front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1263 of 1784

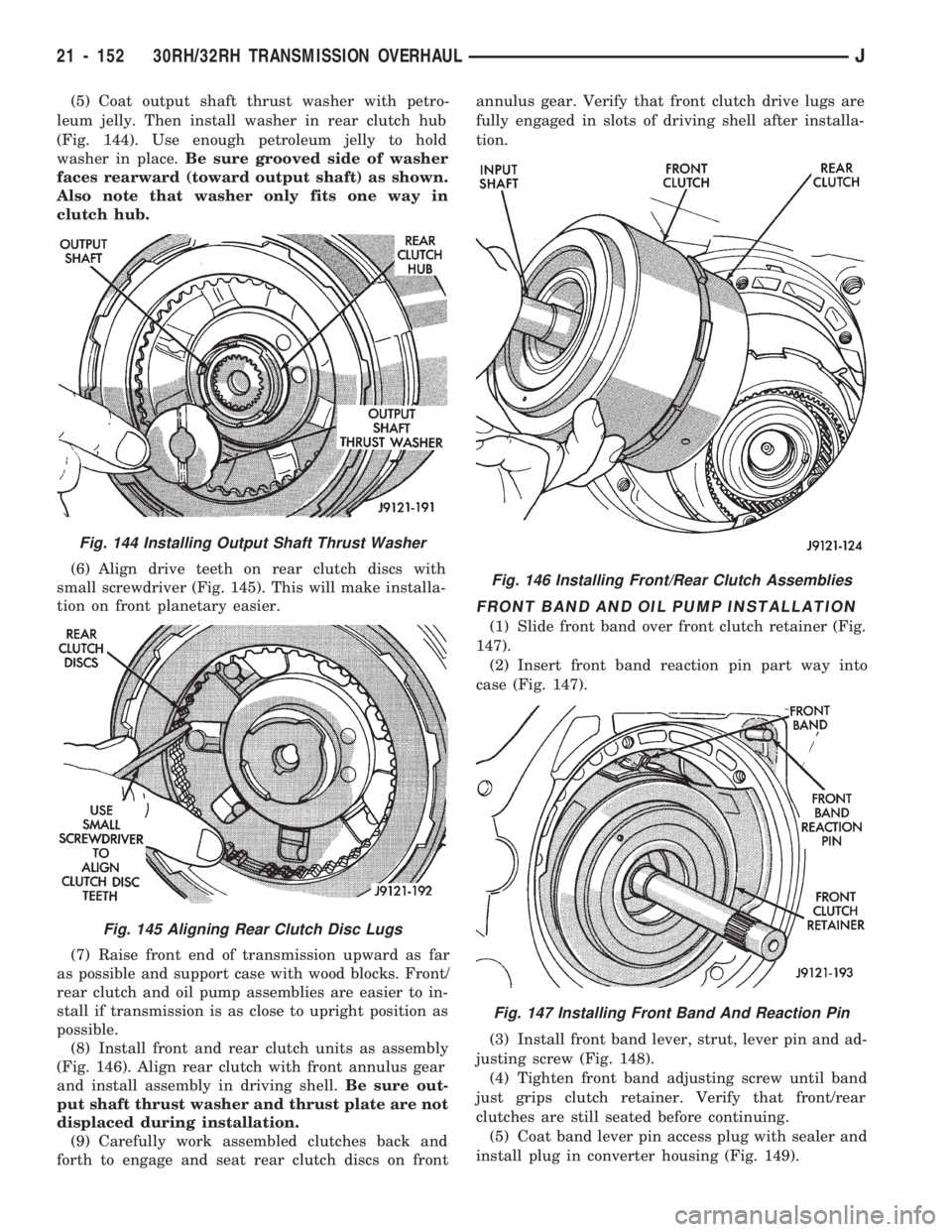

(5) Coat output shaft thrust washer with petro-

leum jelly. Then install washer in rear clutch hub

(Fig. 144). Use enough petroleum jelly to hold

washer in place.Be sure grooved side of washer

faces rearward (toward output shaft) as shown.

Also note that washer only fits one way in

clutch hub.

(6) Align drive teeth on rear clutch discs with

small screwdriver (Fig. 145). This will make installa-

tion on front planetary easier.

(7) Raise front end of transmission upward as far

as possible and support case with wood blocks. Front/

rear clutch and oil pump assemblies are easier to in-

stall if transmission is as close to upright position as

possible.

(8) Install front and rear clutch units as assembly

(Fig. 146). Align rear clutch with front annulus gear

and install assembly in driving shell.Be sure out-

put shaft thrust washer and thrust plate are not

displaced during installation.

(9) Carefully work assembled clutches back and

forth to engage and seat rear clutch discs on frontannulus gear. Verify that front clutch drive lugs are

fully engaged in slots of driving shell after installa-

tion.

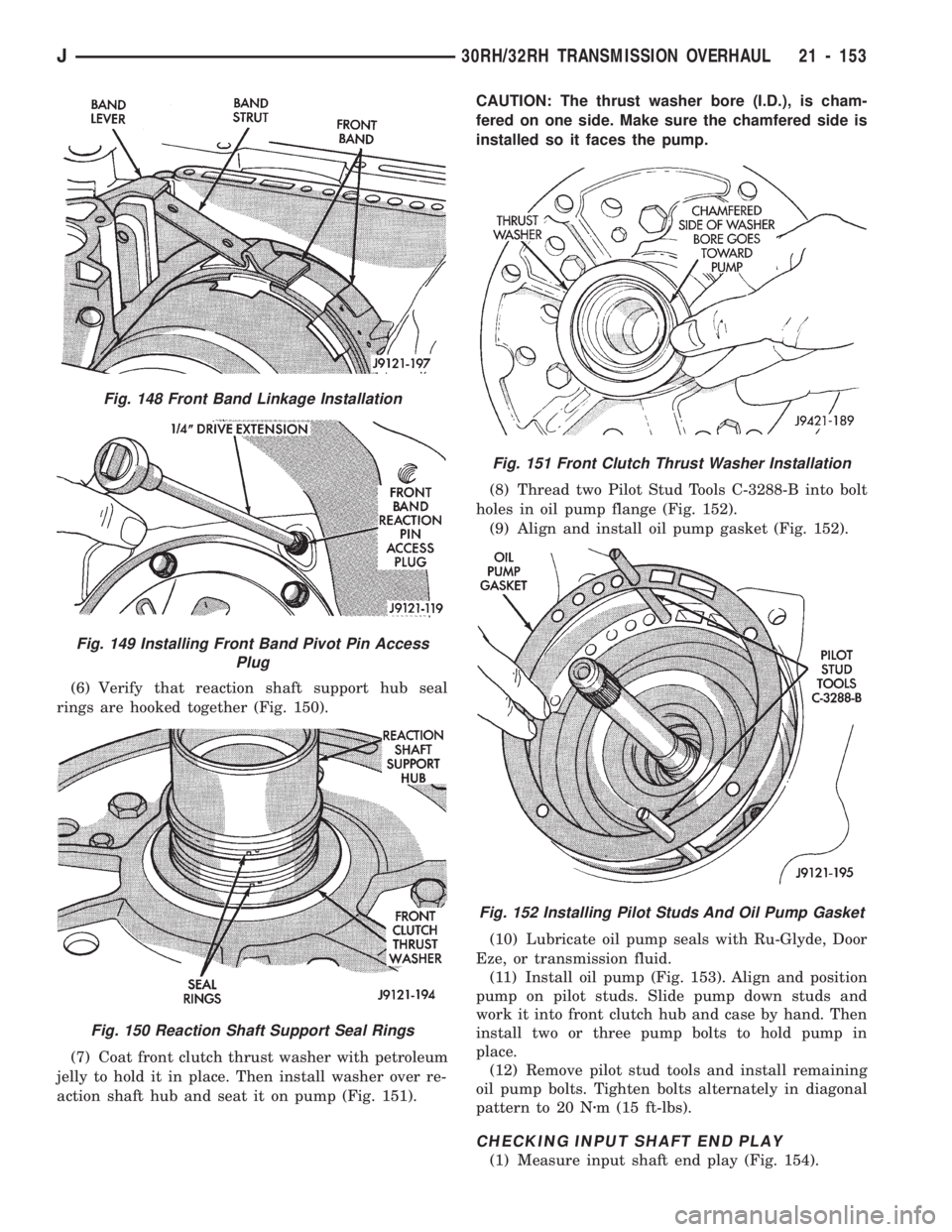

FRONT BAND AND OIL PUMP INSTALLATION

(1) Slide front band over front clutch retainer (Fig.

147).

(2) Insert front band reaction pin part way into

case (Fig. 147).

(3) Install front band lever, strut, lever pin and ad-

justing screw (Fig. 148).

(4) Tighten front band adjusting screw until band

just grips clutch retainer. Verify that front/rear

clutches are still seated before continuing.

(5) Coat band lever pin access plug with sealer and

install plug in converter housing (Fig. 149).

Fig. 144 Installing Output Shaft Thrust Washer

Fig. 145 Aligning Rear Clutch Disc Lugs

Fig. 146 Installing Front/Rear Clutch Assemblies

Fig. 147 Installing Front Band And Reaction Pin

21 - 152 30RH/32RH TRANSMISSION OVERHAULJ

Page 1264 of 1784

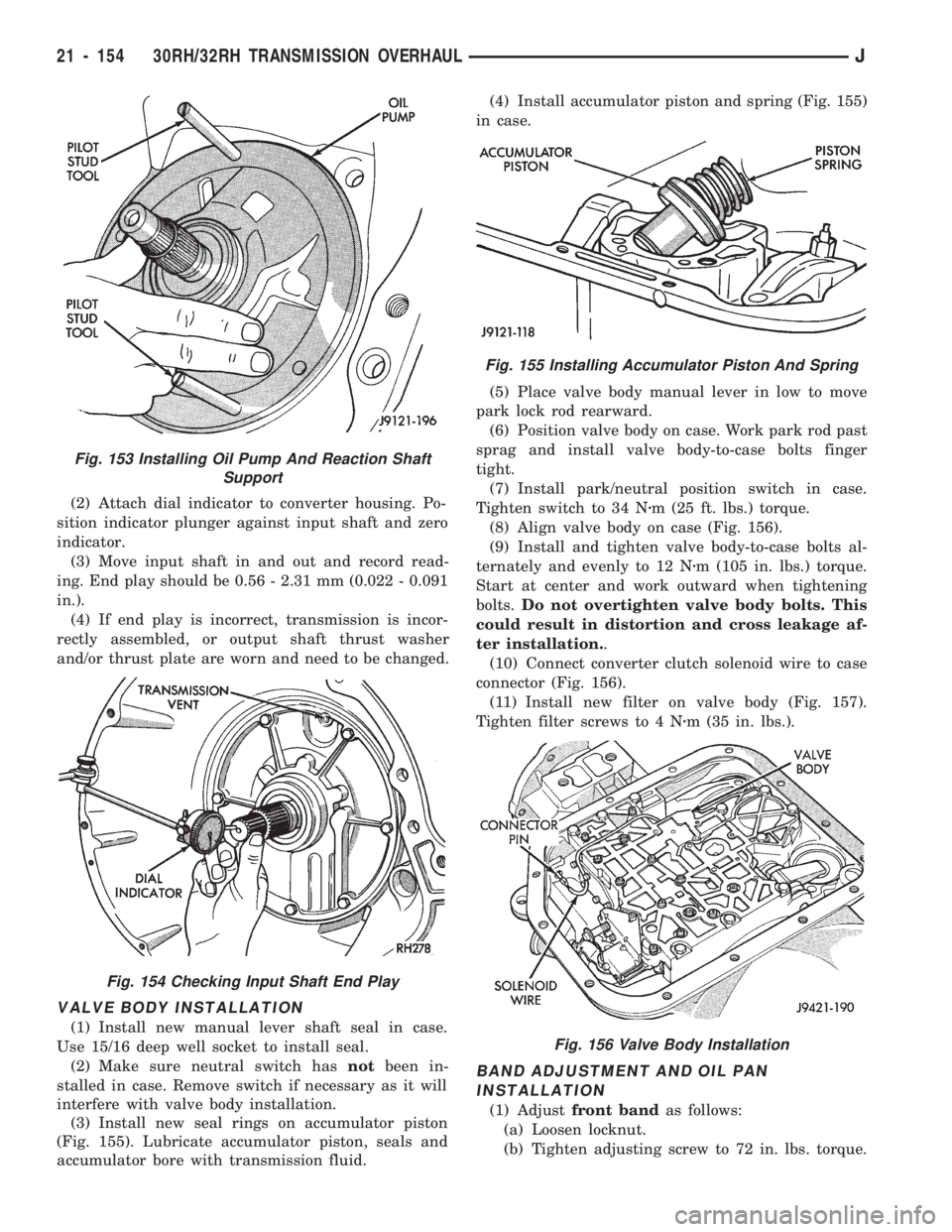

(6) Verify that reaction shaft support hub seal

rings are hooked together (Fig. 150).

(7) Coat front clutch thrust washer with petroleum

jelly to hold it in place. Then install washer over re-

action shaft hub and seat it on pump (Fig. 151).CAUTION: The thrust washer bore (I.D.), is cham-

fered on one side. Make sure the chamfered side is

installed so it faces the pump.

(8) Thread two Pilot Stud Tools C-3288-B into bolt

holes in oil pump flange (Fig. 152).

(9) Align and install oil pump gasket (Fig. 152).

(10) Lubricate oil pump seals with Ru-Glyde, Door

Eze, or transmission fluid.

(11) Install oil pump (Fig. 153). Align and position

pump on pilot studs. Slide pump down studs and

work it into front clutch hub and case by hand. Then

install two or three pump bolts to hold pump in

place.

(12) Remove pilot stud tools and install remaining

oil pump bolts. Tighten bolts alternately in diagonal

pattern to 20 Nzm (15 ft-lbs).

CHECKING INPUT SHAFT END PLAY

(1) Measure input shaft end play (Fig. 154).

Fig. 148 Front Band Linkage Installation

Fig. 149 Installing Front Band Pivot Pin Access

Plug

Fig. 150 Reaction Shaft Support Seal Rings

Fig. 151 Front Clutch Thrust Washer Installation

Fig. 152 Installing Pilot Studs And Oil Pump Gasket

J30RH/32RH TRANSMISSION OVERHAUL 21 - 153

Page 1265 of 1784

(2) Attach dial indicator to converter housing. Po-

sition indicator plunger against input shaft and zero

indicator.

(3) Move input shaft in and out and record read-

ing. End play should be 0.56 - 2.31 mm (0.022 - 0.091

in.).

(4) If end play is incorrect, transmission is incor-

rectly assembled, or output shaft thrust washer

and/or thrust plate are worn and need to be changed.

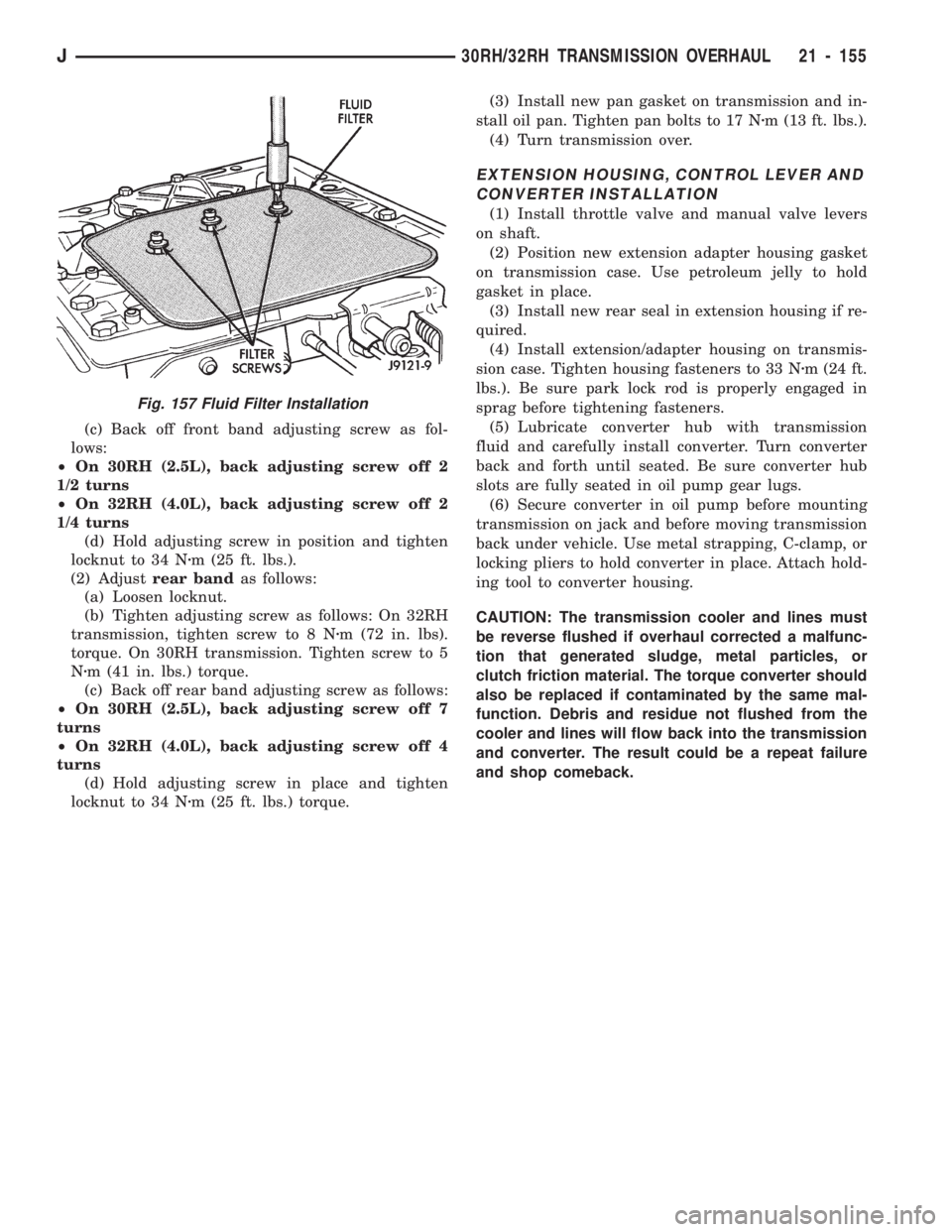

VALVE BODY INSTALLATION

(1) Install new manual lever shaft seal in case.

Use 15/16 deep well socket to install seal.

(2) Make sure neutral switch hasnotbeen in-

stalled in case. Remove switch if necessary as it will

interfere with valve body installation.

(3) Install new seal rings on accumulator piston

(Fig. 155). Lubricate accumulator piston, seals and

accumulator bore with transmission fluid.(4) Install accumulator piston and spring (Fig. 155)

in case.

(5) Place valve body manual lever in low to move

park lock rod rearward.

(6) Position valve body on case. Work park rod past

sprag and install valve body-to-case bolts finger

tight.

(7) Install park/neutral position switch in case.

Tighten switch to 34 Nzm (25 ft. lbs.) torque.

(8) Align valve body on case (Fig. 156).

(9) Install and tighten valve body-to-case bolts al-

ternately and evenly to 12 Nzm (105 in. lbs.) torque.

Start at center and work outward when tightening

bolts.Do not overtighten valve body bolts. This

could result in distortion and cross leakage af-

ter installation..

(10) Connect converter clutch solenoid wire to case

connector (Fig. 156).

(11) Install new filter on valve body (Fig. 157).

Tighten filter screws to 4 Nzm (35 in. lbs.).

BAND ADJUSTMENT AND OIL PAN

INSTALLATION

(1) Adjustfront bandas follows:

(a) Loosen locknut.

(b) Tighten adjusting screw to 72 in. lbs. torque.

Fig. 153 Installing Oil Pump And Reaction Shaft

Support

Fig. 154 Checking Input Shaft End Play

Fig. 155 Installing Accumulator Piston And Spring

Fig. 156 Valve Body Installation

21 - 154 30RH/32RH TRANSMISSION OVERHAULJ

Page 1266 of 1784

(c) Back off front band adjusting screw as fol-

lows:

²On 30RH (2.5L), back adjusting screw off 2

1/2 turns

²On 32RH (4.0L), back adjusting screw off 2

1/4 turns

(d) Hold adjusting screw in position and tighten

locknut to 34 Nzm (25 ft. lbs.).

(2) Adjustrear bandas follows:

(a) Loosen locknut.

(b) Tighten adjusting screw as follows: On 32RH

transmission, tighten screw to 8 Nzm (72 in. lbs).

torque. On 30RH transmission. Tighten screw to 5

Nzm (41 in. lbs.) torque.

(c) Back off rear band adjusting screw as follows:

²On 30RH (2.5L), back adjusting screw off 7

turns

²On 32RH (4.0L), back adjusting screw off 4

turns

(d) Hold adjusting screw in place and tighten

locknut to 34 Nzm (25 ft. lbs.) torque.(3) Install new pan gasket on transmission and in-

stall oil pan. Tighten pan bolts to 17 Nzm (13 ft. lbs.).

(4) Turn transmission over.

EXTENSION HOUSING, CONTROL LEVER AND

CONVERTER INSTALLATION

(1) Install throttle valve and manual valve levers

on shaft.

(2) Position new extension adapter housing gasket

on transmission case. Use petroleum jelly to hold

gasket in place.

(3) Install new rear seal in extension housing if re-

quired.

(4) Install extension/adapter housing on transmis-

sion case. Tighten housing fasteners to 33 Nzm (24 ft.

lbs.). Be sure park lock rod is properly engaged in

sprag before tightening fasteners.

(5) Lubricate converter hub with transmission

fluid and carefully install converter. Turn converter

back and forth until seated. Be sure converter hub

slots are fully seated in oil pump gear lugs.

(6) Secure converter in oil pump before mounting

transmission on jack and before moving transmission

back under vehicle. Use metal strapping, C-clamp, or

locking pliers to hold converter in place. Attach hold-

ing tool to converter housing.

CAUTION: The transmission cooler and lines must

be reverse flushed if overhaul corrected a malfunc-

tion that generated sludge, metal particles, or

clutch friction material. The torque converter should

also be replaced if contaminated by the same mal-

function. Debris and residue not flushed from the

cooler and lines will flow back into the transmission

and converter. The result could be a repeat failure

and shop comeback.

Fig. 157 Fluid Filter Installation

J30RH/32RH TRANSMISSION OVERHAUL 21 - 155

Page 1269 of 1784

net complete one revolution. Sensor signals are sent

to the transmission control module.

The park/neutral position switch is mounted on the

valve body manual shaft. The switch signals shift

linkage and manual valve position to the transmis-

sion control module through an interconnecting har-

ness. The switch prevents engine starting in all gears

other than Park or Neutral.

The brake switch is in circuit with the torque con-

verter clutch solenoid. The switch disengages the

converter clutch whenever the brakes are applied.

The switch is mounted on the brake pedal bracket

and signals the transmission control module when

the pedal is pressed or released.

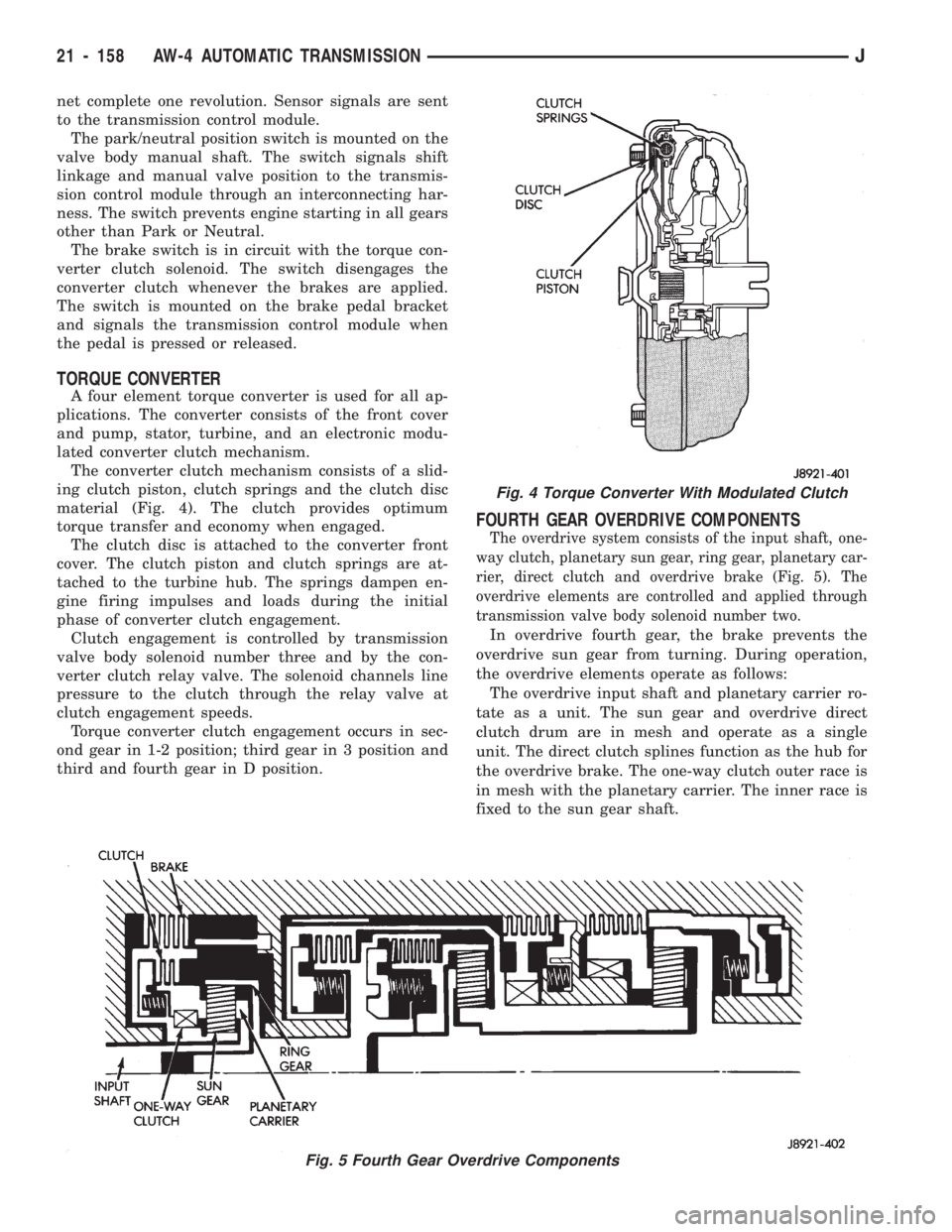

TORQUE CONVERTER

A four element torque converter is used for all ap-

plications. The converter consists of the front cover

and pump, stator, turbine, and an electronic modu-

lated converter clutch mechanism.

The converter clutch mechanism consists of a slid-

ing clutch piston, clutch springs and the clutch disc

material (Fig. 4). The clutch provides optimum

torque transfer and economy when engaged.

The clutch disc is attached to the converter front

cover. The clutch piston and clutch springs are at-

tached to the turbine hub. The springs dampen en-

gine firing impulses and loads during the initial

phase of converter clutch engagement.

Clutch engagement is controlled by transmission

valve body solenoid number three and by the con-

verter clutch relay valve. The solenoid channels line

pressure to the clutch through the relay valve at

clutch engagement speeds.

Torque converter clutch engagement occurs in sec-

ond gear in 1-2 position; third gear in 3 position and

third and fourth gear in D position.

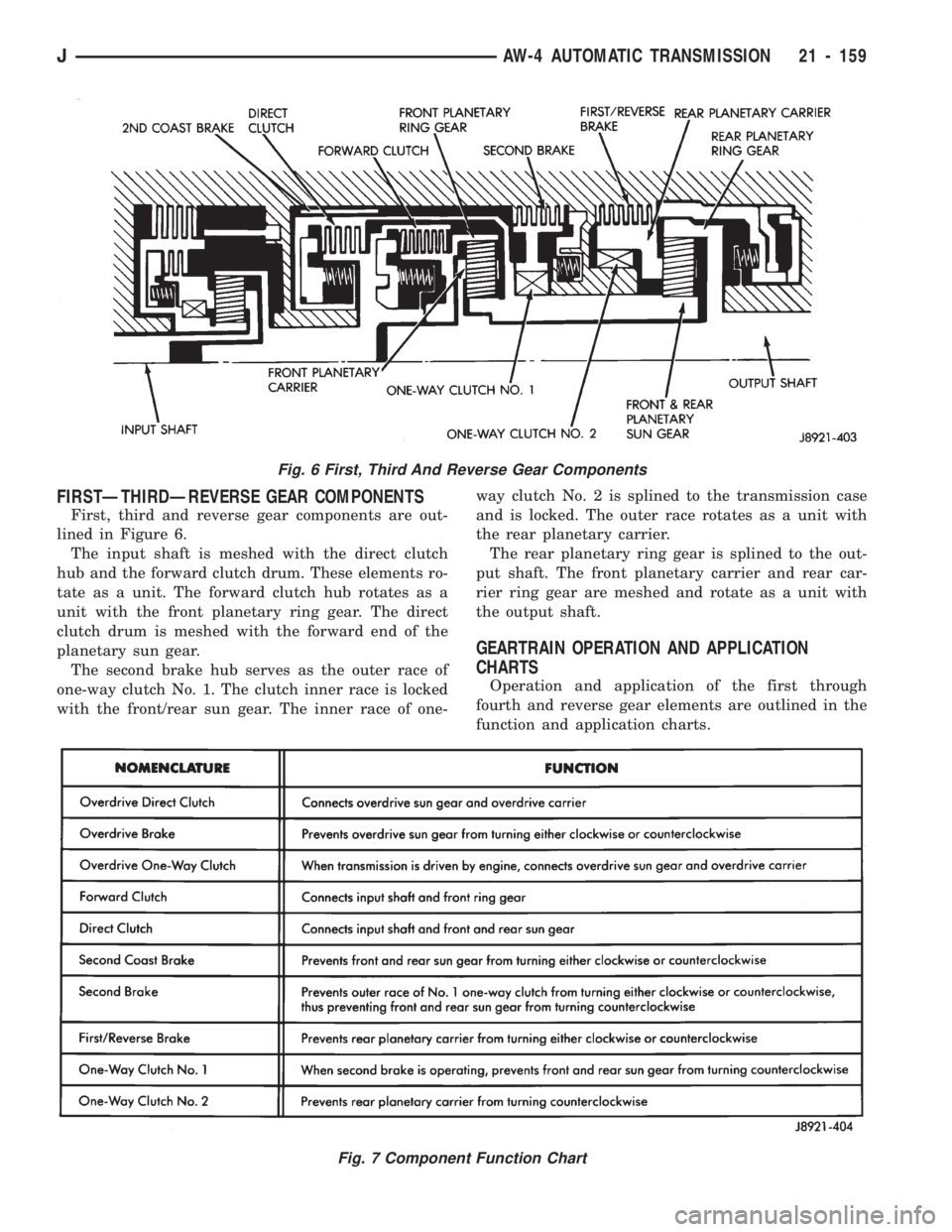

FOURTH GEAR OVERDRIVE COMPONENTS

The overdrive system consists of the input shaft, one-

way clutch, planetary sun gear, ring gear, planetary car-

rier, direct clutch and overdrive brake (Fig. 5). The

overdrive elements are controlled and applied through

transmission valve body solenoid number two.

In overdrive fourth gear, the brake prevents the

overdrive sun gear from turning. During operation,

the overdrive elements operate as follows:

The overdrive input shaft and planetary carrier ro-

tate as a unit. The sun gear and overdrive direct

clutch drum are in mesh and operate as a single

unit. The direct clutch splines function as the hub for

the overdrive brake. The one-way clutch outer race is

in mesh with the planetary carrier. The inner race is

fixed to the sun gear shaft.

Fig. 5 Fourth Gear Overdrive Components

Fig. 4 Torque Converter With Modulated Clutch

21 - 158 AW-4 AUTOMATIC TRANSMISSIONJ

Page 1270 of 1784

FIRSTÐTHIRDÐREVERSE GEAR COMPONENTS

First, third and reverse gear components are out-

lined in Figure 6.

The input shaft is meshed with the direct clutch

hub and the forward clutch drum. These elements ro-

tate as a unit. The forward clutch hub rotates as a

unit with the front planetary ring gear. The direct

clutch drum is meshed with the forward end of the

planetary sun gear.

The second brake hub serves as the outer race of

one-way clutch No. 1. The clutch inner race is locked

with the front/rear sun gear. The inner race of one-way clutch No. 2 is splined to the transmission case

and is locked. The outer race rotates as a unit with

the rear planetary carrier.

The rear planetary ring gear is splined to the out-

put shaft. The front planetary carrier and rear car-

rier ring gear are meshed and rotate as a unit with

the output shaft.

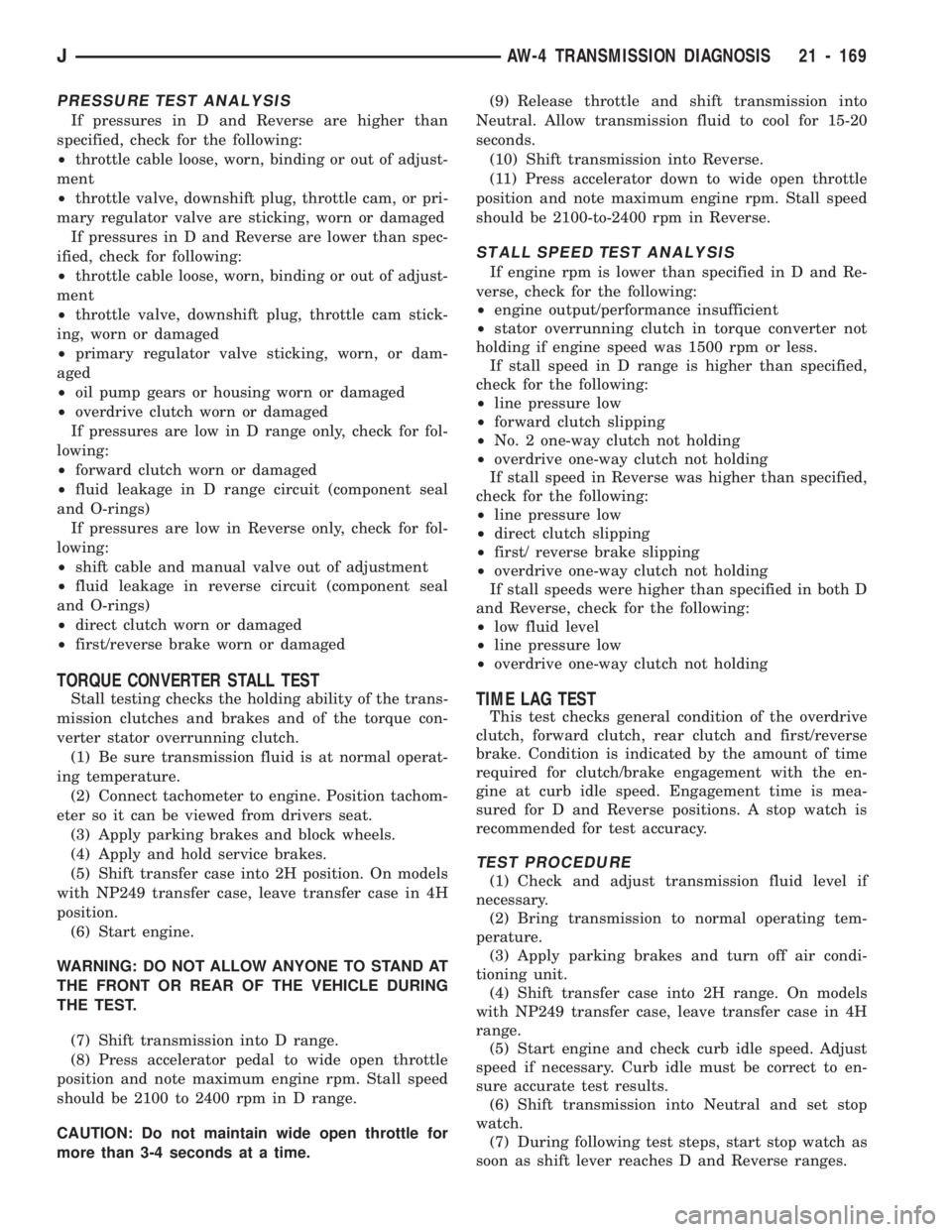

GEARTRAIN OPERATION AND APPLICATION

CHARTS

Operation and application of the first through

fourth and reverse gear elements are outlined in the

function and application charts.

Fig. 6 First, Third And Reverse Gear Components

Fig. 7 Component Function Chart

JAW-4 AUTOMATIC TRANSMISSION 21 - 159

Page 1279 of 1784

(2) Verify transmission throttle cable operation.

Repair or replace cable if necessary.

(3) Check engine throttle operation. Operate accel-

erator pedal and observe injector throttle plate move-

ment. Adjust linkage if throttle plate does not reach

wide open position.

(4) Check transmission fluid level when fluid is at

normal operating temperature. Start engine. Shift

transmission through all gear ranges then back to

Neutral. Correct level is to Full or Add mark on dip-

stick with engine at curb idle speed.

(5) Check and adjust park/neutral position switch

if necessary.

(6) Check throttle position sensor adjustment and

operation. Adjust the sensor if necessary.

MANUAL SHIFTING TEST

(1) This test determines if problem is related to

mechanical or electrical component.

(2) Stop engine and disconnect transmission con-

trol module or module fuse.

(3) Road test vehicle. Shift transmission into each

gear range. Transmission should operate as follows:

²lock in Park

²back up in Reverse

²not move in Neutral

²provide first gear only with shift lever in 1-2 posi-

tion

²operate in third gear only with shift lever in 3 po-

sition

²operate in overdrive fourth gear in D position

(4) If transmission operates as described, proceed

to next step. However, if forward gear ranges were

difficult to distinguish (all feel the same), or vehicle

would not back up, refer to diagnosis charts. Do not

perform stall or time lag tests.

CAUTION: Do not overspeed the engine during the

next test step. Ease off the throttle and allow the

vehicle to slow before downshifting.

(5) Continue road test. Manually downshift trans-

mission from D to 3, and from 3 to 1-2 position. Then

manually upshift transmission through forward

ranges again.

(6) If transmission operation is OK, perform stall,

time lag and pressure tests. If transmission shifting

problem is encountered, refer to diagnosis charts.

(7) If a problem still exists, continue testing with

DRB II scan tool.

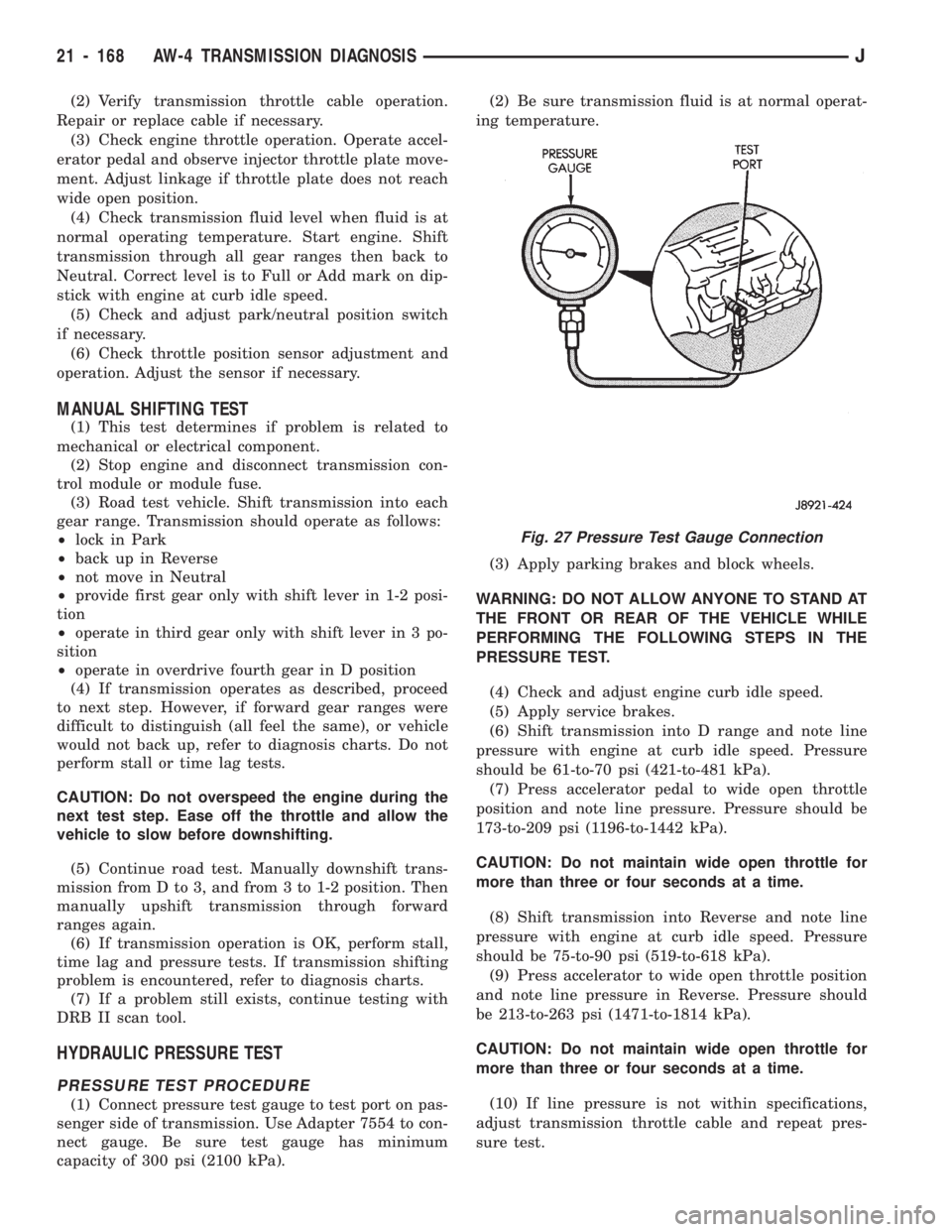

HYDRAULIC PRESSURE TEST

PRESSURE TEST PROCEDURE

(1) Connect pressure test gauge to test port on pas-

senger side of transmission. Use Adapter 7554 to con-

nect gauge. Be sure test gauge has minimum

capacity of 300 psi (2100 kPa).(2) Be sure transmission fluid is at normal operat-

ing temperature.

(3) Apply parking brakes and block wheels.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE WHILE

PERFORMING THE FOLLOWING STEPS IN THE

PRESSURE TEST.

(4) Check and adjust engine curb idle speed.

(5) Apply service brakes.

(6) Shift transmission into D range and note line

pressure with engine at curb idle speed. Pressure

should be 61-to-70 psi (421-to-481 kPa).

(7) Press accelerator pedal to wide open throttle

position and note line pressure. Pressure should be

173-to-209 psi (1196-to-1442 kPa).

CAUTION: Do not maintain wide open throttle for

more than three or four seconds at a time.

(8) Shift transmission into Reverse and note line

pressure with engine at curb idle speed. Pressure

should be 75-to-90 psi (519-to-618 kPa).

(9) Press accelerator to wide open throttle position

and note line pressure in Reverse. Pressure should

be 213-to-263 psi (1471-to-1814 kPa).

CAUTION: Do not maintain wide open throttle for

more than three or four seconds at a time.

(10) If line pressure is not within specifications,

adjust transmission throttle cable and repeat pres-

sure test.

Fig. 27 Pressure Test Gauge Connection

21 - 168 AW-4 TRANSMISSION DIAGNOSISJ

Page 1280 of 1784

PRESSURE TEST ANALYSIS

If pressures in D and Reverse are higher than

specified, check for the following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, throttle cam, or pri-

mary regulator valve are sticking, worn or damaged

If pressures in D and Reverse are lower than spec-

ified, check for following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, throttle cam stick-

ing, worn or damaged

²primary regulator valve sticking, worn, or dam-

aged

²oil pump gears or housing worn or damaged

²overdrive clutch worn or damaged

If pressures are low in D range only, check for fol-

lowing:

²forward clutch worn or damaged

²fluid leakage in D range circuit (component seal

and O-rings)

If pressures are low in Reverse only, check for fol-

lowing:

²shift cable and manual valve out of adjustment

²fluid leakage in reverse circuit (component seal

and O-rings)

²direct clutch worn or damaged

²first/reverse brake worn or damaged

TORQUE CONVERTER STALL TEST

Stall testing checks the holding ability of the trans-

mission clutches and brakes and of the torque con-

verter stator overrunning clutch.

(1) Be sure transmission fluid is at normal operat-

ing temperature.

(2) Connect tachometer to engine. Position tachom-

eter so it can be viewed from drivers seat.

(3) Apply parking brakes and block wheels.

(4) Apply and hold service brakes.

(5) Shift transfer case into 2H position. On models

with NP249 transfer case, leave transfer case in 4H

position.

(6) Start engine.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE DURING

THE TEST.

(7) Shift transmission into D range.

(8) Press accelerator pedal to wide open throttle

position and note maximum engine rpm. Stall speed

should be 2100 to 2400 rpm in D range.

CAUTION: Do not maintain wide open throttle for

more than 3-4 seconds at a time.(9) Release throttle and shift transmission into

Neutral. Allow transmission fluid to cool for 15-20

seconds.

(10) Shift transmission into Reverse.

(11) Press accelerator down to wide open throttle

position and note maximum engine rpm. Stall speed

should be 2100-to-2400 rpm in Reverse.

STALL SPEED TEST ANALYSIS

If engine rpm is lower than specified in D and Re-

verse, check for the following:

²engine output/performance insufficient

²stator overrunning clutch in torque converter not

holding if engine speed was 1500 rpm or less.

If stall speed in D range is higher than specified,

check for the following:

²line pressure low

²forward clutch slipping

²No. 2 one-way clutch not holding

²overdrive one-way clutch not holding

If stall speed in Reverse was higher than specified,

check for the following:

²line pressure low

²direct clutch slipping

²first/ reverse brake slipping

²overdrive one-way clutch not holding

If stall speeds were higher than specified in both D

and Reverse, check for the following:

²low fluid level

²line pressure low

²overdrive one-way clutch not holding

TIME LAG TEST

This test checks general condition of the overdrive

clutch, forward clutch, rear clutch and first/reverse

brake. Condition is indicated by the amount of time

required for clutch/brake engagement with the en-

gine at curb idle speed. Engagement time is mea-

sured for D and Reverse positions. A stop watch is

recommended for test accuracy.

TEST PROCEDURE

(1) Check and adjust transmission fluid level if

necessary.

(2) Bring transmission to normal operating tem-

perature.

(3) Apply parking brakes and turn off air condi-

tioning unit.

(4) Shift transfer case into 2H range. On models

with NP249 transfer case, leave transfer case in 4H

range.

(5) Start engine and check curb idle speed. Adjust

speed if necessary. Curb idle must be correct to en-

sure accurate test results.

(6) Shift transmission into Neutral and set stop

watch.

(7) During following test steps, start stop watch as

soon as shift lever reaches D and Reverse ranges.

JAW-4 TRANSMISSION DIAGNOSIS 21 - 169

Page 1298 of 1784

TRANSMISSION COOLER SERVICE

Main Cooler

The transmission main cooler is located in the ra-

diator. The main cooler can be flushed when neces-

sary, however, the cooler is not a repairable

component. If the cooler is damaged, plugged, or

leaking, the radiator will have to be replaced.

Auxiliary Cooler

The auxiliary cooler is mounted in front of the ra-

diator at the driver side of the vehicle (Fig. 48). The

cooler can be flushed when necessary, while mounted

in the vehicle. The cooler can also be removed for ac-

cess, repair, or replacement as needed.

The main and auxiliary coolers should both be

flushed whenever a transmission or converter clutch

malfunction generates sludge, debris, or particles of

clutch friction material.

Cooler Service

The main cooler (and radiator) and the auxiliary

cooler can be removed for service or access to other

components. Auxiliary cooler removal requires that

the front bumper and radiator support be removed

for access to the cooler lines and attaching bracket.

REVERSE FLUSHING MAIN AND AUXILIARY

COOLERS AND COOLER LINES

Reverse flushing the cooler and lines will prevent

sludge and particles from flowing back into the

transmission after repair. The flushing procedure ap-

plies to standard (in-radiator) coolers and auxiliary

coolers equally.

Pressure equipment is preferred for reverse flush-

ing. However, reverse flushing can be performed us-

ing hand operated equipment as described in the

following procedure.

(1) Disconnect cooler lines at transmission and at

auxiliary cooler (Figs. 48 and 49).

(2) Position drain pan under cooler line to catch

material flushed through coolers and lines.

(3) Reverse flush each cooler using hand operated

suction gun filled with mineral spirits. Insert gun

nozzle (or hose) into cooler inlet (return) line. Then

force mineral spirits through into line and through

cooler.(4) Continue reverse flushing until fluid exiting in-

let (pressure) line is clear and free of debris/residue.

(5) Replace radiator if fluid cannot be pumped

through main cooler. Replace auxiliary cooler if leaks

are evident, or if fluid cannot be pumped through it.

(6) Clear flushing materials from coolers and lines

with short pulses of compressed air. Insert air gun

nozzle into cooler inlet (return) line and continue

short pulses of air until all fluid is cleared from

cooler and lines.

(7) Pump one quart of fresh automatic transmis-

sion fluid through cooler and lines before reconnect-

ing cooler lines.

FLOW TESTING TRANSMISSION MAIN

COOLER

Cooler flow is checked by measuring the amount of

fluid flow through the cooler in a 20 second time pe-

riod. The test is performed with the engine running

and transmission in neutral. Fluid is then pumped

through the cooler by the transmission oil pump.

(1) Disconnect cooler inlet line at transmission fit-

ting.

(2) Securely attach hose to end of inlet line and po-

sition line in a one quart test container.

(3) Add extra quart of fluid to transmission.

(4) Use stopwatch to check flow test time.

(5) Shift transmission into neutral and set parking

brake.

(6) Start and run engine at curb idle speed and im-

mediately note cooler flow. Approximately one quart

of fluid should flow into test container in 20 second

period.

(7) If cooler flow is intermittent, flows less than

one quart in 20 seconds, or does not flow at all,

cooler is faulty and must be replaced.

TRANSMISSION COOLER LINE FITTINGS

Quick disconnect fittings are used at the transmis-

sion cooler line connections. The fitting seals and

guides are serviceable.

Replace the seals and guides whenever the fittings

exhibit leakage, or will not properly snap into place.

JAW-4 IN-VEHICLE SERVICE 21 - 187

Page 1300 of 1784

AW-4 TRANSMISSION REMOVAL AND INSTALLATION

INDEX

page page

Oil Pump Seal Replacement............... 189

Torque Converter Stator Clutch Inspection..... 189Transmission and Torque Converter Installation . 190

Transmission and Torque Converter Removal . . 189

TRANSMISSION AND TORQUE CONVERTER

REMOVAL

(1) Raise vehicle.

(2) Drain transmission fluid and reinstall oil pan

drain plug.

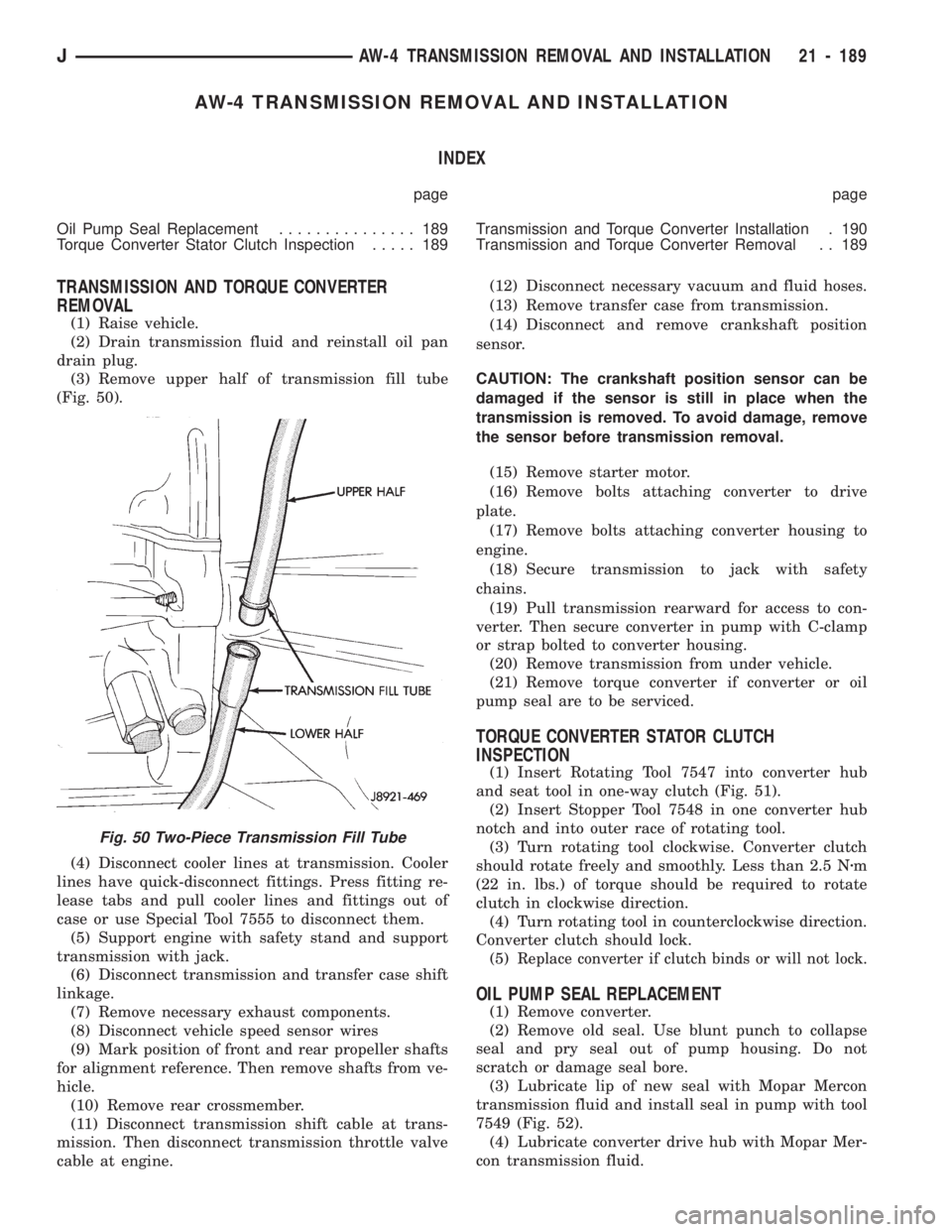

(3) Remove upper half of transmission fill tube

(Fig. 50).

(4) Disconnect cooler lines at transmission. Cooler

lines have quick-disconnect fittings. Press fitting re-

lease tabs and pull cooler lines and fittings out of

case or use Special Tool 7555 to disconnect them.

(5) Support engine with safety stand and support

transmission with jack.

(6) Disconnect transmission and transfer case shift

linkage.

(7) Remove necessary exhaust components.

(8) Disconnect vehicle speed sensor wires

(9) Mark position of front and rear propeller shafts

for alignment reference. Then remove shafts from ve-

hicle.

(10) Remove rear crossmember.

(11) Disconnect transmission shift cable at trans-

mission. Then disconnect transmission throttle valve

cable at engine.(12) Disconnect necessary vacuum and fluid hoses.

(13) Remove transfer case from transmission.

(14) Disconnect and remove crankshaft position

sensor.

CAUTION: The crankshaft position sensor can be

damaged if the sensor is still in place when the

transmission is removed. To avoid damage, remove

the sensor before transmission removal.

(15) Remove starter motor.

(16) Remove bolts attaching converter to drive

plate.

(17) Remove bolts attaching converter housing to

engine.

(18) Secure transmission to jack with safety

chains.

(19) Pull transmission rearward for access to con-

verter. Then secure converter in pump with C-clamp

or strap bolted to converter housing.

(20) Remove transmission from under vehicle.

(21) Remove torque converter if converter or oil

pump seal are to be serviced.

TORQUE CONVERTER STATOR CLUTCH

INSPECTION

(1) Insert Rotating Tool 7547 into converter hub

and seat tool in one-way clutch (Fig. 51).

(2) Insert Stopper Tool 7548 in one converter hub

notch and into outer race of rotating tool.

(3) Turn rotating tool clockwise. Converter clutch

should rotate freely and smoothly. Less than 2.5 Nzm

(22 in. lbs.) of torque should be required to rotate

clutch in clockwise direction.

(4) Turn rotating tool in counterclockwise direction.

Converter clutch should lock.

(5)

Replace converter if clutch binds or will not lock.

OIL PUMP SEAL REPLACEMENT

(1) Remove converter.

(2) Remove old seal. Use blunt punch to collapse

seal and pry seal out of pump housing. Do not

scratch or damage seal bore.

(3) Lubricate lip of new seal with Mopar Mercon

transmission fluid and install seal in pump with tool

7549 (Fig. 52).

(4) Lubricate converter drive hub with Mopar Mer-

con transmission fluid.

Fig. 50 Two-Piece Transmission Fill Tube

JAW-4 TRANSMISSION REMOVAL AND INSTALLATION 21 - 189