interior JEEP CHEROKEE 1995 Service Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1226 of 2198

(11) Obtain a new pull tab. Push the new tab down

until it locks into place in the quick-connect fitting.

(12) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(13) Connect negative cable to battery.

(14) Start engine and check for leaks.

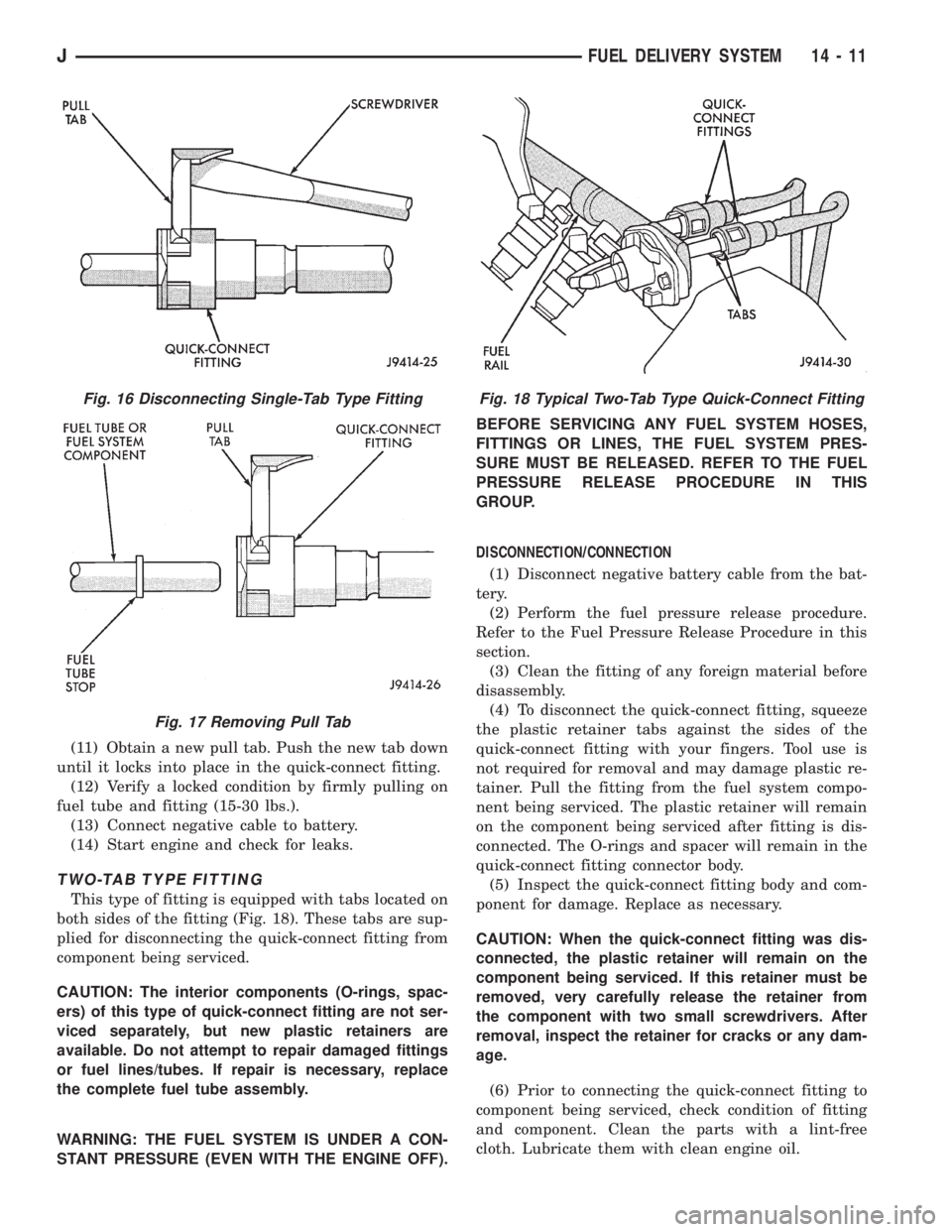

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 18). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP.

DISCONNECTION/CONNECTION

(1) Disconnect negative battery cable from the bat-

tery.

(2) Perform the fuel pressure release procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Clean the fitting of any foreign material before

disassembly.

(4) To disconnect the quick-connect fitting, squeeze

the plastic retainer tabs against the sides of the

quick-connect fitting with your fingers. Tool use is

not required for removal and may damage plastic re-

tainer. Pull the fitting from the fuel system compo-

nent being serviced. The plastic retainer will remain

on the component being serviced after fitting is dis-

connected. The O-rings and spacer will remain in the

quick-connect fitting connector body.

(5) Inspect the quick-connect fitting body and com-

ponent for damage. Replace as necessary.

CAUTION: When the quick-connect fitting was dis-

connected, the plastic retainer will remain on the

component being serviced. If this retainer must be

removed, very carefully release the retainer from

the component with two small screwdrivers. After

removal, inspect the retainer for cracks or any dam-

age.

(6) Prior to connecting the quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean the parts with a lint-free

cloth. Lubricate them with clean engine oil.

Fig. 16 Disconnecting Single-Tab Type Fitting

Fig. 17 Removing Pull Tab

Fig. 18 Typical Two-Tab Type Quick-Connect Fitting

JFUEL DELIVERY SYSTEM 14 - 11

Page 1227 of 2198

(7) Insert the quick-connect fitting to the compo-

nent being serviced and into the plastic retainer.

When a connection is made, a click will be heard.

(8) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(9) Connect negative cable to battery.

(10) Start engine and check for leaks.

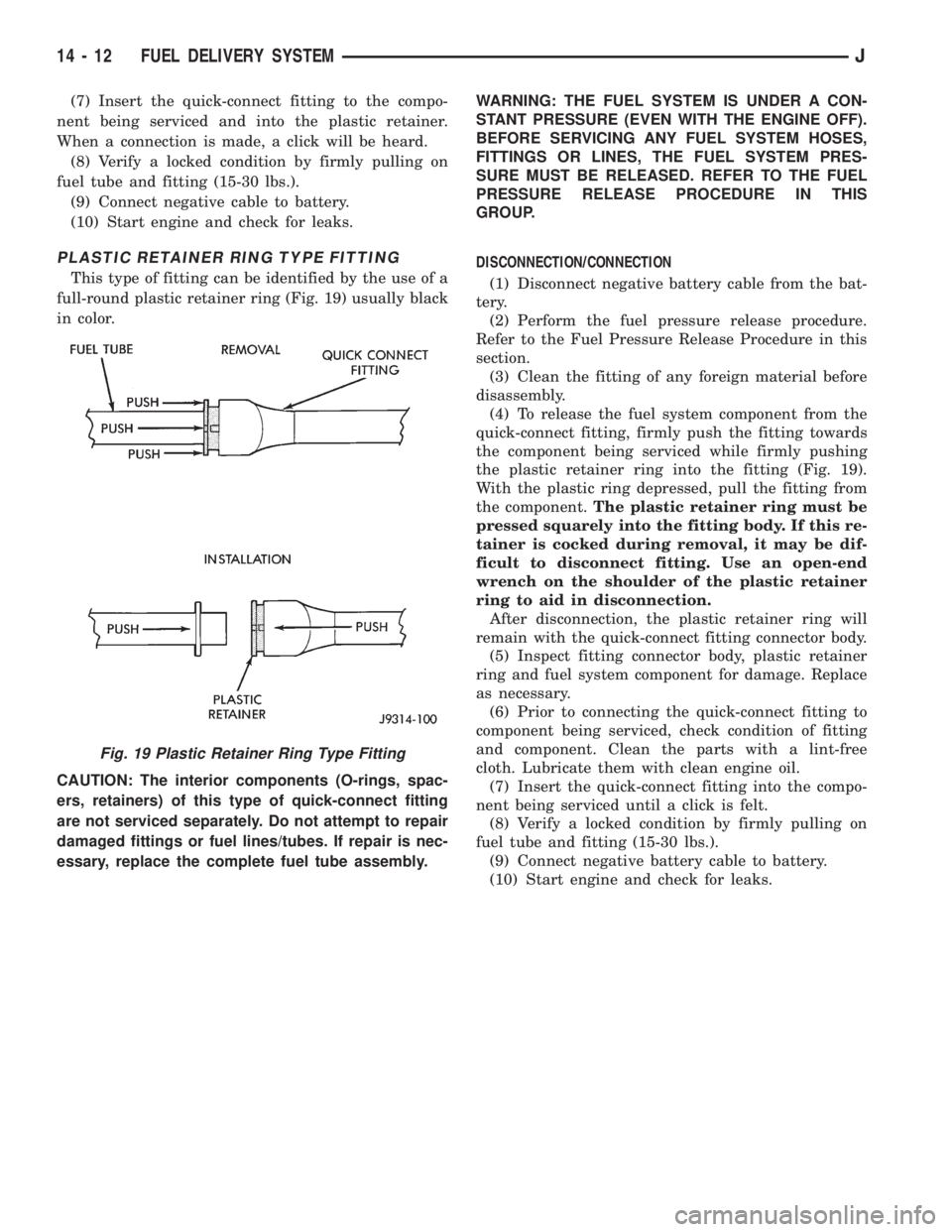

PLASTIC RETAINER RING TYPE FITTING

This type of fitting can be identified by the use of a

full-round plastic retainer ring (Fig. 19) usually black

in color.

CAUTION: The interior components (O-rings, spac-

ers, retainers) of this type of quick-connect fitting

are not serviced separately. Do not attempt to repair

damaged fittings or fuel lines/tubes. If repair is nec-

essary, replace the complete fuel tube assembly.WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP.

DISCONNECTION/CONNECTION

(1) Disconnect negative battery cable from the bat-

tery.

(2) Perform the fuel pressure release procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Clean the fitting of any foreign material before

disassembly.

(4) To release the fuel system component from the

quick-connect fitting, firmly push the fitting towards

the component being serviced while firmly pushing

the plastic retainer ring into the fitting (Fig. 19).

With the plastic ring depressed, pull the fitting from

the component.The plastic retainer ring must be

pressed squarely into the fitting body. If this re-

tainer is cocked during removal, it may be dif-

ficult to disconnect fitting. Use an open-end

wrench on the shoulder of the plastic retainer

ring to aid in disconnection.

After disconnection, the plastic retainer ring will

remain with the quick-connect fitting connector body.

(5) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage. Replace

as necessary.

(6) Prior to connecting the quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean the parts with a lint-free

cloth. Lubricate them with clean engine oil.

(7) Insert the quick-connect fitting into the compo-

nent being serviced until a click is felt.

(8) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(9) Connect negative battery cable to battery.

(10) Start engine and check for leaks.

Fig. 19 Plastic Retainer Ring Type Fitting

14 - 12 FUEL DELIVERY SYSTEMJ

Page 1300 of 2198

STEERING

CONTENTS

page page

GENERAL INFORMATION.................. 1

GENERAL INFORMATION................. 48

MANUAL STEERING GEAR................ 37

POWER STEERING PUMP................. 11

POWER STEERING SYSTEM DIAGNOSIS...... 3

RECIRCULATING BALL POWER STEERING

GEAR............................... 21STEERING COLUMN GENERAL SERVICEÐXJ . 47

STEERING COLUMNÐYJ................. 58

STEERING LINKAGEÐXJ................. 16

STEERING LINKAGEÐYJ................. 19

STEERING RHD......................... 74

TORQUE SPECIFICATIONS................ 78

GENERAL INFORMATION

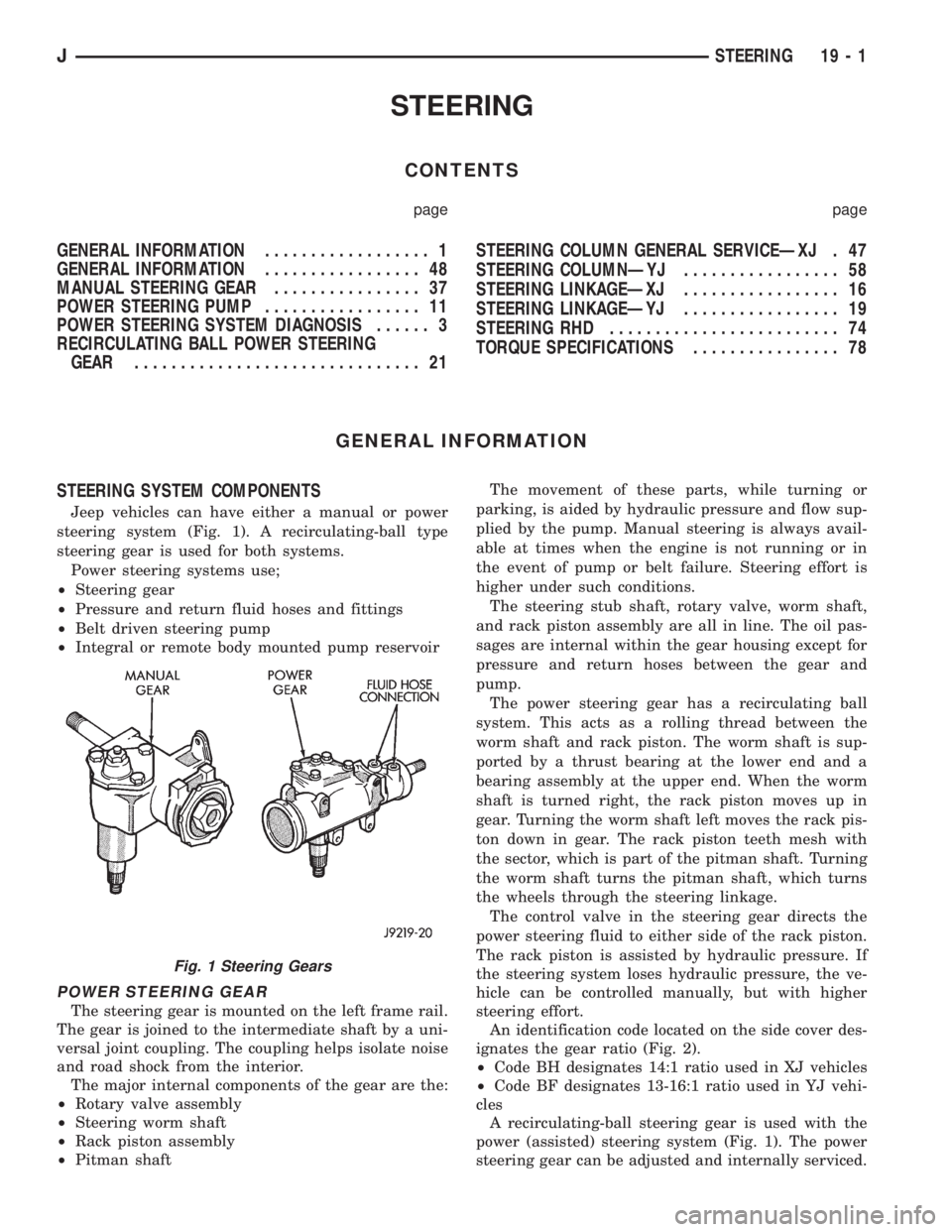

STEERING SYSTEM COMPONENTS

Jeep vehicles can have either a manual or power

steering system (Fig. 1). A recirculating-ball type

steering gear is used for both systems.

Power steering systems use;

²Steering gear

²Pressure and return fluid hoses and fittings

²Belt driven steering pump

²Integral or remote body mounted pump reservoir

POWER STEERING GEAR

The steering gear is mounted on the left frame rail.

The gear is joined to the intermediate shaft by a uni-

versal joint coupling. The coupling helps isolate noise

and road shock from the interior.

The major internal components of the gear are the:

²Rotary valve assembly

²Steering worm shaft

²Rack piston assembly

²Pitman shaftThe movement of these parts, while turning or

parking, is aided by hydraulic pressure and flow sup-

plied by the pump. Manual steering is always avail-

able at times when the engine is not running or in

the event of pump or belt failure. Steering effort is

higher under such conditions.

The steering stub shaft, rotary valve, worm shaft,

and rack piston assembly are all in line. The oil pas-

sages are internal within the gear housing except for

pressure and return hoses between the gear and

pump.

The power steering gear has a recirculating ball

system. This acts as a rolling thread between the

worm shaft and rack piston. The worm shaft is sup-

ported by a thrust bearing at the lower end and a

bearing assembly at the upper end. When the worm

shaft is turned right, the rack piston moves up in

gear. Turning the worm shaft left moves the rack pis-

ton down in gear. The rack piston teeth mesh with

the sector, which is part of the pitman shaft. Turning

the worm shaft turns the pitman shaft, which turns

the wheels through the steering linkage.

The control valve in the steering gear directs the

power steering fluid to either side of the rack piston.

The rack piston is assisted by hydraulic pressure. If

the steering system loses hydraulic pressure, the ve-

hicle can be controlled manually, but with higher

steering effort.

An identification code located on the side cover des-

ignates the gear ratio (Fig. 2).

²Code BH designates 14:1 ratio used in XJ vehicles

²Code BF designates 13-16:1 ratio used in YJ vehi-

cles

A recirculating-ball steering gear is used with the

power (assisted) steering system (Fig. 1). The power

steering gear can be adjusted and internally serviced.

Fig. 1 Steering Gears

JSTEERING 19 - 1

Page 1348 of 2198

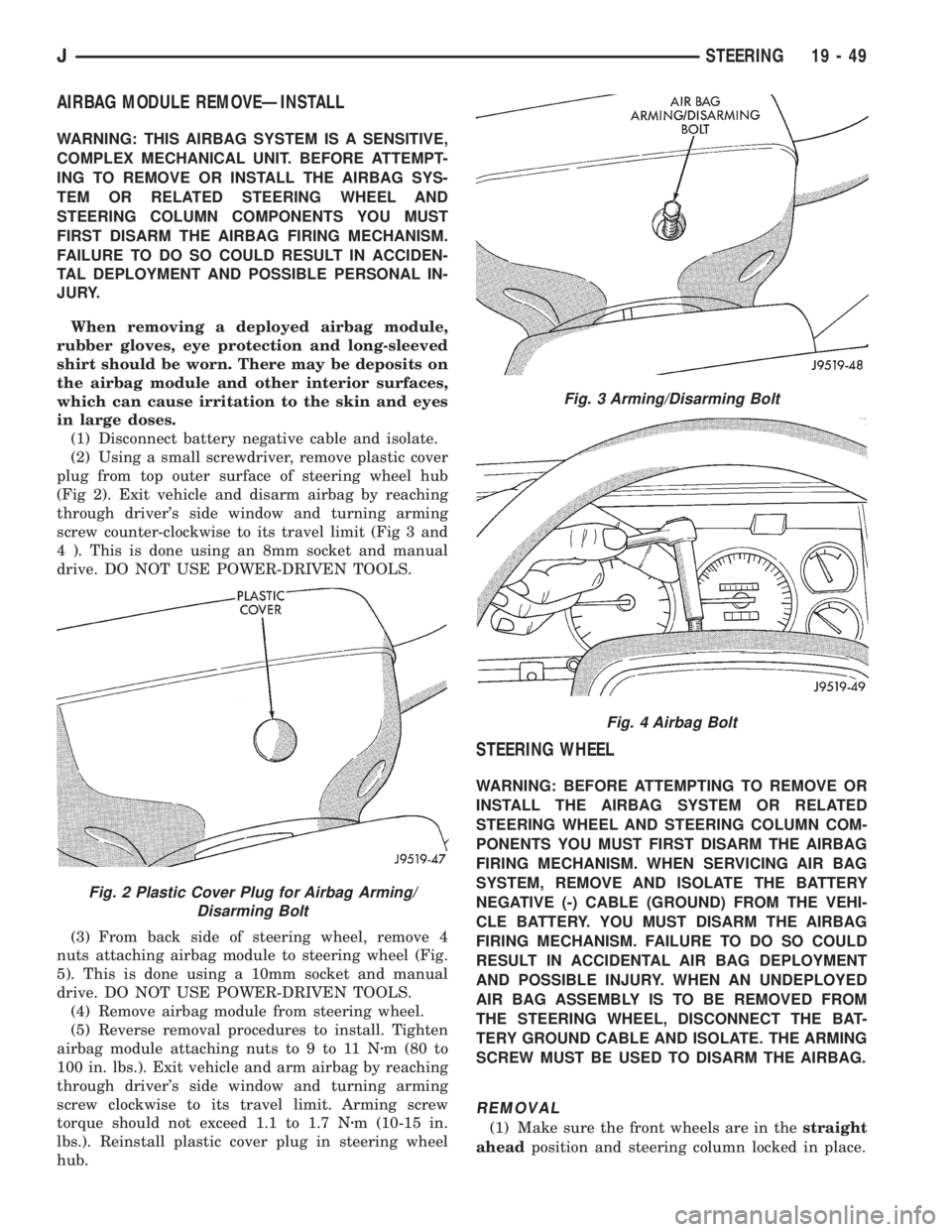

AIRBAG MODULE REMOVEÐINSTALL

WARNING: THIS AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX MECHANICAL UNIT. BEFORE ATTEMPT-

ING TO REMOVE OR INSTALL THE AIRBAG SYS-

TEM OR RELATED STEERING WHEEL AND

STEERING COLUMN COMPONENTS YOU MUST

FIRST DISARM THE AIRBAG FIRING MECHANISM.

FAILURE TO DO SO COULD RESULT IN ACCIDEN-

TAL DEPLOYMENT AND POSSIBLE PERSONAL IN-

JURY.

When removing a deployed airbag module,

rubber gloves, eye protection and long-sleeved

shirt should be worn. There may be deposits on

the airbag module and other interior surfaces,

which can cause irritation to the skin and eyes

in large doses.

(1) Disconnect battery negative cable and isolate.

(2) Using a small screwdriver, remove plastic cover

plug from top outer surface of steering wheel hub

(Fig 2). Exit vehicle and disarm airbag by reaching

through driver's side window and turning arming

screw counter-clockwise to its travel limit (Fig 3 and

4 ). This is done using an 8mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(3) From back side of steering wheel, remove 4

nuts attaching airbag module to steering wheel (Fig.

5). This is done using a 10mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(4) Remove airbag module from steering wheel.

(5) Reverse removal procedures to install. Tighten

airbag module attaching nuts to 9 to 11 Nzm (80 to

100 in. lbs.). Exit vehicle and arm airbag by reaching

through driver's side window and turning arming

screw clockwise to its travel limit. Arming screw

torque should not exceed 1.1 to 1.7 Nzm (10-15 in.

lbs.). Reinstall plastic cover plug in steering wheel

hub.

STEERING WHEEL

WARNING: BEFORE ATTEMPTING TO REMOVE OR

INSTALL THE AIRBAG SYSTEM OR RELATED

STEERING WHEEL AND STEERING COLUMN COM-

PONENTS YOU MUST FIRST DISARM THE AIRBAG

FIRING MECHANISM. WHEN SERVICING AIR BAG

SYSTEM, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. YOU MUST DISARM THE AIRBAG

FIRING MECHANISM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIR BAG DEPLOYMENT

AND POSSIBLE INJURY. WHEN AN UNDEPLOYED

AIR BAG ASSEMBLY IS TO BE REMOVED FROM

THE STEERING WHEEL, DISCONNECT THE BAT-

TERY GROUND CABLE AND ISOLATE. THE ARMING

SCREW MUST BE USED TO DISARM THE AIRBAG.

REMOVAL

(1) Make sure the front wheels are in thestraight

aheadposition and steering column locked in place.

Fig. 2 Plastic Cover Plug for Airbag Arming/

Disarming Bolt

Fig. 3 Arming/Disarming Bolt

Fig. 4 Airbag Bolt

JSTEERING 19 - 49

Page 1513 of 2198

Replace the clutch discs if warped, worn, scored,

burned or charred, or if the facing is flaking off. Re-

place the steel plates if heavily scored, warped, or

broken. Be sure the driving lugs on the plates are in

good condition. The lugs must not be bent, cracked or

damaged in any way.

Replace the clutch spring and spring retainer if ei-

ther is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

steel plates should slide freely in the slots. Replace

the retainer if the grooves are worn or damaged.

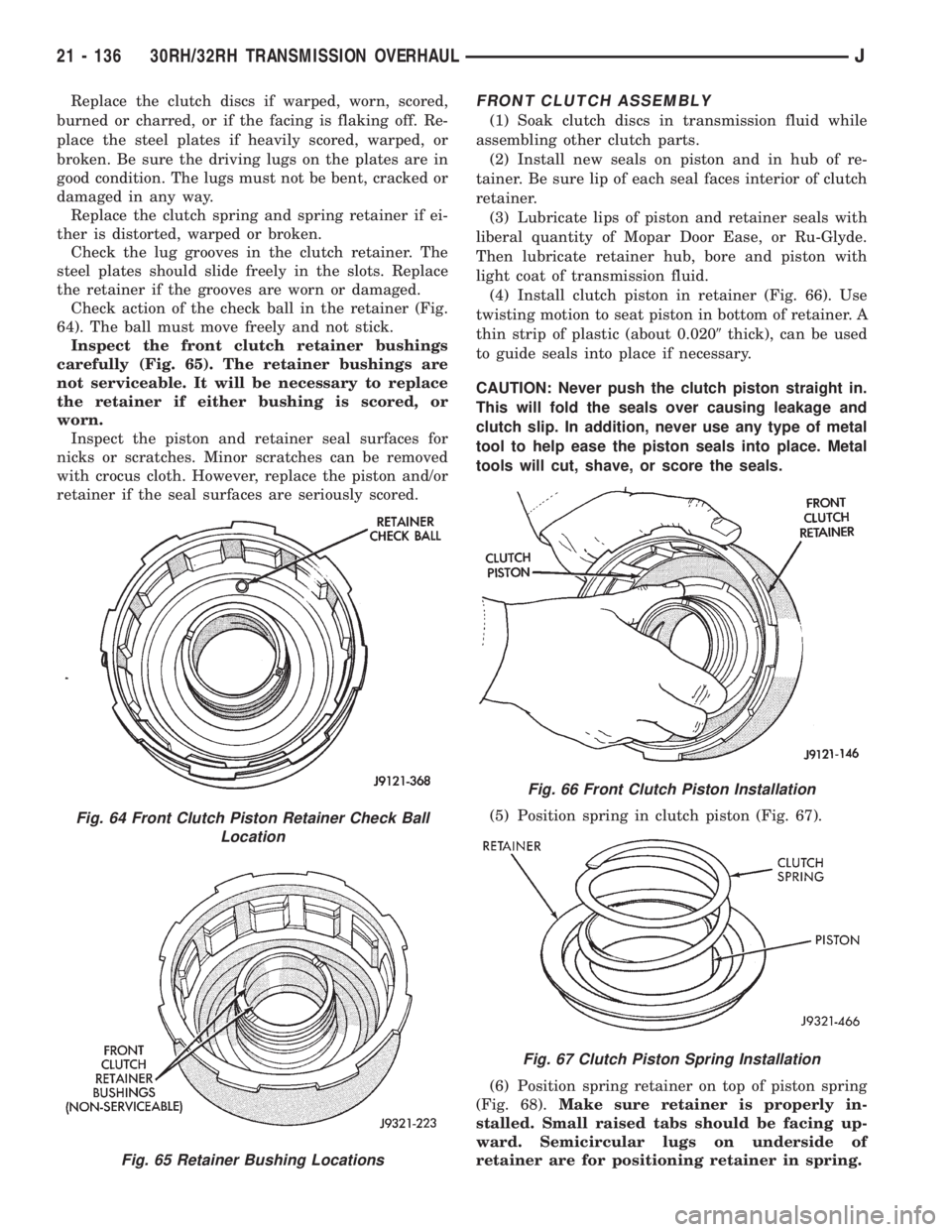

Check action of the check ball in the retainer (Fig.

64). The ball must move freely and not stick.

Inspect the front clutch retainer bushings

carefully (Fig. 65). The retainer bushings are

not serviceable. It will be necessary to replace

the retainer if either bushing is scored, or

worn.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.FRONT CLUTCH ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seals on piston and in hub of re-

tainer. Be sure lip of each seal faces interior of clutch

retainer.

(3) Lubricate lips of piston and retainer seals with

liberal quantity of Mopar Door Ease, or Ru-Glyde.

Then lubricate retainer hub, bore and piston with

light coat of transmission fluid.

(4) Install clutch piston in retainer (Fig. 66). Use

twisting motion to seat piston in bottom of retainer. A

thin strip of plastic (about 0.0209thick), can be used

to guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(5) Position spring in clutch piston (Fig. 67).

(6) Position spring retainer on top of piston spring

(Fig. 68).Make sure retainer is properly in-

stalled. Small raised tabs should be facing up-

ward. Semicircular lugs on underside of

retainer are for positioning retainer in spring.

Fig. 64 Front Clutch Piston Retainer Check Ball

Location

Fig. 65 Retainer Bushing Locations

Fig. 66 Front Clutch Piston Installation

Fig. 67 Clutch Piston Spring Installation

21 - 136 30RH/32RH TRANSMISSION OVERHAULJ

Page 1516 of 2198

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

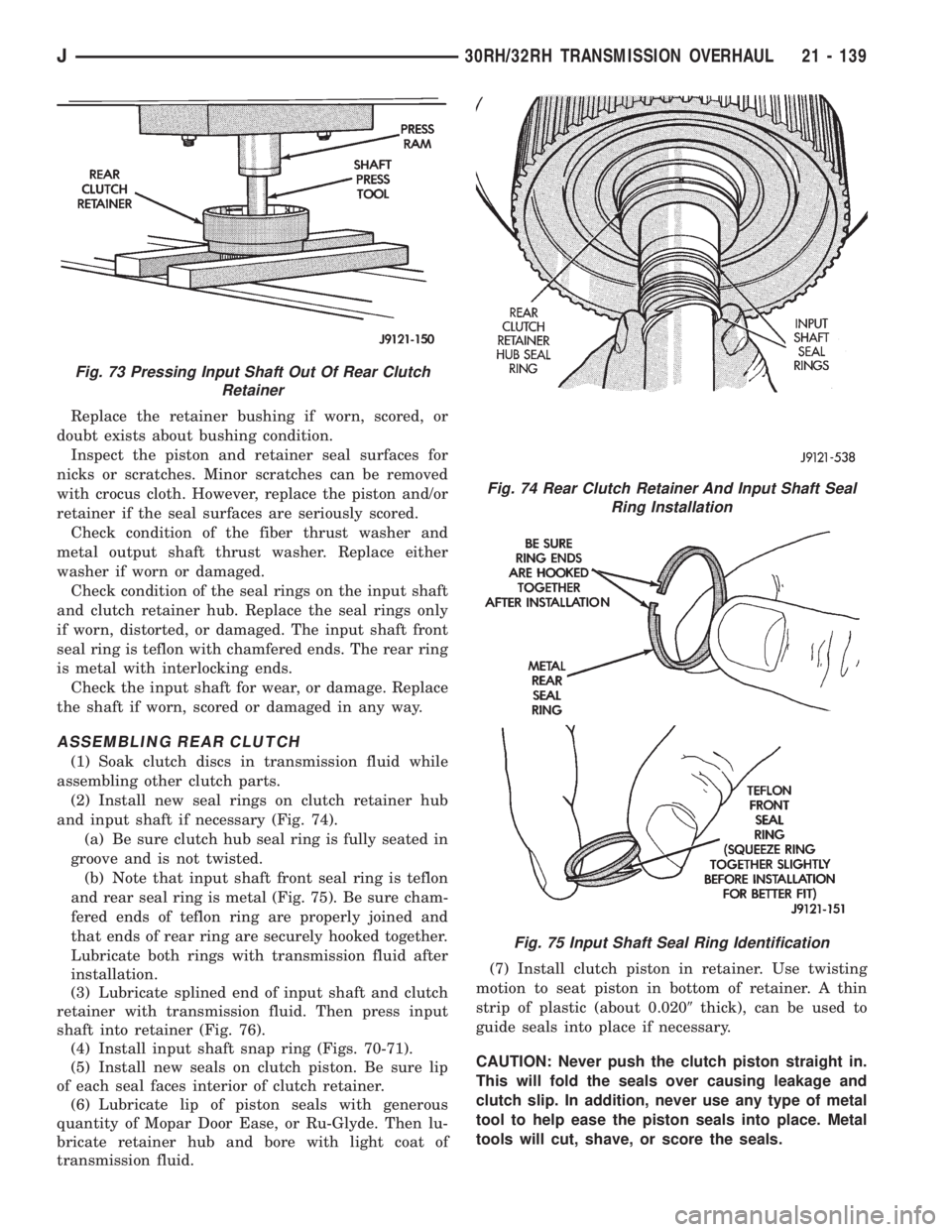

ASSEMBLING REAR CLUTCH

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft if necessary (Fig. 74).

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(b) Note that input shaft front seal ring is teflon

and rear seal ring is metal (Fig. 75). Be sure cham-

fered ends of teflon ring are properly joined and

that ends of rear ring are securely hooked together.

Lubricate both rings with transmission fluid after

installation.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then press input

shaft into retainer (Fig. 76).

(4) Install input shaft snap ring (Figs. 70-71).

(5) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(6) Lubricate lip of piston seals with generous

quantity of Mopar Door Ease, or Ru-Glyde. Then lu-

bricate retainer hub and bore with light coat of

transmission fluid.(7) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

Fig. 73 Pressing Input Shaft Out Of Rear Clutch

Retainer

Fig. 74 Rear Clutch Retainer And Input Shaft Seal

Ring Installation

Fig. 75 Input Shaft Seal Ring Identification

J30RH/32RH TRANSMISSION OVERHAUL 21 - 139

Page 1528 of 2198

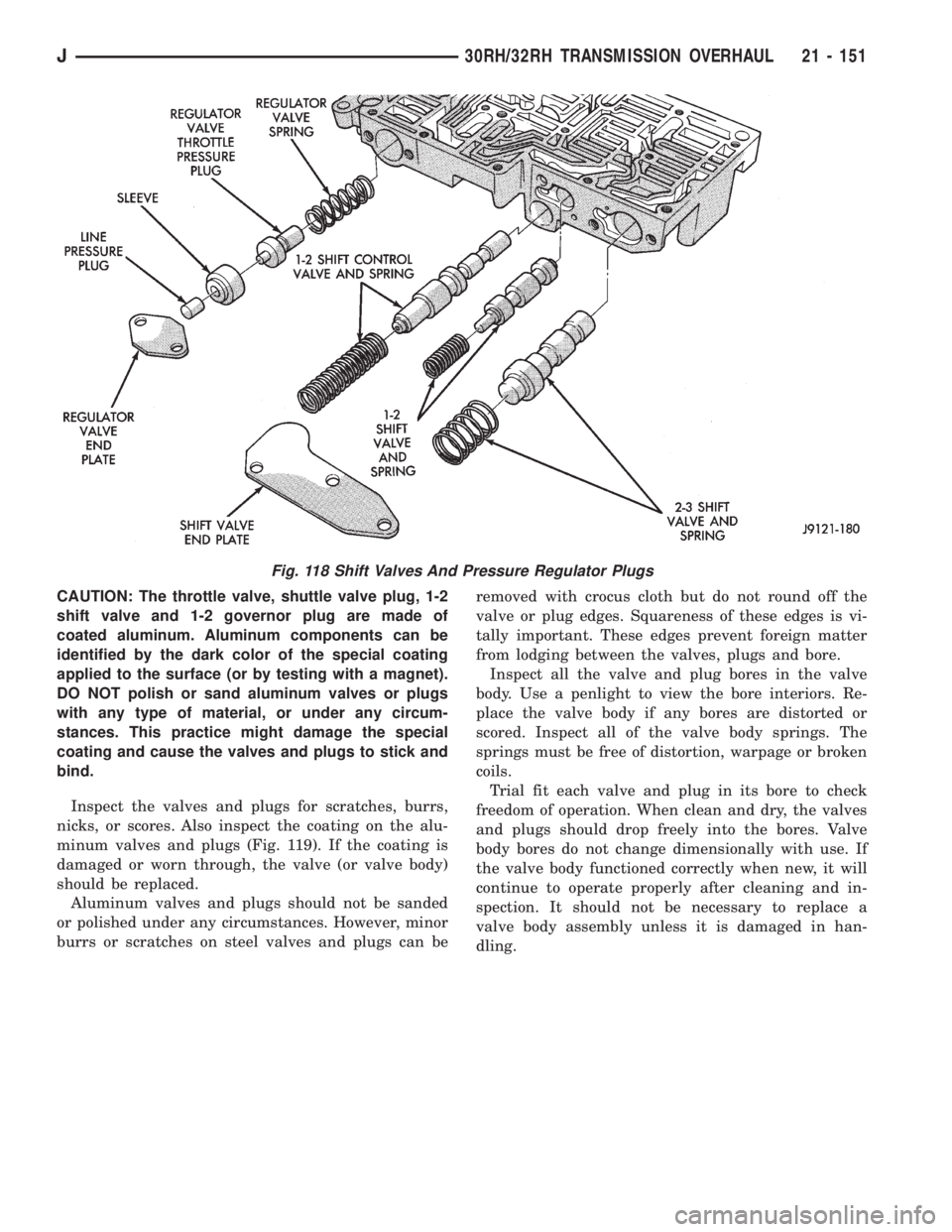

CAUTION: The throttle valve, shuttle valve plug, 1-2

shift valve and 1-2 governor plug are made of

coated aluminum. Aluminum components can be

identified by the dark color of the special coating

applied to the surface (or by testing with a magnet).

DO NOT polish or sand aluminum valves or plugs

with any type of material, or under any circum-

stances. This practice might damage the special

coating and cause the valves and plugs to stick and

bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Also inspect the coating on the alu-

minum valves and plugs (Fig. 119). If the coating is

damaged or worn through, the valve (or valve body)

should be replaced.

Aluminum valves and plugs should not be sanded

or polished under any circumstances. However, minor

burrs or scratches on steel valves and plugs can beremoved with crocus cloth but do not round off the

valve or plug edges. Squareness of these edges is vi-

tally important. These edges prevent foreign matter

from lodging between the valves, plugs and bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors. Re-

place the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores. Valve

body bores do not change dimensionally with use. If

the valve body functioned correctly when new, it will

continue to operate properly after cleaning and in-

spection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

Fig. 118 Shift Valves And Pressure Regulator Plugs

J30RH/32RH TRANSMISSION OVERHAUL 21 - 151

Page 1663 of 2198

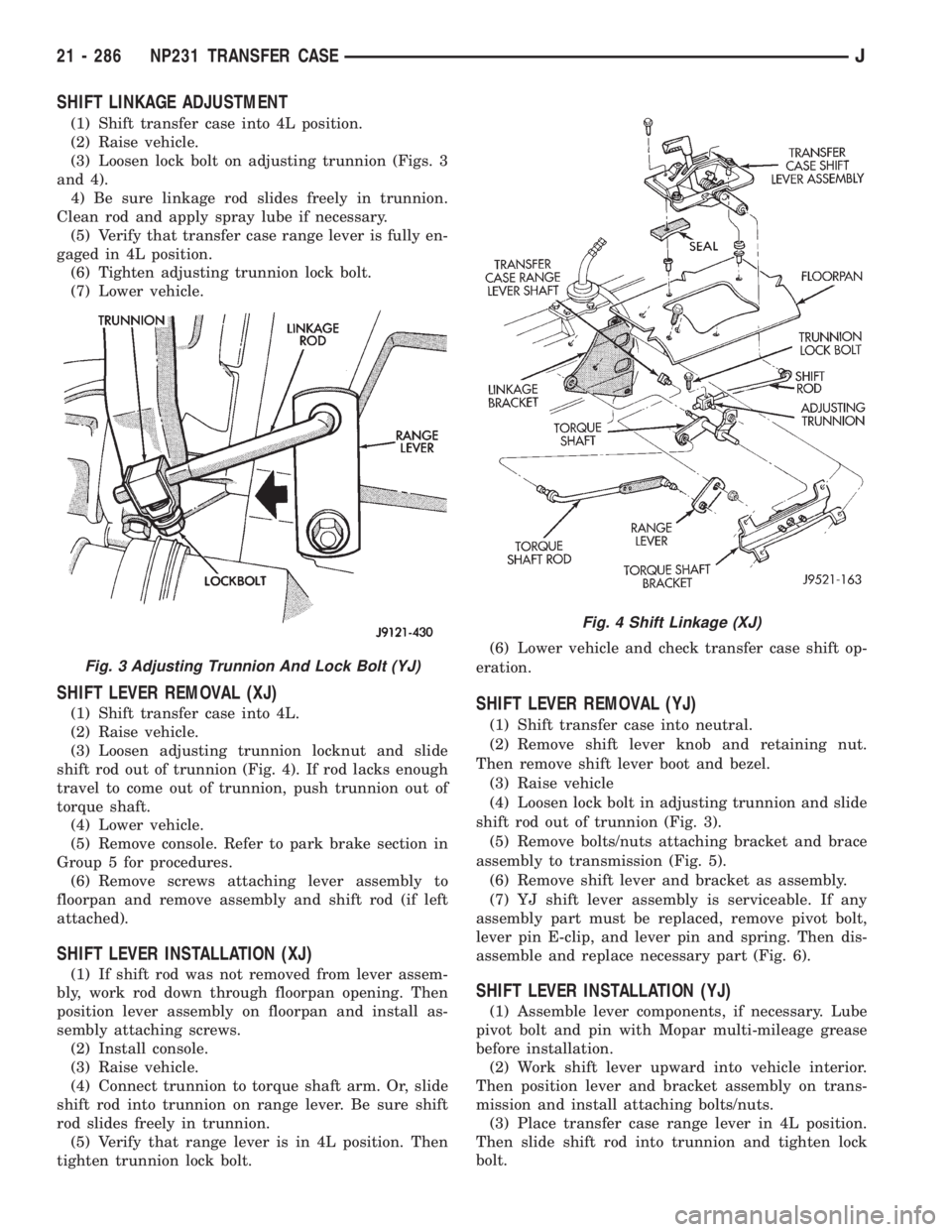

SHIFT LINKAGE ADJUSTMENT

(1) Shift transfer case into 4L position.

(2) Raise vehicle.

(3) Loosen lock bolt on adjusting trunnion (Figs. 3

and 4).

4) Be sure linkage rod slides freely in trunnion.

Clean rod and apply spray lube if necessary.

(5) Verify that transfer case range lever is fully en-

gaged in 4L position.

(6) Tighten adjusting trunnion lock bolt.

(7) Lower vehicle.

SHIFT LEVER REMOVAL (XJ)

(1) Shift transfer case into 4L.

(2) Raise vehicle.

(3) Loosen adjusting trunnion locknut and slide

shift rod out of trunnion (Fig. 4). If rod lacks enough

travel to come out of trunnion, push trunnion out of

torque shaft.

(4) Lower vehicle.

(5) Remove console. Refer to park brake section in

Group 5 for procedures.

(6) Remove screws attaching lever assembly to

floorpan and remove assembly and shift rod (if left

attached).

SHIFT LEVER INSTALLATION (XJ)

(1) If shift rod was not removed from lever assem-

bly, work rod down through floorpan opening. Then

position lever assembly on floorpan and install as-

sembly attaching screws.

(2) Install console.

(3) Raise vehicle.

(4) Connect trunnion to torque shaft arm. Or, slide

shift rod into trunnion on range lever. Be sure shift

rod slides freely in trunnion.

(5) Verify that range lever is in 4L position. Then

tighten trunnion lock bolt.(6) Lower vehicle and check transfer case shift op-

eration.

SHIFT LEVER REMOVAL (YJ)

(1) Shift transfer case into neutral.

(2) Remove shift lever knob and retaining nut.

Then remove shift lever boot and bezel.

(3) Raise vehicle

(4) Loosen lock bolt in adjusting trunnion and slide

shift rod out of trunnion (Fig. 3).

(5) Remove bolts/nuts attaching bracket and brace

assembly to transmission (Fig. 5).

(6) Remove shift lever and bracket as assembly.

(7) YJ shift lever assembly is serviceable. If any

assembly part must be replaced, remove pivot bolt,

lever pin E-clip, and lever pin and spring. Then dis-

assemble and replace necessary part (Fig. 6).

SHIFT LEVER INSTALLATION (YJ)

(1) Assemble lever components, if necessary. Lube

pivot bolt and pin with Mopar multi-mileage grease

before installation.

(2) Work shift lever upward into vehicle interior.

Then position lever and bracket assembly on trans-

mission and install attaching bolts/nuts.

(3) Place transfer case range lever in 4L position.

Then slide shift rod into trunnion and tighten lock

bolt.

Fig. 3 Adjusting Trunnion And Lock Bolt (YJ)

Fig. 4 Shift Linkage (XJ)

21 - 286 NP231 TRANSFER CASEJ

Page 1734 of 2198

BODY COMPONENTSÐXJ VEHICLES

CONTENTS

page page

DOORS................................ 30

EXTERIOR COMPONENTS.................. 3

GENERAL BODY SERVICE INFORMATION..... 1INTERIOR COMPONENTS................. 80

STATIONARY WINDOW GLASS............. 66

TRAILER HITCH......................... 77

GENERAL BODY SERVICE INFORMATION

RIGHT HAND DRIVE VEHICLES

The XJ Body Components procedures in this sec-

tion were developed on a left hand drive (LHD) vehi-

cle. Unless a component is unique to a right hand

drive vehicle, it will not be specifically covered in this

section, i.e. cargo barrier. In general, components on

left hand drive vehicles will be located on the oppo-

site side in right hand drive vehicles.

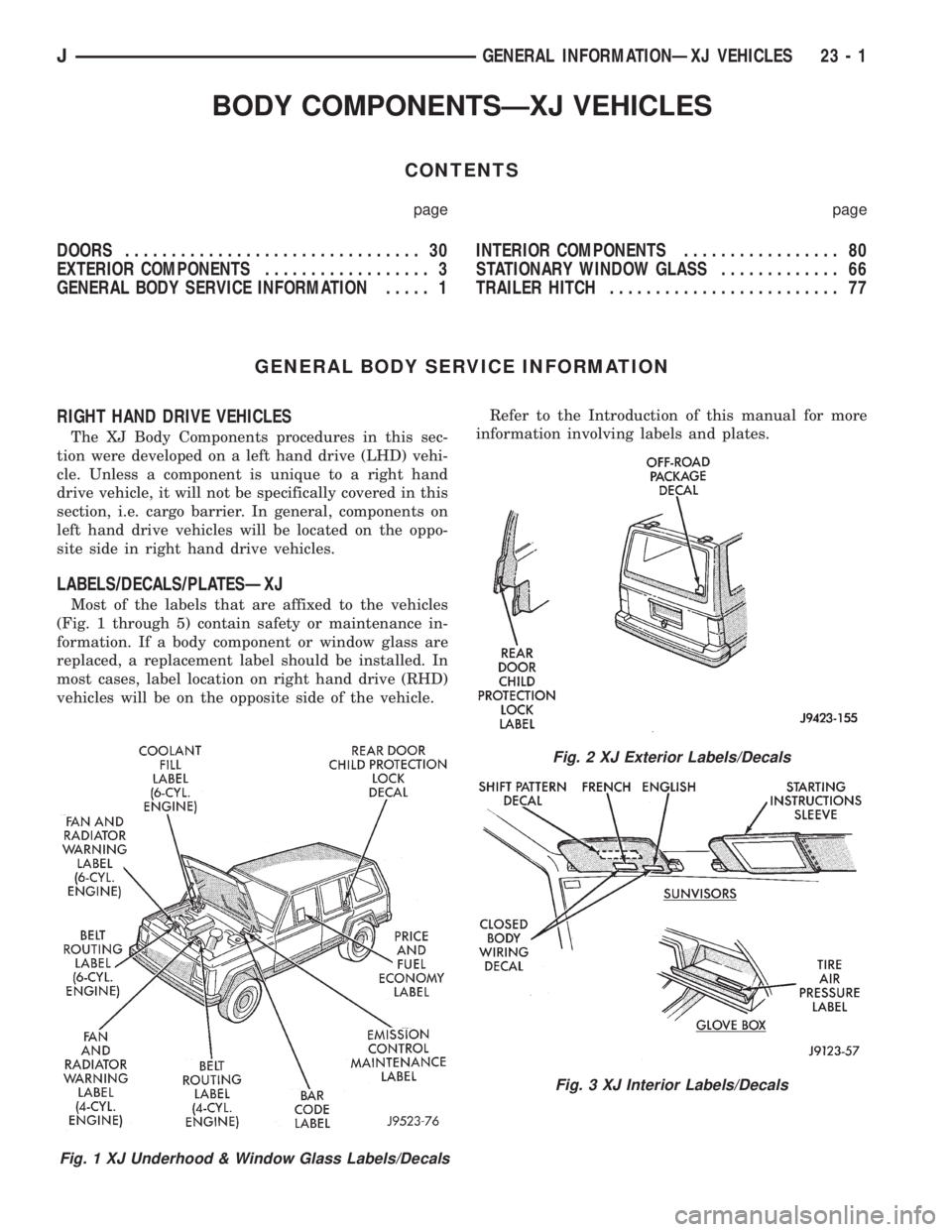

LABELS/DECALS/PLATESÐXJ

Most of the labels that are affixed to the vehicles

(Fig. 1 through 5) contain safety or maintenance in-

formation. If a body component or window glass are

replaced, a replacement label should be installed. In

most cases, label location on right hand drive (RHD)

vehicles will be on the opposite side of the vehicle.Refer to the Introduction of this manual for more

information involving labels and plates.

Fig. 1 XJ Underhood & Window Glass Labels/Decals

Fig. 2 XJ Exterior Labels/Decals

Fig. 3 XJ Interior Labels/Decals

JGENERAL INFORMATIONÐXJ VEHICLES 23 - 1

Page 1770 of 2198

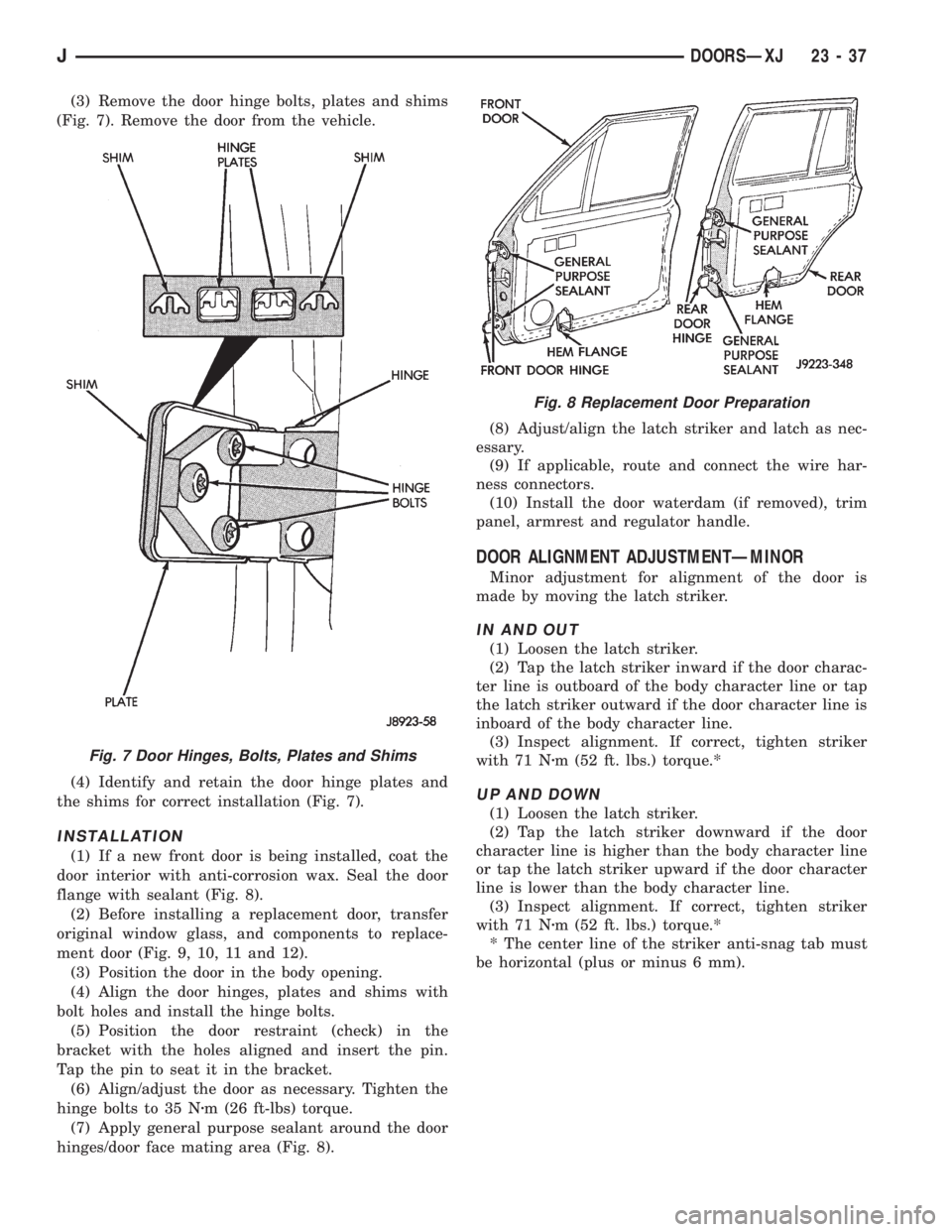

(3) Remove the door hinge bolts, plates and shims

(Fig. 7). Remove the door from the vehicle.

(4) Identify and retain the door hinge plates and

the shims for correct installation (Fig. 7).

INSTALLATION

(1) If a new front door is being installed, coat the

door interior with anti-corrosion wax. Seal the door

flange with sealant (Fig. 8).

(2) Before installing a replacement door, transfer

original window glass, and components to replace-

ment door (Fig. 9, 10, 11 and 12).

(3) Position the door in the body opening.

(4) Align the door hinges, plates and shims with

bolt holes and install the hinge bolts.

(5) Position the door restraint (check) in the

bracket with the holes aligned and insert the pin.

Tap the pin to seat it in the bracket.

(6) Align/adjust the door as necessary. Tighten the

hinge bolts to 35 Nzm (26 ft-lbs) torque.

(7) Apply general purpose sealant around the door

hinges/door face mating area (Fig. 8).(8) Adjust/align the latch striker and latch as nec-

essary.

(9) If applicable, route and connect the wire har-

ness connectors.

(10) Install the door waterdam (if removed), trim

panel, armrest and regulator handle.

DOOR ALIGNMENT ADJUSTMENTÐMINOR

Minor adjustment for alignment of the door is

made by moving the latch striker.

IN AND OUT

(1) Loosen the latch striker.

(2) Tap the latch striker inward if the door charac-

ter line is outboard of the body character line or tap

the latch striker outward if the door character line is

inboard of the body character line.

(3) Inspect alignment. If correct, tighten striker

with 71 Nzm (52 ft. lbs.) torque.*

UP AND DOWN

(1) Loosen the latch striker.

(2) Tap the latch striker downward if the door

character line is higher than the body character line

or tap the latch striker upward if the door character

line is lower than the body character line.

(3) Inspect alignment. If correct, tighten striker

with 71 Nzm (52 ft. lbs.) torque.*

* The center line of the striker anti-snag tab must

be horizontal (plus or minus 6 mm).

Fig. 7 Door Hinges, Bolts, Plates and Shims

Fig. 8 Replacement Door Preparation

JDOORSÐXJ 23 - 37