JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1671 of 2198

OVERHAUL CLEANING AND INSPECTION

Clean the transfer case components thoroughly

with solvent. Remove all traces of sealer from the

case and retainer seal surfaces.

Clean the oil pickup screen with solvent. Shake ex-

cess solvent from screen and allow it air dry. Use

compressed air to remove solvent residue from all oil

feed passages and channels in the case halves.

Inspect the splines and bearing surfaces on the

both shafts. Replace either shaft as necessary if wear,

or damage is evident.

Check condition of the shift forks, fork pads and

shift rail. Minor scratches/nicks on the rail can be

smoothed with 320/400 grit emery cloth. Replace the

mode fork pads if worn. Replace the range fork if the

pads are worn, missing, or damaged.

On synchro equipped models, inspect the synchro

sleeve, hub, struts, springs, and the stop ring. Re-

place worn, or damaged parts as necessary.

Do not attempt to salvage and reuse snap rings

that were bent, or distorted. It is recommended that

all snap rings be replaced during overhaul.Replace the front yoke nut as it should not be re-

used. Also replace the rubber seal if worn, cut, or

torn.

Inspect the low range annulus gear (Fig. 28).If

the gear is damaged, replace the gear and front

case as an assembly. Do not attempt to remove

the gear.

Inspect the case halves, extension housing and re-

tainers for cracks, porosity, or damaged sealing sur-

faces.

Inspect the drive sprockets and drive chain care-

fully. Replace the sprockets if worn, chipped, or

cracked. Also replace the chain if distorted, binds at

any point, or is stretched.

Replace the oil pump if any pump part is worn or

damaged. Do not disassemble the pump as parts are

not available separately. The pump is only available

as an assembly.

Inspect all of the transfer case bearings for wear,

roughness, pitting, or galling. Replace worn or dam-

aged bearings as outlined in the transfer case assem-

bly procedures.

Clean the sealing (mating) surfaces of the case

halves, retainer and extension with a scraper, a wire

brush and 3M All Purpose cleaning solvent. These

surfaces must be clean in order for the sealer to ad-

here properly.

TRANSFER CASE ASSEMBLY

CAUTION: The bearing bores in various transfer

case components contain oil feed holes. Be sure re-

placement bearings do not block these feed holes.

In addition, the drive sprocket, synchro hub and

sleeve are different for non-synchro and synchro

models. Do not interchange these parts. Do not in-

stall synchro struts or a stop ring in a non-synchro

model; this will cause the drive sprocket to bind on

the shaft and hub.

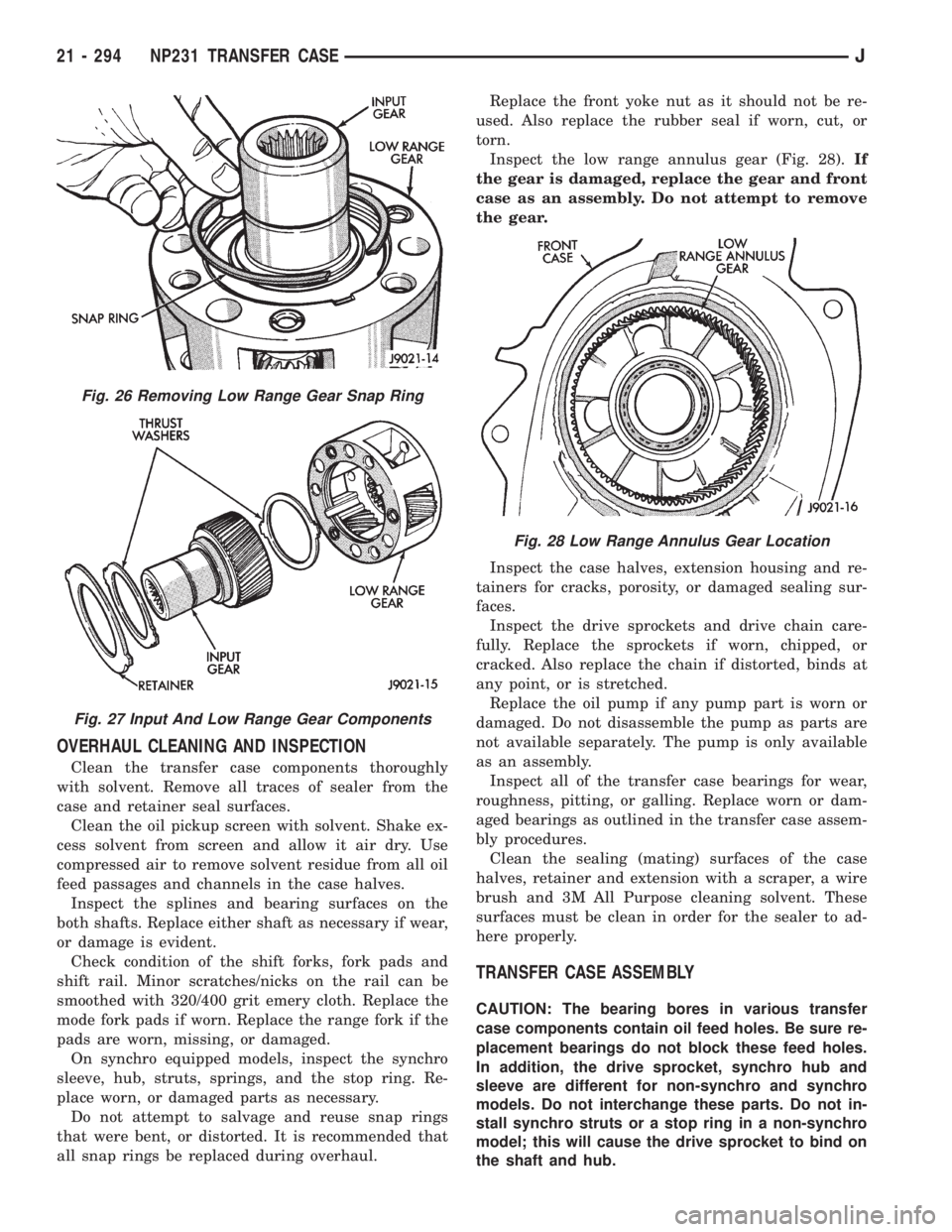

Fig. 26 Removing Low Range Gear Snap Ring

Fig. 27 Input And Low Range Gear Components

Fig. 28 Low Range Annulus Gear Location

21 - 294 NP231 TRANSFER CASEJ

Page 1672 of 2198

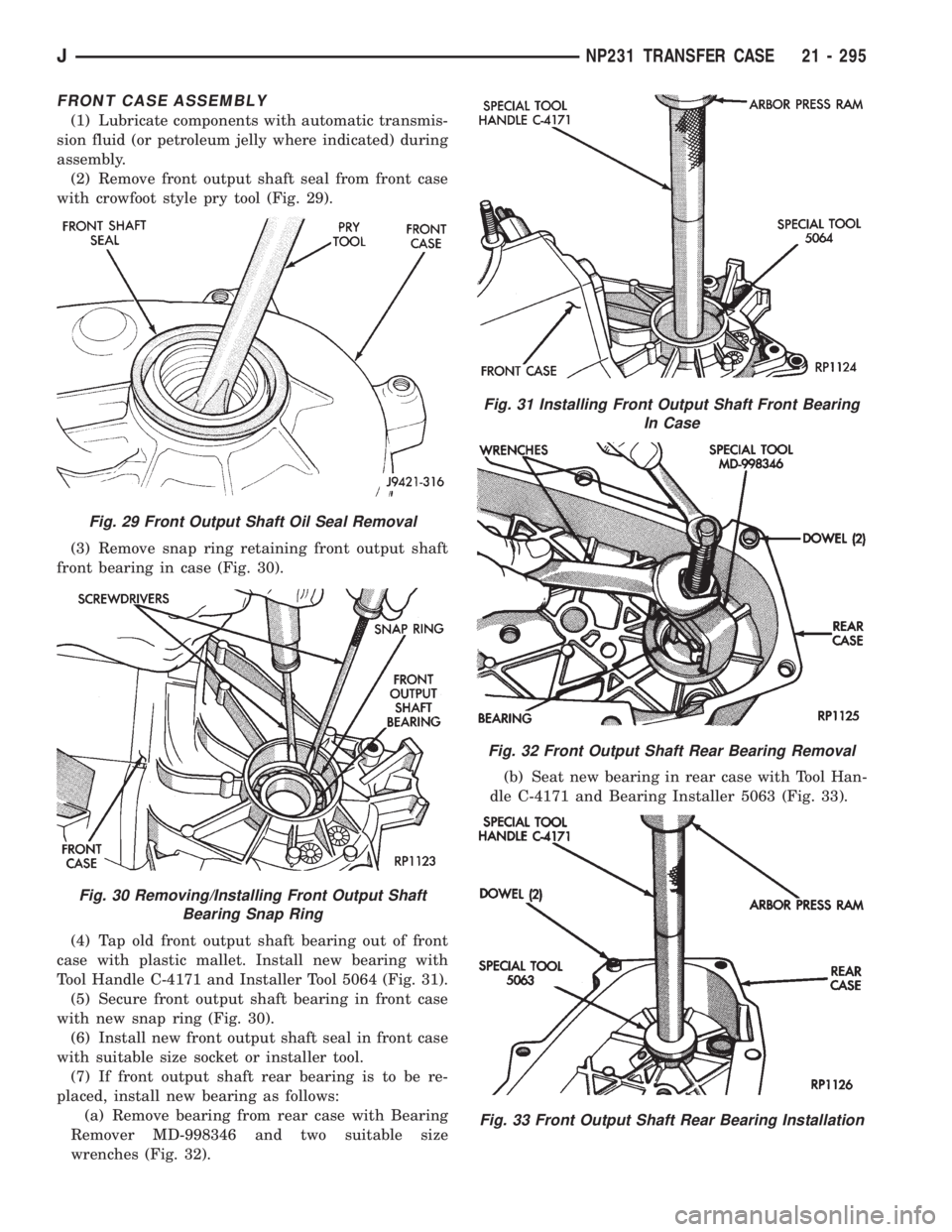

FRONT CASE ASSEMBLY

(1) Lubricate components with automatic transmis-

sion fluid (or petroleum jelly where indicated) during

assembly.

(2) Remove front output shaft seal from front case

with crowfoot style pry tool (Fig. 29).

(3) Remove snap ring retaining front output shaft

front bearing in case (Fig. 30).

(4) Tap old front output shaft bearing out of front

case with plastic mallet. Install new bearing with

Tool Handle C-4171 and Installer Tool 5064 (Fig. 31).

(5) Secure front output shaft bearing in front case

with new snap ring (Fig. 30).

(6) Install new front output shaft seal in front case

with suitable size socket or installer tool.

(7) If front output shaft rear bearing is to be re-

placed, install new bearing as follows:

(a) Remove bearing from rear case with Bearing

Remover MD-998346 and two suitable size

wrenches (Fig. 32).(b) Seat new bearing in rear case with Tool Han-

dle C-4171 and Bearing Installer 5063 (Fig. 33).

Fig. 29 Front Output Shaft Oil Seal Removal

Fig. 30 Removing/Installing Front Output Shaft

Bearing Snap Ring

Fig. 31 Installing Front Output Shaft Front Bearing

In Case

Fig. 32 Front Output Shaft Rear Bearing Removal

Fig. 33 Front Output Shaft Rear Bearing Installation

JNP231 TRANSFER CASE 21 - 295

Page 1673 of 2198

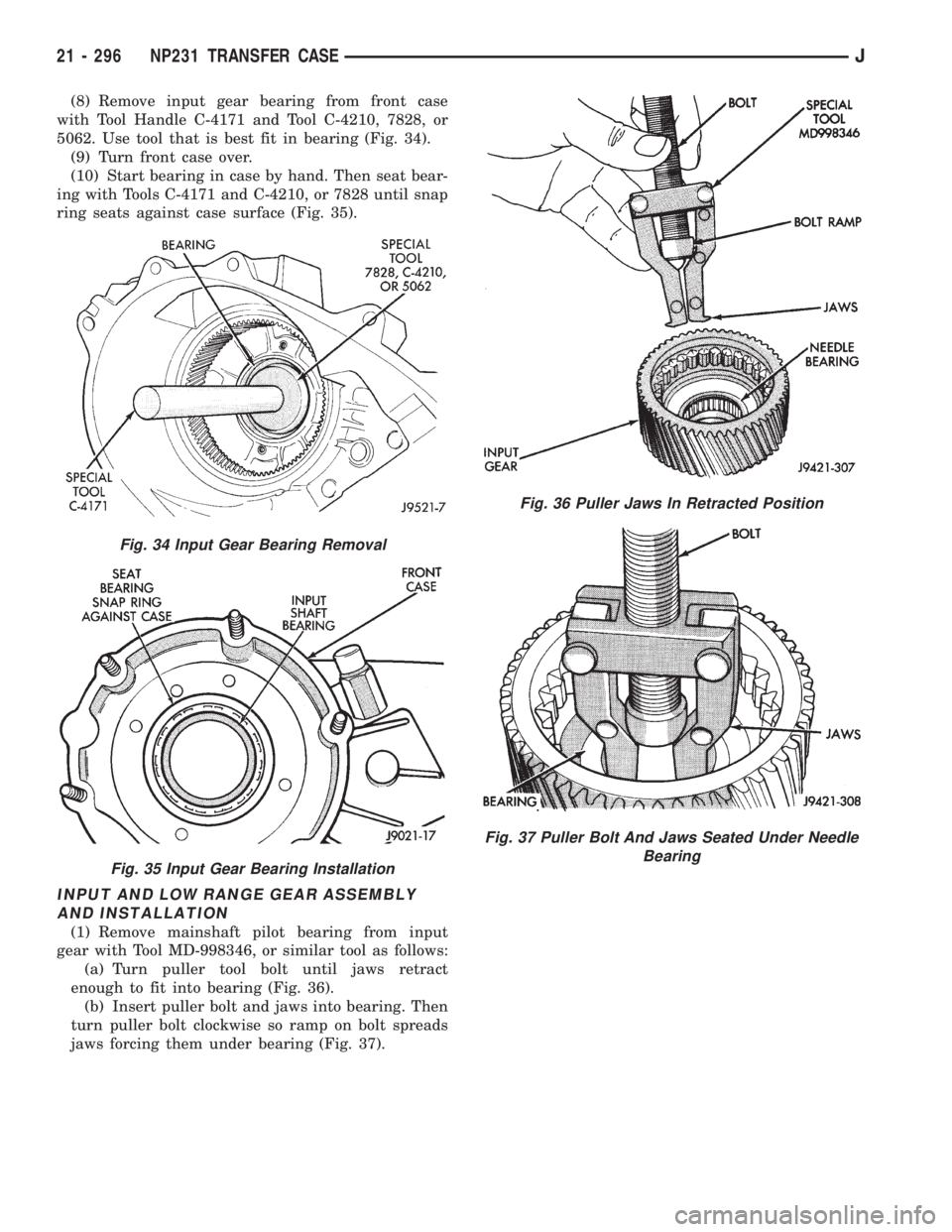

(8) Remove input gear bearing from front case

with Tool Handle C-4171 and Tool C-4210, 7828, or

5062. Use tool that is best fit in bearing (Fig. 34).

(9) Turn front case over.

(10) Start bearing in case by hand. Then seat bear-

ing with Tools C-4171 and C-4210, or 7828 until snap

ring seats against case surface (Fig. 35).

INPUT AND LOW RANGE GEAR ASSEMBLY

AND INSTALLATION

(1) Remove mainshaft pilot bearing from input

gear with Tool MD-998346, or similar tool as follows:

(a) Turn puller tool bolt until jaws retract

enough to fit into bearing (Fig. 36).

(b) Insert puller bolt and jaws into bearing. Then

turn puller bolt clockwise so ramp on bolt spreads

jaws forcing them under bearing (Fig. 37).

Fig. 34 Input Gear Bearing Removal

Fig. 35 Input Gear Bearing Installation

Fig. 36 Puller Jaws In Retracted Position

Fig. 37 Puller Bolt And Jaws Seated Under Needle

Bearing

21 - 296 NP231 TRANSFER CASEJ

Page 1674 of 2198

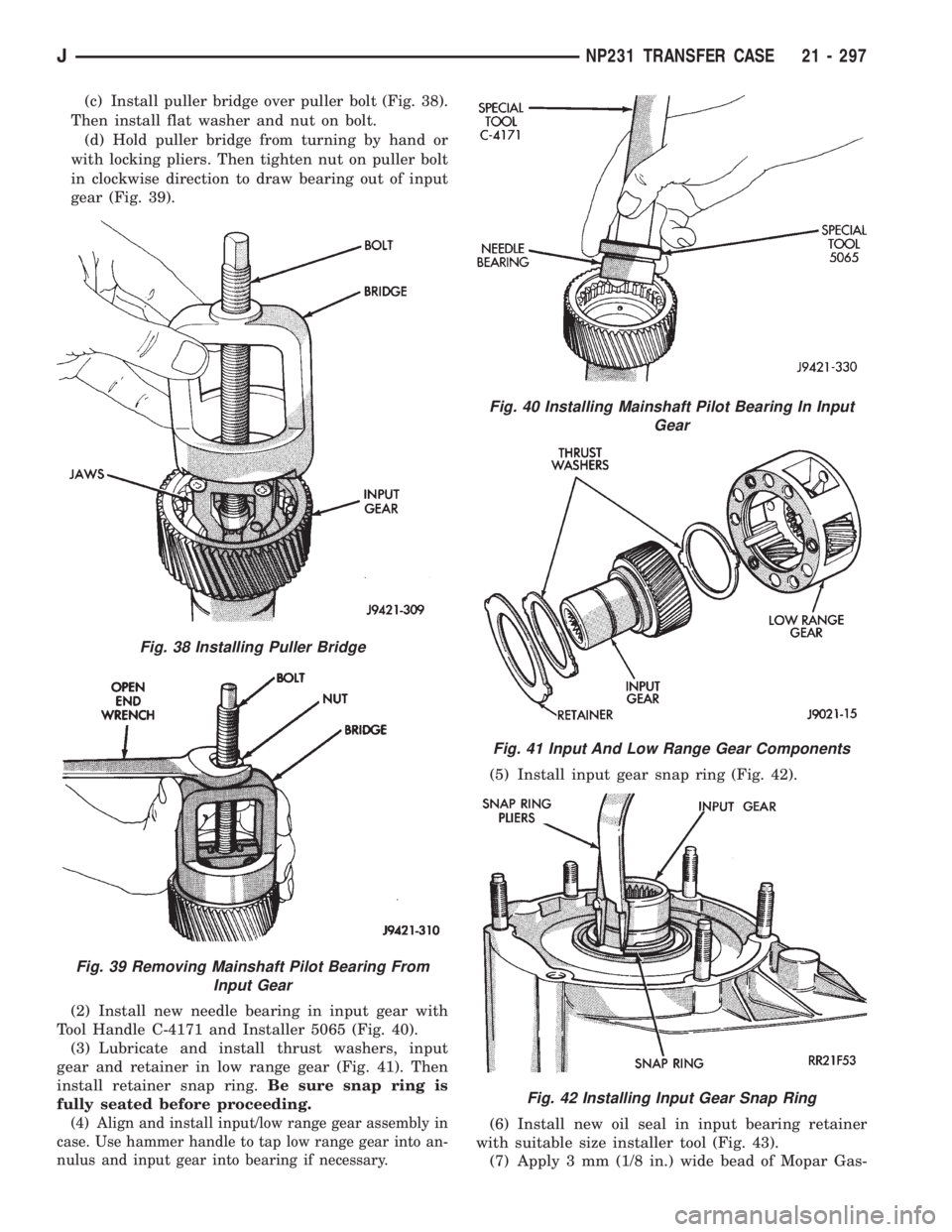

(c) Install puller bridge over puller bolt (Fig. 38).

Then install flat washer and nut on bolt.

(d) Hold puller bridge from turning by hand or

with locking pliers. Then tighten nut on puller bolt

in clockwise direction to draw bearing out of input

gear (Fig. 39).

(2) Install new needle bearing in input gear with

Tool Handle C-4171 and Installer 5065 (Fig. 40).

(3) Lubricate and install thrust washers, input

gear and retainer in low range gear (Fig. 41). Then

install retainer snap ring.Be sure snap ring is

fully seated before proceeding.

(4) Align and install input/low range gear assembly in

case. Use hammer handle to tap low range gear into an-

nulus and input gear into bearing if necessary.

(5) Install input gear snap ring (Fig. 42).

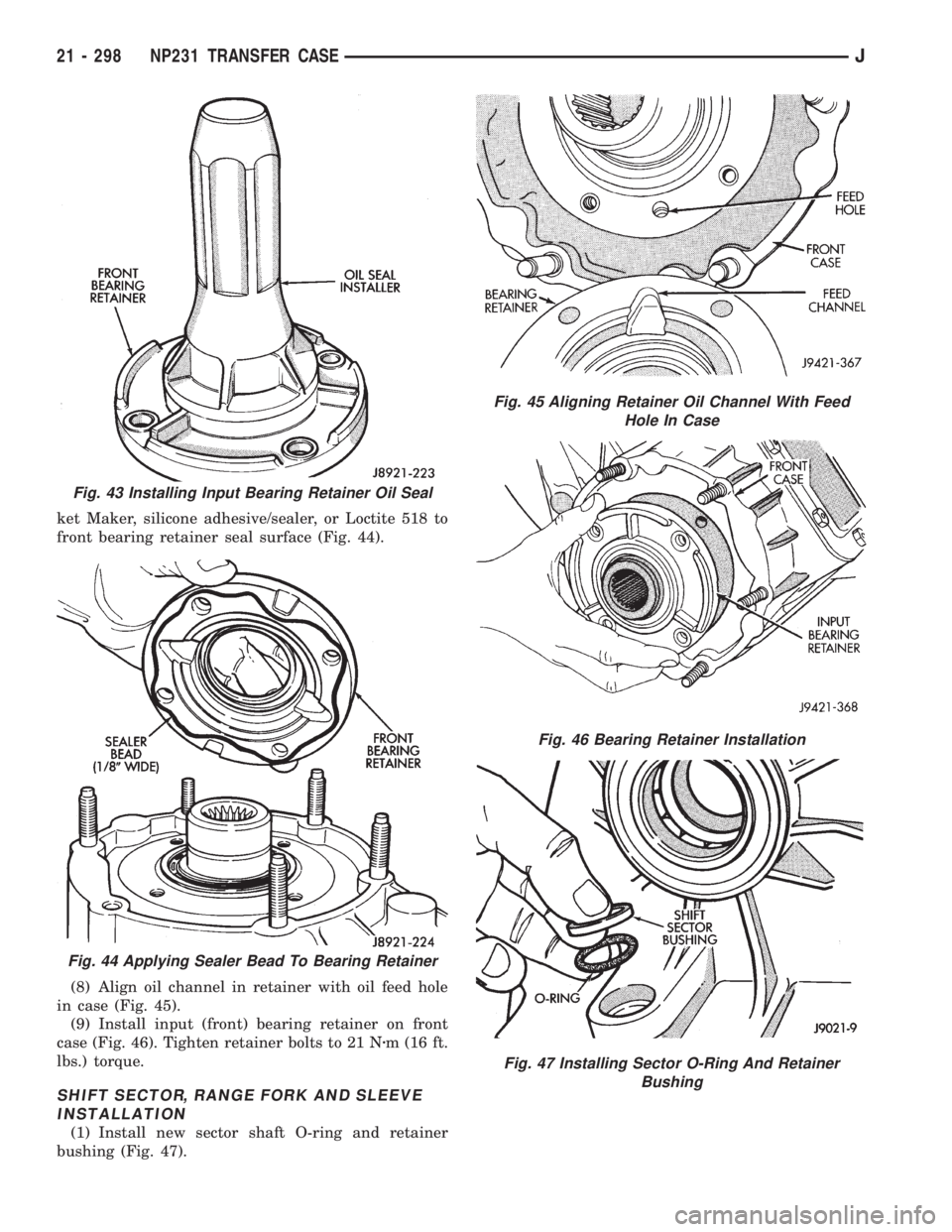

(6) Install new oil seal in input bearing retainer

with suitable size installer tool (Fig. 43).

(7) Apply 3 mm (1/8 in.) wide bead of Mopar Gas-

Fig. 38 Installing Puller Bridge

Fig. 39 Removing Mainshaft Pilot Bearing From

Input Gear

Fig. 40 Installing Mainshaft Pilot Bearing In Input

Gear

Fig. 41 Input And Low Range Gear Components

Fig. 42 Installing Input Gear Snap Ring

JNP231 TRANSFER CASE 21 - 297

Page 1675 of 2198

ket Maker, silicone adhesive/sealer, or Loctite 518 to

front bearing retainer seal surface (Fig. 44).

(8) Align oil channel in retainer with oil feed hole

in case (Fig. 45).

(9) Install input (front) bearing retainer on front

case (Fig. 46). Tighten retainer bolts to 21 Nzm (16 ft.

lbs.) torque.

SHIFT SECTOR, RANGE FORK AND SLEEVE

INSTALLATION

(1) Install new sector shaft O-ring and retainer

bushing (Fig. 47).

Fig. 43 Installing Input Bearing Retainer Oil Seal

Fig. 44 Applying Sealer Bead To Bearing Retainer

Fig. 45 Aligning Retainer Oil Channel With Feed

Hole In Case

Fig. 46 Bearing Retainer Installation

Fig. 47 Installing Sector O-Ring And Retainer

Bushing

21 - 298 NP231 TRANSFER CASEJ

Page 1676 of 2198

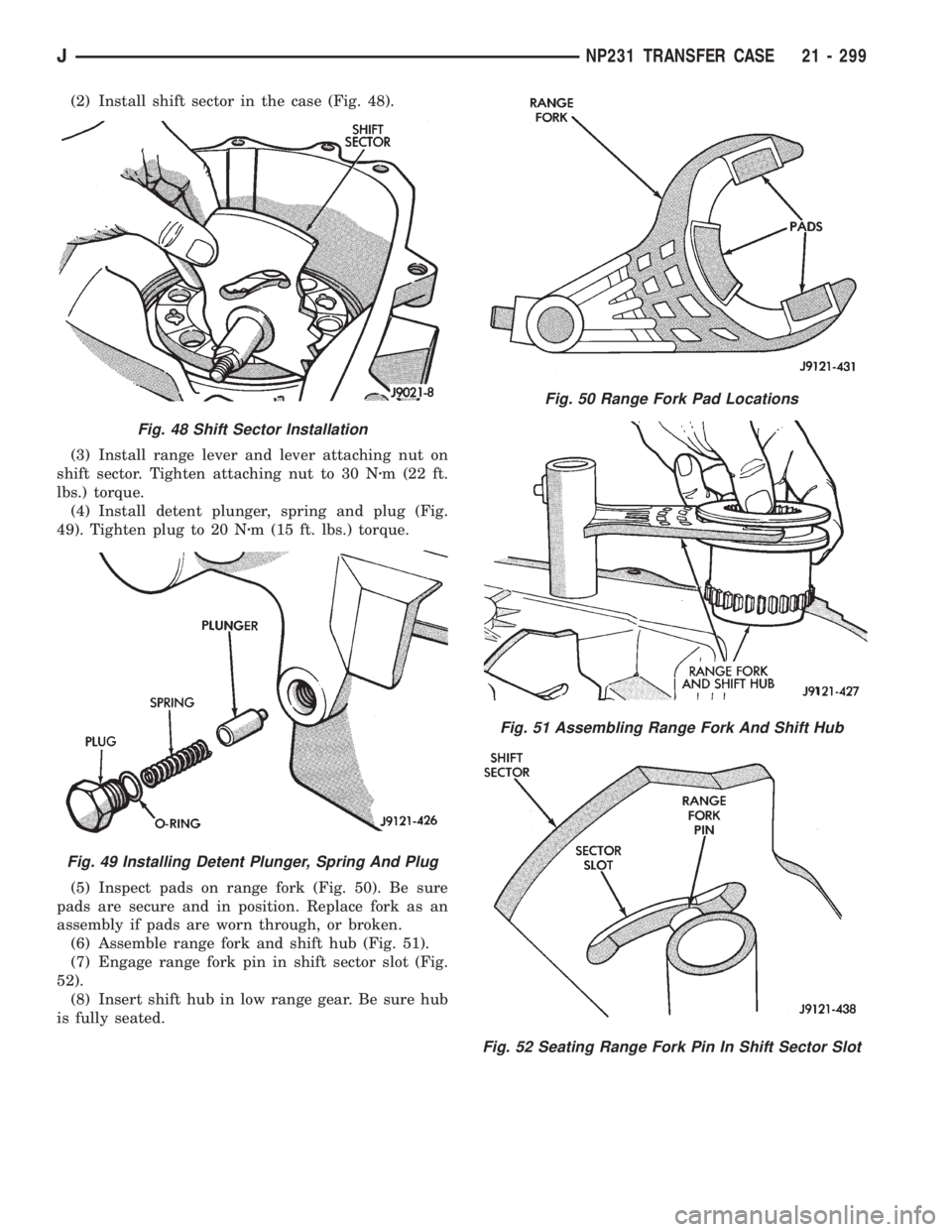

(2) Install shift sector in the case (Fig. 48).

(3) Install range lever and lever attaching nut on

shift sector. Tighten attaching nut to 30 Nzm (22 ft.

lbs.) torque.

(4) Install detent plunger, spring and plug (Fig.

49). Tighten plug to 20 Nzm (15 ft. lbs.) torque.

(5) Inspect pads on range fork (Fig. 50). Be sure

pads are secure and in position. Replace fork as an

assembly if pads are worn through, or broken.

(6) Assemble range fork and shift hub (Fig. 51).

(7) Engage range fork pin in shift sector slot (Fig.

52).

(8) Insert shift hub in low range gear. Be sure hub

is fully seated.

Fig. 48 Shift Sector Installation

Fig. 49 Installing Detent Plunger, Spring And Plug

Fig. 50 Range Fork Pad Locations

Fig. 51 Assembling Range Fork And Shift Hub

Fig. 52 Seating Range Fork Pin In Shift Sector Slot

JNP231 TRANSFER CASE 21 - 299

Page 1677 of 2198

MAINSHAFT ASSEMBLY

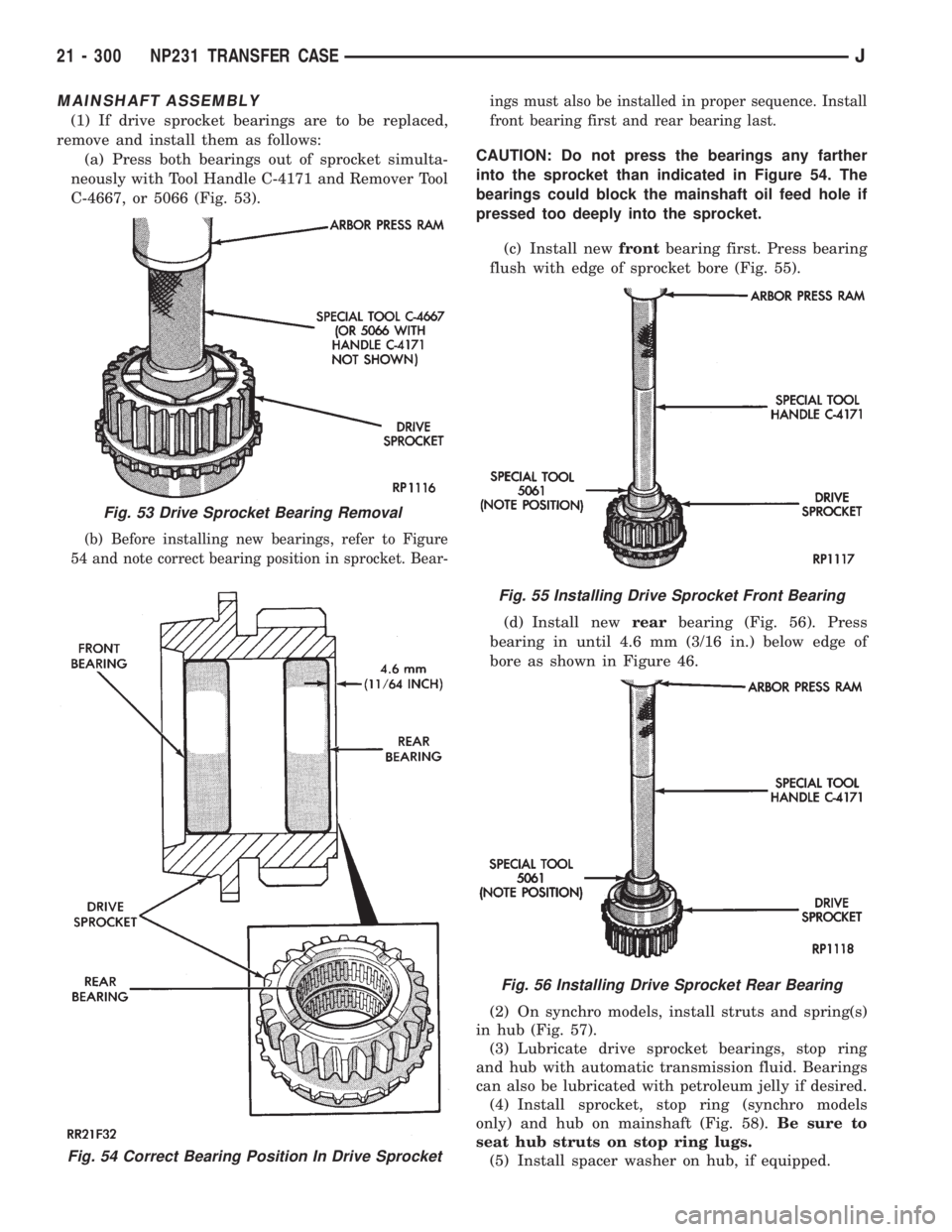

(1) If drive sprocket bearings are to be replaced,

remove and install them as follows:

(a) Press both bearings out of sprocket simulta-

neously with Tool Handle C-4171 and Remover Tool

C-4667, or 5066 (Fig. 53).

(b) Before installing new bearings, refer to Figure

54 and note correct bearing position in sprocket. Bear-ings must also be installed in proper sequence. Install

front bearing first and rear bearing last.

CAUTION: Do not press the bearings any farther

into the sprocket than indicated in Figure 54. The

bearings could block the mainshaft oil feed hole if

pressed too deeply into the sprocket.

(c) Install newfrontbearing first. Press bearing

flush with edge of sprocket bore (Fig. 55).

(d) Install newrearbearing (Fig. 56). Press

bearing in until 4.6 mm (3/16 in.) below edge of

bore as shown in Figure 46.

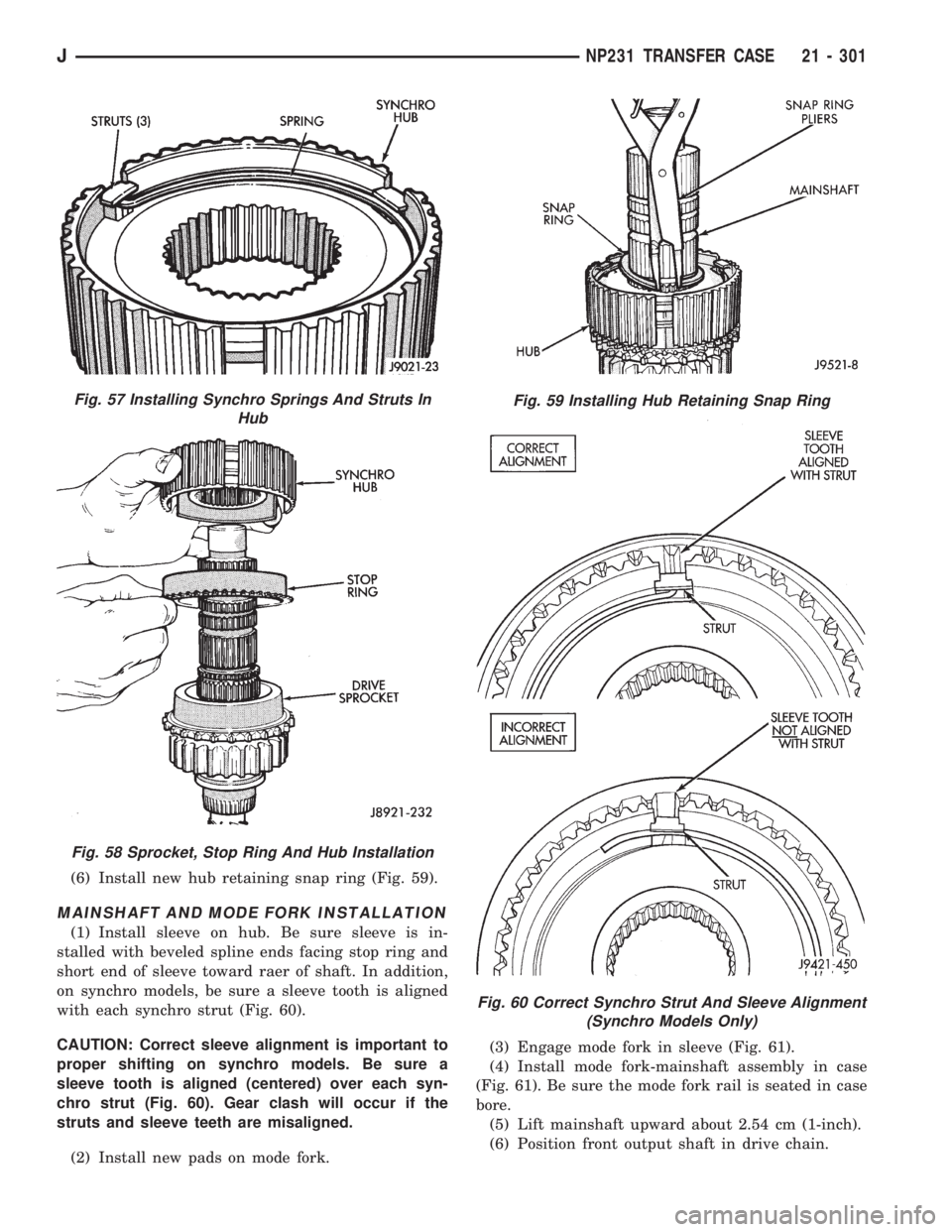

(2) On synchro models, install struts and spring(s)

in hub (Fig. 57).

(3) Lubricate drive sprocket bearings, stop ring

and hub with automatic transmission fluid. Bearings

can also be lubricated with petroleum jelly if desired.

(4) Install sprocket, stop ring (synchro models

only) and hub on mainshaft (Fig. 58).Be sure to

seat hub struts on stop ring lugs.

(5) Install spacer washer on hub, if equipped.

Fig. 54 Correct Bearing Position In Drive Sprocket

Fig. 53 Drive Sprocket Bearing Removal

Fig. 55 Installing Drive Sprocket Front Bearing

Fig. 56 Installing Drive Sprocket Rear Bearing

21 - 300 NP231 TRANSFER CASEJ

Page 1678 of 2198

(6) Install new hub retaining snap ring (Fig. 59).

MAINSHAFT AND MODE FORK INSTALLATION

(1) Install sleeve on hub. Be sure sleeve is in-

stalled with beveled spline ends facing stop ring and

short end of sleeve toward raer of shaft. In addition,

on synchro models, be sure a sleeve tooth is aligned

with each synchro strut (Fig. 60).

CAUTION: Correct sleeve alignment is important to

proper shifting on synchro models. Be sure a

sleeve tooth is aligned (centered) over each syn-

chro strut (Fig. 60). Gear clash will occur if the

struts and sleeve teeth are misaligned.

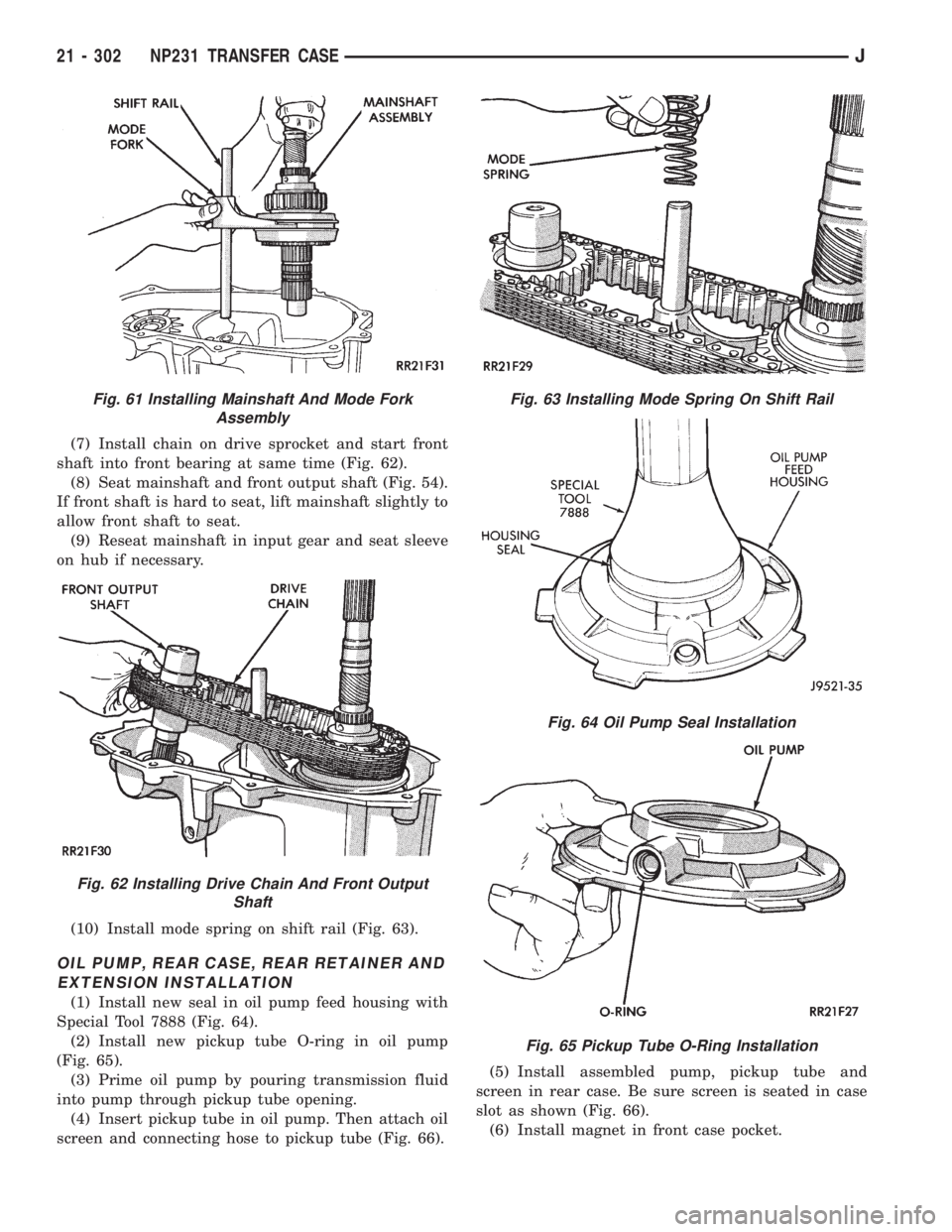

(2) Install new pads on mode fork.(3) Engage mode fork in sleeve (Fig. 61).

(4) Install mode fork-mainshaft assembly in case

(Fig. 61). Be sure the mode fork rail is seated in case

bore.

(5) Lift mainshaft upward about 2.54 cm (1-inch).

(6) Position front output shaft in drive chain.

Fig. 57 Installing Synchro Springs And Struts In

Hub

Fig. 58 Sprocket, Stop Ring And Hub Installation

Fig. 59 Installing Hub Retaining Snap Ring

Fig. 60 Correct Synchro Strut And Sleeve Alignment

(Synchro Models Only)

JNP231 TRANSFER CASE 21 - 301

Page 1679 of 2198

(7) Install chain on drive sprocket and start front

shaft into front bearing at same time (Fig. 62).

(8) Seat mainshaft and front output shaft (Fig. 54).

If front shaft is hard to seat, lift mainshaft slightly to

allow front shaft to seat.

(9) Reseat mainshaft in input gear and seat sleeve

on hub if necessary.

(10) Install mode spring on shift rail (Fig. 63).

OIL PUMP, REAR CASE, REAR RETAINER AND

EXTENSION INSTALLATION

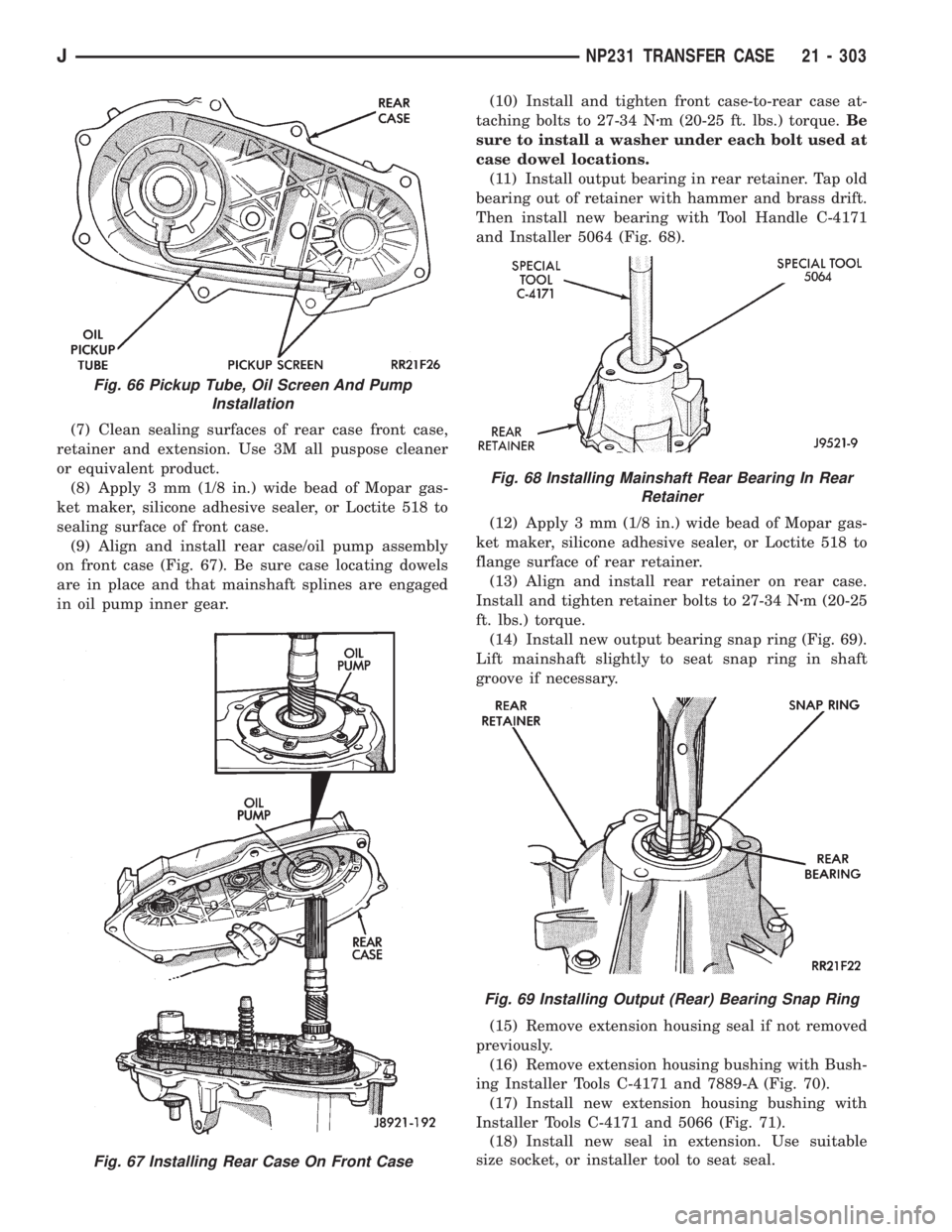

(1) Install new seal in oil pump feed housing with

Special Tool 7888 (Fig. 64).

(2) Install new pickup tube O-ring in oil pump

(Fig. 65).

(3) Prime oil pump by pouring transmission fluid

into pump through pickup tube opening.

(4) Insert pickup tube in oil pump. Then attach oil

screen and connecting hose to pickup tube (Fig. 66).(5) Install assembled pump, pickup tube and

screen in rear case. Be sure screen is seated in case

slot as shown (Fig. 66).

(6) Install magnet in front case pocket.

Fig. 61 Installing Mainshaft And Mode Fork

Assembly

Fig. 62 Installing Drive Chain And Front Output

Shaft

Fig. 63 Installing Mode Spring On Shift Rail

Fig. 64 Oil Pump Seal Installation

Fig. 65 Pickup Tube O-Ring Installation

21 - 302 NP231 TRANSFER CASEJ

Page 1680 of 2198

(7) Clean sealing surfaces of rear case front case,

retainer and extension. Use 3M all puspose cleaner

or equivalent product.

(8) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

sealing surface of front case.

(9) Align and install rear case/oil pump assembly

on front case (Fig. 67). Be sure case locating dowels

are in place and that mainshaft splines are engaged

in oil pump inner gear.(10) Install and tighten front case-to-rear case at-

taching bolts to 27-34 Nzm (20-25 ft. lbs.) torque.Be

sure to install a washer under each bolt used at

case dowel locations.

(11) Install output bearing in rear retainer. Tap old

bearing out of retainer with hammer and brass drift.

Then install new bearing with Tool Handle C-4171

and Installer 5064 (Fig. 68).

(12) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

flange surface of rear retainer.

(13) Align and install rear retainer on rear case.

Install and tighten retainer bolts to 27-34 Nzm (20-25

ft. lbs.) torque.

(14) Install new output bearing snap ring (Fig. 69).

Lift mainshaft slightly to seat snap ring in shaft

groove if necessary.

(15) Remove extension housing seal if not removed

previously.

(16) Remove extension housing bushing with Bush-

ing Installer Tools C-4171 and 7889-A (Fig. 70).

(17) Install new extension housing bushing with

Installer Tools C-4171 and 5066 (Fig. 71).

(18) Install new seal in extension. Use suitable

size socket, or installer tool to seat seal.

Fig. 67 Installing Rear Case On Front Case

Fig. 66 Pickup Tube, Oil Screen And Pump

Installation

Fig. 68 Installing Mainshaft Rear Bearing In Rear

Retainer

Fig. 69 Installing Output (Rear) Bearing Snap Ring

JNP231 TRANSFER CASE 21 - 303