JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1181 of 1784

(8) Check fluid condition. Fluid should be dark to

light red in color and free of dirt or debris.

(9) If fluid is discolored or smells burned but trans-

mission operation was OK, check cooler flow, flush

cooler and lines and change fluid and filter. Then

road test again to confirm proper operation.

(10) If fluid is black or dark brown, burned/turned

to sludge, contains large quantities of metal or fric-

tion material particles, transmission will need over-

haul. Especially if problems were evident during

road test and preliminary diagnosis. Fluid cooler

should also be flow tested and flushed if necessary.

EFFECTS OF INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn

the fluid into foam. This aerates the fluid causing

the same conditions that occur with a low level.

In either case, air bubbles cause fluid overheating,

oxidation and varnish buildup which interferes with

valve, clutch and servo operation. Foaming also

causes fluid expansion which can result in fluid over-

flow from the transmission vent or fill tube. Fluid

overflow can easily be mistaken for a leak if inspec-

tion is not careful.

TRANSMISSION THROTTLE VALVE CABLE

ADJUSTMENT

Throttle cable adjustment is important to proper

operation. This adjustment positions the throttle

valve which controls shift speed, quality and part

throttle downshift sensitivity.

If cable adjustment setting is too short, early shifts

and slippage between shifts may occur. If the setting

is too long, shifts may be delayed and part throttle

downshifts may be very sensitive. Refer to the In-Ve-

hicle Service section for adjustment procedure.

GEARSHIFT LINKAGE

Gearshift linkage adjustment is important because

it positions the valve body manual valve. Incorrect

adjustment will cause creeping in Neutral, prema-

ture clutch wear, delayed engagement in any gear, or

a no-start in Park or Neutral position.

Proper operation of the neutral start switch will

provide a quick check of linkage adjustment. Refer to

the In-Vehicle Service section for adjustment proce-

dure.

ROAD TEST

Before road testing, be sure the fluid level and all

linkage adjustments have been checked and adjusted

if necessary.

Observe engine performance during the road test.

A poorly tuned engine will not allow an accurate

analysis of transmission operation.Operate the transmission in all gear ranges. Check

for slippage and shift variations. Note whether the

shifts are harsh, spongy, delayed, early, or if part

throttle downshifts are sensitive.

Watch closely for slippage or engine flare which

usually indicates clutch, band or overrunning clutch

problems. If the condition is advanced, an overhaul

may be necessary to restore normal operation.

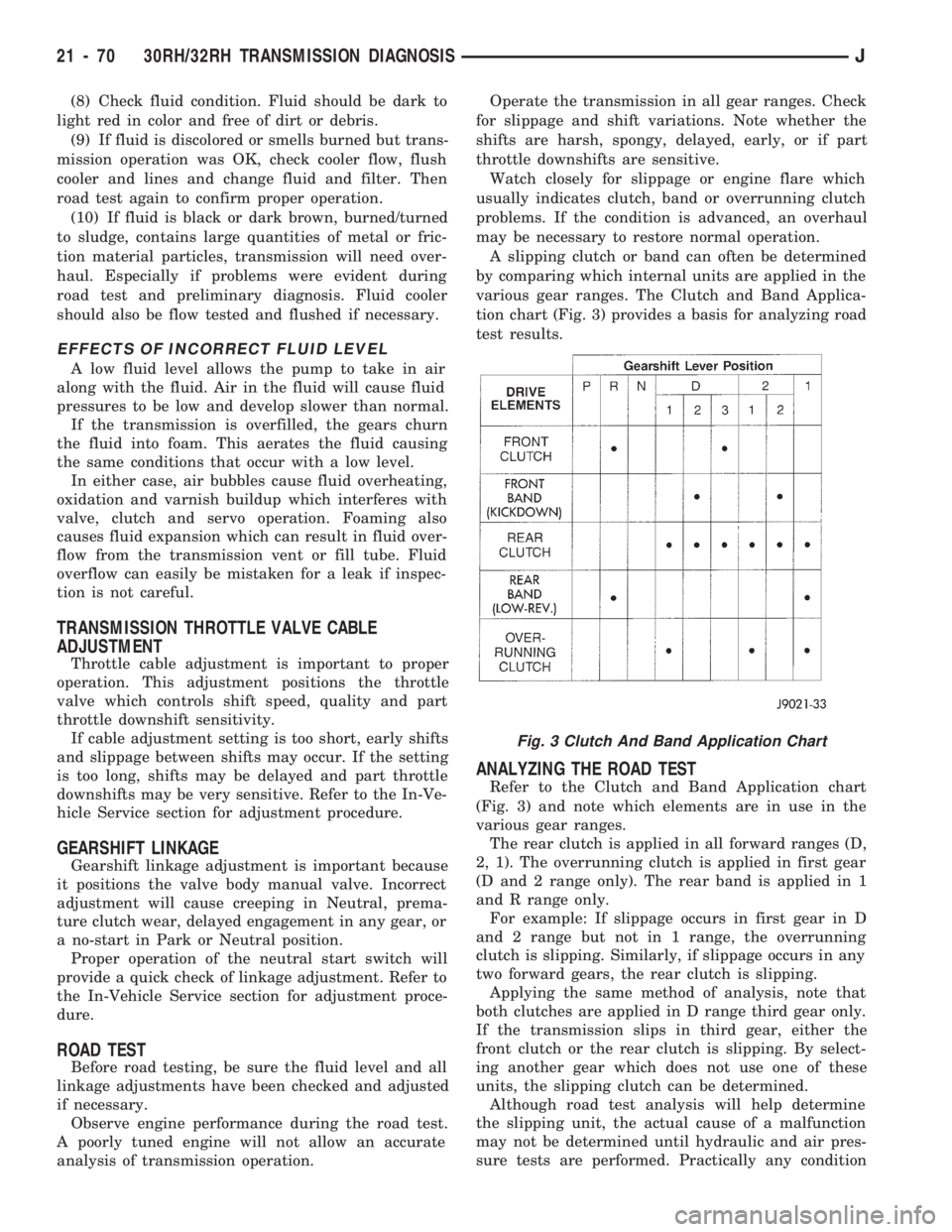

A slipping clutch or band can often be determined

by comparing which internal units are applied in the

various gear ranges. The Clutch and Band Applica-

tion chart (Fig. 3) provides a basis for analyzing road

test results.

ANALYZING THE ROAD TEST

Refer to the Clutch and Band Application chart

(Fig. 3) and note which elements are in use in the

various gear ranges.

The rear clutch is applied in all forward ranges (D,

2, 1). The overrunning clutch is applied in first gear

(D and 2 range only). The rear band is applied in 1

and R range only.

For example: If slippage occurs in first gear in D

and 2 range but not in 1 range, the overrunning

clutch is slipping. Similarly, if slippage occurs in any

two forward gears, the rear clutch is slipping.

Applying the same method of analysis, note that

both clutches are applied in D range third gear only.

If the transmission slips in third gear, either the

front clutch or the rear clutch is slipping. By select-

ing another gear which does not use one of these

units, the slipping clutch can be determined.

Although road test analysis will help determine

the slipping unit, the actual cause of a malfunction

may not be determined until hydraulic and air pres-

sure tests are performed. Practically any condition

Fig. 3 Clutch And Band Application Chart

21 - 70 30RH/32RH TRANSMISSION DIAGNOSISJ

Page 1182 of 1784

can be caused by leaking hydraulic circuits or stick-

ing valves. Unless the problem is an obvious one, do

not remove and disassemble the transmission until

hydraulic and air pressure tests have been per-

formed.

HYDRAULIC PRESSURE TEST

Hydraulic test pressures range from a low of one

psi (6.895 kPa) governor pressure, to 300 psi (2068.5

kPa) at the rear servo pressure port in reverse.

Use 100 psi Pressure Gauge C-3292 to check pres-

sure at the accumulator, front servo, governor and

fluid cooler line. Use 300 psi Gauge C-3293 to check

pressure at the rear servo. The 300 psi gauge can be

used at any other port when more than one gauge is

required for testing.

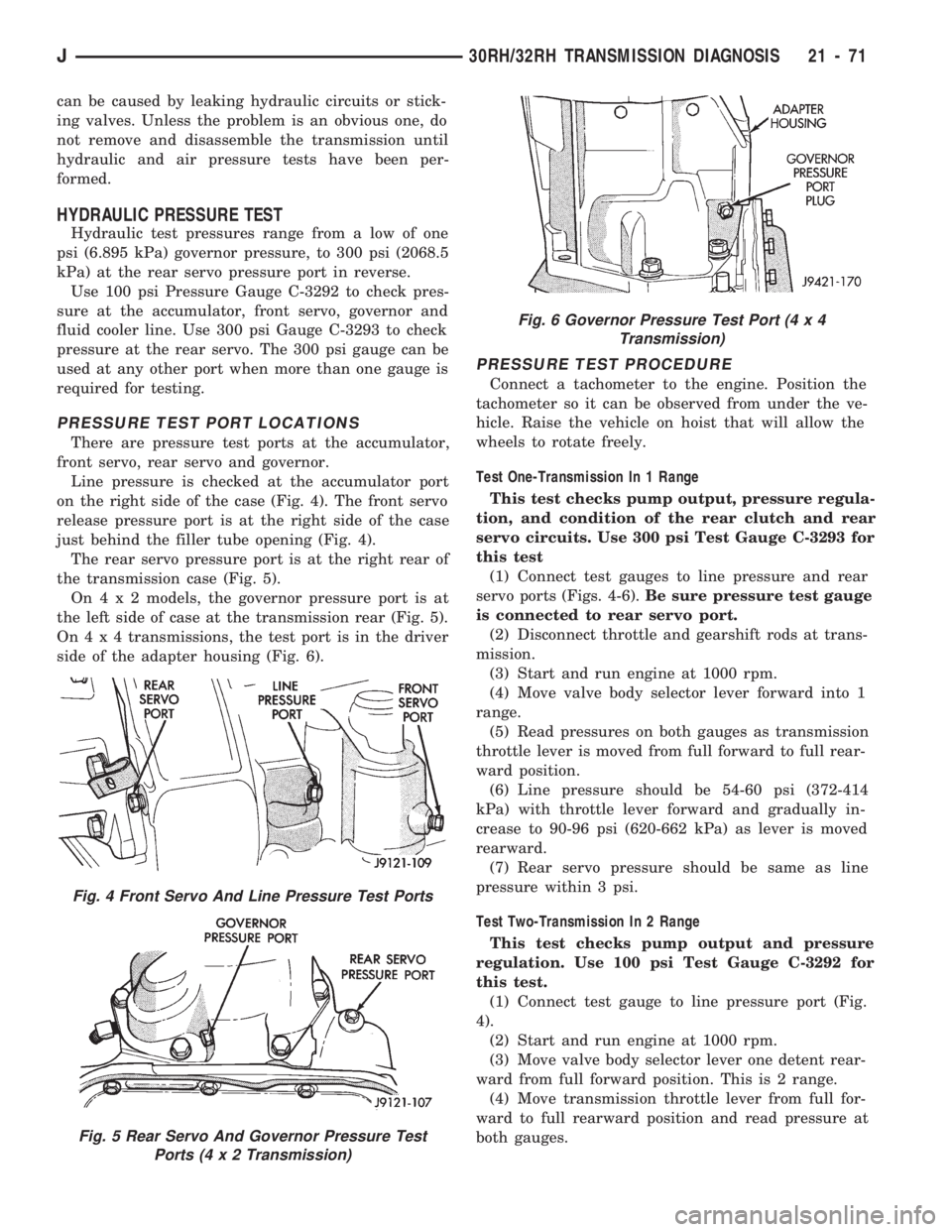

PRESSURE TEST PORT LOCATIONS

There are pressure test ports at the accumulator,

front servo, rear servo and governor.

Line pressure is checked at the accumulator port

on the right side of the case (Fig. 4). The front servo

release pressure port is at the right side of the case

just behind the filler tube opening (Fig. 4).

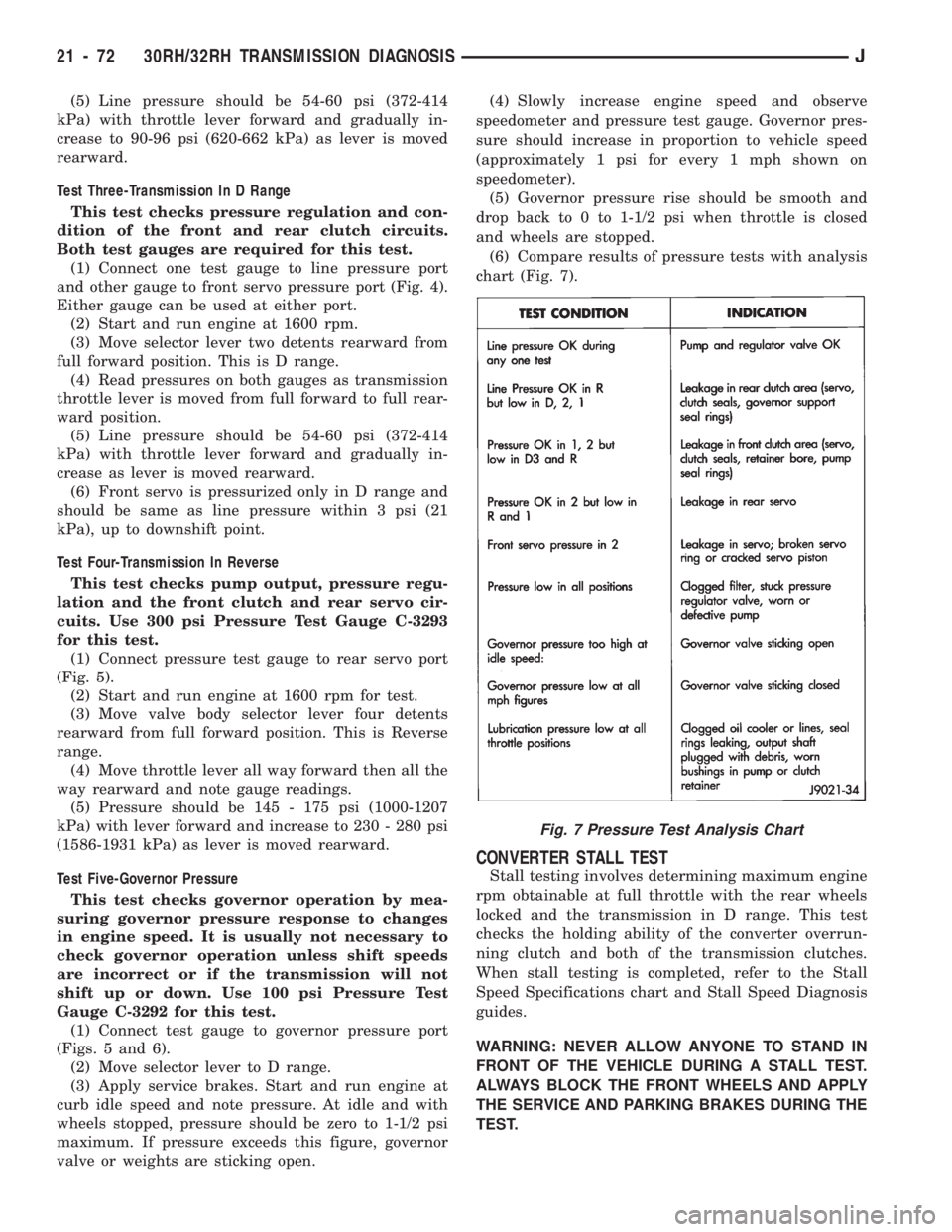

The rear servo pressure port is at the right rear of

the transmission case (Fig. 5).

On4x2models, the governor pressure port is at

the left side of case at the transmission rear (Fig. 5).

On4x4transmissions, the test port is in the driver

side of the adapter housing (Fig. 6).

PRESSURE TEST PROCEDURE

Connect a tachometer to the engine. Position the

tachometer so it can be observed from under the ve-

hicle. Raise the vehicle on hoist that will allow the

wheels to rotate freely.

Test One-Transmission In 1 Range

This test checks pump output, pressure regula-

tion, and condition of the rear clutch and rear

servo circuits. Use 300 psi Test Gauge C-3293 for

this test

(1) Connect test gauges to line pressure and rear

servo ports (Figs. 4-6).Be sure pressure test gauge

is connected to rear servo port.

(2) Disconnect throttle and gearshift rods at trans-

mission.

(3) Start and run engine at 1000 rpm.

(4) Move valve body selector lever forward into 1

range.

(5) Read pressures on both gauges as transmission

throttle lever is moved from full forward to full rear-

ward position.

(6) Line pressure should be 54-60 psi (372-414

kPa) with throttle lever forward and gradually in-

crease to 90-96 psi (620-662 kPa) as lever is moved

rearward.

(7) Rear servo pressure should be same as line

pressure within 3 psi.

Test Two-Transmission In 2 Range

This test checks pump output and pressure

regulation. Use 100 psi Test Gauge C-3292 for

this test.

(1) Connect test gauge to line pressure port (Fig.

4).

(2) Start and run engine at 1000 rpm.

(3) Move valve body selector lever one detent rear-

ward from full forward position. This is 2 range.

(4) Move transmission throttle lever from full for-

ward to full rearward position and read pressure at

both gauges.

Fig. 4 Front Servo And Line Pressure Test Ports

Fig. 5 Rear Servo And Governor Pressure Test

Ports (4 x 2 Transmission)

Fig. 6 Governor Pressure Test Port (4 x 4

Transmission)

J30RH/32RH TRANSMISSION DIAGNOSIS 21 - 71

Page 1183 of 1784

(5) Line pressure should be 54-60 psi (372-414

kPa) with throttle lever forward and gradually in-

crease to 90-96 psi (620-662 kPa) as lever is moved

rearward.

Test Three-Transmission In D Range

This test checks pressure regulation and con-

dition of the front and rear clutch circuits.

Both test gauges are required for this test.

(1) Connect one test gauge to line pressure port

and other gauge to front servo pressure port (Fig. 4).

Either gauge can be used at either port.

(2) Start and run engine at 1600 rpm.

(3) Move selector lever two detents rearward from

full forward position. This is D range.

(4) Read pressures on both gauges as transmission

throttle lever is moved from full forward to full rear-

ward position.

(5) Line pressure should be 54-60 psi (372-414

kPa) with throttle lever forward and gradually in-

crease as lever is moved rearward.

(6) Front servo is pressurized only in D range and

should be same as line pressure within 3 psi (21

kPa), up to downshift point.

Test Four-Transmission In Reverse

This test checks pump output, pressure regu-

lation and the front clutch and rear servo cir-

cuits. Use 300 psi Pressure Test Gauge C-3293

for this test.

(1) Connect pressure test gauge to rear servo port

(Fig. 5).

(2) Start and run engine at 1600 rpm for test.

(3) Move valve body selector lever four detents

rearward from full forward position. This is Reverse

range.

(4) Move throttle lever all way forward then all the

way rearward and note gauge readings.

(5) Pressure should be 145 - 175 psi (1000-1207

kPa) with lever forward and increase to 230 - 280 psi

(1586-1931 kPa) as lever is moved rearward.

Test Five-Governor Pressure

This test checks governor operation by mea-

suring governor pressure response to changes

in engine speed. It is usually not necessary to

check governor operation unless shift speeds

are incorrect or if the transmission will not

shift up or down. Use 100 psi Pressure Test

Gauge C-3292 for this test.

(1) Connect test gauge to governor pressure port

(Figs. 5 and 6).

(2) Move selector lever to D range.

(3) Apply service brakes. Start and run engine at

curb idle speed and note pressure. At idle and with

wheels stopped, pressure should be zero to 1-1/2 psi

maximum. If pressure exceeds this figure, governor

valve or weights are sticking open.(4) Slowly increase engine speed and observe

speedometer and pressure test gauge. Governor pres-

sure should increase in proportion to vehicle speed

(approximately 1 psi for every 1 mph shown on

speedometer).

(5) Governor pressure rise should be smooth and

drop back to 0 to 1-1/2 psi when throttle is closed

and wheels are stopped.

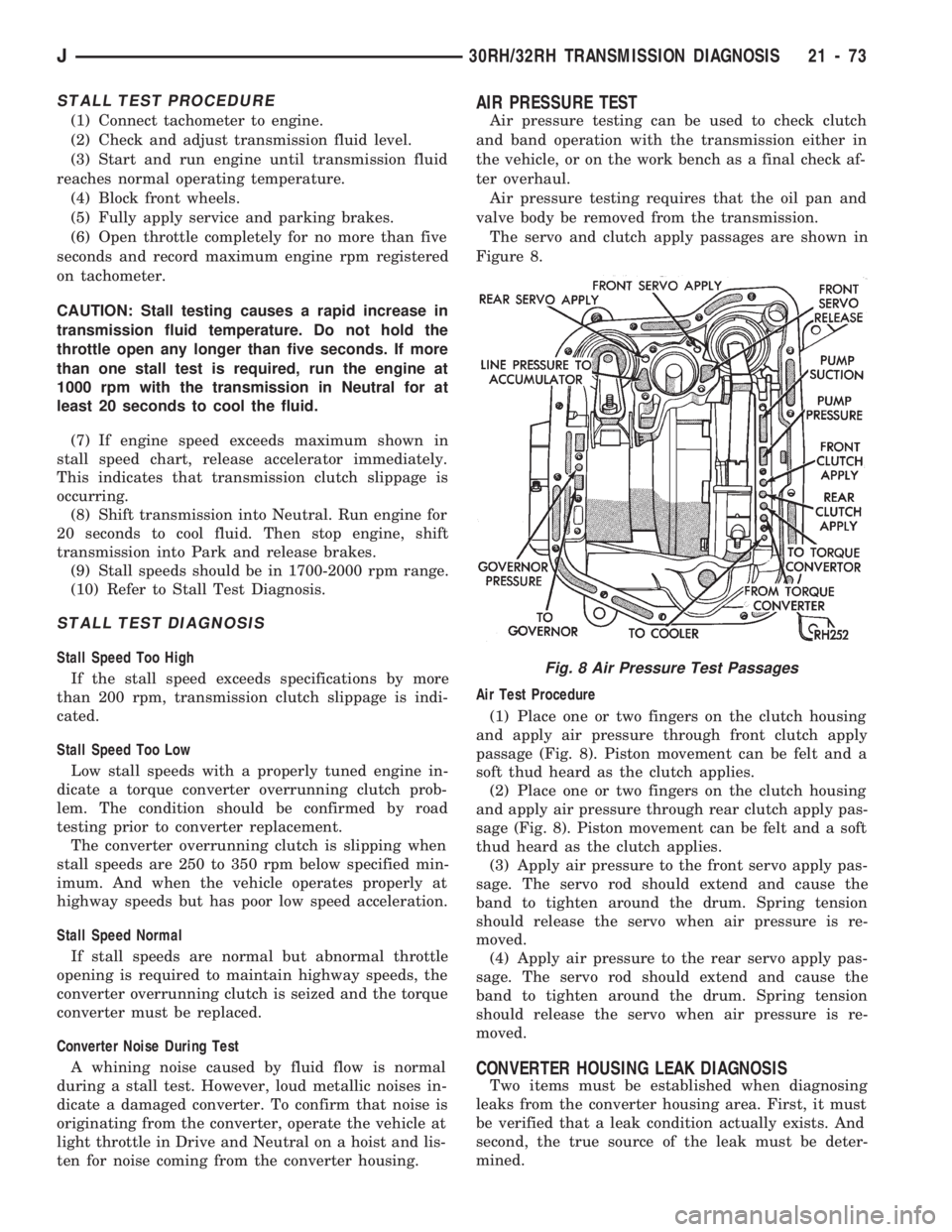

(6) Compare results of pressure tests with analysis

chart (Fig. 7).

CONVERTER STALL TEST

Stall testing involves determining maximum engine

rpm obtainable at full throttle with the rear wheels

locked and the transmission in D range. This test

checks the holding ability of the converter overrun-

ning clutch and both of the transmission clutches.

When stall testing is completed, refer to the Stall

Speed Specifications chart and Stall Speed Diagnosis

guides.

WARNING: NEVER ALLOW ANYONE TO STAND IN

FRONT OF THE VEHICLE DURING A STALL TEST.

ALWAYS BLOCK THE FRONT WHEELS AND APPLY

THE SERVICE AND PARKING BRAKES DURING THE

TEST.

Fig. 7 Pressure Test Analysis Chart

21 - 72 30RH/32RH TRANSMISSION DIAGNOSISJ

Page 1184 of 1784

STALL TEST PROCEDURE

(1) Connect tachometer to engine.

(2) Check and adjust transmission fluid level.

(3) Start and run engine until transmission fluid

reaches normal operating temperature.

(4) Block front wheels.

(5) Fully apply service and parking brakes.

(6) Open throttle completely for no more than five

seconds and record maximum engine rpm registered

on tachometer.

CAUTION: Stall testing causes a rapid increase in

transmission fluid temperature. Do not hold the

throttle open any longer than five seconds. If more

than one stall test is required, run the engine at

1000 rpm with the transmission in Neutral for at

least 20 seconds to cool the fluid.

(7) If engine speed exceeds maximum shown in

stall speed chart, release accelerator immediately.

This indicates that transmission clutch slippage is

occurring.

(8) Shift transmission into Neutral. Run engine for

20 seconds to cool fluid. Then stop engine, shift

transmission into Park and release brakes.

(9) Stall speeds should be in 1700-2000 rpm range.

(10) Refer to Stall Test Diagnosis.

STALL TEST DIAGNOSIS

Stall Speed Too High

If the stall speed exceeds specifications by more

than 200 rpm, transmission clutch slippage is indi-

cated.

Stall Speed Too Low

Low stall speeds with a properly tuned engine in-

dicate a torque converter overrunning clutch prob-

lem. The condition should be confirmed by road

testing prior to converter replacement.

The converter overrunning clutch is slipping when

stall speeds are 250 to 350 rpm below specified min-

imum. And when the vehicle operates properly at

highway speeds but has poor low speed acceleration.

Stall Speed Normal

If stall speeds are normal but abnormal throttle

opening is required to maintain highway speeds, the

converter overrunning clutch is seized and the torque

converter must be replaced.

Converter Noise During Test

A whining noise caused by fluid flow is normal

during a stall test. However, loud metallic noises in-

dicate a damaged converter. To confirm that noise is

originating from the converter, operate the vehicle at

light throttle in Drive and Neutral on a hoist and lis-

ten for noise coming from the converter housing.

AIR PRESSURE TEST

Air pressure testing can be used to check clutch

and band operation with the transmission either in

the vehicle, or on the work bench as a final check af-

ter overhaul.

Air pressure testing requires that the oil pan and

valve body be removed from the transmission.

The servo and clutch apply passages are shown in

Figure 8.

Air Test Procedure

(1) Place one or two fingers on the clutch housing

and apply air pressure through front clutch apply

passage (Fig. 8). Piston movement can be felt and a

soft thud heard as the clutch applies.

(2) Place one or two fingers on the clutch housing

and apply air pressure through rear clutch apply pas-

sage (Fig. 8). Piston movement can be felt and a soft

thud heard as the clutch applies.

(3) Apply air pressure to the front servo apply pas-

sage. The servo rod should extend and cause the

band to tighten around the drum. Spring tension

should release the servo when air pressure is re-

moved.

(4) Apply air pressure to the rear servo apply pas-

sage. The servo rod should extend and cause the

band to tighten around the drum. Spring tension

should release the servo when air pressure is re-

moved.

CONVERTER HOUSING LEAK DIAGNOSIS

Two items must be established when diagnosing

leaks from the converter housing area. First, it must

be verified that a leak condition actually exists. And

second, the true source of the leak must be deter-

mined.

Fig. 8 Air Pressure Test Passages

J30RH/32RH TRANSMISSION DIAGNOSIS 21 - 73

Page 1185 of 1784

Some suspected converter housing fluid leaks may

not be leaks at all. Residual fluid in the housing, or

excess fluid spilled during factory fill or refill after

repair can be mistaken for a leak. In addition, a rear

main seal leak can also be mistaken for a pump seal

leak if care is exercised.

Converter housing leaks have several potential

sources. Through careful observation, a leak source

can be identified before removing the transmission

for repair.

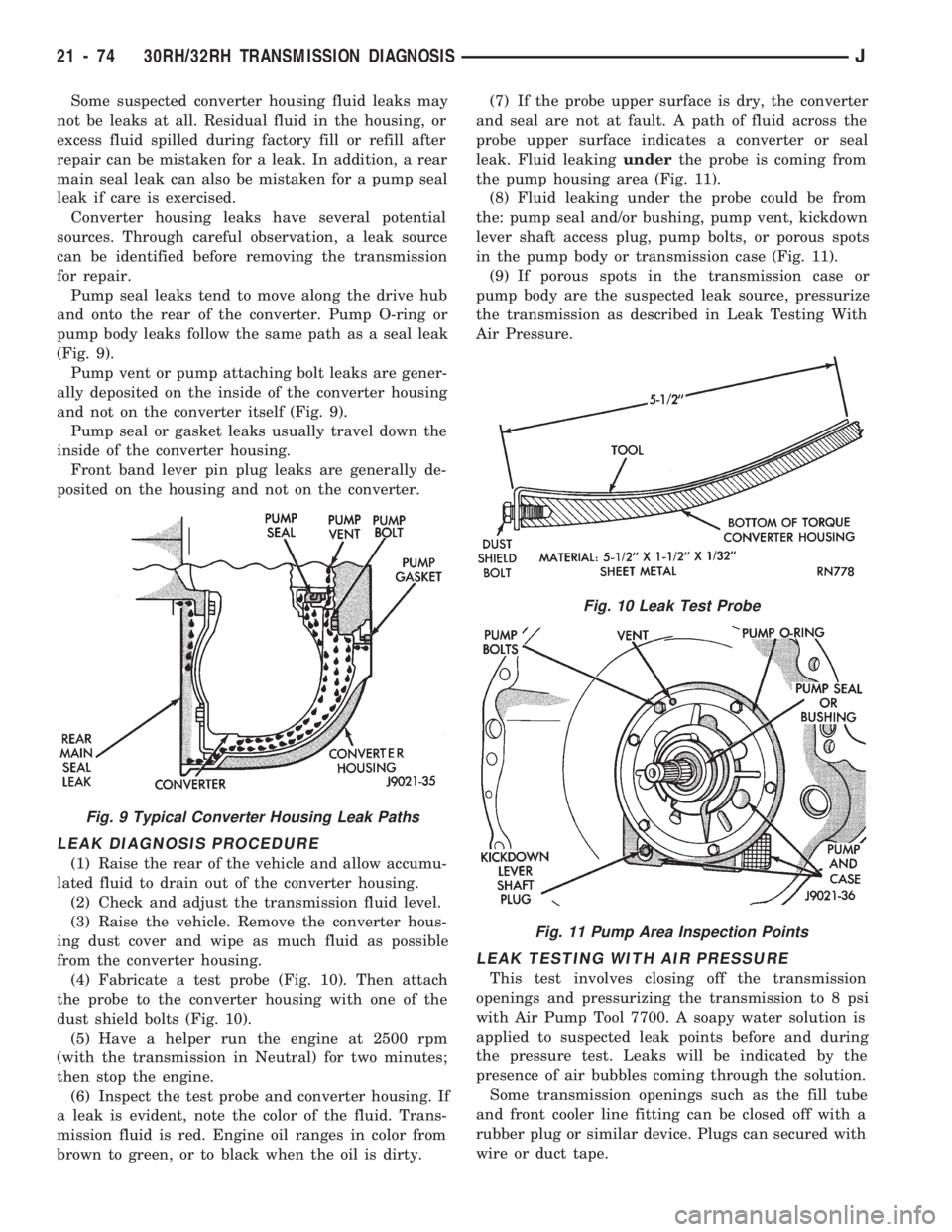

Pump seal leaks tend to move along the drive hub

and onto the rear of the converter. Pump O-ring or

pump body leaks follow the same path as a seal leak

(Fig. 9).

Pump vent or pump attaching bolt leaks are gener-

ally deposited on the inside of the converter housing

and not on the converter itself (Fig. 9).

Pump seal or gasket leaks usually travel down the

inside of the converter housing.

Front band lever pin plug leaks are generally de-

posited on the housing and not on the converter.

LEAK DIAGNOSIS PROCEDURE

(1) Raise the rear of the vehicle and allow accumu-

lated fluid to drain out of the converter housing.

(2) Check and adjust the transmission fluid level.

(3) Raise the vehicle. Remove the converter hous-

ing dust cover and wipe as much fluid as possible

from the converter housing.

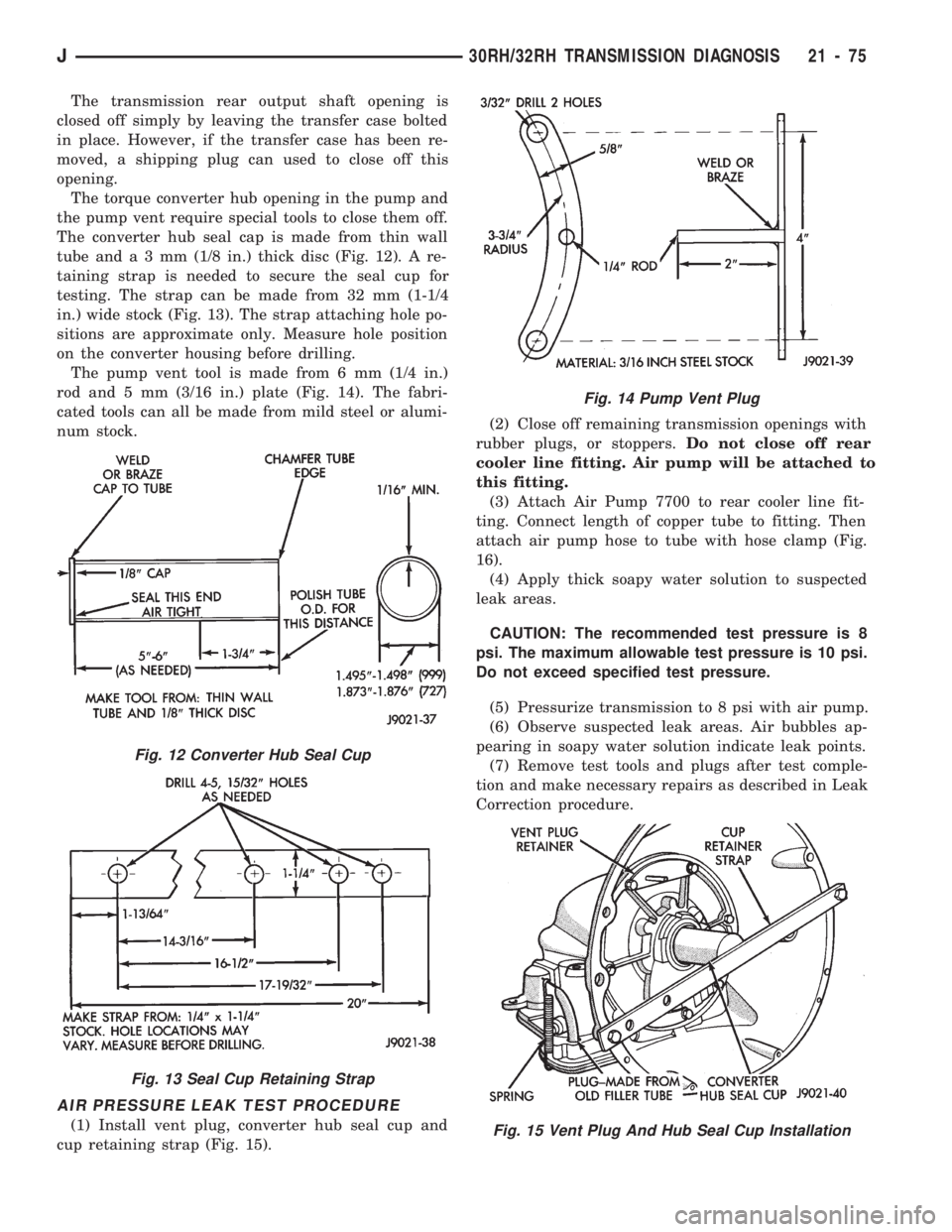

(4) Fabricate a test probe (Fig. 10). Then attach

the probe to the converter housing with one of the

dust shield bolts (Fig. 10).

(5) Have a helper run the engine at 2500 rpm

(with the transmission in Neutral) for two minutes;

then stop the engine.

(6) Inspect the test probe and converter housing. If

a leak is evident, note the color of the fluid. Trans-

mission fluid is red. Engine oil ranges in color from

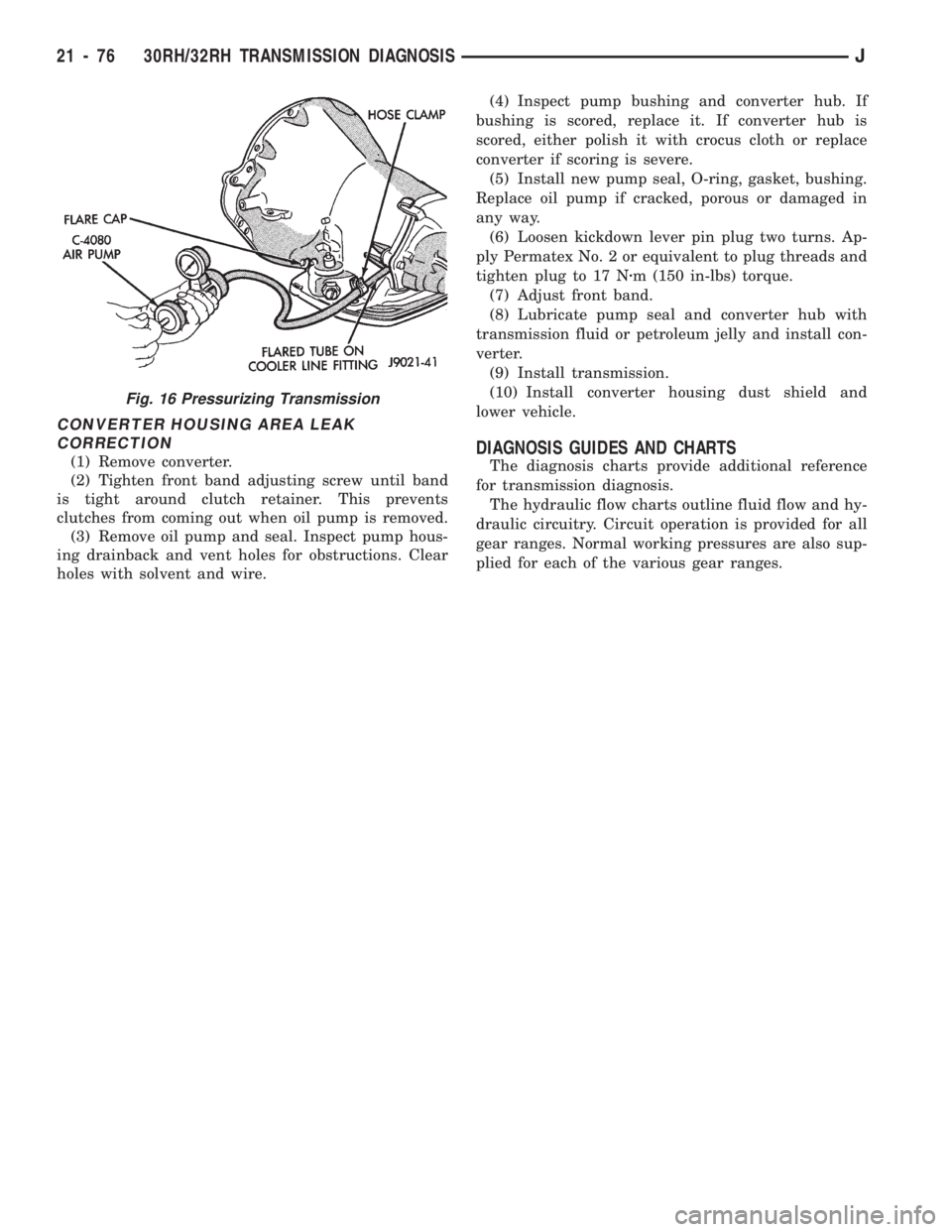

brown to green, or to black when the oil is dirty.(7) If the probe upper surface is dry, the converter

and seal are not at fault. A path of fluid across the

probe upper surface indicates a converter or seal

leak. Fluid leakingunderthe probe is coming from

the pump housing area (Fig. 11).

(8) Fluid leaking under the probe could be from

the: pump seal and/or bushing, pump vent, kickdown

lever shaft access plug, pump bolts, or porous spots

in the pump body or transmission case (Fig. 11).

(9) If porous spots in the transmission case or

pump body are the suspected leak source, pressurize

the transmission as described in Leak Testing With

Air Pressure.

LEAK TESTING WITH AIR PRESSURE

This test involves closing off the transmission

openings and pressurizing the transmission to 8 psi

with Air Pump Tool 7700. A soapy water solution is

applied to suspected leak points before and during

the pressure test. Leaks will be indicated by the

presence of air bubbles coming through the solution.

Some transmission openings such as the fill tube

and front cooler line fitting can be closed off with a

rubber plug or similar device. Plugs can secured with

wire or duct tape.

Fig. 9 Typical Converter Housing Leak Paths

Fig. 10 Leak Test Probe

Fig. 11 Pump Area Inspection Points

21 - 74 30RH/32RH TRANSMISSION DIAGNOSISJ

Page 1186 of 1784

The transmission rear output shaft opening is

closed off simply by leaving the transfer case bolted

in place. However, if the transfer case has been re-

moved, a shipping plug can used to close off this

opening.

The torque converter hub opening in the pump and

the pump vent require special tools to close them off.

The converter hub seal cap is made from thin wall

tube anda3mm(1/8 in.) thick disc (Fig. 12). A re-

taining strap is needed to secure the seal cup for

testing. The strap can be made from 32 mm (1-1/4

in.) wide stock (Fig. 13). The strap attaching hole po-

sitions are approximate only. Measure hole position

on the converter housing before drilling.

The pump vent tool is made from 6 mm (1/4 in.)

rod and 5 mm (3/16 in.) plate (Fig. 14). The fabri-

cated tools can all be made from mild steel or alumi-

num stock.

AIR PRESSURE LEAK TEST PROCEDURE

(1) Install vent plug, converter hub seal cup and

cup retaining strap (Fig. 15).(2) Close off remaining transmission openings with

rubber plugs, or stoppers.Do not close off rear

cooler line fitting. Air pump will be attached to

this fitting.

(3) Attach Air Pump 7700 to rear cooler line fit-

ting. Connect length of copper tube to fitting. Then

attach air pump hose to tube with hose clamp (Fig.

16).

(4) Apply thick soapy water solution to suspected

leak areas.

CAUTION: The recommended test pressure is 8

psi. The maximum allowable test pressure is 10 psi.

Do not exceed specified test pressure.

(5) Pressurize transmission to 8 psi with air pump.

(6) Observe suspected leak areas. Air bubbles ap-

pearing in soapy water solution indicate leak points.

(7) Remove test tools and plugs after test comple-

tion and make necessary repairs as described in Leak

Correction procedure.

Fig. 12 Converter Hub Seal Cup

Fig. 13 Seal Cup Retaining Strap

Fig. 14 Pump Vent Plug

Fig. 15 Vent Plug And Hub Seal Cup Installation

J30RH/32RH TRANSMISSION DIAGNOSIS 21 - 75

Page 1187 of 1784

CONVERTER HOUSING AREA LEAK

CORRECTION

(1) Remove converter.

(2) Tighten front band adjusting screw until band

is tight around clutch retainer. This prevents

clutches from coming out when oil pump is removed.

(3) Remove oil pump and seal. Inspect pump hous-

ing drainback and vent holes for obstructions. Clear

holes with solvent and wire.(4) Inspect pump bushing and converter hub. If

bushing is scored, replace it. If converter hub is

scored, either polish it with crocus cloth or replace

converter if scoring is severe.

(5) Install new pump seal, O-ring, gasket, bushing.

Replace oil pump if cracked, porous or damaged in

any way.

(6) Loosen kickdown lever pin plug two turns. Ap-

ply Permatex No. 2 or equivalent to plug threads and

tighten plug to 17 Nzm (150 in-lbs) torque.

(7) Adjust front band.

(8) Lubricate pump seal and converter hub with

transmission fluid or petroleum jelly and install con-

verter.

(9) Install transmission.

(10) Install converter housing dust shield and

lower vehicle.DIAGNOSIS GUIDES AND CHARTS

The diagnosis charts provide additional reference

for transmission diagnosis.

The hydraulic flow charts outline fluid flow and hy-

draulic circuitry. Circuit operation is provided for all

gear ranges. Normal working pressures are also sup-

plied for each of the various gear ranges.

Fig. 16 Pressurizing Transmission

21 - 76 30RH/32RH TRANSMISSION DIAGNOSISJ

Page 1188 of 1784

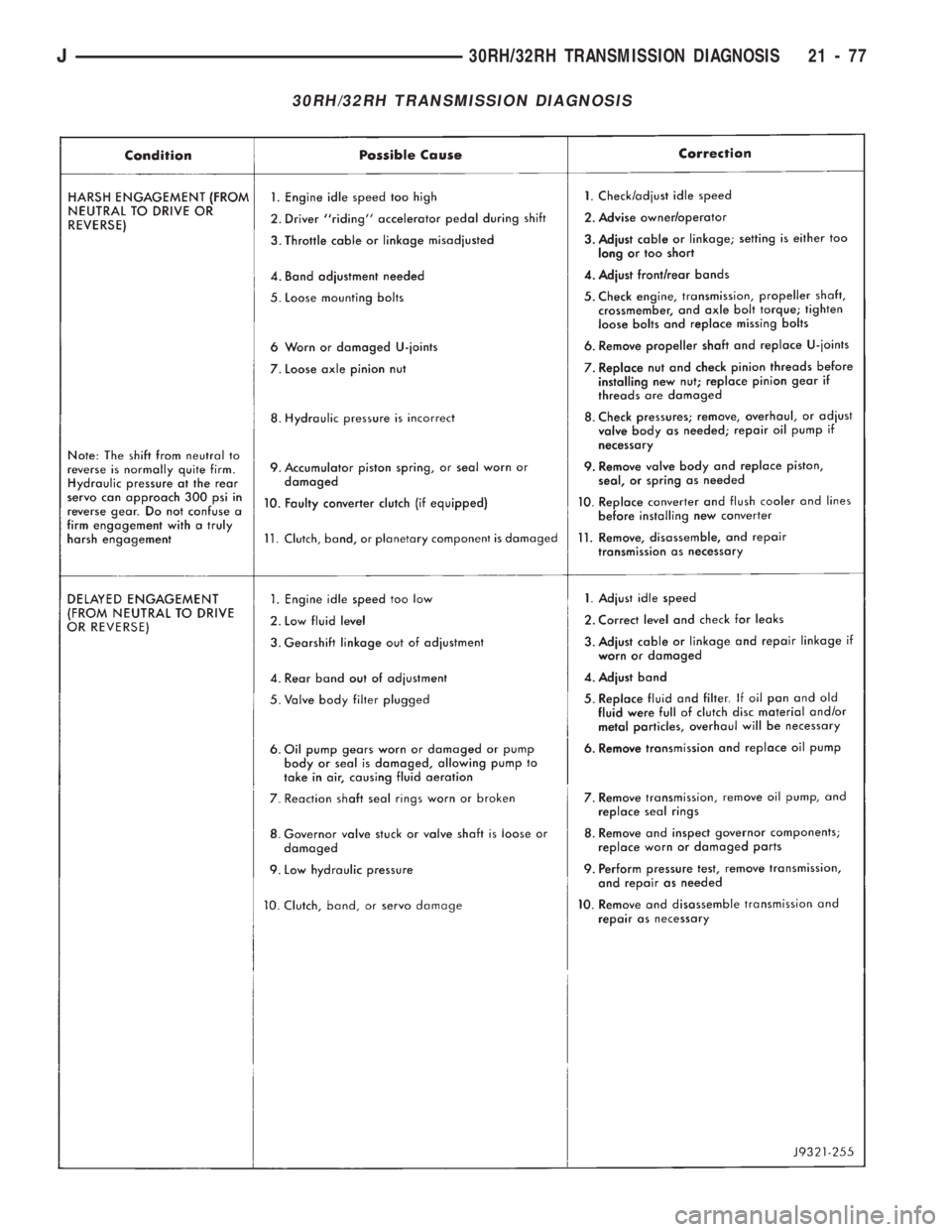

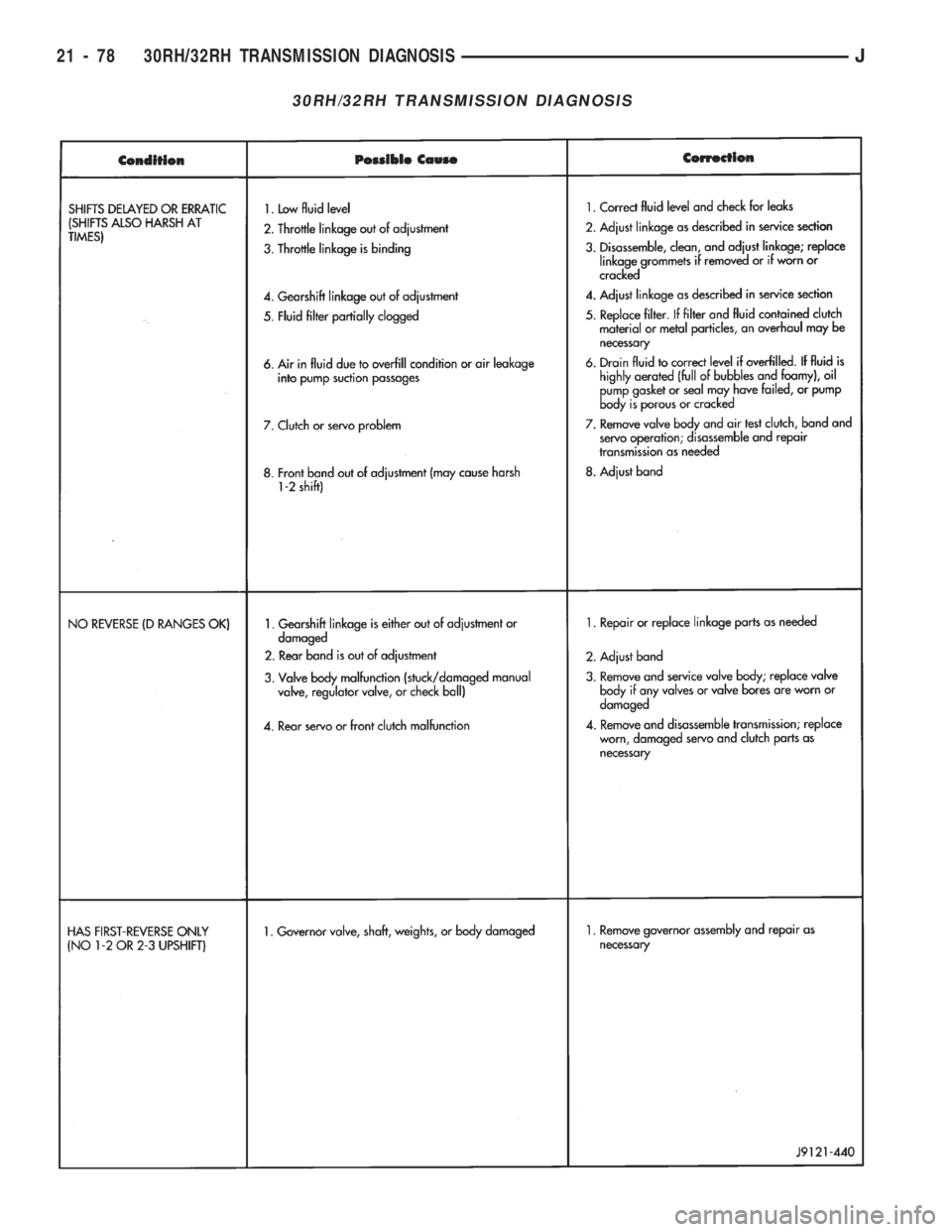

30RH/32RH TRANSMISSION DIAGNOSIS

J30RH/32RH TRANSMISSION DIAGNOSIS 21 - 77

Page 1189 of 1784

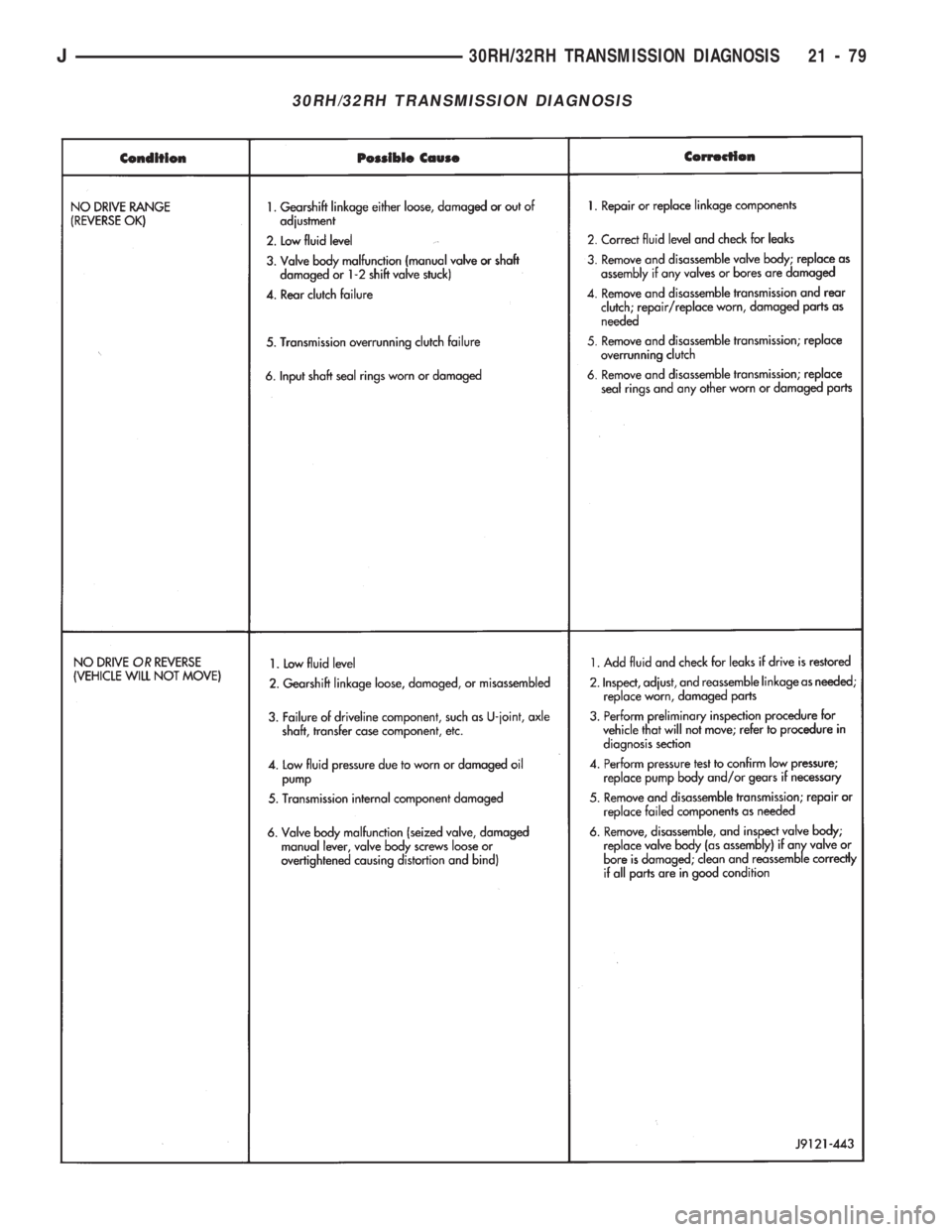

30RH/32RH TRANSMISSION DIAGNOSIS

21 - 78 30RH/32RH TRANSMISSION DIAGNOSISJ

Page 1190 of 1784

30RH/32RH TRANSMISSION DIAGNOSIS

J30RH/32RH TRANSMISSION DIAGNOSIS 21 - 79