lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 370 of 2198

DIAGNOSIS

GAUGES

If an individual gauge is inoperative, see the diag-

nostic procedure under the heading for that gauge. If

more than one gauge in the main cluster or gauge

package cluster is inoperative, perform the following:

(1) Check fuse 9 in the fuseblock module. If OK, go

to next step. If not OK, replace fuse.

(2) Check for battery voltage at fuse 9 with igni-

tion switch in ON position. If OK, go to next step. If

not OK, repair open in circuit from ignition switch

and/or refer to Group 8D - Ignition Systems for test-

ing of ignition switch.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove the affected instrument clus-

ter bezel and cluster assembly. Disconnect the cluster

connector.

(4) Connect battery negative cable. Turn ignition

switch to ON. If problem is in main cluster, check for

battery voltage at cavity 3 and cavity 19 of main

cluster connector. If problem is in gauge package

cluster, check for battery voltage at cavity 2 and cav-

ity 12 of gauge package cluster connector. If OK, go

to next step. If not OK, repair open in circuit from

fuse 9 as required.

(5) Turn ignition switch to OFF. Disconnect battery

negative cable. Probe cavities 14 and 20 of main clus-

ter connector, or cavities 1 and 13 of gauge package

cluster connector. Check for continuity to a good

ground. There should be continuity. If OK, replace

the cluster printed circuit. If not OK, repair open in

circuit as required.

COOLANT TEMPERATURE GAUGE

The diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-

lated to gauge accuracy, be certain to confirm that

problem is with gauge and not with cooling system

performance. Actual engine coolant temperature

should be checked with a test gauge or thermometer

and compared to gauge readings before you proceed

with gauge diagnosis. Refer to Group 7 - Cooling Sys-

tem for more information.

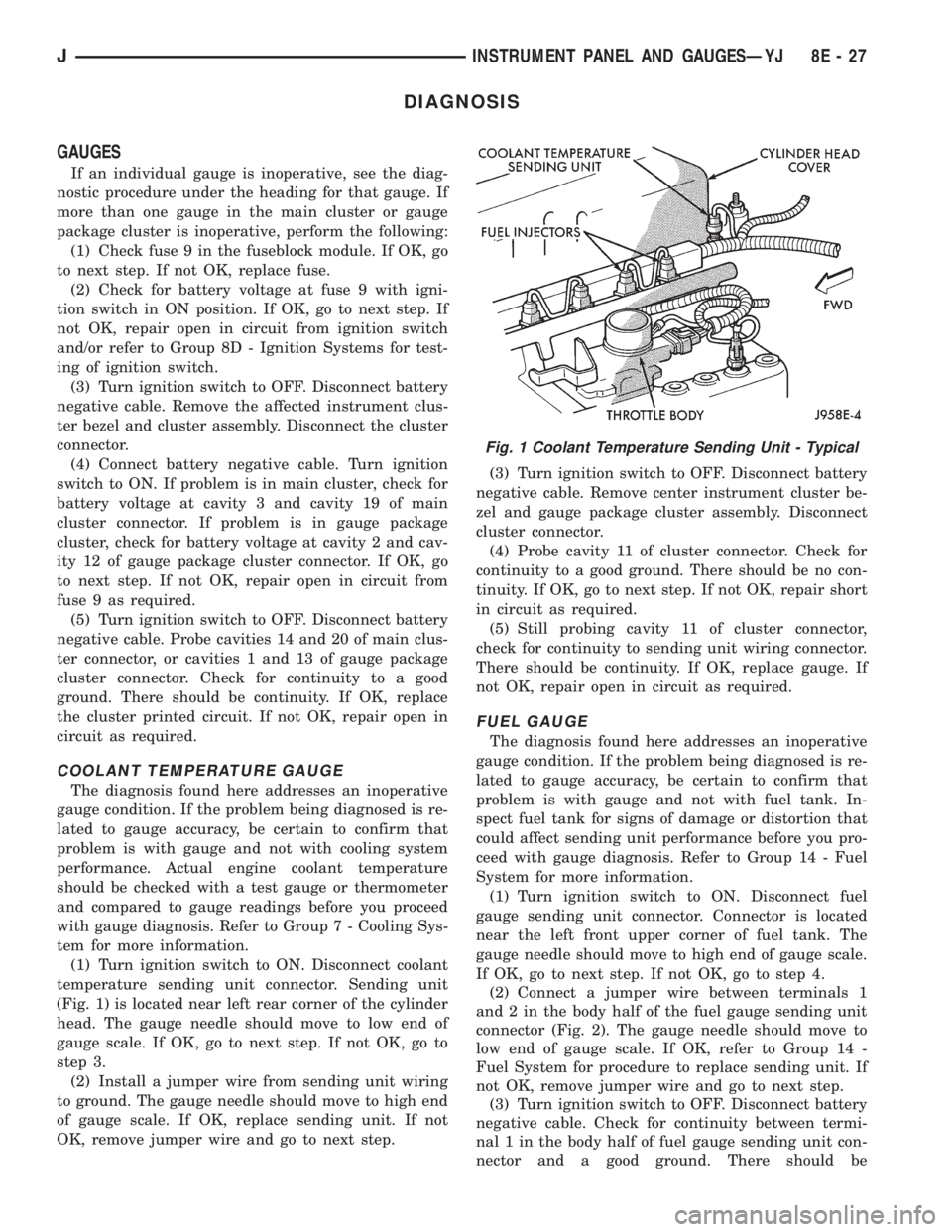

(1) Turn ignition switch to ON. Disconnect coolant

temperature sending unit connector. Sending unit

(Fig. 1) is located near left rear corner of the cylinder

head. The gauge needle should move to low end of

gauge scale. If OK, go to next step. If not OK, go to

step 3.

(2) Install a jumper wire from sending unit wiring

to ground. The gauge needle should move to high end

of gauge scale. If OK, replace sending unit. If not

OK, remove jumper wire and go to next step.(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove center instrument cluster be-

zel and gauge package cluster assembly. Disconnect

cluster connector.

(4) Probe cavity 11 of cluster connector. Check for

continuity to a good ground. There should be no con-

tinuity. If OK, go to next step. If not OK, repair short

in circuit as required.

(5) Still probing cavity 11 of cluster connector,

check for continuity to sending unit wiring connector.

There should be continuity. If OK, replace gauge. If

not OK, repair open in circuit as required.

FUEL GAUGE

The diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-

lated to gauge accuracy, be certain to confirm that

problem is with gauge and not with fuel tank. In-

spect fuel tank for signs of damage or distortion that

could affect sending unit performance before you pro-

ceed with gauge diagnosis. Refer to Group 14 - Fuel

System for more information.

(1) Turn ignition switch to ON. Disconnect fuel

gauge sending unit connector. Connector is located

near the left front upper corner of fuel tank. The

gauge needle should move to high end of gauge scale.

If OK, go to next step. If not OK, go to step 4.

(2) Connect a jumper wire between terminals 1

and 2 in the body half of the fuel gauge sending unit

connector (Fig. 2). The gauge needle should move to

low end of gauge scale. If OK, refer to Group 14 -

Fuel System for procedure to replace sending unit. If

not OK, remove jumper wire and go to next step.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Check for continuity between termi-

nal 1 in the body half of fuel gauge sending unit con-

nector and a good ground. There should be

Fig. 1 Coolant Temperature Sending Unit - Typical

JINSTRUMENT PANEL AND GAUGESÐYJ 8E - 27

Page 371 of 2198

continuity. If OK, go to next step. If not OK, repair

circuit to ground as required.

(4) Remove center instrument cluster bezel and

gauge package cluster assembly. Disconnect cluster

connector.

(5) Probe cavity 6 of cluster connector. Check for

continuity to a good ground. There should be no con-

tinuity. If OK, go to next step. If not OK, repair short

circuit as required.

(6) Still probing cavity 6 of cluster connector, check

for continuity to cavity 2 of sending unit wiring body

half connector. There should be continuity. If OK, re-

place gauge. If not OK, repair open circuit as re-

quired.

OIL PRESSURE GAUGE

The diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-

lated to gauge accuracy, be certain to confirm that

problem is with gauge and not with engine oiling sys-

tem performance. Actual engine oil pressure should

be checked with a test gauge and compared to gauge

readings before you proceed with gauge diagnosis.

Refer to Group 9 - Engines for more information.

(1) Turn ignition switch to ON. Disconnect oil pres-

sure sending unit connector. The sending unit (Fig. 3)

is located on right side of engine block. On 2.5L en-

gine, it is just forward of ignition distributor and just

to the rear of generator mounting bracket. On 4.0L

engine, it is just to the rear of ignition distributor

and above oil filter adapter. The gauge needle should

move to high end of gauge scale. If OK, go to next

step. If not OK, go to step 3.

(2) Install a jumper wire from sending unit wiring

to ground. The gauge needle should move to low end

of gauge scale. If OK, replace sending unit. If not

OK, remove jumper wire and go to next step.(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove center instrument cluster be-

zel and gauge package cluster assembly. Disconnect

cluster connector.

(4) Probe cavity 9 of cluster connector. Check for

continuity to a good ground. There should be no con-

tinuity. If OK, go to next step. If not OK, repair short

circuit as required.

(5) Still probing cavity 9 of cluster connector, check

for continuity to sending unit wire connector. There

should be continuity. If OK, replace gauge. If not OK,

repair open circuit as required.

SPEEDOMETER/ODOMETER

The diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-

lated to gauge accuracy, be certain to confirm that

problem is with gauge and not with incorrect speed-

ometer pinion, axle ratio or tire size. Refer to Group

21 - Transmission and Transfer Case for more infor-

mation.

(1) Perform vehicle speed sensor test as described

in the appropriate Powertrain Diagnostic Procedures

manual. If OK, go to next step. If not OK, replace ve-

hicle speed sensor.

(2) Disconnect battery negative cable. Unplug vehi-

cle speed sensor, PCM, and daytime running lamp

module connectors. Remove left instrument cluster

bezel and main cluster assembly. Disconnect cluster

connector.

(3) Probe cavity 13 of cluster connector. Check for

continuity to a good ground. There should be no con-

tinuity. If OK, go to next step. If not OK, repair short

circuit as required.

(4) Still probing cavity 13 of cluster connector,

check for continuity to cavity 1 of vehicle speed sen-

sor connector (Fig. 4). There should be continuity. If

OK, replace speedometer/odometer. If not OK, repair

open circuit as required.

Fig. 2 Fuel Gauge Sending Unit ConnectorFig. 3 Oil Pressure Sending Unit - Typical

8E - 28 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 375 of 2198

INDICATOR LAMPS

If an individual indicator lamp is inoperative, see

the diagnostic procedure under the heading for that

lamp. If more than one indicator lamp or a combina-

tion of lamps and gauges in the main cluster or the

gauge package cluster is inoperative, see Gauges in

this section for diagnosis.

ANTI-LOCK BRAKE SYSTEM LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the ABS lamp stays on with the ig-

nition switch in the ON position, or comes on and

stays on while driving, refer to Group 5 - Brakes for

diagnosis. If no ABS problem is found, the following

procedure will help locate a short or open in the ABS

lamp circuit.

(1) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Disconnect ABS control module connector.

(2) Install a jumper wire between cavity 6 of clus-

ter connector and a good ground. Connect battery

negative cable. Turn ignition switch to ON. Lamp

should light. If OK, remove jumper wire and go to

next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable and unplug cluster connector. Check

for continuity between cavity 6 of cluster connector

and a good ground. There should be no continuity. If

OK, go to next step. If not OK, repair short circuit as

required.

(4) Check continuity between cavity 6 of cluster

connector and cavity 52 of ABS control module con-

nector (Fig. 6). There should be continuity. If OK, re-

fer to Group 5 - Brakes for diagnosis of ABS control

module. If not OK, repair open circuit as required.

BRAKE WARNING LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the brake warning lamp stays on

with the ignition switch in the ON position and the

parking brake released, refer to Group 5 - Brakes for

diagnosis. If no service brake or parking brake prob-

lem is found, the following procedure will help locate

a short circuit or faulty switch.

(1) Unplug parking brake switch connector. Turn

ignition switch to START position. Lamp should

light. Release ignition switch to ON position. Lamp

should go off. If OK, go to step 10. If not OK, go to

next step.

(2) Unplug brake warning switch connector. Install

a jumper wire between two cavities of connector.

Turn ignition switch to START. Lamp should light.

Remove jumper wire and lamp should go off. If OK,

replace brake warning switch. If not OK, remove

jumper wire and go to next step.

(3) Turn ignition switch to ON position. Install a

jumper wire between brake warning switch connectorcavity for circuit G9 and a good ground. Lamp should

light. If OK, go to step 5. If not OK, go to next step.

(4) Turn ignition switch to OFF. Remove jumper

wire and disconnect battery negative cable. Remove

left instrument cluster bezel and main cluster. Install

a jumper wire between cavity 1 of cluster connector

and a good ground. Connect battery negative cable

and turn ignition switch to ON. Lamp should light. If

OK, repair open in circuit to brake warning switch. If

not OK, replace bulb.

(5) Turn ignition switch to OFF and remove

jumper wire. Disconnect battery negative cable.

Check for continuity between brake warning switch

connector cavity for circuit G11 and a good ground

with ignition switch in START position. There should

be continuity. If not OK, go to next step.

(6) Turn ignition switch to OFF and remove

jumper wire. Unplug ignition switch connectors.

Check for continuity between ignition switch connec-

tor cavity for G11 circuit and a good ground. There

should be no continuity. If OK, go to next step. If not

OK, repair short circuit between ignition switch and

brake warning switch connectors as required.

(7) Check for continuity between ignition switch

connector cavity for G11 circuit and brake warning

switch connector cavity for G11 circuit. There should

be continuity. If OK, go to next step. If not OK, re-

pair open circuit as required.

(8) Check for continuity between metal steering

column jacket and a good ground. There should be

continuity. If OK, go to next step. If not OK, refer to

Group 19 - Steering to check steering column ground

clip installation.

Fig. 6 ABS Control Module Connector

8E - 32 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 376 of 2198

(9) Turn ignition switch to START position and

hold there. Check for continuity between terminal for

circuit G11 of ignition switch and a good ground.

There should be continuity. If not OK, replace igni-

tion switch.

(10) Unplug brake warning switch connector.

Check for continuity between parking brake switch

connector and a good ground. There should be no

continuity. If OK, go to next step. If not OK, repair

short circuit as required.

(11) Check for continuity between parking brake

switch connector and brake warning switch connector

cavity for circuit G11. There should be continuity. If

OK, replace parking brake switch. If not OK, repair

open circuit to brake warning switch as required.

FOUR-WHEEL DRIVE INDICATOR LAMP

(1) Apply parking brake, start engine, vehicle in

4WD Lock or 4WD.

(2) Unplug switch and touch harness side of wire

to ground. Lamp should light. If OK, check switch

operation, replace if bad. If bulb is OK, repair open

to indicator.

HEADLAMP HIGH BEAM INDICATOR LAMP

(1) Check that headlamp high beams are func-

tional. If OK, go to next step. If not OK, refer to

Group 8L - Lamps for diagnosis of headlamp system.

(2) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Unplug cluster connector. Connect battery negative

cable. Turn headlamps on and select high beam.

Check for battery voltage at cavity 17 of cluster con-

nector. If OK, replace indicator bulb. If not OK, re-

pair circuit to headlamp dimmer switch as required.

MALFUNCTION INDICATOR LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the lamp comes on and stays on

with engine running, refer to Group 14 - Fuel System

for diagnosis. If no fuel or emission system problem

is found, the following procedure will help locate a

short or open in the lamp circuit.

(1) Disconnect battery negative cable. Unplug PCM

connector. Install a jumper wire from cavity 32 of

PCM connector (Fig. 5) to a good ground. Connect

battery negative cable. Turn ignition switch to ON.

Lamp should light. Remove jumper wire and lamp

should go OFF. If OK, refer to Powertrain Diagnostic

Procedures to check PCM. If not OK, go to next step.

(2) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove left instrument cluster bezel

and main cluster assembly. Install a jumper wire

from cavity 2 of cluster connector to a good ground.

Connect battery negative cable. Turn ignition switch

to ON. Lamp should light. If OK, go to next step. If

not OK, replace bulb.(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug cluster connector. Check for

continuity between cavity 2 of cluster connector and

a good ground. There should be no continuity. If OK,

go to next step. If not OK, repair short circuit to

PCM as required.

(4) Check continuity between cavity 2 of cluster

connector and cavity 32 of PCM connector. There

should be continuity. If not OK, repair open circuit to

PCM as required.

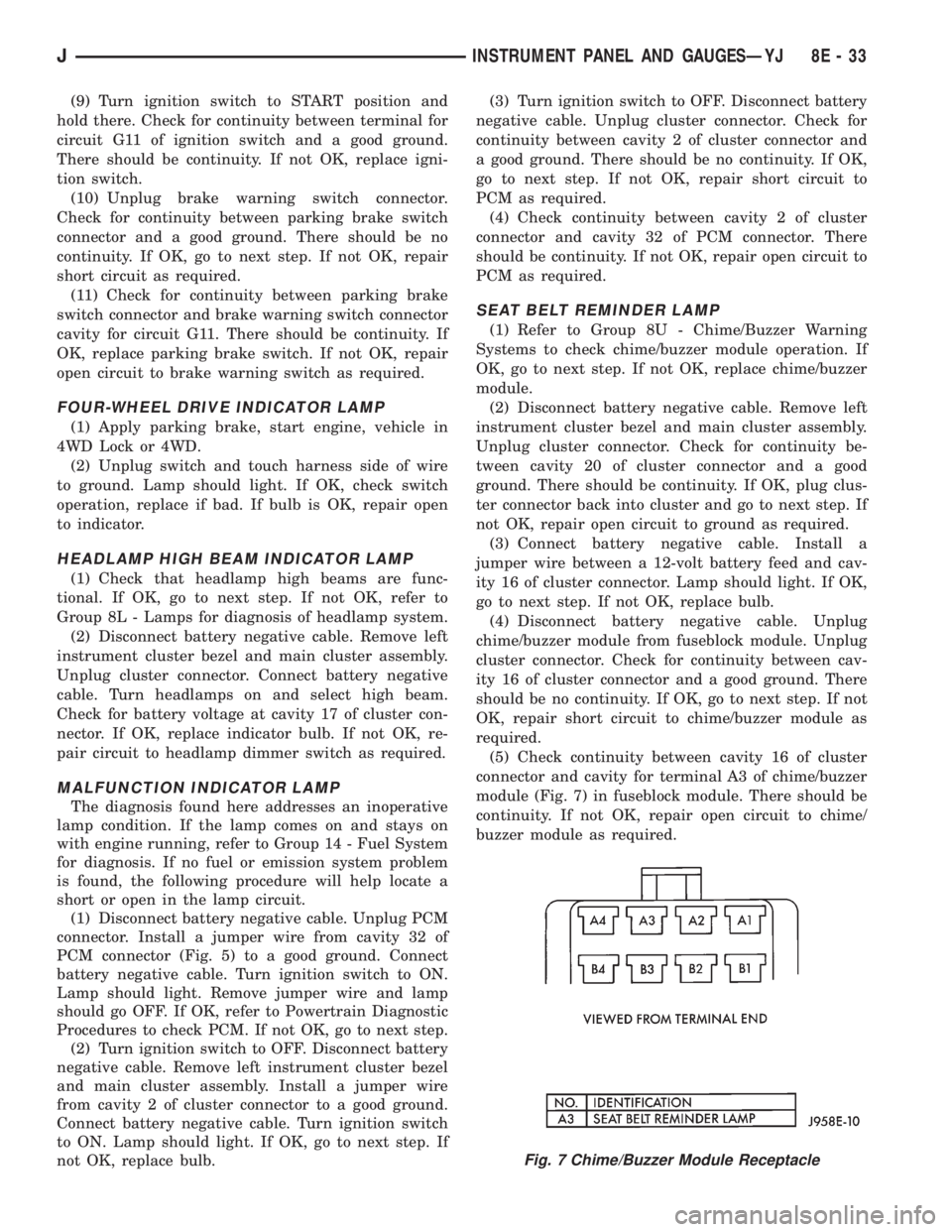

SEAT BELT REMINDER LAMP

(1) Refer to Group 8U - Chime/Buzzer Warning

Systems to check chime/buzzer module operation. If

OK, go to next step. If not OK, replace chime/buzzer

module.

(2) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Unplug cluster connector. Check for continuity be-

tween cavity 20 of cluster connector and a good

ground. There should be continuity. If OK, plug clus-

ter connector back into cluster and go to next step. If

not OK, repair open circuit to ground as required.

(3) Connect battery negative cable. Install a

jumper wire between a 12-volt battery feed and cav-

ity 16 of cluster connector. Lamp should light. If OK,

go to next step. If not OK, replace bulb.

(4) Disconnect battery negative cable. Unplug

chime/buzzer module from fuseblock module. Unplug

cluster connector. Check for continuity between cav-

ity 16 of cluster connector and a good ground. There

should be no continuity. If OK, go to next step. If not

OK, repair short circuit to chime/buzzer module as

required.

(5) Check continuity between cavity 16 of cluster

connector and cavity for terminal A3 of chime/buzzer

module (Fig. 7) in fuseblock module. There should be

continuity. If not OK, repair open circuit to chime/

buzzer module as required.

Fig. 7 Chime/Buzzer Module Receptacle

JINSTRUMENT PANEL AND GAUGESÐYJ 8E - 33

Page 377 of 2198

TURN SIGNAL INDICATOR LAMPS

(1) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Probe cavity 20 of cluster connector. Check for conti-

nuity to a good ground. There should be continuity. If

OK, go to next step. If not OK, repair open circuit to

ground.

(2) Connect battery negative cable. Install a

jumper wire from cavity 18 (left indicator) or cavity 7

(right indicator) of cluster connector to a 12-volt bat-

tery feed. Lamp should light. If OK, continue to next

step. If not OK, replace bulb.

(3) Disconnect battery negative cable. Check for

continuity between cavity 18 (left indicator) or cavity

7 (right indicator) of cluster connector and cavity H

(left front turn signal) or cavity J (right front turn

signal) of steering column wiring connector. There

should be continuity. If OK, refer to Group 8J - Turn

Signal and Hazard Warning Systems for further di-

agnosis. If not OK, repair open circuit as required.

UPSHIFT INDICATOR LAMP

(1) Disconnect battery negative cable. Unplug PCM

connector. Connect battery negative cable. Turn igni-

tion switch to ON. Install a jumper wire from cavity

54 of PCM connector (Fig. 5) to a good ground. Lamp

should light. Remove jumper from ground. Lamp

should go off. If OK, refer to Powertrain Diagnostic

Procedures manual to diagnose PCM. If not OK, turn

ignition switch to OFF and go to next step.

(2) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Install a jumper wire from cavity 5 of cluster connec-

tor to a good ground. Connect battery negative cable.

Turn ignition switch to ON. Lamp should light. If

OK, go to next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug cluster connector. Check for

continuity between cavity 5 of cluster connector and

a good ground. There should be no continuity. If OK,

go to next step. If not OK, repair short circuit as re-

quired.(4) Check for continuity between cavity 5 of cluster

connector and cavity 54 of PCM connector. There

should be continuity. If not OK, repair open circuit as

required.

CLUSTER ILLUMINATION LAMPS

(1) Check fuse 10 in fuseblock module. If OK, go to

next step. If not OK, replace fuse.

(2) Turn park lamps on at headlamp switch. Rotate

panel dimmer switch thumb-wheel to HI position,

just before interior lamps detent. Check for battery

voltage at fuse 10 in fuseblock module. Rotate panel

dimmer thumb-wheel towards LO position while ob-

serving test voltmeter. Reading should go from bat-

tery voltage to zero volts. If OK, go to next step. If

not OK, repair open circuit to headlamp switch or re-

fer to Group 8L - Lamps to diagnose headlamp

switch.

(3) Disconnect battery negative cable. Remove left

or center instrument cluster bezel and main or gauge

package cluster assembly. Unplug cluster connector.

Connect battery negative cable. Turn park lamps on

at headlamp switch. Rotate panel dimmer thumb-

wheel to HI position, just before interior lamps de-

tent. Check for battery voltage at cavity 21 of main

cluster connector, or cavity 7 of gauge package clus-

ter connector. If OK, go to next step. If not OK, re-

pair open circuit to fuse as required.

(4) Turn park lamps off. Disconnect battery nega-

tive cable. Remove fuse 10 from fuseblock module.

Probe cavity 21 of main cluster connector, or cavity 7

of gauge package cluster connector. Check for conti-

nuity to a good ground. There should be no continu-

ity. If OK, go to next step. If not OK, repair short

circuit as required.

(5) Probe cavity 20 of main cluster connector, or

cavities 1 and 13 of gauge package cluster connector.

Check for continuity to ground. There should be con-

tinuity. If not OK, repair open circuit as required.

8E - 34 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 388 of 2198

AUDIO SYSTEMS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 6

GENERAL INFORMATION

Following are general descriptions of major compo-

nents used in XJ (Cherokee)/YJ (Wrangler) audio sys-

tems. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams.

RADIOS

Radio options for the XJ and YJ models include an

AM/FM stereo or an AM/FM stereo/cassette receiver.

Both units are Electronically-Tuned Radios (ETR)

and include a clock function. For more information

on radio features, setting procedures, and control

functions refer to the owner's manual.

IN-LINE FUSE

Each radio receives fused battery feed when the ig-

nition switch is in the ON or ACCESSORY position.

There is an additional in-line fuse in the back of the

radio chassis. The in-line fuse (Fig. 1) will blow to

protect the vehicle electrical system in the event of

internal radio failure.

IGNITION-OFF DRAW FUSE

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed when the vehicle is

shipped from the factory. This fuse feeds various ac-

cessories that require current when the ignition

switch is in the OFF position, including the clock and

radio station preset memory functions. The fuse is re-

moved to prevent battery discharge during vehicle

storage.The IOD fuse should be checked if the radio station

preset memory or clock functions are erratic or inop-

erative. The IOD fuse is located in the Power Distri-

bution Center (PDC). Refer to underside of PDC

cover for IOD fuse identification.

RADIO ILLUMINATION RELAY

All radios are connected to a radio illumination re-

lay. The relay controls the source of battery feed for

radio/clock display illumination.

When the park and headlamp switch is in the OFF

position, the radio illumination relay remains de-en-

ergized. The radio/clock display receives full battery

voltage through the normally closed contacts of the

relay. This results in the radio/clock display being il-

luminated at full brightness for easier visibility in

daylight.

When the park and headlamp switch is in the ON

position, the radio illumination relay coil is ener-

gized. With the relay coil energized, the normally

closed contacts of the relay open, and the normally

open contacts of the relay close. This causes the ra-

dio/clock display to receive battery feed through the

instrument panel dimmer switch. The display illumi-

nation brightness can now be adjusted with other

panel lamps for night visibility.

SPEAKERS

Speaker system options include two, four or six (XJ

only) speaker locations. On XJ model two-speaker

systems, one speaker is located in each front door.

Four-speaker systems add one speaker at each end of

a rear-mounted overhead sound bar. The premium

six-speaker option upgrades all the speakers in the

above locations, and adds one tweeter at each end of

the lower instrument panel.

On YJ model two-speaker systems, one speaker is

located at each end of the instrument panel. Four-

speaker systems add one speaker at each end of a

rear-mounted overhead sound bar.

Fig. 1 In-Line Fuse

JAUDIO SYSTEMS 8F - 1

Page 389 of 2198

ANTENNA

All models use a fixed-length stainless steel rod-

type antenna mast, installed at the right front (fend-

er on XJ, cowl side on YJ) of the vehicle. The

antenna mast is connected to the center wire of the

coaxial antenna cable and is not grounded to any

part of the vehicle.

To eliminate static, the antenna base must have a

good ground. The coaxial antenna cable shield (the

outer wire mesh of the cable) is grounded to the an-

tenna base and the radio chassis.

The factory installed ETRs automatically compen-

sate for radio antenna trim. Therefore, no antenna

trimmer adjustment is required or possible when re-

placing the receiver or the antenna.

RADIO NOISE SUPPRESSION

Radio Frequency Interference (RFI) and Electro-

Magnetic Interference (EMI) noise suppression is ac-

complished primarily through circuitry internal to

the radio receivers. These internal suppression de-

vices are only serviced as a part of the radio receiver.External suppression devices that are serviceable

and should be checked in the case of RFI or EMI

noise complaints include the following:

²radio antenna base ground

²engine-to-body ground strap

²resistor-type spark plugs

²radio suppression-type secondary ignition wiring.

In addition, if the source of RFI or EMI noise is

identified as a component on the vehicle (i.e.:genera-

tor, blower motor, etc.), the ground path for that com-

ponent should be checked. If excessive resistance is

found in that circuit, repair as required before con-

sidering any component replacement.

Fleet vehicles are available with an extra-cost RFI-

suppressed Powertrain Control Module (PCM). This

unit reduces interference generated by the PCM on

some radio frequencies used in two-way radio com-

munications. However, this unit will not resolve com-

plaints of RFI in the commercial AM or FM radio

frequency ranges.

DIAGNOSIS

RADIO

CAUTION: Do not operate the radio with speaker

leads detached since damage to the transistors

may result.

(1) Check fuse 2 in fuseblock module and fuse in

back of radio chassis. If OK, go to next step. If not

OK, replace fuse.

(2) Turn ignition switch to ON position. Check for

battery voltage at fuse 2. If OK, go to next step. If

not OK, repair circuit to ignition switch as required.

(3) Turn ignition switch to OFF position. Discon-

nect battery negative cable. Remove instrument clus-

ter bezel. Remove radio, but do not unplug any

connections. Check for continuity between the radio

chassis and a good ground. There should be continu-

ity. If OK, go to next step. If not OK, repair radio

ground circuit as required.

(4) Connect battery negative cable. Turn ignition

switch to ON position. See Radio Connections chart.

Check for battery voltage at cavity 3 of radio connec-

tor. If OK, go to next step. If not OK, repair circuit to

fuse 2 as required.

(5) Turn ignition switch to OFF position. Check for

battery voltage at cavity 4 of radio connector. If OK,

replace radio. If not OK, repair circuit to IOD fuse in

PDC as required.

SPEAKERS

CAUTION: Do not operate the radio with speaker

leads detached since damage to the transistors

may result.

(1) Turn radio on and adjust balance and fader

controls to check performance of each individual

speaker. Note the speaker locations that are not per-

forming correctly. Go to next step.

(2) Turn radio off. Disconnect battery negative ca-

ble. Remove instrument cluster bezel and remove ra-

dio. See Radio Connections chart. Check both the

speaker feed and return cavities at radio for continu-

ity to a good ground. There should be no continuity.

If OK, go to next step. If not OK, repair wiring cir-

cuit as required.

(3) Check resistance between speaker feed and re-

turn cavities. Meter should read between 3 and 8

ohms (speaker impedance). If OK, see diagnosis for

Radio. If not OK, go to next step.

(4) Unplug speaker wiring connector. Check for

continuity between speaker feed cavity at radio and

at speaker. Repeat check between speaker return

cavity at radio and at speaker. If OK, replace

speaker. If not OK, repair wiring circuit as required.

8F - 2 AUDIO SYSTEMSJ

Page 391 of 2198

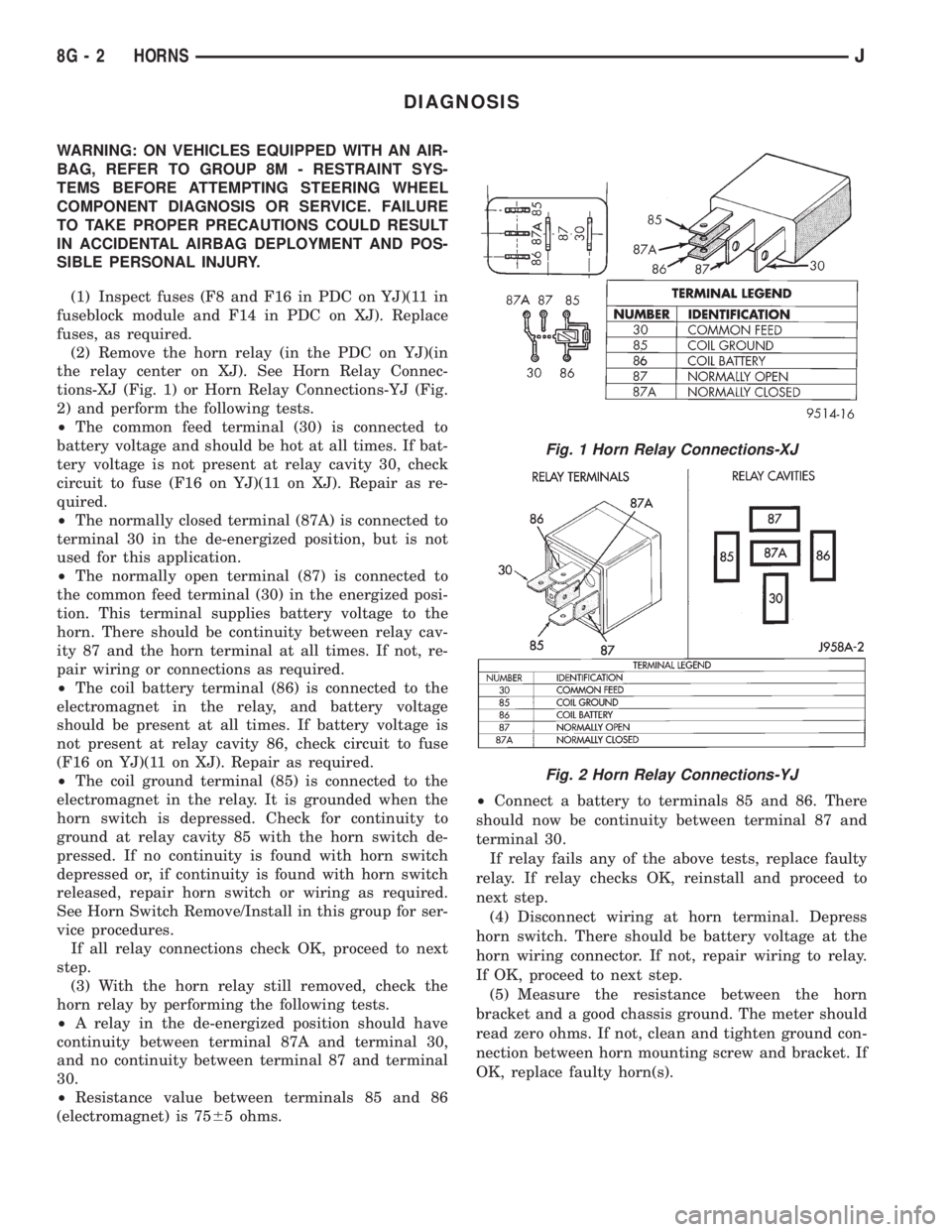

RADIO ILLUMINATION RELAY

If the relay fails any one of Relay Tests, it is faulty

and should be replaced. If the relay passes the Relay

Tests, proceed to the Relay Circuit Tests.

On XJ models, the radio illumination relay is lo-

cated in the relay center (Fig. 2), which is fastened to

the lower instrument panel reinforcement behind the

lower instrument panel near the steering column. On

YJ models, the relay is taped to the instrument panel

wiring harness above and to the right of the radio,

near the glove box.

RELAY TESTS

Remove relay to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30.(2) Resistance value between terminals 85 and 86

(electromagnet) is 7565 ohms.

(3) Connect a battery to terminals 85 and 86. There

should now be continuity between terminals 30 and 87,

and no continuity between terminals 87A and 30.

RELAY CIRCUIT TESTS

With relay still removed, perform the following

tests:

(1) The common feed terminal (30) is connected to

the radio display feed circuit. There should be conti-

nuity between cavity for relay terminal 30 and clock/

radio display feed cavity of radio connector at all

times. If not, repair circuit as required.

(2) The normally closed terminal (87A) is connected

to terminal 30 in the de-energized position. This circuit

provides ignition-switched battery voltage to the radio

display when the headlamp switch is off. There should

be battery voltage present at cavity for relay terminal

87A with the ignition switch in the ON position. If not,

repair circuit to ignition switch as required.

(3) The normally open terminal (87) is connected to

terminal 30 in the energized position. This circuit

provides instrument panel dimmer controlled feed to

the radio display when the headlamp switch is on.

There should be voltage present at cavity for relay

terminal 87 when the headlamp switch is on. Also,

the voltage reading should vary as the panel dimmer

switch is rotated. If not, repair circuit or panel dim-

mer switch as required.

(4) The coil battery terminal (86) connected to the

electromagnet in the relay. Check as follows:

(a) On YJ models, it is energized when the head-

lamp switch is on. There should be battery voltage at

cavity for relay terminal 86 with the headlamp switch

on. If not, repair circuit to headlamp switch as re-

quired.

(b) On XJ models, it is grounded at all times.

There should be continuity to ground at cavity for

relay terminal 86 at all times. If not, repair circuit

to ground as required.

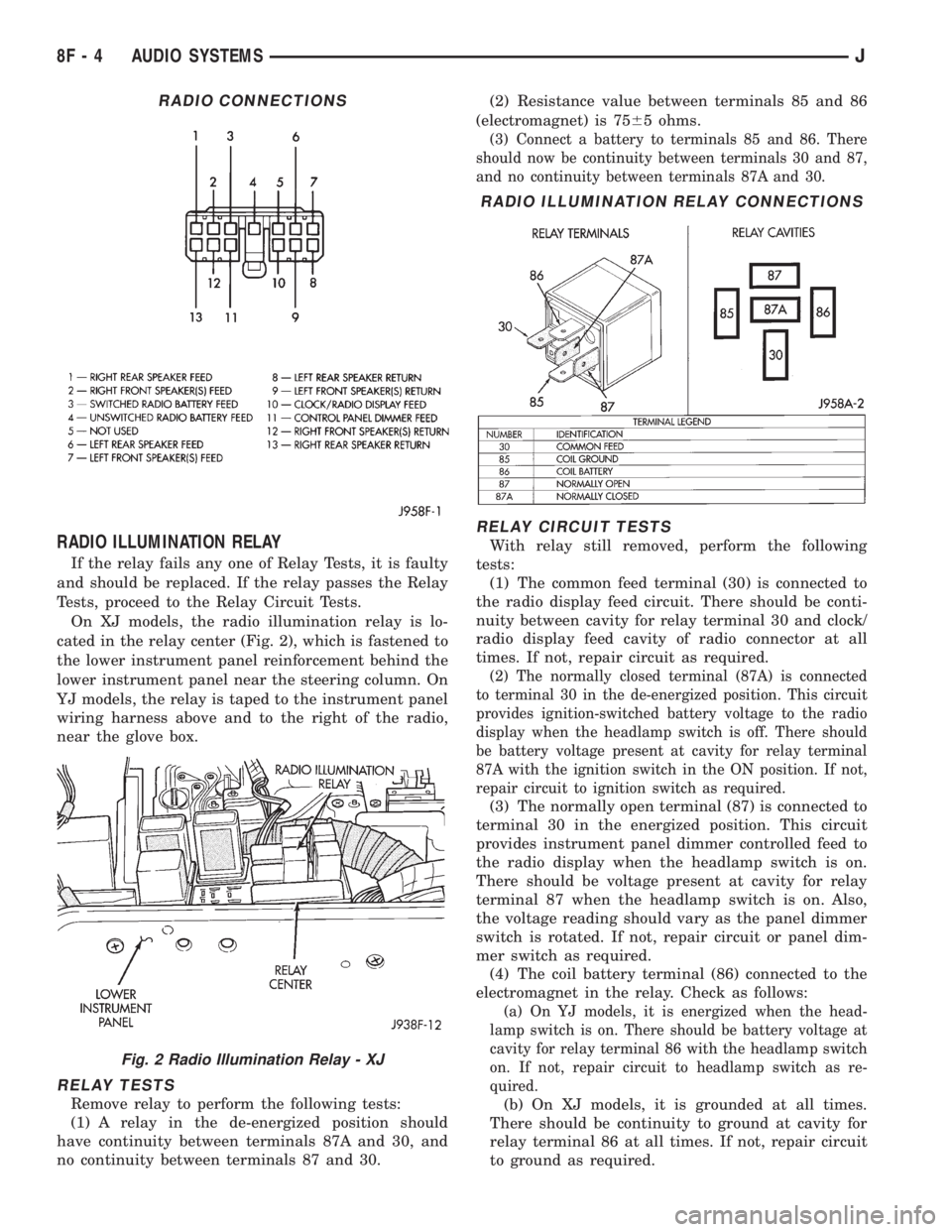

RADIO CONNECTIONS

Fig. 2 Radio Illumination Relay - XJ

RADIO ILLUMINATION RELAY CONNECTIONS

8F - 4 AUDIO SYSTEMSJ

Page 399 of 2198

DIAGNOSIS

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

(1) Inspect fuses (F8 and F16 in PDC on YJ)(11 in

fuseblock module and F14 in PDC on XJ). Replace

fuses, as required.

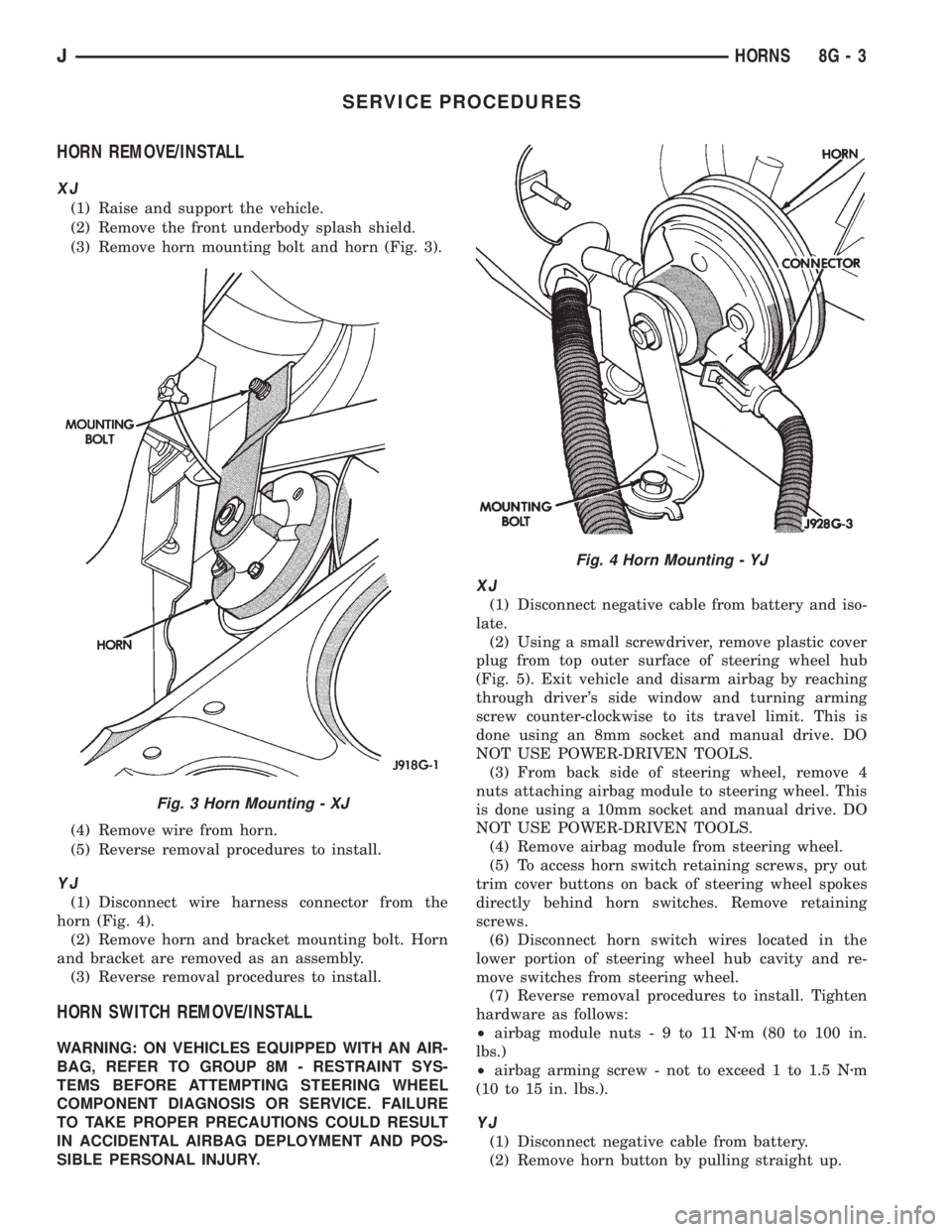

(2) Remove the horn relay (in the PDC on YJ)(in

the relay center on XJ). See Horn Relay Connec-

tions-XJ (Fig. 1) or Horn Relay Connections-YJ (Fig.

2) and perform the following tests.

²The common feed terminal (30) is connected to

battery voltage and should be hot at all times. If bat-

tery voltage is not present at relay cavity 30, check

circuit to fuse (F16 on YJ)(11 on XJ). Repair as re-

quired.

²The normally closed terminal (87A) is connected to

terminal 30 in the de-energized position, but is not

used for this application.

²The normally open terminal (87) is connected to

the common feed terminal (30) in the energized posi-

tion. This terminal supplies battery voltage to the

horn. There should be continuity between relay cav-

ity 87 and the horn terminal at all times. If not, re-

pair wiring or connections as required.

²The coil battery terminal (86) is connected to the

electromagnet in the relay, and battery voltage

should be present at all times. If battery voltage is

not present at relay cavity 86, check circuit to fuse

(F16 on YJ)(11 on XJ). Repair as required.

²The coil ground terminal (85) is connected to the

electromagnet in the relay. It is grounded when the

horn switch is depressed. Check for continuity to

ground at relay cavity 85 with the horn switch de-

pressed. If no continuity is found with horn switch

depressed or, if continuity is found with horn switch

released, repair horn switch or wiring as required.

See Horn Switch Remove/Install in this group for ser-

vice procedures.

If all relay connections check OK, proceed to next

step.

(3) With the horn relay still removed, check the

horn relay by performing the following tests.

²A relay in the de-energized position should have

continuity between terminal 87A and terminal 30,

and no continuity between terminal 87 and terminal

30.

²Resistance value between terminals 85 and 86

(electromagnet) is 7565 ohms.²Connect a battery to terminals 85 and 86. There

should now be continuity between terminal 87 and

terminal 30.

If relay fails any of the above tests, replace faulty

relay. If relay checks OK, reinstall and proceed to

next step.

(4) Disconnect wiring at horn terminal. Depress

horn switch. There should be battery voltage at the

horn wiring connector. If not, repair wiring to relay.

If OK, proceed to next step.

(5) Measure the resistance between the horn

bracket and a good chassis ground. The meter should

read zero ohms. If not, clean and tighten ground con-

nection between horn mounting screw and bracket. If

OK, replace faulty horn(s).

Fig. 1 Horn Relay Connections-XJ

Fig. 2 Horn Relay Connections-YJ

8G - 2 HORNSJ

Page 400 of 2198

SERVICE PROCEDURES

HORN REMOVE/INSTALL

XJ

(1) Raise and support the vehicle.

(2) Remove the front underbody splash shield.

(3) Remove horn mounting bolt and horn (Fig. 3).

(4) Remove wire from horn.

(5) Reverse removal procedures to install.

YJ

(1) Disconnect wire harness connector from the

horn (Fig. 4).

(2) Remove horn and bracket mounting bolt. Horn

and bracket are removed as an assembly.

(3) Reverse removal procedures to install.

HORN SWITCH REMOVE/INSTALL

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

XJ

(1) Disconnect negative cable from battery and iso-

late.

(2) Using a small screwdriver, remove plastic cover

plug from top outer surface of steering wheel hub

(Fig. 5). Exit vehicle and disarm airbag by reaching

through driver's side window and turning arming

screw counter-clockwise to its travel limit. This is

done using an 8mm socket and manual drive. DO

NOT USE POWER-DRIVEN TOOLS.

(3) From back side of steering wheel, remove 4

nuts attaching airbag module to steering wheel. This

is done using a 10mm socket and manual drive. DO

NOT USE POWER-DRIVEN TOOLS.

(4) Remove airbag module from steering wheel.

(5) To access horn switch retaining screws, pry out

trim cover buttons on back of steering wheel spokes

directly behind horn switches. Remove retaining

screws.

(6) Disconnect horn switch wires located in the

lower portion of steering wheel hub cavity and re-

move switches from steering wheel.

(7) Reverse removal procedures to install. Tighten

hardware as follows:

²airbag module nuts-9to11Nzm (80 to 100 in.

lbs.)

²airbag arming screw - not to exceed 1 to 1.5 Nzm

(10 to 15 in. lbs.).

YJ

(1) Disconnect negative cable from battery.

(2) Remove horn button by pulling straight up.

Fig. 3 Horn Mounting - XJ

Fig. 4 Horn Mounting - YJ

JHORNS 8G - 3