front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1388 of 1784

(11) Adjust transfer case shift linkage.

(12) Lower vehicle.

TRANSFER CASE DISASSEMBLY AND OVERHAUL

Two versions of the NP231 are used in current

models. One version retains the synchronizer

components used in previous years. A newly intro-

duced version does not have synchro components.

The non-synchro version does not have a synchro

gear, struts, spring and stop ring. During over-

haul, note which version is being serviced and or-

der needed parts accordingly.

(1) Remove fill and drain plugs.

(2) Remove front yoke. Discard yoke seal washer

and nut. They should not be reused.

(3) Move transfer case range lever rearward to 4L

position.

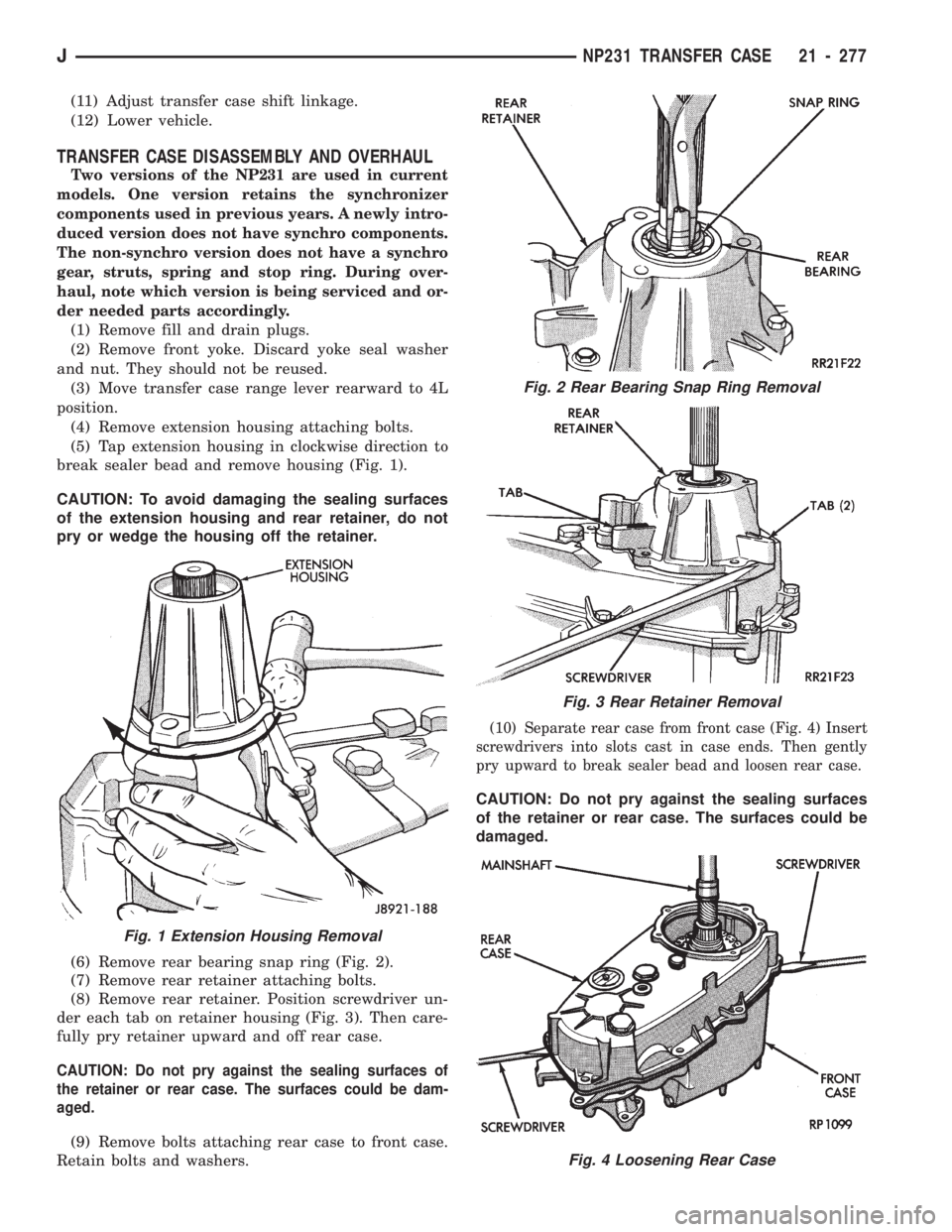

(4) Remove extension housing attaching bolts.

(5) Tap extension housing in clockwise direction to

break sealer bead and remove housing (Fig. 1).

CAUTION: To avoid damaging the sealing surfaces

of the extension housing and rear retainer, do not

pry or wedge the housing off the retainer.

(6) Remove rear bearing snap ring (Fig. 2).

(7) Remove rear retainer attaching bolts.

(8) Remove rear retainer. Position screwdriver un-

der each tab on retainer housing (Fig. 3). Then care-

fully pry retainer upward and off rear case.

CAUTION: Do not pry against the sealing surfaces of

the retainer or rear case. The surfaces could be dam-

aged.

(9) Remove bolts attaching rear case to front case.

Retain bolts and washers.

(10) Separate rear case from front case (Fig. 4) Insert

screwdrivers into slots cast in case ends. Then gently

pry upward to break sealer bead and loosen rear case.

CAUTION: Do not pry against the sealing surfaces

of the retainer or rear case. The surfaces could be

damaged.

Fig. 1 Extension Housing Removal

Fig. 2 Rear Bearing Snap Ring Removal

Fig. 3 Rear Retainer Removal

Fig. 4 Loosening Rear Case

JNP231 TRANSFER CASE 21 - 277

Page 1389 of 1784

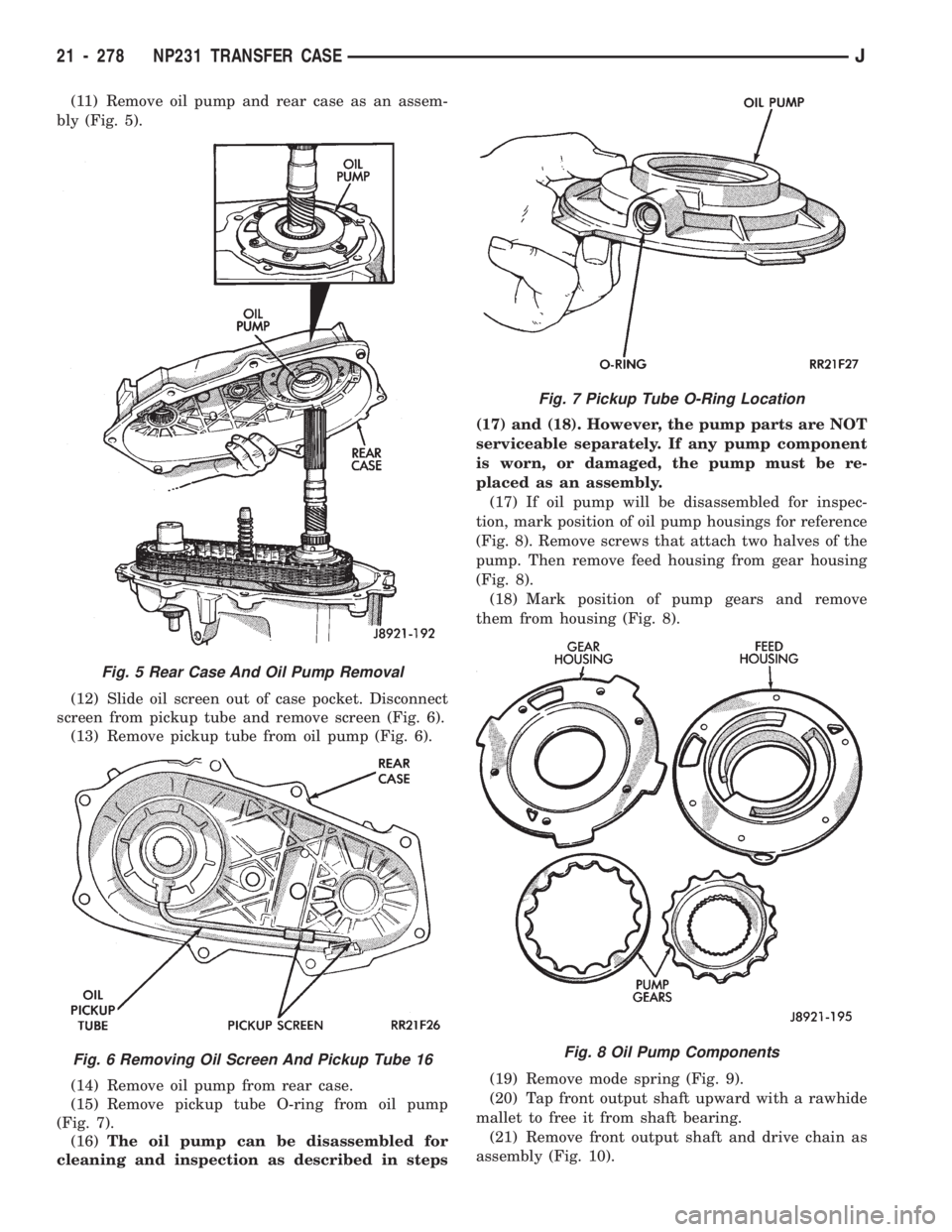

(11) Remove oil pump and rear case as an assem-

bly (Fig. 5).

(12) Slide oil screen out of case pocket. Disconnect

screen from pickup tube and remove screen (Fig. 6).

(13) Remove pickup tube from oil pump (Fig. 6).

(14) Remove oil pump from rear case.

(15) Remove pickup tube O-ring from oil pump

(Fig. 7).

(16)The oil pump can be disassembled for

cleaning and inspection as described in steps(17) and (18). However, the pump parts are NOT

serviceable separately. If any pump component

is worn, or damaged, the pump must be re-

placed as an assembly.

(17) If oil pump will be disassembled for inspec-

tion, mark position of oil pump housings for reference

(Fig. 8). Remove screws that attach two halves of the

pump. Then remove feed housing from gear housing

(Fig. 8).

(18) Mark position of pump gears and remove

them from housing (Fig. 8).

(19) Remove mode spring (Fig. 9).

(20) Tap front output shaft upward with a rawhide

mallet to free it from shaft bearing.

(21) Remove front output shaft and drive chain as

assembly (Fig. 10).

Fig. 5 Rear Case And Oil Pump Removal

Fig. 6 Removing Oil Screen And Pickup Tube 16

Fig. 7 Pickup Tube O-Ring Location

Fig. 8 Oil Pump Components

21 - 278 NP231 TRANSFER CASEJ

Page 1390 of 1784

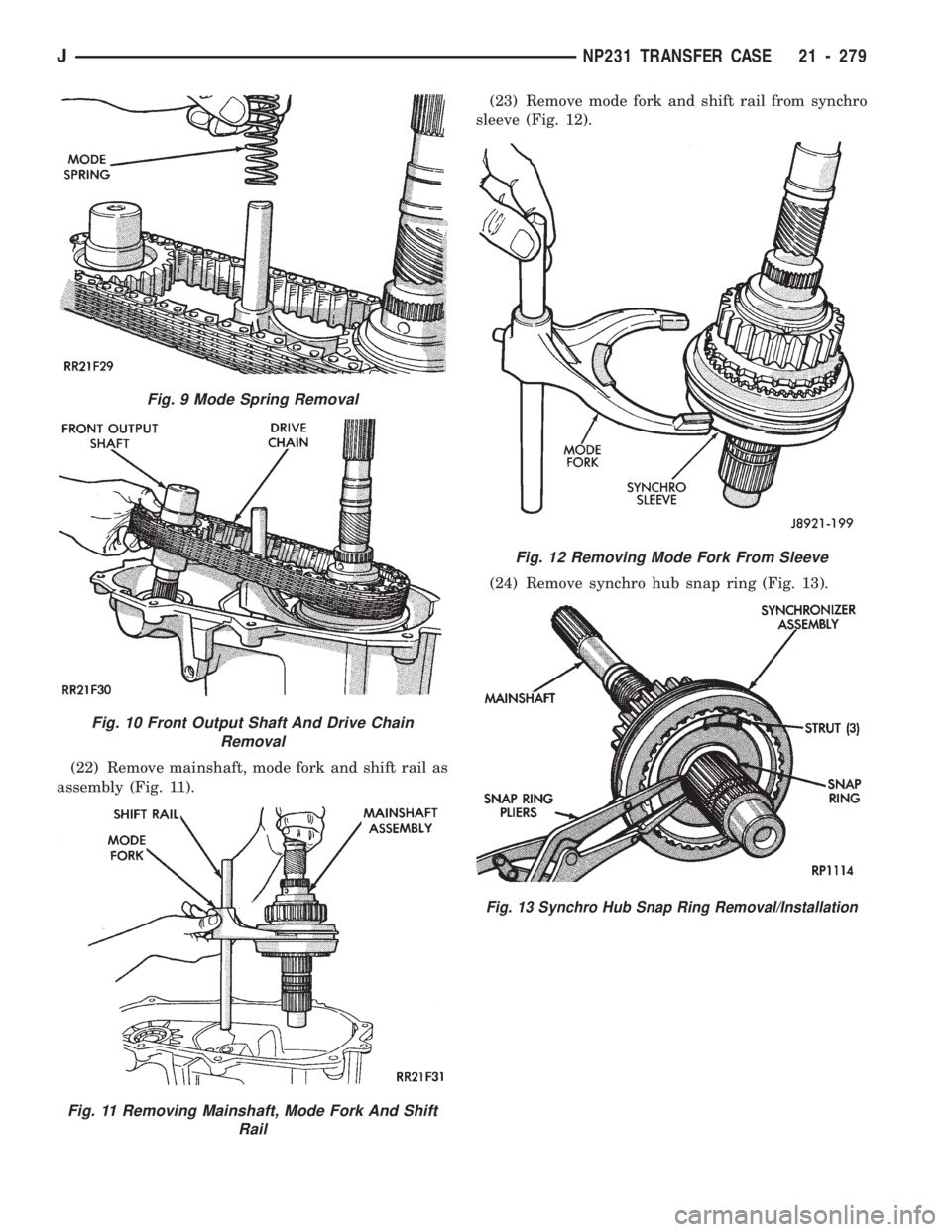

(22) Remove mainshaft, mode fork and shift rail as

assembly (Fig. 11).(23) Remove mode fork and shift rail from synchro

sleeve (Fig. 12).

(24) Remove synchro hub snap ring (Fig. 13).

Fig. 9 Mode Spring Removal

Fig. 10 Front Output Shaft And Drive Chain

Removal

Fig. 11 Removing Mainshaft, Mode Fork And Shift

Rail

Fig. 12 Removing Mode Fork From Sleeve

Fig. 13 Synchro Hub Snap Ring Removal/Installation

JNP231 TRANSFER CASE 21 - 279

Page 1392 of 1784

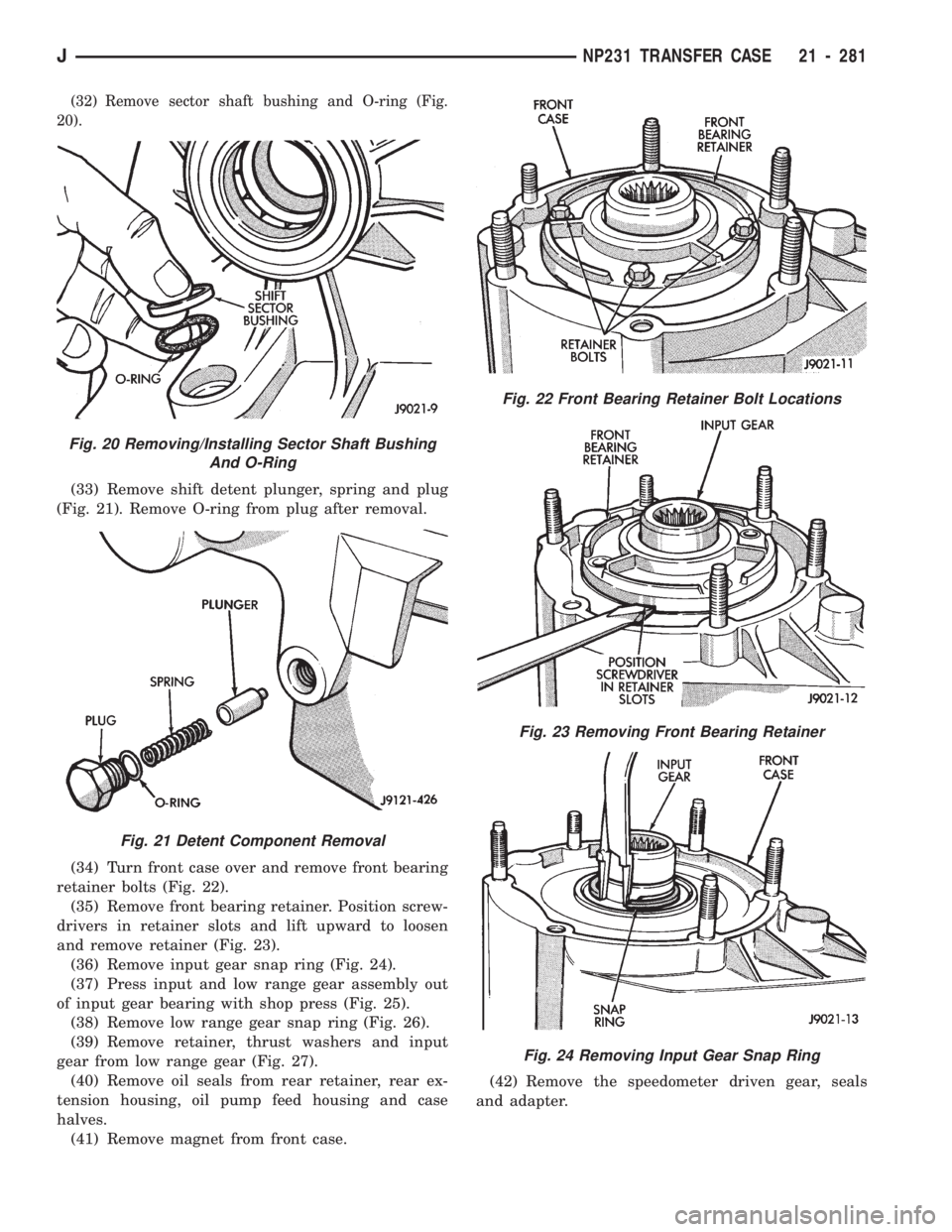

(32) Remove sector shaft bushing and O-ring (Fig.

20).

(33) Remove shift detent plunger, spring and plug

(Fig. 21). Remove O-ring from plug after removal.

(34) Turn front case over and remove front bearing

retainer bolts (Fig. 22).

(35) Remove front bearing retainer. Position screw-

drivers in retainer slots and lift upward to loosen

and remove retainer (Fig. 23).

(36) Remove input gear snap ring (Fig. 24).

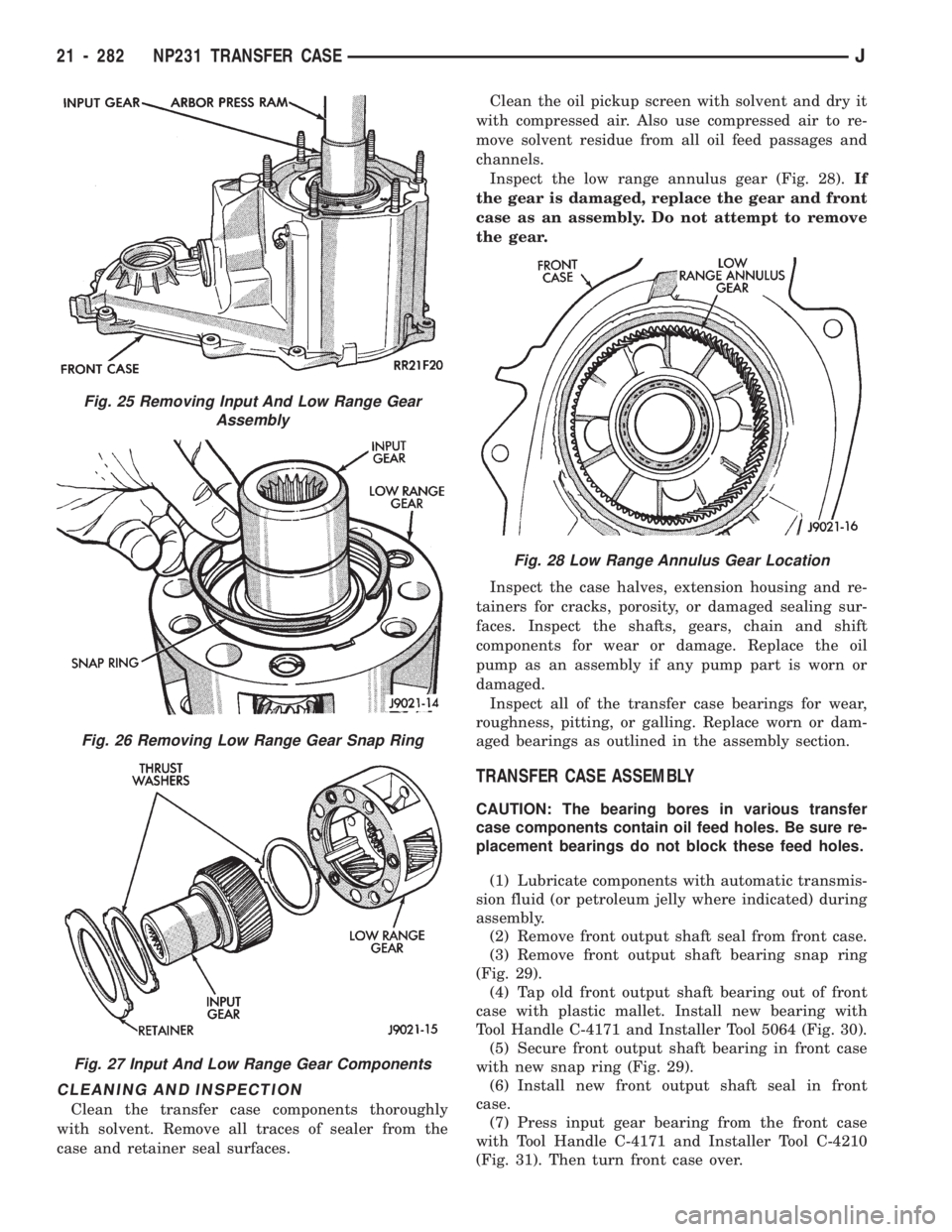

(37) Press input and low range gear assembly out

of input gear bearing with shop press (Fig. 25).

(38) Remove low range gear snap ring (Fig. 26).

(39) Remove retainer, thrust washers and input

gear from low range gear (Fig. 27).

(40) Remove oil seals from rear retainer, rear ex-

tension housing, oil pump feed housing and case

halves.

(41) Remove magnet from front case.(42) Remove the speedometer driven gear, seals

and adapter.

Fig. 20 Removing/Installing Sector Shaft Bushing

And O-Ring

Fig. 21 Detent Component Removal

Fig. 22 Front Bearing Retainer Bolt Locations

Fig. 23 Removing Front Bearing Retainer

Fig. 24 Removing Input Gear Snap Ring

JNP231 TRANSFER CASE 21 - 281

Page 1393 of 1784

CLEANING AND INSPECTION

Clean the transfer case components thoroughly

with solvent. Remove all traces of sealer from the

case and retainer seal surfaces.Clean the oil pickup screen with solvent and dry it

with compressed air. Also use compressed air to re-

move solvent residue from all oil feed passages and

channels.

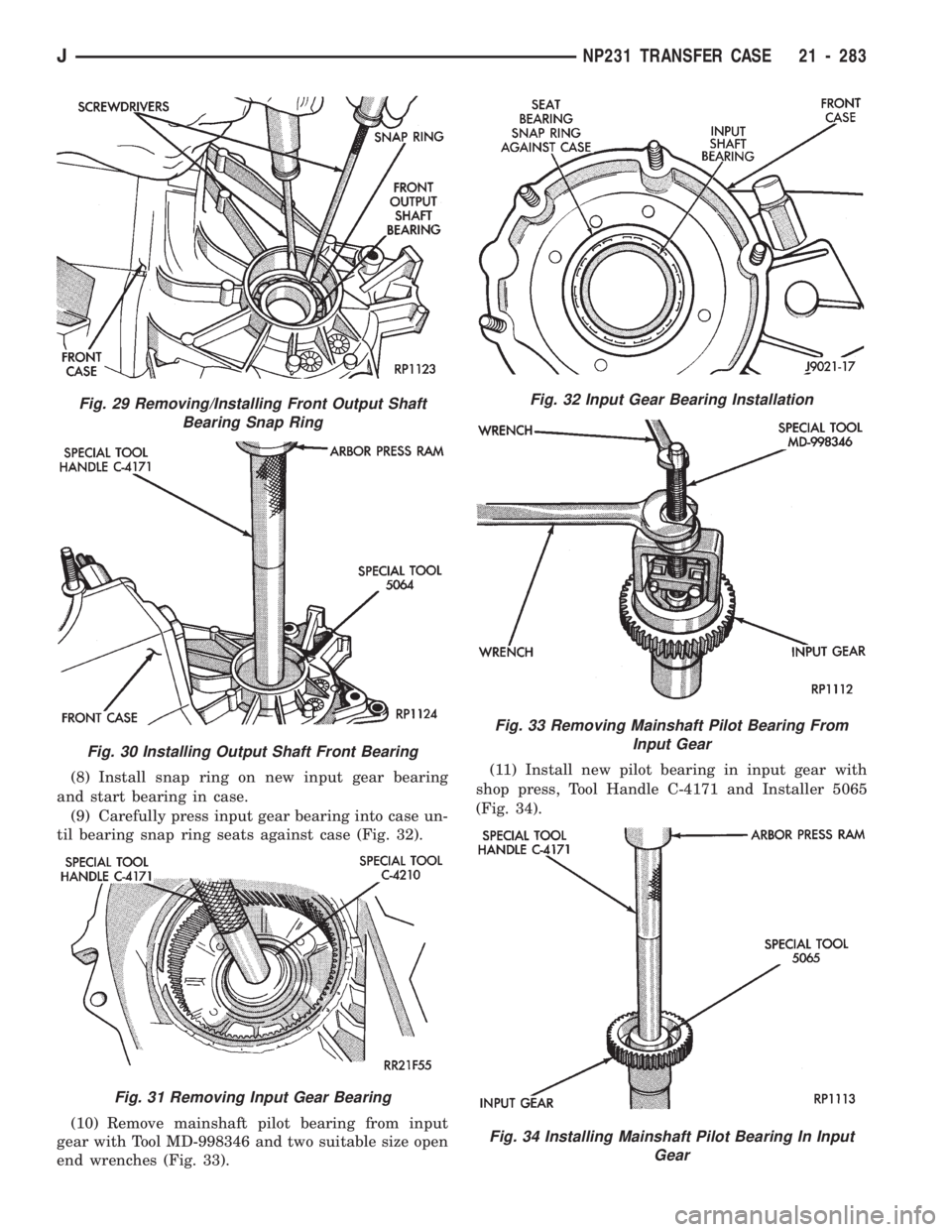

Inspect the low range annulus gear (Fig. 28).If

the gear is damaged, replace the gear and front

case as an assembly. Do not attempt to remove

the gear.

Inspect the case halves, extension housing and re-

tainers for cracks, porosity, or damaged sealing sur-

faces. Inspect the shafts, gears, chain and shift

components for wear or damage. Replace the oil

pump as an assembly if any pump part is worn or

damaged.

Inspect all of the transfer case bearings for wear,

roughness, pitting, or galling. Replace worn or dam-

aged bearings as outlined in the assembly section.

TRANSFER CASE ASSEMBLY

CAUTION: The bearing bores in various transfer

case components contain oil feed holes. Be sure re-

placement bearings do not block these feed holes.

(1) Lubricate components with automatic transmis-

sion fluid (or petroleum jelly where indicated) during

assembly.

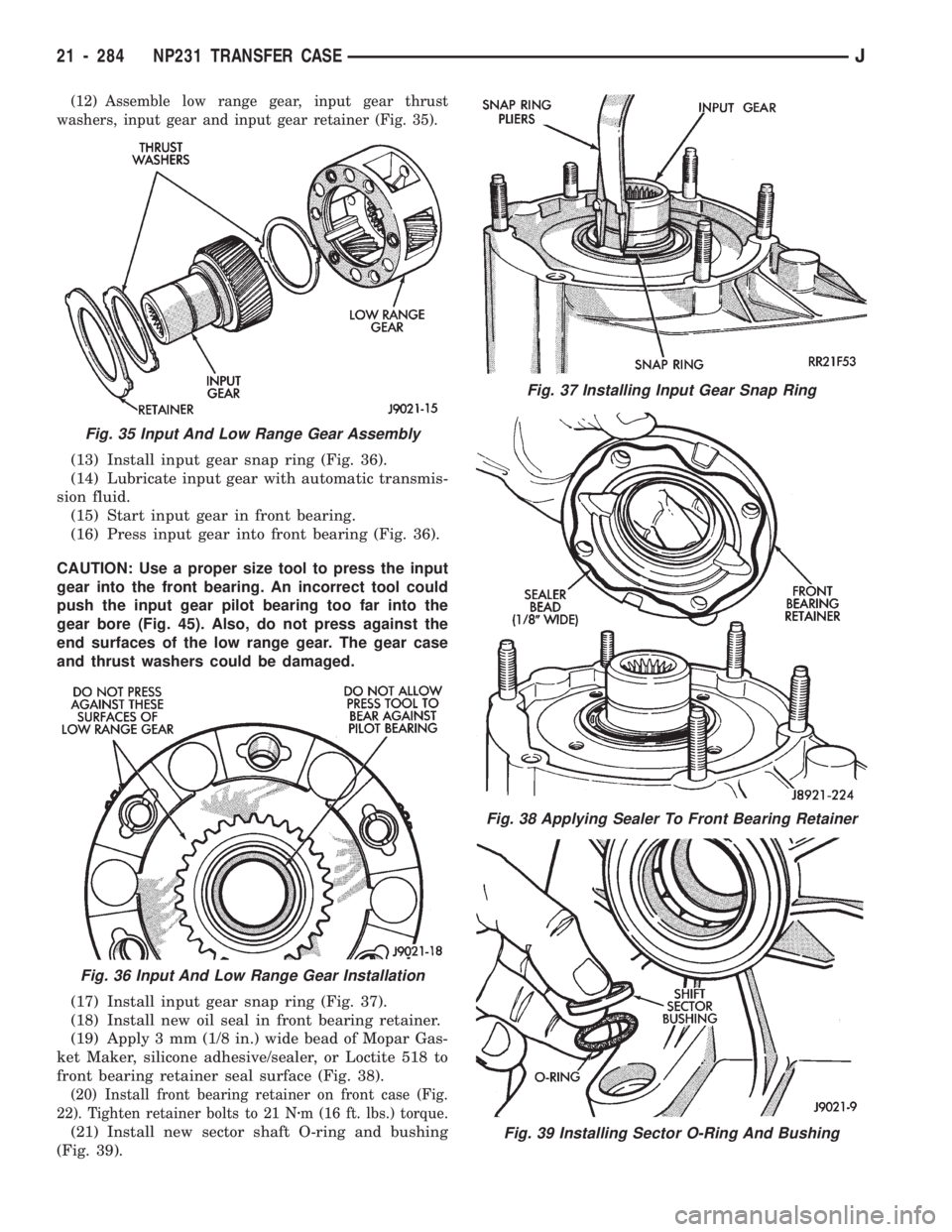

(2) Remove front output shaft seal from front case.

(3) Remove front output shaft bearing snap ring

(Fig. 29).

(4) Tap old front output shaft bearing out of front

case with plastic mallet. Install new bearing with

Tool Handle C-4171 and Installer Tool 5064 (Fig. 30).

(5) Secure front output shaft bearing in front case

with new snap ring (Fig. 29).

(6) Install new front output shaft seal in front

case.

(7) Press input gear bearing from the front case

with Tool Handle C-4171 and Installer Tool C-4210

(Fig. 31). Then turn front case over.

Fig. 25 Removing Input And Low Range Gear

Assembly

Fig. 26 Removing Low Range Gear Snap Ring

Fig. 27 Input And Low Range Gear Components

Fig. 28 Low Range Annulus Gear Location

21 - 282 NP231 TRANSFER CASEJ

Page 1394 of 1784

(8) Install snap ring on new input gear bearing

and start bearing in case.

(9) Carefully press input gear bearing into case un-

til bearing snap ring seats against case (Fig. 32).

(10) Remove mainshaft pilot bearing from input

gear with Tool MD-998346 and two suitable size open

end wrenches (Fig. 33).(11) Install new pilot bearing in input gear with

shop press, Tool Handle C-4171 and Installer 5065

(Fig. 34).

Fig. 29 Removing/Installing Front Output Shaft

Bearing Snap Ring

Fig. 30 Installing Output Shaft Front Bearing

Fig. 31 Removing Input Gear Bearing

Fig. 32 Input Gear Bearing Installation

Fig. 33 Removing Mainshaft Pilot Bearing From

Input Gear

Fig. 34 Installing Mainshaft Pilot Bearing In Input

Gear

JNP231 TRANSFER CASE 21 - 283

Page 1395 of 1784

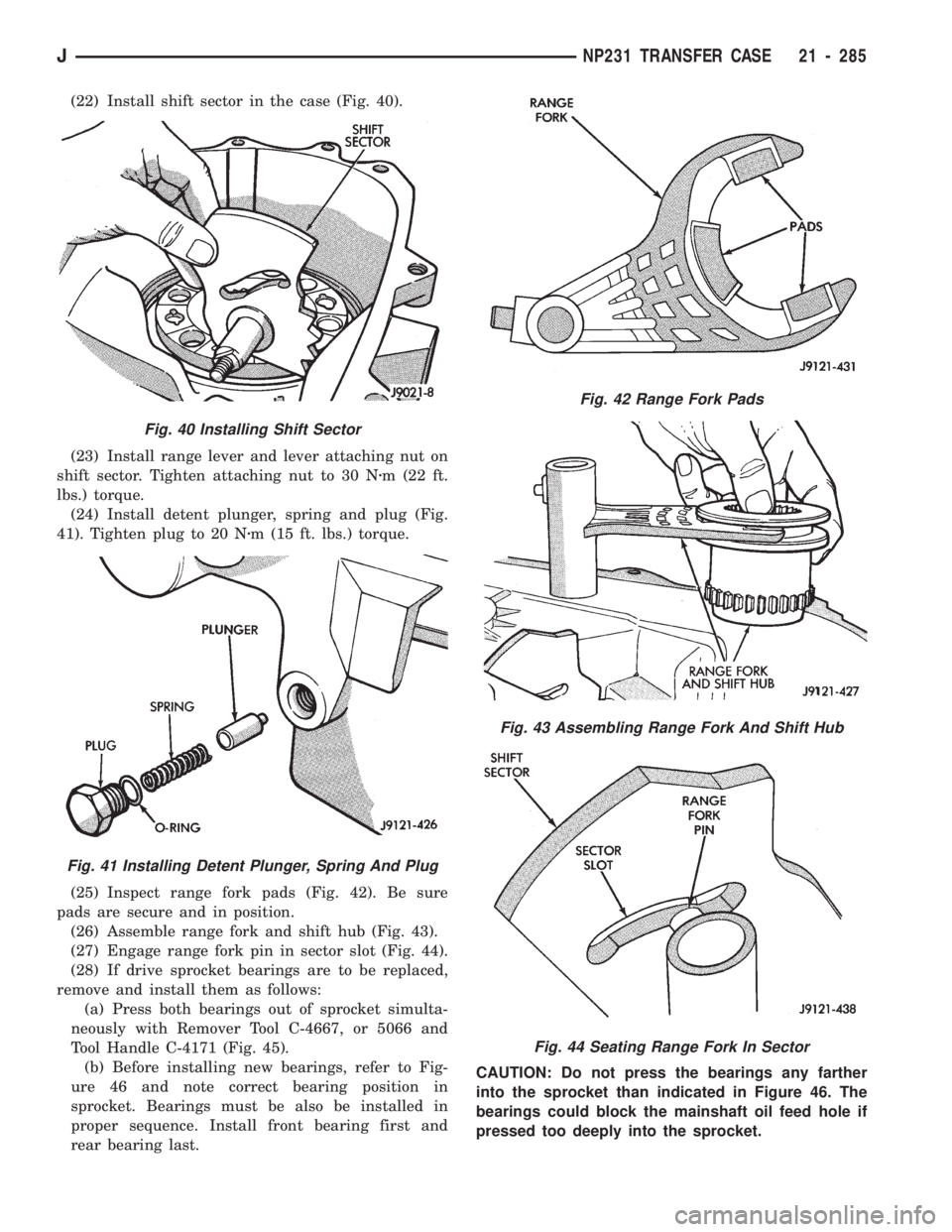

(12) Assemble low range gear, input gear thrust

washers, input gear and input gear retainer (Fig. 35).

(13) Install input gear snap ring (Fig. 36).

(14) Lubricate input gear with automatic transmis-

sion fluid.

(15) Start input gear in front bearing.

(16) Press input gear into front bearing (Fig. 36).

CAUTION: Use a proper size tool to press the input

gear into the front bearing. An incorrect tool could

push the input gear pilot bearing too far into the

gear bore (Fig. 45). Also, do not press against the

end surfaces of the low range gear. The gear case

and thrust washers could be damaged.

(17) Install input gear snap ring (Fig. 37).

(18) Install new oil seal in front bearing retainer.

(19) Apply 3 mm (1/8 in.) wide bead of Mopar Gas-

ket Maker, silicone adhesive/sealer, or Loctite 518 to

front bearing retainer seal surface (Fig. 38).

(20) Install front bearing retainer on front case (Fig.

22). Tighten retainer bolts to 21 Nzm (16 ft. lbs.) torque.

(21) Install new sector shaft O-ring and bushing

(Fig. 39).

Fig. 37 Installing Input Gear Snap Ring

Fig. 38 Applying Sealer To Front Bearing Retainer

Fig. 39 Installing Sector O-Ring And Bushing

Fig. 35 Input And Low Range Gear Assembly

Fig. 36 Input And Low Range Gear Installation

21 - 284 NP231 TRANSFER CASEJ

Page 1396 of 1784

(22) Install shift sector in the case (Fig. 40).

(23) Install range lever and lever attaching nut on

shift sector. Tighten attaching nut to 30 Nzm (22 ft.

lbs.) torque.

(24) Install detent plunger, spring and plug (Fig.

41). Tighten plug to 20 Nzm (15 ft. lbs.) torque.

(25) Inspect range fork pads (Fig. 42). Be sure

pads are secure and in position.

(26) Assemble range fork and shift hub (Fig. 43).

(27) Engage range fork pin in sector slot (Fig. 44).

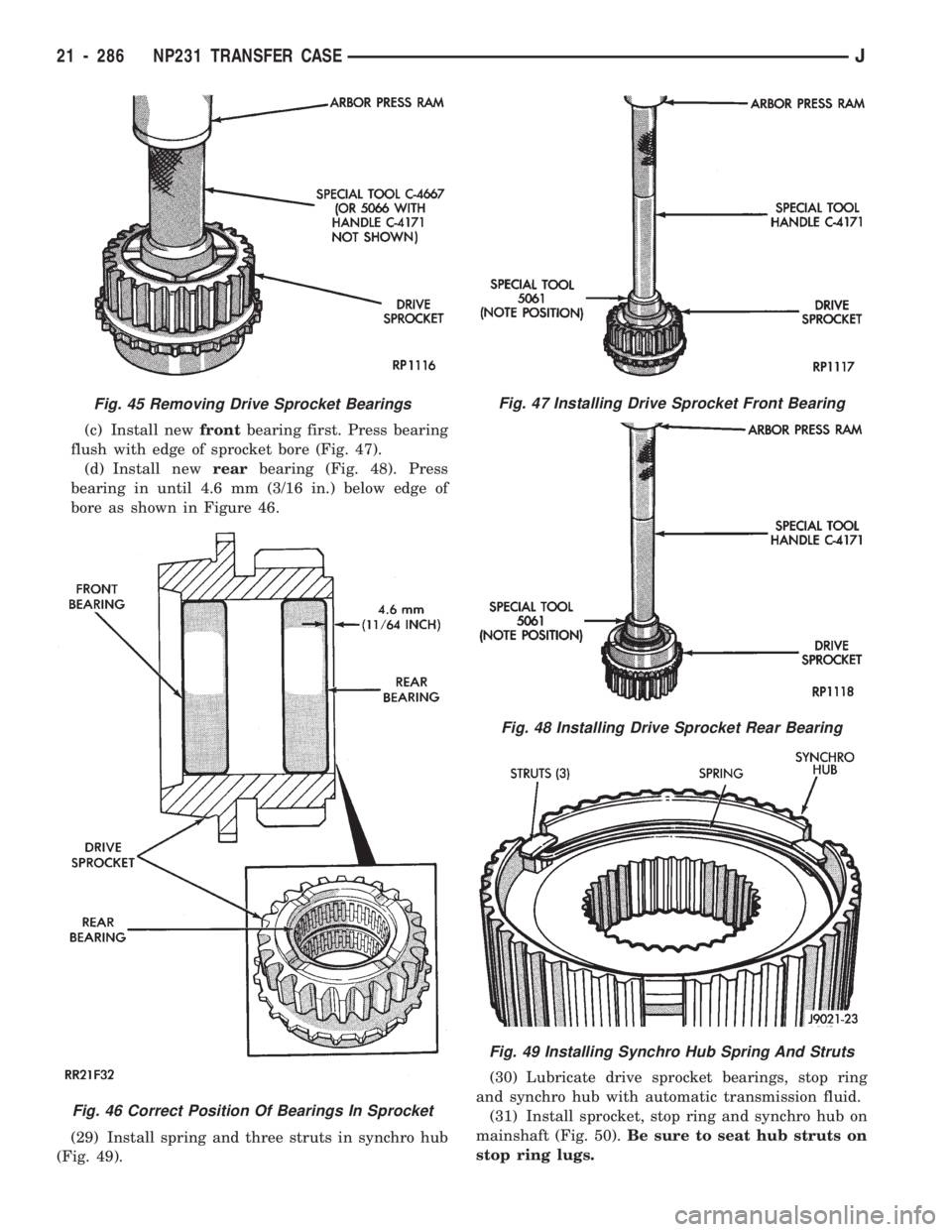

(28) If drive sprocket bearings are to be replaced,

remove and install them as follows:

(a) Press both bearings out of sprocket simulta-

neously with Remover Tool C-4667, or 5066 and

Tool Handle C-4171 (Fig. 45).

(b) Before installing new bearings, refer to Fig-

ure 46 and note correct bearing position in

sprocket. Bearings must be also be installed in

proper sequence. Install front bearing first and

rear bearing last.CAUTION: Do not press the bearings any farther

into the sprocket than indicated in Figure 46. The

bearings could block the mainshaft oil feed hole if

pressed too deeply into the sprocket.

Fig. 42 Range Fork Pads

Fig. 43 Assembling Range Fork And Shift Hub

Fig. 44 Seating Range Fork In Sector

Fig. 40 Installing Shift Sector

Fig. 41 Installing Detent Plunger, Spring And Plug

JNP231 TRANSFER CASE 21 - 285

Page 1397 of 1784

(c) Install newfrontbearing first. Press bearing

flush with edge of sprocket bore (Fig. 47).

(d) Install newrearbearing (Fig. 48). Press

bearing in until 4.6 mm (3/16 in.) below edge of

bore as shown in Figure 46.

(29) Install spring and three struts in synchro hub

(Fig. 49).(30) Lubricate drive sprocket bearings, stop ring

and synchro hub with automatic transmission fluid.

(31) Install sprocket, stop ring and synchro hub on

mainshaft (Fig. 50).Be sure to seat hub struts on

stop ring lugs.

Fig. 45 Removing Drive Sprocket Bearings

Fig. 46 Correct Position Of Bearings In Sprocket

Fig. 47 Installing Drive Sprocket Front Bearing

Fig. 48 Installing Drive Sprocket Rear Bearing

Fig. 49 Installing Synchro Hub Spring And Struts

21 - 286 NP231 TRANSFER CASEJ

Page 1398 of 1784

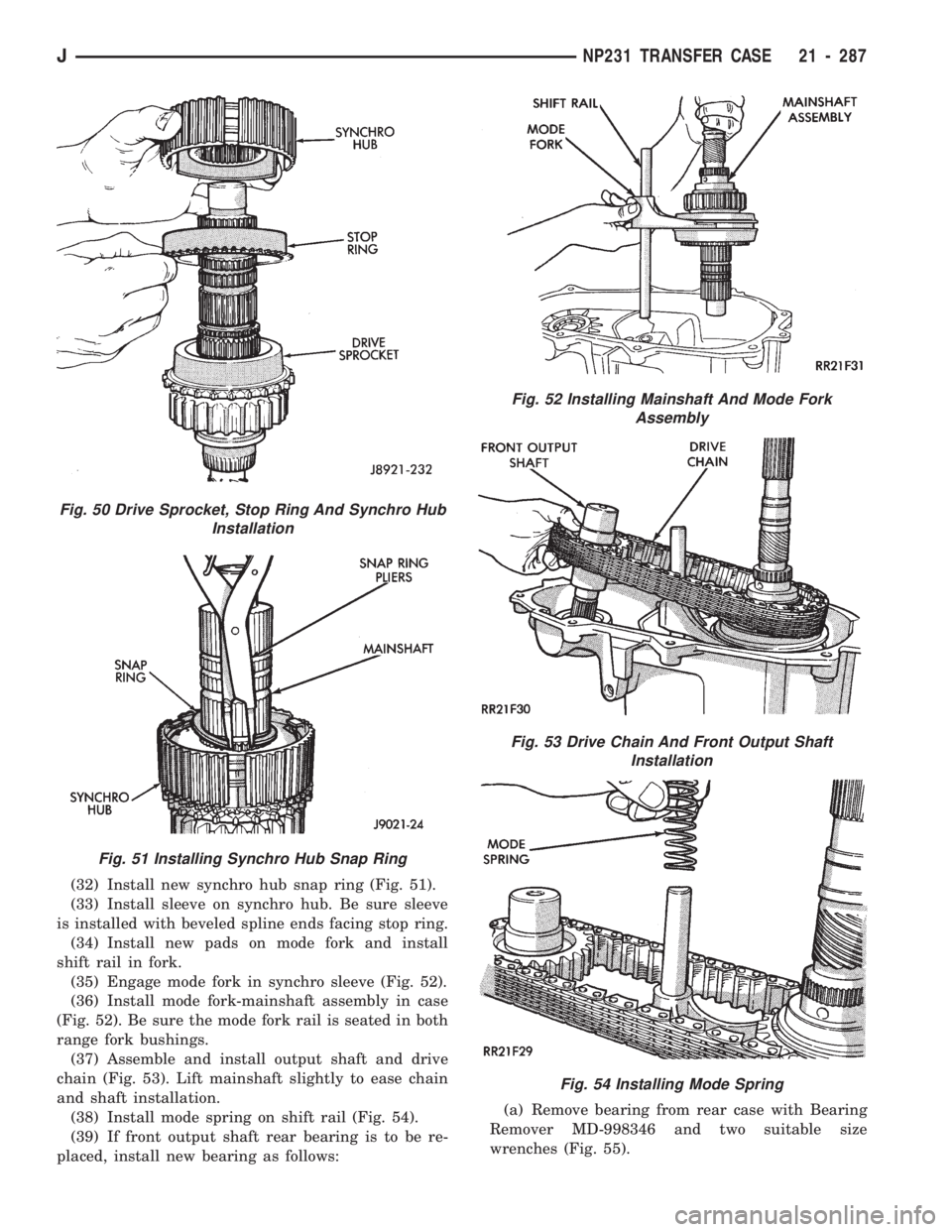

(32) Install new synchro hub snap ring (Fig. 51).

(33) Install sleeve on synchro hub. Be sure sleeve

is installed with beveled spline ends facing stop ring.

(34) Install new pads on mode fork and install

shift rail in fork.

(35) Engage mode fork in synchro sleeve (Fig. 52).

(36) Install mode fork-mainshaft assembly in case

(Fig. 52). Be sure the mode fork rail is seated in both

range fork bushings.

(37) Assemble and install output shaft and drive

chain (Fig. 53). Lift mainshaft slightly to ease chain

and shaft installation.

(38) Install mode spring on shift rail (Fig. 54).

(39) If front output shaft rear bearing is to be re-

placed, install new bearing as follows:(a) Remove bearing from rear case with Bearing

Remover MD-998346 and two suitable size

wrenches (Fig. 55).

Fig. 51 Installing Synchro Hub Snap Ring

Fig. 50 Drive Sprocket, Stop Ring And Synchro Hub

Installation

Fig. 52 Installing Mainshaft And Mode Fork

Assembly

Fig. 53 Drive Chain And Front Output Shaft

Installation

Fig. 54 Installing Mode Spring

JNP231 TRANSFER CASE 21 - 287