lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 444 of 2198

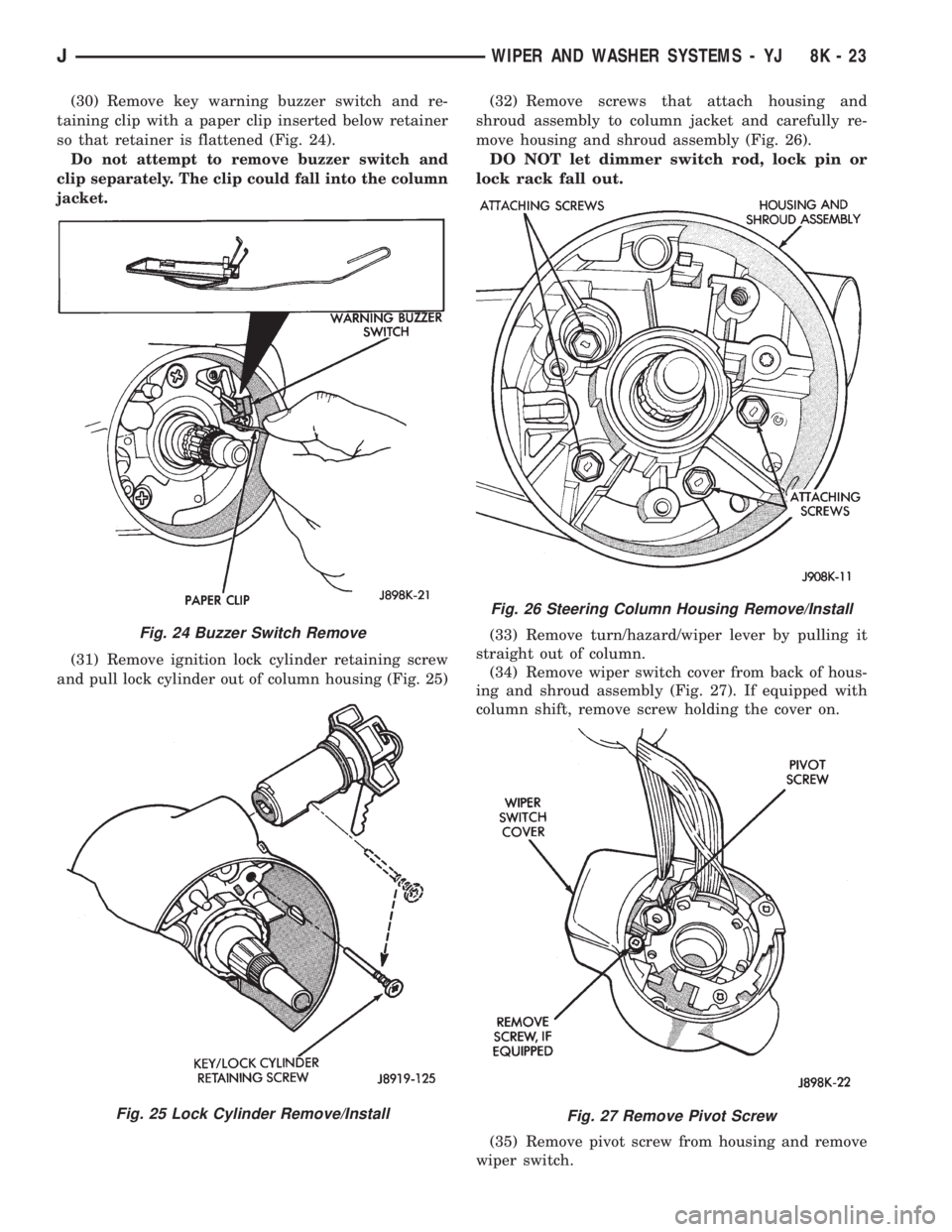

(30) Remove key warning buzzer switch and re-

taining clip with a paper clip inserted below retainer

so that retainer is flattened (Fig. 24).

Do not attempt to remove buzzer switch and

clip separately. The clip could fall into the column

jacket.

(31) Remove ignition lock cylinder retaining screw

and pull lock cylinder out of column housing (Fig. 25)(32) Remove screws that attach housing and

shroud assembly to column jacket and carefully re-

move housing and shroud assembly (Fig. 26).

DO NOT let dimmer switch rod, lock pin or

lock rack fall out.

(33) Remove turn/hazard/wiper lever by pulling it

straight out of column.

(34) Remove wiper switch cover from back of hous-

ing and shroud assembly (Fig. 27). If equipped with

column shift, remove screw holding the cover on.

(35) Remove pivot screw from housing and remove

wiper switch.

Fig. 24 Buzzer Switch Remove

Fig. 25 Lock Cylinder Remove/Install

Fig. 26 Steering Column Housing Remove/Install

Fig. 27 Remove Pivot Screw

JWIPER AND WASHER SYSTEMS - YJ 8K - 23

Page 445 of 2198

(36) Install a new switch and switch cover.

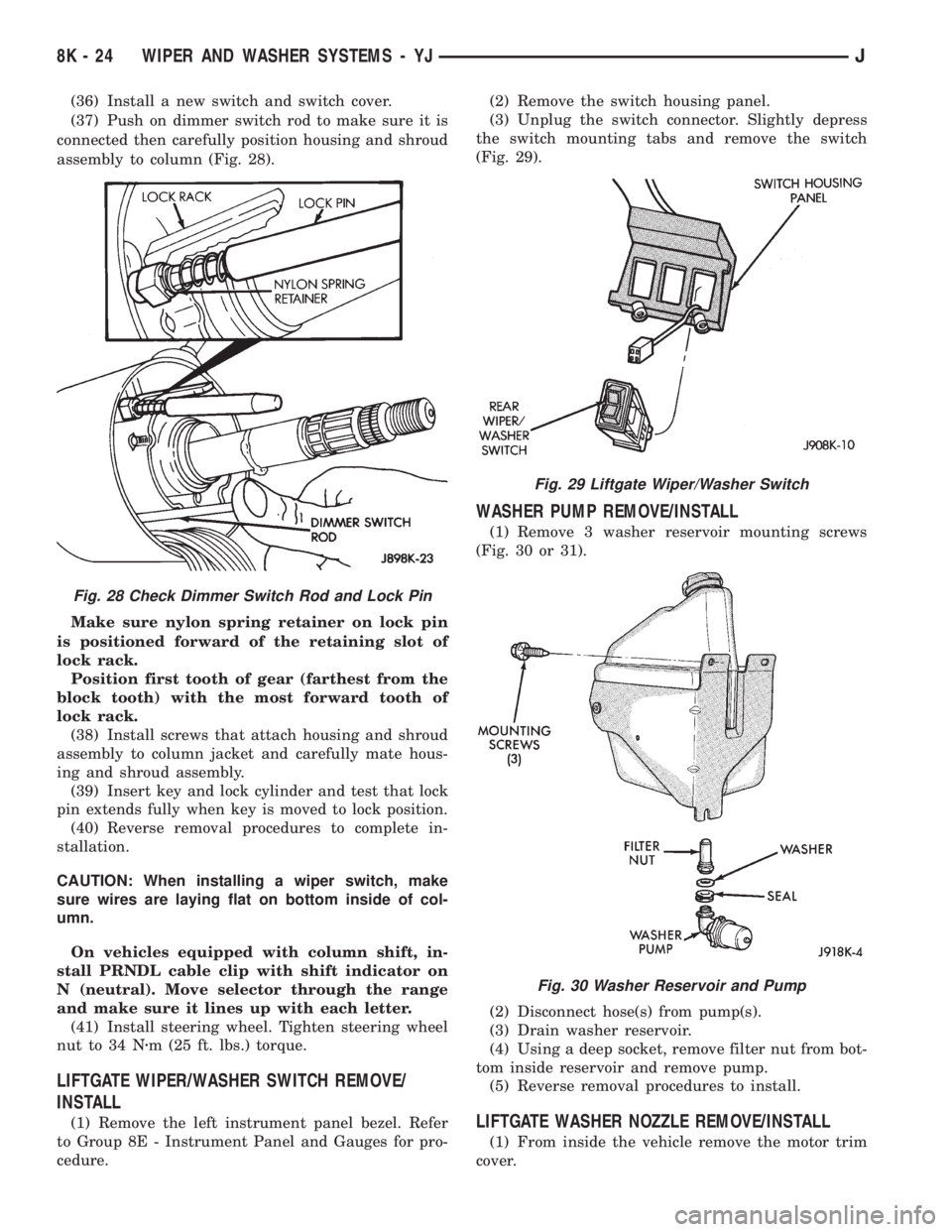

(37) Push on dimmer switch rod to make sure it is

connected then carefully position housing and shroud

assembly to column (Fig. 28).

Make sure nylon spring retainer on lock pin

is positioned forward of the retaining slot of

lock rack.

Position first tooth of gear (farthest from the

block tooth) with the most forward tooth of

lock rack.

(38) Install screws that attach housing and shroud

assembly to column jacket and carefully mate hous-

ing and shroud assembly.

(39) Insert key and lock cylinder and test that lock

pin extends fully when key is moved to lock position.

(40) Reverse removal procedures to complete in-

stallation.

CAUTION: When installing a wiper switch, make

sure wires are laying flat on bottom inside of col-

umn.

On vehicles equipped with column shift, in-

stall PRNDL cable clip with shift indicator on

N (neutral). Move selector through the range

and make sure it lines up with each letter.

(41) Install steering wheel. Tighten steering wheel

nut to 34 Nzm (25 ft. lbs.) torque.

LIFTGATE WIPER/WASHER SWITCH REMOVE/

INSTALL

(1) Remove the left instrument panel bezel. Refer

to Group 8E - Instrument Panel and Gauges for pro-

cedure.(2) Remove the switch housing panel.

(3) Unplug the switch connector. Slightly depress

the switch mounting tabs and remove the switch

(Fig. 29).

WASHER PUMP REMOVE/INSTALL

(1) Remove 3 washer reservoir mounting screws

(Fig. 30 or 31).

(2) Disconnect hose(s) from pump(s).

(3) Drain washer reservoir.

(4) Using a deep socket, remove filter nut from bot-

tom inside reservoir and remove pump.

(5) Reverse removal procedures to install.

LIFTGATE WASHER NOZZLE REMOVE/INSTALL

(1) From inside the vehicle remove the motor trim

cover.

Fig. 28 Check Dimmer Switch Rod and Lock Pin

Fig. 29 Liftgate Wiper/Washer Switch

Fig. 30 Washer Reservoir and Pump

8K - 24 WIPER AND WASHER SYSTEMS - YJJ

Page 451 of 2198

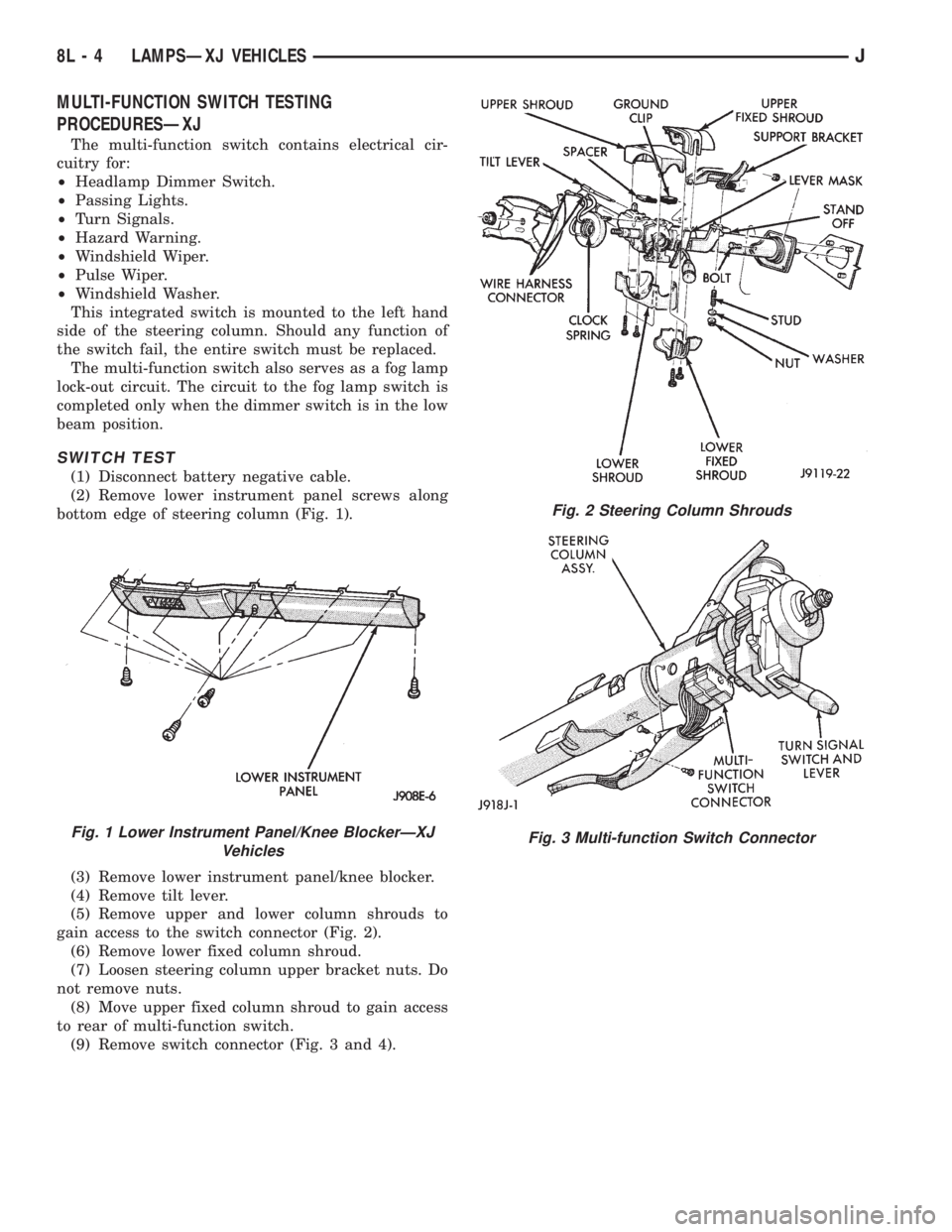

MULTI-FUNCTION SWITCH TESTING

PROCEDURESÐXJ

The multi-function switch contains electrical cir-

cuitry for:

²Headlamp Dimmer Switch.

²Passing Lights.

²Turn Signals.

²Hazard Warning.

²Windshield Wiper.

²Pulse Wiper.

²Windshield Washer.

This integrated switch is mounted to the left hand

side of the steering column. Should any function of

the switch fail, the entire switch must be replaced.

The multi-function switch also serves as a fog lamp

lock-out circuit. The circuit to the fog lamp switch is

completed only when the dimmer switch is in the low

beam position.

SWITCH TEST

(1) Disconnect battery negative cable.

(2) Remove lower instrument panel screws along

bottom edge of steering column (Fig. 1).

(3) Remove lower instrument panel/knee blocker.

(4) Remove tilt lever.

(5) Remove upper and lower column shrouds to

gain access to the switch connector (Fig. 2).

(6) Remove lower fixed column shroud.

(7) Loosen steering column upper bracket nuts. Do

not remove nuts.

(8) Move upper fixed column shroud to gain access

to rear of multi-function switch.

(9) Remove switch connector (Fig. 3 and 4).

Fig. 1 Lower Instrument Panel/Knee BlockerÐXJ

Vehicles

Fig. 2 Steering Column Shrouds

Fig. 3 Multi-function Switch Connector

8L - 4 LAMPSÐXJ VEHICLESJ

Page 458 of 2198

INSTALLATION

(1) Squeeze the tabs on the side of the fog lamp

switch and insert the switch in the instrument panel

cavity.

(2) Connect the wire harness connector to the

switch.

(3) Install the fog lamp switch cover.

(4) Position the bezel on the instrument panel and

install the attaching screws. Tighten the screws se-

curely.

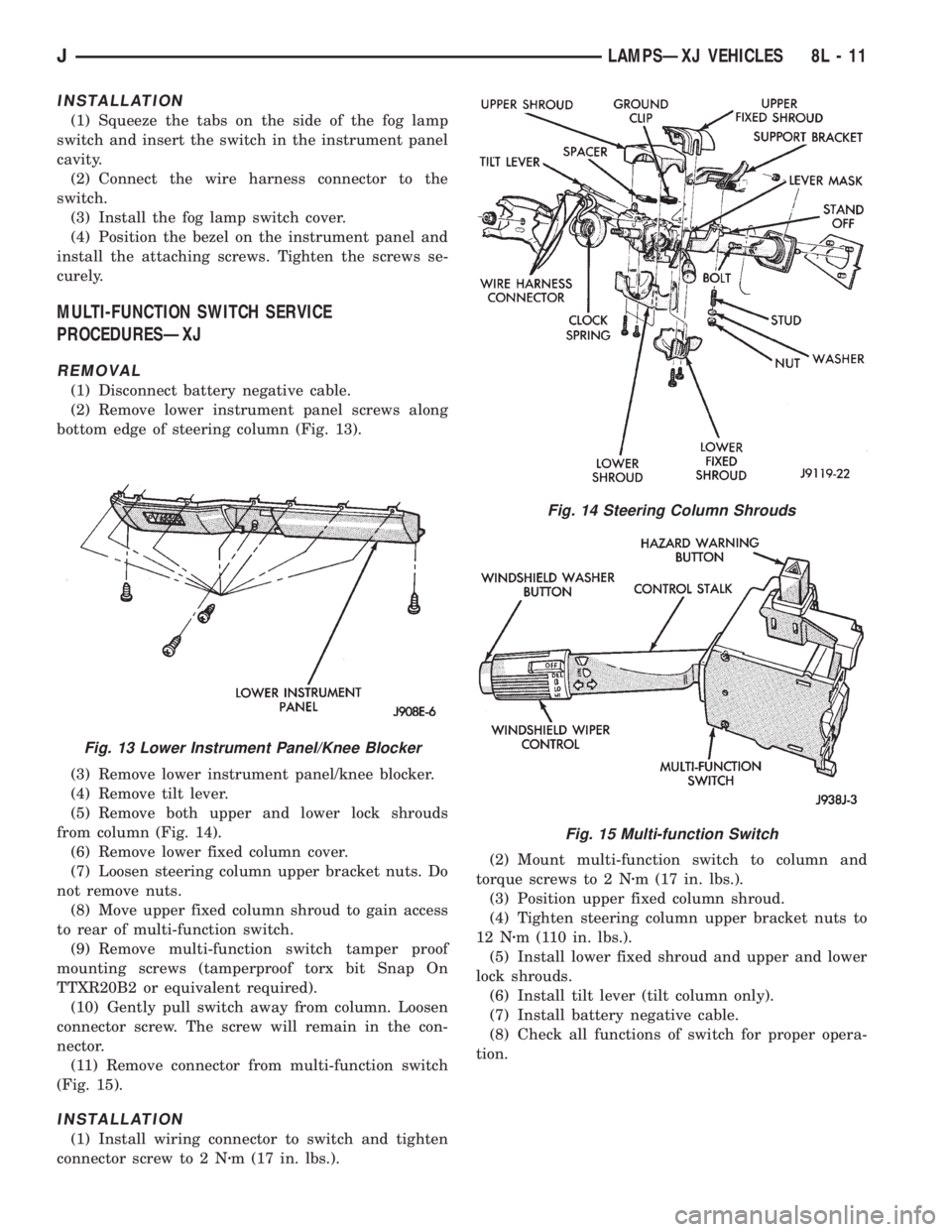

MULTI-FUNCTION SWITCH SERVICE

PROCEDURESÐXJ

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove lower instrument panel screws along

bottom edge of steering column (Fig. 13).

(3) Remove lower instrument panel/knee blocker.

(4) Remove tilt lever.

(5) Remove both upper and lower lock shrouds

from column (Fig. 14).

(6) Remove lower fixed column cover.

(7) Loosen steering column upper bracket nuts. Do

not remove nuts.

(8) Move upper fixed column shroud to gain access

to rear of multi-function switch.

(9) Remove multi-function switch tamper proof

mounting screws (tamperproof torx bit Snap On

TTXR20B2 or equivalent required).

(10) Gently pull switch away from column. Loosen

connector screw. The screw will remain in the con-

nector.

(11) Remove connector from multi-function switch

(Fig. 15).

INSTALLATION

(1) Install wiring connector to switch and tighten

connector screw to 2 Nzm (17 in. lbs.).(2) Mount multi-function switch to column and

torque screws to 2 Nzm (17 in. lbs.).

(3) Position upper fixed column shroud.

(4) Tighten steering column upper bracket nuts to

12 Nzm (110 in. lbs.).

(5) Install lower fixed shroud and upper and lower

lock shrouds.

(6) Install tilt lever (tilt column only).

(7) Install battery negative cable.

(8) Check all functions of switch for proper opera-

tion.

Fig. 13 Lower Instrument Panel/Knee Blocker

Fig. 14 Steering Column Shrouds

Fig. 15 Multi-function Switch

JLAMPSÐXJ VEHICLES 8L - 11

Page 460 of 2198

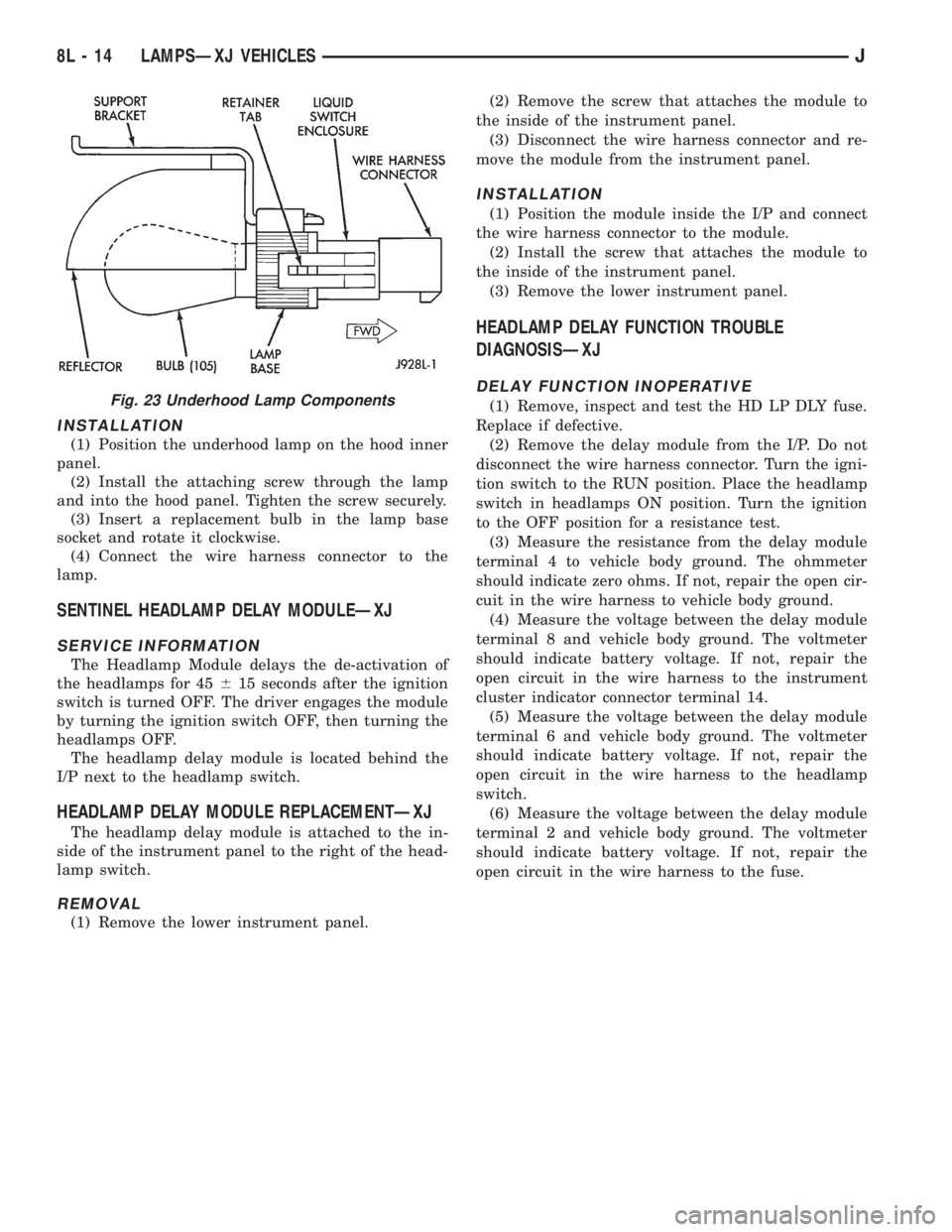

UNDERHOOD LAMP BULB REPLACEMENTÐXJ

REMOVAL

(1) Disconnect the wire harness connector from the

underhood lamp (Fig. 23).

(2) Rotate the bulb counter-clockwise and remove

it from the lamp base socket.

INSTALLATION

(1) Insert a replacement bulb in the lamp base

socket and rotate it clockwise.

(2) Connect the wire harness connector to the

lamp.

UNDERHOOD LAMP REPLACEMENTÐXJ

REMOVAL

(1) Disconnect the wire harness connector from the

lamp.

(2) Rotate the bulb counter-clockwise and remove

it from the lamp base socket.

(3) Remove the screw that attaches the lamp re-

flector and support bracket to the hood inner panel.

(4) Remove the lamp from the hood inner panel.

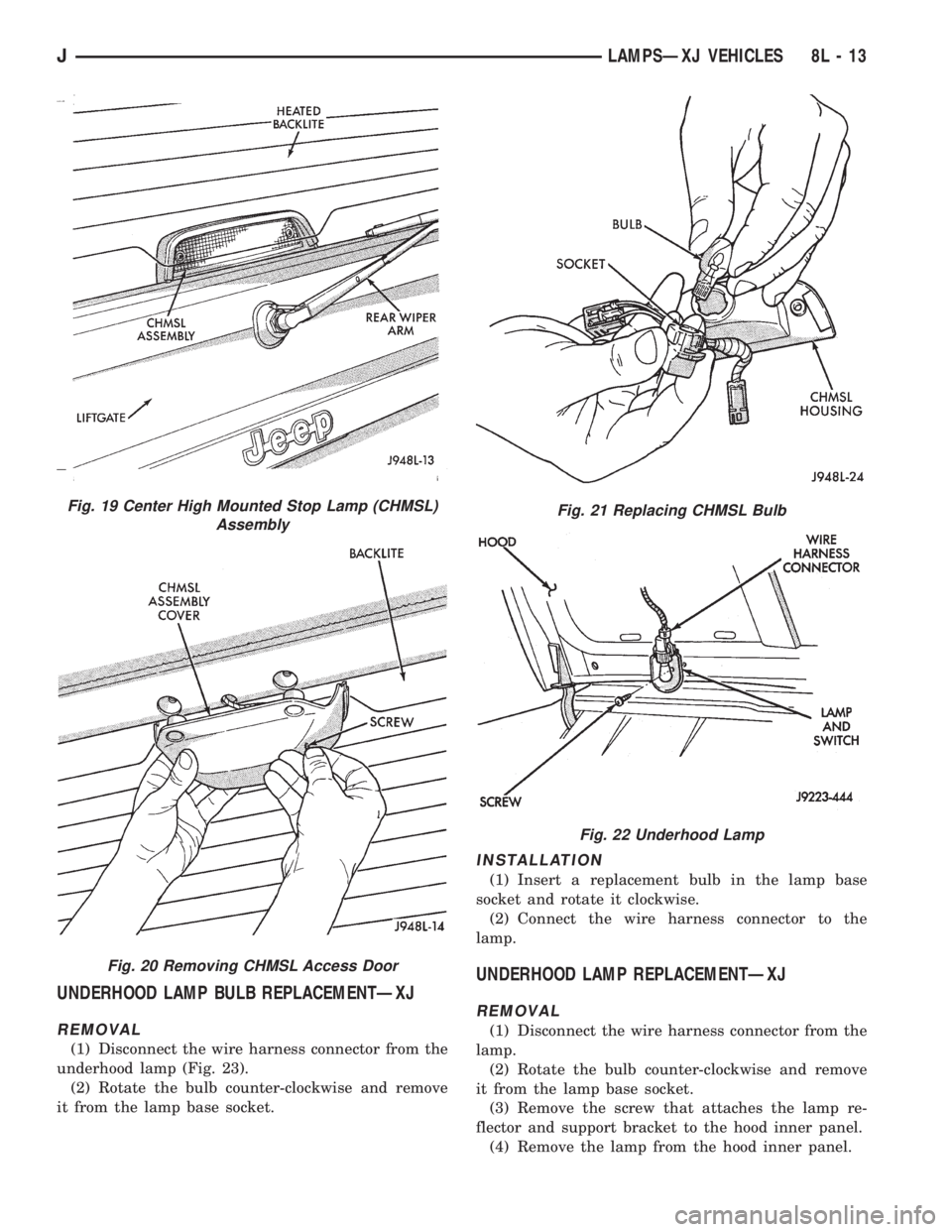

Fig. 19 Center High Mounted Stop Lamp (CHMSL)

Assembly

Fig. 20 Removing CHMSL Access Door

Fig. 21 Replacing CHMSL Bulb

Fig. 22 Underhood Lamp

JLAMPSÐXJ VEHICLES 8L - 13

Page 461 of 2198

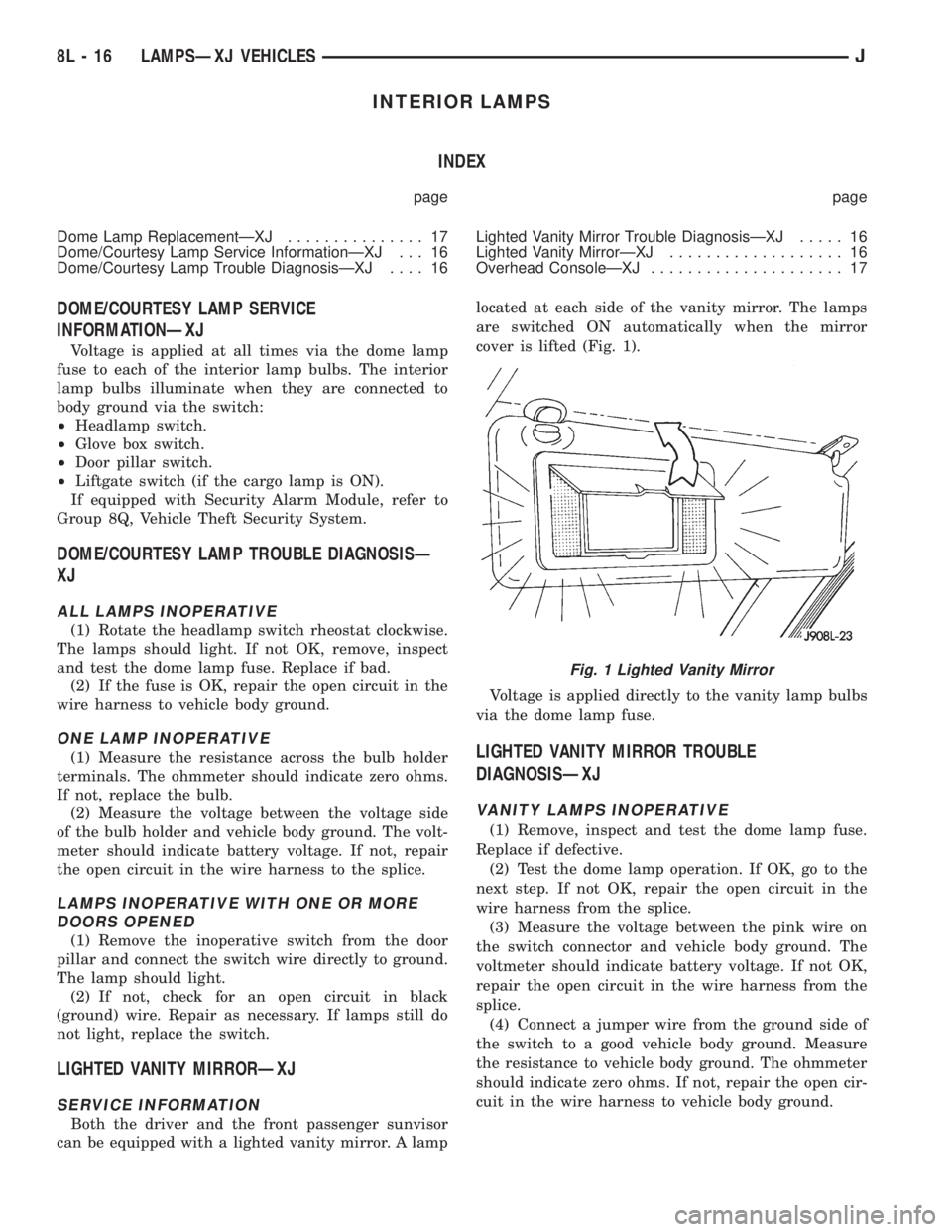

INSTALLATION

(1) Position the underhood lamp on the hood inner

panel.

(2) Install the attaching screw through the lamp

and into the hood panel. Tighten the screw securely.

(3) Insert a replacement bulb in the lamp base

socket and rotate it clockwise.

(4) Connect the wire harness connector to the

lamp.

SENTINEL HEADLAMP DELAY MODULEÐXJ

SERVICE INFORMATION

The Headlamp Module delays the de-activation of

the headlamps for 45615 seconds after the ignition

switch is turned OFF. The driver engages the module

by turning the ignition switch OFF, then turning the

headlamps OFF.

The headlamp delay module is located behind the

I/P next to the headlamp switch.

HEADLAMP DELAY MODULE REPLACEMENTÐXJ

The headlamp delay module is attached to the in-

side of the instrument panel to the right of the head-

lamp switch.

REMOVAL

(1) Remove the lower instrument panel.(2) Remove the screw that attaches the module to

the inside of the instrument panel.

(3) Disconnect the wire harness connector and re-

move the module from the instrument panel.

INSTALLATION

(1) Position the module inside the I/P and connect

the wire harness connector to the module.

(2) Install the screw that attaches the module to

the inside of the instrument panel.

(3) Remove the lower instrument panel.

HEADLAMP DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ

DELAY FUNCTION INOPERATIVE

(1) Remove, inspect and test the HD LP DLY fuse.

Replace if defective.

(2) Remove the delay module from the I/P. Do not

disconnect the wire harness connector. Turn the igni-

tion switch to the RUN position. Place the headlamp

switch in headlamps ON position. Turn the ignition

to the OFF position for a resistance test.

(3) Measure the resistance from the delay module

terminal 4 to vehicle body ground. The ohmmeter

should indicate zero ohms. If not, repair the open cir-

cuit in the wire harness to vehicle body ground.

(4) Measure the voltage between the delay module

terminal 8 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the instrument

cluster indicator connector terminal 14.

(5) Measure the voltage between the delay module

terminal 6 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the headlamp

switch.

(6) Measure the voltage between the delay module

terminal 2 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the fuse.Fig. 23 Underhood Lamp Components

8L - 14 LAMPSÐXJ VEHICLESJ

Page 463 of 2198

INTERIOR LAMPS

INDEX

page page

Dome Lamp ReplacementÐXJ............... 17

Dome/Courtesy Lamp Service InformationÐXJ . . . 16

Dome/Courtesy Lamp Trouble DiagnosisÐXJ.... 16Lighted Vanity Mirror Trouble DiagnosisÐXJ..... 16

Lighted Vanity MirrorÐXJ................... 16

Overhead ConsoleÐXJ..................... 17

DOME/COURTESY LAMP SERVICE

INFORMATIONÐXJ

Voltage is applied at all times via the dome lamp

fuse to each of the interior lamp bulbs. The interior

lamp bulbs illuminate when they are connected to

body ground via the switch:

²Headlamp switch.

²Glove box switch.

²Door pillar switch.

²Liftgate switch (if the cargo lamp is ON).

If equipped with Security Alarm Module, refer to

Group 8Q, Vehicle Theft Security System.

DOME/COURTESY LAMP TROUBLE DIAGNOSISÐ

XJ

ALL LAMPS INOPERATIVE

(1) Rotate the headlamp switch rheostat clockwise.

The lamps should light. If not OK, remove, inspect

and test the dome lamp fuse. Replace if bad.

(2) If the fuse is OK, repair the open circuit in the

wire harness to vehicle body ground.

ONE LAMP INOPERATIVE

(1) Measure the resistance across the bulb holder

terminals. The ohmmeter should indicate zero ohms.

If not, replace the bulb.

(2) Measure the voltage between the voltage side

of the bulb holder and vehicle body ground. The volt-

meter should indicate battery voltage. If not, repair

the open circuit in the wire harness to the splice.

LAMPS INOPERATIVE WITH ONE OR MORE

DOORS OPENED

(1) Remove the inoperative switch from the door

pillar and connect the switch wire directly to ground.

The lamp should light.

(2) If not, check for an open circuit in black

(ground) wire. Repair as necessary. If lamps still do

not light, replace the switch.

LIGHTED VANITY MIRRORÐXJ

SERVICE INFORMATION

Both the driver and the front passenger sunvisor

can be equipped with a lighted vanity mirror. A lamplocated at each side of the vanity mirror. The lamps

are switched ON automatically when the mirror

cover is lifted (Fig. 1).

Voltage is applied directly to the vanity lamp bulbs

via the dome lamp fuse.

LIGHTED VANITY MIRROR TROUBLE

DIAGNOSISÐXJ

VANITY LAMPS INOPERATIVE

(1) Remove, inspect and test the dome lamp fuse.

Replace if defective.

(2) Test the dome lamp operation. If OK, go to the

next step. If not OK, repair the open circuit in the

wire harness from the splice.

(3) Measure the voltage between the pink wire on

the switch connector and vehicle body ground. The

voltmeter should indicate battery voltage. If not OK,

repair the open circuit in the wire harness from the

splice.

(4) Connect a jumper wire from the ground side of

the switch to a good vehicle body ground. Measure

the resistance to vehicle body ground. The ohmmeter

should indicate zero ohms. If not, repair the open cir-

cuit in the wire harness to vehicle body ground.

Fig. 1 Lighted Vanity Mirror

8L - 16 LAMPSÐXJ VEHICLESJ

Page 465 of 2198

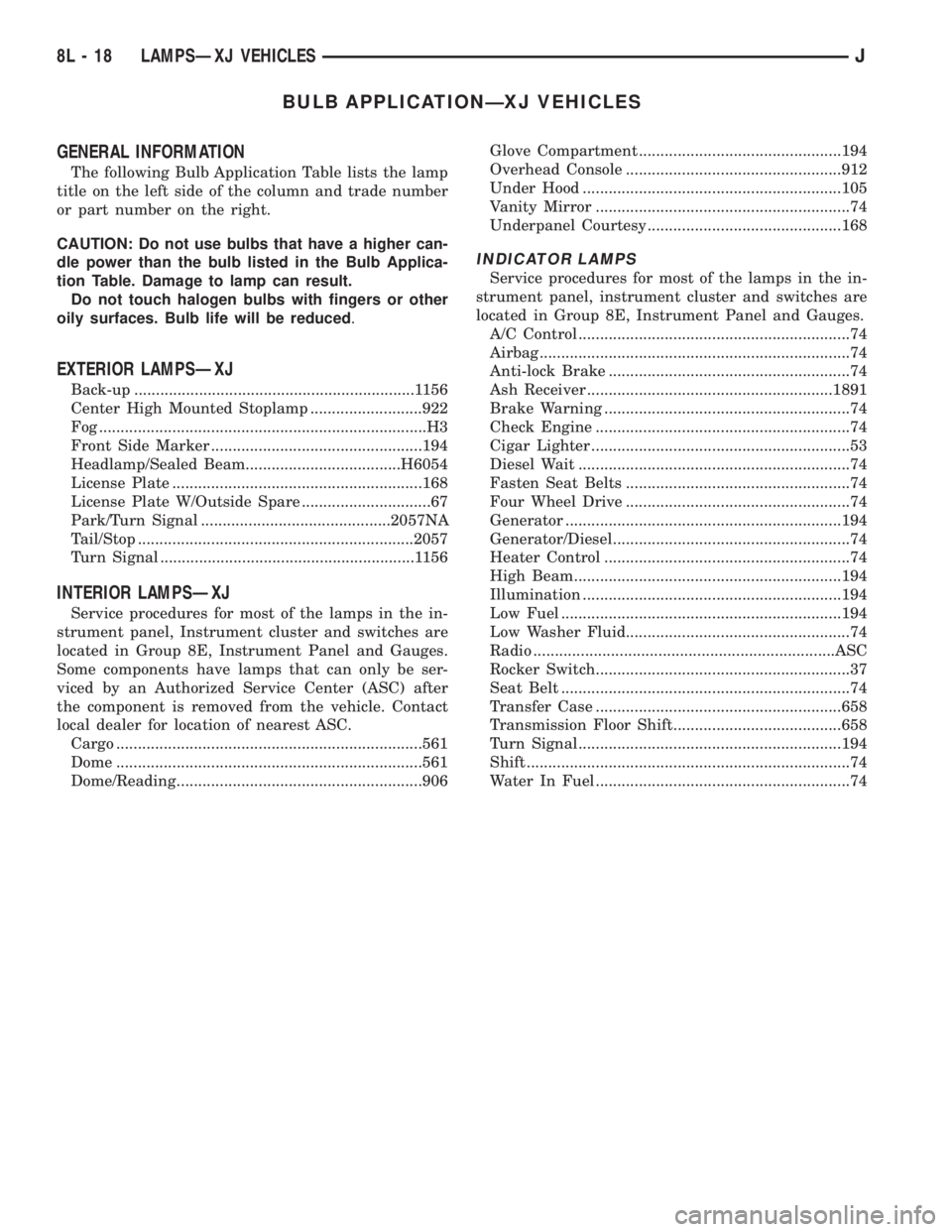

BULB APPLICATIONÐXJ VEHICLES

GENERAL INFORMATION

The following Bulb Application Table lists the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the Bulb Applica-

tion Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

oily surfaces. Bulb life will be reduced.

EXTERIOR LAMPSÐXJ

Back-up .................................................................1156

Center High Mounted Stoplamp ..........................922

Fog ............................................................................H3

Front Side Marker .................................................194

Headlamp/Sealed Beam....................................H6054

License Plate ..........................................................168

License Plate W/Outside Spare ..............................67

Park/Turn Signal ............................................2057NA

Tail/Stop ................................................................2057

Turn Signal ...........................................................1156

INTERIOR LAMPSÐXJ

Service procedures for most of the lamps in the in-

strument panel, Instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

Some components have lamps that can only be ser-

viced by an Authorized Service Center (ASC) after

the component is removed from the vehicle. Contact

local dealer for location of nearest ASC.

Cargo .......................................................................561

Dome .......................................................................561

Dome/Reading.........................................................906Glove Compartment ...............................................194

Overhead Console ..................................................912

Under Hood ............................................................105

Vanity Mirror ...........................................................74

Underpanel Courtesy.............................................168

INDICATOR LAMPS

Service procedures for most of the lamps in the in-

strument panel, instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

A/C Control ...............................................................74

Airbag ........................................................................74

Anti-lock Brake ........................................................74

Ash Receiver .........................................................1891

Brake Warning .........................................................74

Check Engine ...........................................................74

Cigar Lighter ............................................................53

Diesel Wait ...............................................................74

Fasten Seat Belts ....................................................74

Four Wheel Drive ....................................................74

Generator ................................................................194

Generator/Diesel.......................................................74

Heater Control .........................................................74

High Beam..............................................................194

Illumination ............................................................194

Low Fuel .................................................................194

Low Washer Fluid....................................................74

Radio ......................................................................ASC

Rocker Switch...........................................................37

Seat Belt ...................................................................74

Transfer Case .........................................................658

Transmission Floor Shift.......................................658

Turn Signal.............................................................194

Shift ...........................................................................74

Water In Fuel ...........................................................74

8L - 18 LAMPSÐXJ VEHICLESJ

Page 476 of 2198

provides automatic ON/OFF functions each time the

hood is opened and closed.

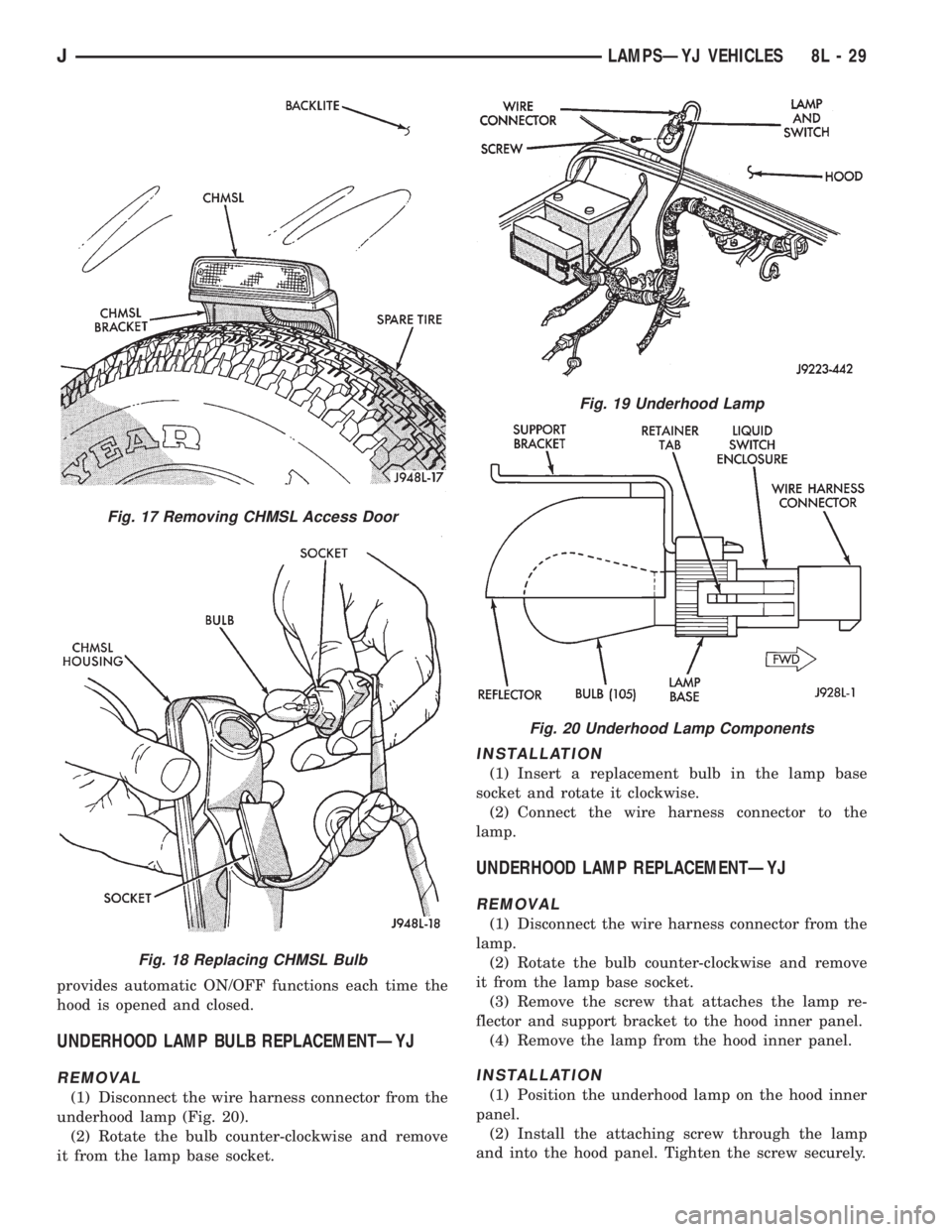

UNDERHOOD LAMP BULB REPLACEMENTÐYJ

REMOVAL

(1) Disconnect the wire harness connector from the

underhood lamp (Fig. 20).

(2) Rotate the bulb counter-clockwise and remove

it from the lamp base socket.

INSTALLATION

(1) Insert a replacement bulb in the lamp base

socket and rotate it clockwise.

(2) Connect the wire harness connector to the

lamp.

UNDERHOOD LAMP REPLACEMENTÐYJ

REMOVAL

(1) Disconnect the wire harness connector from the

lamp.

(2) Rotate the bulb counter-clockwise and remove

it from the lamp base socket.

(3) Remove the screw that attaches the lamp re-

flector and support bracket to the hood inner panel.

(4) Remove the lamp from the hood inner panel.

INSTALLATION

(1) Position the underhood lamp on the hood inner

panel.

(2) Install the attaching screw through the lamp

and into the hood panel. Tighten the screw securely.

Fig. 17 Removing CHMSL Access Door

Fig. 18 Replacing CHMSL Bulb

Fig. 19 Underhood Lamp

Fig. 20 Underhood Lamp Components

JLAMPSÐYJ VEHICLES 8L - 29

Page 477 of 2198

(3) Insert a replacement bulb in the lamp base

socket and rotate it clockwise.

(4) Connect the wire harness connector to the

lamp.

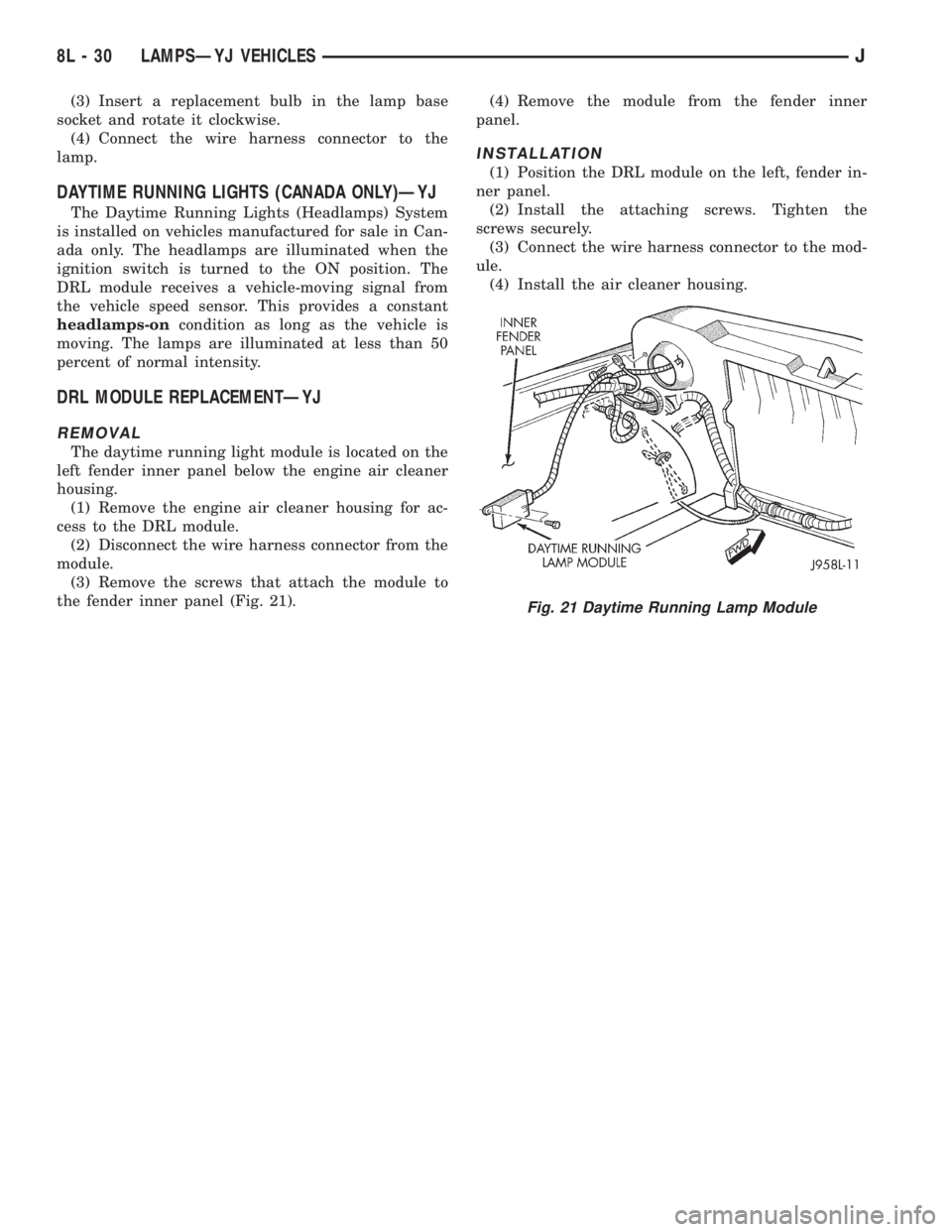

DAYTIME RUNNING LIGHTS (CANADA ONLY)ÐYJ

The Daytime Running Lights (Headlamps) System

is installed on vehicles manufactured for sale in Can-

ada only. The headlamps are illuminated when the

ignition switch is turned to the ON position. The

DRL module receives a vehicle-moving signal from

the vehicle speed sensor. This provides a constant

headlamps-oncondition as long as the vehicle is

moving. The lamps are illuminated at less than 50

percent of normal intensity.

DRL MODULE REPLACEMENTÐYJ

REMOVAL

The daytime running light module is located on the

left fender inner panel below the engine air cleaner

housing.

(1) Remove the engine air cleaner housing for ac-

cess to the DRL module.

(2) Disconnect the wire harness connector from the

module.

(3) Remove the screws that attach the module to

the fender inner panel (Fig. 21).(4) Remove the module from the fender inner

panel.

INSTALLATION

(1) Position the DRL module on the left, fender in-

ner panel.

(2) Install the attaching screws. Tighten the

screws securely.

(3) Connect the wire harness connector to the mod-

ule.

(4) Install the air cleaner housing.

Fig. 21 Daytime Running Lamp Module

8L - 30 LAMPSÐYJ VEHICLESJ