JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1451 of 1784

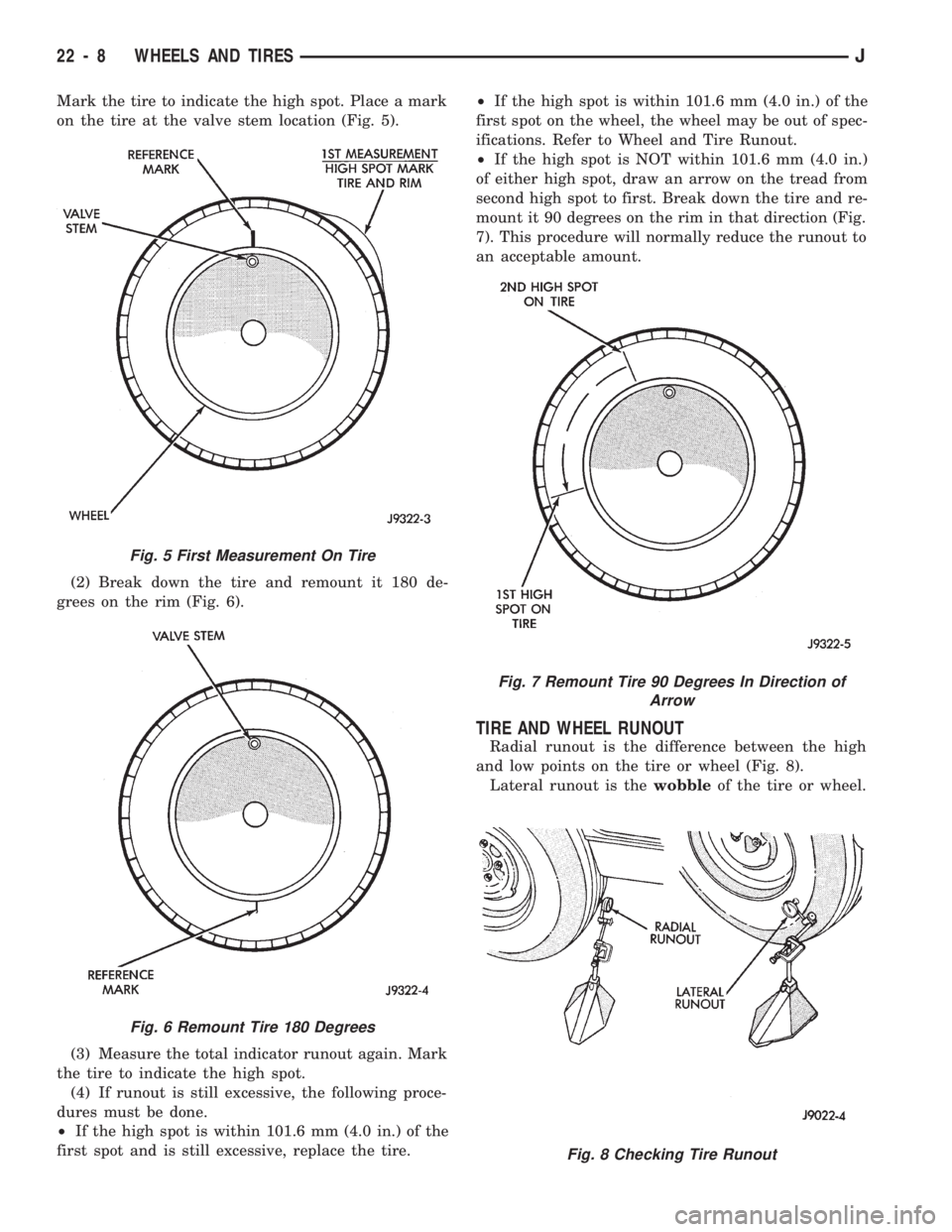

Mark the tire to indicate the high spot. Place a mark

on the tire at the valve stem location (Fig. 5).

(2) Break down the tire and remount it 180 de-

grees on the rim (Fig. 6).

(3) Measure the total indicator runout again. Mark

the tire to indicate the high spot.

(4) If runout is still excessive, the following proce-

dures must be done.

²If the high spot is within 101.6 mm (4.0 in.) of the

first spot and is still excessive, replace the tire.²If the high spot is within 101.6 mm (4.0 in.) of the

first spot on the wheel, the wheel may be out of spec-

ifications. Refer to Wheel and Tire Runout.

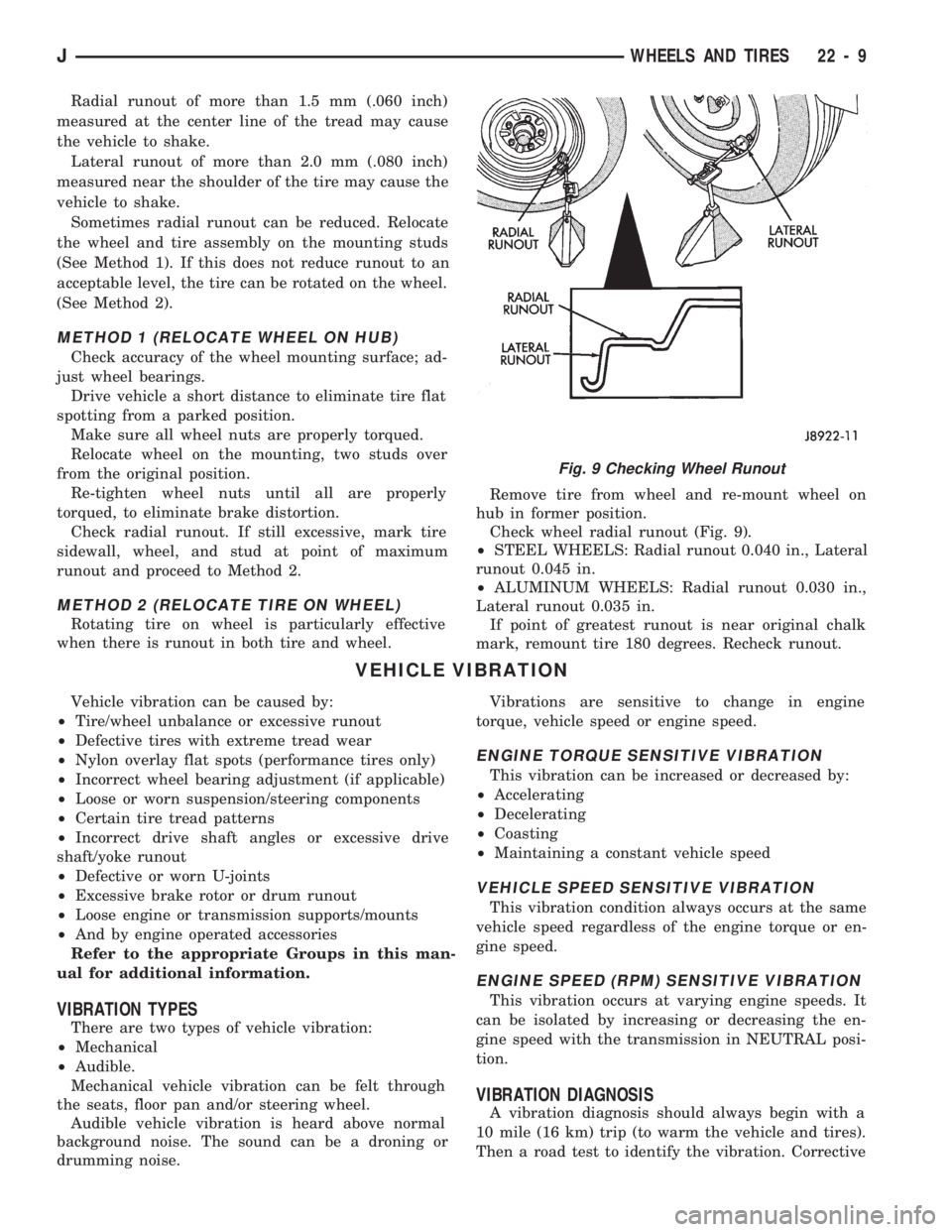

²If the high spot is NOT within 101.6 mm (4.0 in.)

of either high spot, draw an arrow on the tread from

second high spot to first. Break down the tire and re-

mount it 90 degrees on the rim in that direction (Fig.

7). This procedure will normally reduce the runout to

an acceptable amount.

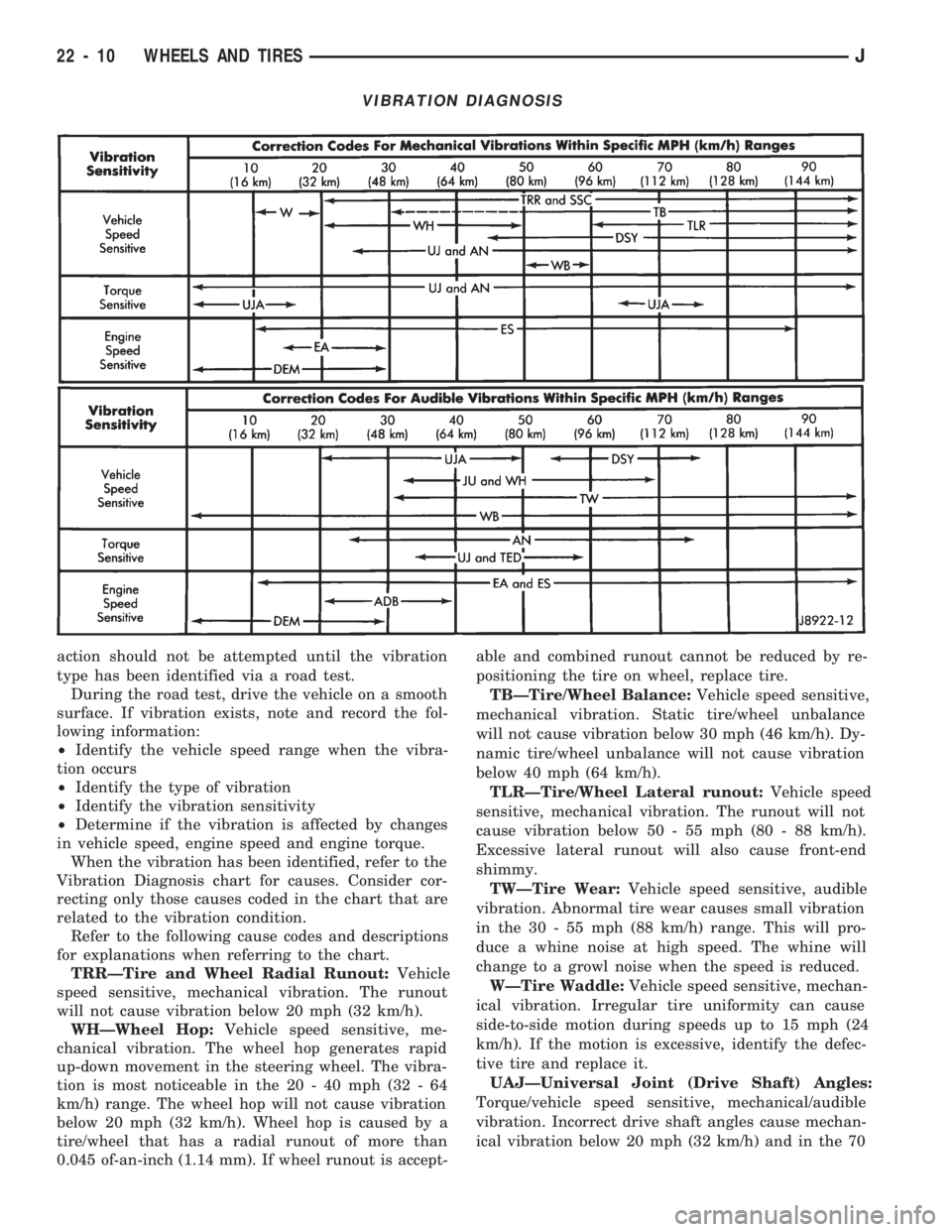

TIRE AND WHEEL RUNOUT

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 8).

Lateral runout is thewobbleof the tire or wheel.

Fig. 5 First Measurement On Tire

Fig. 6 Remount Tire 180 Degrees

Fig. 7 Remount Tire 90 Degrees In Direction of

Arrow

Fig. 8 Checking Tire Runout

22 - 8 WHEELS AND TIRESJ

Page 1452 of 1784

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

Check accuracy of the wheel mounting surface; ad-

just wheel bearings.

Drive vehicle a short distance to eliminate tire flat

spotting from a parked position.

Make sure all wheel nuts are properly torqued.

Relocate wheel on the mounting, two studs over

from the original position.

Re-tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

Check radial runout. If still excessive, mark tire

sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

Rotating tire on wheel is particularly effective

when there is runout in both tire and wheel.Remove tire from wheel and re-mount wheel on

hub in former position.

Check wheel radial runout (Fig. 9).

²STEEL WHEELS: Radial runout 0.040 in., Lateral

runout 0.045 in.

²ALUMINUM WHEELS: Radial runout 0.030 in.,

Lateral runout 0.035 in.

If point of greatest runout is near original chalk

mark, remount tire 180 degrees. Recheck runout.

VEHICLE VIBRATION

Vehicle vibration can be caused by:

²Tire/wheel unbalance or excessive runout

²Defective tires with extreme tread wear

²Nylon overlay flat spots (performance tires only)

²Incorrect wheel bearing adjustment (if applicable)

²Loose or worn suspension/steering components

²Certain tire tread patterns

²Incorrect drive shaft angles or excessive drive

shaft/yoke runout

²Defective or worn U-joints

²Excessive brake rotor or drum runout

²Loose engine or transmission supports/mounts

²And by engine operated accessories

Refer to the appropriate Groups in this man-

ual for additional information.

VIBRATION TYPES

There are two types of vehicle vibration:

²Mechanical

²Audible.

Mechanical vehicle vibration can be felt through

the seats, floor pan and/or steering wheel.

Audible vehicle vibration is heard above normal

background noise. The sound can be a droning or

drumming noise.Vibrations are sensitive to change in engine

torque, vehicle speed or engine speed.

ENGINE TORQUE SENSITIVE VIBRATION

This vibration can be increased or decreased by:

²Accelerating

²Decelerating

²Coasting

²Maintaining a constant vehicle speed

VEHICLE SPEED SENSITIVE VIBRATION

This vibration condition always occurs at the same

vehicle speed regardless of the engine torque or en-

gine speed.

ENGINE SPEED (RPM) SENSITIVE VIBRATION

This vibration occurs at varying engine speeds. It

can be isolated by increasing or decreasing the en-

gine speed with the transmission in NEUTRAL posi-

tion.

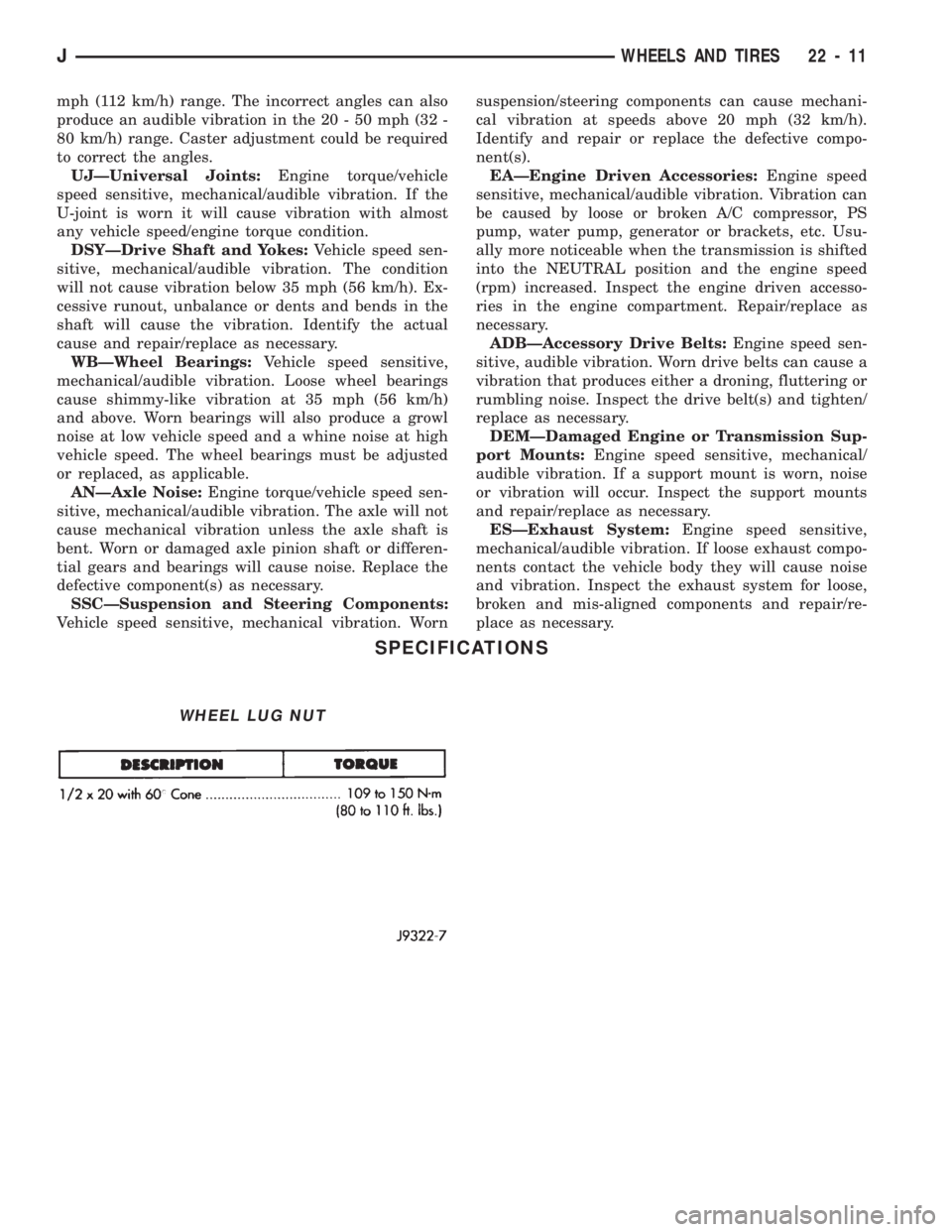

VIBRATION DIAGNOSIS

A vibration diagnosis should always begin with a

10 mile (16 km) trip (to warm the vehicle and tires).

Then a road test to identify the vibration. Corrective

Fig. 9 Checking Wheel Runout

JWHEELS AND TIRES 22 - 9

Page 1453 of 1784

action should not be attempted until the vibration

type has been identified via a road test.

During the road test, drive the vehicle on a smooth

surface. If vibration exists, note and record the fol-

lowing information:

²Identify the vehicle speed range when the vibra-

tion occurs

²Identify the type of vibration

²Identify the vibration sensitivity

²Determine if the vibration is affected by changes

in vehicle speed, engine speed and engine torque.

When the vibration has been identified, refer to the

Vibration Diagnosis chart for causes. Consider cor-

recting only those causes coded in the chart that are

related to the vibration condition.

Refer to the following cause codes and descriptions

for explanations when referring to the chart.

TRRÐTire and Wheel Radial Runout:Vehicle

speed sensitive, mechanical vibration. The runout

will not cause vibration below 20 mph (32 km/h).

WHÐWheel Hop:Vehicle speed sensitive, me-

chanical vibration. The wheel hop generates rapid

up-down movement in the steering wheel. The vibra-

tion is most noticeable in the 20 - 40 mph (32 - 64

km/h) range. The wheel hop will not cause vibration

below 20 mph (32 km/h). Wheel hop is caused by a

tire/wheel that has a radial runout of more than

0.045 of-an-inch (1.14 mm). If wheel runout is accept-able and combined runout cannot be reduced by re-

positioning the tire on wheel, replace tire.

TBÐTire/Wheel Balance:Vehicle speed sensitive,

mechanical vibration. Static tire/wheel unbalance

will not cause vibration below 30 mph (46 km/h). Dy-

namic tire/wheel unbalance will not cause vibration

below 40 mph (64 km/h).

TLRÐTire/Wheel Lateral runout:Vehicle speed

sensitive, mechanical vibration. The runout will not

cause vibration below 50 - 55 mph (80 - 88 km/h).

Excessive lateral runout will also cause front-end

shimmy.

TWÐTire Wear:Vehicle speed sensitive, audible

vibration. Abnormal tire wear causes small vibration

in the 30 - 55 mph (88 km/h) range. This will pro-

duce a whine noise at high speed. The whine will

change to a growl noise when the speed is reduced.

WÐTire Waddle:Vehicle speed sensitive, mechan-

ical vibration. Irregular tire uniformity can cause

side-to-side motion during speeds up to 15 mph (24

km/h). If the motion is excessive, identify the defec-

tive tire and replace it.

UAJÐUniversal Joint (Drive Shaft) Angles:

Torque/vehicle speed sensitive, mechanical/audible

vibration. Incorrect drive shaft angles cause mechan-

ical vibration below 20 mph (32 km/h) and in the 70

VIBRATION DIAGNOSIS

22 - 10 WHEELS AND TIRESJ

Page 1454 of 1784

mph (112 km/h) range. The incorrect angles can also

produce an audible vibration in the 20 - 50 mph (32 -

80 km/h) range. Caster adjustment could be required

to correct the angles.

UJÐUniversal Joints:Engine torque/vehicle

speed sensitive, mechanical/audible vibration. If the

U-joint is worn it will cause vibration with almost

any vehicle speed/engine torque condition.

DSYÐDrive Shaft and Yokes:Vehicle speed sen-

sitive, mechanical/audible vibration. The condition

will not cause vibration below 35 mph (56 km/h). Ex-

cessive runout, unbalance or dents and bends in the

shaft will cause the vibration. Identify the actual

cause and repair/replace as necessary.

WBÐWheel Bearings:Vehicle speed sensitive,

mechanical/audible vibration. Loose wheel bearings

cause shimmy-like vibration at 35 mph (56 km/h)

and above. Worn bearings will also produce a growl

noise at low vehicle speed and a whine noise at high

vehicle speed. The wheel bearings must be adjusted

or replaced, as applicable.

ANÐAxle Noise:Engine torque/vehicle speed sen-

sitive, mechanical/audible vibration. The axle will not

cause mechanical vibration unless the axle shaft is

bent. Worn or damaged axle pinion shaft or differen-

tial gears and bearings will cause noise. Replace the

defective component(s) as necessary.

SSCÐSuspension and Steering Components:

Vehicle speed sensitive, mechanical vibration. Wornsuspension/steering components can cause mechani-

cal vibration at speeds above 20 mph (32 km/h).

Identify and repair or replace the defective compo-

nent(s).

EAÐEngine Driven Accessories:Engine speed

sensitive, mechanical/audible vibration. Vibration can

be caused by loose or broken A/C compressor, PS

pump, water pump, generator or brackets, etc. Usu-

ally more noticeable when the transmission is shifted

into the NEUTRAL position and the engine speed

(rpm) increased. Inspect the engine driven accesso-

ries in the engine compartment. Repair/replace as

necessary.

ADBÐAccessory Drive Belts:Engine speed sen-

sitive, audible vibration. Worn drive belts can cause a

vibration that produces either a droning, fluttering or

rumbling noise. Inspect the drive belt(s) and tighten/

replace as necessary.

DEMÐDamaged Engine or Transmission Sup-

port Mounts:Engine speed sensitive, mechanical/

audible vibration. If a support mount is worn, noise

or vibration will occur. Inspect the support mounts

and repair/replace as necessary.

ESÐExhaust System:Engine speed sensitive,

mechanical/audible vibration. If loose exhaust compo-

nents contact the vehicle body they will cause noise

and vibration. Inspect the exhaust system for loose,

broken and mis-aligned components and repair/re-

place as necessary.

SPECIFICATIONS

WHEEL LUG NUT

JWHEELS AND TIRES 22 - 11

Page 1455 of 1784

Page 1456 of 1784

BODY COMPONENTSÐXJ VEHICLES

CONTENTS

page page

DOORS............................... 34

EXTERIOR COMPONENTS................. 3

FIXED WINDOW GLASS................. 73GENERAL BODY SERVICE INFORMATION.... 1

INTERIOR COMPONENTS................ 91

UNDERBODY COMPONENTS.............. 84

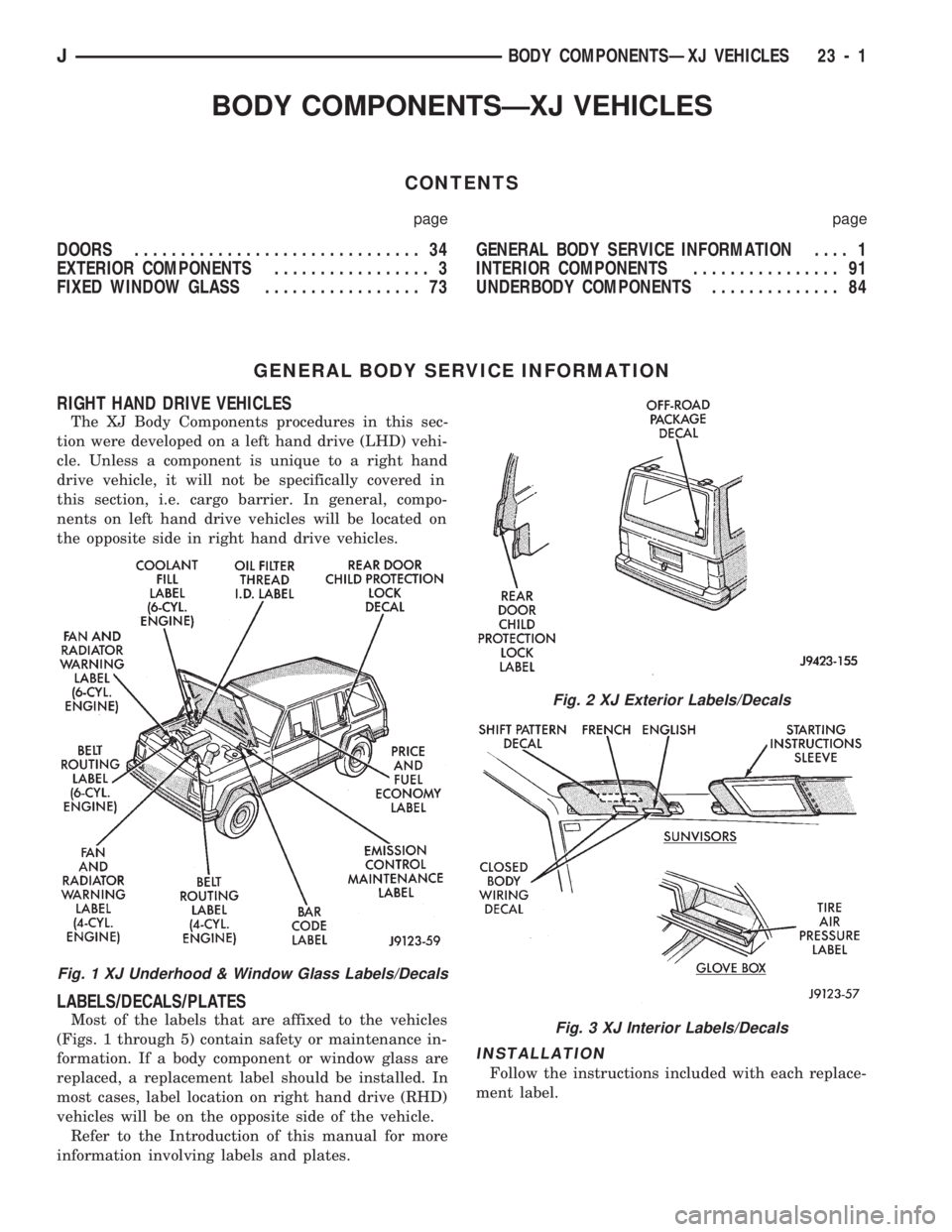

GENERAL BODY SERVICE INFORMATION

RIGHT HAND DRIVE VEHICLES

The XJ Body Components procedures in this sec-

tion were developed on a left hand drive (LHD) vehi-

cle. Unless a component is unique to a right hand

drive vehicle, it will not be specifically covered in

this section, i.e. cargo barrier. In general, compo-

nents on left hand drive vehicles will be located on

the opposite side in right hand drive vehicles.

LABELS/DECALS/PLATES

Most of the labels that are affixed to the vehicles

(Figs. 1 through 5) contain safety or maintenance in-

formation. If a body component or window glass are

replaced, a replacement label should be installed. In

most cases, label location on right hand drive (RHD)

vehicles will be on the opposite side of the vehicle.

Refer to the Introduction of this manual for more

information involving labels and plates.

INSTALLATION

Follow the instructions included with each replace-

ment label.

Fig. 1 XJ Underhood & Window Glass Labels/Decals

Fig. 2 XJ Exterior Labels/Decals

Fig. 3 XJ Interior Labels/Decals

JBODY COMPONENTSÐXJ VEHICLES 23 - 1

Page 1457 of 1784

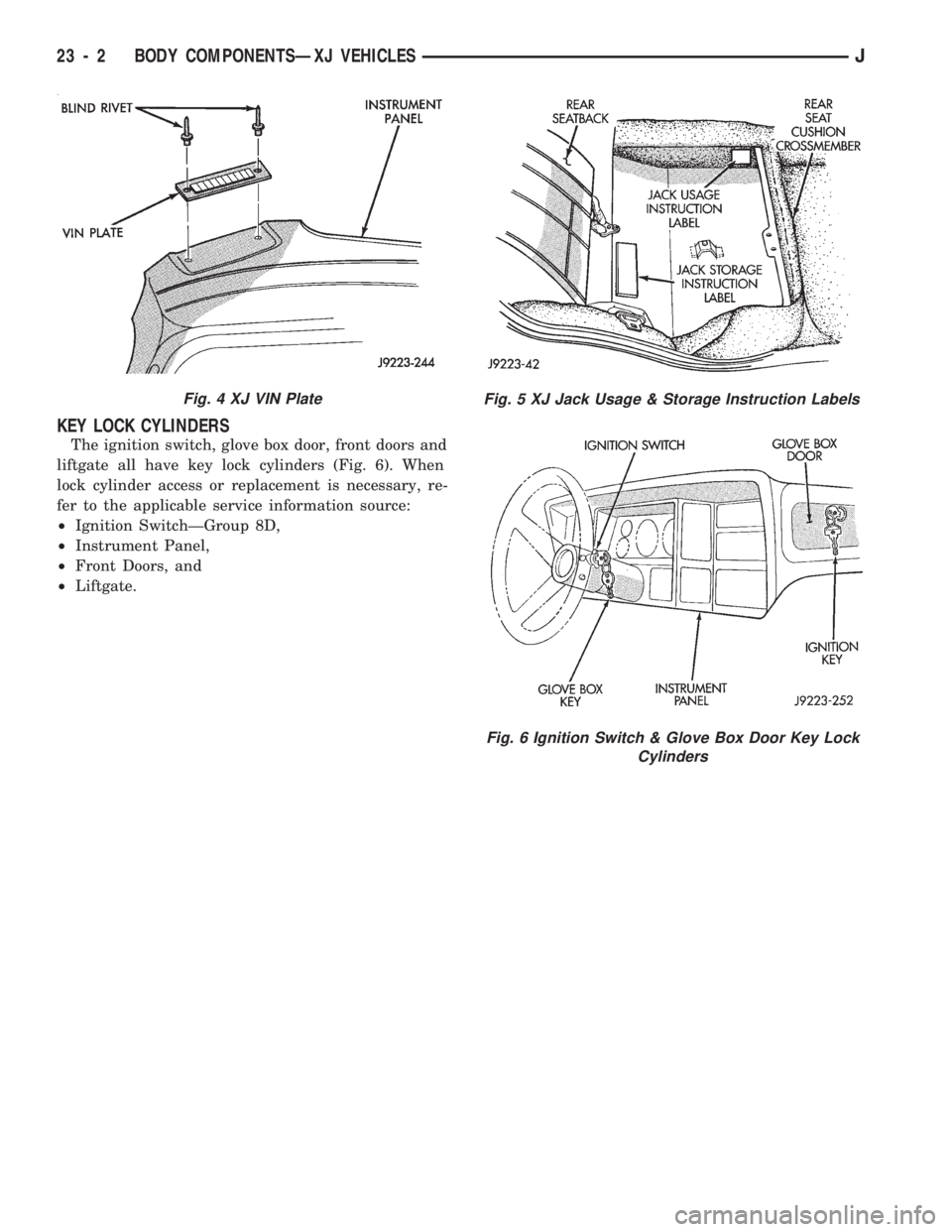

KEY LOCK CYLINDERS

The ignition switch, glove box door, front doors and

liftgate all have key lock cylinders (Fig. 6). When

lock cylinder access or replacement is necessary, re-

fer to the applicable service information source:

²Ignition SwitchÐGroup 8D,

²Instrument Panel,

²Front Doors, and

²Liftgate.

Fig. 4 XJ VIN PlateFig. 5 XJ Jack Usage & Storage Instruction Labels

Fig. 6 Ignition Switch & Glove Box Door Key Lock

Cylinders

23 - 2 BODY COMPONENTSÐXJ VEHICLESJ

Page 1458 of 1784

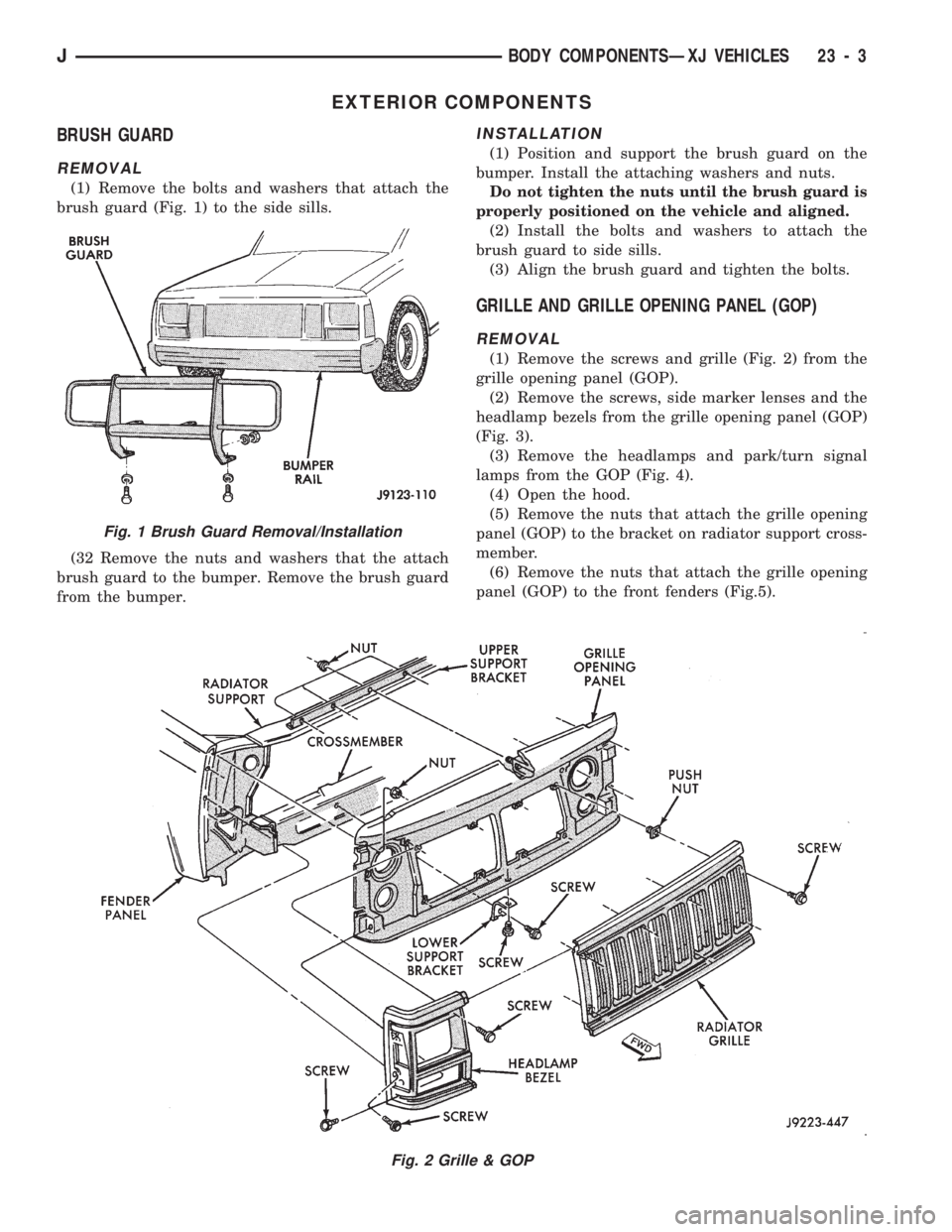

EXTERIOR COMPONENTS

BRUSH GUARD

REMOVAL

(1) Remove the bolts and washers that attach the

brush guard (Fig. 1) to the side sills.

(32 Remove the nuts and washers that the attach

brush guard to the bumper. Remove the brush guard

from the bumper.

INSTALLATION

(1) Position and support the brush guard on the

bumper. Install the attaching washers and nuts.

Do not tighten the nuts until the brush guard is

properly positioned on the vehicle and aligned.

(2) Install the bolts and washers to attach the

brush guard to side sills.

(3) Align the brush guard and tighten the bolts.

GRILLE AND GRILLE OPENING PANEL (GOP)

REMOVAL

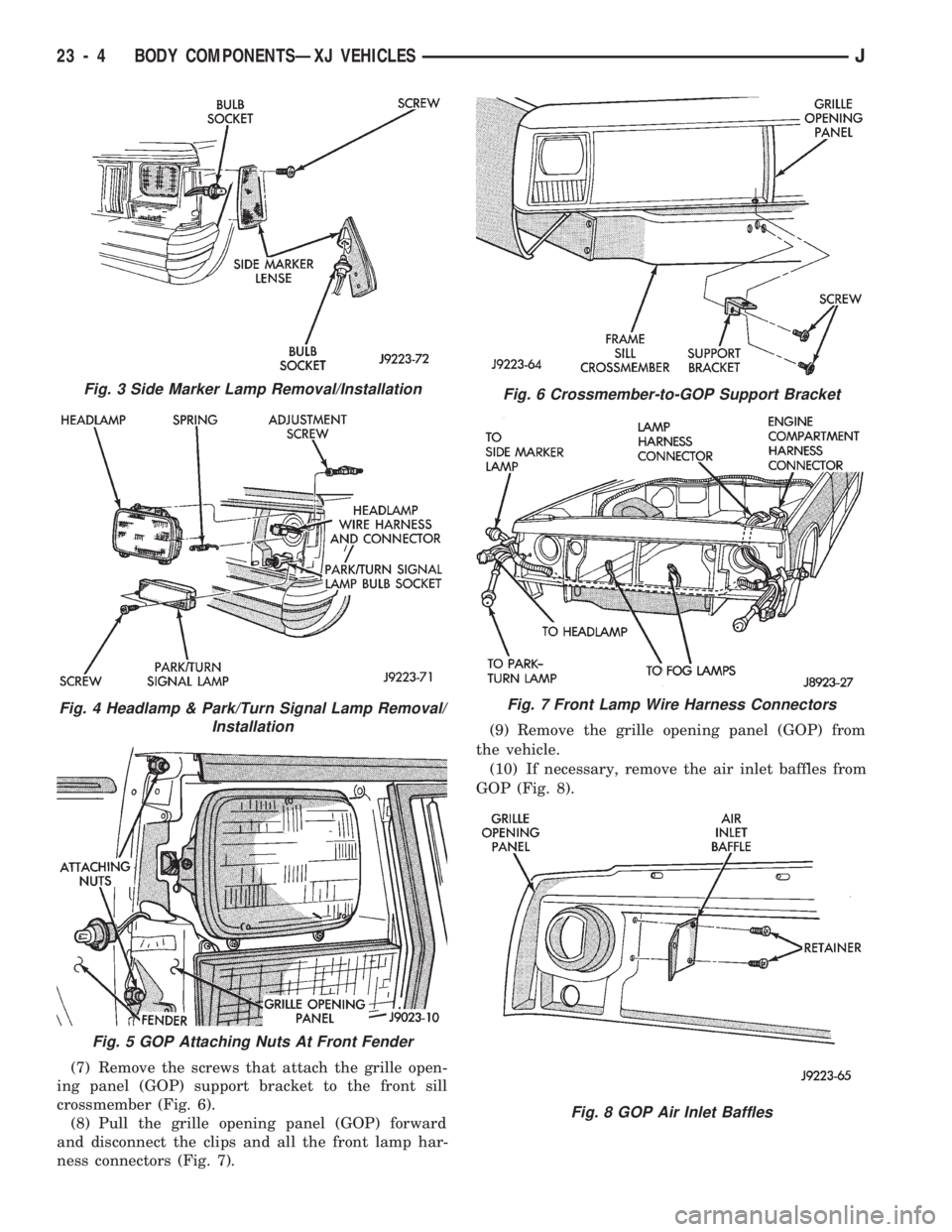

(1) Remove the screws and grille (Fig. 2) from the

grille opening panel (GOP).

(2) Remove the screws, side marker lenses and the

headlamp bezels from the grille opening panel (GOP)

(Fig. 3).

(3) Remove the headlamps and park/turn signal

lamps from the GOP (Fig. 4).

(4) Open the hood.

(5) Remove the nuts that attach the grille opening

panel (GOP) to the bracket on radiator support cross-

member.

(6) Remove the nuts that attach the grille opening

panel (GOP) to the front fenders (Fig.5).

Fig. 2 Grille & GOP

Fig. 1 Brush Guard Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 3

Page 1459 of 1784

(7) Remove the screws that attach the grille open-

ing panel (GOP) support bracket to the front sill

crossmember (Fig. 6).

(8) Pull the grille opening panel (GOP) forward

and disconnect the clips and all the front lamp har-

ness connectors (Fig. 7).(9) Remove the grille opening panel (GOP) from

the vehicle.

(10) If necessary, remove the air inlet baffles from

GOP (Fig. 8).

Fig. 3 Side Marker Lamp Removal/Installation

Fig. 4 Headlamp & Park/Turn Signal Lamp Removal/

Installation

Fig. 5 GOP Attaching Nuts At Front Fender

Fig. 6 Crossmember-to-GOP Support Bracket

Fig. 7 Front Lamp Wire Harness Connectors

Fig. 8 GOP Air Inlet Baffles

23 - 4 BODY COMPONENTSÐXJ VEHICLESJ

Page 1460 of 1784

INSTALLATION

(1) Place the grille opening panel (GOP) on bumper

and connect all front lamp wire harness connectors.

(2) Position the grille opening panel (GOP) on the

vehicle and install the side and upper nuts. Tighten

nuts to 7 Nzm (58 in-lbs) torque.

(3) Install the screw to attach grille opening panel

(GOP) to the crossmember support bracket. Tighten

the screw to 1 Nzm (11 in-lbs) torque.

(4) Install headlamps and park/turn signal lamps

in GOP.(5) Install the headlamp bezels on the GOP.

Tighten the screws to 1 Nzm (13 in-lbs) torque.

(6) Install the side marker lenses and screws on

the grille opening panel (GOP). Tighten the screws to

1Nzm (13 in-lbs) torque.

(7) Install the grille on the GOP. Tighten screws to

1Nzm (13 in-lbs) torque.

(8) Adjust the headlamp aim, if necessary. Refer to

the headlamp beam adjustment procedure within

Group 8L.

RADIATOR SUPPORT CROSSMEMBER

REMOVAL

(1) Remove the grille opening panel (GOP) (Fig. 2).

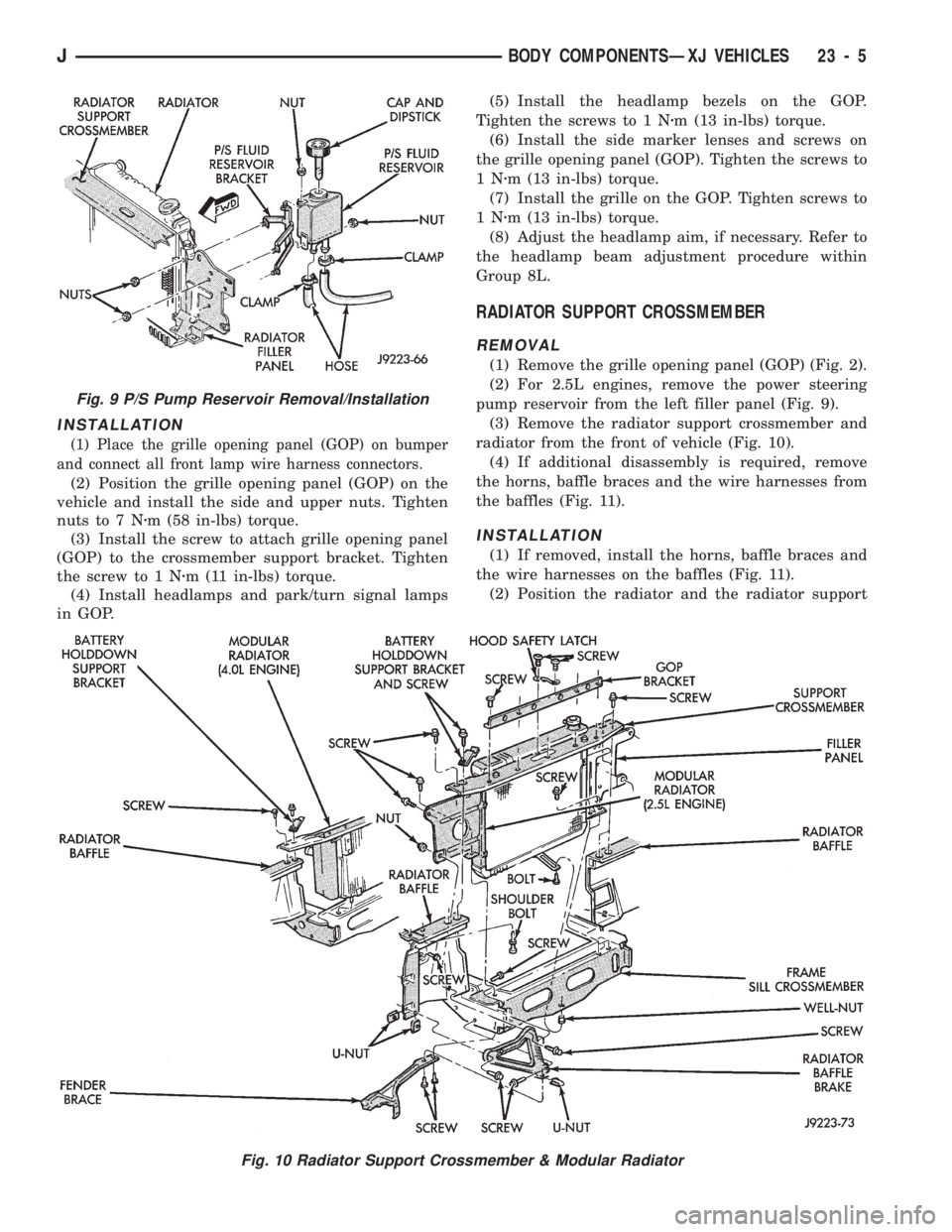

(2) For 2.5L engines, remove the power steering

pump reservoir from the left filler panel (Fig. 9).

(3) Remove the radiator support crossmember and

radiator from the front of vehicle (Fig. 10).

(4) If additional disassembly is required, remove

the horns, baffle braces and the wire harnesses from

the baffles (Fig. 11).

INSTALLATION

(1) If removed, install the horns, baffle braces and

the wire harnesses on the baffles (Fig. 11).

(2) Position the radiator and the radiator support

Fig. 9 P/S Pump Reservoir Removal/Installation

Fig. 10 Radiator Support Crossmember & Modular Radiator

JBODY COMPONENTSÐXJ VEHICLES 23 - 5