lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1623 of 2198

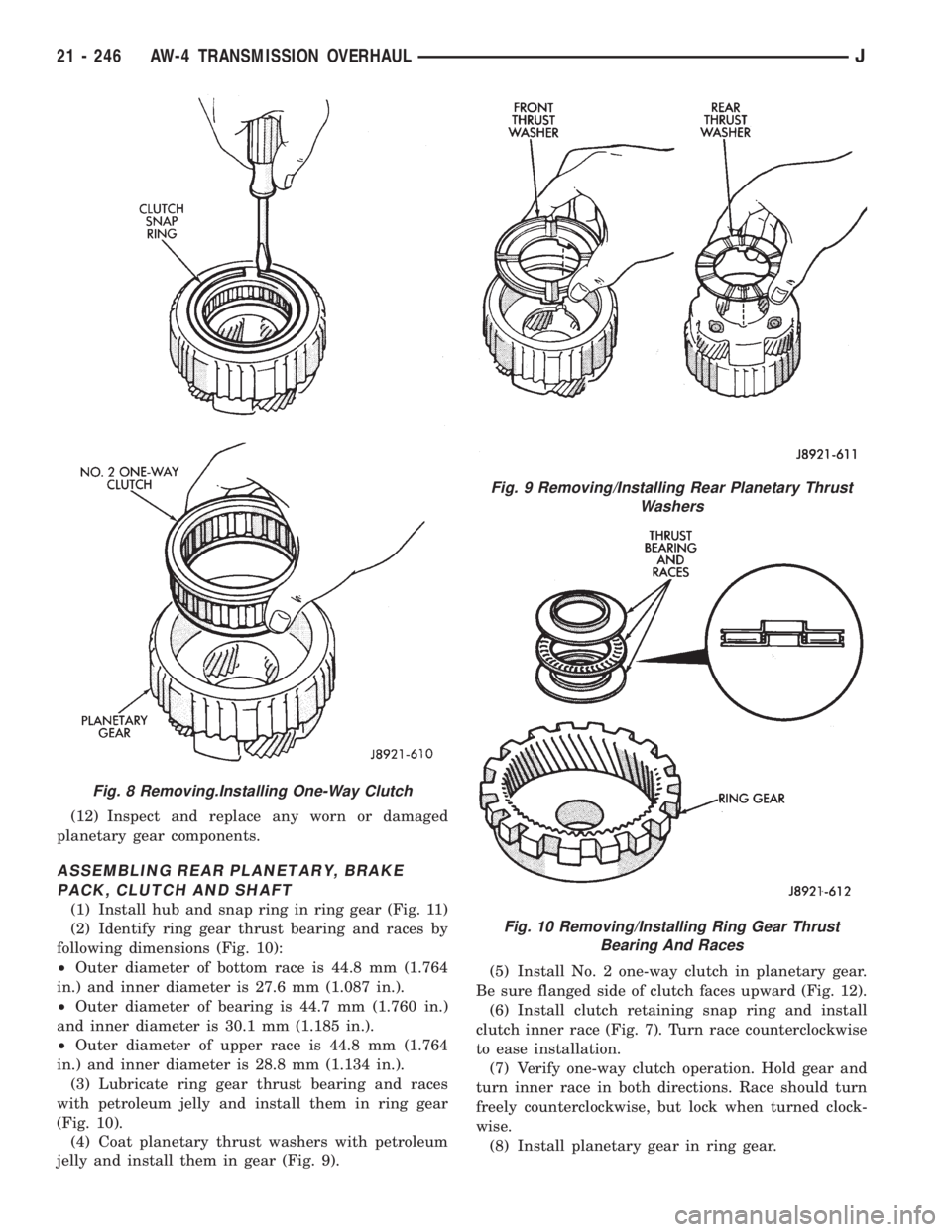

(12) Inspect and replace any worn or damaged

planetary gear components.

ASSEMBLING REAR PLANETARY, BRAKE

PACK, CLUTCH AND SHAFT

(1) Install hub and snap ring in ring gear (Fig. 11)

(2) Identify ring gear thrust bearing and races by

following dimensions (Fig. 10):

²Outer diameter of bottom race is 44.8 mm (1.764

in.) and inner diameter is 27.6 mm (1.087 in.).

²Outer diameter of bearing is 44.7 mm (1.760 in.)

and inner diameter is 30.1 mm (1.185 in.).

²Outer diameter of upper race is 44.8 mm (1.764

in.) and inner diameter is 28.8 mm (1.134 in.).

(3) Lubricate ring gear thrust bearing and races

with petroleum jelly and install them in ring gear

(Fig. 10).

(4) Coat planetary thrust washers with petroleum

jelly and install them in gear (Fig. 9).(5) Install No. 2 one-way clutch in planetary gear.

Be sure flanged side of clutch faces upward (Fig. 12).

(6) Install clutch retaining snap ring and install

clutch inner race (Fig. 7). Turn race counterclockwise

to ease installation.

(7) Verify one-way clutch operation. Hold gear and

turn inner race in both directions. Race should turn

freely counterclockwise, but lock when turned clock-

wise.

(8) Install planetary gear in ring gear.

Fig. 8 Removing.Installing One-Way Clutch

Fig. 9 Removing/Installing Rear Planetary Thrust

Washers

Fig. 10 Removing/Installing Ring Gear Thrust

Bearing And Races

21 - 246 AW-4 TRANSMISSION OVERHAULJ

Page 1624 of 2198

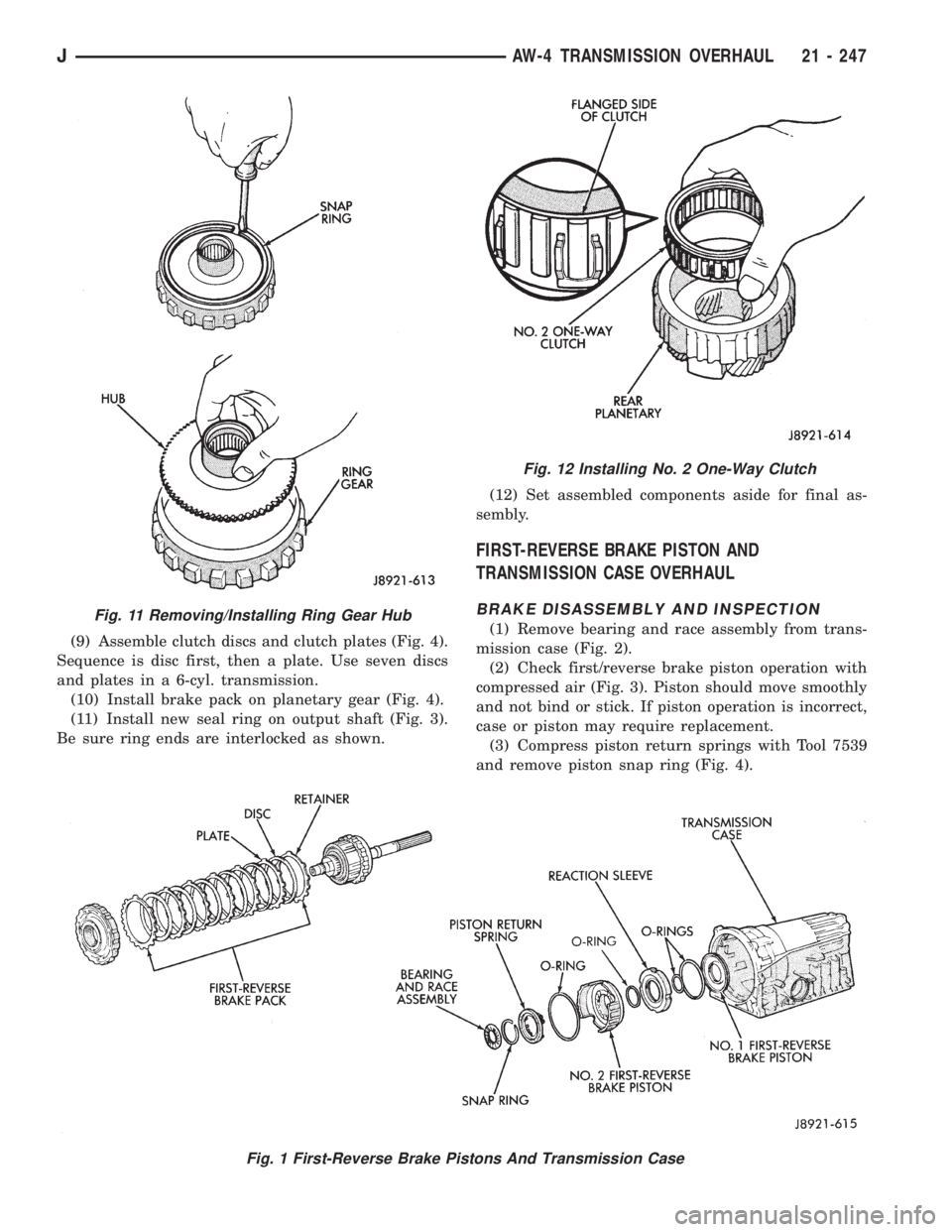

(9) Assemble clutch discs and clutch plates (Fig. 4).

Sequence is disc first, then a plate. Use seven discs

and plates in a 6-cyl. transmission.

(10) Install brake pack on planetary gear (Fig. 4).

(11) Install new seal ring on output shaft (Fig. 3).

Be sure ring ends are interlocked as shown.(12) Set assembled components aside for final as-

sembly.

FIRST-REVERSE BRAKE PISTON AND

TRANSMISSION CASE OVERHAUL

BRAKE DISASSEMBLY AND INSPECTION

(1) Remove bearing and race assembly from trans-

mission case (Fig. 2).

(2) Check first/reverse brake piston operation with

compressed air (Fig. 3). Piston should move smoothly

and not bind or stick. If piston operation is incorrect,

case or piston may require replacement.

(3) Compress piston return springs with Tool 7539

and remove piston snap ring (Fig. 4).

Fig. 12 Installing No. 2 One-Way Clutch

Fig. 1 First-Reverse Brake Pistons And Transmission Case

Fig. 11 Removing/Installing Ring Gear Hub

JAW-4 TRANSMISSION OVERHAUL 21 - 247

Page 1635 of 2198

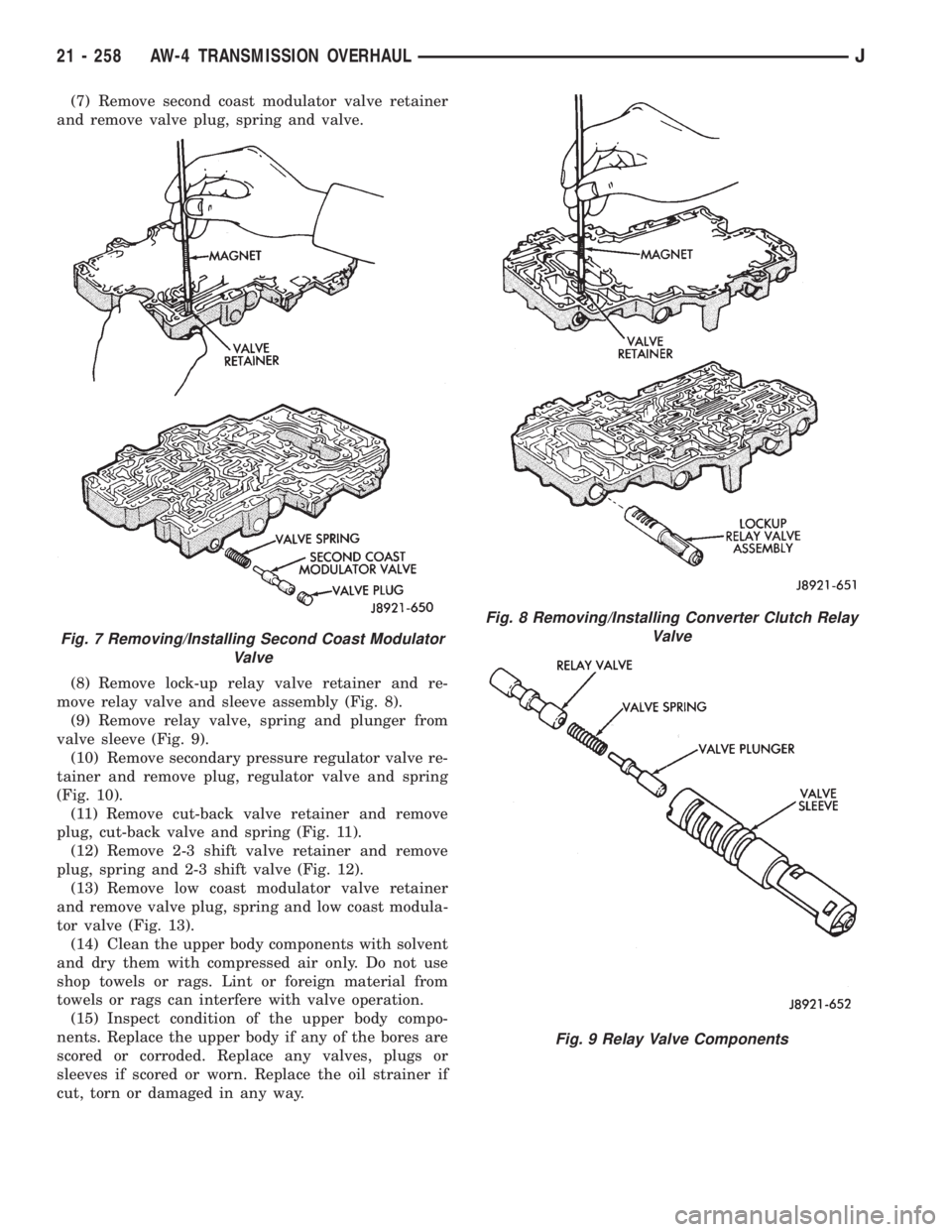

(7) Remove second coast modulator valve retainer

and remove valve plug, spring and valve.

(8) Remove lock-up relay valve retainer and re-

move relay valve and sleeve assembly (Fig. 8).

(9) Remove relay valve, spring and plunger from

valve sleeve (Fig. 9).

(10) Remove secondary pressure regulator valve re-

tainer and remove plug, regulator valve and spring

(Fig. 10).

(11) Remove cut-back valve retainer and remove

plug, cut-back valve and spring (Fig. 11).

(12) Remove 2-3 shift valve retainer and remove

plug, spring and 2-3 shift valve (Fig. 12).

(13) Remove low coast modulator valve retainer

and remove valve plug, spring and low coast modula-

tor valve (Fig. 13).

(14) Clean the upper body components with solvent

and dry them with compressed air only. Do not use

shop towels or rags. Lint or foreign material from

towels or rags can interfere with valve operation.

(15) Inspect condition of the upper body compo-

nents. Replace the upper body if any of the bores are

scored or corroded. Replace any valves, plugs or

sleeves if scored or worn. Replace the oil strainer if

cut, torn or damaged in any way.

Fig. 7 Removing/Installing Second Coast Modulator

Valve

Fig. 8 Removing/Installing Converter Clutch Relay

Valve

Fig. 9 Relay Valve Components

21 - 258 AW-4 TRANSMISSION OVERHAULJ

Page 1637 of 2198

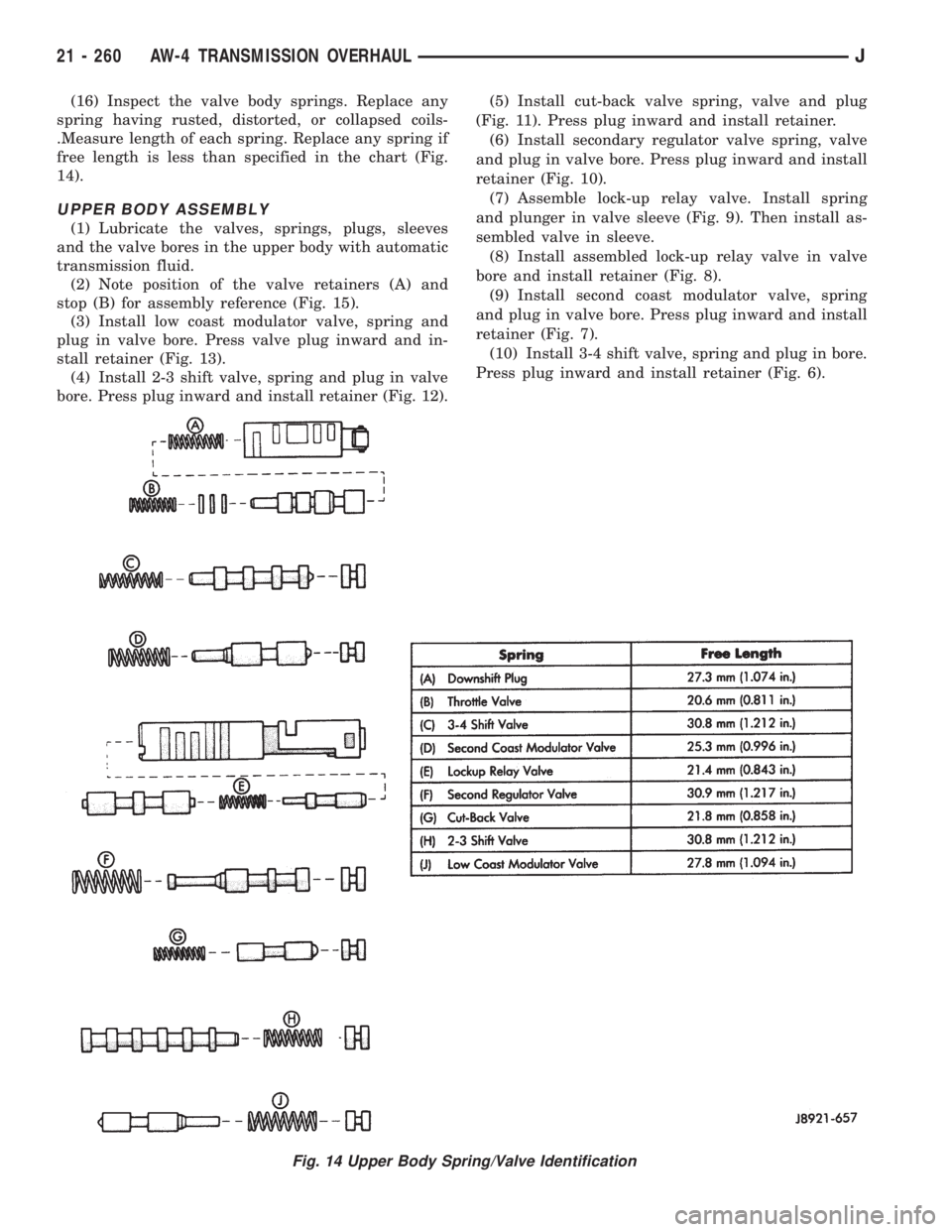

(16) Inspect the valve body springs. Replace any

spring having rusted, distorted, or collapsed coils-

.Measure length of each spring. Replace any spring if

free length is less than specified in the chart (Fig.

14).

UPPER BODY ASSEMBLY

(1) Lubricate the valves, springs, plugs, sleeves

and the valve bores in the upper body with automatic

transmission fluid.

(2) Note position of the valve retainers (A) and

stop (B) for assembly reference (Fig. 15).

(3) Install low coast modulator valve, spring and

plug in valve bore. Press valve plug inward and in-

stall retainer (Fig. 13).

(4) Install 2-3 shift valve, spring and plug in valve

bore. Press plug inward and install retainer (Fig. 12).(5) Install cut-back valve spring, valve and plug

(Fig. 11). Press plug inward and install retainer.

(6) Install secondary regulator valve spring, valve

and plug in valve bore. Press plug inward and install

retainer (Fig. 10).

(7) Assemble lock-up relay valve. Install spring

and plunger in valve sleeve (Fig. 9). Then install as-

sembled valve in sleeve.

(8) Install assembled lock-up relay valve in valve

bore and install retainer (Fig. 8).

(9) Install second coast modulator valve, spring

and plug in valve bore. Press plug inward and install

retainer (Fig. 7).

(10) Install 3-4 shift valve, spring and plug in bore.

Press plug inward and install retainer (Fig. 6).

Fig. 14 Upper Body Spring/Valve Identification

21 - 260 AW-4 TRANSMISSION OVERHAULJ

Page 1644 of 2198

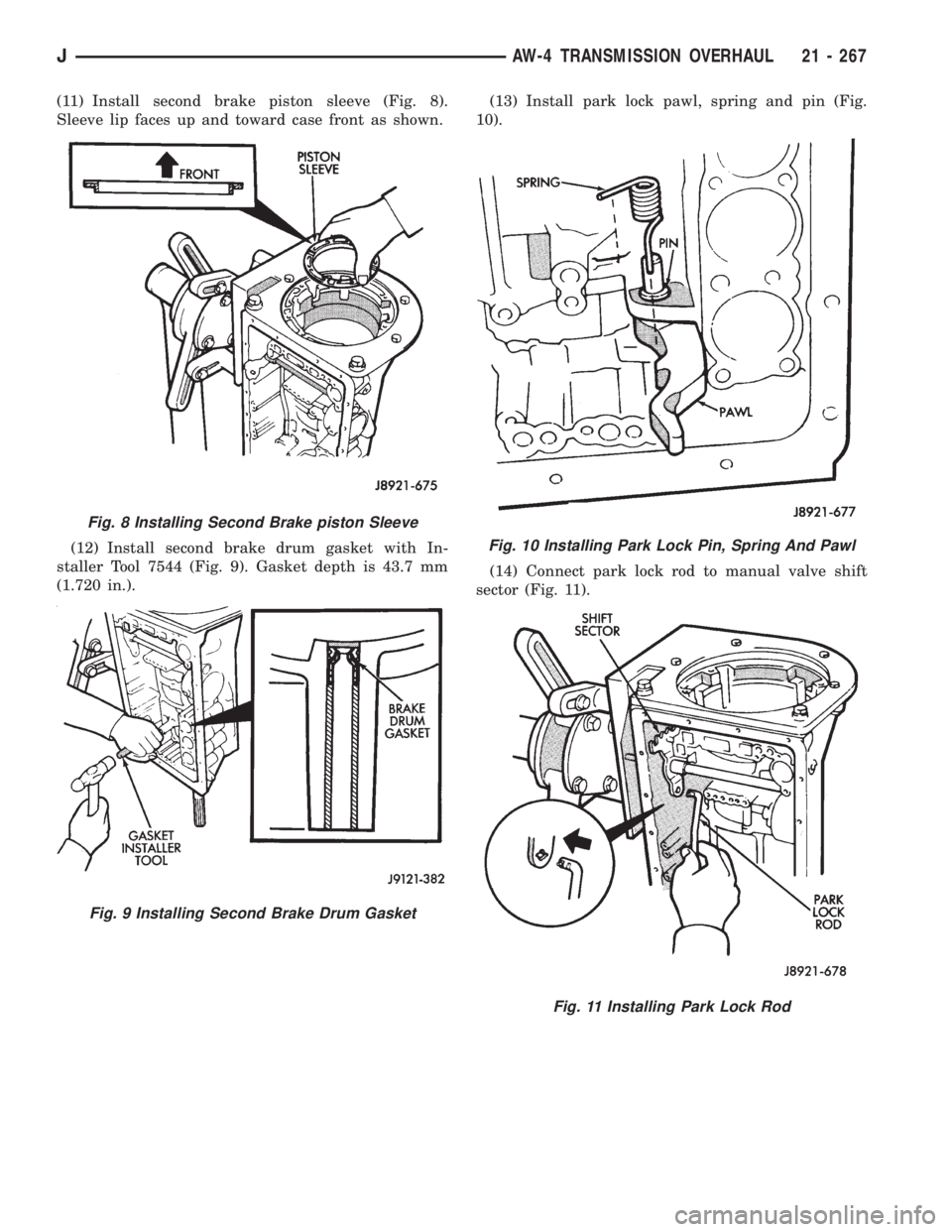

(11) Install second brake piston sleeve (Fig. 8).

Sleeve lip faces up and toward case front as shown.

(12) Install second brake drum gasket with In-

staller Tool 7544 (Fig. 9). Gasket depth is 43.7 mm

(1.720 in.).(13) Install park lock pawl, spring and pin (Fig.

10).

(14) Connect park lock rod to manual valve shift

sector (Fig. 11).

Fig. 8 Installing Second Brake piston Sleeve

Fig. 9 Installing Second Brake Drum Gasket

Fig. 10 Installing Park Lock Pin, Spring And Pawl

Fig. 11 Installing Park Lock Rod

JAW-4 TRANSMISSION OVERHAUL 21 - 267

Page 1645 of 2198

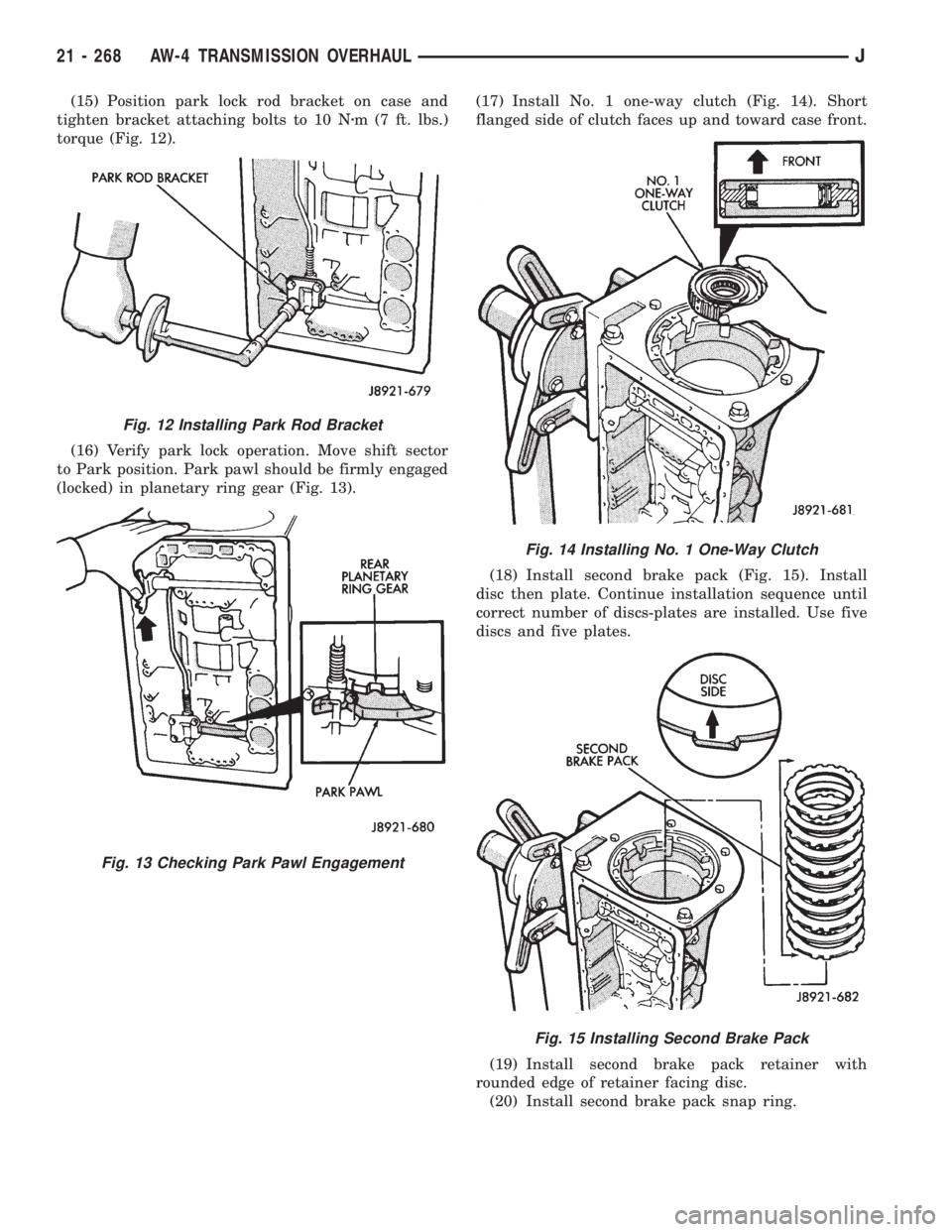

(15) Position park lock rod bracket on case and

tighten bracket attaching bolts to 10 Nzm (7 ft. lbs.)

torque (Fig. 12).

(16) Verify park lock operation. Move shift sector

to Park position. Park pawl should be firmly engaged

(locked) in planetary ring gear (Fig. 13).(17) Install No. 1 one-way clutch (Fig. 14). Short

flanged side of clutch faces up and toward case front.

(18) Install second brake pack (Fig. 15). Install

disc then plate. Continue installation sequence until

correct number of discs-plates are installed. Use five

discs and five plates.

(19) Install second brake pack retainer with

rounded edge of retainer facing disc.

(20) Install second brake pack snap ring.

Fig. 12 Installing Park Rod Bracket

Fig. 13 Checking Park Pawl Engagement

Fig. 14 Installing No. 1 One-Way Clutch

Fig. 15 Installing Second Brake Pack

21 - 268 AW-4 TRANSMISSION OVERHAULJ

Page 1646 of 2198

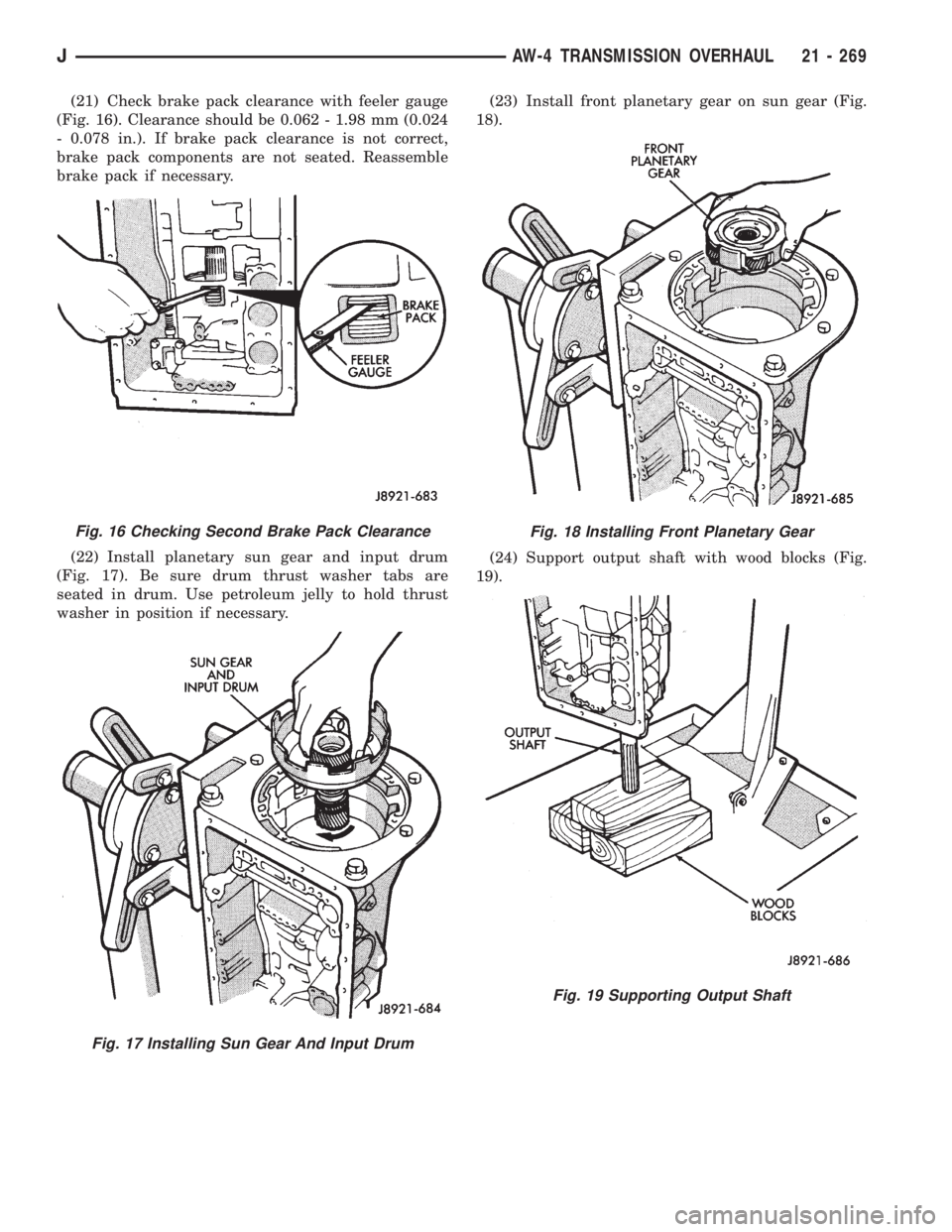

(21) Check brake pack clearance with feeler gauge

(Fig. 16). Clearance should be 0.062 - 1.98 mm (0.024

- 0.078 in.). If brake pack clearance is not correct,

brake pack components are not seated. Reassemble

brake pack if necessary.

(22) Install planetary sun gear and input drum

(Fig. 17). Be sure drum thrust washer tabs are

seated in drum. Use petroleum jelly to hold thrust

washer in position if necessary.(23) Install front planetary gear on sun gear (Fig.

18).

(24) Support output shaft with wood blocks (Fig.

19).

Fig. 16 Checking Second Brake Pack Clearance

Fig. 17 Installing Sun Gear And Input Drum

Fig. 18 Installing Front Planetary Gear

Fig. 19 Supporting Output Shaft

JAW-4 TRANSMISSION OVERHAUL 21 - 269

Page 1655 of 2198

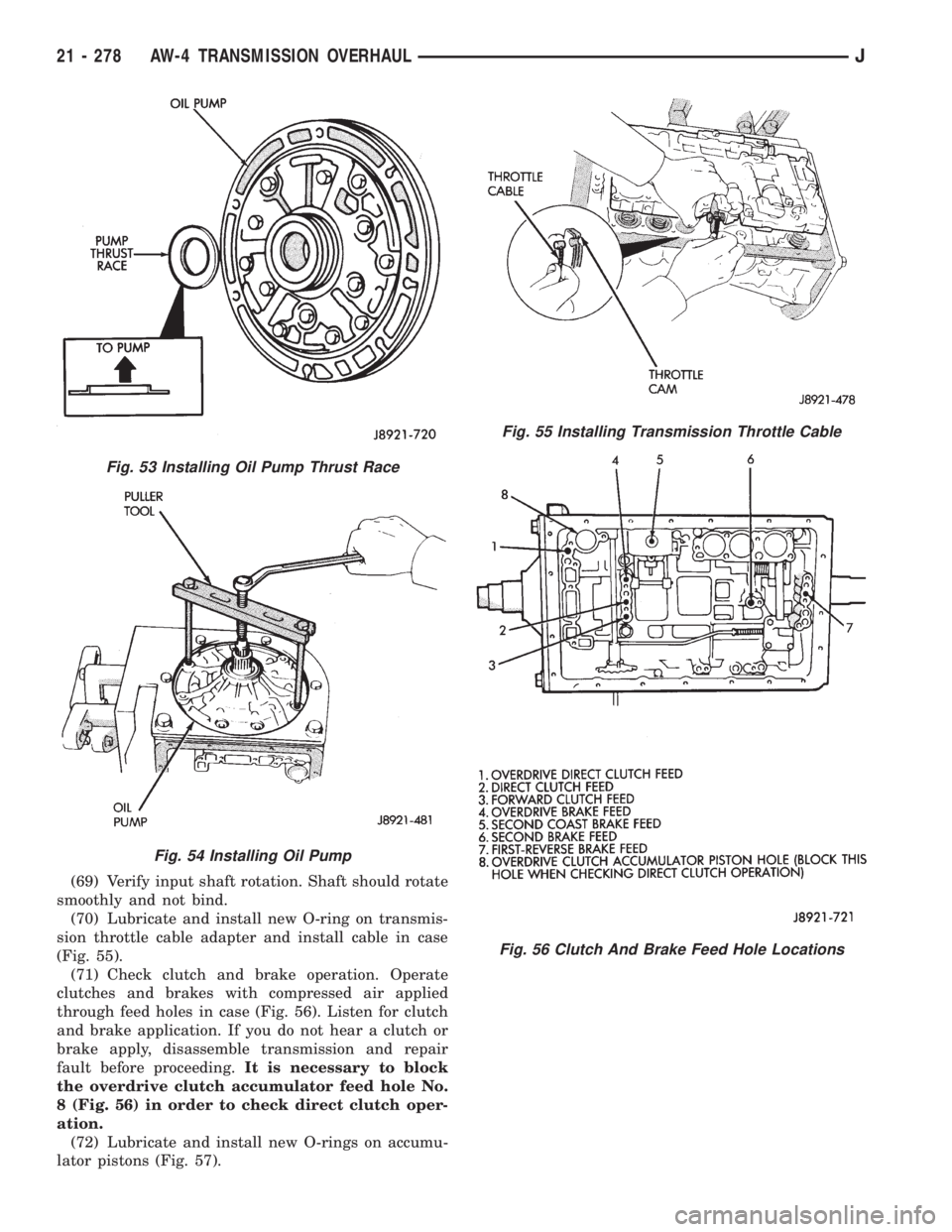

(69) Verify input shaft rotation. Shaft should rotate

smoothly and not bind.

(70) Lubricate and install new O-ring on transmis-

sion throttle cable adapter and install cable in case

(Fig. 55).

(71) Check clutch and brake operation. Operate

clutches and brakes with compressed air applied

through feed holes in case (Fig. 56). Listen for clutch

and brake application. If you do not hear a clutch or

brake apply, disassemble transmission and repair

fault before proceeding.It is necessary to block

the overdrive clutch accumulator feed hole No.

8 (Fig. 56) in order to check direct clutch oper-

ation.

(72) Lubricate and install new O-rings on accumu-

lator pistons (Fig. 57).

Fig. 53 Installing Oil Pump Thrust Race

Fig. 54 Installing Oil Pump

Fig. 55 Installing Transmission Throttle Cable

Fig. 56 Clutch And Brake Feed Hole Locations

21 - 278 AW-4 TRANSMISSION OVERHAULJ

Page 1663 of 2198

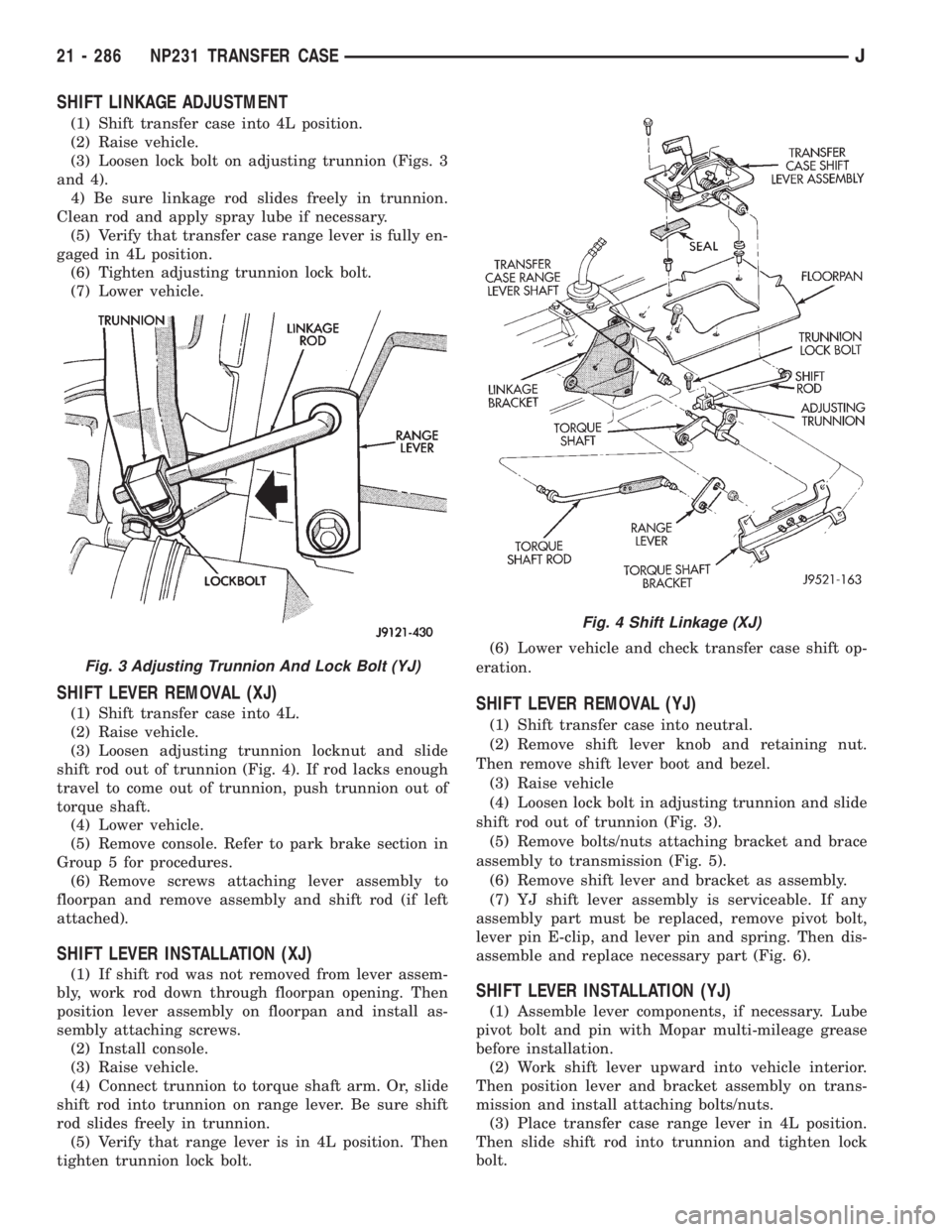

SHIFT LINKAGE ADJUSTMENT

(1) Shift transfer case into 4L position.

(2) Raise vehicle.

(3) Loosen lock bolt on adjusting trunnion (Figs. 3

and 4).

4) Be sure linkage rod slides freely in trunnion.

Clean rod and apply spray lube if necessary.

(5) Verify that transfer case range lever is fully en-

gaged in 4L position.

(6) Tighten adjusting trunnion lock bolt.

(7) Lower vehicle.

SHIFT LEVER REMOVAL (XJ)

(1) Shift transfer case into 4L.

(2) Raise vehicle.

(3) Loosen adjusting trunnion locknut and slide

shift rod out of trunnion (Fig. 4). If rod lacks enough

travel to come out of trunnion, push trunnion out of

torque shaft.

(4) Lower vehicle.

(5) Remove console. Refer to park brake section in

Group 5 for procedures.

(6) Remove screws attaching lever assembly to

floorpan and remove assembly and shift rod (if left

attached).

SHIFT LEVER INSTALLATION (XJ)

(1) If shift rod was not removed from lever assem-

bly, work rod down through floorpan opening. Then

position lever assembly on floorpan and install as-

sembly attaching screws.

(2) Install console.

(3) Raise vehicle.

(4) Connect trunnion to torque shaft arm. Or, slide

shift rod into trunnion on range lever. Be sure shift

rod slides freely in trunnion.

(5) Verify that range lever is in 4L position. Then

tighten trunnion lock bolt.(6) Lower vehicle and check transfer case shift op-

eration.

SHIFT LEVER REMOVAL (YJ)

(1) Shift transfer case into neutral.

(2) Remove shift lever knob and retaining nut.

Then remove shift lever boot and bezel.

(3) Raise vehicle

(4) Loosen lock bolt in adjusting trunnion and slide

shift rod out of trunnion (Fig. 3).

(5) Remove bolts/nuts attaching bracket and brace

assembly to transmission (Fig. 5).

(6) Remove shift lever and bracket as assembly.

(7) YJ shift lever assembly is serviceable. If any

assembly part must be replaced, remove pivot bolt,

lever pin E-clip, and lever pin and spring. Then dis-

assemble and replace necessary part (Fig. 6).

SHIFT LEVER INSTALLATION (YJ)

(1) Assemble lever components, if necessary. Lube

pivot bolt and pin with Mopar multi-mileage grease

before installation.

(2) Work shift lever upward into vehicle interior.

Then position lever and bracket assembly on trans-

mission and install attaching bolts/nuts.

(3) Place transfer case range lever in 4L position.

Then slide shift rod into trunnion and tighten lock

bolt.

Fig. 3 Adjusting Trunnion And Lock Bolt (YJ)

Fig. 4 Shift Linkage (XJ)

21 - 286 NP231 TRANSFER CASEJ

Page 1666 of 2198

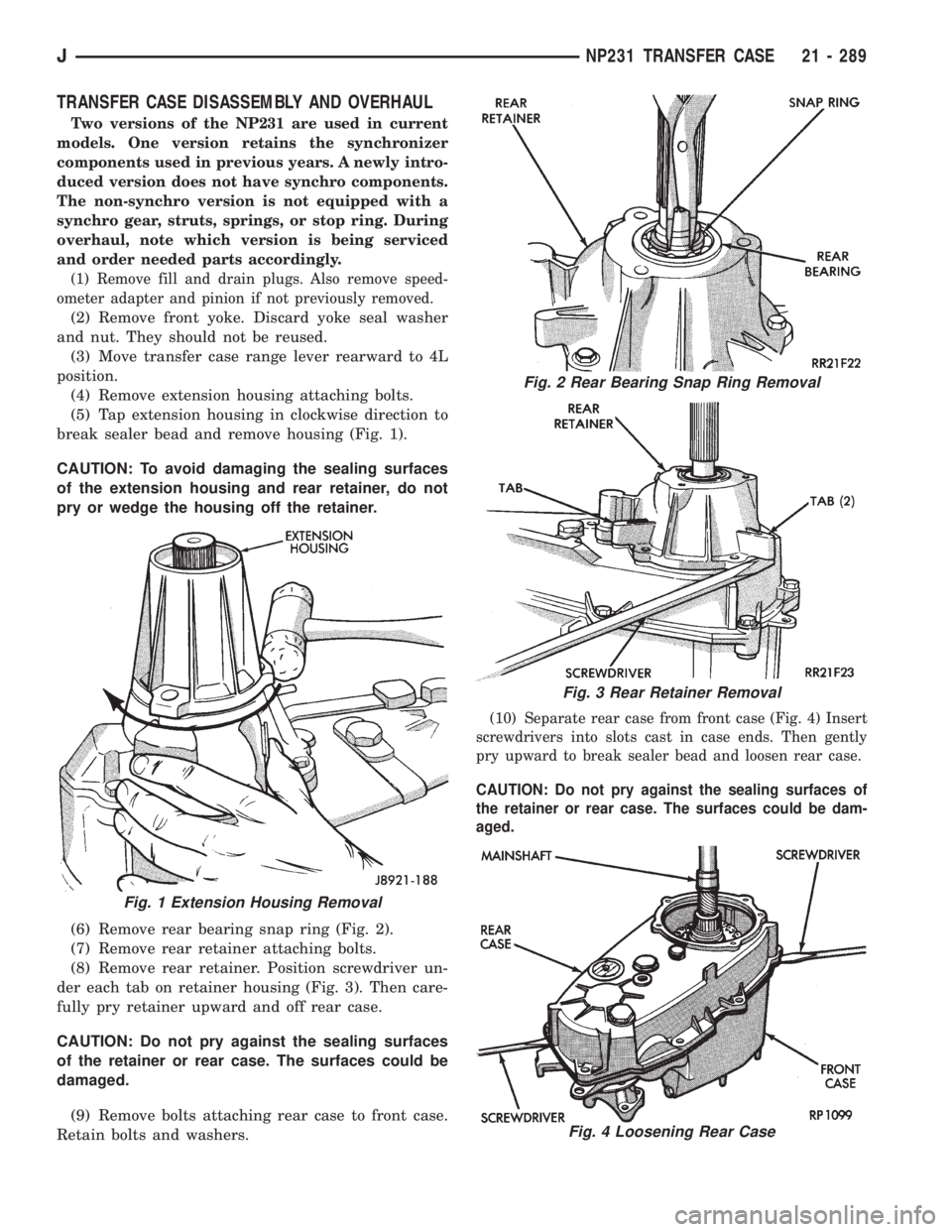

TRANSFER CASE DISASSEMBLY AND OVERHAUL

Two versions of the NP231 are used in current

models. One version retains the synchronizer

components used in previous years. A newly intro-

duced version does not have synchro components.

The non-synchro version is not equipped with a

synchro gear, struts, springs, or stop ring. During

overhaul, note which version is being serviced

and order needed parts accordingly.

(1) Remove fill and drain plugs. Also remove speed-

ometer adapter and pinion if not previously removed.

(2) Remove front yoke. Discard yoke seal washer

and nut. They should not be reused.

(3) Move transfer case range lever rearward to 4L

position.

(4) Remove extension housing attaching bolts.

(5) Tap extension housing in clockwise direction to

break sealer bead and remove housing (Fig. 1).

CAUTION: To avoid damaging the sealing surfaces

of the extension housing and rear retainer, do not

pry or wedge the housing off the retainer.

(6) Remove rear bearing snap ring (Fig. 2).

(7) Remove rear retainer attaching bolts.

(8) Remove rear retainer. Position screwdriver un-

der each tab on retainer housing (Fig. 3). Then care-

fully pry retainer upward and off rear case.

CAUTION: Do not pry against the sealing surfaces

of the retainer or rear case. The surfaces could be

damaged.

(9) Remove bolts attaching rear case to front case.

Retain bolts and washers.

(10) Separate rear case from front case (Fig. 4) Insert

screwdrivers into slots cast in case ends. Then gently

pry upward to break sealer bead and loosen rear case.

CAUTION: Do not pry against the sealing surfaces of

the retainer or rear case. The surfaces could be dam-

aged.

Fig. 1 Extension Housing Removal

Fig. 2 Rear Bearing Snap Ring Removal

Fig. 3 Rear Retainer Removal

Fig. 4 Loosening Rear Case

JNP231 TRANSFER CASE 21 - 289