radiator JAGUAR XJ6 1997 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 98 of 227

of these sensors and their corresponding

ECU-controlled relays are not contained

within EFI components, but are located

throughout the engine compartment. For

further information regarding the ECU and its

relationship to the engine electrical and

ignition system, see Chapter 6.

12 Electronic Fuel Injection

(EFI) system- check

2

1Check the earth wire connections for

tightness. Check all wiring and electrical

connectors that are related to the system.

Loose electrical connectors and poor grounds

can cause many problems that resemble

more serious malfunctions.

2Check to see that the battery is fully

charged, as the control unit and sensors

depend on an accurate supply voltage in

order to properly meter the fuel.

3Check the air filter element - a dirty or

partially blocked filter will severely impede

performance and economy (see Chapter 1).

4If a blown fuse is found, renew it and see if

it blows again. If it does, search for a shorted

wire in the harness related to the system.

5Check the air intake duct from the MAF

sensor to the intake manifold for leaks, which

will result in an excessively lean mixture. Also

check the condition of the vacuum hoses

connected to the intake manifold.

6Remove the air intake duct from the throttle

body and check for carbon and residue build-

up. If it’s dirty, clean with aerosol carburettor

cleaner (make sure the can says it’s safe for

use with oxygen sensors and catalytic

converters) and a toothbrush.

7With the engine running, place a

stethoscope against each injector, one at a

time, and listen for a clicking sound, indicating

operation (see illustration).8If there is a problem with an injector,

purchase a special injector test light (noid

light) and refit it into the injector electrical

connector (see illustration). Start the engine

and make sure that each injector connector

flashes the noid light. This will test for the

proper voltage signal to the injector.Caution:

If the engine will not start and the noid

light indicates that each injector is

receiving the proper signal, there is a good

possibility that the injector(s) is stuck open

and allowing fuel into the combustion

chamber in excessive amounts. If the spark

plugs are fouled, detach the primary (low

voltage) wires from the ignition coil, disable

the fuel pump by removing the fuel pump

relay (see Section 2), remove the spark plugs

and crank the engine over. If fuel sprays from

the spark plug holes, the engine is flooded

and the fuel must be removed from the

combustion chambers.

9With the engine OFF and the fuel injector

electrical connectors disconnected, measure

the resistance of each injector (see

illustration). Each injector should measure

about 2.0 to 3.0 ohms. If not, the injector is

probably faulty.10The remainder of the system checks

should be left to a Jaguar service department

or other qualified repair workshop, as there is

a chance that the control unit may be

damaged if not performed properly.

13 Electronic Fuel Injection

(EFI) system- component

check and renewal

3

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. See

the Warning in Section 2.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

Throttle body

Check

1Verify that the throttle linkage operates

smoothly.

2Start the engine, detach each vacuum hose

and, using your finger, check the vacuum at

each port on the throttle body with the engine

at idle and above idle. The vacuum available

from the throttle body is ported. Raise the

engine rpm and watch as vacuum increases.

It may be necessary to use a vacuum gauge.

Refer to Chapter 2B for additional information

concerning vacuum checks.

Renewal

Warning: Wait until the engine is

completely cool before

beginning this procedure.

3Detach the cable from the negative terminal

of the battery (see the Cautionat the

beginning of this Section).

4Drain the radiator (see Chapter 1).

4•10 Fuel and exhaust systems

12.9 Using an ohmmeter, measure the

resistance across both terminals

of the injector

3261 Jaguar XJ6 12.7 Use a stethoscope or a screwdriver to determine if the

injectors are working properly - they should make a steady

clicking sound that rises and falls with engine speed changes

12.8 Refit the “noid” light into the fuel injector electrical

connector and check to see that it blinks with the engine running

Page 149 of 227

3261 Jaguar XJ6

11

Chapter 11

Bodywork and fittings

Body - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Body repair - major damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Body repair - minor damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bonnet - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . 10

Bonnet and boot lid support struts - removal and refitting . . . . . . . . 9

Bonnet release latch and cable - removal and refitting . . . . . . . . . . . 11

Boot lid - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . 16

Boot lid latch and lock cylinder - removal and refitting . . . . . . . . . . . 17

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 24

Cowl cover - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Dashboard trim panels - removal and refitting . . . . . . . . . . . . . . . . . 26

Door - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . 19

Door latch, lock cylinder and handles - removal and refitting . . . . . . 20

Door trim panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 18Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . . 22

Door window glass regulator - removal and refitting . . . . . . . . . . . . . 21

Front spoiler - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 13

Front wing - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hinges and locks - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Instrument cluster housing - removal and refitting . . . . . . . . . . . . . . 25

Outside mirrors - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 23

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 12

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Steering column cover - removal and refitting . . . . . . . . . . . . . . . . . 27

Upholstery and carpets - maintenance . . . . . . . . . . . . . . . . . . . . . . . 4

Vinyl trim - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Windscreen and fixed glass - replacement . . . . . . . . . . . . . . . . . . . . 8

11•1

Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

These models feature a “unibody”

construction, using a floor pan with front and

rear frame side rails which support the body

components, front and rear suspension

systems and other mechanical components.

Certain components are particularly vulnerable

to accident damage and can be unbolted and

repaired or replaced. Among these parts are

the body mouldings, bumpers, front wings,

bonnet and boot lids and all glass.

Only general body maintenance practices

and body panel repair procedures within the

scope of the do-it-yourselfer are included in

this Chapter.

2 Body- maintenance

1

1The condition of your vehicle’s body is very

important, because the resale value depends

a great deal on it. It’s much more difficult to

repair a neglected or damaged body than it is

to repair mechanical components. The hidden

areas of the body, such as the wheel wells,

the frame and the engine compartment, areequally important, although they don’t require

as frequent attention as the rest of the body.

2Once a year, or every 12,000 miles, it’s a

good idea to have the underside of the body

steam cleaned. All traces of dirt and oil will be

removed and the area can then be inspected

carefully for rust, damaged brake lines, frayed

electrical wires, damaged cables and other

problems. The front suspension components

should be greased after completion of this job.

3At the same time, clean the engine and the

engine compartment with a steam cleaner or

water soluble degreaser.

4The wheel wells should be given close

attention, since undercoating can peel away

and stones and dirt thrown up by the tyres

can cause the paint to chip and flake, allowing

rust to set in. If rust is found, clean down to

the bare metal and apply an anti-rust paint.

5The body should be washed about once a

week. Wet the vehicle thoroughly to soften the

dirt, then wash it down with a soft sponge and

plenty of clean soapy water. If the surplus dirt

is not washed off very carefully, it can wear

down the paint.

6Spots of tar or asphalt thrown up from the

road should be removed with a cloth soaked

in solvent.

7Once every six months, wax the body and

chrome trim. If a chrome cleaner is used to

remove rust from any of the vehicle’s plated

parts, remember that the cleaner also removes

part of the chrome, so use it sparingly.

3 Vinyl trim- maintenance

1

Don’t clean vinyl trim with detergents,

caustic soap or petroleum-based cleaners.

Plain soap and water works just fine, with a

soft brush to clean dirt that may be ingrained.

Wash the vinyl as frequently as the rest of the

vehicle.

After cleaning, application of a high quality

rubber and vinyl protectant will help prevent

oxidation and cracks. The protectant can also

be applied to weather-stripping, vacuum lines

and rubber hoses (which often fail as a result

of chemical degradation) and to the tyres.

4 Upholstery and carpets-

maintenance

1

1Every three months remove the carpets or

mats and clean the interior of the vehicle

(more frequently if necessary). Vacuum the

upholstery and carpets to remove loose dirt

and dust.

2Leather upholstery requires special care.

Stains should be removed with warm water

and a very mild soap solution. Use a clean,

damp cloth to remove the soap, then wipe

Page 153 of 227

7Attach a piece of thin wire or string to the

end of the cables to help aid the refitting

process.

8Working in the engine compartment, pull

the cables and grommet out of the bulkhead

until you can see the wire or string. Ensure

that the new cable has a grommet attached

then remove the old cable from the wire or

string and replace it with the new cable.

9Working from passenger compartment pull

the wire or string back through the bulkhead.

10Refitting is the reverse of removal.Note:

Push on the grommet with your fingers from

the engine compartment to seat the grommet

in the bulkhead.

12 Radiator grille-

removal and refitting

1

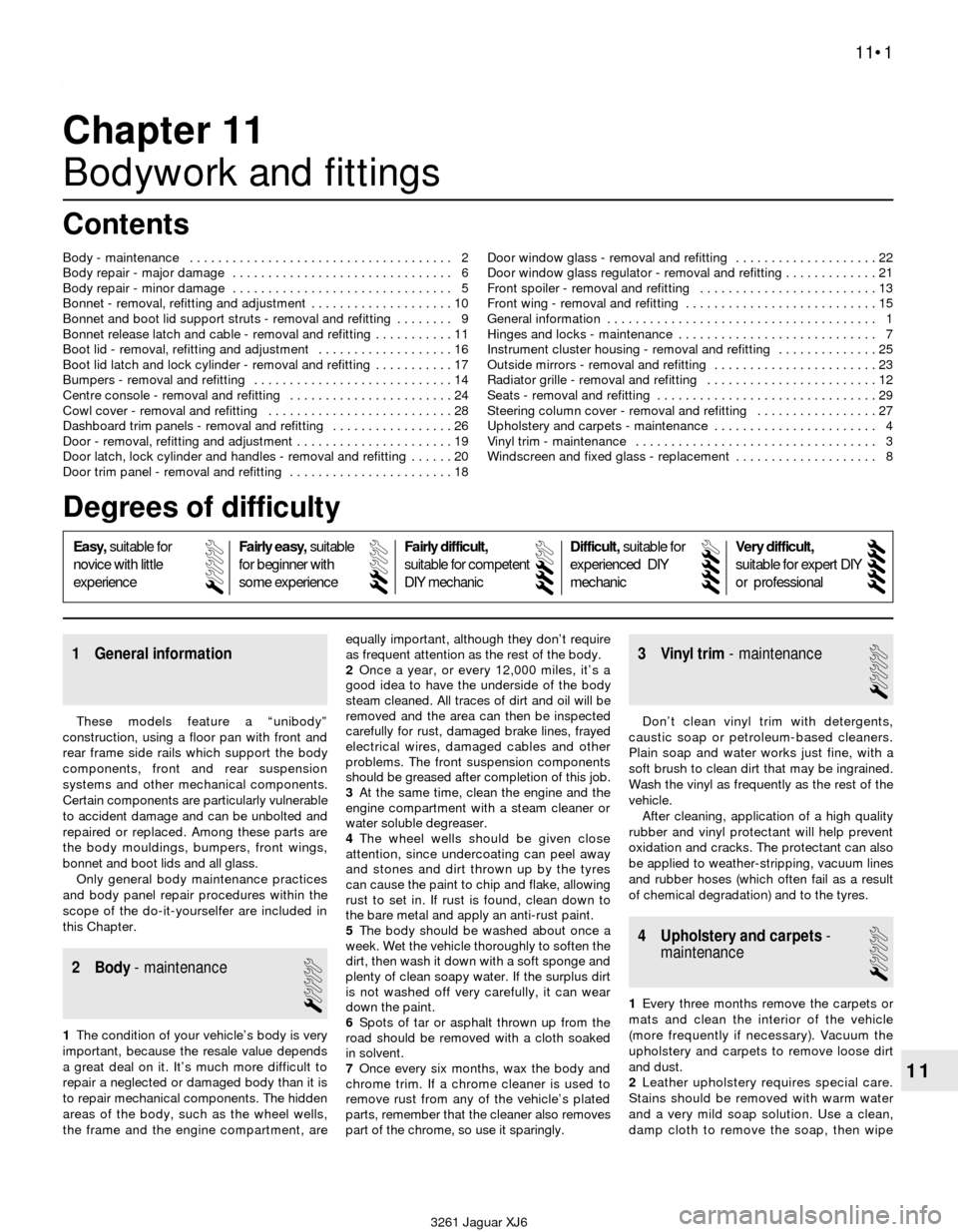

1Using a Phillips screwdriver, detach the

right and left hand grille inserts from the grille

assembly (see illustration).Note: The grille

can be removed without removing the inserts,

but reaching the mounting screws from above

is quite difficult.

2Working through the grille insert openings,

remove the retaining screws securing both

ends of the grille frame (see illustration).

3Pull the grille frame forward and remove it

from the vehicle.

4Refitting is the reverse of removal.

13 Front spoiler-

removal and refitting

1

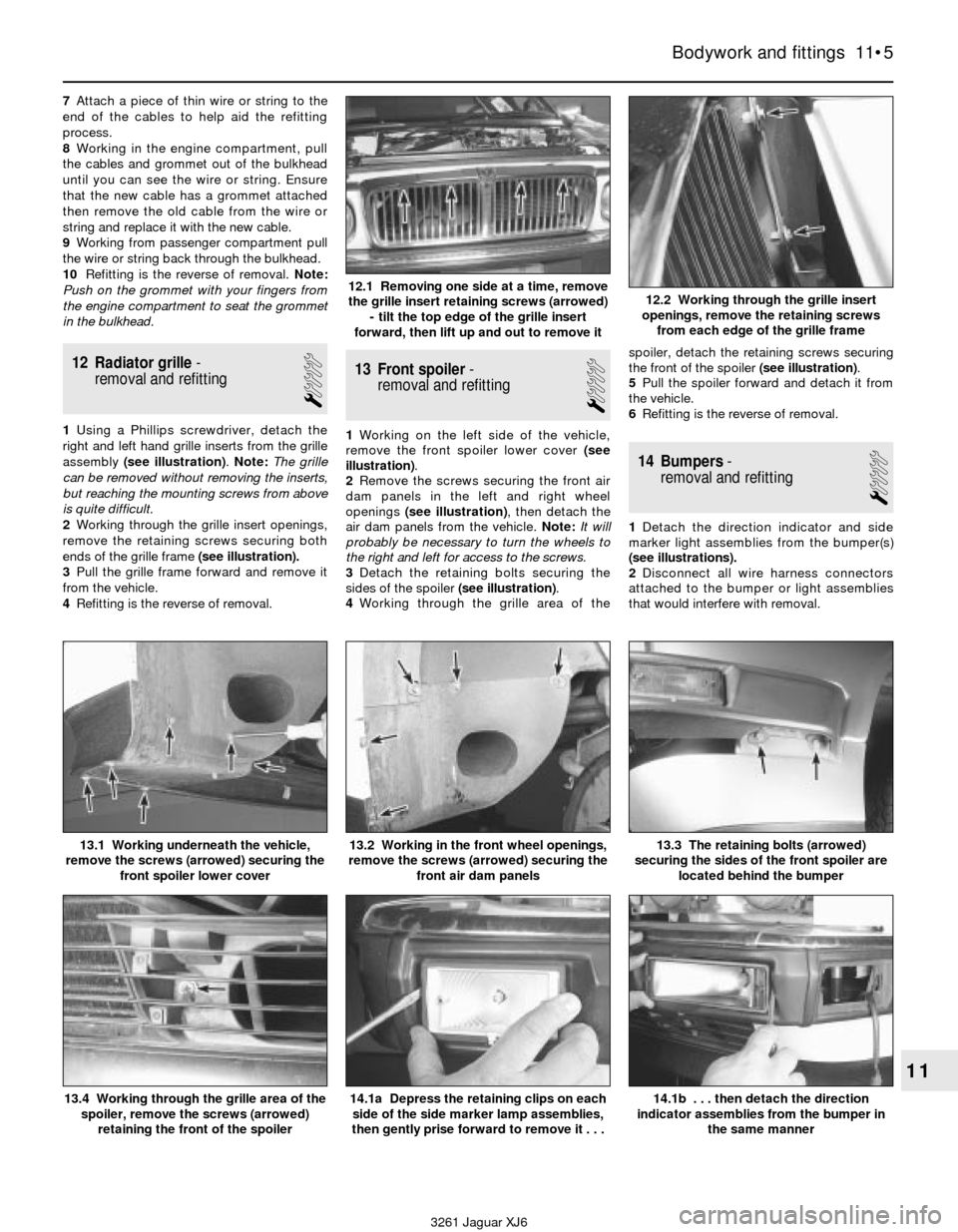

1Working on the left side of the vehicle,

remove the front spoiler lower cover (see

illustration).

2Remove the screws securing the front air

dam panels in the left and right wheel

openings (see illustration), then detach the

air dam panels from the vehicle. Note:It will

probably be necessary to turn the wheels to

the right and left for access to the screws.

3Detach the retaining bolts securing the

sides of the spoiler (see illustration).

4Working through the grille area of thespoiler, detach the retaining screws securing

the front of the spoiler (see illustration).

5Pull the spoiler forward and detach it from

the vehicle.

6Refitting is the reverse of removal.

14 Bumpers-

removal and refitting

1

1Detach the direction indicator and side

marker light assemblies from the bumper(s)

(see illustrations).

2Disconnect all wire harness connectors

attached to the bumper or light assemblies

that would interfere with removal.

Bodywork and fittings 11•5

11

12.1 Removing one side at a time, remove

the grille insert retaining screws (arrowed)

- tilt the top edge of the grille insert

forward, then lift up and out to remove it12.2 Working through the grille insert

openings, remove the retaining screws

from each edge of the grille frame

13.4 Working through the grille area of the

spoiler, remove the screws (arrowed)

retaining the front of the spoiler14.1a Depress the retaining clips on each

side of the side marker lamp assemblies,

then gently prise forward to remove it . . .14.1b . . . then detach the direction

indicator assemblies from the bumper in

the same manner

13.1 Working underneath the vehicle,

remove the screws (arrowed) securing the

front spoiler lower cover13.2 Working in the front wheel openings,

remove the screws (arrowed) securing the

front air dam panels13.3 The retaining bolts (arrowed)

securing the sides of the front spoiler are

located behind the bumper

3261 Jaguar XJ6

Page 154 of 227

3Remove two bumper retaining bolts located

on the bottom side of the bumper (see

illustration). Pull the bumper assembly out

and away from the vehicle to remove it.

4Refitting is the reverse of removal.

15 Front wing-

removal and refitting

3

1Loosen the front wheel nuts. Raise the

vehicle, support it securely on axle stands and

remove the front wheel.

2Remove the front bumper assembly (see

Section 14).

3Remove the front spoiler (see Section 13).4Detach the inner wing splash shield (see

illustration).

5On 1988 and 1989 models, remove the

coolant overflow reservoir located behind the

splash shield (see Chapter 3).

6On models with round headlights, remove

the headlight bezel. On models with

composite headlights (1992 Vanden Plas, all

1993 and later models), remove the headlight

(see Chapter 12).

7Remove the wing mounting bolts and nuts

(see illustrations).

8Detach the wing. It’s a good idea to have an

assistant support the wing while it’s being

moved away from the vehicle to prevent

damage to the surrounding body panels.

9Refitting is the reverse of removal.

16 Boot lid- removal,

refitting and adjustment

2

Note:The boot lid is heavy and somewhat

awkward to remove and refit - at least two

people should perform this procedure.

Removal and refitting

1Open the boot lid and cover the edges of

the boot compartment with pads or cloths to

protect the painted surfaces when the lid is

removed.

2Disconnect any cables or wire harness

connectors attached to the boot lid that would

interfere with removal.

3Make alignment marks around the hinge

mounting bolts with a marking pen.

4While an assistant supports the boot lid,

remove the lid-to-hinge bolts on both sides

and lift it off(see illustration).

5Refitting is the reverse of removal. Note:

When refitting the boot lid, align the lid-to-

hinge bolts with the marks made during

removal.

Adjustment

6Fore-and-aft and side-to-side adjustment

of the boot lid is done by moving the bonnet in

relation to the hinge plate after loosening the

bolts or nuts.

7Scribe a line around the entire hinge plate

as described earlier in this section so you can

judge the amount of movement.

11•6 Bodywork and fittings

14.3 Remove the two retaining bolts from

the bottom of the bumper, then remove the

bumper from the vehicle15.4 Remove the bolts (arrowed) securing

the inner wing splash shield15.7a Detach the wing retaining bolts

(arrowed) at the front of the wing

15.7c Working in the wheel opening,

remove the wing-to-rocker panel bolt

(arrowed)

15.7d Remove the wing-to-door pillar bolt

(arrow; lower bolt not visible)15.7e Detach the bolts along the

top of the wing

3261 Jaguar XJ6

15.7b Remove the wing-to-radiator

support bolt (arrowed)

16.4 With the help of an assistant to hold

the boot lid, remove the retaining bolts and

lift off the boot lid

Page 171 of 227

6If the voltage is 6 volts, the element is okay

(there is no break). If the voltage is 12 volts,

the element is broken between the centre

of the element and the positive end. If the

voltage is 0 volts the element is broken

between the centre of the element and earth.

7To find the break, place the voltmeter

positive lead against the defogger positive

terminal. Place the voltmeter negative lead

with the foil strip against the heating element

at the positive terminal end and slide it toward

the negative terminal end. The point at which

the voltmeter deflects from zero to several

volts is the point at which the heating element

is broken (see illustration).

Repair

8Repair the break in the element using a

repair kit specifically recommended for this

purpose.

9Prior to repairing a break, turn off the system

and allow it to cool off for a few minutes.

10Lightly buff the element area with fine

steel wool, then clean it thoroughly with

rubbing alcohol.

11Use masking tape to mask off the area

being repaired.

12Thoroughly mix the epoxy, following the

instructions provided with the repair kit.

13Apply the epoxy material to the slit in the

masking tape, overlapping the undamaged

area about 3/4-inch on either end (see

illustration).

14Allow the repair to cure for 24 hours before

removing the tape and using the system.

17 Headlights- renewal

1

Warning: Later models are

equipped with halogen gas-filled

headlight bulbs which are underpressure and may shatter if the surface is

damaged or the bulb is dropped. Wear eye

protection and handle the bulbs carefully,

grasping only the base whenever possible.

Do not touch the surface of the bulb with

your fingers because the oil from your skin

could cause it to overheat and fail

prematurely. If you do touch the bulb

surface, clean it with rubbing alcohol.

Sealed beam units

1Remove the radiator grille (see Chapter 11).

2Detach the headlight bezel trim cover (see

illustration).

3Remove the headlight bezel (see

illustrations).

4Remove the screws which secure the

retaining ring and withdraw the ring. Support

the light as this is done (see illustration).

Body electrical system 12•9

12

16.13 Apply masking tape to the inside of

the window at the damaged area, then

brush on the special conductive coating17.2 Remove the screws (arrowed) and

detach the headlight bezel trim cover

17.3a Remove the two retaining screws

at the top and the one in the grille opening

(arrowed)17.3b The retaining screw at the

outside lower corner can be accessed

from under the bumper

3261 Jaguar XJ6 16.5 To determine if a heating element has broken, check the

voltage at the centre of each element. If the voltage is 6-volts, the

element is unbroken; if the voltage is 12-volts, the element is

broken between the centre and the positive end. If there is no

voltage, the element is broken between the centre and earth

16.7 To find the break, place the voltmeter positive lead against

the heated window positive terminal, place the voltmeter negative

lead with the foil strip against the heating element at the positive

terminal end and slide it toward the negative terminal end -

the point at which the voltmeter reading changes abruptly is the

point at which the element is broken

Page 172 of 227

5Pull the headlight out slightly and

disconnect the electrical connector from the

rear of the light, then remove the light from the

vehicle.

6To refit, position the new unit close enough

to connect the electrical connector. Make

sure that the numbers moulded into the lens

are at the top.

7Refit and tighten the retaining ring. Test the

headlight operation.

8The remainder of the refitting is the reverse

of removal.

Halogen gas-filled bulbs

9Disconnect the electrical connector from

the bulb assembly. Rotate the headlight bulb

connector 1/4-turn anti-clockwise (viewed

from the rear) (see illustration).

10Withdraw the bulb assembly from the

headlight housing.

11Without touching the glass with your bare

fingers (see the Warningat the start of the

Section), insert the new bulb assembly into

the headlight housing and rotate the bulb

socket 1/4-turn clockwise to refit it.

12Plug in the electrical connector and test

headlight operation.

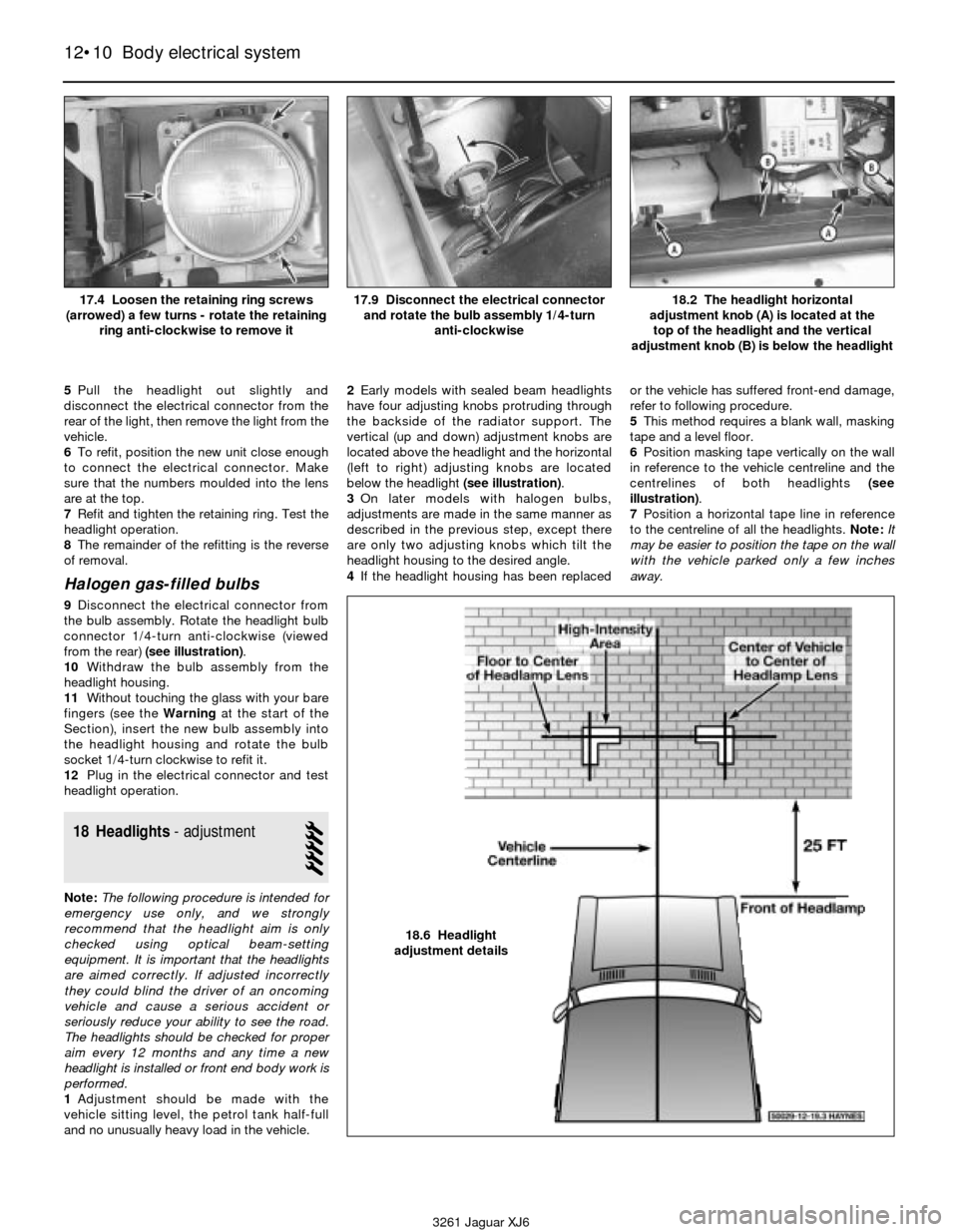

18 Headlights- adjustment

5

Note:The following procedure is intended for

emergency use only, and we strongly

recommend that the headlight aim is only

checked using optical beam-setting

equipment. It is important that the headlights

are aimed correctly. If adjusted incorrectly

they could blind the driver of an oncoming

vehicle and cause a serious accident or

seriously reduce your ability to see the road.

The headlights should be checked for proper

aim every 12 months and any time a new

headlight is installed or front end body work is

performed.

1Adjustment should be made with the

vehicle sitting level, the petrol tank half-full

and no unusually heavy load in the vehicle.2Early models with sealed beam headlights

have four adjusting knobs protruding through

the backside of the radiator support. The

vertical (up and down) adjustment knobs are

located above the headlight and the horizontal

(left to right) adjusting knobs are located

below the headlight (see illustration).

3On later models with halogen bulbs,

adjustments are made in the same manner as

described in the previous step, except there

are only two adjusting knobs which tilt the

headlight housing to the desired angle.

4If the headlight housing has been replacedor the vehicle has suffered front-end damage,

refer to following procedure.

5This method requires a blank wall, masking

tape and a level floor.

6Position masking tape vertically on the wall

in reference to the vehicle centreline and the

centrelines of both headlights (see

illustration).

7Position a horizontal tape line in reference

to the centreline of all the headlights. Note:It

may be easier to position the tape on the wall

with the vehicle parked only a few inches

away.

12•10 Body electrical system

3261 Jaguar XJ618.2 The headlight horizontal

adjustment knob (A) is located at the

top of the headlight and the vertical

adjustment knob (B) is below the headlight

17.4 Loosen the retaining ring screws

(arrowed) a few turns - rotate the retaining

ring anti-clockwise to remove it17.9 Disconnect the electrical connector

and rotate the bulb assembly 1/4-turn

anti-clockwise

18.6 Headlight

adjustment details

Page 173 of 227

8Adjustment should be made with the

vehicle parked 25 feet from the wall, sitting

level, the petrol tank half-full and no unusually

heavy load in the vehicle.

9Starting with the low beam adjustment,

position the high intensity zone so it is two

inches below the horizontal line and two

inches to the right of the headlight vertical

line. Adjustments are made by turning the

knobs located behind the headlight housings

(see illustration 18.2).

10With the high beams on, the high intensity

zone should be vertically centred with the

exact centre just below the horizontal line.

Note:It may not be possible to position the

headlight aim exactly for both high and low

beams. If a compromise must be made, keep

in mind that the low beams are the most used

and have the greatest effect on safety.

11Have the headlights adjusted by a dealer

service department or service station at the

earliest opportunity.

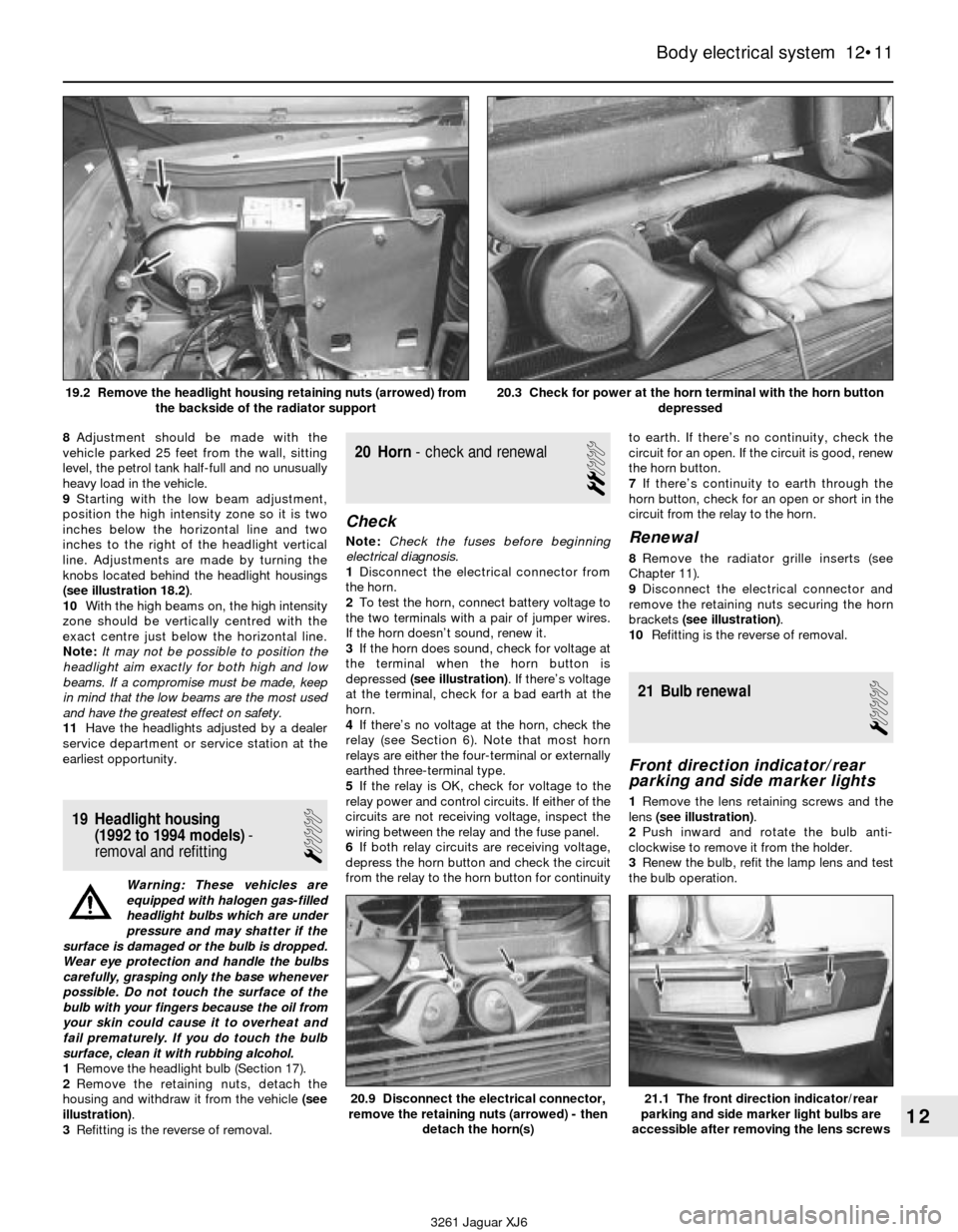

19 Headlight housing

(1992 to 1994 models)-

removal and refitting

1

Warning: These vehicles are

equipped with halogen gas-filled

headlight bulbs which are under

pressure and may shatter if the

surface is damaged or the bulb is dropped.

Wear eye protection and handle the bulbs

carefully, grasping only the base whenever

possible. Do not touch the surface of the

bulb with your fingers because the oil from

your skin could cause it to overheat and

fail prematurely. If you do touch the bulb

surface, clean it with rubbing alcohol.

1Remove the headlight bulb (Section 17).

2Remove the retaining nuts, detach the

housing and withdraw it from the vehicle (see

illustration).

3Refitting is the reverse of removal.

20 Horn- check and renewal

2

Check

Note:Check the fuses before beginning

electrical diagnosis.

1Disconnect the electrical connector from

the horn.

2To test the horn, connect battery voltage to

the two terminals with a pair of jumper wires.

If the horn doesn’t sound, renew it.

3If the horn does sound, check for voltage at

the terminal when the horn button is

depressed (see illustration). If there’s voltage

at the terminal, check for a bad earth at the

horn.

4If there’s no voltage at the horn, check the

relay (see Section 6). Note that most horn

relays are either the four-terminal or externally

earthed three-terminal type.

5If the relay is OK, check for voltage to the

relay power and control circuits. If either of the

circuits are not receiving voltage, inspect the

wiring between the relay and the fuse panel.

6If both relay circuits are receiving voltage,

depress the horn button and check the circuit

from the relay to the horn button for continuityto earth. If there’s no continuity, check the

circuit for an open. If the circuit is good, renew

the horn button.

7If there’s continuity to earth through the

horn button, check for an open or short in the

circuit from the relay to the horn.Renewal

8Remove the radiator grille inserts (see

Chapter 11).

9Disconnect the electrical connector and

remove the retaining nuts securing the horn

brackets (see illustration).

10Refitting is the reverse of removal.

21 Bulb renewal

1

Front direction indicator/rear

parking and side marker lights

1Remove the lens retaining screws and the

lens (see illustration).

2Push inward and rotate the bulb anti-

clockwise to remove it from the holder.

3Renew the bulb, refit the lamp lens and test

the bulb operation.

Body electrical system 12•11

12

20.9 Disconnect the electrical connector,

remove the retaining nuts (arrowed) - then

detach the horn(s)21.1 The front direction indicator/rear

parking and side marker light bulbs are

accessible after removing the lens screws

3261 Jaguar XJ6 19.2 Remove the headlight housing retaining nuts (arrowed) from

the backside of the radiator support

20.3 Check for power at the horn terminal with the horn button

depressed

Page 215 of 227

3261 Jaguar XJ6

REF•14Fault finding

2 Fuel system

Engine surges while holding accelerator steady

m mIntake air leak (Chapter 4).

m mFuel pump faulty (Chapter 4).

m mLoose fuel injector harness connections (Chapters 4 and 6).

m mDefective ECU (Chapter 6).

Pinking or knocking engine sounds during

acceleration or uphill

m mIncorrect grade of fuel.

m mDistributor installed incorrectly (Chapter 5).

m mFuel injection system in need of adjustment (Chapter 4).

m mImproper or damaged spark plugs or wires (Chapter 1).

m mWorn or damaged distributor components (Chapter 5).

m mFaulty emission system (Chapter 6).

m mVacuum leak (Chapter 4).

m mFuel rail feed (inlet) hose has hardened, resulting in knocking noise

near dash (see Chapter 4).

Engine lacks power

m mIncorrect ignition timing (Chapter 5).

m mExcessive play in distributor shaft (Chapter 5).

m mWorn rotor, distributor cap or wires (Chapters 1 and 5).

m mFaulty or incorrectly gapped spark plugs (Chapter 1).

m mFuel injection system malfunctioning (Chapter 4).

m mFaulty coil (Chapter 5).

m mBrakes binding (Chapter 1).

m mAutomatic transmission fluid level incorrect (Chapter 1).

m mFuel filter clogged and/or impurities in the fuel system (Chapter 1).

m mEmission control system not functioning properly (Chapter 6).

m mLow or uneven cylinder compression pressures (Chapter 2).

Engine rattles at start-up

m

mFailure of upper timing chain tensioner (Chapter 2).

Engine backfires

m

mEmissions system not functioning properly (Chapter 6).

m mIgnition timing incorrect (Chapter 1).

m mFaulty secondary ignition system (cracked spark plug insulator,

faulty plug leads, distributor cap and/or rotor) (Chapters 1 and 5).

m mFuel injection system malfunctioning (Chapter 4).

m mVacuum leak at fuel injector(s), intake manifold or vacuum hoses

(Chapter 4).

Engine stalls

m mIdle speed incorrect (Chapter 1).

m mFuel filter clogged and/or water and impurities in the fuel system

(Chapter 1).

m mDistributor components damp or damaged (Chapter 5).

m mFaulty emissions system components (Chapter 6).

m mFaulty or incorrectly gapped spark plugs (Chapter 1).

m mFaulty spark plug leads (Chapter 1).

m mVacuum leak in the fuel injection system, intake manifold or

vacuum hoses (Chapter 4).

Engine runs with oil pressure light on

m mLow oil level (Chapter 1).

m mIdle rpm too low (Chapter 1).

m mShort in wiring circuit (Chapter 12).

m mFaulty oil pressure sending unit (Chapter 2).

m mWorn engine bearings and/or oil pump (Chapter 2).

Engine diesels (continues to run)

after switching off

m mIdle speed too high (Chapter 4).

m mExcessive engine operating temperature (Chapter 3).

m mIncorrect fuel octane grade.

Excessive fuel consumption

m

mDirty or clogged air filter element (Chapter 1).

m mIncorrectly set ignition timing (Chapter 5).

m mEmissions system not functioning properly (Chapter 6).

m mFuel injection internal parts worn or damaged (Chapter 4).

m mLow tyre pressure or incorrect tyre size (Chapter 1).

Fuel leakage and/or fuel odour

m

mLeak in a fuel feed or vent line (Chapter 4).

m mTank overfilled.

m mFuel injector internal parts excessively worn (Chapter 4).

3 Cooling system

Overheating

m

mInsufficient coolant in system (Chapter 1).

m mWater pump drivebelt defective or out of adjustment (Chapter 1).

m mRadiator core blocked or grille restricted (Chapter 3).

m mThermostat faulty (Chapter 3).

m mRadiator cap not maintaining proper pressure (Chapter 3).

m mIgnition timing incorrect (Chapter 5).

Overcooling

m

mFaulty thermostat (Chapter 3).

External coolant leakage

m

mDeteriorated/damaged hoses; loose clamps (Chapters 1 and 3).

m mWater pump seal defective (Chapters 1 and 3).

m mLeakage from radiator core or manifold tank (Chapter 3).

m mEngine drain or water jacket core plugs leaking (Chapter 2).

m mHoses behind water pump leaking (Chapter 3).

Internal coolant leakage

m

mLeaking cylinder head gasket (Chapter 2).

m mCracked cylinder bore or cylinder head (Chapter 2).

Coolant loss

m

mToo much coolant in system (Chapter 1).

m mCoolant boiling away because of overheating (Chapter 3).

m mInternal or external leakage (Chapter 3).

m mFaulty radiator cap (Chapter 3).

Poor coolant circulation

m

mInoperative water pump (Chapter 3).

m mRestriction in cooling system (Chapters 1 and 3).

m mWater pump drivebelt defective/out of adjustment (Chapter 1).

m mThermostat sticking (Chapter 3).

1 Engine (continued)

Page 219 of 227

3261 Jaguar XJ6

REF•18Glossary of technical terms

A

ABS (Anti-lock brake system)A system,

usually electronically controlled, that senses

incipient wheel lockup during braking and

relieves hydraulic pressure at wheels that are

about to skid.

Air bag An inflatable bag hidden in the

steering wheel (driver’s side) or the dash or

glovebox (passenger side). In a head-on

collision, the bags inflate, preventing the

driver and front passenger from being thrown

forward into the steering wheel or windscreen.

Air cleanerA metal or plastic housing,

containing a filter element, which removes

dust and dirt from the air being drawn into the

engine.

Air filter elementThe actual filter in an air

cleaner system, usually manufactured from

pleated paper and requiring renewal at regular

intervals.

Allen keyA hexagonal wrench which fits into

a recessed hexagonal hole.

Alligator clipA long-nosed spring-loaded

metal clip with meshing teeth. Used to make

temporary electrical connections.

AlternatorA component in the electrical

system which converts mechanical energy

from a drivebelt into electrical energy to

charge the battery and to operate the starting

system, ignition system and electrical

accessories.

Ampere (amp)A unit of measurement for the

flow of electric current. One amp is the

amount of current produced by one volt

acting through a resistance of one ohm.

Anaerobic sealerA substance used to

prevent bolts and screws from loosening.

Anaerobic means that it does not require

oxygen for activation. The Loctite brand is

widely used.

AntifreezeA substance (usually ethylene

glycol) mixed with water, and added to a

vehicle’s cooling system, to prevent freezing

of the coolant in winter. Antifreeze also

contains chemicals to inhibit corrosion and

the formation of rust and other deposits that

would tend to clog the radiator and coolant

passages and reduce cooling efficiency.

Anti-seize compoundA coating that

reduces the risk of seizing on fasteners that

are subjected to high temperatures, such as

exhaust manifold bolts and nuts.

AsbestosA natural fibrous mineral with great

heat resistance, commonly used in the

composition of brake friction materials.Asbestos is a health hazard and the dust

created by brake systems should never be

inhaled or ingested.

AxleA shaft on which a wheel revolves, or

which revolves with a wheel. Also, a solid

beam that connects the two wheels at one

end of the vehicle. An axle which also

transmits power to the wheels is known as a

live axle.

AxleshaftA single rotating shaft, on either

side of the differential, which delivers power

from the final drive assembly to the drive

wheels. Also called a driveshaft or a halfshaft.

BBall bearingAn anti-friction bearing

consisting of a hardened inner and outer race

with hardened steel balls between two races.

BearingThe curved surface on a shaft or in a

bore, or the part assembled into either, that

permits relative motion between them with

minimum wear and friction.

Big-end bearingThe bearing in the end of

the connecting rod that’s attached to the

crankshaft.

Bleed nippleA valve on a brake wheel

cylinder, caliper or other hydraulic component

that is opened to purge the hydraulic system

of air. Also called a bleed screw.

Brake bleedingProcedure for removing air

from lines of a hydraulic brake system.

Brake discThe component of a disc brake

that rotates with the wheels.Brake drumThe component of a drum brake

that rotates with the wheels.

Brake liningsThe friction material which

contacts the brake disc or drum to retard the

vehicle’s speed. The linings are bonded or

riveted to the brake pads or shoes.

Brake padsThe replaceable friction pads

that pinch the brake disc when the brakes are

applied. Brake pads consist of a friction

material bonded or riveted to a rigid backing

plate.

Brake shoeThe crescent-shaped carrier to

which the brake linings are mounted and

which forces the lining against the rotating

drum during braking.

Braking systemsFor more information on

braking systems, consult the Haynes

Automotive Brake Manual.

Breaker barA long socket wrench handle

providing greater leverage.

BulkheadThe insulated partition between

the engine and the passenger compartment.

CCaliperThe non-rotating part of a disc-brake

assembly that straddles the disc and carries

the brake pads. The caliper also contains the

hydraulic components that cause the pads to

pinch the disc when the brakes are applied. A

caliper is also a measuring tool that can be set

to measure inside or outside dimensions of an

object.

CamshaftA rotating shaft on which a series

of cam lobes operate the valve mechanisms.

The camshaft may be driven by gears, by

sprockets and chain or by sprockets and a

belt.

CanisterA container in an evaporative

emission control system; contains activated

charcoal granules to trap vapours from the

fuel system.

CarburettorA device which mixes fuel with

air in the proper proportions to provide a

desired power output from a spark ignition

internal combustion engine.

CastellatedResembling the parapets along

the top of a castle wall. For example, a

castellated balljoint stud nut.

CastorIn wheel alignment, the backward or

forward tilt of the steering axis. Castor is

positive when the steering axis is inclined

rearward at the top.

Canister

Brake bleeding

Bearing

Air filter

Page 221 of 227

3261 Jaguar XJ6

REF•20Glossary of technical terms

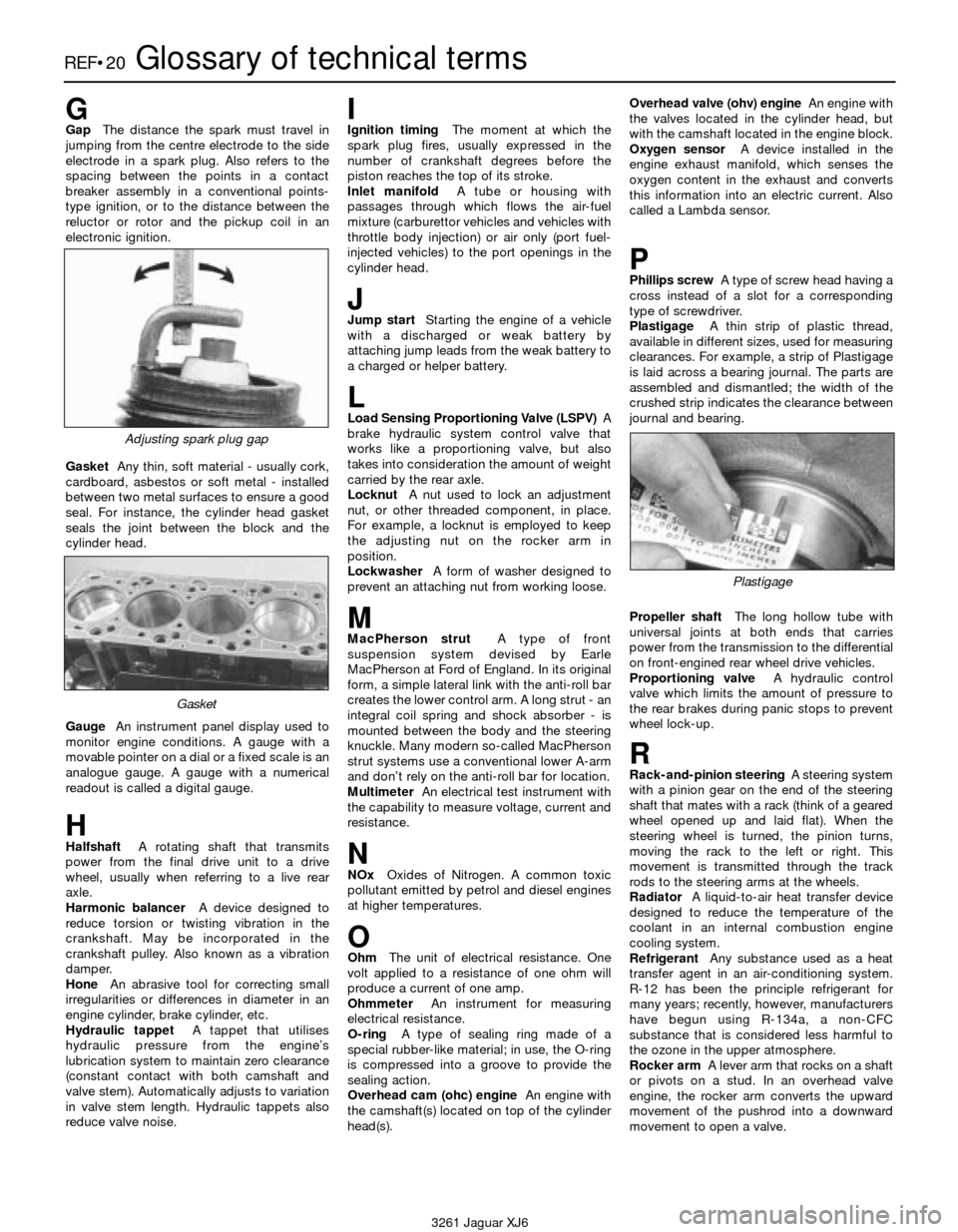

GGapThe distance the spark must travel in

jumping from the centre electrode to the side

electrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.

Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to

the ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Adjusting spark plug gap

Plastigage

Gasket