lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1575 of 2198

AW-4 TRANSMISSION REMOVAL AND INSTALLATION

INDEX

page page

Oil Pump Seal Replacement................ 199

Torque Converter Stator Clutch Inspection...... 199Transmission and Torque Converter Installation . . 199

Transmission and Torque Converter Removal.... 198

TRANSMISSION AND TORQUE CONVERTER

REMOVAL

(1) Raise vehicle.

(2) Drain transmission fluid and reinstall oil pan

drain plug.

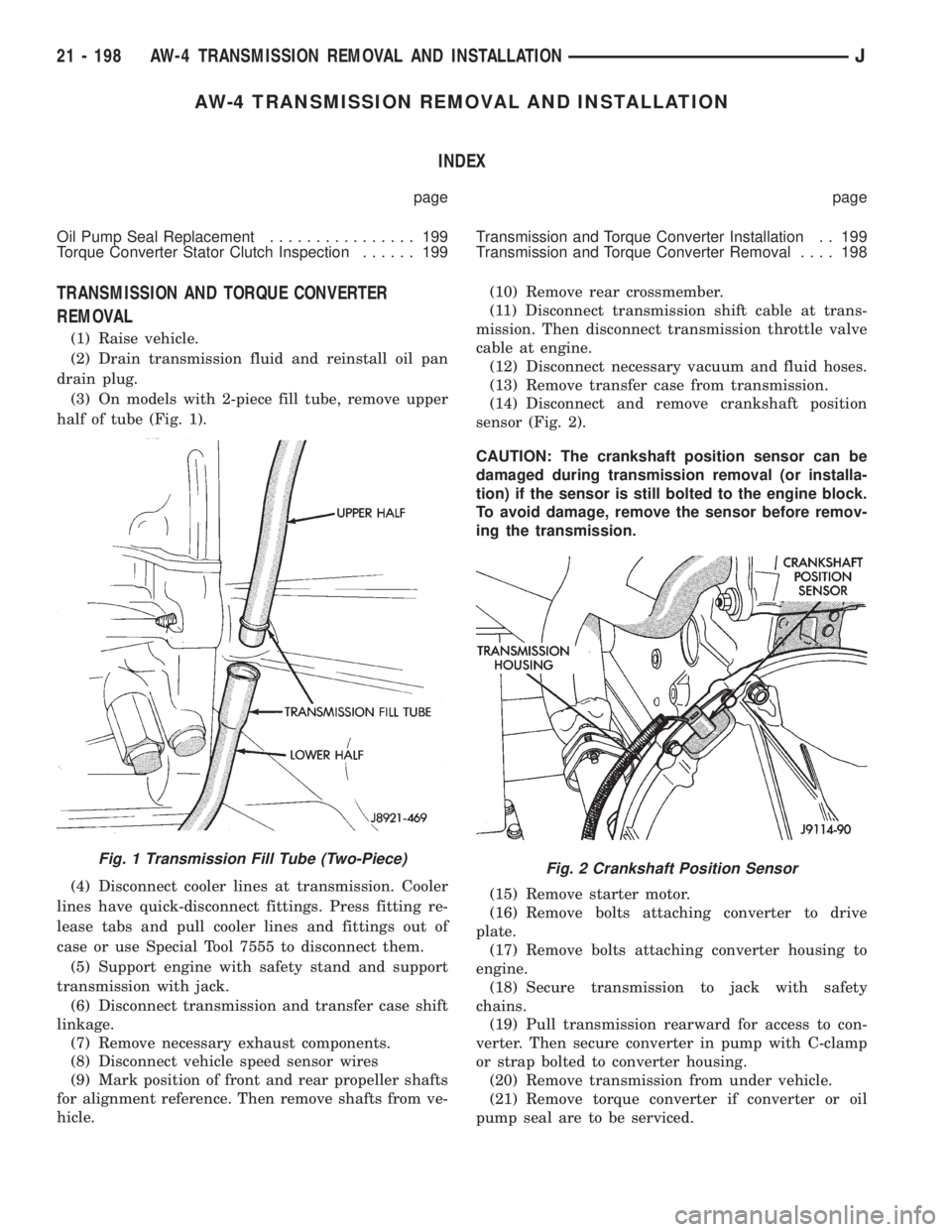

(3) On models with 2-piece fill tube, remove upper

half of tube (Fig. 1).

(4) Disconnect cooler lines at transmission. Cooler

lines have quick-disconnect fittings. Press fitting re-

lease tabs and pull cooler lines and fittings out of

case or use Special Tool 7555 to disconnect them.

(5) Support engine with safety stand and support

transmission with jack.

(6) Disconnect transmission and transfer case shift

linkage.

(7) Remove necessary exhaust components.

(8) Disconnect vehicle speed sensor wires

(9) Mark position of front and rear propeller shafts

for alignment reference. Then remove shafts from ve-

hicle.(10) Remove rear crossmember.

(11) Disconnect transmission shift cable at trans-

mission. Then disconnect transmission throttle valve

cable at engine.

(12) Disconnect necessary vacuum and fluid hoses.

(13) Remove transfer case from transmission.

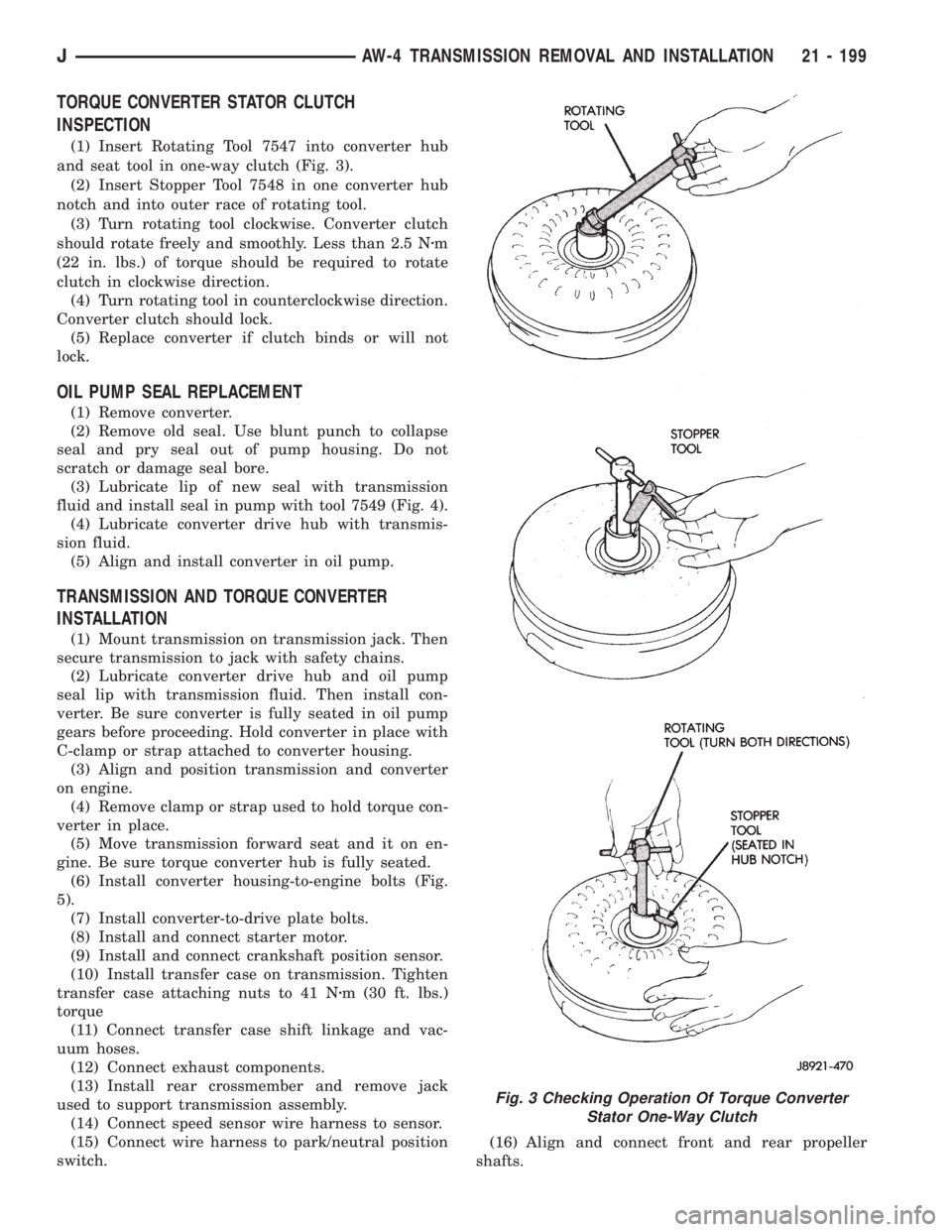

(14) Disconnect and remove crankshaft position

sensor (Fig. 2).

CAUTION: The crankshaft position sensor can be

damaged during transmission removal (or installa-

tion) if the sensor is still bolted to the engine block.

To avoid damage, remove the sensor before remov-

ing the transmission.

(15) Remove starter motor.

(16) Remove bolts attaching converter to drive

plate.

(17) Remove bolts attaching converter housing to

engine.

(18) Secure transmission to jack with safety

chains.

(19) Pull transmission rearward for access to con-

verter. Then secure converter in pump with C-clamp

or strap bolted to converter housing.

(20) Remove transmission from under vehicle.

(21) Remove torque converter if converter or oil

pump seal are to be serviced.

Fig. 1 Transmission Fill Tube (Two-Piece)Fig. 2 Crankshaft Position Sensor

21 - 198 AW-4 TRANSMISSION REMOVAL AND INSTALLATIONJ

Page 1576 of 2198

TORQUE CONVERTER STATOR CLUTCH

INSPECTION

(1) Insert Rotating Tool 7547 into converter hub

and seat tool in one-way clutch (Fig. 3).

(2) Insert Stopper Tool 7548 in one converter hub

notch and into outer race of rotating tool.

(3) Turn rotating tool clockwise. Converter clutch

should rotate freely and smoothly. Less than 2.5 Nzm

(22 in. lbs.) of torque should be required to rotate

clutch in clockwise direction.

(4) Turn rotating tool in counterclockwise direction.

Converter clutch should lock.

(5) Replace converter if clutch binds or will not

lock.

OIL PUMP SEAL REPLACEMENT

(1) Remove converter.

(2) Remove old seal. Use blunt punch to collapse

seal and pry seal out of pump housing. Do not

scratch or damage seal bore.

(3) Lubricate lip of new seal with transmission

fluid and install seal in pump with tool 7549 (Fig. 4).

(4) Lubricate converter drive hub with transmis-

sion fluid.

(5) Align and install converter in oil pump.

TRANSMISSION AND TORQUE CONVERTER

INSTALLATION

(1) Mount transmission on transmission jack. Then

secure transmission to jack with safety chains.

(2) Lubricate converter drive hub and oil pump

seal lip with transmission fluid. Then install con-

verter. Be sure converter is fully seated in oil pump

gears before proceeding. Hold converter in place with

C-clamp or strap attached to converter housing.

(3) Align and position transmission and converter

on engine.

(4) Remove clamp or strap used to hold torque con-

verter in place.

(5) Move transmission forward seat and it on en-

gine. Be sure torque converter hub is fully seated.

(6) Install converter housing-to-engine bolts (Fig.

5).

(7) Install converter-to-drive plate bolts.

(8) Install and connect starter motor.

(9) Install and connect crankshaft position sensor.

(10) Install transfer case on transmission. Tighten

transfer case attaching nuts to 41 Nzm (30 ft. lbs.)

torque

(11) Connect transfer case shift linkage and vac-

uum hoses.

(12) Connect exhaust components.

(13) Install rear crossmember and remove jack

used to support transmission assembly.

(14) Connect speed sensor wire harness to sensor.

(15) Connect wire harness to park/neutral position

switch.(16) Align and connect front and rear propeller

shafts.

Fig. 3 Checking Operation Of Torque Converter

Stator One-Way Clutch

JAW-4 TRANSMISSION REMOVAL AND INSTALLATION 21 - 199

Page 1588 of 2198

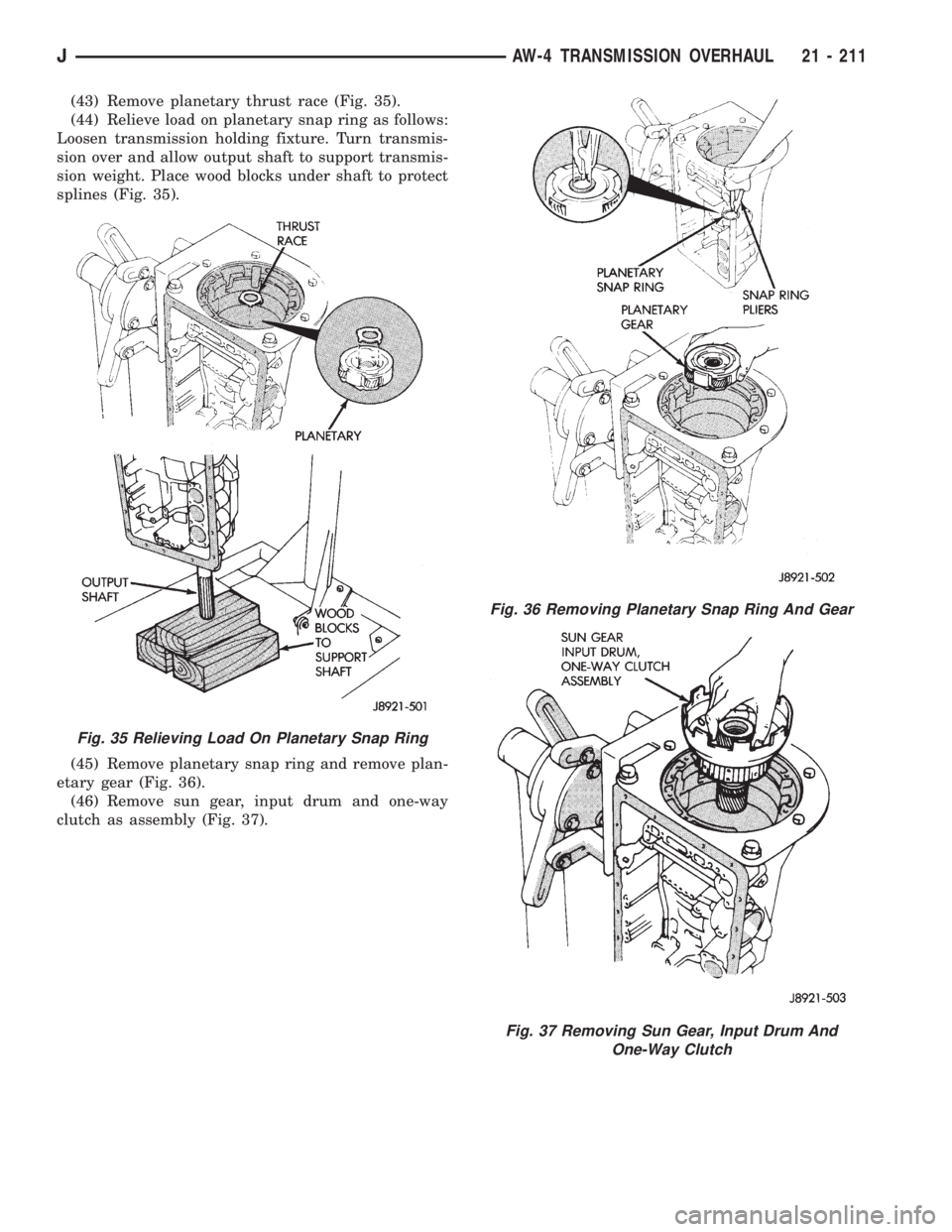

(43) Remove planetary thrust race (Fig. 35).

(44) Relieve load on planetary snap ring as follows:

Loosen transmission holding fixture. Turn transmis-

sion over and allow output shaft to support transmis-

sion weight. Place wood blocks under shaft to protect

splines (Fig. 35).

(45) Remove planetary snap ring and remove plan-

etary gear (Fig. 36).

(46) Remove sun gear, input drum and one-way

clutch as assembly (Fig. 37).

Fig. 35 Relieving Load On Planetary Snap Ring

Fig. 36 Removing Planetary Snap Ring And Gear

Fig. 37 Removing Sun Gear, Input Drum And

One-Way Clutch

JAW-4 TRANSMISSION OVERHAUL 21 - 211

Page 1595 of 2198

(13) Install pump in torque converter and check

pump gear rotation. Gears must rotate smoothly

when turned clockwise and counterclockwise.

(14) Lubricate pump O-ring and seal rings with pe-

troleum jelly.

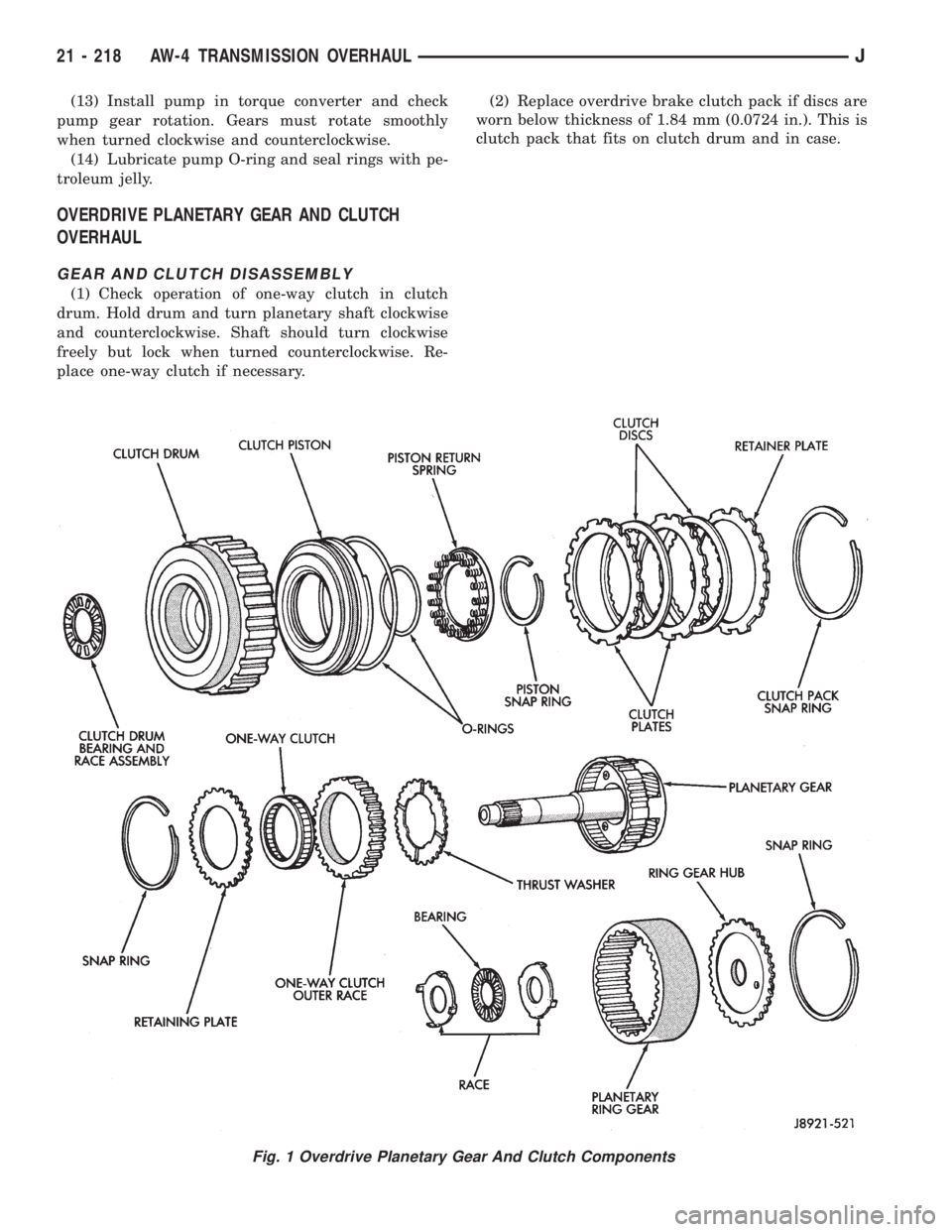

OVERDRIVE PLANETARY GEAR AND CLUTCH

OVERHAUL

GEAR AND CLUTCH DISASSEMBLY

(1) Check operation of one-way clutch in clutch

drum. Hold drum and turn planetary shaft clockwise

and counterclockwise. Shaft should turn clockwise

freely but lock when turned counterclockwise. Re-

place one-way clutch if necessary.(2) Replace overdrive brake clutch pack if discs are

worn below thickness of 1.84 mm (0.0724 in.). This is

clutch pack that fits on clutch drum and in case.

Fig. 1 Overdrive Planetary Gear And Clutch Components

21 - 218 AW-4 TRANSMISSION OVERHAULJ

Page 1602 of 2198

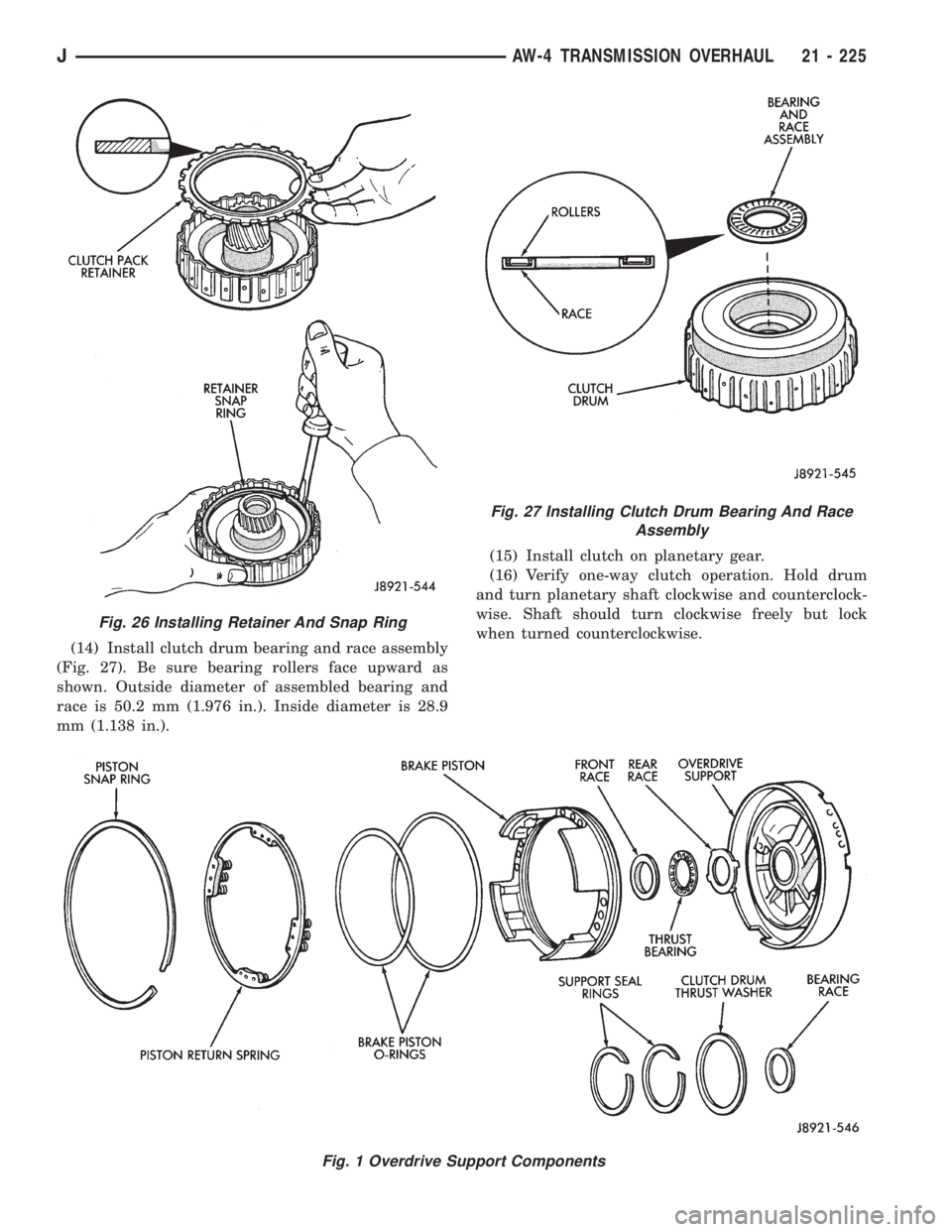

(14) Install clutch drum bearing and race assembly

(Fig. 27). Be sure bearing rollers face upward as

shown. Outside diameter of assembled bearing and

race is 50.2 mm (1.976 in.). Inside diameter is 28.9

mm (1.138 in.).(15) Install clutch on planetary gear.

(16) Verify one-way clutch operation. Hold drum

and turn planetary shaft clockwise and counterclock-

wise. Shaft should turn clockwise freely but lock

when turned counterclockwise.

Fig. 1 Overdrive Support Components

Fig. 26 Installing Retainer And Snap Ring

Fig. 27 Installing Clutch Drum Bearing And Race

Assembly

JAW-4 TRANSMISSION OVERHAUL 21 - 225

Page 1609 of 2198

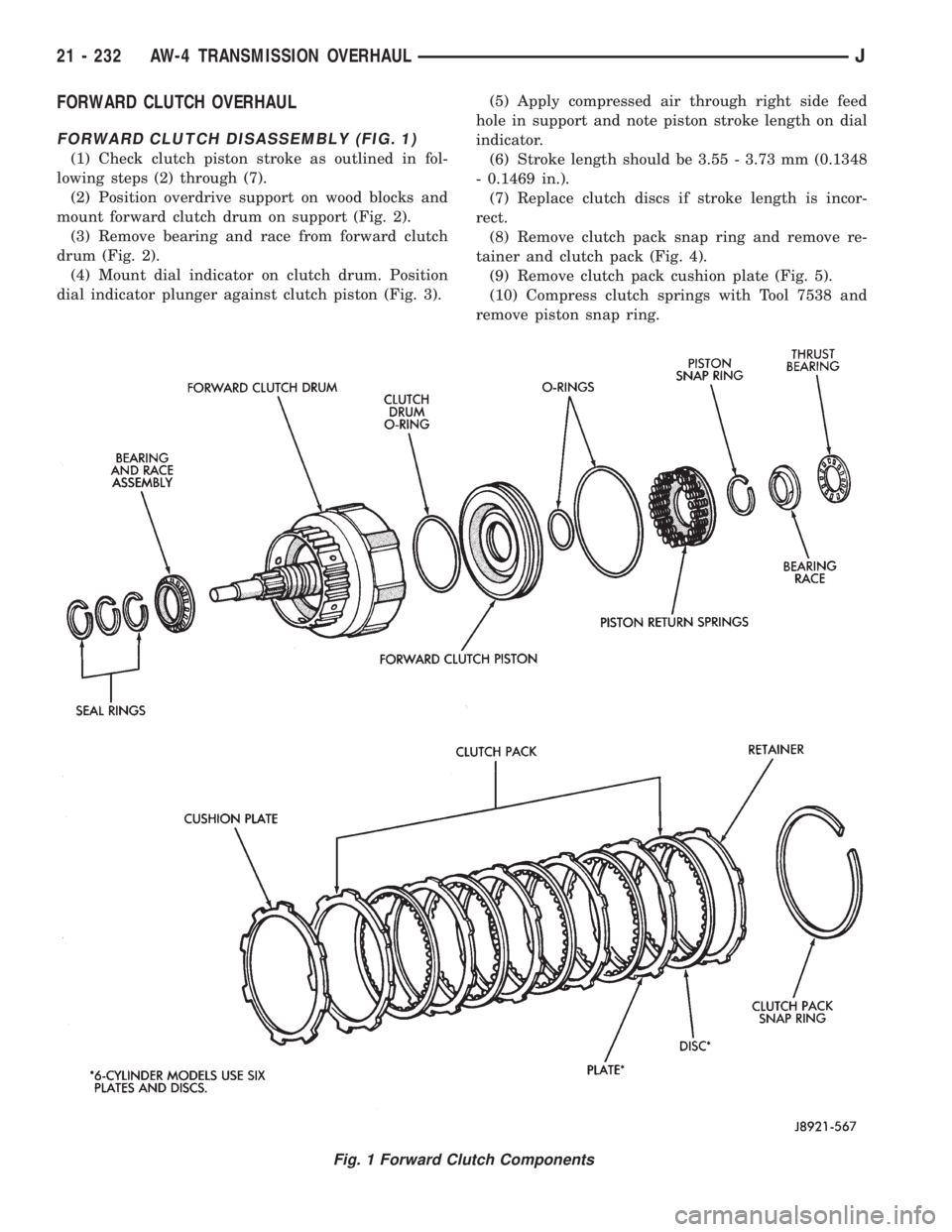

FORWARD CLUTCH OVERHAUL

FORWARD CLUTCH DISASSEMBLY (FIG. 1)

(1) Check clutch piston stroke as outlined in fol-

lowing steps (2) through (7).

(2) Position overdrive support on wood blocks and

mount forward clutch drum on support (Fig. 2).

(3) Remove bearing and race from forward clutch

drum (Fig. 2).

(4) Mount dial indicator on clutch drum. Position

dial indicator plunger against clutch piston (Fig. 3).(5) Apply compressed air through right side feed

hole in support and note piston stroke length on dial

indicator.

(6) Stroke length should be 3.55 - 3.73 mm (0.1348

- 0.1469 in.).

(7) Replace clutch discs if stroke length is incor-

rect.

(8) Remove clutch pack snap ring and remove re-

tainer and clutch pack (Fig. 4).

(9) Remove clutch pack cushion plate (Fig. 5).

(10) Compress clutch springs with Tool 7538 and

remove piston snap ring.

Fig. 1 Forward Clutch Components

21 - 232 AW-4 TRANSMISSION OVERHAULJ

Page 1610 of 2198

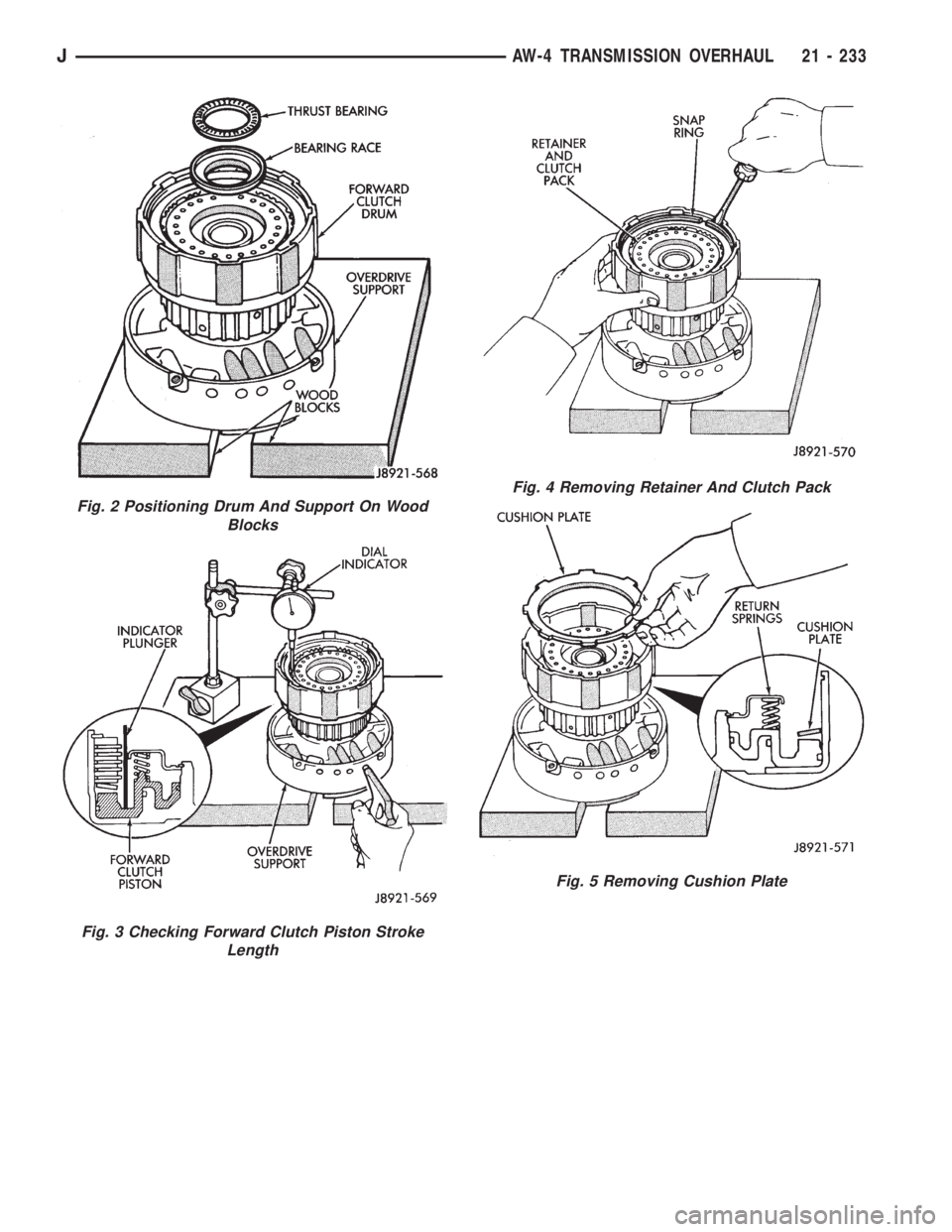

Fig. 2 Positioning Drum And Support On Wood

Blocks

Fig. 3 Checking Forward Clutch Piston Stroke

Length

Fig. 4 Removing Retainer And Clutch Pack

Fig. 5 Removing Cushion Plate

JAW-4 TRANSMISSION OVERHAUL 21 - 233

Page 1615 of 2198

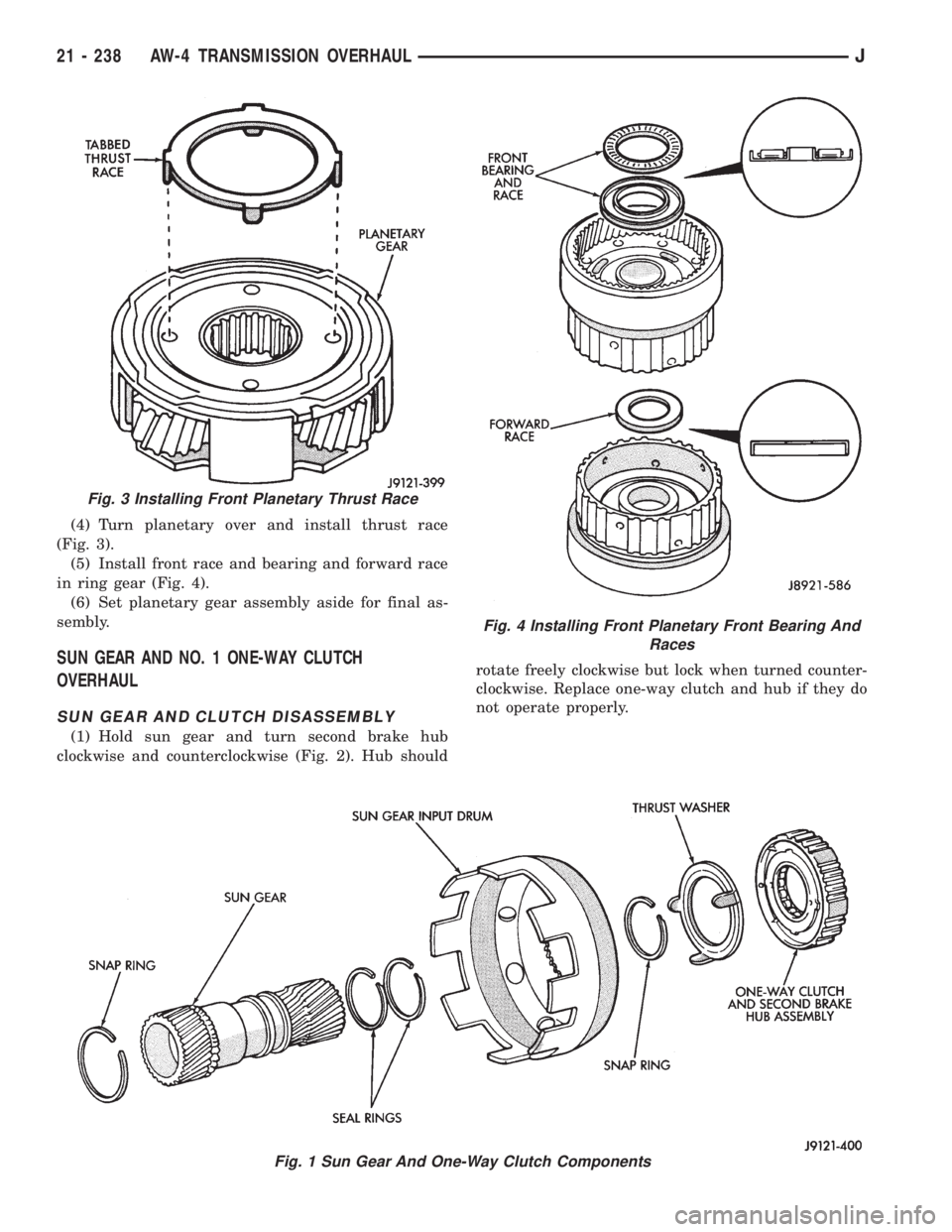

(4) Turn planetary over and install thrust race

(Fig. 3).

(5) Install front race and bearing and forward race

in ring gear (Fig. 4).

(6) Set planetary gear assembly aside for final as-

sembly.

SUN GEAR AND NO. 1 ONE-WAY CLUTCH

OVERHAUL

SUN GEAR AND CLUTCH DISASSEMBLY

(1) Hold sun gear and turn second brake hub

clockwise and counterclockwise (Fig. 2). Hub shouldrotate freely clockwise but lock when turned counter-

clockwise. Replace one-way clutch and hub if they do

not operate properly.

Fig. 3 Installing Front Planetary Thrust Race

Fig. 1 Sun Gear And One-Way Clutch Components

Fig. 4 Installing Front Planetary Front Bearing And

Races

21 - 238 AW-4 TRANSMISSION OVERHAULJ

Page 1617 of 2198

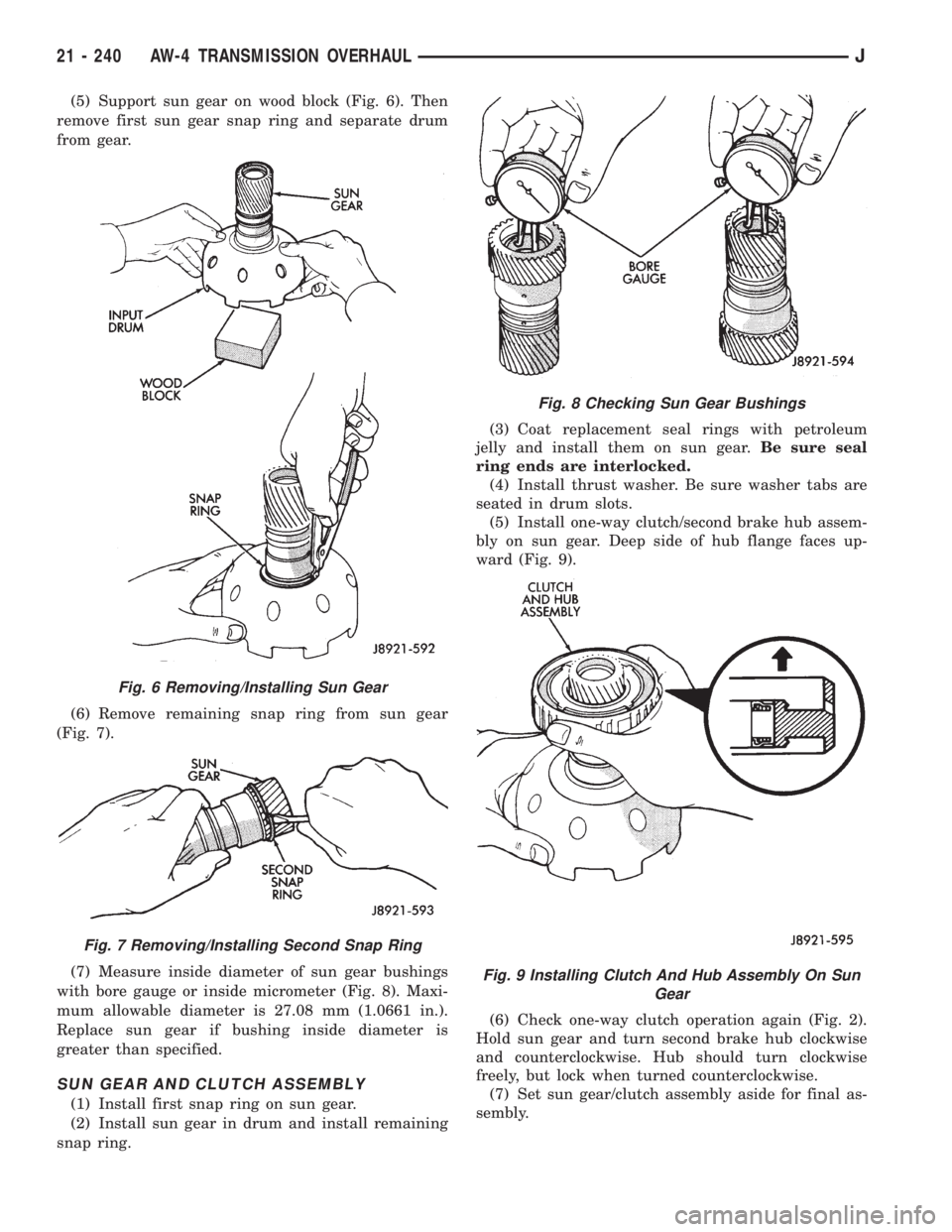

(5) Support sun gear on wood block (Fig. 6). Then

remove first sun gear snap ring and separate drum

from gear.

(6) Remove remaining snap ring from sun gear

(Fig. 7).

(7) Measure inside diameter of sun gear bushings

with bore gauge or inside micrometer (Fig. 8). Maxi-

mum allowable diameter is 27.08 mm (1.0661 in.).

Replace sun gear if bushing inside diameter is

greater than specified.

SUN GEAR AND CLUTCH ASSEMBLY

(1) Install first snap ring on sun gear.

(2) Install sun gear in drum and install remaining

snap ring.(3) Coat replacement seal rings with petroleum

jelly and install them on sun gear.Be sure seal

ring ends are interlocked.

(4) Install thrust washer. Be sure washer tabs are

seated in drum slots.

(5) Install one-way clutch/second brake hub assem-

bly on sun gear. Deep side of hub flange faces up-

ward (Fig. 9).

(6) Check one-way clutch operation again (Fig. 2).

Hold sun gear and turn second brake hub clockwise

and counterclockwise. Hub should turn clockwise

freely, but lock when turned counterclockwise.

(7) Set sun gear/clutch assembly aside for final as-

sembly.

Fig. 6 Removing/Installing Sun Gear

Fig. 7 Removing/Installing Second Snap Ring

Fig. 8 Checking Sun Gear Bushings

Fig. 9 Installing Clutch And Hub Assembly On Sun

Gear

21 - 240 AW-4 TRANSMISSION OVERHAULJ

Page 1622 of 2198

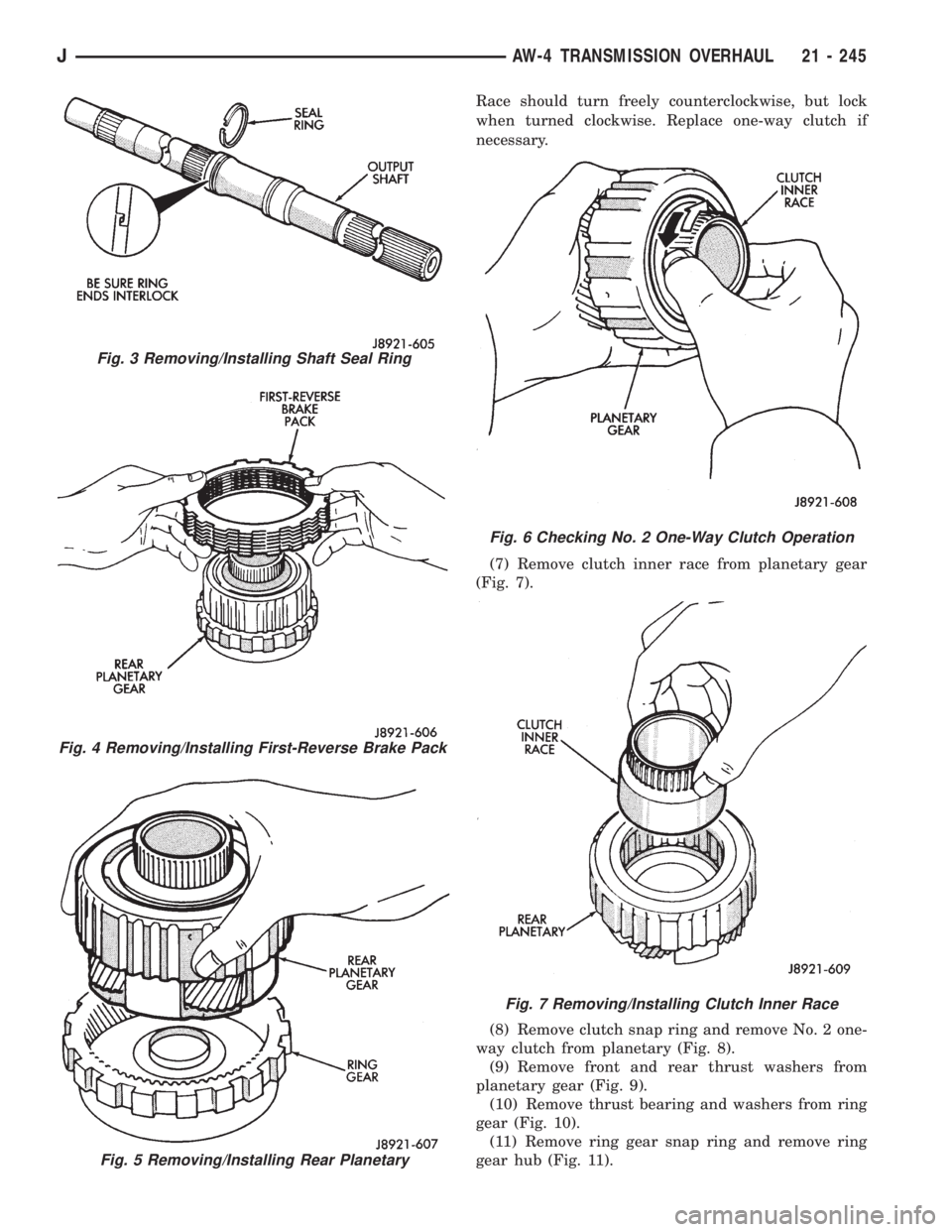

Race should turn freely counterclockwise, but lock

when turned clockwise. Replace one-way clutch if

necessary.

(7) Remove clutch inner race from planetary gear

(Fig. 7).

(8) Remove clutch snap ring and remove No. 2 one-

way clutch from planetary (Fig. 8).

(9) Remove front and rear thrust washers from

planetary gear (Fig. 9).

(10) Remove thrust bearing and washers from ring

gear (Fig. 10).

(11) Remove ring gear snap ring and remove ring

gear hub (Fig. 11).

Fig. 3 Removing/Installing Shaft Seal Ring

Fig. 4 Removing/Installing First-Reverse Brake Pack

Fig. 5 Removing/Installing Rear Planetary

Fig. 6 Checking No. 2 One-Way Clutch Operation

Fig. 7 Removing/Installing Clutch Inner Race

JAW-4 TRANSMISSION OVERHAUL 21 - 245