wheel alignment JAGUAR XJ6 1997 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 147 of 227

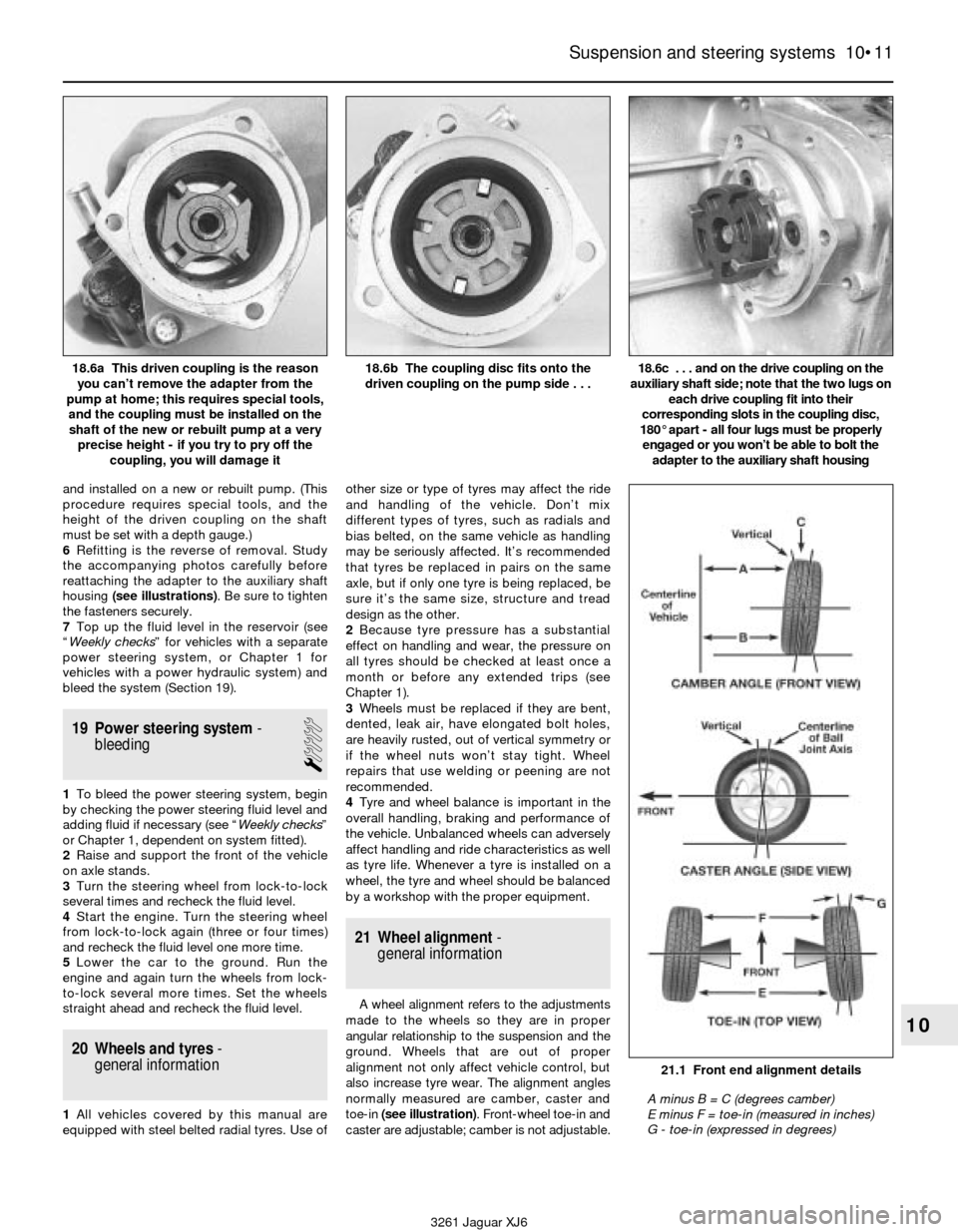

and installed on a new or rebuilt pump. (This

procedure requires special tools, and the

height of the driven coupling on the shaft

must be set with a depth gauge.)

6Refitting is the reverse of removal. Study

the accompanying photos carefully before

reattaching the adapter to the auxiliary shaft

housing (see illustrations). Be sure to tighten

the fasteners securely.

7Top up the fluid level in the reservoir (see

“Weekly checks” for vehicles with a separate

power steering system, or Chapter 1 for

vehicles with a power hydraulic system) and

bleed the system (Section 19).

19 Power steering system-

bleeding

1

1To bleed the power steering system, begin

by checking the power steering fluid level and

adding fluid if necessary (see “Weekly checks”

or Chapter 1, dependent on system fitted).

2Raise and support the front of the vehicle

on axle stands.

3Turn the steering wheel from lock-to-lock

several times and recheck the fluid level.

4Start the engine. Turn the steering wheel

from lock-to-lock again (three or four times)

and recheck the fluid level one more time.

5Lower the car to the ground. Run the

engine and again turn the wheels from lock-

to-lock several more times. Set the wheels

straight ahead and recheck the fluid level.

20 Wheels and tyres-

general information

1All vehicles covered by this manual are

equipped with steel belted radial tyres. Use ofother size or type of tyres may affect the ride

and handling of the vehicle. Don’t mix

different types of tyres, such as radials and

bias belted, on the same vehicle as handling

may be seriously affected. It’s recommended

that tyres be replaced in pairs on the same

axle, but if only one tyre is being replaced, be

sure it’s the same size, structure and tread

design as the other.

2Because tyre pressure has a substantial

effect on handling and wear, the pressure on

all tyres should be checked at least once a

month or before any extended trips (see

Chapter 1).

3Wheels must be replaced if they are bent,

dented, leak air, have elongated bolt holes,

are heavily rusted, out of vertical symmetry or

if the wheel nuts won’t stay tight. Wheel

repairs that use welding or peening are not

recommended.

4Tyre and wheel balance is important in the

overall handling, braking and performance of

the vehicle. Unbalanced wheels can adversely

affect handling and ride characteristics as well

as tyre life. Whenever a tyre is installed on a

wheel, the tyre and wheel should be balanced

by a workshop with the proper equipment.

21 Wheel alignment-

general information

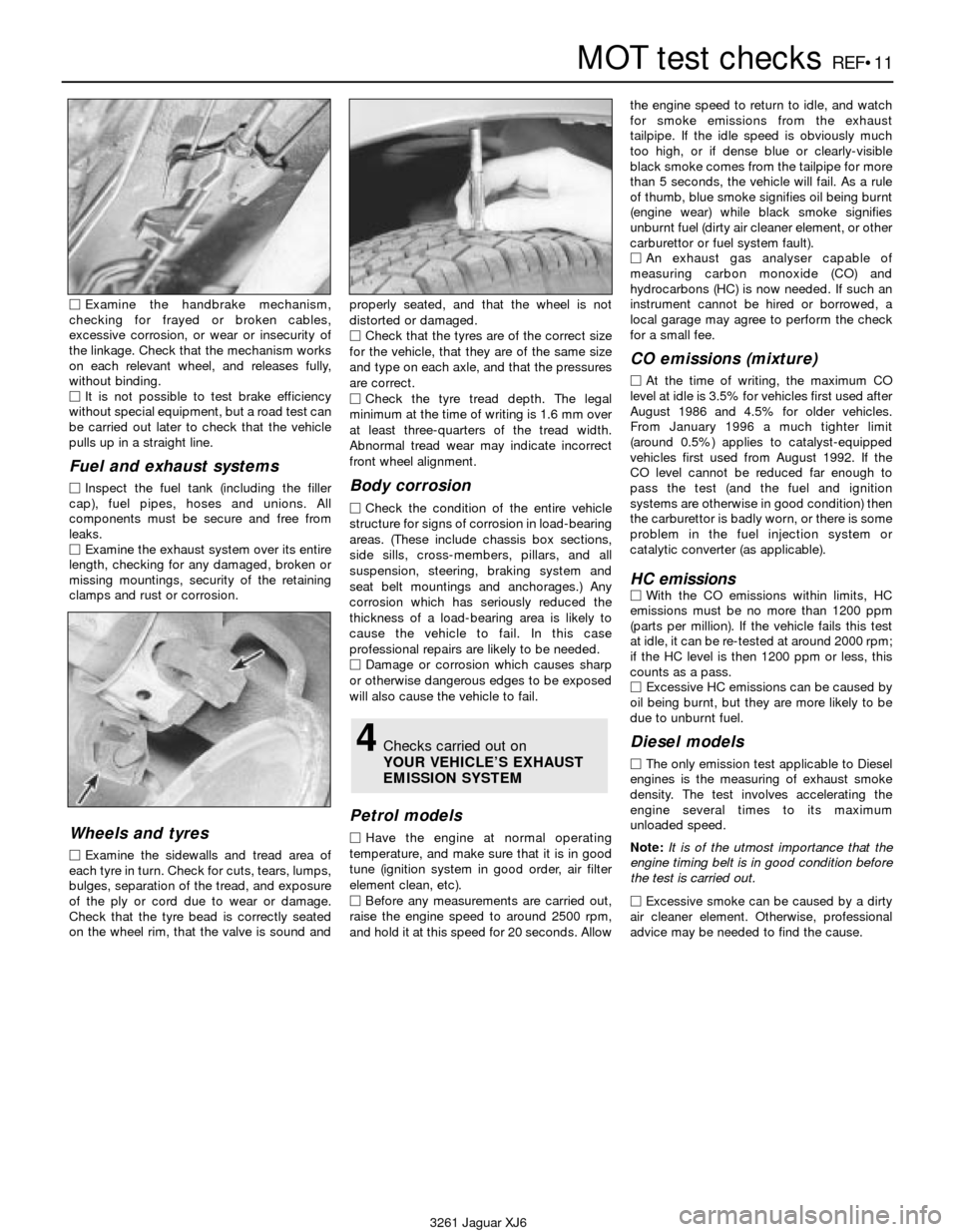

A wheel alignment refers to the adjustments

made to the wheels so they are in proper

angular relationship to the suspension and the

ground. Wheels that are out of proper

alignment not only affect vehicle control, but

also increase tyre wear. The alignment angles

normally measured are camber, caster and

toe-in (see illustration). Front-wheel toe-in and

caster are adjustable; camber is not adjustable.

Suspension and steering systems 10•11

10

3261 Jaguar XJ6 18.6a This driven coupling is the reason

you can’t remove the adapter from the

pump at home; this requires special tools,

and the coupling must be installed on the

shaft of the new or rebuilt pump at a very

precise height - if you try to pry off the

coupling, you will damage it

18.6b The coupling disc fits onto the

driven coupling on the pump side . . .18.6c . . . and on the drive coupling on the

auxiliary shaft side; note that the two lugs on

each drive coupling fit into their

corresponding slots in the coupling disc,

180° apart - all four lugs must be properly

engaged or you won’t be able to bolt the

adapter to the auxiliary shaft housing

21.1 Front end alignment details

A minus B = C (degrees camber)

E minus F = toe-in (measured in inches)

G - toe-in (expressed in degrees)

Page 148 of 227

None of these three angles are adjustable on

the rear wheels. Even the non-adjustable

angles should be checked to determine if any

of the suspension components are bent.

Getting the proper wheel alignment is a

very exacting process, one in which

complicated and expensive machines are

necessary to perform the job properly.

Because of this, you should have a technician

with the proper equipment perform these

tasks. We will, however, use this space to give

you a basic idea of what is involved with a

wheel alignment so you can better understand

the process and deal intelligently with the

workshop that does the work.Toe-in is the turning in of the wheels. The

purpose of a toe specification is to ensure

parallel rolling of the wheels. In a vehicle with

zero toe-in, the distance between the front

edges of the wheels will be the same as the

distance between the rear edges of the

wheels. The actual amount of toe-in is

normally only a fraction of an inch. Toe-in is

controlled by the tie-rod end position on the

tie-rod. Incorrect toe-in will cause the tyres to

wear improperly by making them scrub

against the road surface.

Camber is the tilting of the wheels from

vertical when viewed from one end of the

vehicle. When the wheels tilt out at the top, the camber is said to be positive (+). When

the wheels tilt in at the top the camber is

negative (-). The amount of tilt is measured in

degrees from vertical and this measurement is

called the camber angle. This angle affects the

amount of tyre tread which contacts the road

and compensates for changes in the suspension

geometry when the vehicle is cornering or

travelling over an undulating surface.

Caster is the tilting of the front steering axis

from the vertical. A tilt toward the rear is

positive caster and a tilt toward the front is

negative caster. Caster is adjusted by moving

shims from one side of the upper control arm

balljoint to the other.

10•12 Suspension and steering systems

3261 Jaguar XJ6

Page 154 of 227

3Remove two bumper retaining bolts located

on the bottom side of the bumper (see

illustration). Pull the bumper assembly out

and away from the vehicle to remove it.

4Refitting is the reverse of removal.

15 Front wing-

removal and refitting

3

1Loosen the front wheel nuts. Raise the

vehicle, support it securely on axle stands and

remove the front wheel.

2Remove the front bumper assembly (see

Section 14).

3Remove the front spoiler (see Section 13).4Detach the inner wing splash shield (see

illustration).

5On 1988 and 1989 models, remove the

coolant overflow reservoir located behind the

splash shield (see Chapter 3).

6On models with round headlights, remove

the headlight bezel. On models with

composite headlights (1992 Vanden Plas, all

1993 and later models), remove the headlight

(see Chapter 12).

7Remove the wing mounting bolts and nuts

(see illustrations).

8Detach the wing. It’s a good idea to have an

assistant support the wing while it’s being

moved away from the vehicle to prevent

damage to the surrounding body panels.

9Refitting is the reverse of removal.

16 Boot lid- removal,

refitting and adjustment

2

Note:The boot lid is heavy and somewhat

awkward to remove and refit - at least two

people should perform this procedure.

Removal and refitting

1Open the boot lid and cover the edges of

the boot compartment with pads or cloths to

protect the painted surfaces when the lid is

removed.

2Disconnect any cables or wire harness

connectors attached to the boot lid that would

interfere with removal.

3Make alignment marks around the hinge

mounting bolts with a marking pen.

4While an assistant supports the boot lid,

remove the lid-to-hinge bolts on both sides

and lift it off(see illustration).

5Refitting is the reverse of removal. Note:

When refitting the boot lid, align the lid-to-

hinge bolts with the marks made during

removal.

Adjustment

6Fore-and-aft and side-to-side adjustment

of the boot lid is done by moving the bonnet in

relation to the hinge plate after loosening the

bolts or nuts.

7Scribe a line around the entire hinge plate

as described earlier in this section so you can

judge the amount of movement.

11•6 Bodywork and fittings

14.3 Remove the two retaining bolts from

the bottom of the bumper, then remove the

bumper from the vehicle15.4 Remove the bolts (arrowed) securing

the inner wing splash shield15.7a Detach the wing retaining bolts

(arrowed) at the front of the wing

15.7c Working in the wheel opening,

remove the wing-to-rocker panel bolt

(arrowed)

15.7d Remove the wing-to-door pillar bolt

(arrow; lower bolt not visible)15.7e Detach the bolts along the

top of the wing

3261 Jaguar XJ6

15.7b Remove the wing-to-radiator

support bolt (arrowed)

16.4 With the help of an assistant to hold

the boot lid, remove the retaining bolts and

lift off the boot lid

Page 210 of 227

3261 Jaguar XJ6

MOT test checksREF•9

Seat belts and seats

Note: The following checks are applicable to

all seat belts, front and rear.

MExamine the webbing of all the belts

(including rear belts if fitted) for cuts, serious

fraying or deterioration. Fasten and unfasten

each belt to check the buckles. If applicable,

check the retracting mechanism. Check the

security of all seat belt mountings accessible

from inside the vehicle.

MThe front seats themselves must be

securely attached and the backrests must

lock in the upright position.

Doors

MBoth front doors must be able to be opened

and closed from outside and inside, and must

latch securely when closed.

Vehicle identification

MNumber plates must be in good condition,

secure and legible, with letters and numbers

correctly spaced – spacing at (A) should be

twice that at (B).

MThe VIN plate and/or homologation plate

must be legible.

Electrical equipment

MSwitch on the ignition and check the

operation of the horn.

MCheck the windscreen washers and wipers,

examining the wiper blades; renew damaged

or perished blades. Also check the operation

of the stop-lights.

MCheck the operation of the sidelights and

number plate lights. The lenses and reflectors

must be secure, clean and undamaged.

MCheck the operation and alignment of the

headlights. The headlight reflectors must not

be tarnished and the lenses must be

undamaged.

MSwitch on the ignition and check the

operation of the direction indicators (including

the instrument panel tell-tale) and the hazard

warning lights. Operation of the sidelights and

stop-lights must not affect the indicators - if it

does, the cause is usually a bad earth at the

rear light cluster.

MCheck the operation of the rear foglight(s),

including the warning light on the instrument

panel or in the switch.

Footbrake

MExamine the master cylinder, brake pipes

and servo unit for leaks, loose mountings,

corrosion or other damage.

MThe fluid reservoir must be secure and the

fluid level must be between the upper (A) and

lower (B) markings.MInspect both front brake flexible hoses for

cracks or deterioration of the rubber. Turn the

steering from lock to lock, and ensure that the

hoses do not contact the wheel, tyre, or any

part of the steering or suspension mechanism.

With the brake pedal firmly depressed, check

the hoses for bulges or leaks under pressure.

Steering and suspension

MHave your assistant turn the steering wheel

from side to side slightly, up to the point where

the steering gear just begins to transmit this

movement to the roadwheels. Check for

excessive free play between the steering

wheel and the steering gear, indicating wear or

insecurity of the steering column joints, the

column-to-steering gear coupling, or the

steering gear itself.

MHave your assistant turn the steering wheel

more vigorously in each direction, so that the

roadwheels just begin to turn. As this is done,

examine all the steering joints, linkages,

fittings and attachments. Renew any

component that shows signs of wear or

damage. On vehicles with power steering,

check the security and condition of the

steering pump, drivebelt and hoses.

MCheck that the vehicle is standing level,

and at approximately the correct ride height.

Shock absorbers

MDepress each corner of the vehicle in turn,

then release it. The vehicle should rise and

then settle in its normal position. If the vehicle

continues to rise and fall, the shock absorber

is defective. A shock absorber which has

seized will also cause the vehicle to fail.

2Checks carried out

WITH THE VEHICLE ON THE

GROUND

Page 212 of 227

3261 Jaguar XJ6

MOT test checksREF•11

MExamine the handbrake mechanism,

checking for frayed or broken cables,

excessive corrosion, or wear or insecurity of

the linkage. Check that the mechanism works

on each relevant wheel, and releases fully,

without binding.

MIt is not possible to test brake efficiency

without special equipment, but a road test can

be carried out later to check that the vehicle

pulls up in a straight line.

Fuel and exhaust systems

MInspect the fuel tank (including the filler

cap), fuel pipes, hoses and unions. All

components must be secure and free from

leaks.

MExamine the exhaust system over its entire

length, checking for any damaged, broken or

missing mountings, security of the retaining

clamps and rust or corrosion.

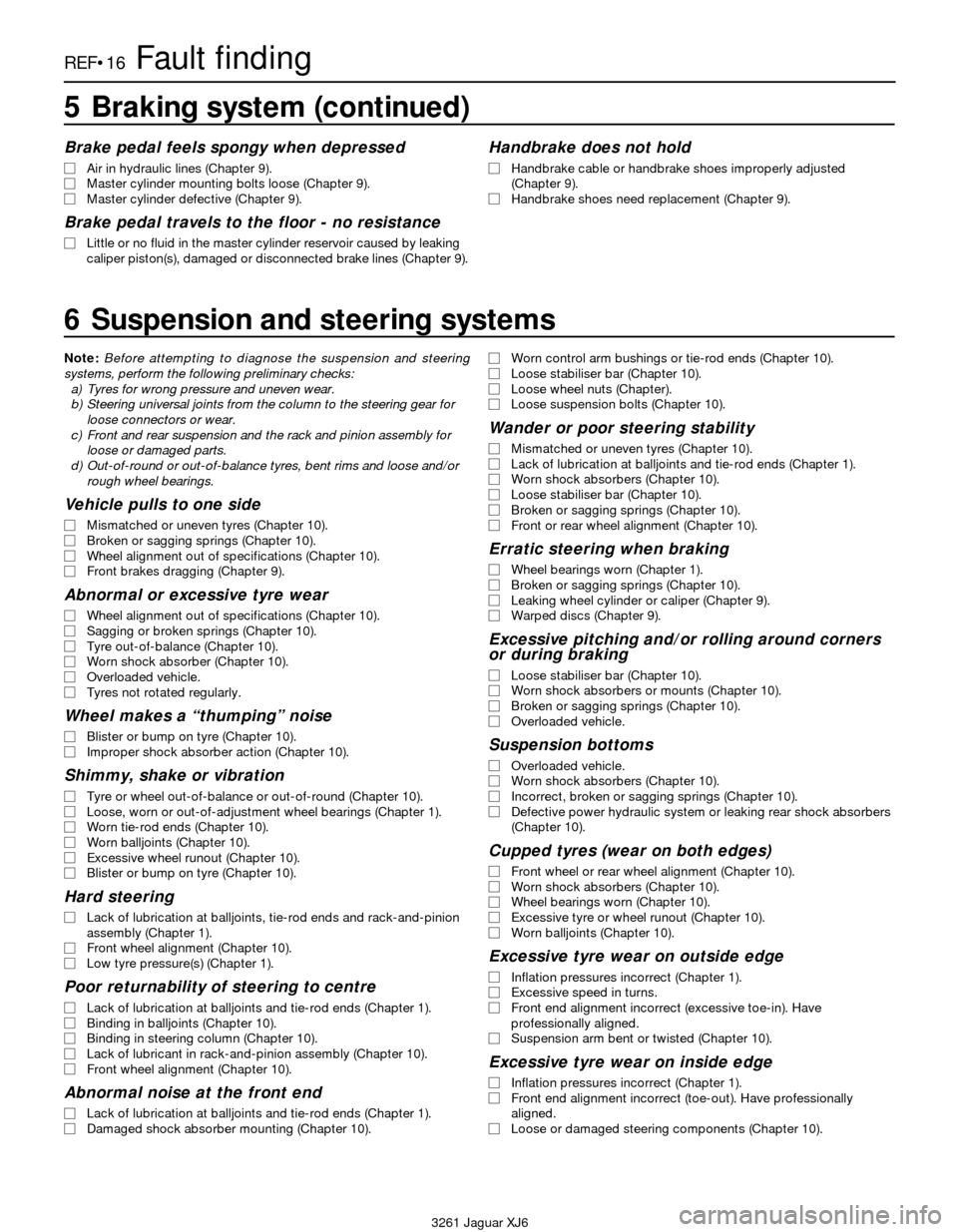

Wheels and tyres

MExamine the sidewalls and tread area of

each tyre in turn. Check for cuts, tears, lumps,

bulges, separation of the tread, and exposure

of the ply or cord due to wear or damage.

Check that the tyre bead is correctly seated

on the wheel rim, that the valve is sound andproperly seated, and that the wheel is not

distorted or damaged.

MCheck that the tyres are of the correct size

for the vehicle, that they are of the same size

and type on each axle, and that the pressures

are correct.

MCheck the tyre tread depth. The legal

minimum at the time of writing is 1.6 mm over

at least three-quarters of the tread width.

Abnormal tread wear may indicate incorrect

front wheel alignment.

Body corrosion

MCheck the condition of the entire vehicle

structure for signs of corrosion in load-bearing

areas. (These include chassis box sections,

side sills, cross-members, pillars, and all

suspension, steering, braking system and

seat belt mountings and anchorages.) Any

corrosion which has seriously reduced the

thickness of a load-bearing area is likely to

cause the vehicle to fail. In this case

professional repairs are likely to be needed.

MDamage or corrosion which causes sharp

or otherwise dangerous edges to be exposed

will also cause the vehicle to fail.

Petrol models

MHave the engine at normal operating

temperature, and make sure that it is in good

tune (ignition system in good order, air filter

element clean, etc).

MBefore any measurements are carried out,

raise the engine speed to around 2500 rpm,

and hold it at this speed for 20 seconds. Allowthe engine speed to return to idle, and watch

for smoke emissions from the exhaust

tailpipe. If the idle speed is obviously much

too high, or if dense blue or clearly-visible

black smoke comes from the tailpipe for more

than 5 seconds, the vehicle will fail. As a rule

of thumb, blue smoke signifies oil being burnt

(engine wear) while black smoke signifies

unburnt fuel (dirty air cleaner element, or other

carburettor or fuel system fault).

MAn exhaust gas analyser capable of

measuring carbon monoxide (CO) and

hydrocarbons (HC) is now needed. If such an

instrument cannot be hired or borrowed, a

local garage may agree to perform the check

for a small fee.

CO emissions (mixture)

MAt the time of writing, the maximum CO

level at idle is 3.5% for vehicles first used after

August 1986 and 4.5% for older vehicles.

From January 1996 a much tighter limit

(around 0.5%) applies to catalyst-equipped

vehicles first used from August 1992. If the

CO level cannot be reduced far enough to

pass the test (and the fuel and ignition

systems are otherwise in good condition) then

the carburettor is badly worn, or there is some

problem in the fuel injection system or

catalytic converter (as applicable).

HC emissionsMWith the CO emissions within limits, HC

emissions must be no more than 1200 ppm

(parts per million). If the vehicle fails this test

at idle, it can be re-tested at around 2000 rpm;

if the HC level is then 1200 ppm or less, this

counts as a pass.

MExcessive HC emissions can be caused by

oil being burnt, but they are more likely to be

due to unburnt fuel.

Diesel models

MThe only emission test applicable to Diesel

engines is the measuring of exhaust smoke

density. The test involves accelerating the

engine several times to its maximum

unloaded speed.

Note: It is of the utmost importance that the

engine timing belt is in good condition before

the test is carried out.

M

Excessive smoke can be caused by a dirty

air cleaner element. Otherwise, professional

advice may be needed to find the cause.

4Checks carried out on

YOUR VEHICLE’S EXHAUST

EMISSION SYSTEM

Page 217 of 227

3261 Jaguar XJ6

REF•16Fault finding

6 Suspension and steering systems

5 Braking system (continued)

Brake pedal feels spongy when depressed

m mAir in hydraulic lines (Chapter 9).

m mMaster cylinder mounting bolts loose (Chapter 9).

m mMaster cylinder defective (Chapter 9).

Brake pedal travels to the floor - no resistance

m

mLittle or no fluid in the master cylinder reservoir caused by leaking

caliper piston(s), damaged or disconnected brake lines (Chapter 9).

Handbrake does not hold

m mHandbrake cable or handbrake shoes improperly adjusted

(Chapter 9).

m mHandbrake shoes need replacement (Chapter 9).

Note:Before attempting to diagnose the suspension and steering

systems, perform the following preliminary checks:

a) Tyres for wrong pressure and uneven wear.

b) Steering universal joints from the column to the steering gear for

loose connectors or wear.

c) Front and rear suspension and the rack and pinion assembly for

loose or damaged parts.

d) Out-of-round or out-of-balance tyres, bent rims and loose and/or

rough wheel bearings.

Vehicle pulls to one side

m mMismatched or uneven tyres (Chapter 10).

m mBroken or sagging springs (Chapter 10).

m mWheel alignment out of specifications (Chapter 10).

m mFront brakes dragging (Chapter 9).

Abnormal or excessive tyre wear

m

mWheel alignment out of specifications (Chapter 10).

m mSagging or broken springs (Chapter 10).

m mTyre out-of-balance (Chapter 10).

m mWorn shock absorber (Chapter 10).

m mOverloaded vehicle.

m mTyres not rotated regularly.

Wheel makes a “thumping” noise

m

mBlister or bump on tyre (Chapter 10).

m mImproper shock absorber action (Chapter 10).

Shimmy, shake or vibration

m

mTyre or wheel out-of-balance or out-of-round (Chapter 10).

m mLoose, worn or out-of-adjustment wheel bearings (Chapter 1).

m mWorn tie-rod ends (Chapter 10).

m mWorn balljoints (Chapter 10).

m mExcessive wheel runout (Chapter 10).

m mBlister or bump on tyre (Chapter 10).

Hard steering

m

mLack of lubrication at balljoints, tie-rod ends and rack-and-pinion

assembly (Chapter 1).

m mFront wheel alignment (Chapter 10).

m mLow tyre pressure(s) (Chapter 1).

Poor returnability of steering to centre

m

mLack of lubrication at balljoints and tie-rod ends (Chapter 1).

m mBinding in balljoints (Chapter 10).

m mBinding in steering column (Chapter 10).

m mLack of lubricant in rack-and-pinion assembly (Chapter 10).

m mFront wheel alignment (Chapter 10).

Abnormal noise at the front end

m

mLack of lubrication at balljoints and tie-rod ends (Chapter 1).

m mDamaged shock absorber mounting (Chapter 10).m mWorn control arm bushings or tie-rod ends (Chapter 10).

m mLoose stabiliser bar (Chapter 10).

m mLoose wheel nuts (Chapter).

m mLoose suspension bolts (Chapter 10).

Wander or poor steering stability

m

mMismatched or uneven tyres (Chapter 10).

m mLack of lubrication at balljoints and tie-rod ends (Chapter 1).

m mWorn shock absorbers (Chapter 10).

m mLoose stabiliser bar (Chapter 10).

m mBroken or sagging springs (Chapter 10).

m mFront or rear wheel alignment (Chapter 10).

Erratic steering when braking

m

mWheel bearings worn (Chapter 1).

m mBroken or sagging springs (Chapter 10).

m mLeaking wheel cylinder or caliper (Chapter 9).

m mWarped discs (Chapter 9).

Excessive pitching and/or rolling around corners

or during braking

m mLoose stabiliser bar (Chapter 10).

m mWorn shock absorbers or mounts (Chapter 10).

m mBroken or sagging springs (Chapter 10).

m mOverloaded vehicle.

Suspension bottoms

m

mOverloaded vehicle.

m mWorn shock absorbers (Chapter 10).

m mIncorrect, broken or sagging springs (Chapter 10).

m mDefective power hydraulic system or leaking rear shock absorbers

(Chapter 10).

Cupped tyres (wear on both edges)

m mFront wheel or rear wheel alignment (Chapter 10).

m mWorn shock absorbers (Chapter 10).

m mWheel bearings worn (Chapter 10).

m mExcessive tyre or wheel runout (Chapter 10).

m mWorn balljoints (Chapter 10).

Excessive tyre wear on outside edge

m

mInflation pressures incorrect (Chapter 1).

m mExcessive speed in turns.

m mFront end alignment incorrect (excessive toe-in). Have

professionally aligned.

m mSuspension arm bent or twisted (Chapter 10).

Excessive tyre wear on inside edge

m

mInflation pressures incorrect (Chapter 1).

m mFront end alignment incorrect (toe-out). Have professionally

aligned.

m mLoose or damaged steering components (Chapter 10).

Page 219 of 227

3261 Jaguar XJ6

REF•18Glossary of technical terms

A

ABS (Anti-lock brake system)A system,

usually electronically controlled, that senses

incipient wheel lockup during braking and

relieves hydraulic pressure at wheels that are

about to skid.

Air bag An inflatable bag hidden in the

steering wheel (driver’s side) or the dash or

glovebox (passenger side). In a head-on

collision, the bags inflate, preventing the

driver and front passenger from being thrown

forward into the steering wheel or windscreen.

Air cleanerA metal or plastic housing,

containing a filter element, which removes

dust and dirt from the air being drawn into the

engine.

Air filter elementThe actual filter in an air

cleaner system, usually manufactured from

pleated paper and requiring renewal at regular

intervals.

Allen keyA hexagonal wrench which fits into

a recessed hexagonal hole.

Alligator clipA long-nosed spring-loaded

metal clip with meshing teeth. Used to make

temporary electrical connections.

AlternatorA component in the electrical

system which converts mechanical energy

from a drivebelt into electrical energy to

charge the battery and to operate the starting

system, ignition system and electrical

accessories.

Ampere (amp)A unit of measurement for the

flow of electric current. One amp is the

amount of current produced by one volt

acting through a resistance of one ohm.

Anaerobic sealerA substance used to

prevent bolts and screws from loosening.

Anaerobic means that it does not require

oxygen for activation. The Loctite brand is

widely used.

AntifreezeA substance (usually ethylene

glycol) mixed with water, and added to a

vehicle’s cooling system, to prevent freezing

of the coolant in winter. Antifreeze also

contains chemicals to inhibit corrosion and

the formation of rust and other deposits that

would tend to clog the radiator and coolant

passages and reduce cooling efficiency.

Anti-seize compoundA coating that

reduces the risk of seizing on fasteners that

are subjected to high temperatures, such as

exhaust manifold bolts and nuts.

AsbestosA natural fibrous mineral with great

heat resistance, commonly used in the

composition of brake friction materials.Asbestos is a health hazard and the dust

created by brake systems should never be

inhaled or ingested.

AxleA shaft on which a wheel revolves, or

which revolves with a wheel. Also, a solid

beam that connects the two wheels at one

end of the vehicle. An axle which also

transmits power to the wheels is known as a

live axle.

AxleshaftA single rotating shaft, on either

side of the differential, which delivers power

from the final drive assembly to the drive

wheels. Also called a driveshaft or a halfshaft.

BBall bearingAn anti-friction bearing

consisting of a hardened inner and outer race

with hardened steel balls between two races.

BearingThe curved surface on a shaft or in a

bore, or the part assembled into either, that

permits relative motion between them with

minimum wear and friction.

Big-end bearingThe bearing in the end of

the connecting rod that’s attached to the

crankshaft.

Bleed nippleA valve on a brake wheel

cylinder, caliper or other hydraulic component

that is opened to purge the hydraulic system

of air. Also called a bleed screw.

Brake bleedingProcedure for removing air

from lines of a hydraulic brake system.

Brake discThe component of a disc brake

that rotates with the wheels.Brake drumThe component of a drum brake

that rotates with the wheels.

Brake liningsThe friction material which

contacts the brake disc or drum to retard the

vehicle’s speed. The linings are bonded or

riveted to the brake pads or shoes.

Brake padsThe replaceable friction pads

that pinch the brake disc when the brakes are

applied. Brake pads consist of a friction

material bonded or riveted to a rigid backing

plate.

Brake shoeThe crescent-shaped carrier to

which the brake linings are mounted and

which forces the lining against the rotating

drum during braking.

Braking systemsFor more information on

braking systems, consult the Haynes

Automotive Brake Manual.

Breaker barA long socket wrench handle

providing greater leverage.

BulkheadThe insulated partition between

the engine and the passenger compartment.

CCaliperThe non-rotating part of a disc-brake

assembly that straddles the disc and carries

the brake pads. The caliper also contains the

hydraulic components that cause the pads to

pinch the disc when the brakes are applied. A

caliper is also a measuring tool that can be set

to measure inside or outside dimensions of an

object.

CamshaftA rotating shaft on which a series

of cam lobes operate the valve mechanisms.

The camshaft may be driven by gears, by

sprockets and chain or by sprockets and a

belt.

CanisterA container in an evaporative

emission control system; contains activated

charcoal granules to trap vapours from the

fuel system.

CarburettorA device which mixes fuel with

air in the proper proportions to provide a

desired power output from a spark ignition

internal combustion engine.

CastellatedResembling the parapets along

the top of a castle wall. For example, a

castellated balljoint stud nut.

CastorIn wheel alignment, the backward or

forward tilt of the steering axis. Castor is

positive when the steering axis is inclined

rearward at the top.

Canister

Brake bleeding

Bearing

Air filter

Page 226 of 227

3261 Jaguar XJ6

WWasher fluid -0•12

Water pump -3•6

Weekly checks-0•10et seq

Weights - REF•1

Wheel alignment -1•18, 10•11

Wheel bearings -1•17, 10•8, REF•10

Wheel changing -0•8Wheels - 10•11, REF•11

Windows - 11•10, 11•11, 12•13

Windscreen - 11•3, REF•8

Wing - 11•6

Wiper blades -0•13

Wiper motor - 12•8

Wiring diagrams- 12•15et seq

Working facilities- REF•7

IndexREF•25