).

MExamine all the rigid brake pipes

underneath the vehicle, and the flexible

hose(s) at the rear. Look for corrosion, chafing

or insecurity of the pipes, and for signs of

bulging under pressure, chafing, splits or

deterioration of the flexible hoses.

MLook for signs of fluid leaks at the brake

calipers or on the brake backplates. Repair or

renew leaking components.

MSlowly spin each wheel, while your

assistant depresses and releases the

footbrake. Ensure that each brake is operating

and does not bind when the pedal is released.

3Checks carried out

WITH THE VEHICLE RAISED

AND THE WHEELS FREE TO

TURN

Page 212 of 227

3261 Jaguar XJ6

MOT test checksREF•11

MExamine the handbrake mechanism,

checking for frayed or broken cables,

excessive corrosion, or wear or insecurity of

the linkage. Check that the mechanism works

on each relevant wheel, and releases fully,

without binding.

MIt is not possible to test brake efficiency

without special equipment, but a road test can

be carried out later to check that the vehicle

pulls up in a straight line.

Fuel and exhaust systems

MInspect the fuel tank (including the filler

cap), fuel pipes, hoses and unions. All

components must be secure and free from

leaks.

MExamine the exhaust system over its entire

length, checking for any damaged, broken or

missing mountings, security of the retaining

clamps and rust or corrosion.

Wheels and tyres

MExamine the sidewalls and tread area of

each tyre in turn. Check for cuts, tears, lumps,

bulges, separation of the tread, and exposure

of the ply or cord due to wear or damage.

Check that the tyre bead is correctly seated

on the wheel rim, that the valve is sound andproperly seated, and that the wheel is not

distorted or damaged.

MCheck that the tyres are of the correct size

for the vehicle, that they are of the same size

and type on each axle, and that the pressures

are correct.

MCheck the tyre tread depth. The legal

minimum at the time of writing is 1.6 mm over

at least three-quarters of the tread width.

Abnormal tread wear may indicate incorrect

front wheel alignment.

Body corrosion

MCheck the condition of the entire vehicle

structure for signs of corrosion in load-bearing

areas. (These include chassis box sections,

side sills, cross-members, pillars, and all

suspension, steering, braking system and

seat belt mountings and anchorages.) Any

corrosion which has seriously reduced the

thickness of a load-bearing area is likely to

cause the vehicle to fail. In this case

professional repairs are likely to be needed.

MDamage or corrosion which causes sharp

or otherwise dangerous edges to be exposed

will also cause the vehicle to fail.

Petrol models

MHave the engine at normal operating

temperature, and make sure that it is in good

tune (ignition system in good order, air filter

element clean, etc).

MBefore any measurements are carried out,

raise the engine speed to around 2500 rpm,

and hold it at this speed for 20 seconds. Allowthe engine speed to return to idle, and watch

for smoke emissions from the exhaust

tailpipe. If the idle speed is obviously much

too high, or if dense blue or clearly-visible

black smoke comes from the tailpipe for more

than 5 seconds, the vehicle will fail. As a rule

of thumb, blue smoke signifies oil being burnt

(engine wear) while black smoke signifies

unburnt fuel (dirty air cleaner element, or other

carburettor or fuel system fault).

MAn exhaust gas analyser capable of

measuring carbon monoxide (CO) and

hydrocarbons (HC) is now needed. If such an

instrument cannot be hired or borrowed, a

local garage may agree to perform the check

for a small fee.

CO emissions (mixture)

MAt the time of writing, the maximum CO

level at idle is 3.5% for vehicles first used after

August 1986 and 4.5% for older vehicles.

From January 1996 a much tighter limit

(around 0.5%) applies to catalyst-equipped

vehicles first used from August 1992. If the

CO level cannot be reduced far enough to

pass the test (and the fuel and ignition

systems are otherwise in good condition) then

the carburettor is badly worn, or there is some

problem in the fuel injection system or

catalytic converter (as applicable).

HC emissionsMWith the CO emissions within limits, HC

emissions must be no more than 1200 ppm

(parts per million). If the vehicle fails this test

at idle, it can be re-tested at around 2000 rpm;

if the HC level is then 1200 ppm or less, this

counts as a pass.

MExcessive HC emissions can be caused by

oil being burnt, but they are more likely to be

due to unburnt fuel.

Diesel models

MThe only emission test applicable to Diesel

engines is the measuring of exhaust smoke

density. The test involves accelerating the

engine several times to its maximum

unloaded speed.

Note: It is of the utmost importance that the

engine timing belt is in good condition before

the test is carried out.

M

Excessive smoke can be caused by a dirty

air cleaner element. Otherwise, professional

advice may be needed to find the cause.

4Checks carried out on

YOUR VEHICLE’S EXHAUST

EMISSION SYSTEM