lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 423 of 2198

The two pivot cranks are joined by a connecting link,

and a drive link connects the motor crank to the drive

link near the left pivot. Pressed-in plastic bushings in

the ends of the links can be replaced if worn or dam-

aged.

WINDSHIELD WIPER MOTOR

The two-speed permanent magnet wiper motor has

an integral transmission and park switch. The motor

is mounted to the engine side of the cowl panel with

a reinforcement/stud plate and a rubber-isolated

mounting bracket. The wiper motor output shaft

passes through the cowl panel into the cowl plenum

area, where a crank arm attached to the output shaft

drives the wiper drive link.

Wiper speed is controlled by current flow to the ap-

propriate set of brushes. The wiper motor completes

its wipe cycle when the switch is turned OFF, and

parks the blades in the lowest portion of the wipe

pattern. The wiper motor assembly can not be re-

paired. If faulty, the entire motor assembly must be

replaced. The crank arm, mounting bracket, and re-

inforcement/stud plate are available for service.

LIFTGATE WIPER MOTOR

The liftgate wiper motor contains integral elec-

tronic controls and a transmission to provide three

operating modes:

²intermittent wipe with a fixed 5 to 8 second delay

between wipes

²constant wipe that operates when the liftgate

washer is operated

²a park mode that runs the motor until the wiper

blade reaches the park position after the liftgate

wiper switch or ignition switch is turned OFF.

The liftgate wiper motor can not be repaired. If

faulty, the entire assembly must be replaced.

WINDSHIELD WIPER/WASHER SWITCH

Controls for the windshield wiper and washer sys-

tems are contained in the multi-function switch con-

trol lever. The multi-function switch is mounted on

the left side of the steering column between the

steering wheel and the instrument panel. This switch

also controls many other functions. The multi-func-

tion switch can not be repaired. If any function of the

switch is faulty, the entire switch must be replaced.

LIFTGATE WIPER/WASHER SWITCH

The single two-function switch on the instrument

panel right of the steering column controls the lift-

gate wiper and washer functions. The rocker-type

switch features a detent in the WIPE position, but

only momentary contact in the WASH position. Both

the liftgate wiper and liftgate washer motors will op-

erate continuously for as long as the switch is held in

the WASH position. The switch can not be repaired;

if faulty, it must be replaced.

INTERMITTENT WIPE MODULE

In addition to low and high speed, the optional inter-

mittent wipe system has a delay mode. The delay mode

has a range of 2 to 15 seconds. The length of the delay

is selected with a variable resistor in the wiper (multi-

function) switch and is accomplished by electronic cir-

cuitry within the intermittent wipe module. If the

washer knob is depressed while the wiper (multi-func-

tion) switch is in the OFF position, the intermittent

wipe module will operate the wiper motor for approxi-

mately 2 wipes and automatically turn the motor off.

The intermittent wipe module is mounted to the

lower instrument panel, behind the knee blocker and

near the steering column with a hook and loop fas-

tener patch. The module can not be repaired.

WINDSHIELD WASHER NOZZLES

The two fluidic washer nozzles are riveted into

openings in the cowl grille panel below the wind-

shield and are not adjustable. Washer fluid is fed to

the nozzles through hoses clipped to the underside of

the cowl grille panel. The nozzles can not be repaired

and, if faulty, should be replaced.

LIFTGATE WASHER NOZZLE

The single liftgate washer nozzle snaps into place

on the liftgate wiper arm. Washer fluid is fed to the

nozzle from the washer reservoir in the engine com-

partment. A liftgate washer hose system is routed

through the body of the vehicle with the body wiring

harness from the reservoir to the liftgate. The fluid

passes through a nipple on the liftgate wiper motor

output shaft bezel to a hose clipped to the underside

of the wiper arm. The nozzle can not be repaired and,

if faulty, should be replaced.

WASHER RESERVOIR

The washer solvent reservoir is mounted to the left

front inner fender shield near the cowl panel. The

same reservoir is used for both the standard front

and optional liftgate washer systems. It also has a

provision for a low washer fluid level sensor. Refer to

Group 8E - Instrument Panel and Gauges for diagno-

sis and service of the sensor. The reservoir and filler

cap are available for service.

WASHER PUMPS

The washer pump and motor are press-fit into a

rubber grommet near the bottom of the washer res-

ervoir. Vehicles with the optional liftgate wiper/

washer system have two pumps installed in the

single reservoir. A permanently lubricated and sealed

motor is coupled to a rotor-type pump. Washer fluid

is gravity fed from the reservoir to the pump. The

pump then pressurizes the fluid and forces it through

the plumbing to the nozzles when the motor is ener-

gized. The pump and motor can not be repaired. If

faulty, the entire assembly must be replaced.

8K - 2 WIPER AND WASHER SYSTEMS - XJJ

Page 424 of 2198

DIAGNOSIS - XJ

WINDSHIELD WIPER SYSTEM

(1) Remove in-line circuit breaker near fuseblock

module and turn ignition switch to ACCESSORY or

ON.

(a) Measure voltage at battery side of circuit

breaker cavity. Meter should read battery voltage.

If not OK, repair wiring from ignition switch.

(b) Measure resistance across circuit breaker ter-

minals. Meter should read zero ohms. If not OK,

replace failed circuit breaker.

(2) Unplug wiper motor side of wiring harness con-

nector (gray) from wiper (multi-function) switch side

of wiring harness connector (black), or from intermit-

tent wipe module (if equipped) at base of steering col-

umn. Turn ignition switch to ACCESSORY or ON.

(a) Measure voltage at unplugged wiper motor

side of wiring harness connector (gray) terminal D.

Meter should read battery voltage. If not OK, re-

pair wiring from circuit breaker.

(b) Turn ignition switch to OFF and measure re-

sistance from unplugged wiper motor side of wiring

harness connector (gray) terminal G to ground.

Meter should read zero ohms. If not OK, repair

wiring to ground.

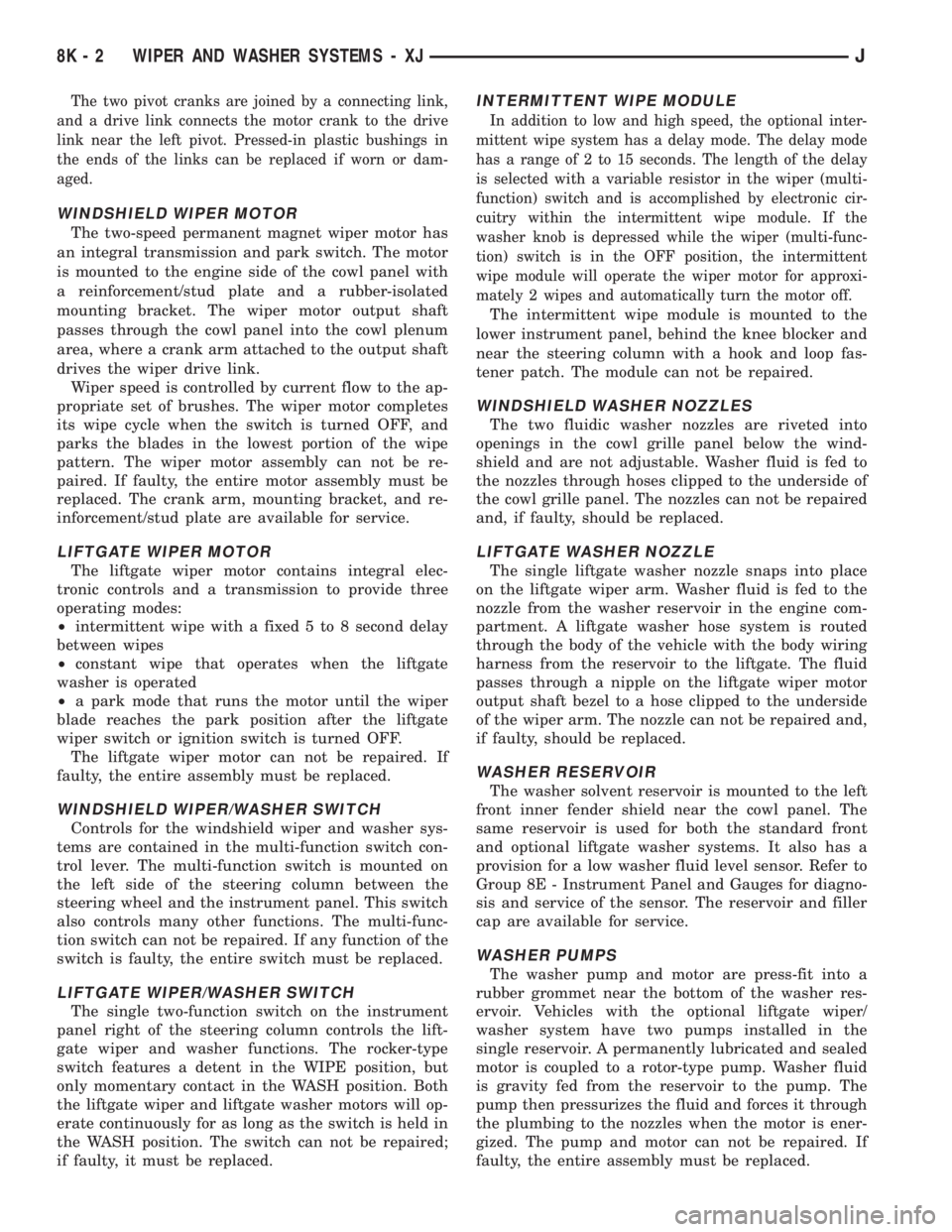

(3) Leave ignition switch in OFF, and back probe

wiring harness connector at wiper motor (Fig. 1).

Measure resistance from terminal 4 of wiper motor

side of connector to ground. Meter should read zero

ohms. If not OK, repair wiring to ground.

(4) If equipped with intermittent wipe, replace the

intermittent wipe module with a known good unitand test wiper operation in all modes. If OK, replace

faulty intermittent wipe module. If not OK, re-install

original module and go to next step.

(5) To test the wiper/washer (multi-function)

switch, see Windshield Wiper/Washer Switch. If

switch tests OK, go to step 6. If not OK, replace

switch and go to step 7.

(6) To test the wiper (multi-function) switch cir-

cuits, turn ignition switch to ACCESSORY or ON.

Position the wiper switch as indicated in the tests be-

low, and back probe switch side of wiring harness

connector (black).

(a) Measure voltage at connector terminal E with

wiper switch in LOW, MIST and with washer

switch depressed. Meter should read battery volt-

age. If not OK, repair wiring to switch.

(b) Measure voltage at connector terminal C with

wiper switch in HIGH. Meter should read battery

voltage. If not OK, repair wiring to switch.

(c) With wiper switch in LOW or HIGH, measure

voltage at connector terminal F, then move wiper

switch to OFF. Meter should read battery voltage

until wipers park and then zero volts. If OK, go to

step 7. If not OK, check wiring to wiper motor, then

go to step 7.

(7) To test the wiper motor, turn the ignition

switch to ACCESSORY or ON. Position the wiper

(multi-function) switch and back probe the motor

connector (Fig. 1) as indicated.

(a) Wiper switch in any position, measure volt-

age at terminal 1. Meter should read battery volt-

age. If not OK, repair wiring from circuit breaker.

(b) Wiper switch in LOW, measure voltage at ter-

minal 5. Meter should read battery voltage. If OK,

but wipers do not operate, replace failed wiper mo-

tor. If not OK, repair wiring from switch or inter-

mittent wipe module connector.

(c) Wiper switch in HIGH, measure voltage at

terminal 6. Meter should read battery voltage. If

OK, but wipers do not operate, replace failed wiper

motor. If not OK, repair wiring from switch or in-

termittent wipe module connector.

(d) Wiper switch in LOW or HIGH, voltmeter

connected to terminal 2. Turn wiper switch to OFF

and observe meter. Meter should read battery volt-

age when switch goes to OFF, then zero volts after

wipers park. If battery voltage is present, but wip-

ers fail to park; or, if no battery voltage present, re-

place failed wiper motor.

Fig. 1 Windshield Wiper Motor Connector

JWIPER AND WASHER SYSTEMS - XJ 8K - 3

Page 427 of 2198

SERVICE PROCEDURES - XJ

WINDSHIELD WIPER MOTOR REMOVE/INSTALL

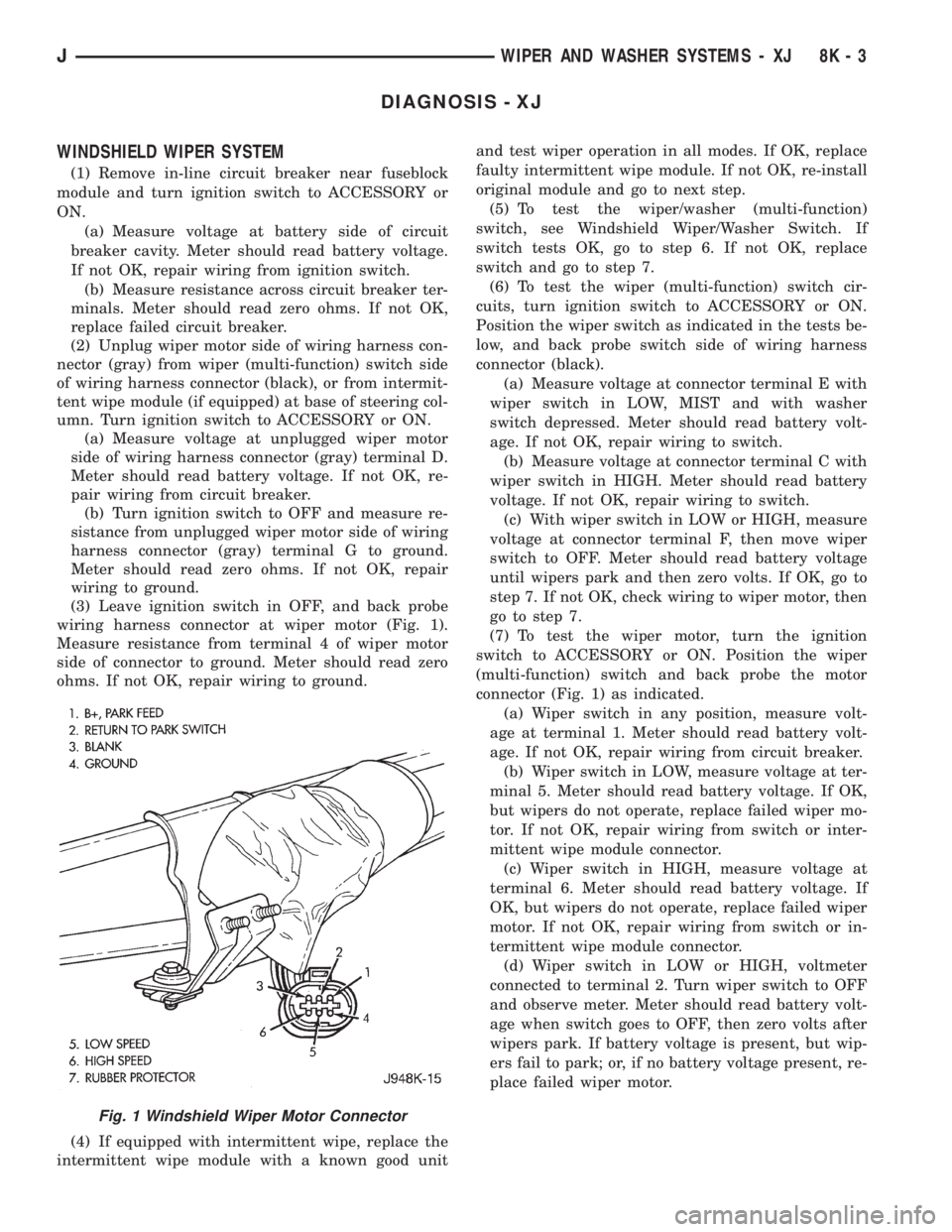

(1) Remove wiper arm assemblies by lifting blade

off windshield and pulling out on the tab (Fig. 4) to

lock wiper arm in up position.

(2) Remove cowl trim panel. Disconnect the washer

hose. Remove the cowl mounting bracket attaching

nuts (Fig. 5) and pivot pin attaching screws.

(3) Disconnect wiring harness and remove the as-

sembly.

(4) Remove the plastic motor cover.

(5) Remove bolts and nuts holding motor to linkage

and remove motor.

The wiper motor is shrouded in a protective

rubber boot. Care should be taken not to punc-

ture the boot during removal or installation.

(6) Reverse removal procedures to install. Tighten

wiper motor screws and nuts to 4 Nzm (35 in. lbs.)

torque. Install wiper arms and position as shown in

Fig. 6.

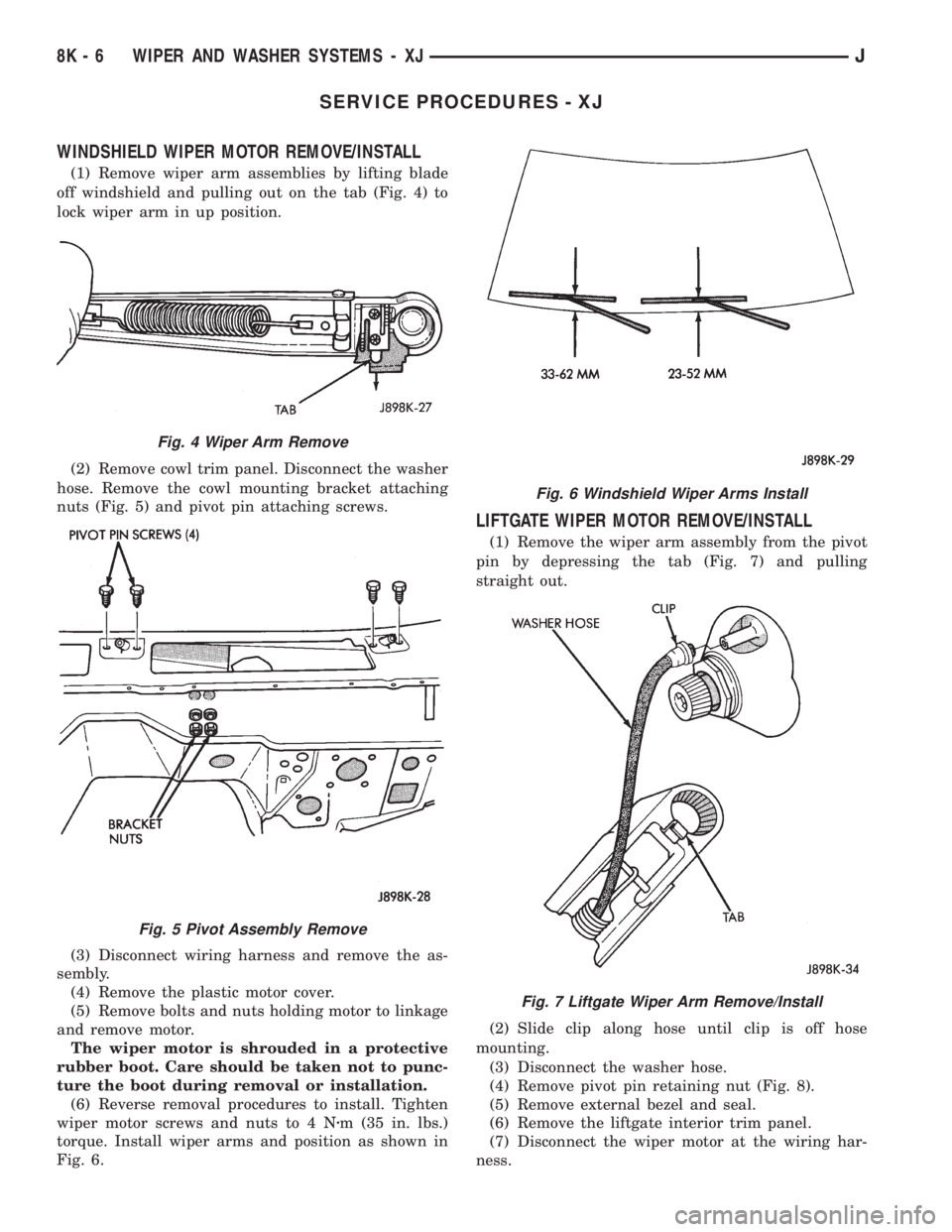

LIFTGATE WIPER MOTOR REMOVE/INSTALL

(1) Remove the wiper arm assembly from the pivot

pin by depressing the tab (Fig. 7) and pulling

straight out.

(2) Slide clip along hose until clip is off hose

mounting.

(3) Disconnect the washer hose.

(4) Remove pivot pin retaining nut (Fig. 8).

(5) Remove external bezel and seal.

(6) Remove the liftgate interior trim panel.

(7) Disconnect the wiper motor at the wiring har-

ness.

Fig. 4 Wiper Arm Remove

Fig. 5 Pivot Assembly Remove

Fig. 6 Windshield Wiper Arms Install

Fig. 7 Liftgate Wiper Arm Remove/Install

8K - 6 WIPER AND WASHER SYSTEMS - XJJ

Page 428 of 2198

(8) Remove the wiper motor mounting screws.

(9) Remove the wiper motor.

(10) Reverse removal procedures to install. Tighten

pivot pin retaining nut to 4 Nzm (32 in. lbs.). Lubri-

cate the bezel nipples with a small amount of water

when installing washer hoses. The liftgate wiper

blade should be installed parallel to window opening

and no closer than 5mm to window seal when oper-

ated on a wet window (Fig. 9).

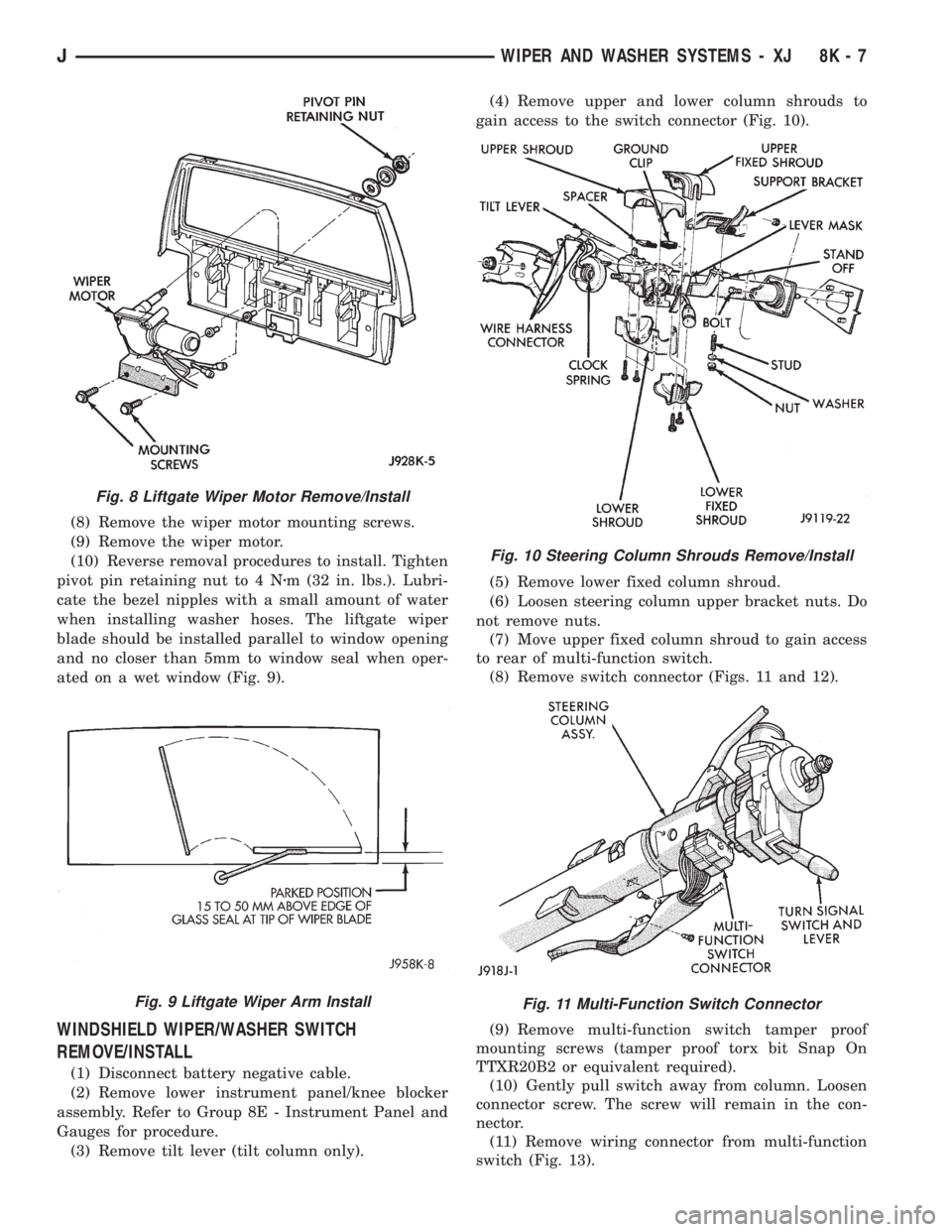

WINDSHIELD WIPER/WASHER SWITCH

REMOVE/INSTALL

(1) Disconnect battery negative cable.

(2) Remove lower instrument panel/knee blocker

assembly. Refer to Group 8E - Instrument Panel and

Gauges for procedure.

(3) Remove tilt lever (tilt column only).(4) Remove upper and lower column shrouds to

gain access to the switch connector (Fig. 10).

(5) Remove lower fixed column shroud.

(6) Loosen steering column upper bracket nuts. Do

not remove nuts.

(7) Move upper fixed column shroud to gain access

to rear of multi-function switch.

(8) Remove switch connector (Figs. 11 and 12).

(9) Remove multi-function switch tamper proof

mounting screws (tamper proof torx bit Snap On

TTXR20B2 or equivalent required).

(10) Gently pull switch away from column. Loosen

connector screw. The screw will remain in the con-

nector.

(11) Remove wiring connector from multi-function

switch (Fig. 13).

Fig. 8 Liftgate Wiper Motor Remove/Install

Fig. 9 Liftgate Wiper Arm Install

Fig. 10 Steering Column Shrouds Remove/Install

Fig. 11 Multi-Function Switch Connector

JWIPER AND WASHER SYSTEMS - XJ 8K - 7

Page 431 of 2198

GENERAL INFORMATION - YJ

Following are general descriptions of the major

components in the YJ (Wrangler) wiper and washer

systems. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams.

WINDSHIELD WIPER SYSTEM

A two-speed wiper system is standard equipment

on all YJ models. An optional intermittent wipe sys-

tem is available. The standard system allows the

driver to select from two wiper speeds. The optional

intermittent wipe system allows the driver to select

from two wiper speeds or an intermittent wipe fea-

ture that allows a delay between wipes of 2 to 15 sec-

onds. Refer to the owner's manual for more

information on wiper system controls and operation.

The wipers will operate only when the ignition

switch is in the ACCESSORY or ON position. A cir-

cuit breaker in the fuseblock module protects the cir-

cuitry of the wiper system.

WINDSHIELD WASHER SYSTEM

A electrically-operated windshield washer system is

standard equipment on all YJ models. The washers

will operate only when the ignition switch is in the

ACCESSORY or ON position. A circuit breaker in the

fuseblock module protects the circuitry of the washer

system. Refer to the owner's manual for more infor-

mation on washer system controls and operation.

LIFTGATE WIPER/WASHER SYSTEM

A liftgate wiper/washer system is an available op-

tion on YJ models equipped with the optional hard-

top. The liftgate wiper is a fixed cycle wipe system. A

single switch on the instrument panel controls both

the liftgate wiper and washer functions. These sys-

tems will operate only when the ignition switch is in

the ON position. Fuse 1 in the fuseblock module pro-

tects the circuitry of both the liftgate wiper and

washer. Refer to the owner's manual for more infor-

mation on liftgate wiper/washer system controls and

operation.

WIPER ARMS, BLADES, AND ELEMENTS

All YJ models have two 12-inch windshield wiper

blades with replaceable rubber elements (squeegees).

Models with the liftgate wiper option use a single 16-

inch wiper blade with a replaceable rubber element

(squeegee).

Caution should be exercised to protect the rubber

squeegees from any petroleum-based cleaners or con-

taminants, which will rapidly deteriorate the squee-

gee rubber. If squeegees are damaged, worn or

contaminated they must be replaced.

Wiper squeegees exposed to the weather for a long

time tend to lose their wiping effectiveness. Periodiccleaning of the squeegees is suggested to remove de-

posits of salt and road film. The wiper blades, arms

and windshield or liftgate glass should be cleaned

with a sponge or cloth and a mild detergent or non-

abrasive cleaner. If the squeegees continue to streak

or smear, they should be replaced.

The blades are mounted to spring-loaded wiper

arms. Spring tension of the wiper arms controls the

pressure applied to the blades on the glass. The

windshield wiper arms are attached by an integral

latch to the two wiper pivots on the windshield frame

at the base of the windshield. The liftgate wiper arm

is attached by an integral latch directly to the lift-

gate wiper motor output shaft on the liftgate glass.

The wiper arms and blades can not be adjusted or re-

paired. If faulty, they must be replaced.

WIPER LINKAGE AND PIVOTS

The wiper pivots are fastened to the windshield

frame with nuts. The pivots and linkage are serviced

through access holes in the interior side of the lower

windshield frame. The two pivots and their connect-

ing link are serviced as a unit. The drive link, which

connects the motor crank arm to the left pivot, is ser-

viced separately.

WINDSHIELD WIPER MOTOR

The two-speed permanent magnet wiper motor has

an integral transmission and park switch. The motor

is mounted to a cover plate on the interior side of the

lower windshield frame. The wiper motor output

shaft passes through a gasket and the cover plate

into the space between the inner and outer lower

windshield frame, where the crank arm attached to

the output shaft drives the wiper drive link.

Wiper speed is controlled by current flow to the ap-

propriate set of brushes. The wiper motor completes

its wipe cycle when the switch is turned OFF, and

parks the blades in the lowest portion of the wipe

pattern. The wiper motor assembly can not be re-

paired. If faulty, the entire motor assembly must be

replaced. The cover plate, gasket and drive link to

crank arm retaining ring are available for service.

LIFTGATE WIPER MOTOR

The liftgate wiper motor operates in three modes:

²constant wipe that operates when the liftgate

wiper/washer switch is placed in the Wipe position

²constant wipe that operates when the liftgate

washers are operated

²a park mode that runs the motor until the wiper

blade reaches the park position after the liftgate

wiper switch or ignition switch is turned OFF.

8K - 10 WIPER AND WASHER SYSTEMS - YJJ

Page 433 of 2198

DIAGNOSIS - YJ

WINDSHIELD WIPER SYSTEM

(1) Remove circuit breaker from fuseblock module

and turn ignition switch to ACCESSORY or ON.

(a) Measure voltage at battery side of circuit

breaker cavity. Meter should read battery voltage.

If not OK, repair wiring from ignition switch.

(b) Measure resistance across circuit breaker ter-

minals. Meter should read zero ohms. If not OK,

replace failed circuit breaker.

(2) Unplug wiper motor side of wiring harness con-

nector (gray) from wiper switch side of wiring har-

ness connector (black), or from intermittent wipe

module (if equipped) at base of steering column. Turn

ignition switch to ACCESSORY or ON.

(a) Measure voltage at unplugged wiper motor

side of wiring harness connector (gray) terminal D.

Meter should read battery voltage. If not OK, re-

pair wiring from circuit breaker.

(b) Turn ignition switch to OFF and measure re-

sistance from unplugged wiper motor side of wiring

harness connector (gray) terminal G to ground.

Meter should read zero ohms. If not OK, repair

wiring to ground.

(3) Leave ignition switch in OFF, and back probe

wiring harness connector at wiper motor. Measure re-

sistance from terminal E of wiper motor side of con-

nector to ground. Meter should read zero ohms. If not

OK, repair wiring to ground.

(4) If equipped with intermittent wipe, turn igni-

tion switch to ACCESSORY or ON. Turn wiper

switch to LOW or HIGH. Unplug wiper switch side of

wiring harness connector (black) from intermittent

wipe module. Then plug both connectors that have

been removed from intermittent wipe module into

each other.

CAUTION: DO NOT move the wiper switch to DE-

LAY with the intermittent wipe module removed

from the circuit. If the switch is moved to the DE-

LAY position during the next step, the switch will be

damaged.

Test wiper operation in LOW and HIGH speed

modes, and test washer operation. If these modes

were inoperative, but are OK now, replace failed in-

termittent wipe module.

(5) To test the wiper/washer switch, see Windshield

Wiper/Washer Switch Testing. Turn ignition switch to

OFF. Position the wiper switch as indicated, and

back probe wiper switch side of wiring harness con-

nector (black). If switch tests OK, go to step 6. If not

OK, replace switch and go to step 7.

(6) To further test the wiper/washer switch, turn

ignition switch to ACCESSORY or ON. Position thewiper switch as indicated in the tests below, and

back probe wiper switch side of wiring harness con-

nector (black).

(a) Measure voltage at connector terminal E with

wiper switch in LOW, MIST and with washer

switch depressed. Meter should read battery volt-

age. If not OK, replace switch.

(b) Measure voltage at connector terminal C with

wiper switch in HIGH. Meter should read battery

voltage. If not OK, replace switch.

(c) With wiper switch in LOW or HIGH, measure

voltage at connector terminal F, then move wiper

switch to OFF. Meter should read battery voltage

until wipers park and then zero volts. If OK, go to

step 7. If not OK, check wiring to wiper motor, then

go to step 8.

(7) To test the wiper motor, turn the ignition

switch to ACCESSORY or ON. Position the wiper

switch and back probe the motor connector as indi-

cated.

(a) Wiper switch in any position, measure volt-

age at terminal B. Meter should read battery volt-

age. If not OK, repair wiring from circuit breaker.

(b) Wiper switch in LOW, measure voltage at ter-

minal A. Meter should read battery voltage. If OK,

but wipers do not operate, replace failed wiper mo-

tor. If not OK, repair wiring from switch or inter-

mittent wipe module connector.

(c) Wiper switch in HIGH, measure voltage at

terminal H. Meter should read battery voltage. If

OK, but wipers do not operate, replace failed wiper

motor. If not OK, repair wiring from switch or in-

termittent wipe module connector.

(d) Wiper switch in LOW or HIGH, voltmeter

connected to terminal D. Turn wiper switch to OFF

and observe meter. Meter should read battery volt-

age when switch goes to OFF, then zero volts after

wipers park. If battery voltage is present, but wip-

ers fail to park; or, if no battery voltage present, re-

place failed wiper motor.

WINDSHIELD WASHER SYSTEM

WITH NON-INTERMITTENT WIPE

(1) Measure resistance from washer pump connec-

tor terminal B to a clean chassis ground. Meter

should read zero ohms. If not OK, repair open be-

tween terminal B and ground.

(2) Turn ignition switch to ON and press washer

switch.

(a) Measure voltage at switch connector terminal

B. Meter should read battery voltage. If not OK, re-

place wiper/washer switch.

(b) Measure voltage at washer pump connector

terminal A. Meter should read battery voltage. If

8K - 12 WIPER AND WASHER SYSTEMS - YJJ

Page 438 of 2198

SERVICE PROCEDURES - YJ

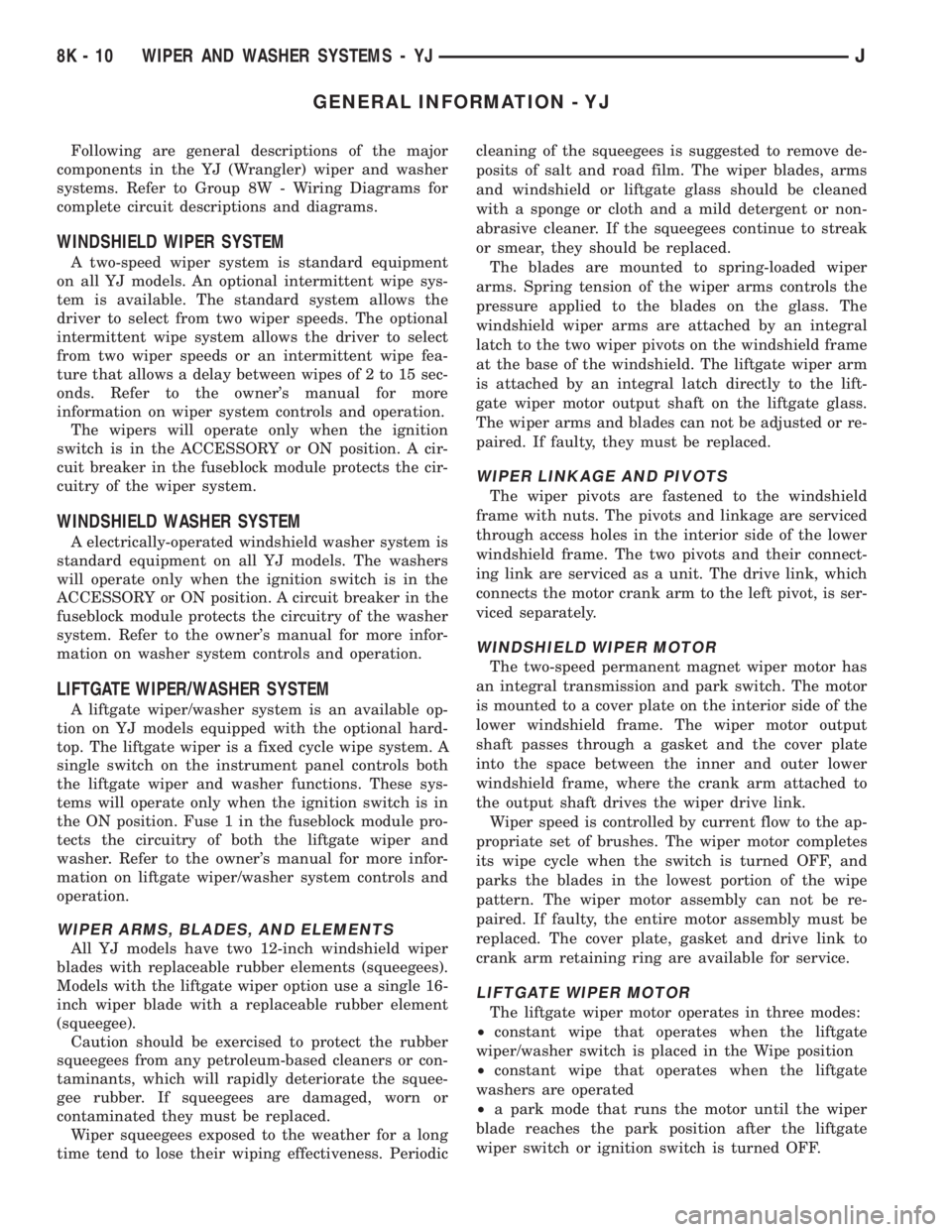

WINDSHIELD WIPER BLADE REMOVE/INSTALL

(1) Rotate the wiper blade release (Fig. 3) clock-

wise. This will release the wiper blade from the pivot

pin.

CAUTION: Take care to ensure that the wiper arm

does not strike the windshield after the wiper blade

has been removed.

(2) To install, place the blade assembly on the

wiper arm and snap the blade assembly into position.

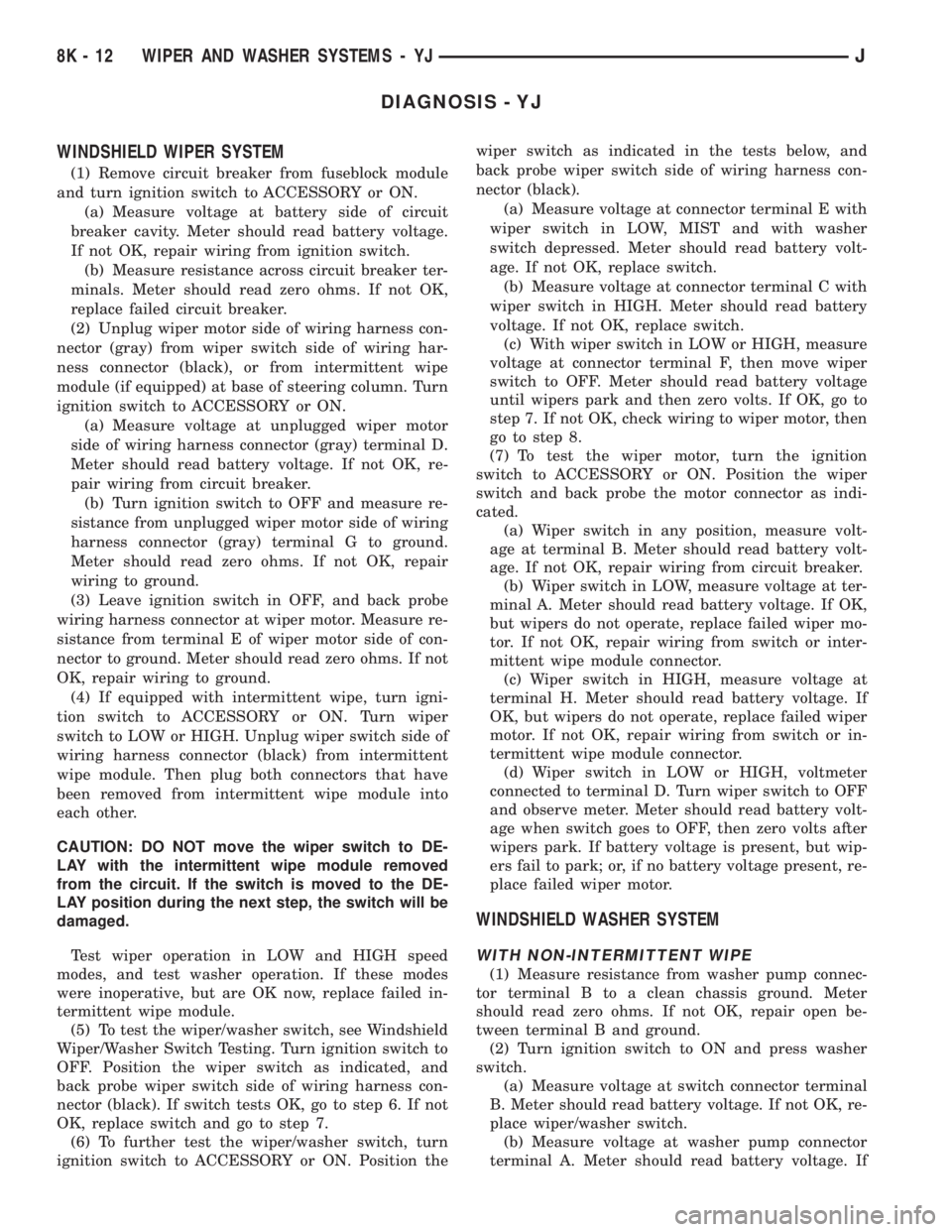

WINDSHIELD WIPER ARM REMOVE/INSTALL

(1) Pull the wiper arm forward.

(2) Insert an ice pick type tool into the hole (Fig.

4).

(3) Grasp the wiper arm above the pivot nut.

(4) Pull and remove the wiper arm assembly.

(5) To install, push the wiper arm over the pivot

shaft. Be sure the pivot shaft is in the park position

and the wiper arm is positioned correctly on the

windshield (Fig. 5).

LIFTGATE WIPER ARM REMOVE/INSTALL

(1) Install wiper arm remover, Snap On A192 or

equivalent, on wiper arm (Fig. 6). Lift arm and then

remove from pivot shaft.

CAUTION: Do not use a screwdriver or other pry-

ing tool to remove an arm. This may distort it in a

way that will allow it to come off the pivot shaft in

the future despite how carefully it is installed.

NEVER push or bend the spring clip in the base of

the arm in an attempt to release the arm. This clip

is self releasing.(2) Reverse removal procedures to install.

(3) Wet the liftgate glass and check the park posi-

tion by operating the wiper motor several times.

WINDSHIELD WIPER LINKAGE AND PIVOTS

REMOVE/INSTALL

(1) Remove the left and right wiper arms.

Fig. 3 Wiper Blade Remove/Install

Fig. 4 Windshield Wiper Arm Remove/Install

Fig. 5 Windshield Wiper Arm Indexing

JWIPER AND WASHER SYSTEMS - YJ 8K - 17

Page 441 of 2198

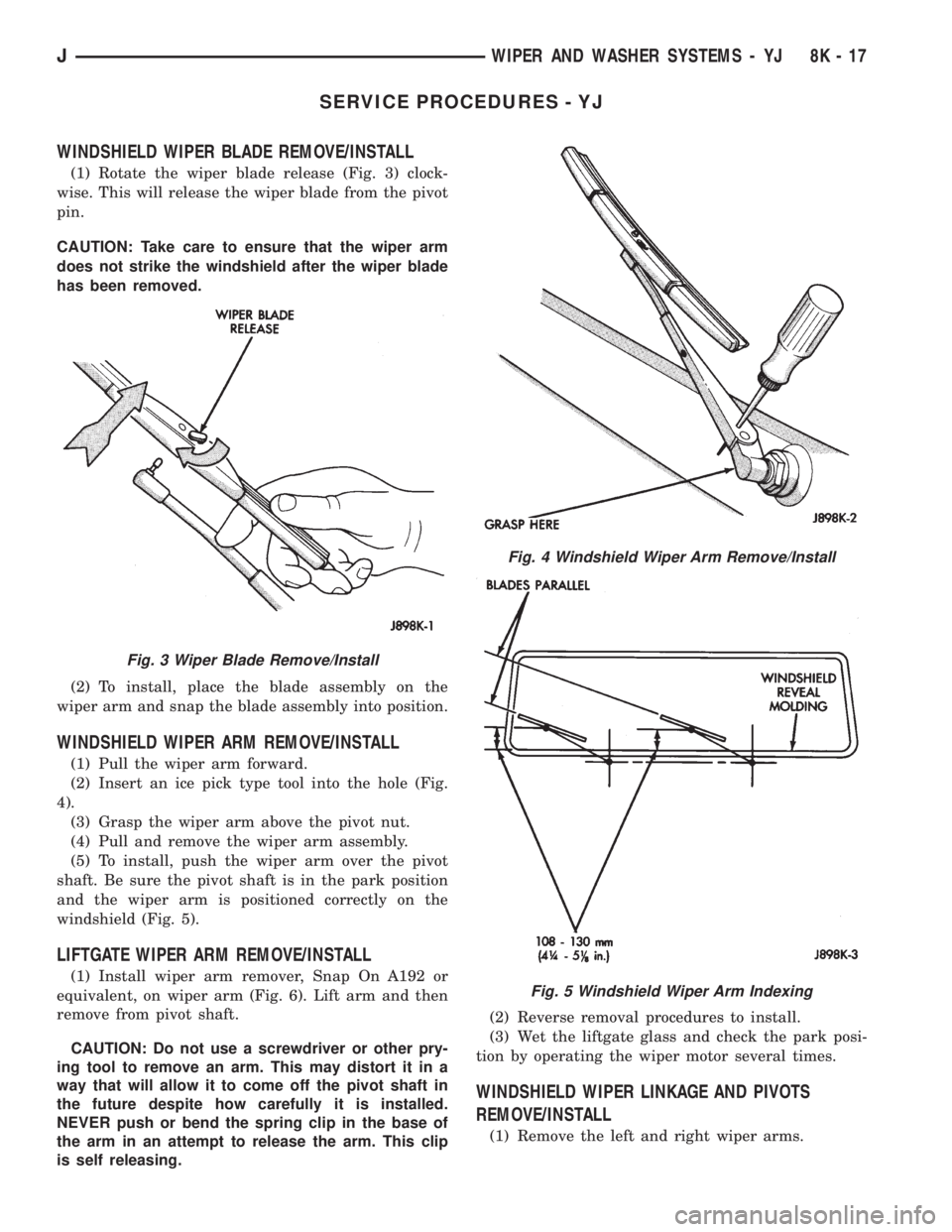

LIFTGATE WIPER MOTOR REMOVE/INSTALL

(1) Remove wiper arm from motor (see Liftgate

Wiper Arm Remove/Install).

(2) Remove pivot shaft retaining nut.

(3) Remove motor trim cover (Fig. 13).

(4) Disconnect electrical connector (Fig. 14).

(5) Remove hinge nut holding motor to top.

(6) Reverse removal procedures to install.

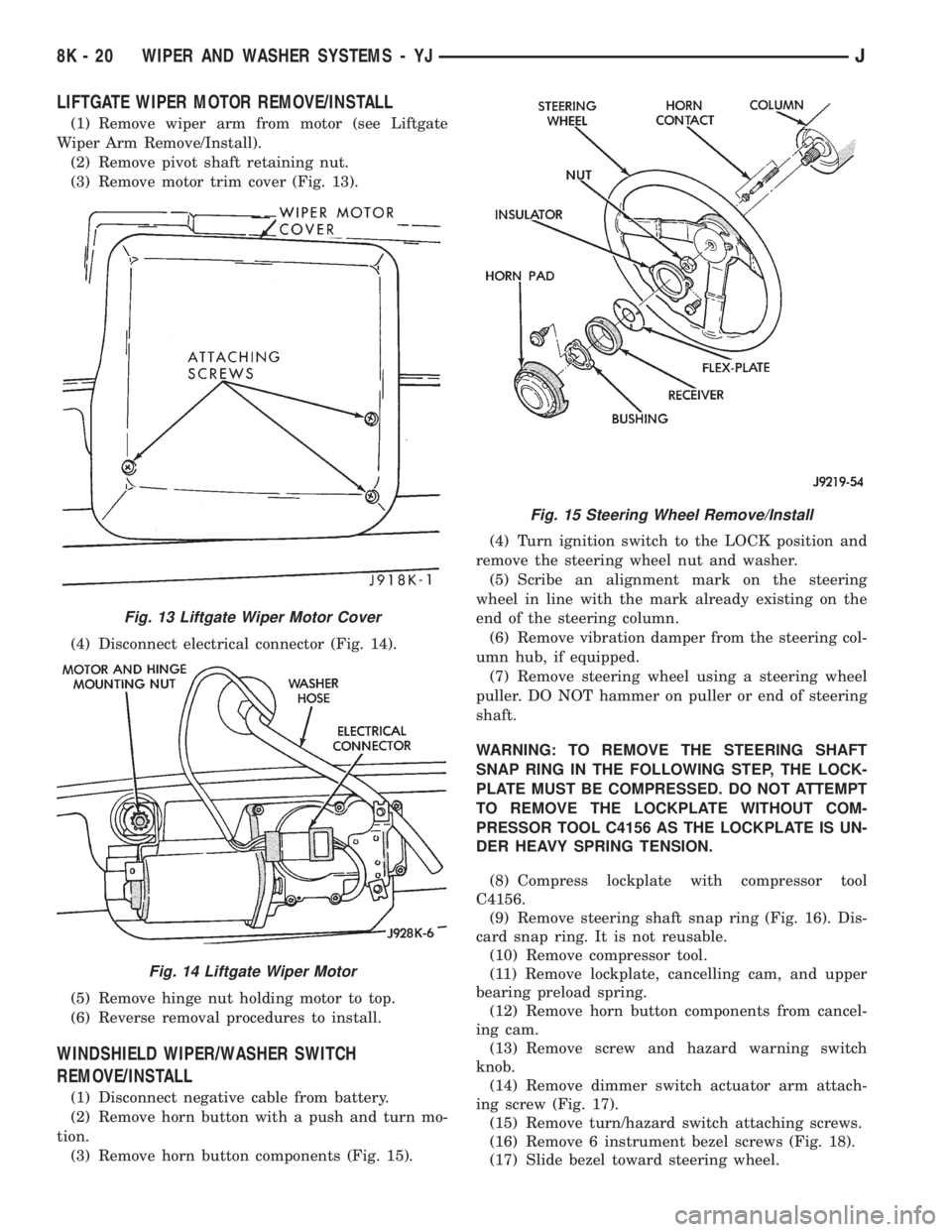

WINDSHIELD WIPER/WASHER SWITCH

REMOVE/INSTALL

(1) Disconnect negative cable from battery.

(2) Remove horn button with a push and turn mo-

tion.

(3) Remove horn button components (Fig. 15).(4) Turn ignition switch to the LOCK position and

remove the steering wheel nut and washer.

(5) Scribe an alignment mark on the steering

wheel in line with the mark already existing on the

end of the steering column.

(6) Remove vibration damper from the steering col-

umn hub, if equipped.

(7) Remove steering wheel using a steering wheel

puller. DO NOT hammer on puller or end of steering

shaft.

WARNING: TO REMOVE THE STEERING SHAFT

SNAP RING IN THE FOLLOWING STEP, THE LOCK-

PLATE MUST BE COMPRESSED. DO NOT ATTEMPT

TO REMOVE THE LOCKPLATE WITHOUT COM-

PRESSOR TOOL C4156 AS THE LOCKPLATE IS UN-

DER HEAVY SPRING TENSION.

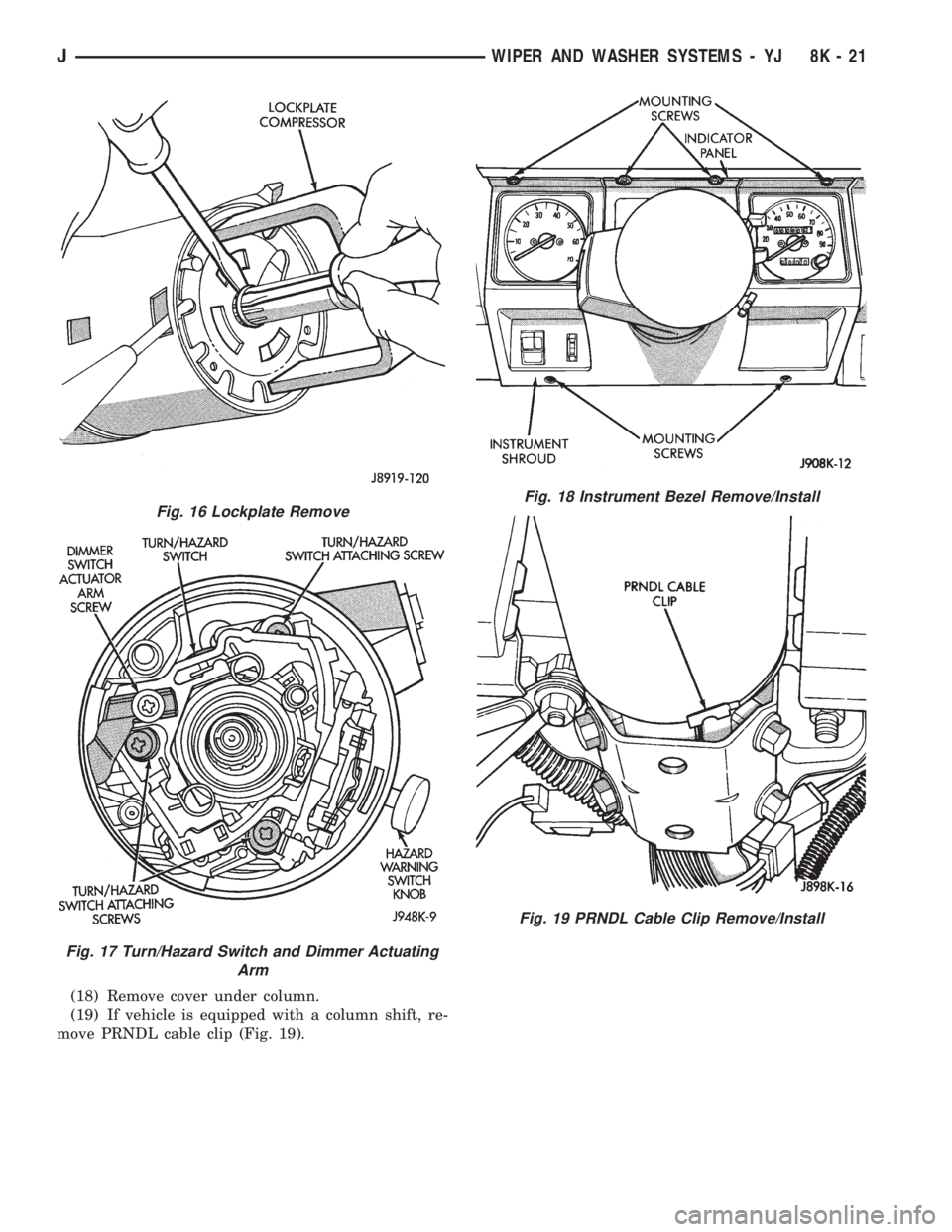

(8) Compress lockplate with compressor tool

C4156.

(9) Remove steering shaft snap ring (Fig. 16). Dis-

card snap ring. It is not reusable.

(10) Remove compressor tool.

(11) Remove lockplate, cancelling cam, and upper

bearing preload spring.

(12) Remove horn button components from cancel-

ing cam.

(13) Remove screw and hazard warning switch

knob.

(14) Remove dimmer switch actuator arm attach-

ing screw (Fig. 17).

(15) Remove turn/hazard switch attaching screws.

(16) Remove 6 instrument bezel screws (Fig. 18).

(17) Slide bezel toward steering wheel.

Fig. 13 Liftgate Wiper Motor Cover

Fig. 14 Liftgate Wiper Motor

Fig. 15 Steering Wheel Remove/Install

8K - 20 WIPER AND WASHER SYSTEMS - YJJ

Page 442 of 2198

(18) Remove cover under column.

(19) If vehicle is equipped with a column shift, re-

move PRNDL cable clip (Fig. 19).

Fig. 16 Lockplate Remove

Fig. 17 Turn/Hazard Switch and Dimmer Actuating

Arm

Fig. 18 Instrument Bezel Remove/Install

Fig. 19 PRNDL Cable Clip Remove/Install

JWIPER AND WASHER SYSTEMS - YJ 8K - 21

Page 443 of 2198

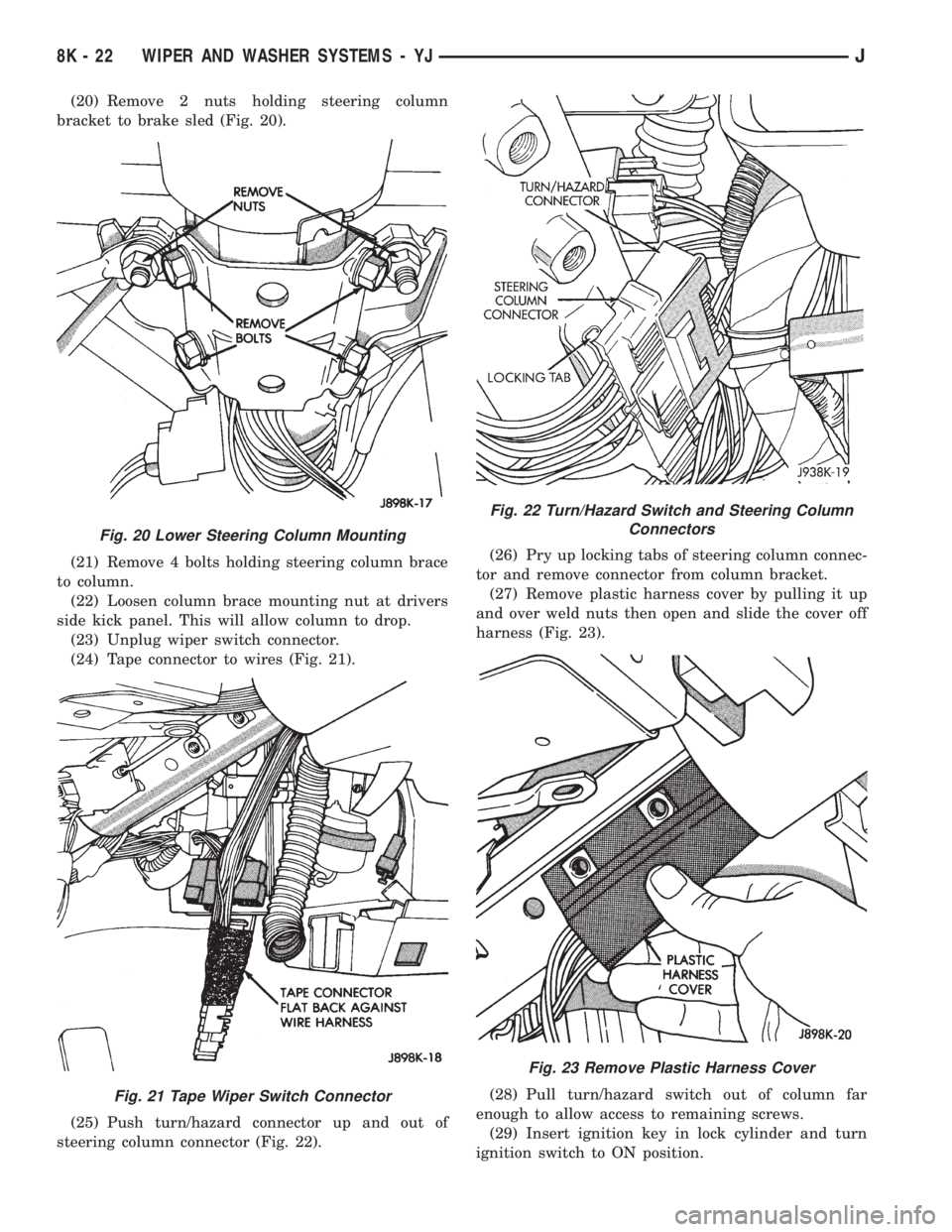

(20) Remove 2 nuts holding steering column

bracket to brake sled (Fig. 20).

(21) Remove 4 bolts holding steering column brace

to column.

(22) Loosen column brace mounting nut at drivers

side kick panel. This will allow column to drop.

(23) Unplug wiper switch connector.

(24) Tape connector to wires (Fig. 21).

(25) Push turn/hazard connector up and out of

steering column connector (Fig. 22).(26) Pry up locking tabs of steering column connec-

tor and remove connector from column bracket.

(27) Remove plastic harness cover by pulling it up

and over weld nuts then open and slide the cover off

harness (Fig. 23).

(28) Pull turn/hazard switch out of column far

enough to allow access to remaining screws.

(29) Insert ignition key in lock cylinder and turn

ignition switch to ON position.

Fig. 20 Lower Steering Column Mounting

Fig. 21 Tape Wiper Switch Connector

Fig. 22 Turn/Hazard Switch and Steering Column

Connectors

Fig. 23 Remove Plastic Harness Cover

8K - 22 WIPER AND WASHER SYSTEMS - YJJ