front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1301 of 1784

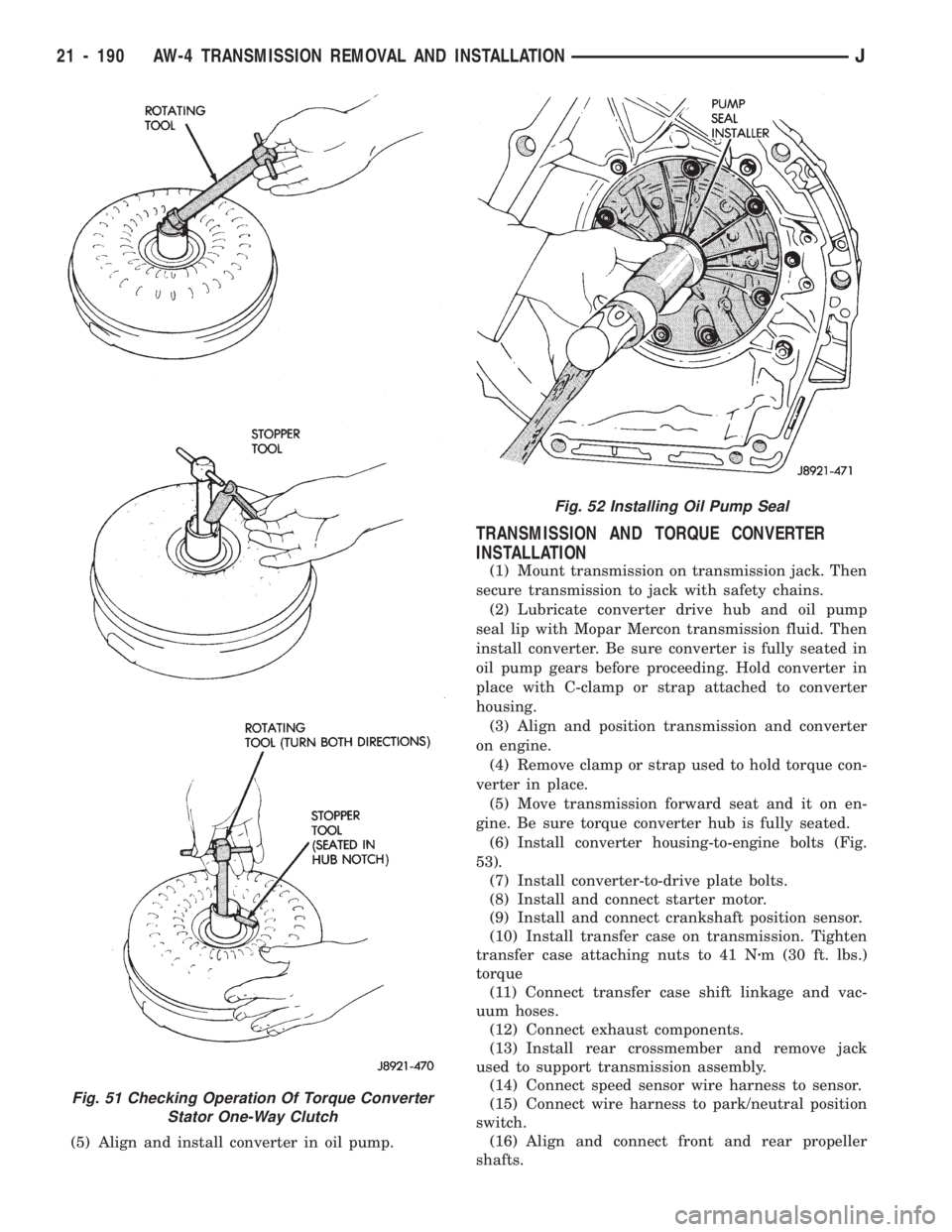

(5) Align and install converter in oil pump.

TRANSMISSION AND TORQUE CONVERTER

INSTALLATION

(1) Mount transmission on transmission jack. Then

secure transmission to jack with safety chains.

(2) Lubricate converter drive hub and oil pump

seal lip with Mopar Mercon transmission fluid. Then

install converter. Be sure converter is fully seated in

oil pump gears before proceeding. Hold converter in

place with C-clamp or strap attached to converter

housing.

(3) Align and position transmission and converter

on engine.

(4) Remove clamp or strap used to hold torque con-

verter in place.

(5) Move transmission forward seat and it on en-

gine. Be sure torque converter hub is fully seated.

(6)

Install converter housing-to-engine bolts (Fig.

53).

(7) Install converter-to-drive plate bolts.

(8) Install and connect starter motor.

(9) Install and connect crankshaft position sensor.

(10) Install transfer case on transmission. Tighten

transfer case attaching nuts to 41 Nzm (30 ft. lbs.)

torque

(11) Connect transfer case shift linkage and vac-

uum hoses.

(12) Connect exhaust components.

(13) Install rear crossmember and remove jack

used to support transmission assembly.

(14) Connect speed sensor wire harness to sensor.

(15) Connect wire harness to park/neutral position

switch.

(16) Align and connect front and rear propeller

shafts.

Fig. 51 Checking Operation Of Torque Converter

Stator One-Way Clutch

Fig. 52 Installing Oil Pump Seal

21 - 190 AW-4 TRANSMISSION REMOVAL AND INSTALLATIONJ

Page 1303 of 1784

AW-4 TRANSMISSION OVERHAUL

INDEX

page page

Cleaning and Inspection................... 76

Direct Clutch Overhaul................... 219

First-Reverse Brake Piston and Transmission

Case Overhaul........................ 237

Forward Clutch Overhaul.................. 223

Front Planetary Gear Overhaul............. 228

Manual Valve Shaft Overhaul.............. 205

Oil Pump Overhaul...................... 206

Overdrive Planetary Gear and Clutch Overhaul . 209Overdrive Support Overhaul................ 216

Overhaul Service Tools................... 192

Rear Planetary, No. 2 One-Way Clutch and

Output Shaft Overhaul.................. 100

Second Brake Overhaul................... 100

Sun Gear and No. 1 One-Way Clutch Overhaul . 99

Transmission Assembly and Adjustment....... 255

Transmission Disassembly................. 192

Transmission Valve Body Overhaul.......... 101

OVERHAUL SERVICE TOOLS

The special tools needed to overhaul the AW-4

transmission are provided in Tool Kit 6294. However,

Pressure Test Port Adapter 7554 is not included in

this kit and must be ordered separately. The over-

haul tool kit and test port adapter are available

through the parts division and dealer special tool

program.

TRANSMISSION DISASSEMBLY

(1) Remove torque converter.

(2) Remove lower half of filler tube if not previ-

ously removed.

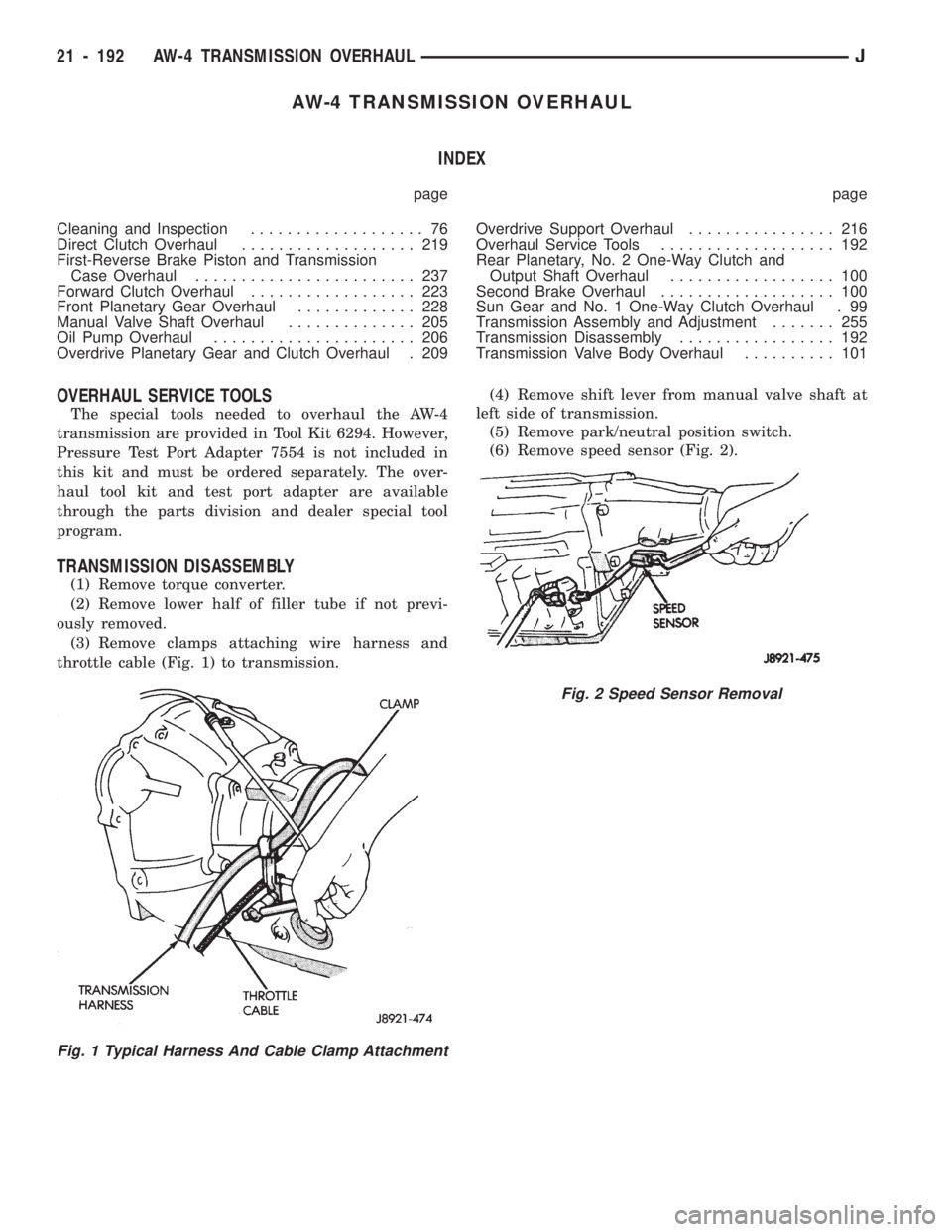

(3) Remove clamps attaching wire harness and

throttle cable (Fig. 1) to transmission.(4) Remove shift lever from manual valve shaft at

left side of transmission.

(5) Remove park/neutral position switch.

(6) Remove speed sensor (Fig. 2).

Fig. 1 Typical Harness And Cable Clamp Attachment

Fig. 2 Speed Sensor Removal

21 - 192 AW-4 TRANSMISSION OVERHAULJ

Page 1311 of 1784

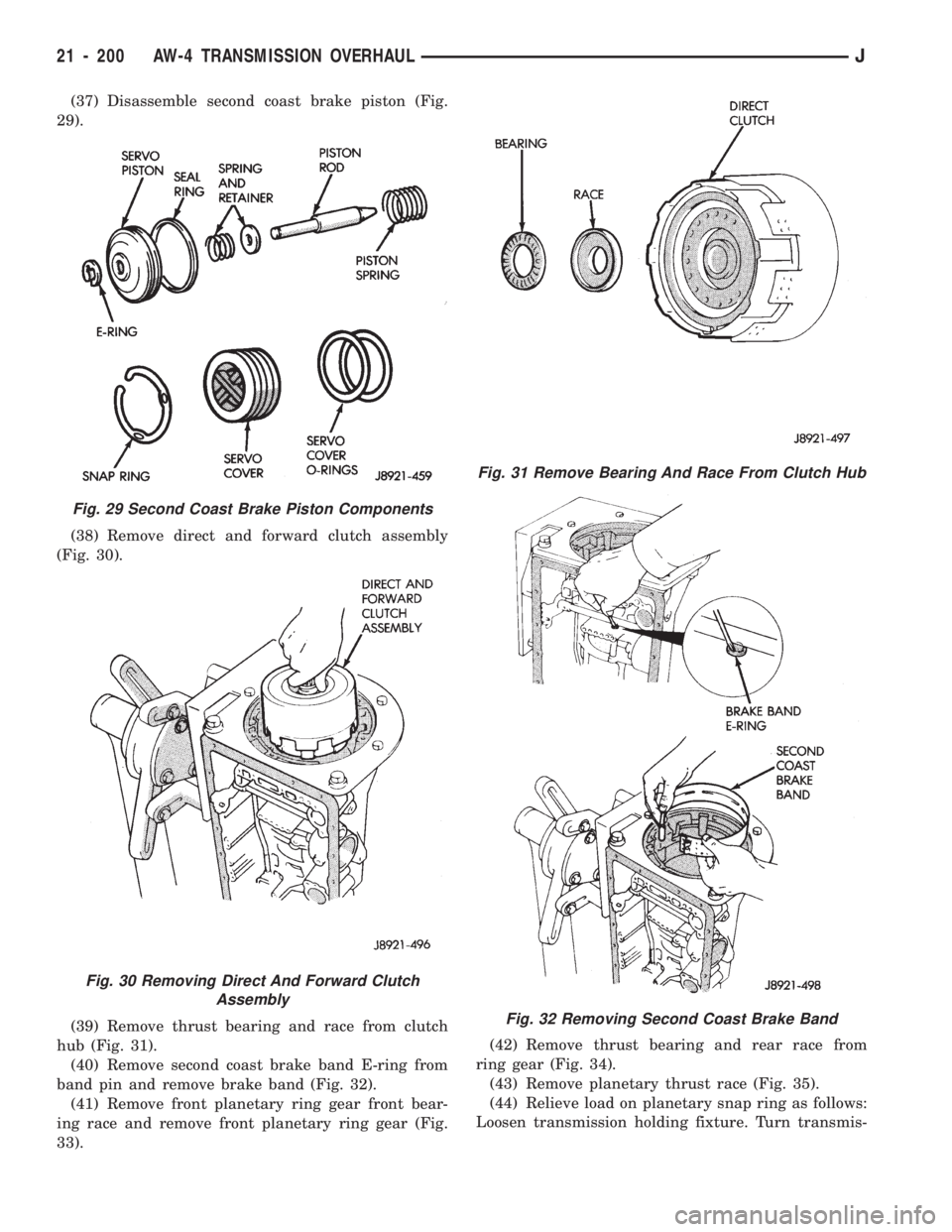

(37) Disassemble second coast brake piston (Fig.

29).

(38) Remove direct and forward clutch assembly

(Fig. 30).

(39) Remove thrust bearing and race from clutch

hub (Fig. 31).

(40) Remove second coast brake band E-ring from

band pin and remove brake band (Fig. 32).

(41) Remove front planetary ring gear front bear-

ing race and remove front planetary ring gear (Fig.

33).(42) Remove thrust bearing and rear race from

ring gear (Fig. 34).

(43) Remove planetary thrust race (Fig. 35).

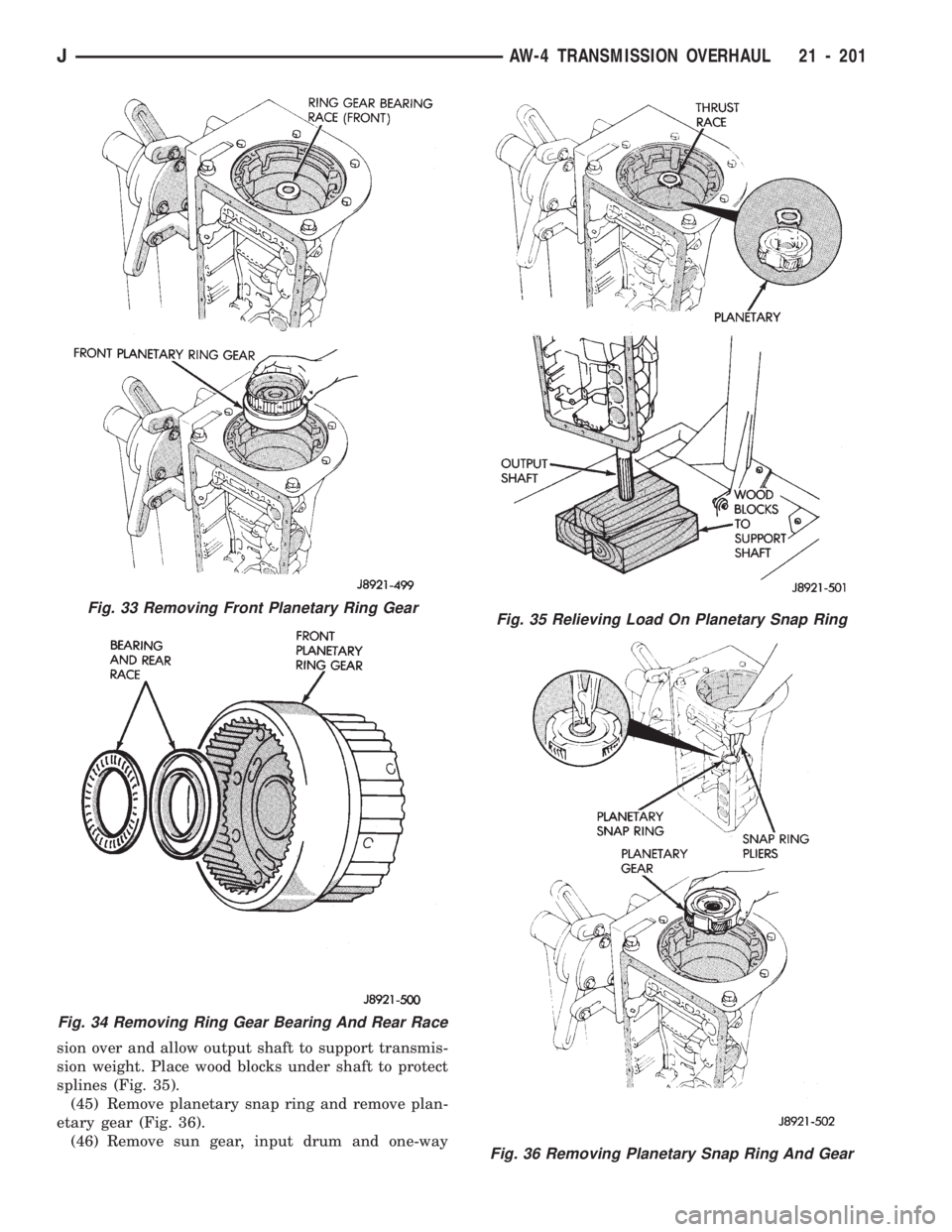

(44) Relieve load on planetary snap ring as follows:

Loosen transmission holding fixture. Turn transmis-

Fig. 29 Second Coast Brake Piston Components

Fig. 30 Removing Direct And Forward Clutch

Assembly

Fig. 31 Remove Bearing And Race From Clutch Hub

Fig. 32 Removing Second Coast Brake Band

21 - 200 AW-4 TRANSMISSION OVERHAULJ

Page 1312 of 1784

sion over and allow output shaft to support transmis-

sion weight. Place wood blocks under shaft to protect

splines (Fig. 35).

(45) Remove planetary snap ring and remove plan-

etary gear (Fig. 36).

(46) Remove sun gear, input drum and one-way

Fig. 33 Removing Front Planetary Ring Gear

Fig. 34 Removing Ring Gear Bearing And Rear Race

Fig. 35 Relieving Load On Planetary Snap Ring

Fig. 36 Removing Planetary Snap Ring And Gear

JAW-4 TRANSMISSION OVERHAUL 21 - 201

Page 1318 of 1784

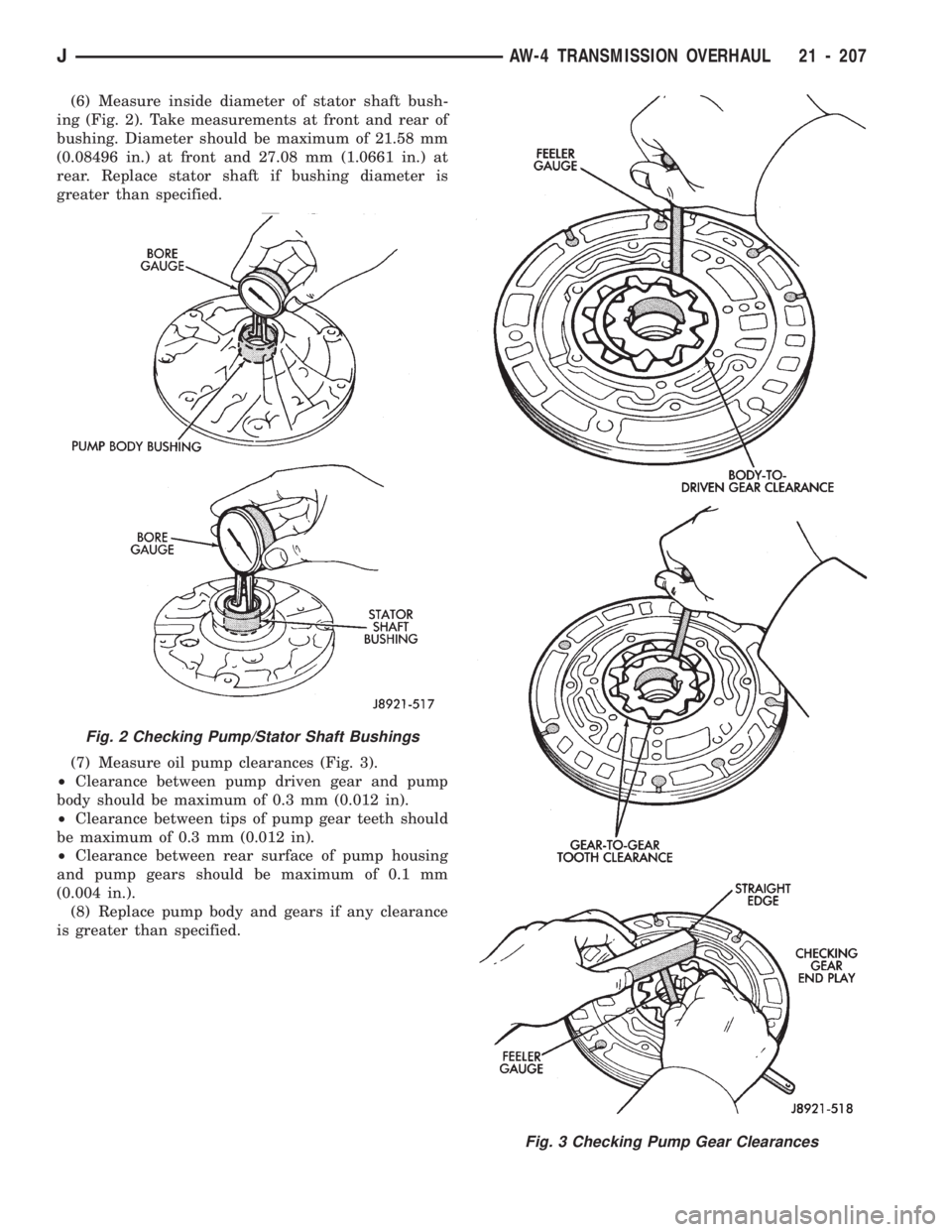

(6) Measure inside diameter of stator shaft bush-

ing (Fig. 2). Take measurements at front and rear of

bushing. Diameter should be maximum of 21.58 mm

(0.08496 in.) at front and 27.08 mm (1.0661 in.) at

rear. Replace stator shaft if bushing diameter is

greater than specified.

(7) Measure oil pump clearances (Fig. 3).

²Clearance between pump driven gear and pump

body should be maximum of 0.3 mm (0.012 in).

²Clearance between tips of pump gear teeth should

be maximum of 0.3 mm (0.012 in).

²Clearance between rear surface of pump housing

and pump gears should be maximum of 0.1 mm

(0.004 in.).

(8) Replace pump body and gears if any clearance

is greater than specified.

Fig. 2 Checking Pump/Stator Shaft Bushings

Fig. 3 Checking Pump Gear Clearances

JAW-4 TRANSMISSION OVERHAUL 21 - 207

Page 1325 of 1784

(20) Check inside diameter of clutch drum bush-

ings with bore gauge or inside micrometer (Fig. 18).

Maximum inside diameter is 27.11 mm (1.0673 in.).

Replace drum if bushing inside diameter is greater

than specified.

(21) Check inside diameter of planetary gear bush-

ing (Fig. 19). Maximum inside diameter is 11.27 mm

(0.4437 in.). Replace planetary gear if bushing inside

diameter is greater then specified.

Assembling Gear And Clutch

(1) Install thrust washer in planetary gear (Fig.

20).Grooved side of washer faces up and to-

ward front.(2) Install one-way clutch in race (Fig. 21). Flanged

side of clutch must face upward as shown.

(3) Install assembled one-way clutch and outer

race in planetary gear. Be sure flanged side of clutch

is facing upward.

(4) Install clutch pack retaining plate and snap

ring in planetary gear.

(5) Coat planetary race with petroleum jelly and

install it on planetary gear. Outside diameter of race

is 41.8 mm (1.646 in.); inside diameter is 27.1 mm

(1.067 in.).

(6) Install hub in planetary ring gear and install

snap ring.

Fig. 18 Checking Clutch Drum Bushings

Fig. 19 Checking Planetary Bushing

Fig. 20 Install Planetary Thrust Washer

Fig. 21 Assembling One-Way Clutch And Race

21 - 214 AW-4 TRANSMISSION OVERHAULJ

Page 1328 of 1784

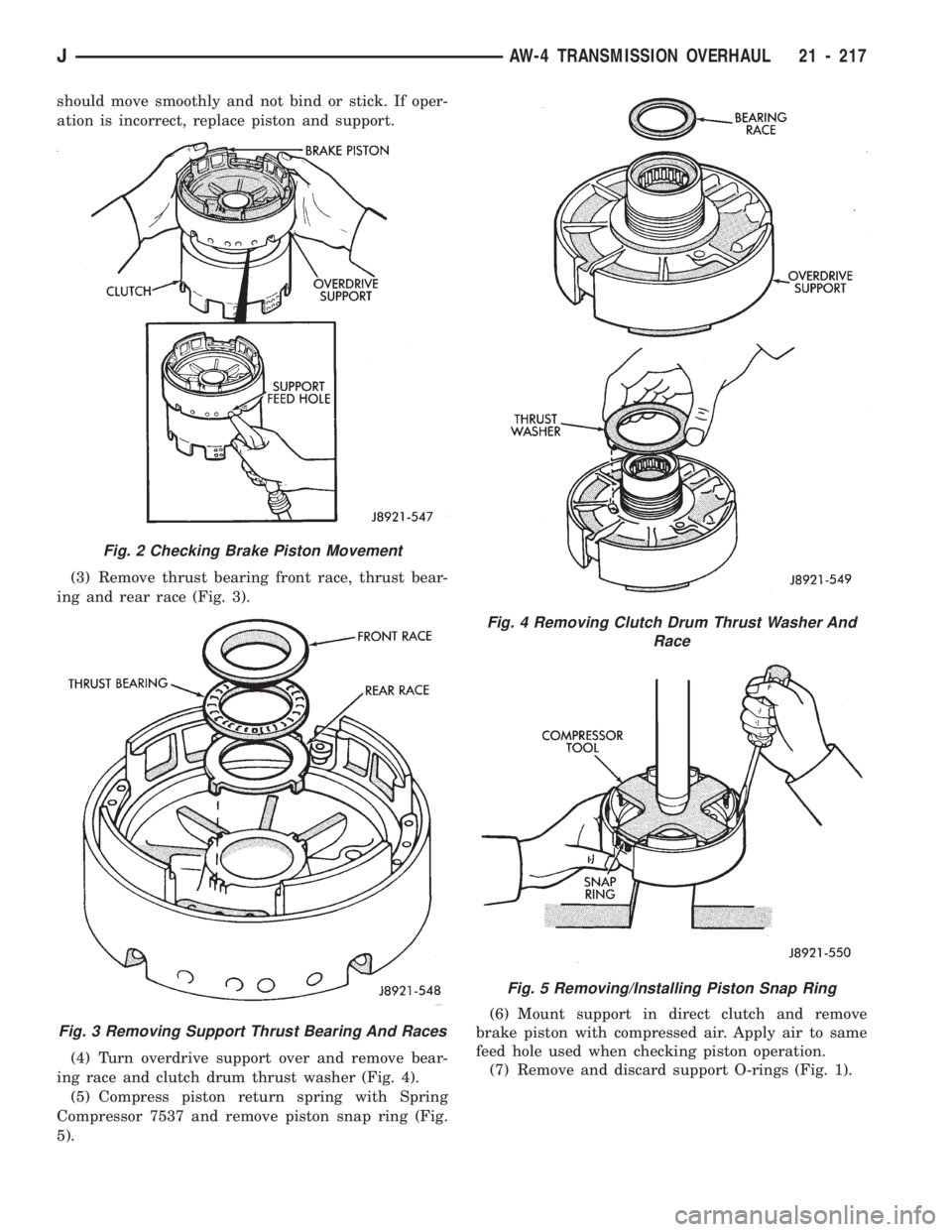

should move smoothly and not bind or stick. If oper-

ation is incorrect, replace piston and support.

(3) Remove thrust bearing front race, thrust bear-

ing and rear race (Fig. 3).

(4) Turn overdrive support over and remove bear-

ing race and clutch drum thrust washer (Fig. 4).

(5) Compress piston return spring with Spring

Compressor 7537 and remove piston snap ring (Fig.

5).(6) Mount support in direct clutch and remove

brake piston with compressed air. Apply air to same

feed hole used when checking piston operation.

(7) Remove and discard support O-rings (Fig. 1).

Fig. 2 Checking Brake Piston Movement

Fig. 3 Removing Support Thrust Bearing And Races

Fig. 4 Removing Clutch Drum Thrust Washer And

Race

Fig. 5 Removing/Installing Piston Snap Ring

JAW-4 TRANSMISSION OVERHAUL 21 - 217

Page 1329 of 1784

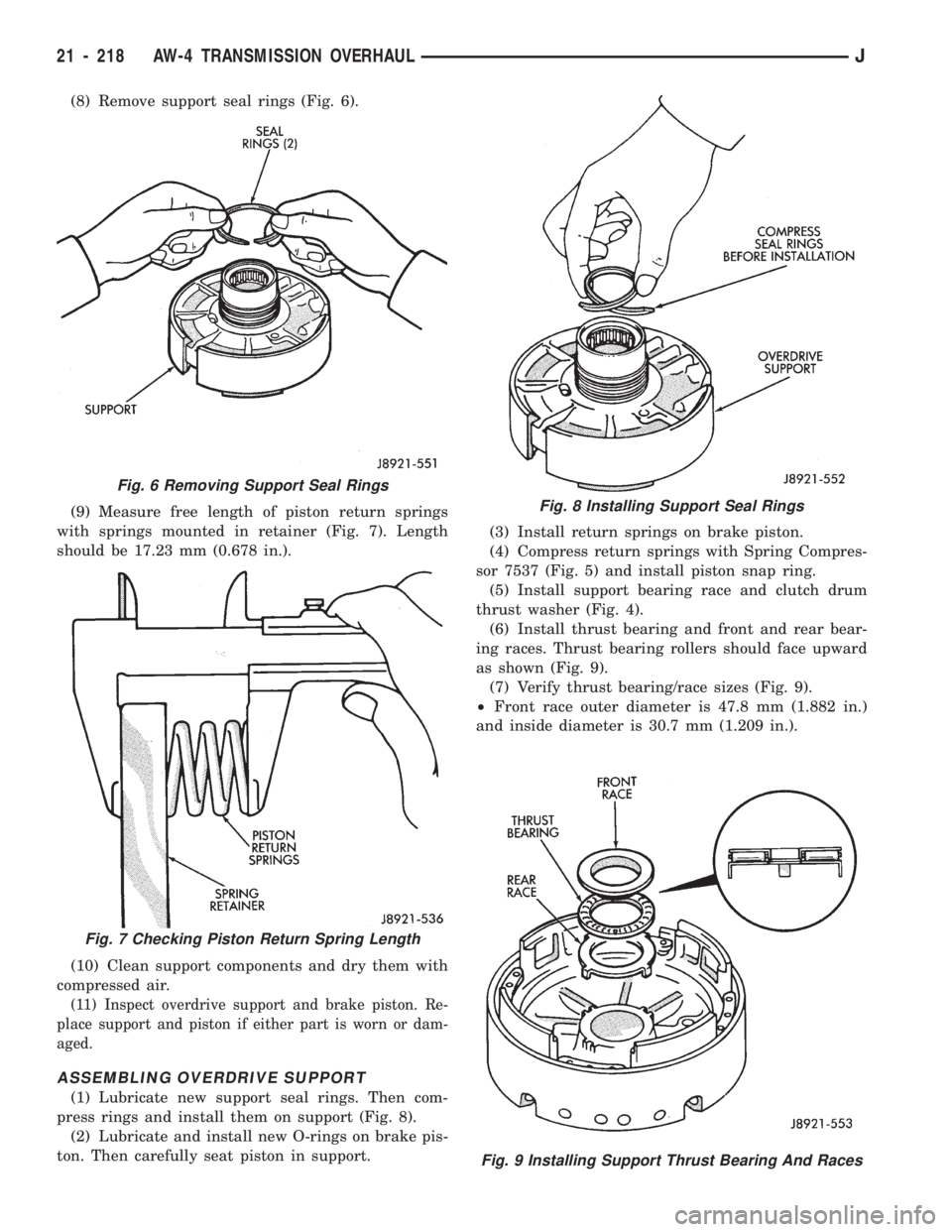

(8) Remove support seal rings (Fig. 6).

(9) Measure free length of piston return springs

with springs mounted in retainer (Fig. 7). Length

should be 17.23 mm (0.678 in.).

(10) Clean support components and dry them with

compressed air.

(11) Inspect overdrive support and brake piston. Re-

place support and piston if either part is worn or dam-

aged.

ASSEMBLING OVERDRIVE SUPPORT

(1) Lubricate new support seal rings. Then com-

press rings and install them on support (Fig. 8).

(2) Lubricate and install new O-rings on brake pis-

ton. Then carefully seat piston in support.(3) Install return springs on brake piston.

(4) Compress return springs with Spring Compres-

sor 7537 (Fig. 5) and install piston snap ring.

(5) Install support bearing race and clutch drum

thrust washer (Fig. 4).

(6) Install thrust bearing and front and rear bear-

ing races. Thrust bearing rollers should face upward

as shown (Fig. 9).

(7) Verify thrust bearing/race sizes (Fig. 9).

²Front race outer diameter is 47.8 mm (1.882 in.)

and inside diameter is 30.7 mm (1.209 in.).

Fig. 9 Installing Support Thrust Bearing And Races

Fig. 6 Removing Support Seal Rings

Fig. 7 Checking Piston Return Spring Length

Fig. 8 Installing Support Seal Rings

21 - 218 AW-4 TRANSMISSION OVERHAULJ

Page 1339 of 1784

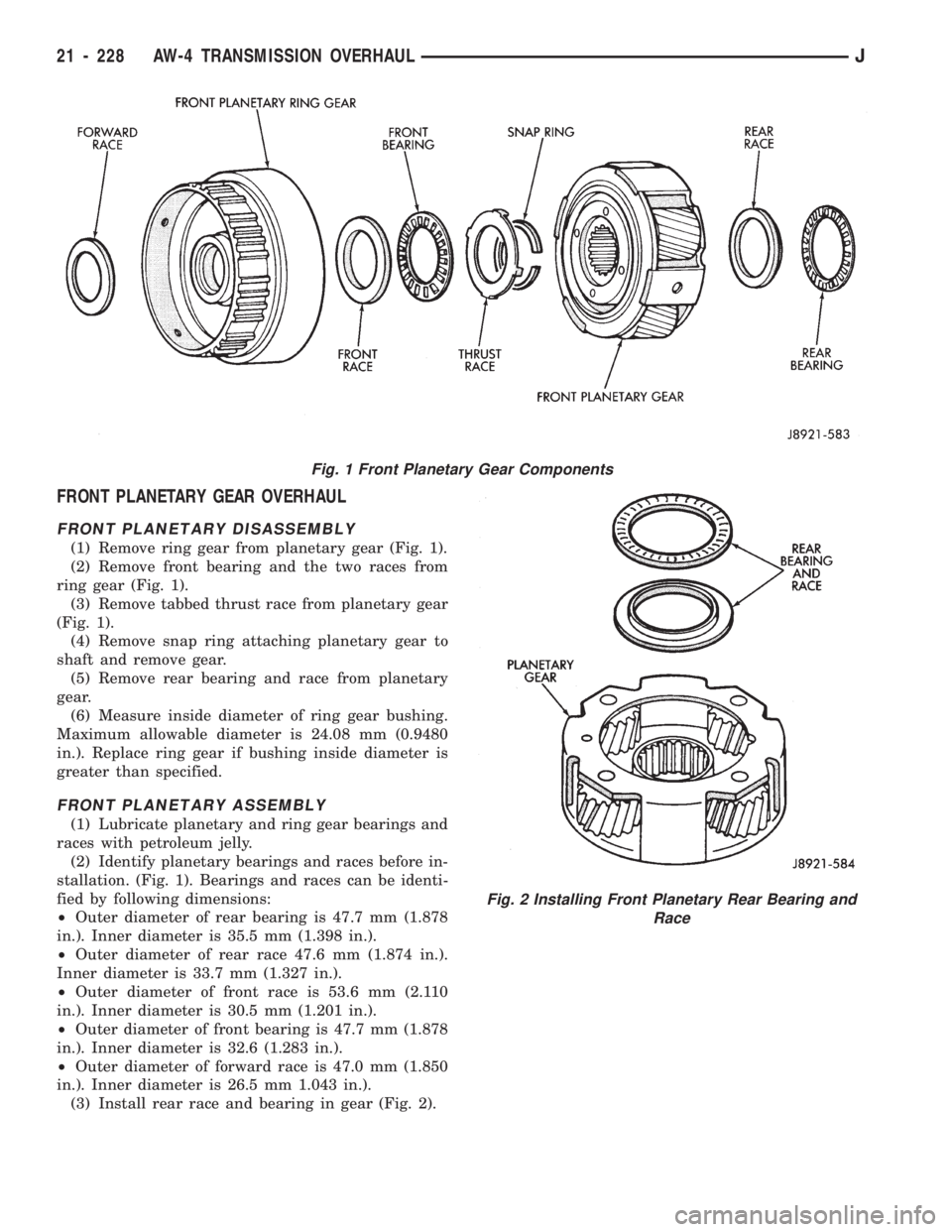

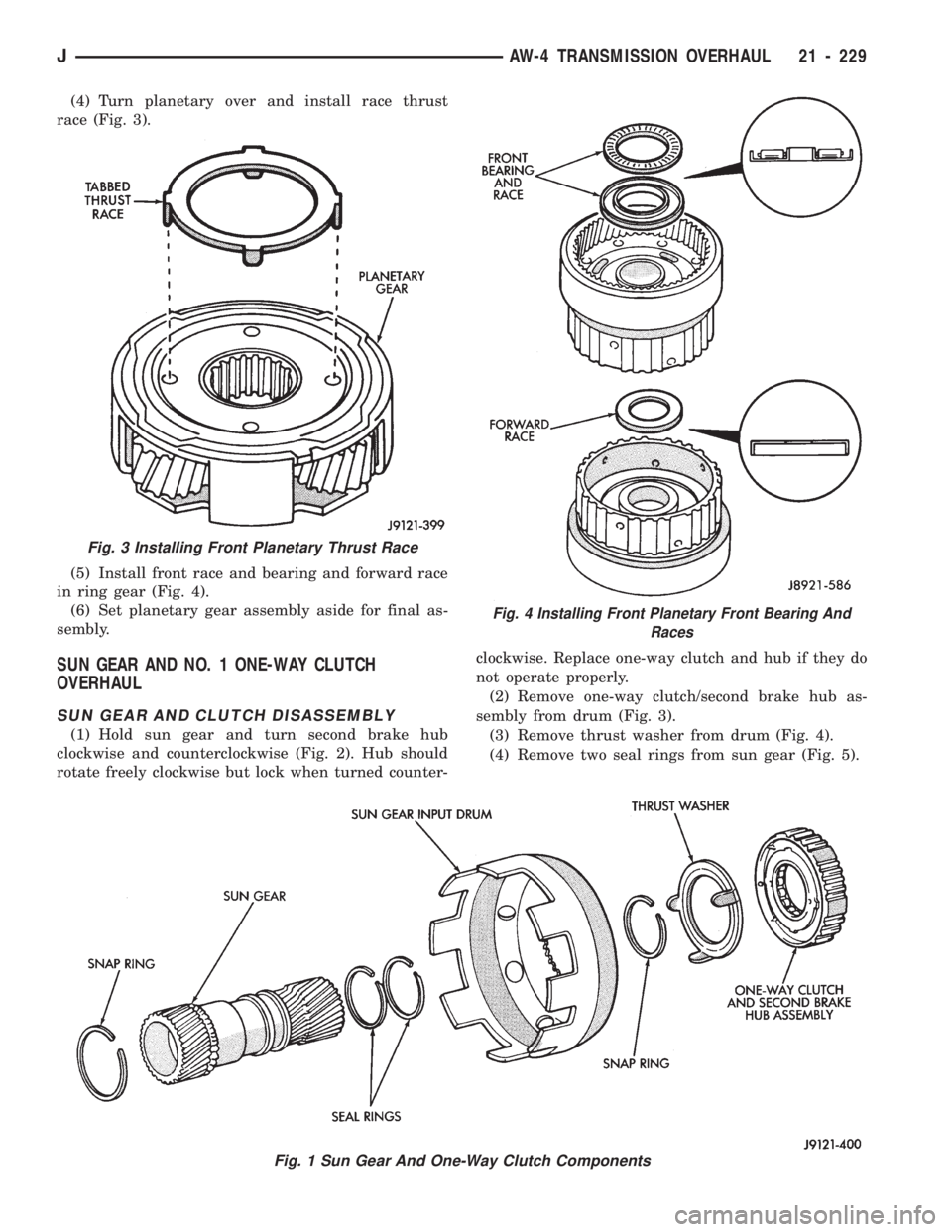

FRONT PLANETARY GEAR OVERHAUL

FRONT PLANETARY DISASSEMBLY

(1) Remove ring gear from planetary gear (Fig. 1).

(2) Remove front bearing and the two races from

ring gear (Fig. 1).

(3) Remove tabbed thrust race from planetary gear

(Fig. 1).

(4) Remove snap ring attaching planetary gear to

shaft and remove gear.

(5) Remove rear bearing and race from planetary

gear.

(6) Measure inside diameter of ring gear bushing.

Maximum allowable diameter is 24.08 mm (0.9480

in.). Replace ring gear if bushing inside diameter is

greater than specified.

FRONT PLANETARY ASSEMBLY

(1) Lubricate planetary and ring gear bearings and

races with petroleum jelly.

(2) Identify planetary bearings and races before in-

stallation. (Fig. 1). Bearings and races can be identi-

fied by following dimensions:

²Outer diameter of rear bearing is 47.7 mm (1.878

in.). Inner diameter is 35.5 mm (1.398 in.).

²Outer diameter of rear race 47.6 mm (1.874 in.).

Inner diameter is 33.7 mm (1.327 in.).

²Outer diameter of front race is 53.6 mm (2.110

in.). Inner diameter is 30.5 mm (1.201 in.).

²Outer diameter of front bearing is 47.7 mm (1.878

in.). Inner diameter is 32.6 (1.283 in.).

²Outer diameter of forward race is 47.0 mm (1.850

in.). Inner diameter is 26.5 mm 1.043 in.).

(3) Install rear race and bearing in gear (Fig. 2).

Fig. 1 Front Planetary Gear Components

Fig. 2 Installing Front Planetary Rear Bearing and

Race

21 - 228 AW-4 TRANSMISSION OVERHAULJ

Page 1340 of 1784

(4) Turn planetary over and install race thrust

race (Fig. 3).

(5) Install front race and bearing and forward race

in ring gear (Fig. 4).

(6) Set planetary gear assembly aside for final as-

sembly.

SUN GEAR AND NO. 1 ONE-WAY CLUTCH

OVERHAUL

SUN GEAR AND CLUTCH DISASSEMBLY

(1) Hold sun gear and turn second brake hub

clockwise and counterclockwise (Fig. 2). Hub should

rotate freely clockwise but lock when turned counter-clockwise. Replace one-way clutch and hub if they do

not operate properly.

(2) Remove one-way clutch/second brake hub as-

sembly from drum (Fig. 3).

(3) Remove thrust washer from drum (Fig. 4).

(4) Remove two seal rings from sun gear (Fig. 5).

Fig. 1 Sun Gear And One-Way Clutch Components

Fig. 3 Installing Front Planetary Thrust Race

Fig. 4 Installing Front Planetary Front Bearing And

Races

JAW-4 TRANSMISSION OVERHAUL 21 - 229