front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1346 of 1784

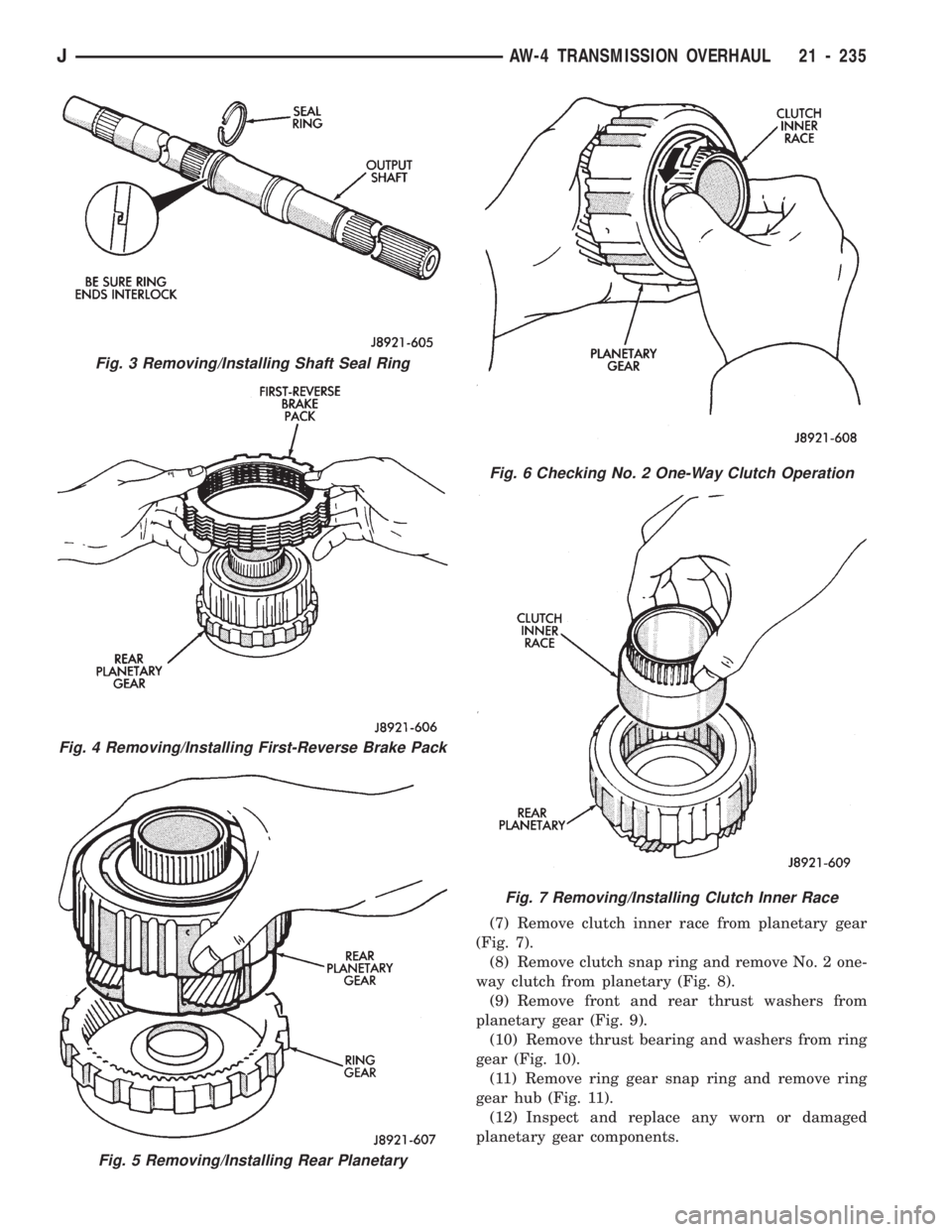

(7) Remove clutch inner race from planetary gear

(Fig. 7).

(8) Remove clutch snap ring and remove No. 2 one-

way clutch from planetary (Fig. 8).

(9) Remove front and rear thrust washers from

planetary gear (Fig. 9).

(10) Remove thrust bearing and washers from ring

gear (Fig. 10).

(11) Remove ring gear snap ring and remove ring

gear hub (Fig. 11).

(12) Inspect and replace any worn or damaged

planetary gear components.

Fig. 7 Removing/Installing Clutch Inner Race

Fig. 5 Removing/Installing Rear Planetary

Fig. 3 Removing/Installing Shaft Seal Ring

Fig. 4 Removing/Installing First-Reverse Brake Pack

Fig. 6 Checking No. 2 One-Way Clutch Operation

JAW-4 TRANSMISSION OVERHAUL 21 - 235

Page 1367 of 1784

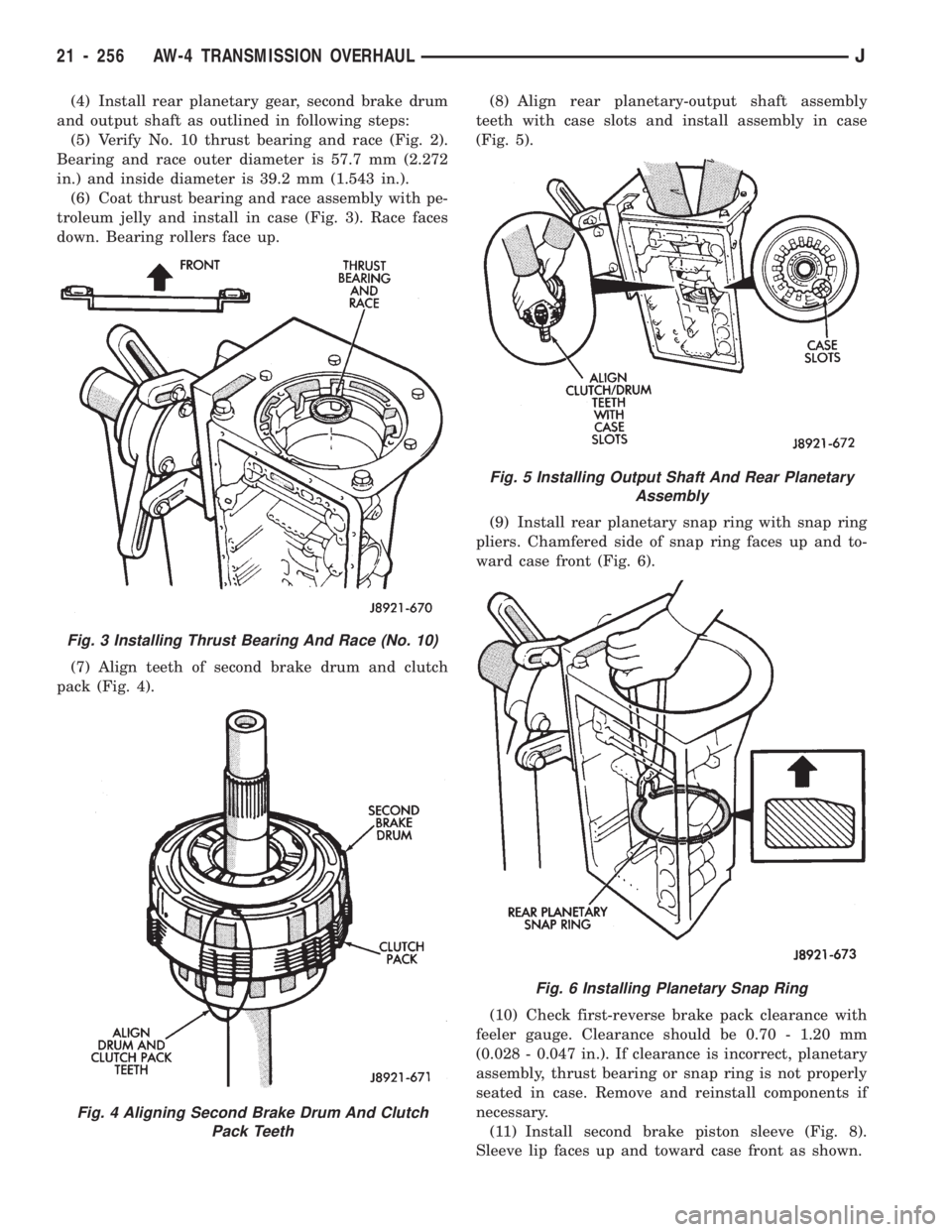

(4) Install rear planetary gear, second brake drum

and output shaft as outlined in following steps:

(5) Verify No. 10 thrust bearing and race (Fig. 2).

Bearing and race outer diameter is 57.7 mm (2.272

in.) and inside diameter is 39.2 mm (1.543 in.).

(6) Coat thrust bearing and race assembly with pe-

troleum jelly and install in case (Fig. 3). Race faces

down. Bearing rollers face up.

(7) Align teeth of second brake drum and clutch

pack (Fig. 4).(8) Align rear planetary-output shaft assembly

teeth with case slots and install assembly in case

(Fig. 5).

(9) Install rear planetary snap ring with snap ring

pliers. Chamfered side of snap ring faces up and to-

ward case front (Fig. 6).

(10) Check first-reverse brake pack clearance with

feeler gauge. Clearance should be 0.70 - 1.20 mm

(0.028 - 0.047 in.). If clearance is incorrect, planetary

assembly, thrust bearing or snap ring is not properly

seated in case. Remove and reinstall components if

necessary.

(11) Install second brake piston sleeve (Fig. 8).

Sleeve lip faces up and toward case front as shown.

Fig. 3 Installing Thrust Bearing And Race (No. 10)

Fig. 4 Aligning Second Brake Drum And Clutch

Pack Teeth

Fig. 5 Installing Output Shaft And Rear Planetary

Assembly

Fig. 6 Installing Planetary Snap Ring

21 - 256 AW-4 TRANSMISSION OVERHAULJ

Page 1369 of 1784

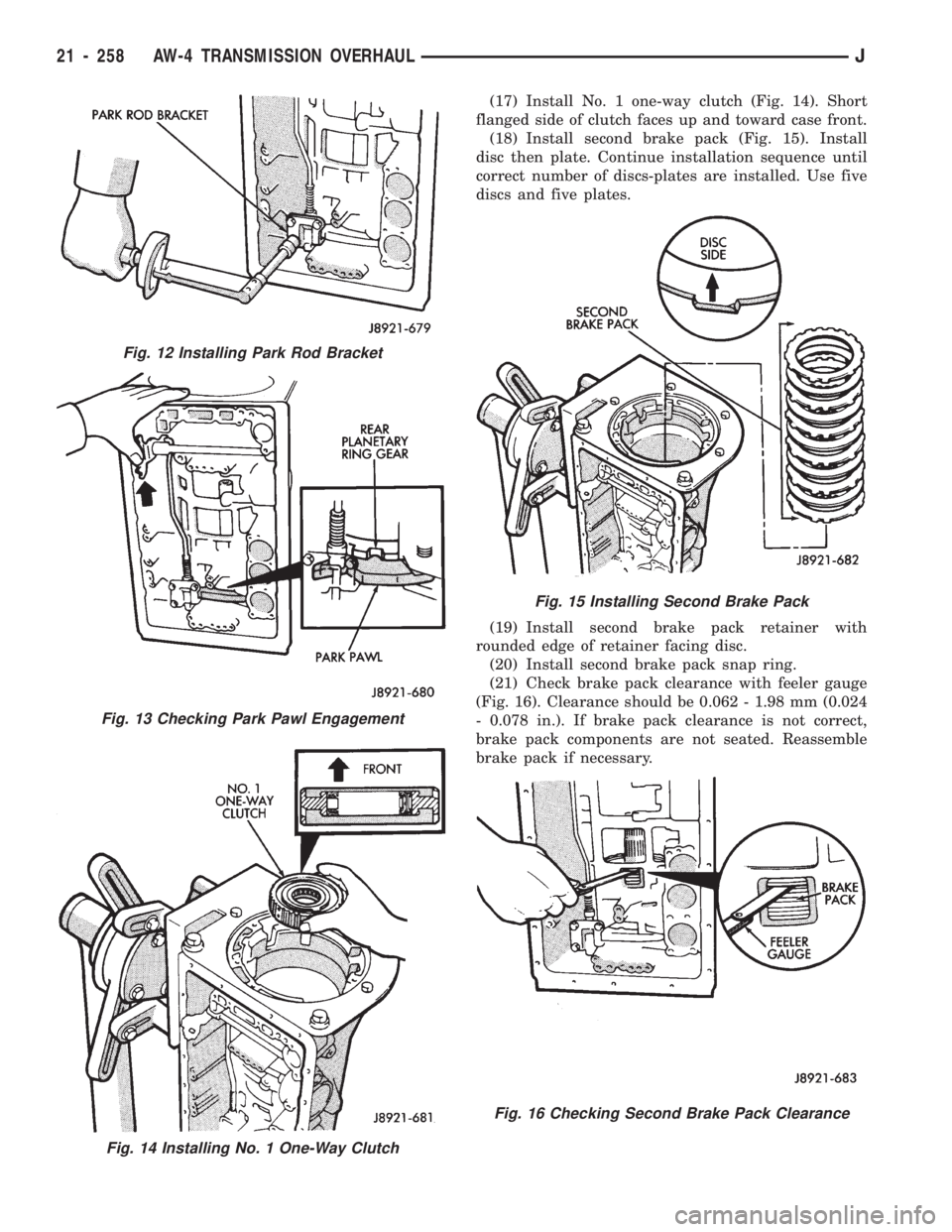

(17) Install No. 1 one-way clutch (Fig. 14). Short

flanged side of clutch faces up and toward case front.

(18) Install second brake pack (Fig. 15). Install

disc then plate. Continue installation sequence until

correct number of discs-plates are installed. Use five

discs and five plates.

(19) Install second brake pack retainer with

rounded edge of retainer facing disc.

(20) Install second brake pack snap ring.

(21) Check brake pack clearance with feeler gauge

(Fig. 16). Clearance should be 0.062 - 1.98 mm (0.024

- 0.078 in.). If brake pack clearance is not correct,

brake pack components are not seated. Reassemble

brake pack if necessary.

Fig. 14 Installing No. 1 One-Way Clutch

Fig. 12 Installing Park Rod Bracket

Fig. 13 Checking Park Pawl Engagement

Fig. 15 Installing Second Brake Pack

Fig. 16 Checking Second Brake Pack Clearance

21 - 258 AW-4 TRANSMISSION OVERHAULJ

Page 1370 of 1784

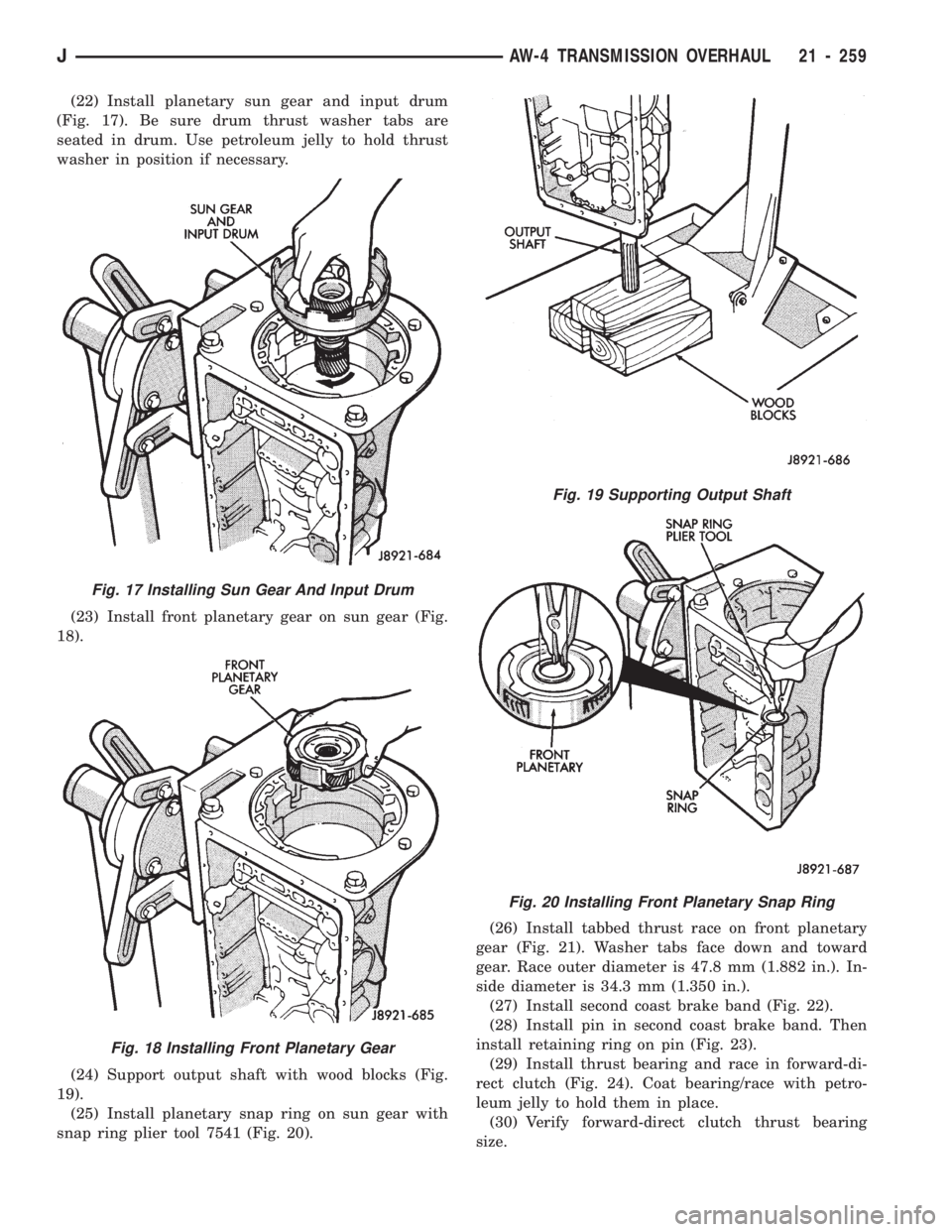

(22) Install planetary sun gear and input drum

(Fig. 17). Be sure drum thrust washer tabs are

seated in drum. Use petroleum jelly to hold thrust

washer in position if necessary.

(23) Install front planetary gear on sun gear (Fig.

18).

(24) Support output shaft with wood blocks (Fig.

19).

(25) Install planetary snap ring on sun gear with

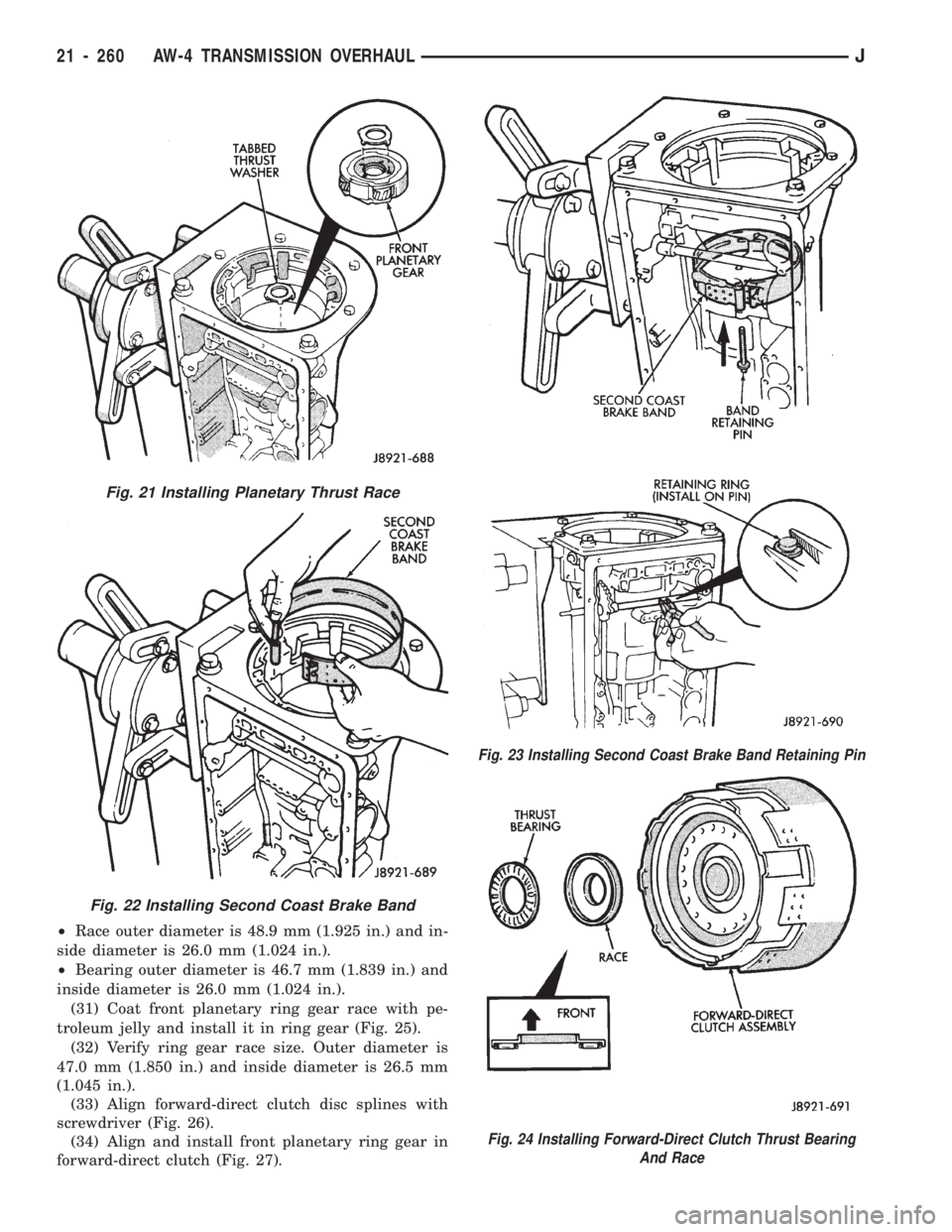

snap ring plier tool 7541 (Fig. 20).(26) Install tabbed thrust race on front planetary

gear (Fig. 21). Washer tabs face down and toward

gear. Race outer diameter is 47.8 mm (1.882 in.). In-

side diameter is 34.3 mm (1.350 in.).

(27) Install second coast brake band (Fig. 22).

(28) Install pin in second coast brake band. Then

install retaining ring on pin (Fig. 23).

(29) Install thrust bearing and race in forward-di-

rect clutch (Fig. 24). Coat bearing/race with petro-

leum jelly to hold them in place.

(30) Verify forward-direct clutch thrust bearing

size.

Fig. 17 Installing Sun Gear And Input Drum

Fig. 18 Installing Front Planetary Gear

Fig. 19 Supporting Output Shaft

Fig. 20 Installing Front Planetary Snap Ring

JAW-4 TRANSMISSION OVERHAUL 21 - 259

Page 1371 of 1784

²Race outer diameter is 48.9 mm (1.925 in.) and in-

side diameter is 26.0 mm (1.024 in.).

²Bearing outer diameter is 46.7 mm (1.839 in.) and

inside diameter is 26.0 mm (1.024 in.).

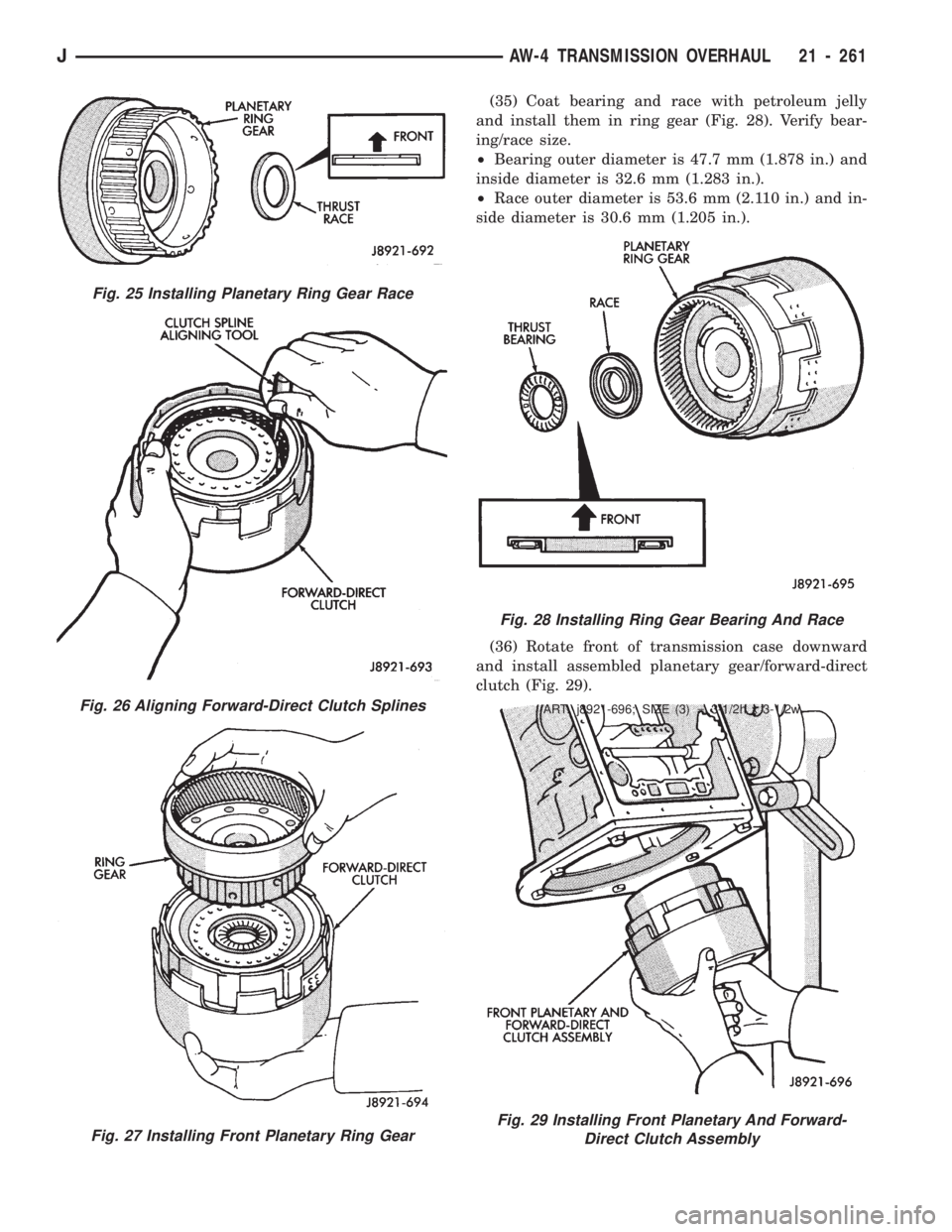

(31) Coat front planetary ring gear race with pe-

troleum jelly and install it in ring gear (Fig. 25).

(32) Verify ring gear race size. Outer diameter is

47.0 mm (1.850 in.) and inside diameter is 26.5 mm

(1.045 in.).

(33) Align forward-direct clutch disc splines with

screwdriver (Fig. 26).

(34) Align and install front planetary ring gear in

forward-direct clutch (Fig. 27).

Fig. 24 Installing Forward-Direct Clutch Thrust Bearing

And Race

Fig. 21 Installing Planetary Thrust Race

Fig. 22 Installing Second Coast Brake Band

Fig. 23 Installing Second Coast Brake Band Retaining Pin

21 - 260 AW-4 TRANSMISSION OVERHAULJ

Page 1372 of 1784

(35) Coat bearing and race with petroleum jelly

and install them in ring gear (Fig. 28). Verify bear-

ing/race size.

²Bearing outer diameter is 47.7 mm (1.878 in.) and

inside diameter is 32.6 mm (1.283 in.).

²Race outer diameter is 53.6 mm (2.110 in.) and in-

side diameter is 30.6 mm (1.205 in.).

(36) Rotate front of transmission case downward

and install assembled planetary gear/forward-direct

clutch (Fig. 29).

Fig. 25 Installing Planetary Ring Gear Race

Fig. 26 Aligning Forward-Direct Clutch Splines

Fig. 27 Installing Front Planetary Ring Gear

Fig. 28 Installing Ring Gear Bearing And Race

ART: j8921-696; SIZE (3) = 3-1/2h x 3-1/2w

Fig. 29 Installing Front Planetary And Forward-

Direct Clutch Assembly

JAW-4 TRANSMISSION OVERHAUL 21 - 261

Page 1373 of 1784

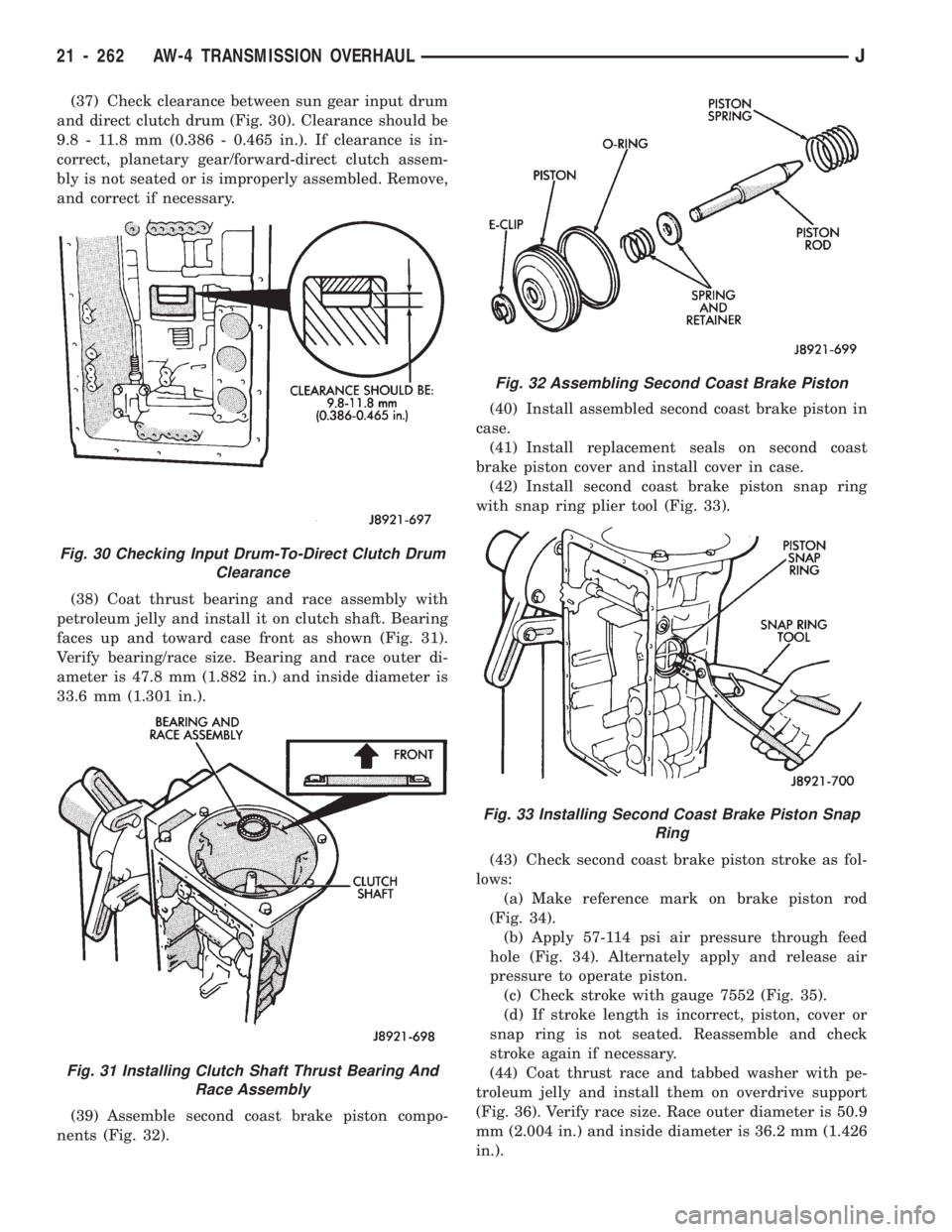

(37) Check clearance between sun gear input drum

and direct clutch drum (Fig. 30). Clearance should be

9.8 - 11.8 mm (0.386 - 0.465 in.). If clearance is in-

correct, planetary gear/forward-direct clutch assem-

bly is not seated or is improperly assembled. Remove,

and correct if necessary.

(38) Coat thrust bearing and race assembly with

petroleum jelly and install it on clutch shaft. Bearing

faces up and toward case front as shown (Fig. 31).

Verify bearing/race size. Bearing and race outer di-

ameter is 47.8 mm (1.882 in.) and inside diameter is

33.6 mm (1.301 in.).

(39) Assemble second coast brake piston compo-

nents (Fig. 32).(40) Install assembled second coast brake piston in

case.

(41) Install replacement seals on second coast

brake piston cover and install cover in case.

(42) Install second coast brake piston snap ring

with snap ring plier tool (Fig. 33).

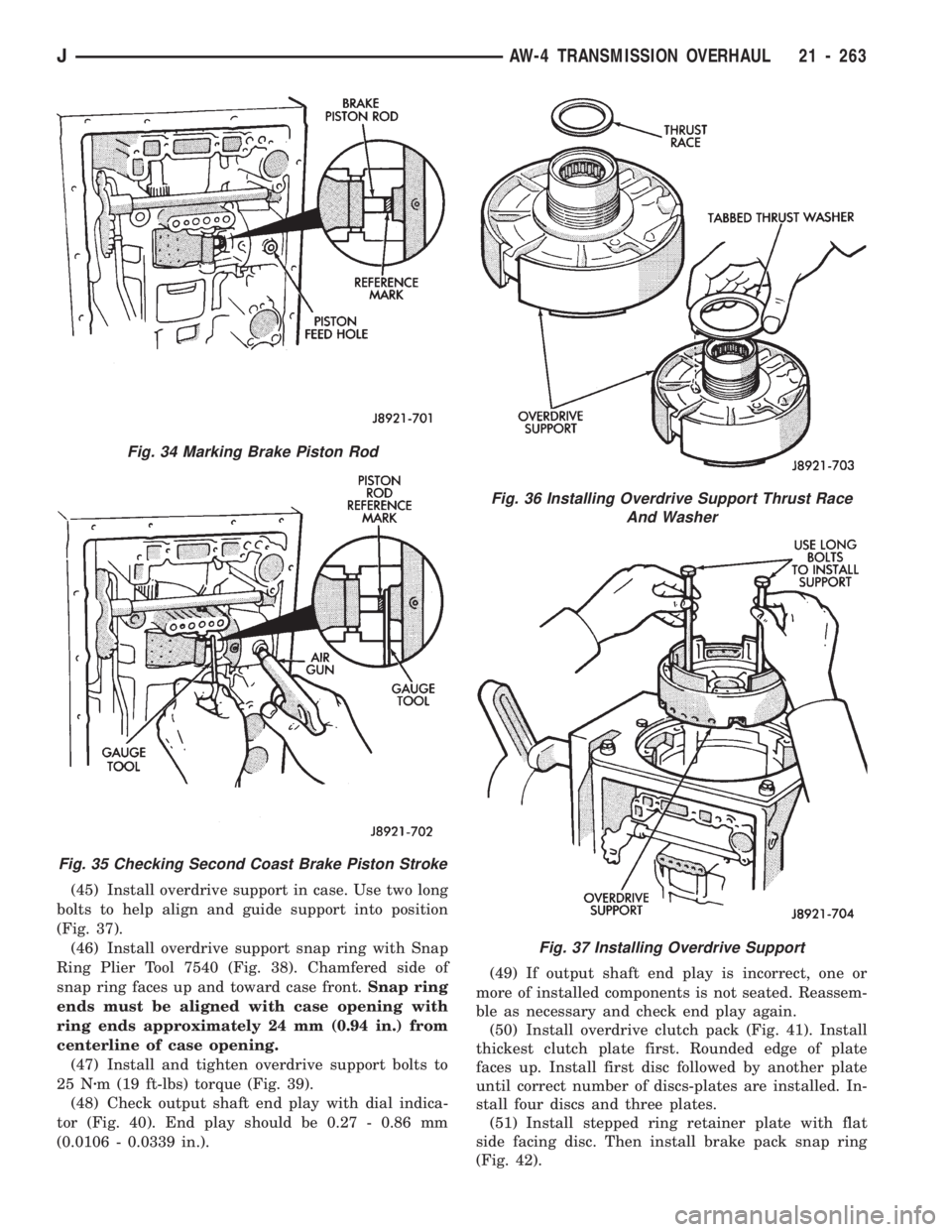

(43) Check second coast brake piston stroke as fol-

lows:

(a) Make reference mark on brake piston rod

(Fig. 34).

(b) Apply 57-114 psi air pressure through feed

hole (Fig. 34). Alternately apply and release air

pressure to operate piston.

(c) Check stroke with gauge 7552 (Fig. 35).

(d) If stroke length is incorrect, piston, cover or

snap ring is not seated. Reassemble and check

stroke again if necessary.

(44) Coat thrust race and tabbed washer with pe-

troleum jelly and install them on overdrive support

(Fig. 36). Verify race size. Race outer diameter is 50.9

mm (2.004 in.) and inside diameter is 36.2 mm (1.426

in.).

Fig. 30 Checking Input Drum-To-Direct Clutch Drum

Clearance

Fig. 31 Installing Clutch Shaft Thrust Bearing And

Race Assembly

Fig. 32 Assembling Second Coast Brake Piston

Fig. 33 Installing Second Coast Brake Piston Snap

Ring

21 - 262 AW-4 TRANSMISSION OVERHAULJ

Page 1374 of 1784

(45) Install overdrive support in case. Use two long

bolts to help align and guide support into position

(Fig. 37).

(46) Install overdrive support snap ring with Snap

Ring Plier Tool 7540 (Fig. 38). Chamfered side of

snap ring faces up and toward case front.Snap ring

ends must be aligned with case opening with

ring ends approximately 24 mm (0.94 in.) from

centerline of case opening.

(47) Install and tighten overdrive support bolts to

25 Nzm (19 ft-lbs) torque (Fig. 39).

(48) Check output shaft end play with dial indica-

tor (Fig. 40). End play should be 0.27 - 0.86 mm

(0.0106 - 0.0339 in.).(49) If output shaft end play is incorrect, one or

more of installed components is not seated. Reassem-

ble as necessary and check end play again.

(50) Install overdrive clutch pack (Fig. 41). Install

thickest clutch plate first. Rounded edge of plate

faces up. Install first disc followed by another plate

until correct number of discs-plates are installed. In-

stall four discs and three plates.

(51) Install stepped ring retainer plate with flat

side facing disc. Then install brake pack snap ring

(Fig. 42).

Fig. 36 Installing Overdrive Support Thrust Race

And Washer

Fig. 37 Installing Overdrive Support

Fig. 34 Marking Brake Piston Rod

Fig. 35 Checking Second Coast Brake Piston Stroke

JAW-4 TRANSMISSION OVERHAUL 21 - 263

Page 1384 of 1784

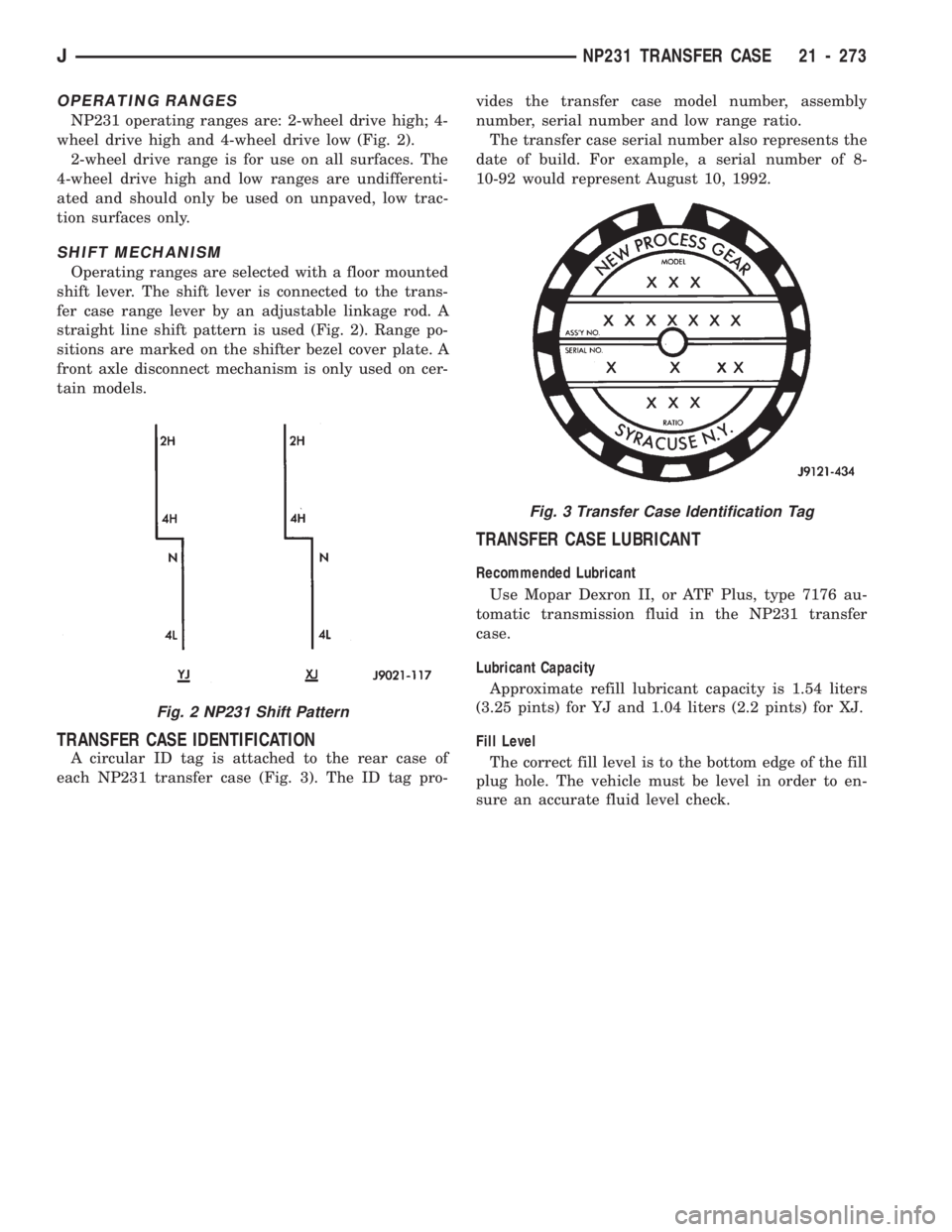

OPERATING RANGES

NP231 operating ranges are: 2-wheel drive high; 4-

wheel drive high and 4-wheel drive low (Fig. 2).

2-wheel drive range is for use on all surfaces. The

4-wheel drive high and low ranges are undifferenti-

ated and should only be used on unpaved, low trac-

tion surfaces only.

SHIFT MECHANISM

Operating ranges are selected with a floor mounted

shift lever. The shift lever is connected to the trans-

fer case range lever by an adjustable linkage rod. A

straight line shift pattern is used (Fig. 2). Range po-

sitions are marked on the shifter bezel cover plate. A

front axle disconnect mechanism is only used on cer-

tain models.

TRANSFER CASE IDENTIFICATION

A circular ID tag is attached to the rear case of

each NP231 transfer case (Fig. 3). The ID tag pro-vides the transfer case model number, assembly

number, serial number and low range ratio.

The transfer case serial number also represents the

date of build. For example, a serial number of 8-

10-92 would represent August 10, 1992.

TRANSFER CASE LUBRICANT

Recommended Lubricant

Use Mopar Dexron II, or ATF Plus, type 7176 au-

tomatic transmission fluid in the NP231 transfer

case.

Lubricant Capacity

Approximate refill lubricant capacity is 1.54 liters

(3.25 pints) for YJ and 1.04 liters (2.2 pints) for XJ.

Fill Level

The correct fill level is to the bottom edge of the fill

plug hole. The vehicle must be level in order to en-

sure an accurate fluid level check.

Fig. 2 NP231 Shift Pattern

Fig. 3 Transfer Case Identification Tag

JNP231 TRANSFER CASE 21 - 273

Page 1387 of 1784

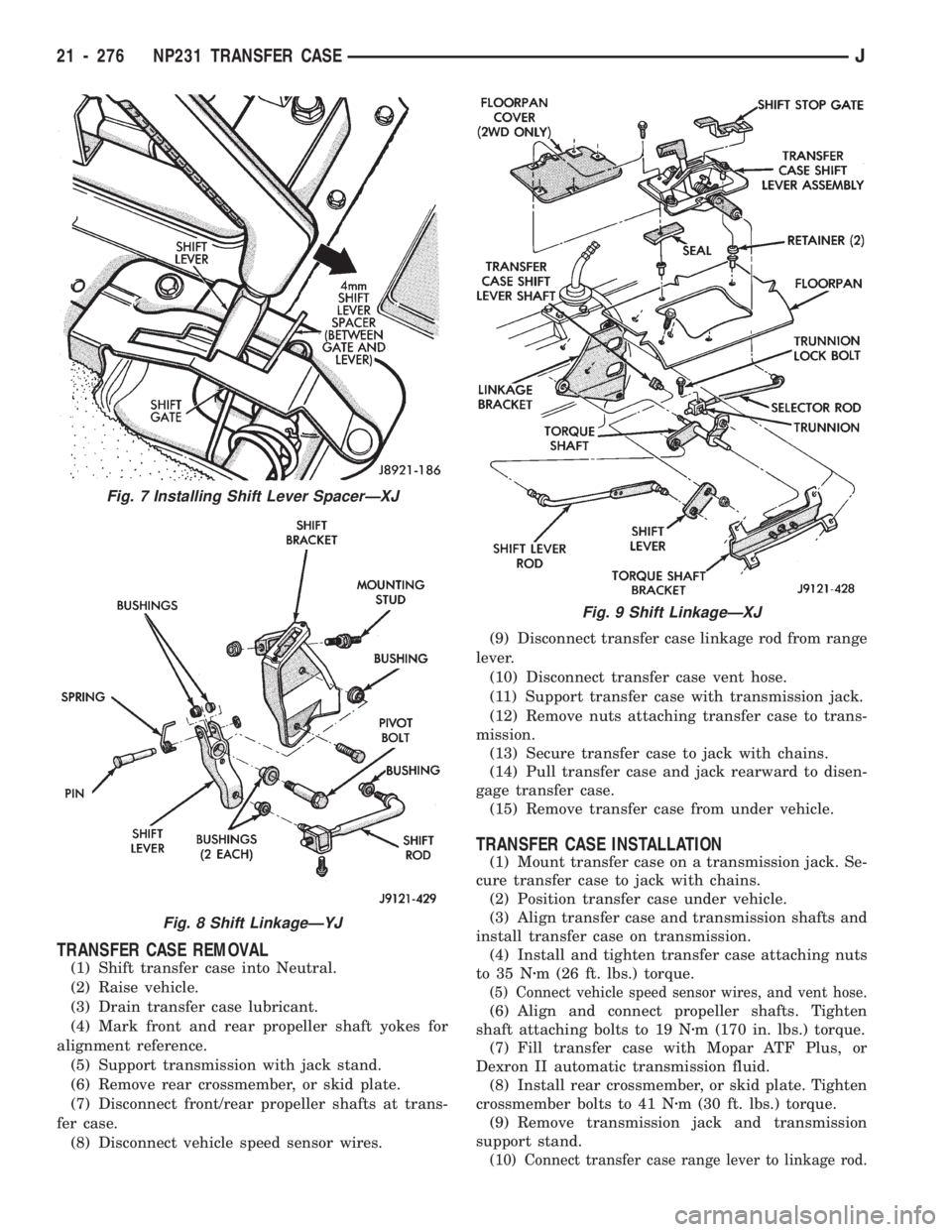

TRANSFER CASE REMOVAL

(1) Shift transfer case into Neutral.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shaft yokes for

alignment reference.

(5) Support transmission with jack stand.

(6) Remove rear crossmember, or skid plate.

(7) Disconnect front/rear propeller shafts at trans-

fer case.

(8) Disconnect vehicle speed sensor wires.(9) Disconnect transfer case linkage rod from range

lever.

(10) Disconnect transfer case vent hose.

(11) Support transfer case with transmission jack.

(12) Remove nuts attaching transfer case to trans-

mission.

(13) Secure transfer case to jack with chains.

(14) Pull transfer case and jack rearward to disen-

gage transfer case.

(15) Remove transfer case from under vehicle.

TRANSFER CASE INSTALLATION

(1) Mount transfer case on a transmission jack. Se-

cure transfer case to jack with chains.

(2) Position transfer case under vehicle.

(3) Align transfer case and transmission shafts and

install transfer case on transmission.

(4) Install and tighten transfer case attaching nuts

to 35 Nzm (26 ft. lbs.) torque.

(5) Connect vehicle speed sensor wires, and vent hose.

(6) Align and connect propeller shafts. Tighten

shaft attaching bolts to 19 Nzm (170 in. lbs.) torque.

(7) Fill transfer case with Mopar ATF Plus, or

Dexron II automatic transmission fluid.

(8) Install rear crossmember, or skid plate. Tighten

crossmember bolts to 41 Nzm (30 ft. lbs.) torque.

(9) Remove transmission jack and transmission

support stand.

(10) Connect transfer case range lever to linkage rod.

Fig. 7 Installing Shift Lever SpacerÐXJ

Fig. 8 Shift LinkageÐYJ

Fig. 9 Shift LinkageÐXJ

21 - 276 NP231 TRANSFER CASEJ